lights MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 841 of 1449

MANUAL TRANSMISSION - Troubleshooting

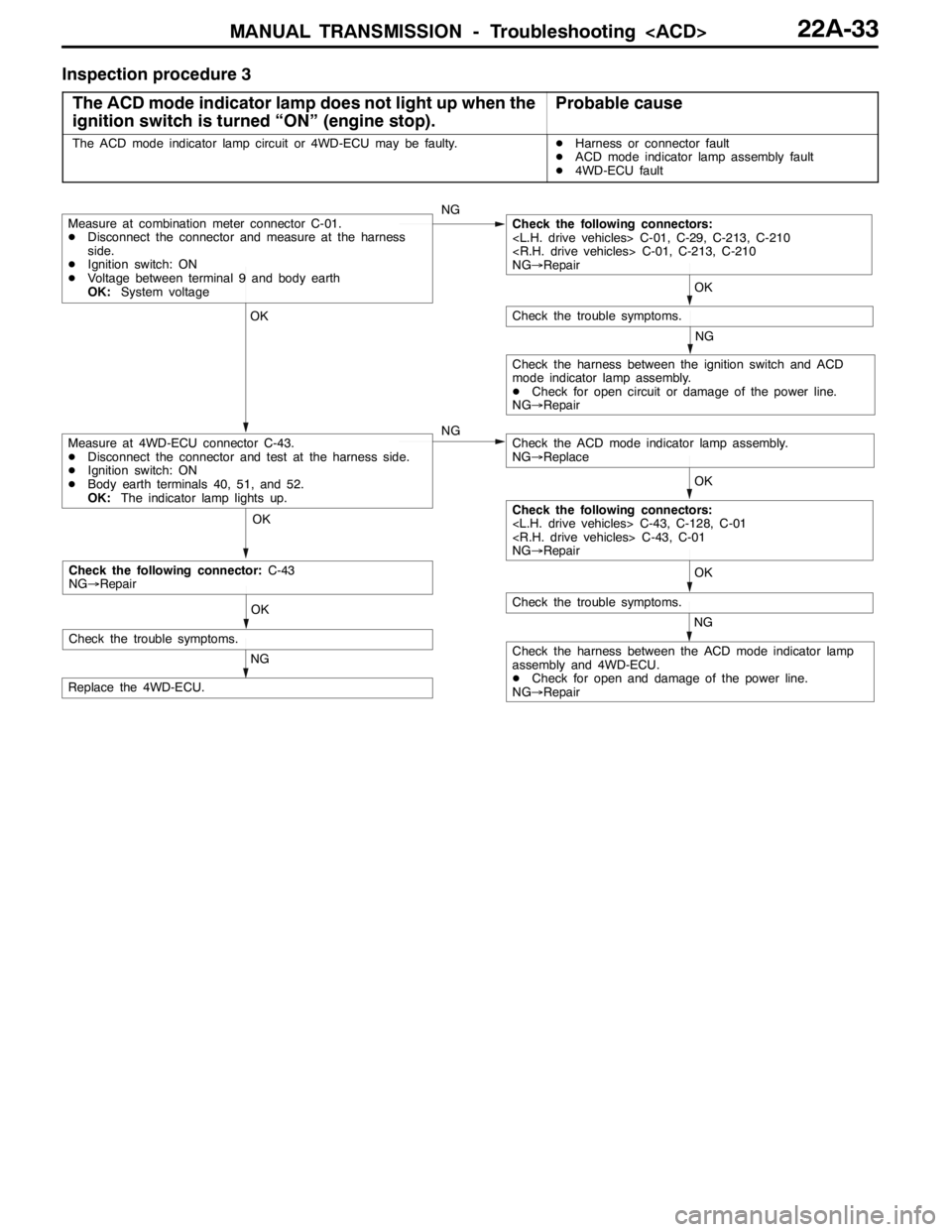

Inspection procedure 3

The ACD mode indicator lamp does not light up when the

ignition switch is turned “ON” (engine stop).

Probable cause

The ACD mode indicator lamp circuit or 4WD-ECU may be faulty.DHarness or connector fault

DACD mode indicator lamp assembly fault

D4WD-ECU fault

OK OK OKOK

NG

OK

NG

NG

NG

Check the harness between the ACD mode indicator lamp

assembly and 4WD-ECU.

DCheck for open and damage of the power line.

NG→Repair

Replace the 4WD-ECU.

Measure at 4WD-ECU connector C-43.

DDisconnect the connector and test at the harness side.

DIgnition switch: ON

DBody earth terminals 40, 51, and 52.

OK:The indicator lamp lights up.

Check the trouble symptoms.

Measure at combination meter connector C-01.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 9 and body earth

OK:System voltageCheck the following connectors:

NG→Repair

Check the trouble symptoms.

Check the ACD mode indicator lamp assembly.

NG→Replace

Check the harness between the ignition switch and ACD

mode indicator lamp assembly.

DCheck for open circuit or damage of the power line.

NG→Repair

Check the following connectors:

NG→Repair

OK

NG

Check the trouble symptoms.

