manual transmission MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1 of 1449

00

11

12

13

14

15

16

17

21

22

25

26

27

31

32

33

34

35

36

37

42

51

52

54

55

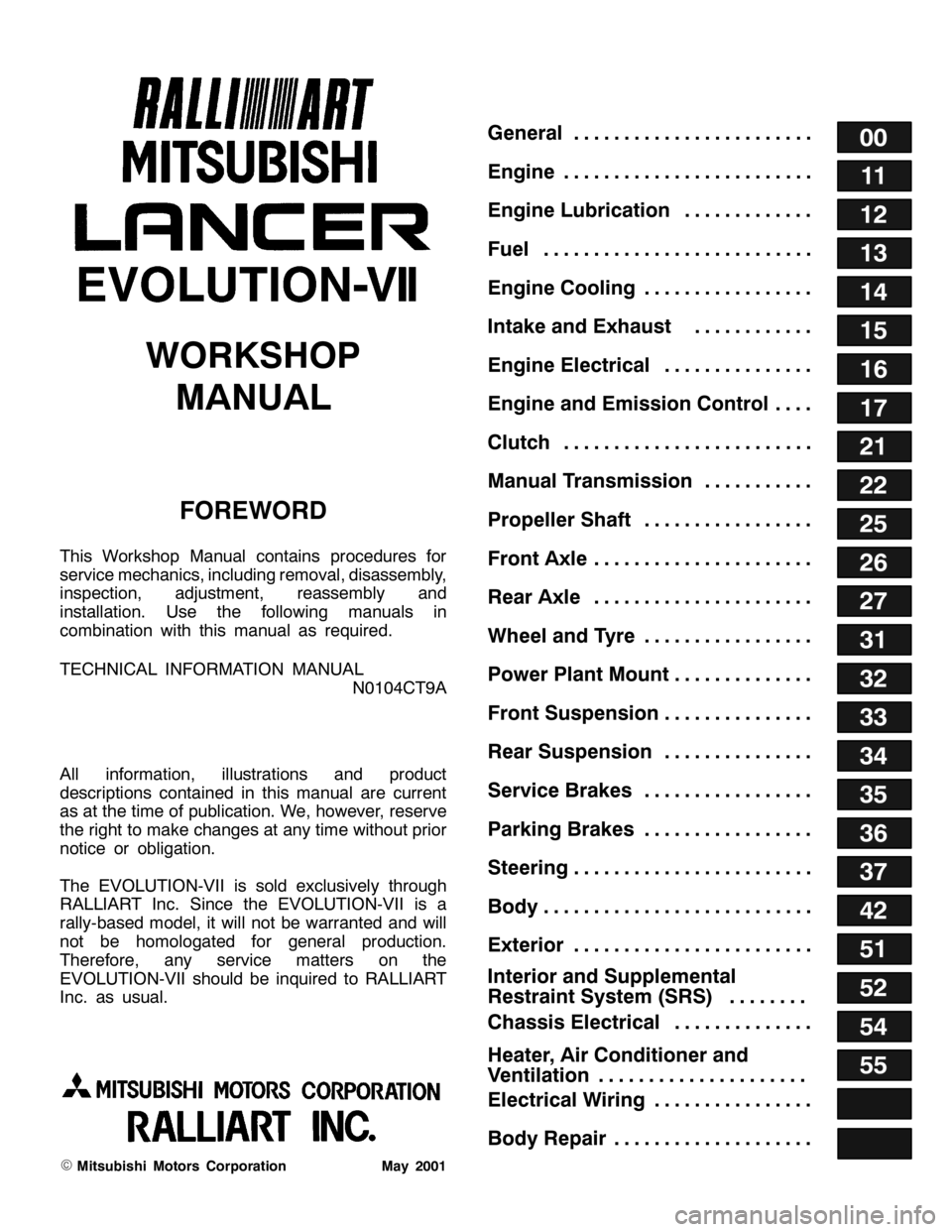

General........................

Engine .........................

Engine Lubrication .............

Fuel ...........................

Engine Cooling .................

Intake and Exhaust ............

Engine Electrical ...............

Engine and Emission Control ....

Clutch .........................

Manual Transmission ...........

Propeller Shaft .................

