boot MITSUBISHI LANCER IX 2006 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 133 of 800

26-1

GROUP 26

FRONT AXLE

CONTENTS

GENERAL INFORMATION . . . . . . . .26-2

SERVICE SPECIFICATIONS . . . . . . .26-3

LUBRICANTS . . . . . . . . . . . . . . . . . .26-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .26-4

ON-VEHICLE SERVICE . . . . . . . . . . .26-7

WHEEL BEARING AXIAL PLAY CHECK . . 26-7

HUB BOLT REPLACEMENT . . . . . . . . . . . 26-7

FRONT AXLE HUB ASSEMBLY . . . .26-8

REMOVAL AND INSTALLATION . . . . . . . . 26-8

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-11

DISASSEMBLY AND REASSEMBLY . . . . . 26-11

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-13

DRIVESHAFT ASSEMBLY. . . . . . . . .26-14

REMOVAL AND INSTALLATION . . . . . . . . 26-14

DISASSEMBLY AND REASSEMBLY . . . . . 26-18

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 26-21

BJ BOOT (RESIN BOOT)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 26-21

Page 135 of 800

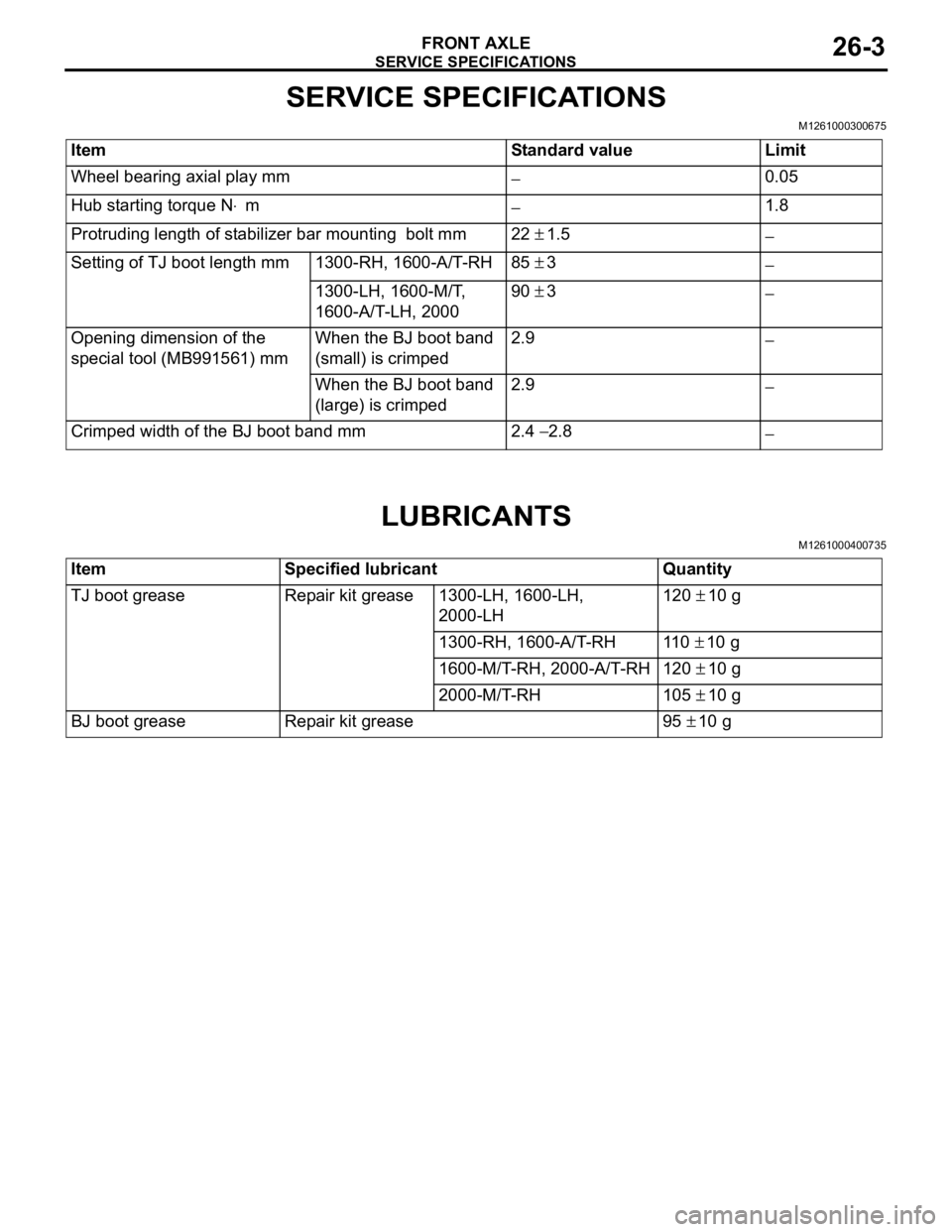

SERVICE SPECIFICATIONS

FRONT AXLE26-3