Check the following connector:C-43

NG→Repair

Page 970 of 1449

REAR AXLE -On-vehicle Service27B-24

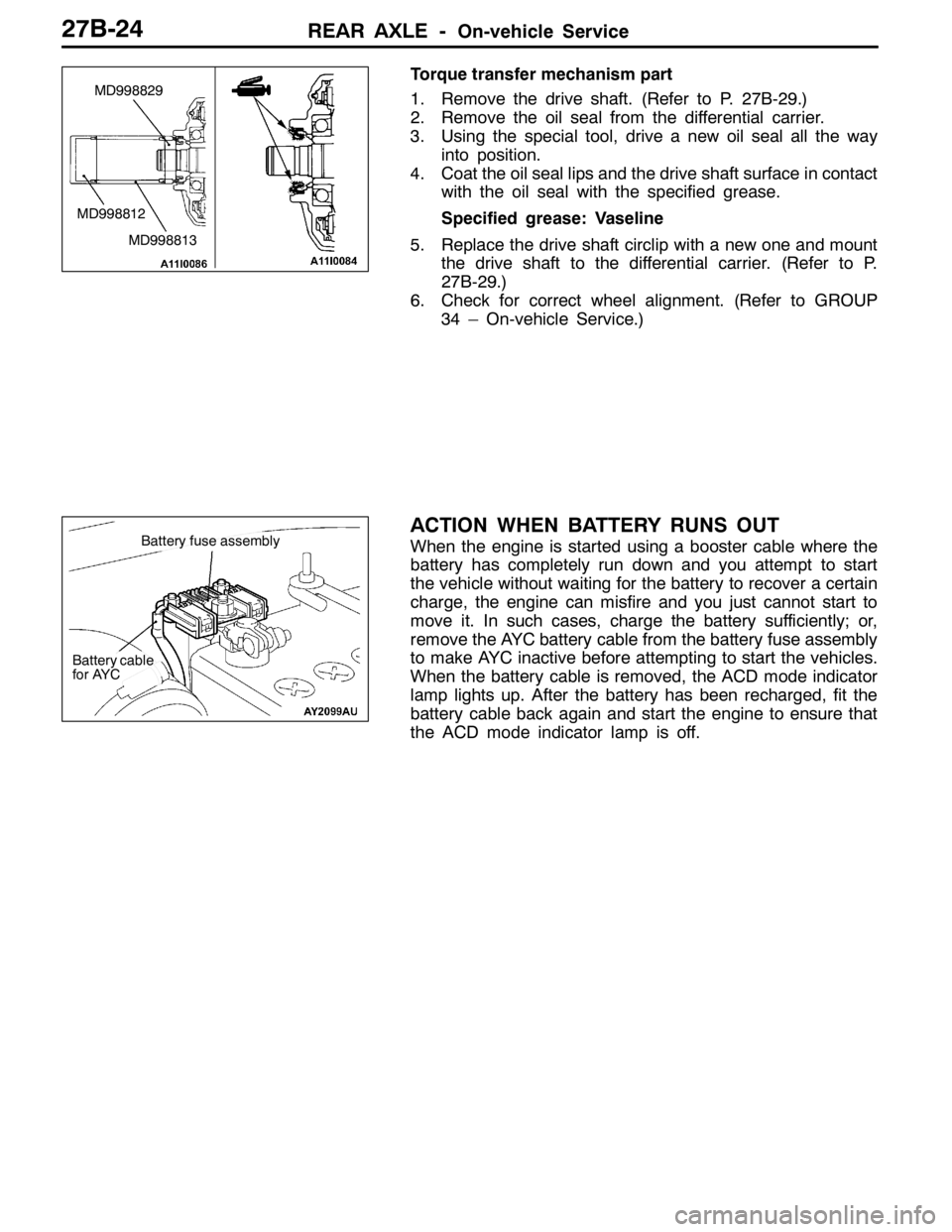

Torque transfer mechanism part

1. Remove the drive shaft. (Refer to P. 27B-29.)

2. Remove the oil seal from the differential carrier.

3. Using the special tool, drive a new oil seal all the way

into position.

4. Coat the oil seal lips and the drive shaft surface in contact

with the oil seal with the specified grease.

Specified grease: Vaseline

5. Replace the drive shaft circlip with a new one and mount

the drive shaft to the differential carrier. (Refer to P.

27B-29.)

6. Check for correct wheel alignment. (Refer to GROUP

34 – On-vehicle Service.)

ACTION WHEN BATTERY RUNS OUT

When the engine is started using a booster cable where the

battery has completely run down and you attempt to start

the vehicle without waiting for the battery to recover a certain

charge, the engine can misfire and you just cannot start to

move it. In such cases, charge the battery sufficiently; or,

remove the AYC battery cable from the battery fuse assembly

to make AYC inactive before attempting to start the vehicles.

When the battery cable is removed, the ACD mode indicator

lamp lights up. After the battery has been recharged, fit the

battery cable back again and start the engine to ensure that

the ACD mode indicator lamp is off.

MD998829

MD998813 MD998812

Battery fuse assembly

Battery cable

for AYC

Page 1371 of 1449

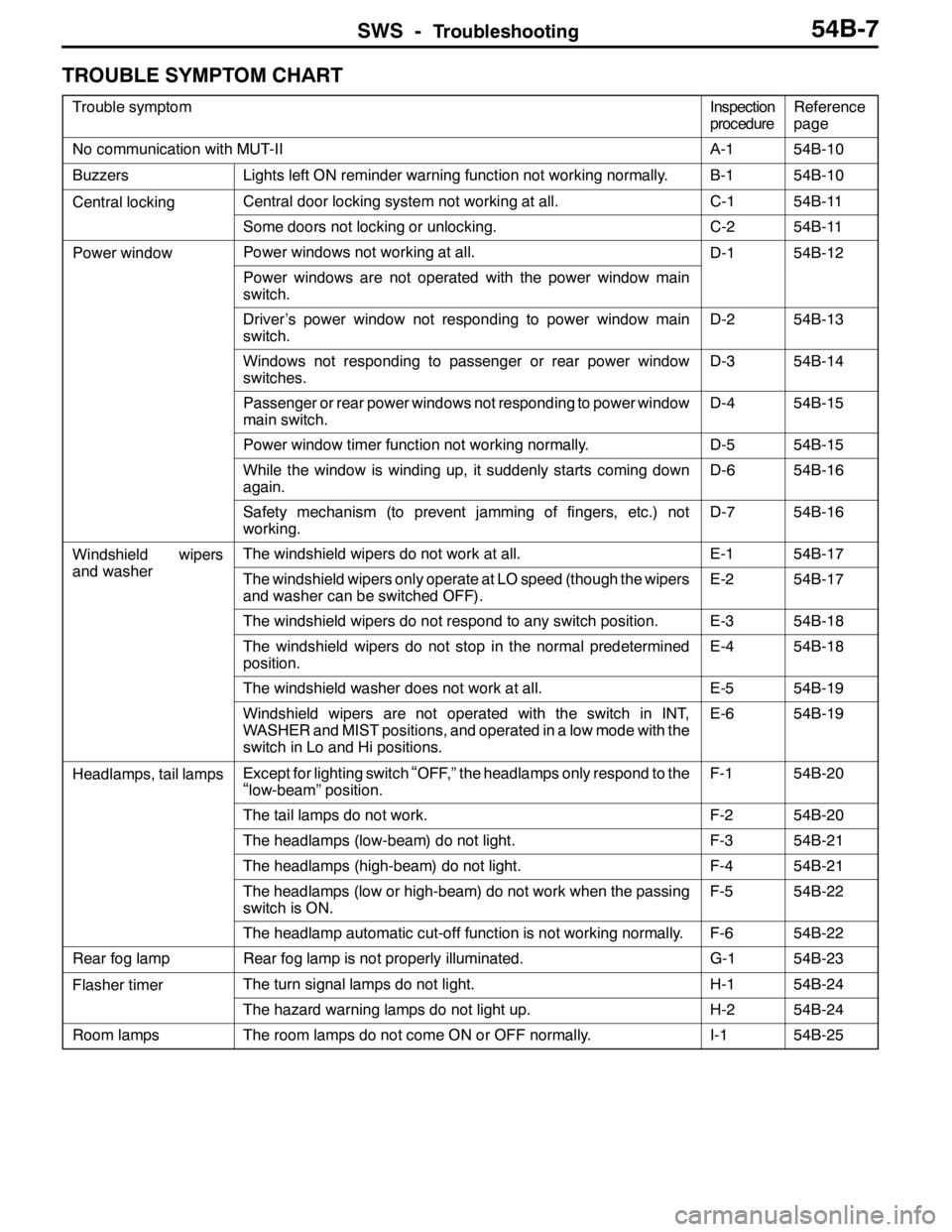

SWS -Troubleshooting54B-7

TROUBLE SYMPTOM CHART

Trouble symptomInspection

procedureReference

page

No communication with MUT-IIA-154B-10

BuzzersLights left ON reminder warning function not working normally.B-154B-10

Central lockingCentral door locking system not working at all.C-154B-11g

Some doors not locking or unlocking.C-254B-11

Power windowPower windows not working at all.D-154B-12

Power windows are not operated with the power window main

switch.