Front Axle ......................

Rear Axle ......................

Wheel and Tyre .................

Power Plant Mount ..............

Front Suspension ...............

Rear Suspension ...............

Service Brakes .................

Parking Brakes .................

Steering ........................

Body ...........................

Exterior ........................

Chassis Electrical ..............

Electrical Wiring ................

Body Repair ....................

WORKSHOP

MANUAL

FOREWORD

This Workshop Manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and

installation. Use the following manuals in

combination with this manual as required.

TECHNICAL INFORMATION MANUAL N0104CT9A

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

The EVOLUTION-VII is sold exclusively through

RALLIART Inc. Since the EVOLUTION-VII is a

rally-based model, it will not be warranted and will

not be homologated for general production.

Therefore, any service matters on the

EVOLUTION-VII should be inquired to RALLIART

Inc. as usual.

EMitsubishi Motors Corporation May 2001

Interior and Supplemental

Restraint System (SRS) ........

Heater, Air Conditioner and

Ventilation .....................

Page 380 of 1449

GENERAL -How to Use This Manual00-2

HOW TO USE THIS MANUAL

SCOPE OF MAINTENANCE, REPAIR

AND SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Note, however,

that for engine and transmission-related component

parts, this manual covers only on-vehicle

inspections, adjustments, and the removal and

installation procedures for major components.

For detailed information concerning the inspection,

checking, adjustment, disassembly and reassembly

of the engine, transmission and major components

after they have been removed from the vehicle,

please refer to separate manuals covering the

engine and the transmission.

ON-VEHICLE SERVICE

“On-vehicle Service” is procedures for performing

inspections and adjustments of particularly

important locations with regard to the construction

and for maintenance and servicing, but other

inspection (for looseness, play, cracking, damage,

etc.) must also be performed.

INSPECTION

Under this title are presented inspection and

checking procedures to be performed by using

special tools and measuring instruments and by

feeling, but, for actual maintenance and servicing

procedures, visual inspections should always be

performed as well.

INDICATION OF DESTINATION

General Export and GCC are used for convenience

to indicate destination.

NOTE

(1) “General Export” means territories other than

Europe, GCC, Australia, New Zealand, the

U.S.A. and Canada.

(2) “GCC” indicates countries that are members

of the (Persian) Gulf Cooperation Council of

nations.

(3) In some instances, vehicles with other

specifications may be shipped to some

countries.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection

or the value to which the part or assembly is

corrected and adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a

part or assembly on inspection and means the

maximum or minimum value within which the part

or assembly must be kept functionally or in strength.

It is a value established outside the range of

standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be

completed in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of

maintenance and servicing procedures in order to

avoid the possibility of injury to the worker, or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUE

Tightening torques (units: N·m) are set to take into

account the central value and the allowable

tolerance. The central value is the target value,

and the allowable tolerance provides the checking

range for tightening torques. If bolts and nuts are

not provided with tightening torques, refer to

P.00-28.

Page 381 of 1449

GENERAL -How to Use This Manual00-3

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

MPI: Indicates the multipoint injection, or engine equipped with the multipoint injection.

DOHC: Indicates an engine with the double overhead camshaft, or a model equipped with such an

engine.

M/T: Indicates the manual transmission, or models equipped with the manual transmission.

A/C: Indicates the air conditioner.

Page 382 of 1449

GENERAL -How to Use This Manual00-4

EXPLANATION OF MANUAL CONTENTS

Indicates procedures to be performed

before the work in that section is started,

and procedures to be performed after

the work in that section is finished.

Indicates (by symbols) where lubrica-

tion is necessary.

Maintenance and Servicing Procedures

The numbers provided within the diagram indi-

cate the sequence for maintenance and servic-

ing procedures.

DRemoval steps:

The part designation number corresponds

to the number in the illustration to indicate

removal steps.

DDisassembly steps:

The part designation number corresponds

to the number in the illustration to indicate

disassembly steps.DInstallation steps:

Specified in case installation is impossible

in reverse order of removal steps. Omitted

if installation is possible in reverse order of

removal steps.

DReassembly steps:

Specified in case reassembly is impossible

in reverse order of disassembly steps.