SERVICE SPECIFICATIONS

M1261000300675

ItemStandard valueLimit

Wheel bearing axial play mm−0.05

Hub starting torque N⋅m−1.8

Protruding length of stabilizer bar mounting bolt mm22 ± 1.5−

Setting of TJ boot length mm1300-RH, 1600-A/T-RH85 ± 3−

1300-LH, 1600-M/T,

1600-A/T-LH, 200090 ± 3−

Opening dimension of the

special tool (MB991561) mmWhen the BJ boot band

(small) is crimped2.9−

When the BJ boot band

(large) is crimped2.9 −

Crimped width of the BJ boot band mm2.4 − 2.8−

LUBRICANTS

M1261000400735

ItemSpecified lubricantQuantity

TJ boot greaseRepair kit grease1300-LH, 1600-LH,

2000-LH120 ± 10 g

1300-RH, 1600-A/T-RH11 0 ± 10 g

1600-M/T-RH, 2000-A/T-RH120 ± 10 g

2000-M/T-RH105 ± 10 g

BJ boot greaseRepair kit grease95 ± 10 g

Page 137 of 800

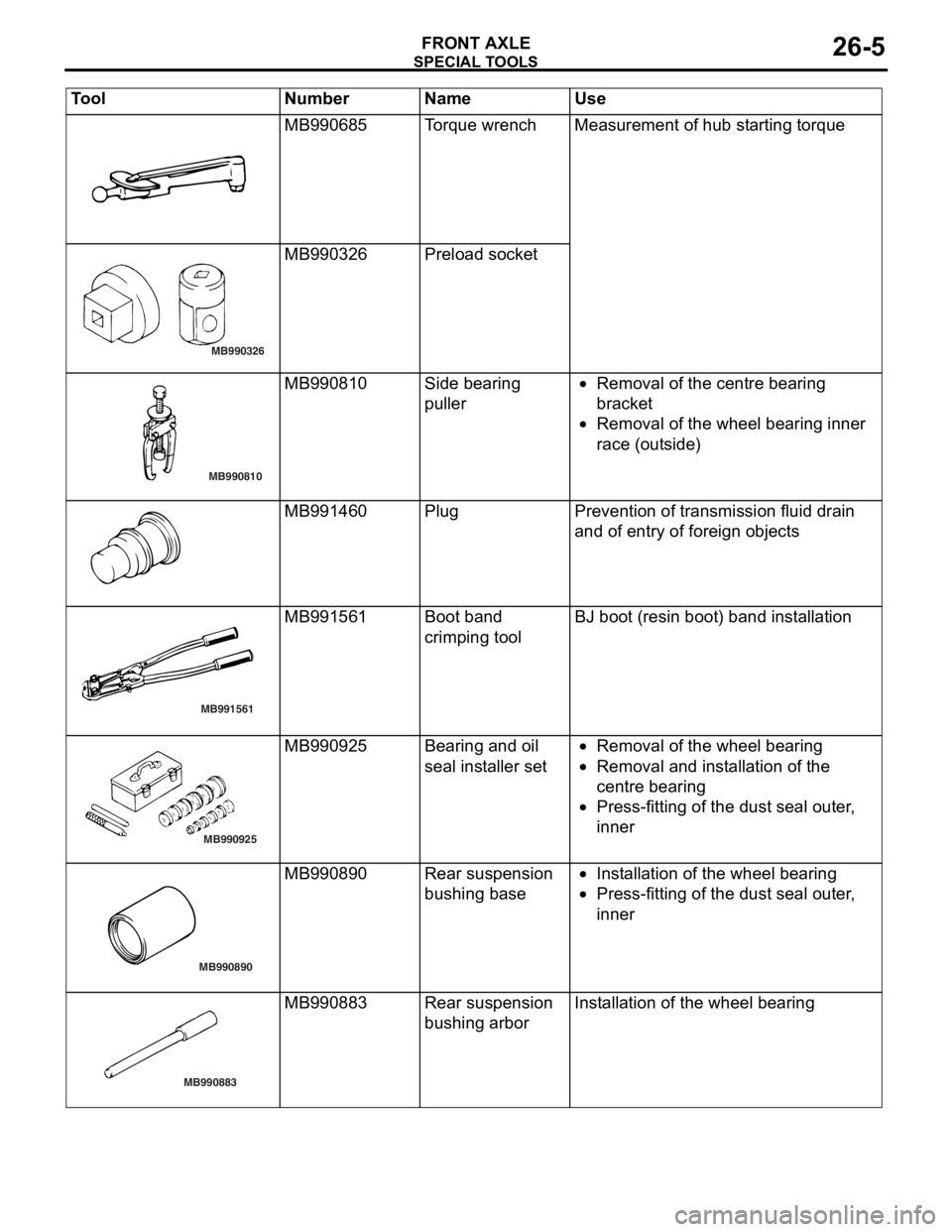

SPECIA L T OOLS

FRONT AXLE26-5

MB990685To rqu e wrenchMeas urement o f hub st arting torque

MB990326

MB990326 Prel oad socket

MB990810

MB990810Side be aring

puller•Removal of the centre b earing

bra

c ke t

•Removal of the whee l bea ring inner

r

a ce (o ut side )