Driver’s power window not responding to power window main

switch.D-254B-13

Windows not responding to passenger or rear power window

switches.D-354B-14

Passenger or rear power windows not responding to power window

main switch.D-454B-15

Power window timer function not working normally.D-554B-15

While the window is winding up, it suddenly starts coming down

again.D-654B-16

Safety mechanism (to prevent jamming of fingers, etc.) not

working.D-754B-16

Windshield wipers

dh

The windshield wipers do not work at all.E-154B-17p

and washerThe windshield wipers only operate at LO speed (though the wipers

and washer can be switched OFF).E-254B-17

The windshield wipers do not respond to any switch position.E-354B-18

The windshield wipers do not stop in the normal predetermined

position.E-454B-18

The windshield washer does not work at all.E-554B-19

Windshield wipers are not operated with the switch in INT,

WASHER and MIST positions, and operated in a low mode with the

switch in Lo and Hi positions.E-654B-19

Headlamps, tail lampsExcept for lighting switch“OFF,” the headlamps only respond to the

“low-beam” position.

F-154B-20

The tail lamps do not work.F-254B-20

The headlamps (low-beam) do not light.F-354B-21

The headlamps (high-beam) do not light.F-454B-21

The headlamps (low or high-beam) do not work when the passing

switch is ON.F-554B-22

The headlamp automatic cut-off function is not working normally.F-654B-22

Rear fog lampRear fog lamp is not properly illuminated.G-154B-23

Flasher timerThe turn signal lamps do not light.H-154B-24

The hazard warning lamps do not light up.H-254B-24

Room lampsThe room lamps do not come ON or OFF normally.I-154B-25

Page 1374 of 1449

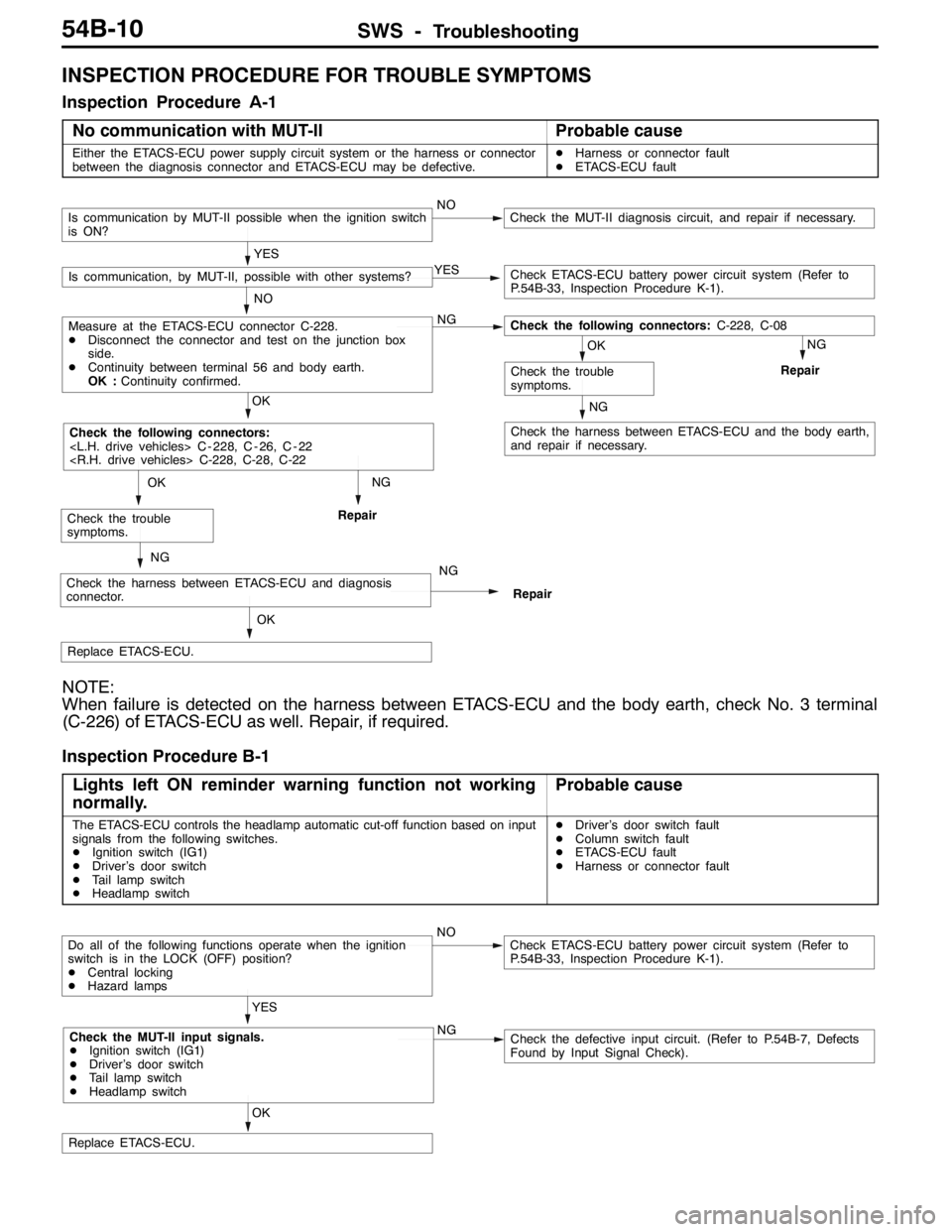

SWS -Troubleshooting54B-10

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure A-1

No communication with MUT-II

Probable cause

Either the ETACS-ECU power supply circuit system or the harness or connector

between the diagnosis connector and ETACS-ECU may be defective.DHarness or connector fault

DETACS-ECU fault

NG

Check the harness between ETACS-ECU and the body earth,

and repair if necessary.

NG

Repair

NG

Repair

OK

Replace ETACS-ECU.

NG

Check the harness between ETACS-ECU and diagnosis

connector.NG

Repair

OK

Check the trouble

symptoms.

OK

Check the following connectors:

OK

Check the trouble

symptoms.

NO

Measure at the ETACS-ECU connector C-228.

DDisconnect the connector and test on the junction box

side.

DContinuity between terminal 56 and body earth.

OK :Continuity confirmed.NGCheck the following connectors:C-228, C-08

YES

Is communication, by MUT-II, possible with other systems?YESCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).

Is communication by MUT-II possible when the ignition switch

is ON?NOCheck the MUT-II diagnosis circuit, and repair if necessary.