Omitted if reassembly is possible in reverse

order of disassembly steps.

Classifications of Major Maintenance/Service Points

When there are major points relative to maintenance and servicing procedures

(such as essential maintenance and service points, maintenance and service stan-

dard values, information regarding the use of special tools, etc.), these are ar-

ranged together as major maintenance and service points and explained in detail.

AA": Indicates that there are essential points for removal or disassembly.

"AA: Indicates that there are essential points for installation or reassembly.

Symbols for Lubrication, Sealants and Adhesives

Information concerning the locations for lubrica-

tion and for application of sealants and adhe-

sives is provided, by using symbols, in the dia-

gram of component parts or on the page follow-

ing the component parts page, and explained.: Grease

(multipurpose grease unless there is

a brand or type specified)

: Sealant or adhesive

: Brake fluid or automatic transmission fluid

: Engine oil, gear oil or air conditioner

compressor oil

: Adhesive tape or butyl rubber tape

Component Diagram

A diagram of the component parts is

provided near the front of each section

in order to give a reader a better under-

standing of the installed condition of

component parts.

Page 393 of 1449

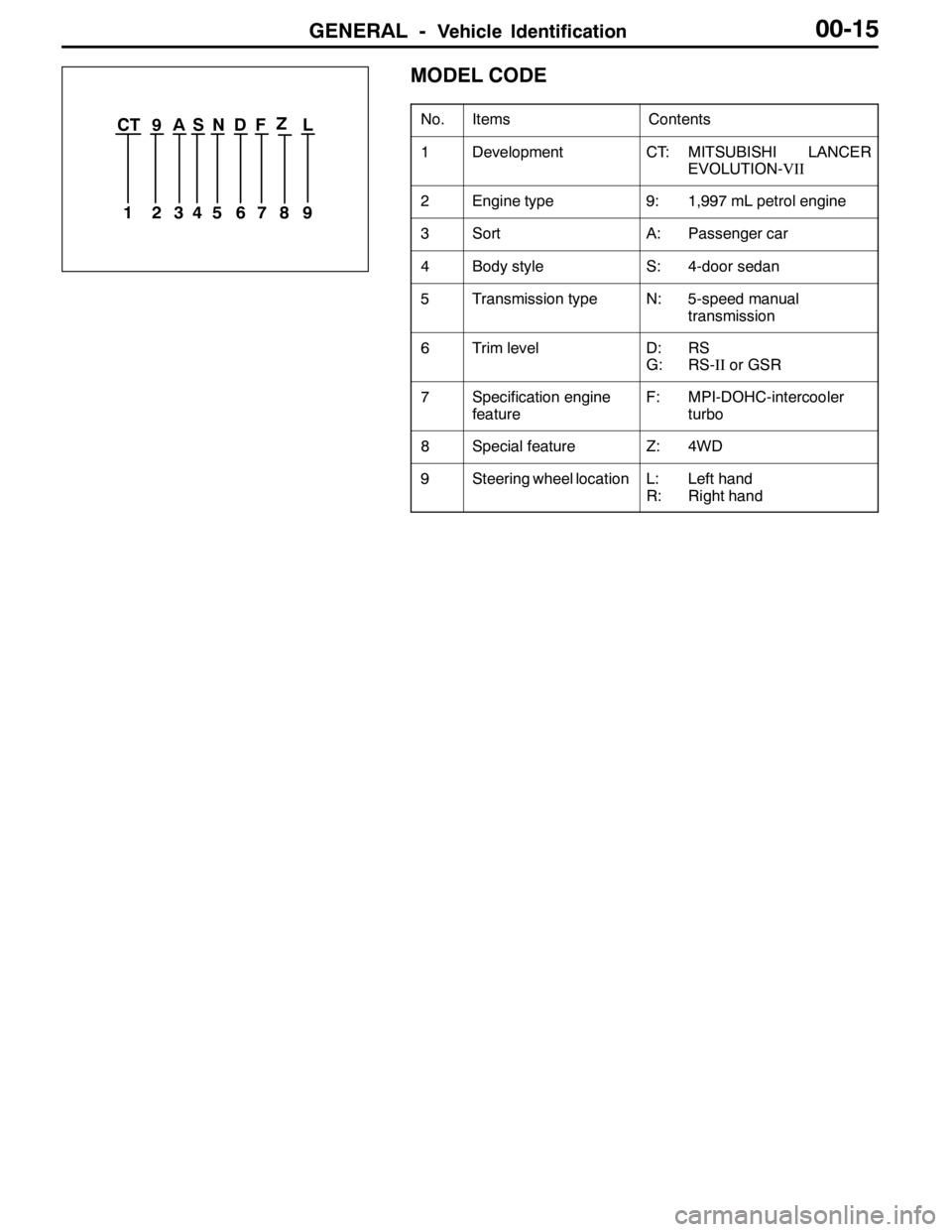

GENERAL -Vehicle Identification00-15