MB991460PlugPreven tion of transmission fluid drain

and o

f entry of fore ign o b ject s

MB991561

MB991561Boot ban d

crimpin

g toolBJ boot (resin bo ot) ban d inst a lla tion

MB990925

MB990925Bearing and o il

seal

inst a lle r set•Removal of the whee l bea ring

•Removal and inst a lla tion o f the

centre

bearing

•Press-f i ttin g of th e dust se al ou ter ,

inner

MB990890

MB990890Rear suspension

bush

i ng b a se•In st allatio n of th e wheel bearing

•Press-f i ttin g of th e dust se al ou ter ,

inner

MB990883

MB990883Rear suspension

bush

i ng a r borInstallation of t he wheel bearing

Tool Nu mber Na me Use

Page 150 of 800

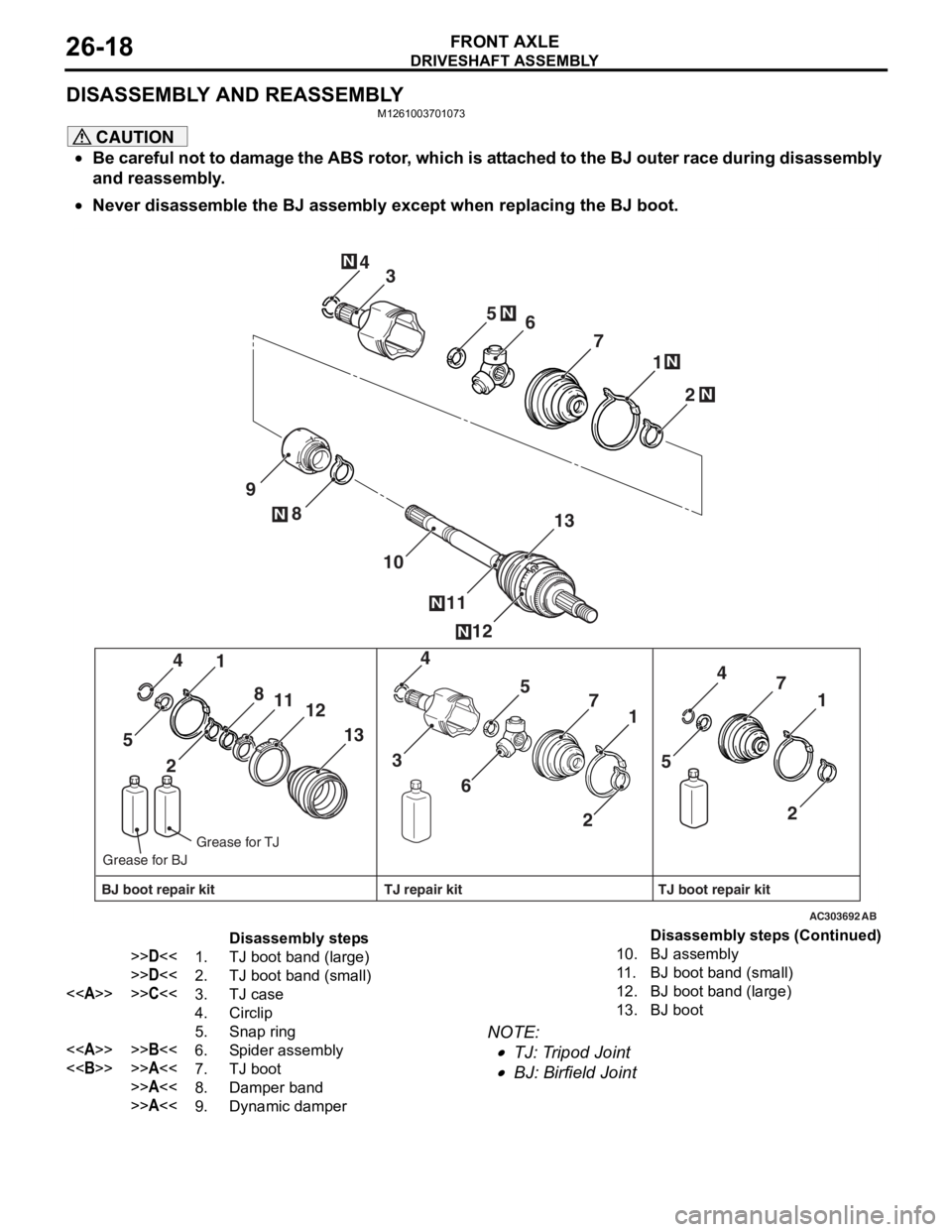

DRIVESHAFT ASSEMBLY

FRONT AXLE26-18

DISASSEMBLY AND REASSEMBLY

M1261003701073

CAUTION

•Be careful not to damage the ABS rotor, which is attached to the BJ outer race during disassembly

and reassembly.

•

AC303692

2

1

4

12

8

11

10

9 7

13

6

5N

N

N

3

N

N

2 1

4

13

8

11

12

5

21

4

7

6 5

3 21

4

7

5

AB

N

N

BJ boot repair kit TJ boot repair kit

TJ repair kit

Grease for TJ

Grease for BJ

Disassembly steps

>>D<<1.TJ boot band (large)

>>D<<2.TJ boot band (small)

<>>>C<<3.TJ case

4.Circlip

5.Snap ring

<>>>B<<6.Spider assembly

<>>>A<<7.TJ boot

>>A<<8.Damper band

>>A<<9.Dynamic damper

10.BJ assembly

11 .BJ boot band (small)

12.BJ boot band (large)

13.BJ boot

Never disassemble the BJ assembly except when replacing the BJ boot.

NOTE: .