NOTE:

When failure is detected on the harness between ETACS-ECU and the body earth, check No. 3 terminal

(C-226) of ETACS-ECU as well. Repair, if required.

Inspection Procedure B-1

Lights left ON reminder warning function not working

normally.

Probable cause

The ETACS-ECU controls the headlamp automatic cut-off function based on input

signals from the following switches.

DIgnition switch (IG1)

DDriver’s door switch

DTail lamp switch

DHeadlamp switchDDriver’s door switch fault

DColumn switch fault

DETACS-ECU fault

DHarness or connector fault

OK

Replace ETACS-ECU.

YES

Check the MUT-II input signals.

DIgnition switch (IG1)

DDriver’s door switch

DTail lamp switch

DHeadlamp switchNGCheck the defective input circuit. (Refer to P.54B-7, Defects

Found by Input Signal Check).

Do all of the following functions operate when the ignition

switch is in the LOCK (OFF) position?

DCentral locking

DHazard lampsNOCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).

Page 1375 of 1449

SWS -Troubleshooting54B-11

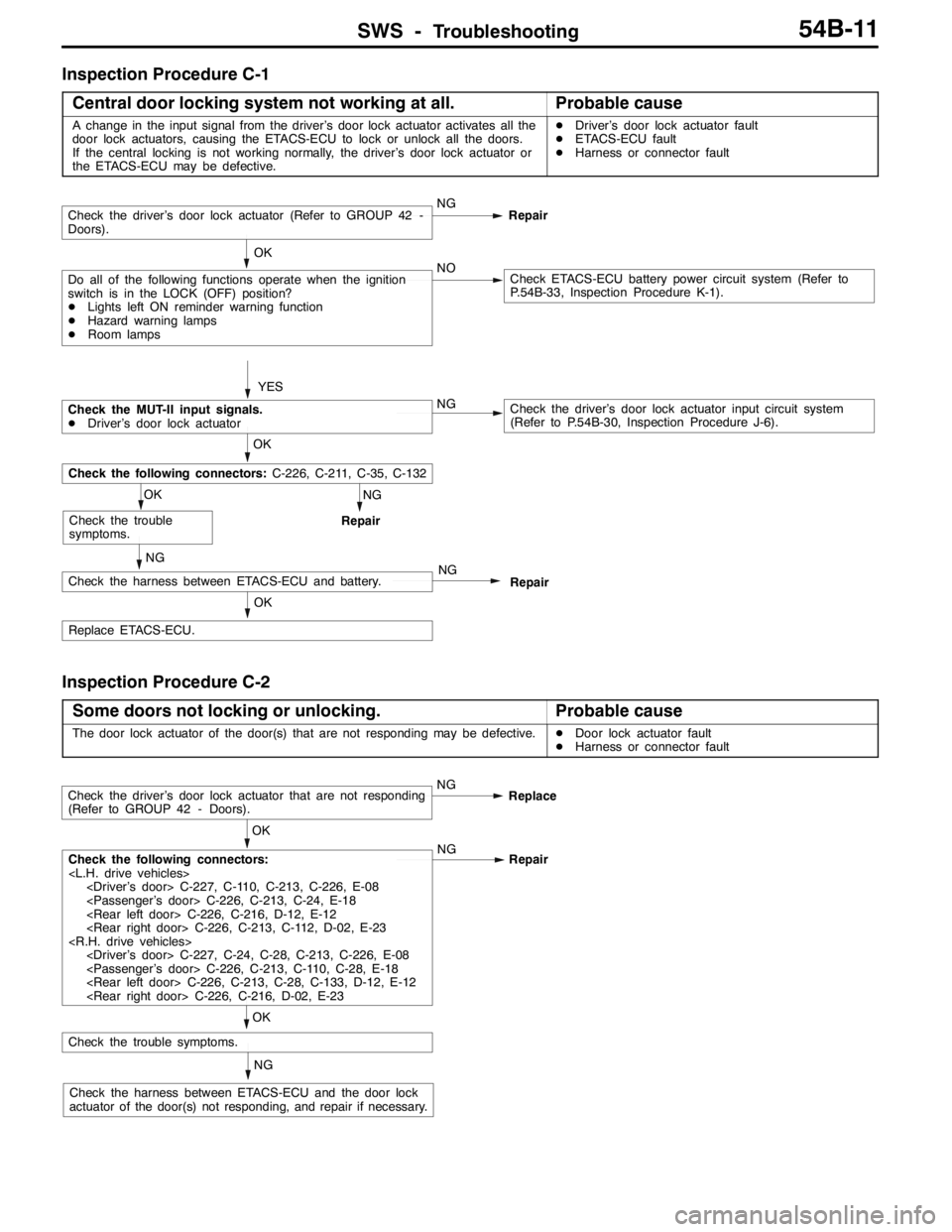

Inspection Procedure C-1

Central door locking system not working at all.

Probable cause

A change in the input signal from the driver’s door lock actuator activates all the

door lock actuators, causing the ETACS-ECU to lock or unlock all the doors.

If the central locking is not working normally, the driver’s door lock actuator or

the ETACS-ECU may be defective.DDriver’s door lock actuator fault

DETACS-ECU fault

DHarness or connector fault

NG

Repair

OK

Replace ETACS-ECU.

NG

Check the harness between ETACS-ECU and battery.NG

Repair

OK

Check the trouble

symptoms.

OK

Check the following connectors:C-226, C-211, C-35, C-132

YES

Check the driver’s door lock actuator (Refer to GROUP 42 -

Doors).NG

Repair

Do all of the following functions operate when the ignition

switch is in the LOCK (OFF) position?

DLights left ON reminder warning function

DHazard warning lamps

DRoom lampsNOCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1). OK

Check the MUT-II input signals.

DDriver’s door lock actuatorNGCheck the driver’s door lock actuator input circuit system

(Refer to P.54B-30, Inspection Procedure J-6).

Inspection Procedure C-2

Some doors not locking or unlocking.

Probable cause

The door lock actuator of the door(s) that are not responding may be defective.DDoor lock actuator fault

DHarness or connector fault

NG

Check the harness between ETACS-ECU and the door lock

actuator of the door(s) not responding, and repair if necessary.

OK

Check the trouble symptoms.