MODEL CODE

No.ItemsContents

1DevelopmentCT: MITSUBISHI LANCER

EVOLUTION-VII

2Engine type9: 1,997 mL petrol engine

3SortA: Passenger car

4Body styleS: 4-door sedan

5Transmission typeN: 5-speed manual

transmission

6Trim levelD: RS

G: RS-IIor GSR

7Specification engine

featureF: MPI-DOHC-intercooler

turbo

8Special featureZ: 4WD

9Steering wheel locationL: Left hand

R: Right hand

123456789 CT 9 A S N D F L

Z

Page 394 of 1449

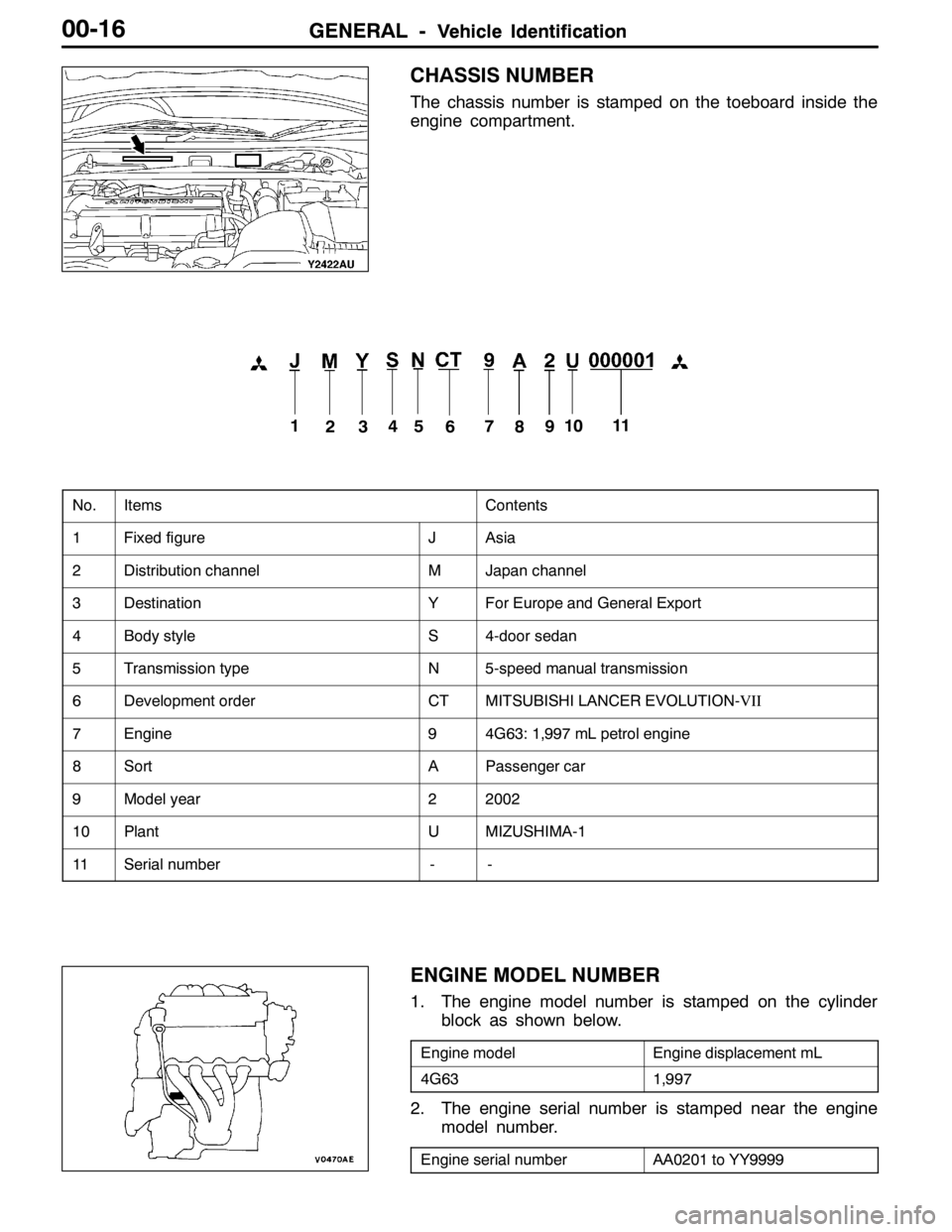

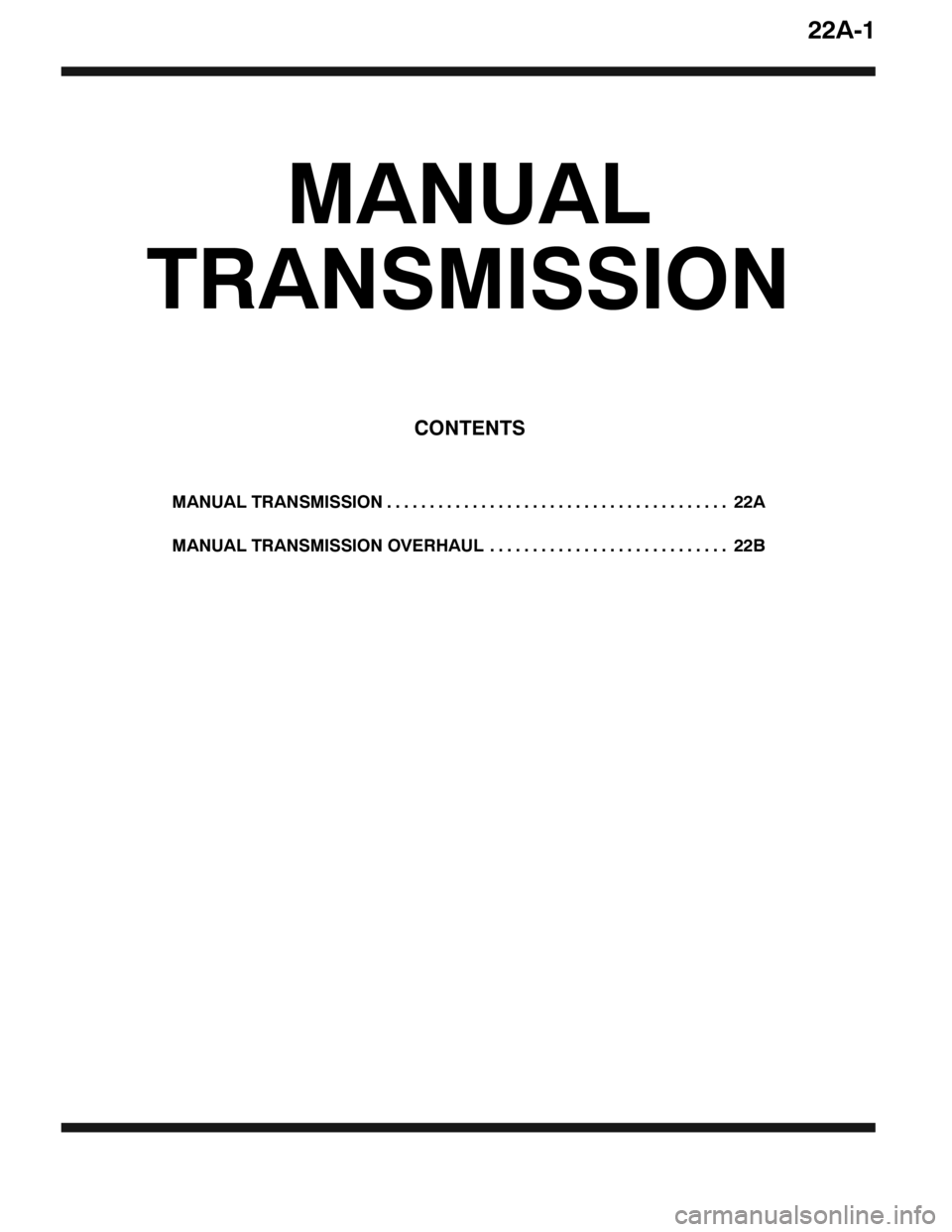

GENERAL -Vehicle IdentificationGENERAL -Vehicle Identification00-16

CHASSIS NUMBER

The chassis number is stamped on the toeboard inside the

engine compartment.