•TJ: Tripod Joint

•BJ: Birfield Joint

Disassembly steps (Continued)

Page 151 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-19

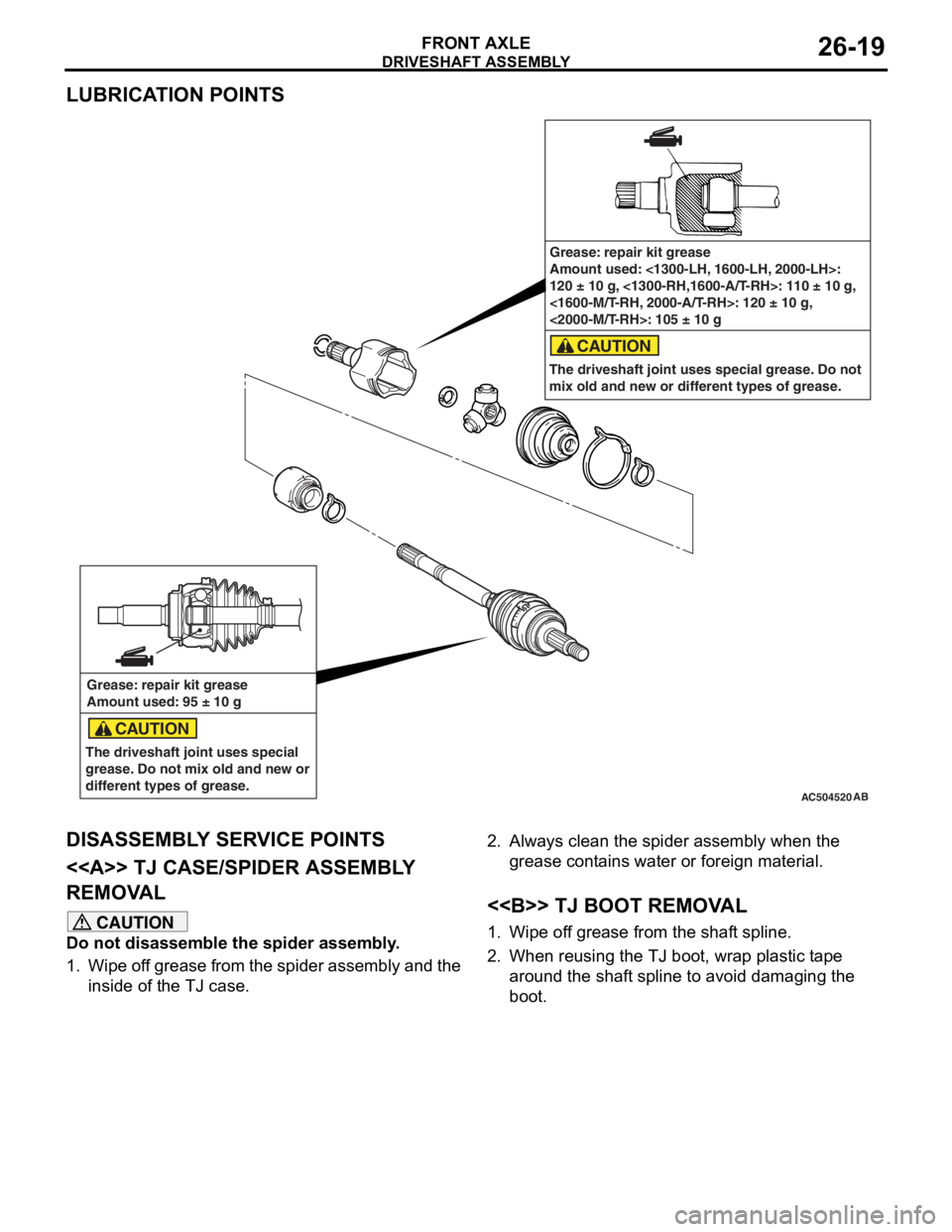

LUBRICATION POINTS

AC504520AB

Grease: repair kit grease

Amount used: 95 ± 10 g

The driveshaft joint uses special

grease. Do not mix old and new or

different types of grease.

CAUTION

Grease: repair kit grease

Amount used: <1300-LH, 1600-LH, 2000-LH>:

120 ± 10 g, <1300-RH,1600-A/T-RH>: 110 ± 10 g,

<1600-M/T-RH, 2000-A/T-RH>: 120 ± 10 g,

<2000-M/T-RH>: 105 ± 10 g

The driveshaft joint uses special grease. Do not

mix old and new or different types of grease.

CAUTION

DISASSEMBL Y SER V ICE POINTS

<> TJ CASE/SPIDER ASSEMBL Y

REMOV

A L

CAUTION

Do not disassemble the spider assembly.

1. Wipe off grease from the spider assembly and the inside of the TJ case.

2. Always clean the spider assembly when the

grease contains water or foreign material.

<> TJ BOOT REMOVAL

1. Wipe off grease from the shaft spline.

2. When reusing the TJ boot, wrap plastic tape around the shaft spline to avoid damaging the

boot.