OK

Check the following connectors:

Repair

Check the driver’s door lock actuator that are not responding

(Refer to GROUP 42 - Doors).NG

Replace

Page 1385 of 1449

SWS -Troubleshooting54B-21

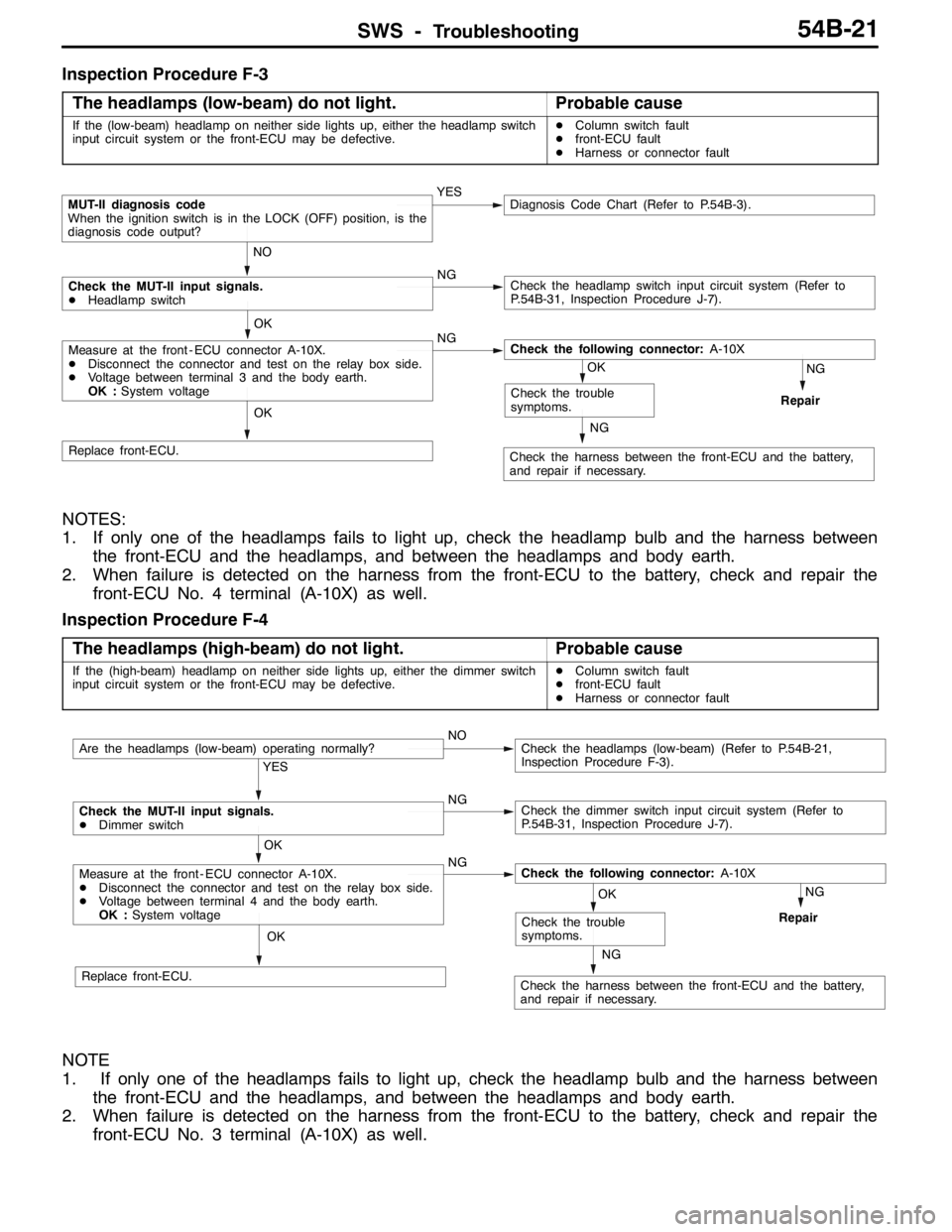

Inspection Procedure F-3

The headlamps (low-beam) do not light.

Probable cause

If the (low-beam) headlamp on neither side lights up, either the headlamp switch

input circuit system or the front-ECU may be defective.DColumn switch fault

Dfront-ECU fault

DHarness or connector fault

NO

Check the MUT-II input signals.

DHeadlamp switchNGCheck the headlamp switch input circuit system (Refer to

P.54B-31, Inspection Procedure J-7).

NG

Repair

NG

Check the harness between the front-ECU and the battery,

and repair if necessary.

OK

Replace front-ECU.

OK

Check the trouble

symptoms.

OK

Measure at the front - ECU connector A-10X.

DDisconnect the connector and test on the relay box side.

DVoltage between terminal 3 and the body earth.

OK :System voltageNGCheck the following connector:A-10X

MUT-II diagnosis code

When the ignition switch is in the LOCK (OFF) position, is the

diagnosis code output?YESDiagnosis Code Chart (Refer to P.54B-3).

NOTES:

1. If only one of the headlamps fails to light up, check the headlamp bulb and the harness between

the front-ECU and the headlamps, and between the headlamps and body earth.

2. When failure is detected on the harness from the front-ECU to the battery, check and repair the

front-ECU No. 4 terminal (A-10X) as well.

Inspection Procedure F-4

The headlamps (high-beam) do not light.

Probable cause

If the (high-beam) headlamp on neither side lights up, either the dimmer switch

input circuit system or the front-ECU may be defective.DColumn switch fault

Dfront-ECU fault

DHarness or connector fault

NG

Check the harness between the front-ECU and the battery,

and repair if necessary.OK

Check the trouble

symptoms.

NG

Repair

OK

Measure at the front - ECU connector A-10X.

DDisconnect the connector and test on the relay box side.

DVoltage between terminal 4 and the body earth.

OK :System voltageNGCheck the following connector:A-10X

YES

Check the MUT-II input signals.

DDimmer switchNGCheck the dimmer switch input circuit system (Refer to

P.54B-31, Inspection Procedure J-7).

OK

Replace front-ECU.

Are the headlamps (low-beam) operating normally?NOCheck the headlamps (low-beam) (Refer to P.54B-21,

Inspection Procedure F-3).

NOTE

1. If only one of the headlamps fails to light up, check the headlamp bulb and the harness between

the front-ECU and the headlamps, and between the headlamps and body earth.

2. When failure is detected on the harness from the front-ECU to the battery, check and repair the

front-ECU No. 3 terminal (A-10X) as well.

