Idle MITSUBISHI LANCER IX 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 108 of 800

ENGINE CONTROL

ENGINE AND EMISSION CONTROL17-2

ENGINE CONTROL

GENERAL INFORMATIONM1171000100277

A cable-type accelerator mechanical sus-

pended-type pedal has been adopted.

SERVICE SPECIFICATIONS

M1171000300088

ItemStandard value

Accel cable play mm1.0 − 2.0

Engine idle speed r/min4G1750 ± 50

4G6750 ± 100

ON-VEHICLE SERVICE

ACCEL CABLE CHECK AND

ADJUSTMENT

M1171000900314

1. Turn A/C and lights OFF. Inspect and adjust at no load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at standard value.

Standard value:

750 ± 50 r/min <4G1>

750 ± 100 r/min <4G6>

4. Stop engine. [ignition switch: LOCK (OFF)

position].

5. Confirm there are no sharp bends in the accelerator cable.

6. Check the inner cable for correct slack.

Standard value: 1.0 − 2.0 mm

7. If there is too much slack or no slack, adjust play by the following procedures.

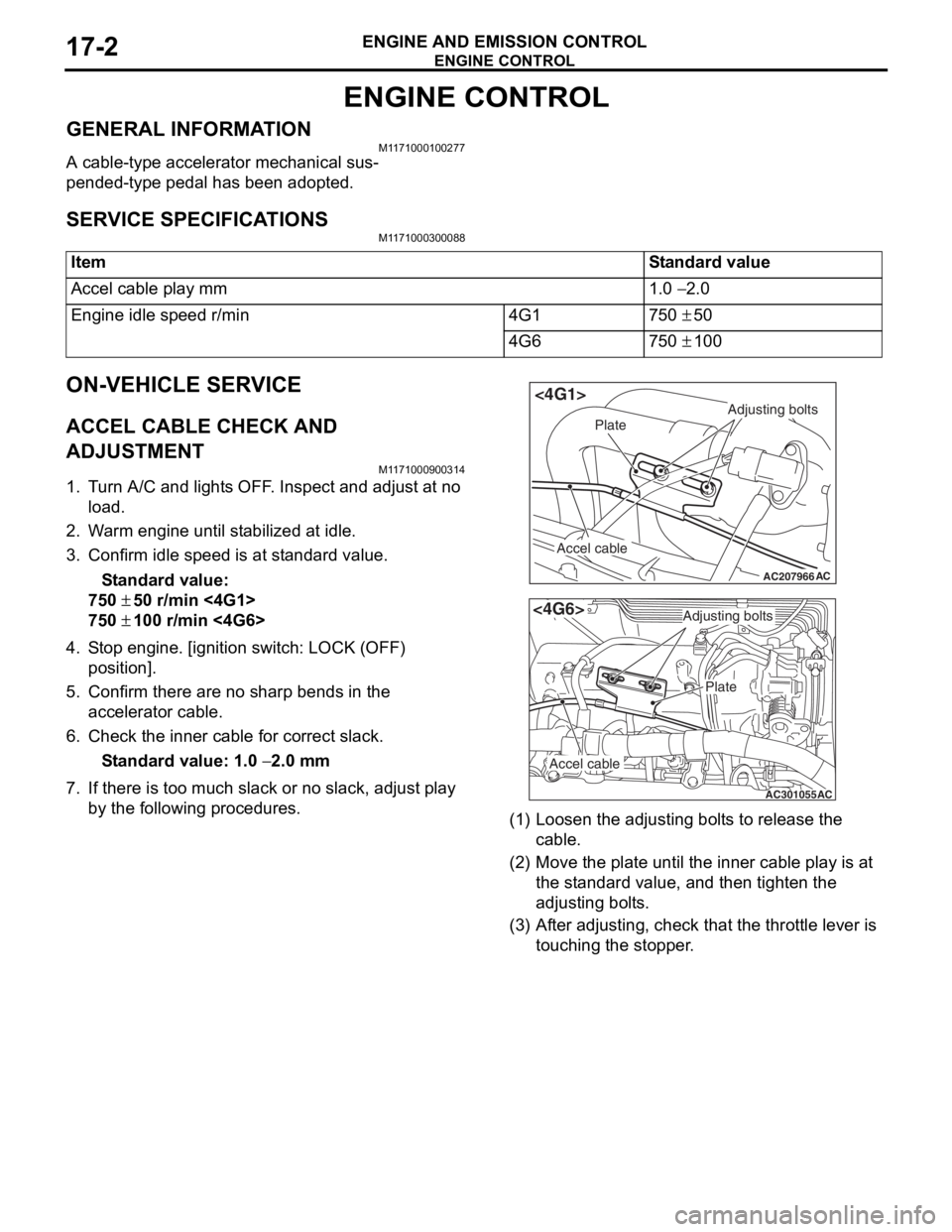

AC207966

Adjusting bolts

Plate

Accel cable

AC

<4G1>

AC301055

Adjusting bolts

Plate

Accel cable

AC

<4G6>

(1) Loosen th e adjusting bo lt s to re lease the

cab l e.

(2) M o v e th e pla t e until the inne r cab l e play is a t

the st andard value, an d then tighte n the

adjusting bo lt s.

(3) A f t e r adju s ting, check that the thro ttle leve r is

touching the stoppe r .