1

234

5

67

8911

10

No.ItemsContents

1Fixed figureJAsia

2Distribution channelMJapan channel

3DestinationYFor Europe and General Export

4Body styleS4-door sedan

5Transmission typeN5-speed manual transmission

6Development orderCTMITSUBISHI LANCER EVOLUTION-VII

7Engine94G63: 1,997 mL petrol engine

8SortAPassenger car

9Model year22002

10PlantUMIZUSHIMA-1

11Serial number--

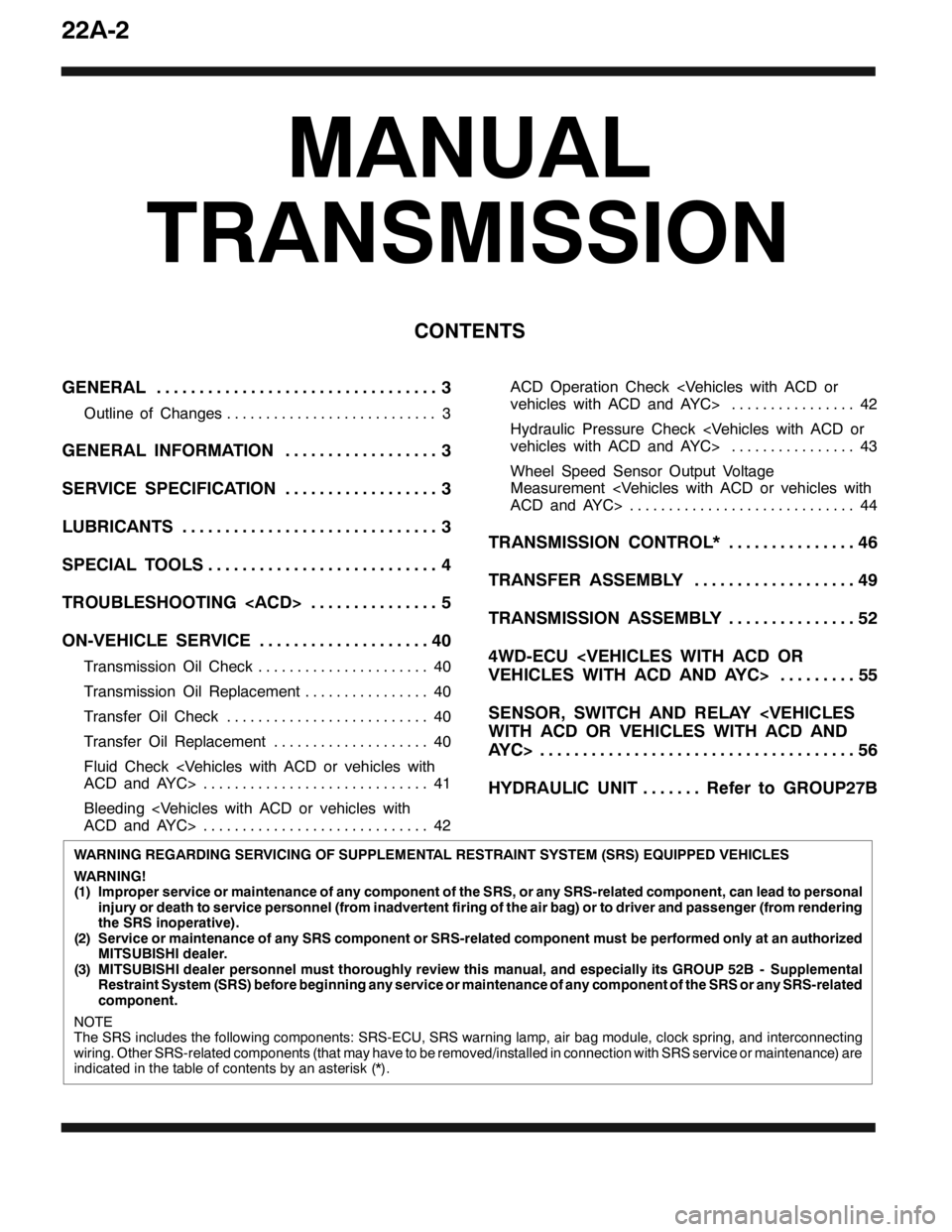

ENGINE MODEL NUMBER

1. The engine model number is stamped on the cylinder

block as shown below.

Engine modelEngine displacement mL

4G631,997

2. The engine serial number is stamped near the engine

model number.

Engine serial numberAA0201 to YY9999

Page 809 of 1449

MANUAL TRANSMISSION 22A........................................

MANUAL TRANSMISSION OVERHAUL 22B............................

22A-1

MANUAL

TRANSMISSION

CONTENTS

Page 810 of 1449

22A-2

MANUAL

TRANSMISSION

CONTENTS

GENERAL 3.................................

Outline of Changes 3...........................

GENERAL INFORMATION 3..................

SERVICE SPECIFICATION 3..................

LUBRICANTS 3..............................

SPECIAL TOOLS 4...........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 40....................

Transmission Oil Check 40......................