Page 1388 of 1449

SWS -TroubleshootingSWS -Troubleshooting54B-24

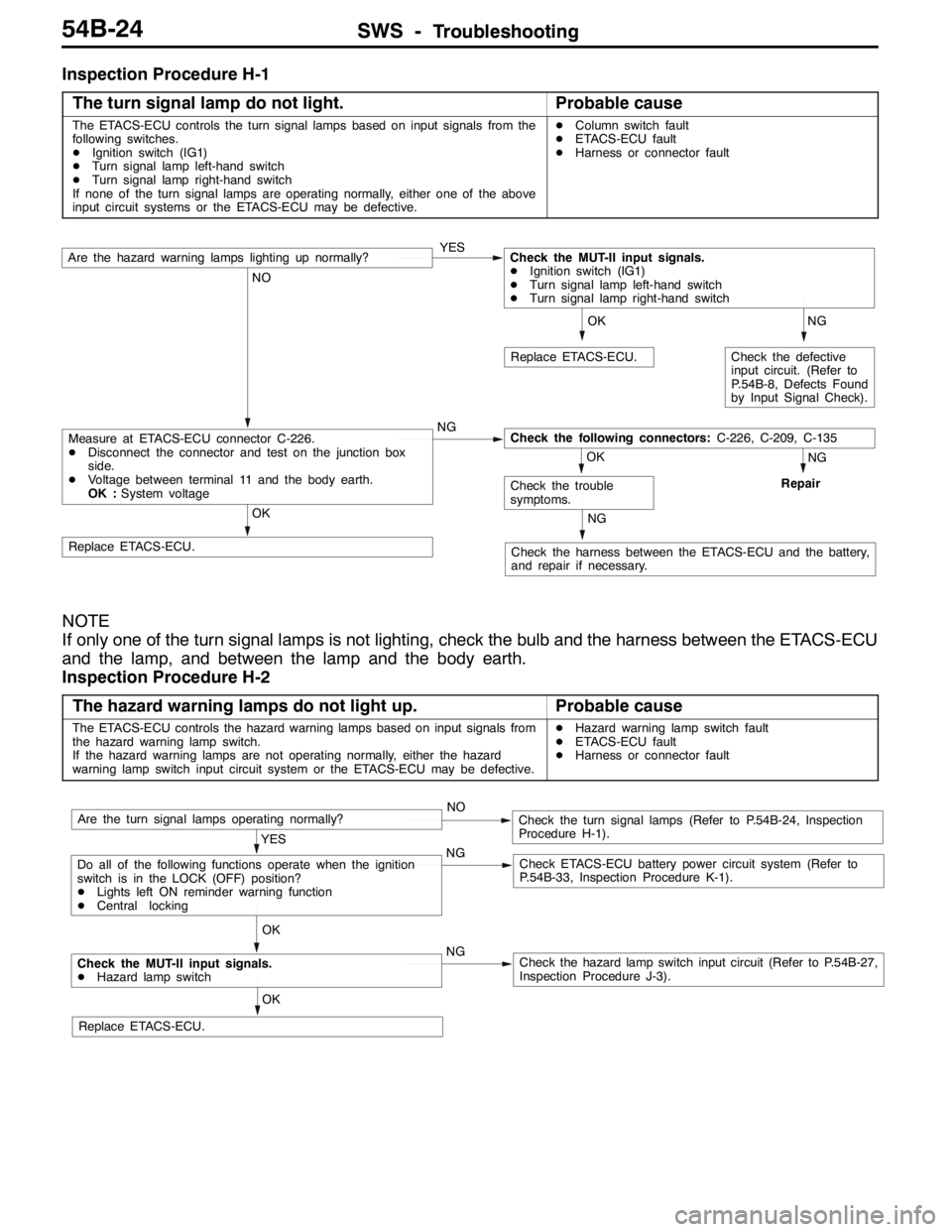

Inspection Procedure H-1

The turn signal lamp do not light.

Probable cause

The ETACS-ECU controls the turn signal lamps based on input signals from the

following switches.

DIgnition switch (IG1)

DTurn signal lamp left-hand switch

DTurn signal lamp right-hand switch

If none of the turn signal lamps are operating normally, either one of the above

input circuit systems or the ETACS-ECU may be defective.DColumn switch fault

DETACS-ECU fault

DHarness or connector fault

NG

Check the defective

input circuit. (Refer to

P.54B-8, Defects Found

by Input Signal Check).

OK

Replace ETACS-ECU.

NG

Repair

NG

Check the harness between the ETACS-ECU and the battery,

and repair if necessary.Replace ETACS-ECU.

OK

OK

Check the trouble

symptoms.

NO

Measure at ETACS-ECU connector C-226.

DDisconnect the connector and test on the junction box

side.

DVoltage between terminal 11 and the body earth.

OK :System voltageNGCheck the following connectors:C-226, C-209, C-135

Are the hazard warning lamps lighting up normally?YESCheck the MUT-II input signals.

DIgnition switch (IG1)

DTurn signal lamp left-hand switch

DTurn signal lamp right-hand switch

NOTE

If only one of the turn signal lamps is not lighting, check the bulb and the harness between the ETACS-ECU

and the lamp, and between the lamp and the body earth.

Inspection Procedure H-2

The hazard warning lamps do not light up.

Probable cause

The ETACS-ECU controls the hazard warning lamps based on input signals from

the hazard warning lamp switch.

If the hazard warning lamps are not operating normally, either the hazard

warning lamp switch input circuit system or the ETACS-ECU may be defective.DHazard warning lamp switch fault

DETACS-ECU fault

DHarness or connector fault

OK

Replace ETACS-ECU.

OK

Check the MUT-II input signals.

DHazard lamp switchNGCheck the hazard lamp switch input circuit (Refer to P.54B-27,

Inspection Procedure J-3).

YES

Do all of the following functions operate when the ignition

switch is in the LOCK (OFF) position?

DLights left ON reminder warning function

DCentral lockingNGCheck ETACS-ECU battery power circuit system (Refer to

P.54B-33, Inspection Procedure K-1).

Are the turn signal lamps operating normally?NOCheck the turn signal lamps (Refer to P.54B-24, Inspection

Procedure H-1).