Page 152 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-20

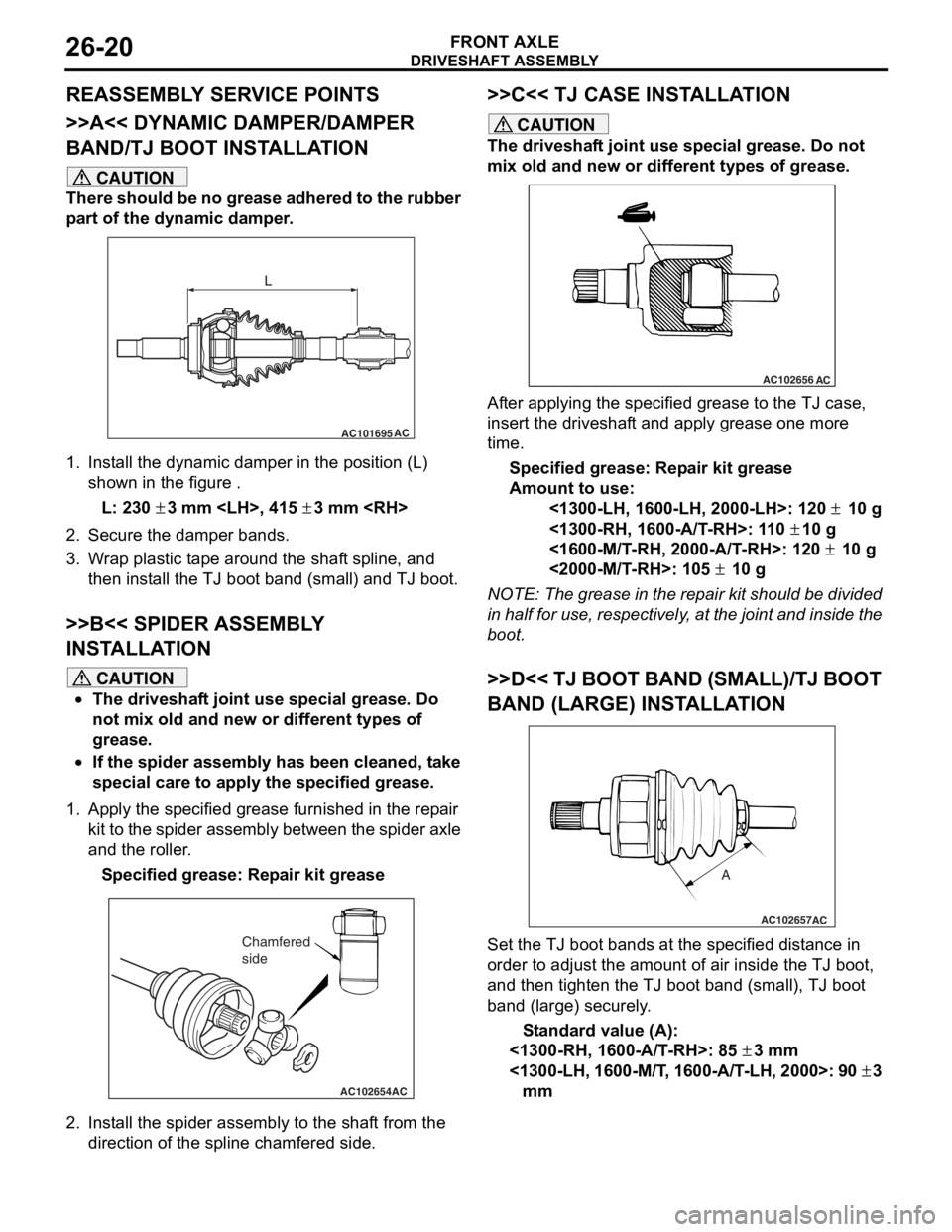

REASSEMBLY SERVICE POINTS

>>A<< DYNAMIC DAMPER/DAMPER

BAND/TJ BOOT INSTALLATION

CAUTION

There should be no grease adhered to the rubber

part of the dynamic damper.

AC101695AC

L

1. Install the dynamic damper in the position (L)

shown in the figure .

L: 230 ± 3 mm

2. Secure the damper bands.

3. Wrap plastic tape around the shaft spline, and then install the TJ boot band (small) and TJ boot.

>>B<< SPIDER ASSEMBLY

INSTALLATION

CAUTION

•The driveshaft joint use special grease. Do

not mix old and new or different types of

grease.

•If the spider assembly has been cleaned, take

special care to apply the specified grease.

1. Apply the specified grease furnished in the repair kit to the spider assembly between the spider axle

and the roller.

Specified grease: Repair kit grease

AC102654AC

Chamfered

side

2. Install the spider assembly to the shaft from the direction of the spline chamfered side.

>>C<< TJ CASE INSTALLATION

CAUTION

The driveshaft joint use special grease. Do not

mix old and new or different types of grease.

AC102656AC

After applying the specified grease to the TJ case,

insert the driveshaft and apply grease one more

time.

Specified grease: Repair kit grease

Amount to use:

<1300-LH, 1600-LH, 2000-LH>: 120 ± 10 g

<1300-RH, 1600-A/T-RH>: 110 ± 10 g

<1600-M/T-RH, 2000-A/T-RH>: 120 ± 10 g

<2000-M/T-RH>: 105 ± 10 g

NOTE: The grease in the repair kit should be divided

in half for use, respectively, at the joint and inside the

boot.

>>D<< TJ BOOT BAND (SMALL)/TJ BOOT

BAND (LARGE) INSTALLATION

AC102657

A

AC

Set the TJ boot bands at the specified distance in

order to adjust the amount of air inside the TJ boot,

and then tighten the TJ boot band (small), TJ boot

band (large) securely.

Standard value (A):