Transmission Oil Replacement 40................

Transfer Oil Check 40..........................

Transfer Oil Replacement 40....................

Fluid Check

Bleeding

Hydraulic Pressure Check

Wheel Speed Sensor Output Voltage

Measurement

TRANSMISSION CONTROL* 46...............

TRANSFER ASSEMBLY 49...................

TRANSMISSION ASSEMBLY 52...............

4WD-ECU

SENSOR, SWITCH AND RELAY

AYC> 56.....................................

HYDRAULIC UNIT Refer to GROUP27B.......

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 811 of 1449

MANUAL TRANSMISSION -General/General Information/

Service Specification/Lubricants22A-3

GENERAL

OUTLINE OF CHANGE

With the addition of the EVOLUTION-VII, the W5M51 transmission service adjustment procedure has

been set as follows.

GENERAL INFORMATION

ItemsSpecifications

GradeRS, RS IIRS, RS II (With super cross gear)

Transmission modelW5M51

Engine model4G63-DOHC-T/C

Type5-speed, floor-shift

Gear ratio1st2.7852.785

2nd1.9501.950

3rd1.4071.444

4th1.0311.096

5th0.7200.825

Reverse3.4163.416

Final reduction ratio

(Differential gear ratio)4.5294.529

Front limited-slip differential

(Helical-gear type)Not providedProvided

TransferReduction ratio3.3073.307

Limited-slipdifferentialVCU or hydraulic multi plate

clutch (ACD)VCU or hydraulic multi plate

clutch (ACD)