Page 1390 of 1449

SWS -Troubleshooting54B-26

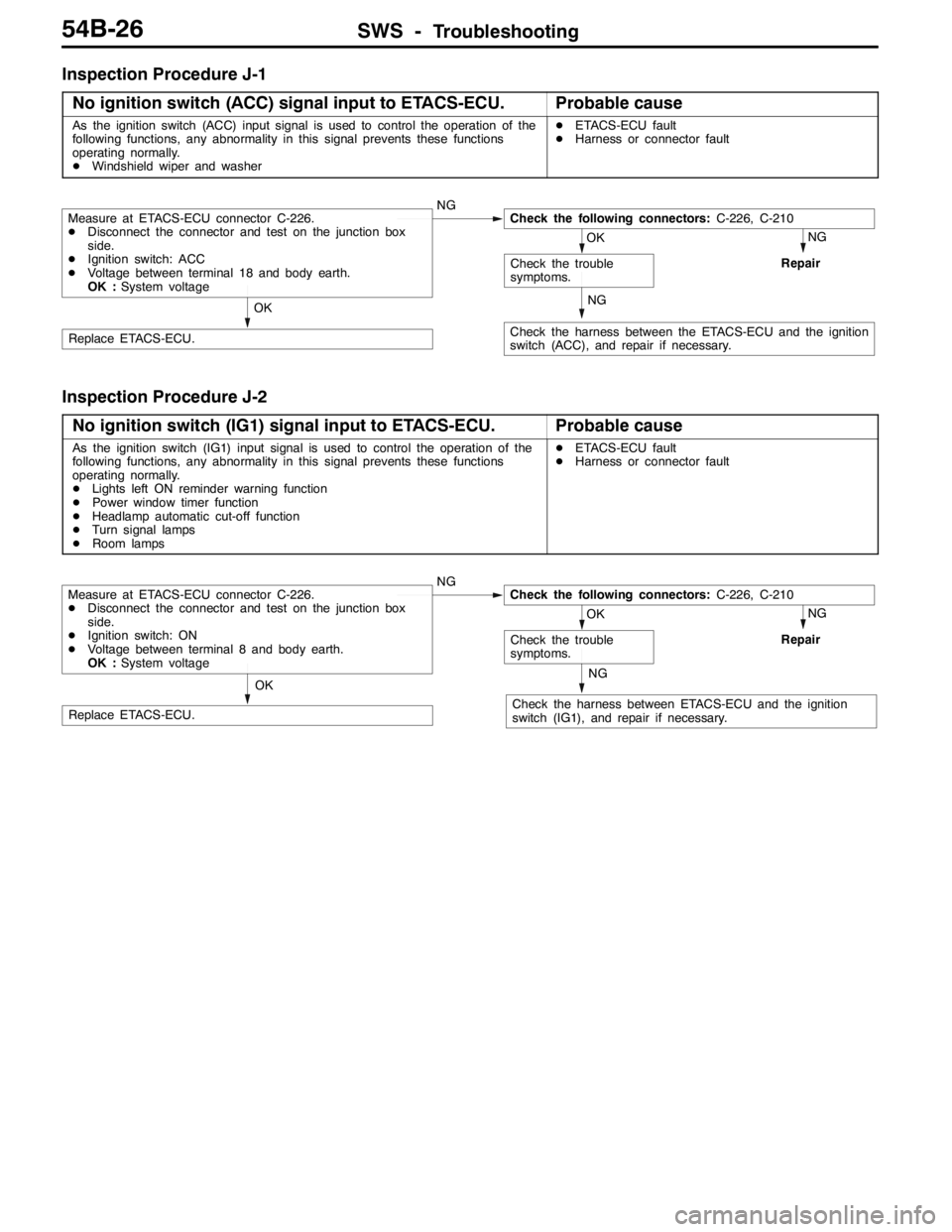

Inspection Procedure J-1

No ignition switch (ACC) signal input to ETACS-ECU.

Probable cause

As the ignition switch (ACC) input signal is used to control the operation of the

following functions, any abnormality in this signal prevents these functions

operating normally.

DWindshield wiper and washerDETACS-ECU fault

DHarness or connector fault

NG

Repair

NG

Check the harness between the ETACS-ECU and the ignition

switch (ACC), and repair if necessary.

OK

Replace ETACS-ECU.

OK

Check the trouble

symptoms.

Measure at ETACS-ECU connector C-226.

DDisconnect the connector and test on the junction box

side.

DIgnition switch: ACC

DVoltage between terminal 18 and body earth.

OK :System voltageNGCheck the following connectors:C-226, C-210

Inspection Procedure J-2

No ignition switch (IG1) signal input to ETACS-ECU.

Probable cause

As the ignition switch (IG1) input signal is used to control the operation of the

following functions, any abnormality in this signal prevents these functions

operating normally.

DLights left ON reminder warning function

DPower window timer function

DHeadlamp automatic cut-off function

DTurn signal lamps

DRoom lampsDETACS-ECU fault

DHarness or connector fault

NG

Repair

NG

Check the harness between ETACS-ECU and the ignition

switch (IG1), and repair if necessary.

OK

Replace ETACS-ECU.

OK

Check the trouble

symptoms.

Measure at ETACS-ECU connector C-226.

DDisconnect the connector and test on the junction box

side.

DIgnition switch: ON

DVoltage between terminal 8 and body earth.

OK :System voltageNGCheck the following connectors:C-226, C-210

Page 1393 of 1449

SWS -Troubleshooting54B-29

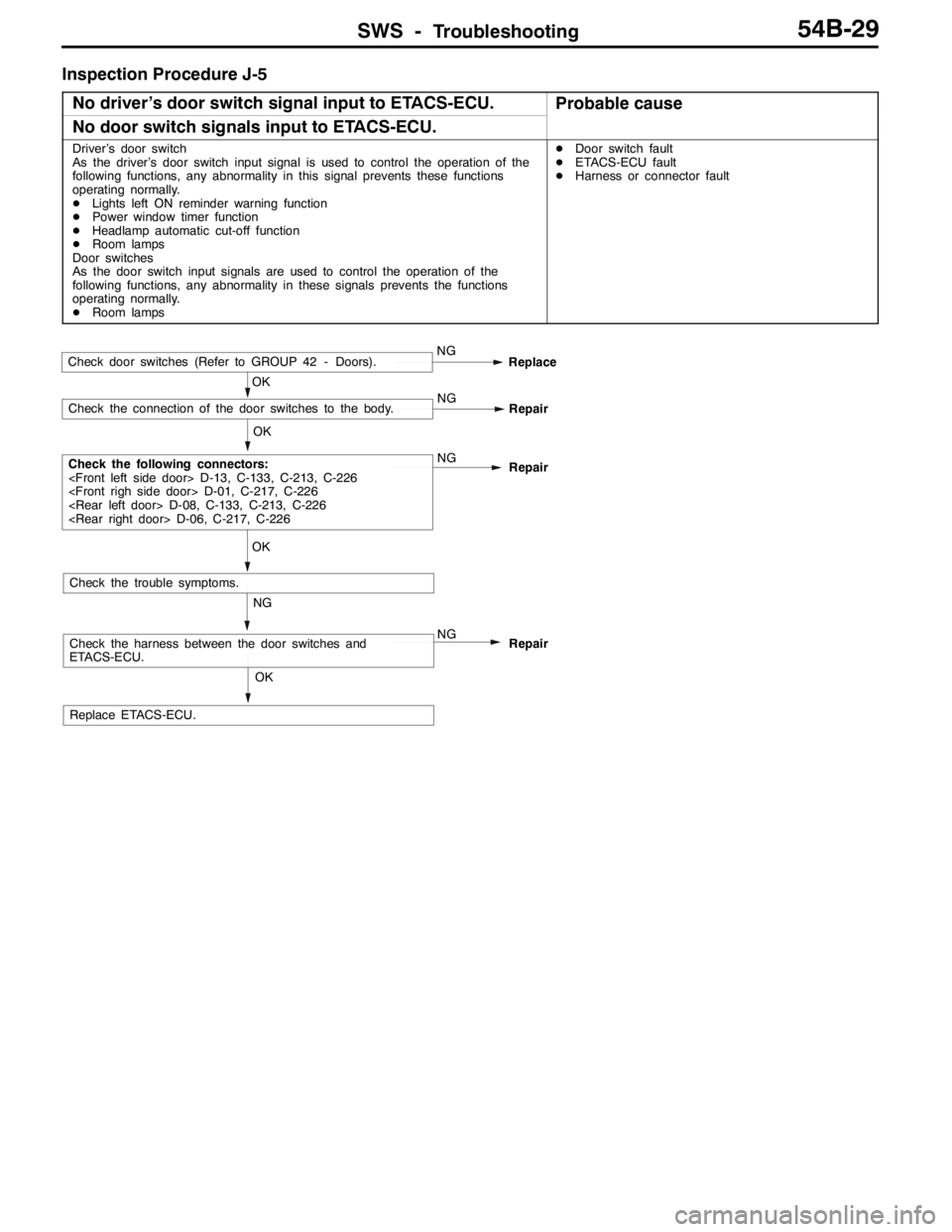

Inspection Procedure J-5

No driver’s door switch signal input to ETACS-ECU.