Page 115 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-9

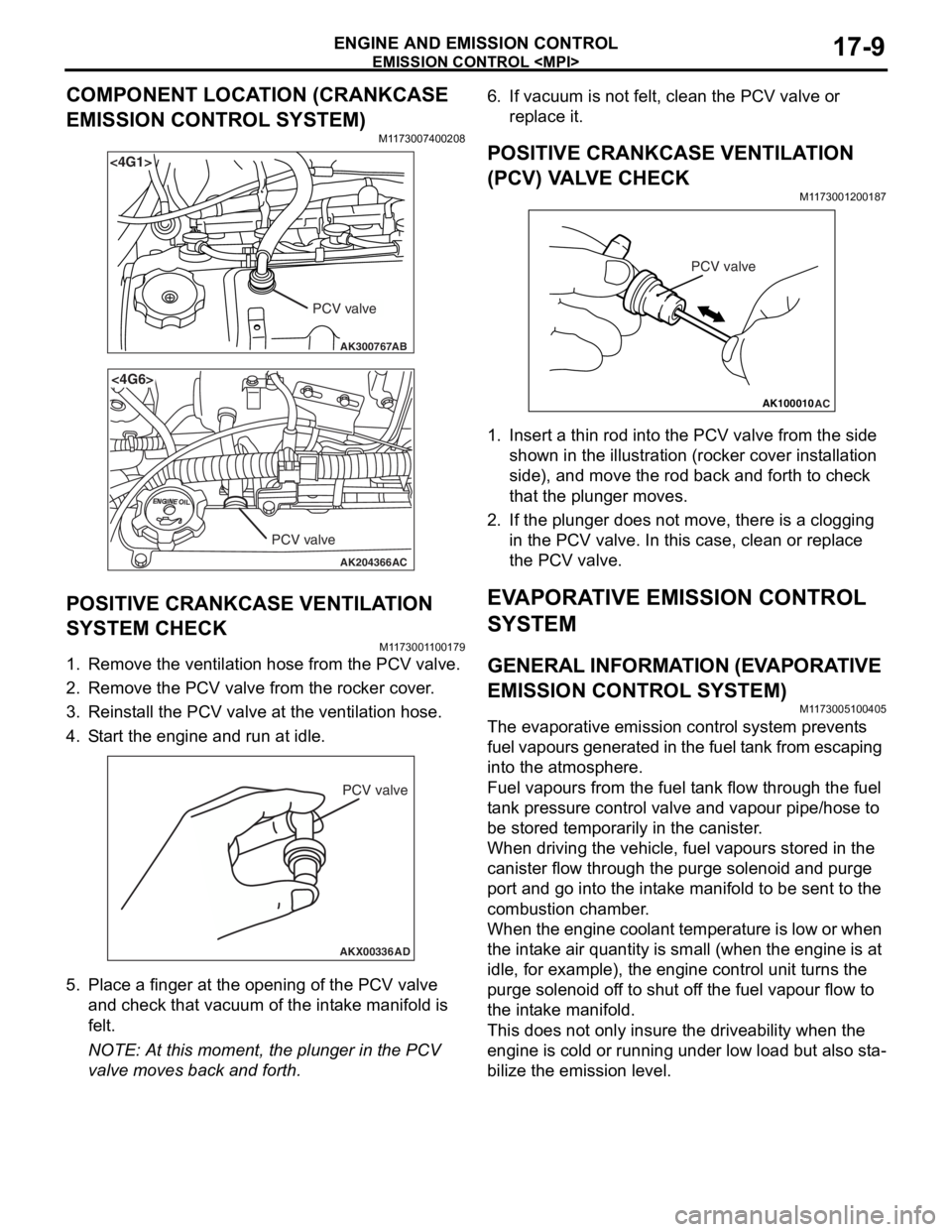

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173007400208

AK300767

<4G1>

AB

PCV valve

AK204366

<4G6>

AC

PCV valve

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK

M11 7300 1 1 0017 9

1.Remove the ventilatio n hose from the PCV valve.

2.Remove the PCV valve from t he rocker cove r .

3.Reinst all the PCV valve at the ven t ila tion h o se.

4.S t art the engin e and run at idle .

AKX00336

PCV valve

AD

5.Pla c e a fing er at the open ing o f the PCV va lve

an d ch eck that vacu um o f the int a ke manifold is

fe lt.

NOTE: At this mo men t, the p l unge r in t he PCV

valve mo ves back an d forth.

6.If vacuum is not felt, clean t he PCV valve o r

re place it.

POSITIVE CRANKCASE VENTILA TION

(

P CV) V A L VE CHECK

M1173 0012 0018 7

AK100010

PCV valve

AC

1.In sert a thin rod in to the PCV valve from the side

shown in the illu strat i on (ro cke r cover in st allation

side) , and move the ro d back an d forth to ch eck

th at the plung er mo ves.

2.If the plunger does not move , there is a clo ggin g

in the PCV valve. In th is case, clean o r repla c e

th e PCV valve.

EVAPORA T IVE EMISSION CONTROL

SYSTEM

GENERAL INFORMA T ION (EV A PORA TIVE

EMISSION CONTROL SYSTEM)

M1173 0051 0040 5

The evaporat ive emission contro l syste m pre v ent s

f

uel vapours generat ed in t he fuel t ank from escaping

into t

he atmosp here.

Fuel vapours fro m the fuel t a n k flow throug h the f uel

t

a n k pre ssu re co ntrol valve an d vap our pipe/ho se to

be st

ored te mpora r ily in t he ca nister .

When dr iving the veh i cle, fue l va pours stor ed in the

canister

flow thro ugh th e purge solenoid and purge

port an

d go into the int a ke ma nifold to b e sen t to th e

combust

i on chamber .

When the eng ine co ola n t te mp eratu r e is low o r when

the int

a ke air q uantity is small (wh en the engine is at

idle

, for example), t he eng ine contro l unit turns the

purge sole

noid of f to shu t of f the fue l va pour flow to

the in

t a ke manif o ld.

This does not on ly insure the driveability when t he

engin

e is cold or runn ing und er low load b u t also st a

-

bilize the emissio n level.

Page 117 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-11

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53 kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40°C or less)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min

When engine is hot

(Engine coolant temperature: 80°C or higher)

Engine conditionNormal condition

At idleVacuum is maintained.

3,000 r/min (within 3

minutes after engine

starts)Vacuum will leak.