SERVICE SPECIFICATION

ItemStandard value

Hydraulic unit generation oil pressureMPa1.0 - 1.6

LUBRICANTS

ItemSpecified lubricantQuantity L

Transmission oilGear oil SAE 75W-90 or 75W-85W conforming to API GL-42.8

Transfer

oilVehicles without ACD or ve-

hicles without ACD and AYCMITSUBISHI Genuine Gear Oil Part No.8149630 EX,

CASTROL HYPOY LS (GL-5, SAE 90), SHELL-LSD

(GL 5SAE80W90)orequivalent

0.55

Vehicles with ACD or vehicles

with ACD and AYC(GL-5, SAE 80W - 90) or equivalent0.6

FluidPiping between ACD and

hydraulic unitDIA QUEEN ATF SP III0.9

Pipes between ACD and hy-

draulic unit and between AYC

and hydraulic unit1.0

Page 812 of 1449

MANUAL TRANSMISSION - Special Tools22A-4

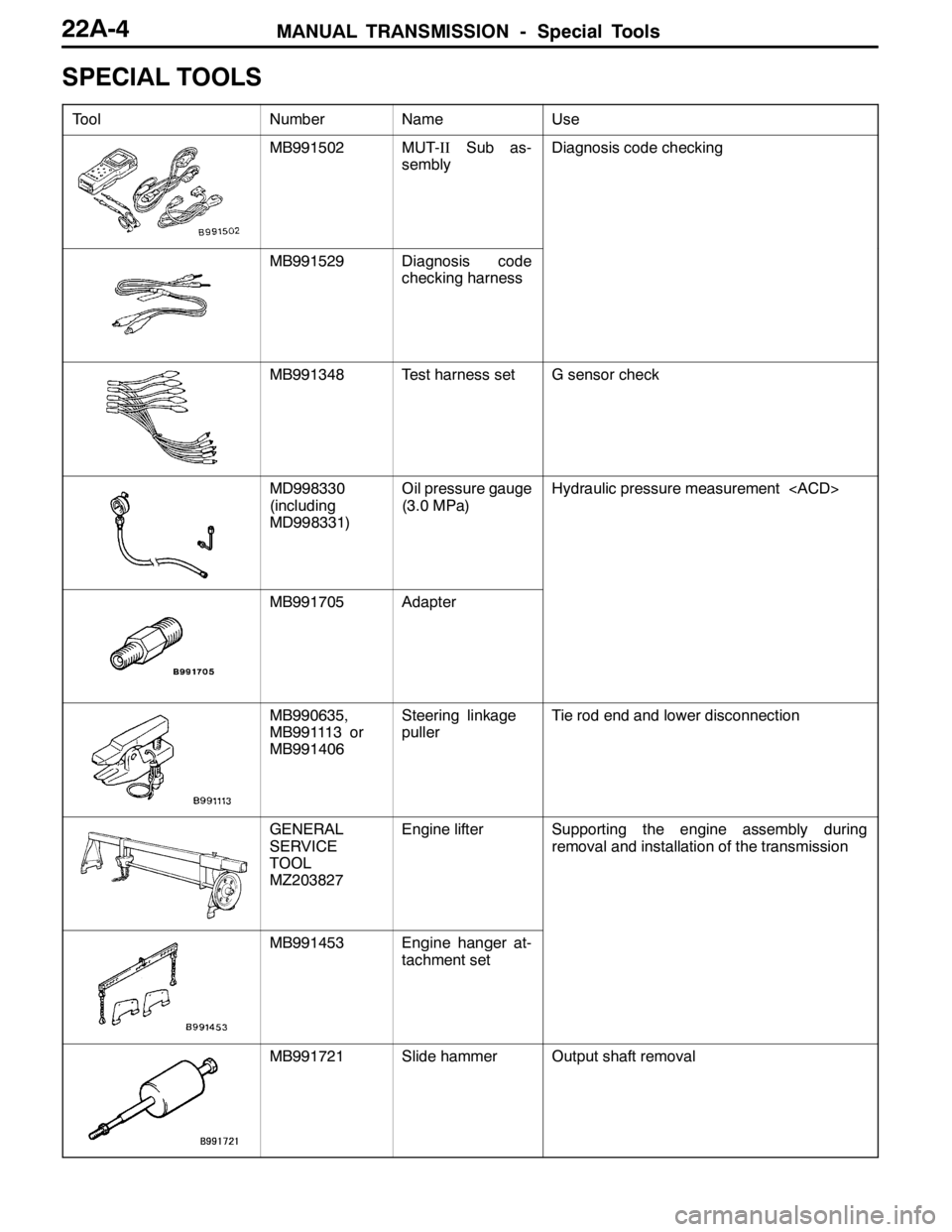

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-IISub as-

semblyDiagnosis code checking

MB991529Diagnosis code

checking harness

MB991348Test harness setGsensor check

MD998330

(including

MD998331)Oil pressure gauge

(3.0 MPa)Hydraulic pressure measurement

MB991705Adapter

MB990635,

MB991113 or

MB991406

Steering linkage

pullerTie rod end and lower disconnection

GENERAL

SERVICE

TOOL

MZ203827Engine lifterSupporting the engine assembly during

removal and installation of the transmission

MB991453Engine hangerat-

tachment set

MB991721Slide hammerOutput shaft removal