<1300-RH, 1600-A/T-RH>: 85 ± 3 mm

<1300-LH, 1600-M/T, 1600-A/T-LH, 2000>: 90 ± 3

mm

Page 153 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-21

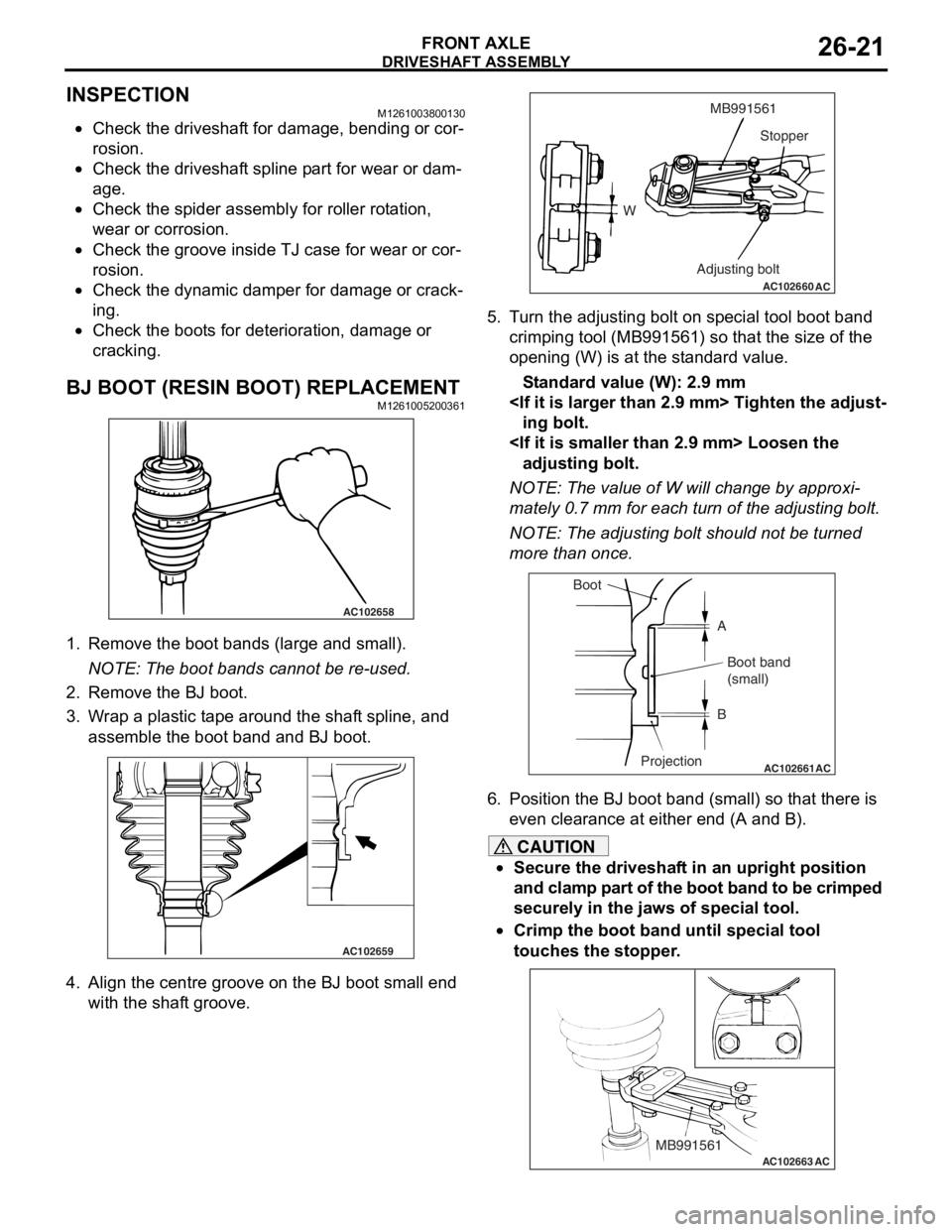

INSPECTION

M1261003800130

•Check the driveshaft for damage, bending or cor-

rosion.

•Check the driveshaft spline part for wear or dam-

age.

•Check the spider assembly for roller rotation,

wear or corrosion.

•Check the groove inside TJ case for wear or cor-

rosion.

•Check the dynamic damper for damage or crack-

ing.

•Check the boots for deterioration, damage or

cracking.

BJ BOOT (RESIN BOOT) REPLACEMENTM1261005200361

AC102658

1.Remove the bo ot ban ds (large a nd small).

NOTE: The boot ba nds canno t be re -used .

2.Remove the BJ boot.

3.W r ap a plastic t a pe arou nd the shaf t spline, an d

asse mble the b oot ba nd and BJ boo t.

AC102659

4.Align th e ce ntre gro o ve o n the BJ boot small end

wit h the shaf t groo ve.

AC102660

WMB991561

Stopper

Adjusting bolt

AC

5. T u rn the ad justing bolt o n sp ecial too l boo t band

crimping tool (MB9915 61) so that the size of the

o penin g (W) is at t he st and ard value .

St andard va lue (W): 2 . 9 mm

ing bolt.

adjustin g bolt.

NOTE: The value of W will chang e by approxi-

mately 0.7 mm for ea ch tu rn of th e adjusting bolt.

NOTE: The ad justing bolt shou ld no t be tu rned

more th an once.

AC102661AC

Boot

ABoot band

(small)

B

Projection

6. Position the BJ boo t band (small) so th at there is

e v en clea rance at either en d (A and B).

CAUTION

•Secure the driveshaft in an upright position

and clamp part of the boot band to be crimped

securely in the jaws of special tool.

•

AC102663 ACMB991561

Crimp the boot band until special tool

touches the stopper.