Probable cause

No door switch signals input to ETACS-ECU.

Driver’s door switch

As the driver’s door switch input signal is used to control the operation of the

following functions, any abnormality in this signal prevents these functions

operating normally.

DLights left ON reminder warning function

DPower window timer function

DHeadlamp automatic cut-off function

DRoom lamps

Door switches

As the door switch input signals are used to control the operation of the

following functions, any abnormality in these signals prevents the functions

operating normally.

DRoom lampsDDoor switch fault

DETACS-ECU fault

DHarness or connector fault

OK

Replace ETACS-ECU.

NG

Check the harness between the door switches and

ETACS-ECU.NG

Repair

OK

Check the trouble symptoms.

OK

Check the following connectors:

Repair

OK

Check the connection of the door switches to the body.NG

Repair

Check door switches (Refer to GROUP 42 - Doors).NG

Replace

Page 1395 of 1449

SWS -Troubleshooting54B-31

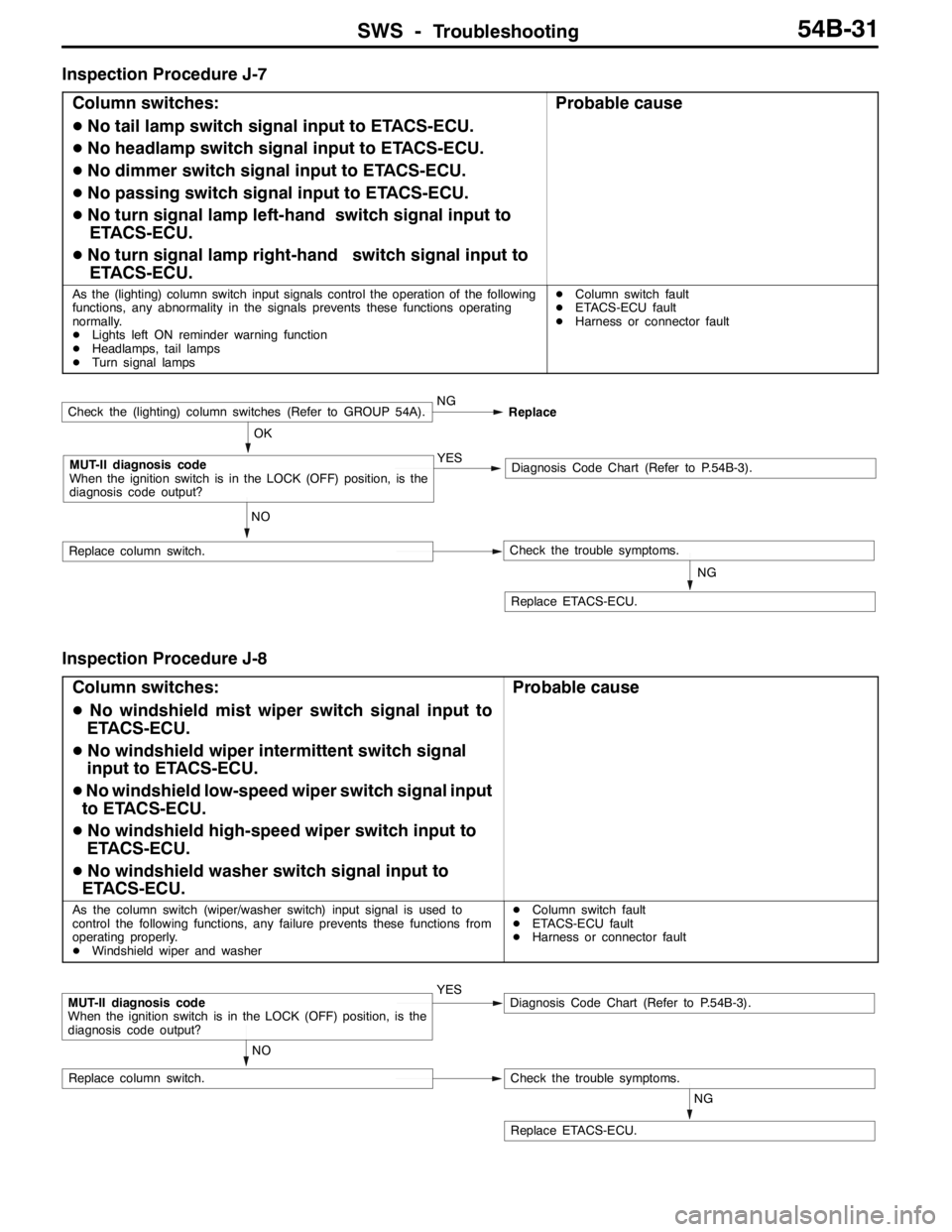

Inspection Procedure J-7

Column switches:

DNo tail lamp switch signal input to ETACS-ECU.

DNo headlamp switch signal input to ETACS-ECU.

DNo dimmer switch signal input to ETACS-ECU.

DNo passing switch signal input to ETACS-ECU.

DNo turn signal lamp left-hand switch signal input to

ETACS-ECU.

DNo turn signal lamp right-hand switch signal input to

ETACS-ECU.

Probable cause

As the (lighting) column switch input signals control the operation of the following

functions, any abnormality in the signals prevents these functions operating

normally.

DLights left ON reminder warning function

DHeadlamps, tail lamps

DTurn signal lampsDColumn switch fault

DETACS-ECU fault

DHarness or connector fault

NG

Replace ETACS-ECU.

NO

Replace column switch.Check the trouble symptoms.

OK

MUT-II diagnosis code

When the ignition switch is in the LOCK (OFF) position, is the

diagnosis code output?YESDiagnosis Code Chart (Refer to P.54B-3).

Check the (lighting) column switches (Refer to GROUP 54A).NG

Replace

Inspection Procedure J-8

Column switches:

DNo windshield mist wiper switch signal input to

ETACS-ECU.

DNo windshield wiper intermittent switch signal

input to ETACS-ECU.

DNo windshield low-speed wiper switch signal input

to ETACS-ECU.

DNo windshield high-speed wiper switch input to

ETACS-ECU.

DNo windshield washer switch signal input to

ETACS-ECU.

Probable cause

As the column switch (wiper/washer switch) input signal is used to

control the following functions, any failure prevents these functions from

operating properly.

DWindshield wiper and washerDColumn switch fault

DETACS-ECU fault

DHarness or connector fault

NG

Replace ETACS-ECU.

NO

Replace column switch.Check the trouble symptoms.

MUT-II diagnosis code

When the ignition switch is in the LOCK (OFF) position, is the

diagnosis code output?YESDiagnosis Code Chart (Refer to P.54B-3).