Page 154 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-22

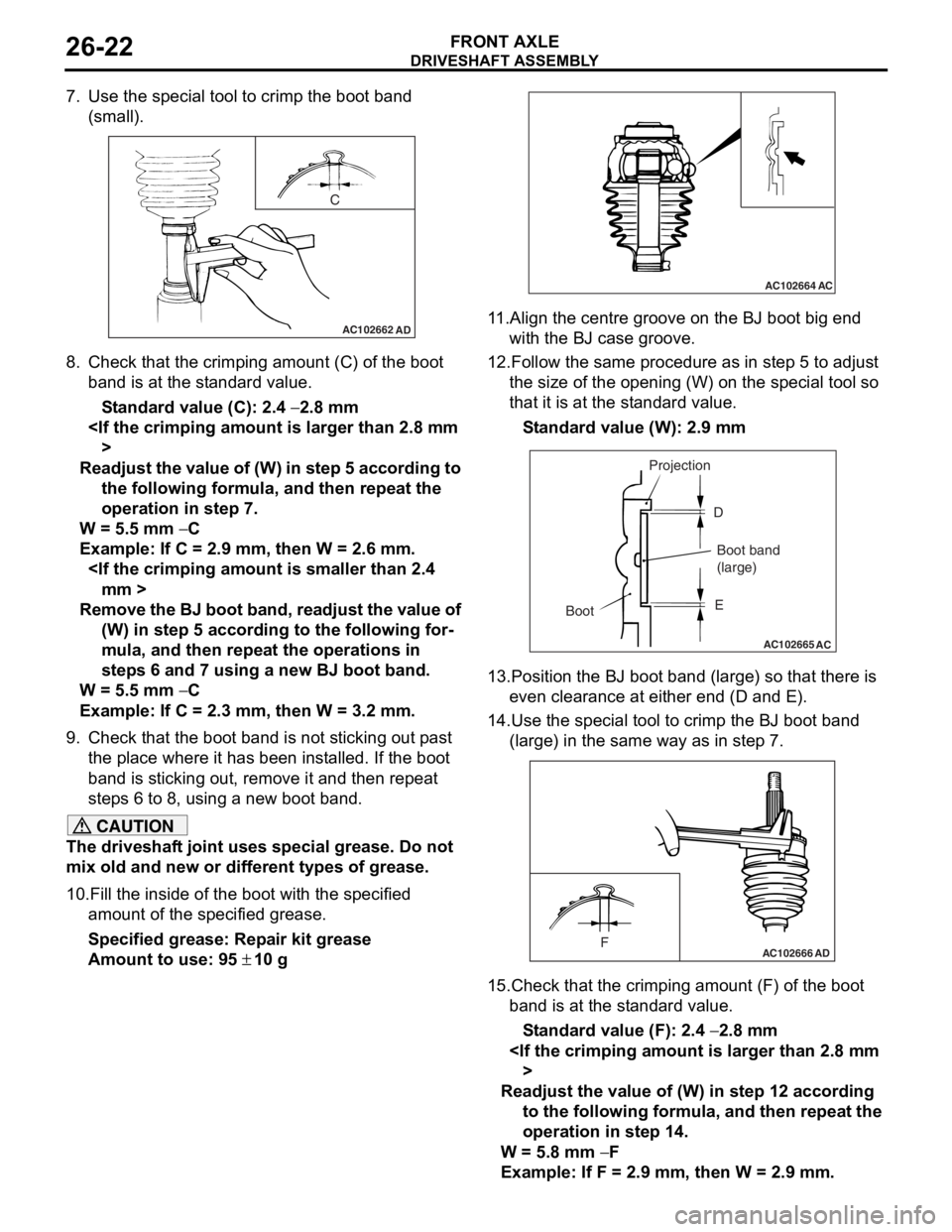

7. Use the special tool to crimp the boot band (small).

AC102662

C

AD

8.Check t hat the crimpin g amount (C) of the bo ot

ba nd is at th e st and ard value.

St andard va lue (C): 2.4 − 2.8 mm

Readjust th e value of (W) in s t ep 5 acc ord i ng to

the following fo rm ula, and then repea t the

operation in step 7.

W = 5.5 mm − C

Example : If C = 2.9 mm, the n W = 2.6 mm.

Rem o v e the BJ bo ot ba nd , re ad ju st the v a l ue of

(W) in ste p 5 acc ord i ng to the following for

-

mula, and then repe at the o perations i n

step

s 6 and 7 using a new BJ boot band .

W = 5.5 mm − C

Example : If C = 2.3 mm, the n W = 3.2 mm.

9.Check t hat the boot b and is no t sticking o u t p a st

th e pla c e wher e it h a s be en in st alled. If t he boo t

ba nd is st icking out, remove it a nd the n repea t

step s 6 to 8, u s in g a new b oot ban d.

CAUTION

The driveshaft joint uses special grease. Do not

mix old and new or different types of grease.

10.Fill the inside of the boot with the specified amount of the specified grease.

Specified grease: Repair kit grease

Amount to use: 95 ± 10 g

AC102664AC

11.Align the centre groove on the BJ boot big end with the BJ case groove.

12.Follow the same procedure as in step 5 to adjust

the size of the opening (W) on the special tool so

that it is at the standard value.

Standard value (W): 2.9 mm

AC102665 AC

Boot Projection

Boot band

(large)

D

E

13.Position the BJ boot band (large) so that there is even clearance at either end (D and E).

14.Use the special tool to crimp the BJ boot band

(large) in the same way as in step 7.

AC102666FAD

15.Check that the crimping amount (F) of the boot band is at the standard value.

Standard value (F): 2.4 − 2.8 mm

Readjust the value of (W) in step 12 according to the following formula, and then repeat the

operation in step 14.

W = 5.8 mm − F

Example: If F = 2.9 mm, then W = 2.9 mm.

Page 155 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-23

Remove the BJ boot band, readjust the value of

(W) in step 12 according to the following for

-

mula, and then repeat the operations in

steps 13 and 14 using a new BJ boot band.

W = 5.8 mm − F

Example: If F = 2.3 mm, then W = 3.5 mm.

16.Check that the boot band is not sticking out past

the place where it has been installed. If the boot

band is sticking out, remove it and then repeat

steps 13 to 15, using a new boot band.

Page 236 of 800

SERVICE SPECIFICATIONS

POWER STEERING37-6

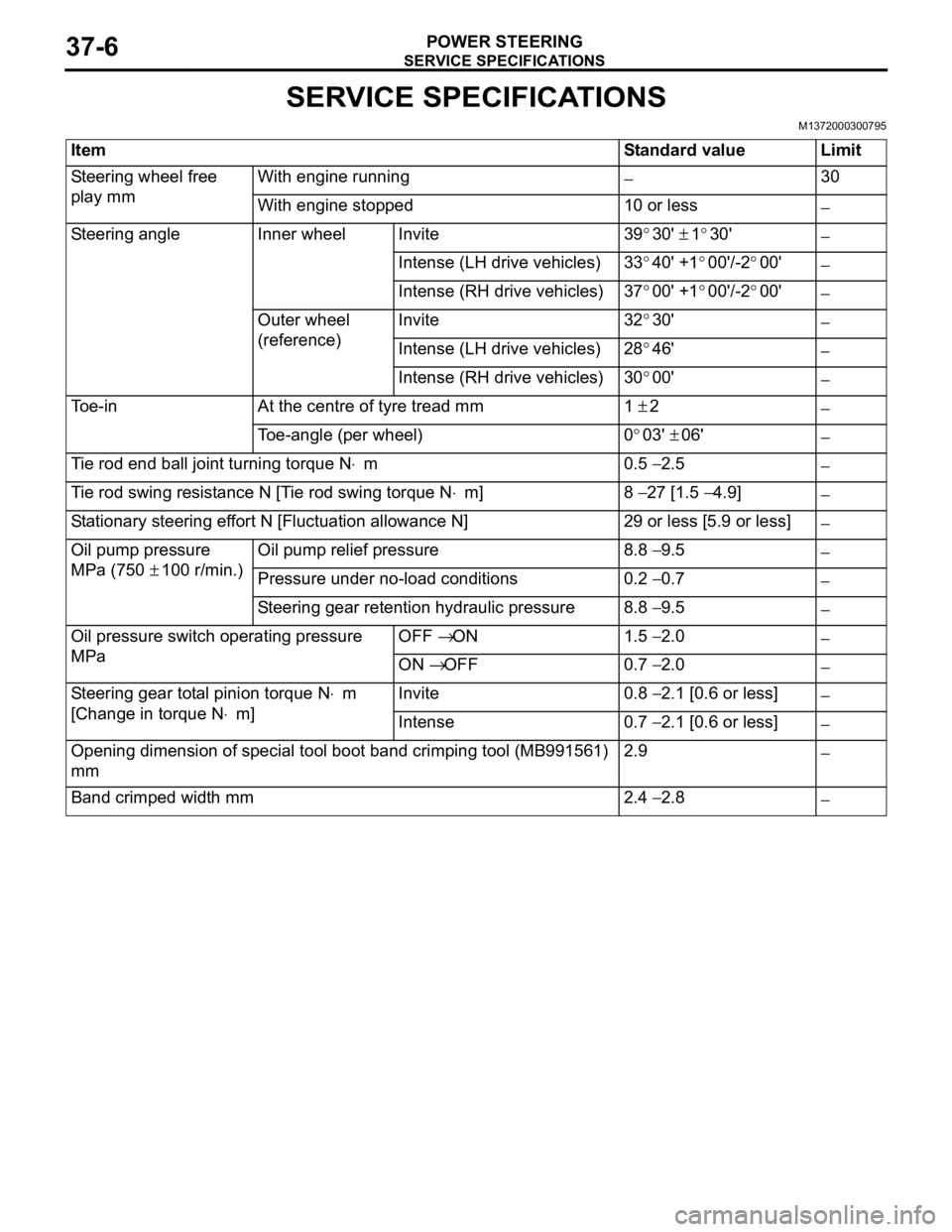

SERVICE SPECIFICATIONS

M1372000300795

ItemStandard valueLimit

Steering wheel free

play mmWith engine running−30

With engine stopped10 or less−

Steering angleInner wheelInvite39°30' ± 1°30'−

Intense (LH drive vehicles)33°40' +1°00'/-2°00'−

Intense (RH drive vehicles)37°00' +1°00'/-2°00'−

Outer wheel

(reference)Invite32°30'−

Intense (LH drive vehicles)28°46'−

Intense (RH drive vehicles)30°00'−

Toe-inAt the centre of tyre tread mm1 ± 2−

Toe-angle (per wheel)0°03' ± 06'−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5−

Tie rod swing resistance N [Tie rod swing torque N⋅m]8 − 27 [1.5 − 4.9]−

Stationary steering effort N [Fluctuation allowance N]29 or less [5.9 or less]−

Oil pump pressure

MPa (750

± 100 r/min.)

Oil pump relief pressure8.8 − 9.5−

Pressure under no-load conditions0.2 − 0.7−

Steering gear retention hydraulic pressure8.8 − 9.5−

Oil pressure switch operating pressure

MPaOFF → ON1.5 − 2.0−

ON → OFF0.7 − 2.0−

Steering gear total pinion torque N⋅m

[Change in torque N

⋅m]

Invite0.8 − 2.1 [0.6 or less]−

Intense0.7 − 2.1 [0.6 or less]−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9−

Band crimped width mm2.4 − 2.8−