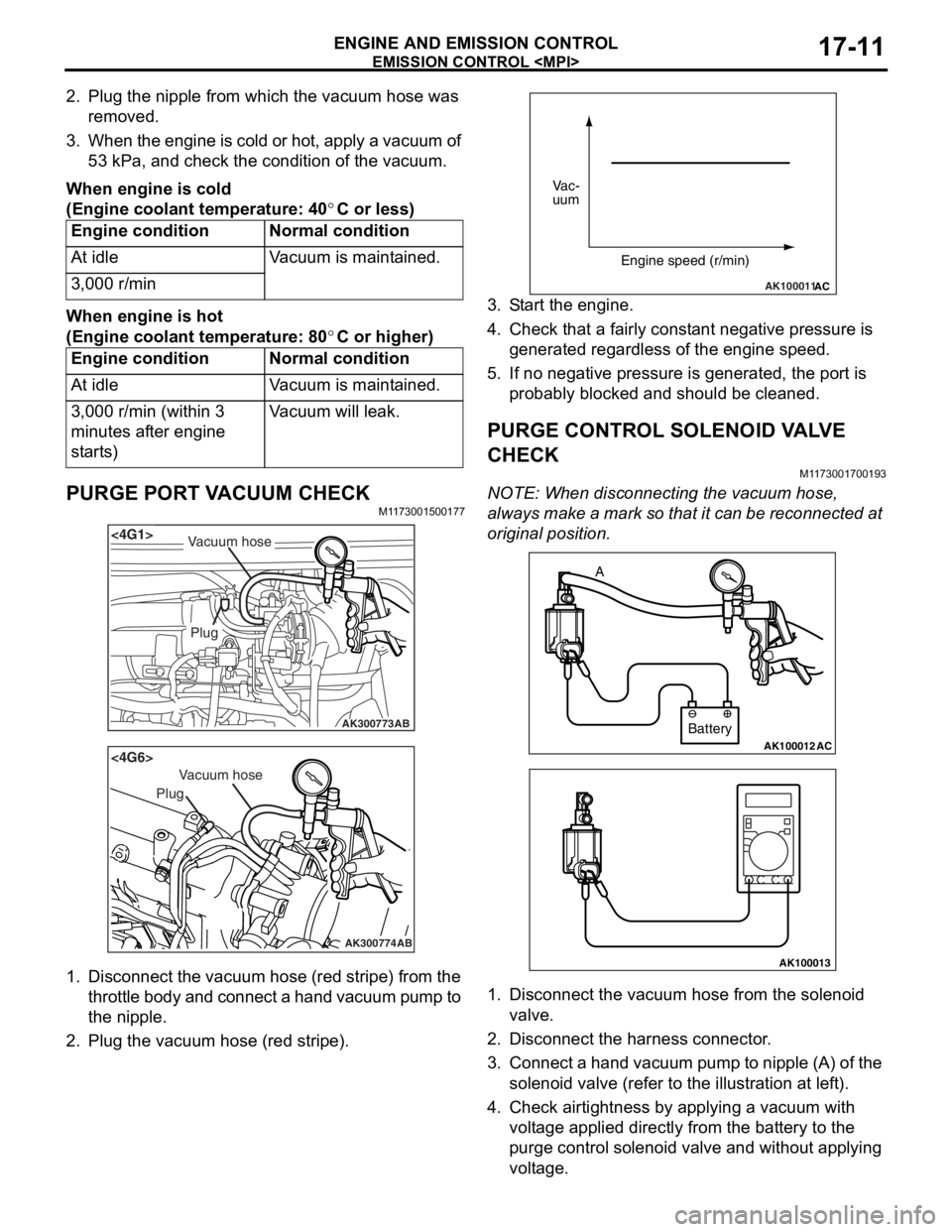

PURGE PORT VACUUM CHECKM1173001500177

AK300773

<4G1>

AB

Plug

Vacuum hose

AK300774

<4G6>

AB

Plug

Vacuum hose

1.Disco nnect th e vacuum ho se (red st ripe) from the

throttle body and connect a hand vacuum pump to

th e nip p le.

2.Plu g the vacuum hose (red stripe).

AK100011AC

Vac-

uum

Engine speed (r/min)

3.S t art the engine.

4.Check t hat a f a irly co nst ant n egative p r essure is

g enerate d regard l ess of the en gine spee d.

5.If no neg ative pressur e is genera t ed, th e port is

p r obably blocked an d sh ould be cleane d.

PURGE CONTROL SOLENOID VA L V E

CHECK

M1173 0017 0019 3

NOTE: Whe n discon nect i ng th e va cuum hose,

always make a mark so th at it can be reconnected at

original p o sition.

AK100012AC

Battery

A

AK100013

1.

Disco nnect the vacu um h o se f r om th e solenoid

valve.

2.Disco nnect the ha rness connector .

3.Con nect a ha nd vacu um pump to nipp le (A) of the

solen o id valve (ref e r to th e ill ust r ation at le f t ).

4.Check a i rtig htness b y app lying a vacuum with

volt age applied d i rectly from t he batt e ry to the

p u rge con t rol so leno id valve an d without app lying

volt age .

Page 118 of 800

Battery voltageNormal condition

AppliedVacuum leaks

Not appliedVacuum maintained

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

5. Measure the resistance between the terminals of the solenoid valve.

Standard value: 30 − 34 Ω (at 20°C)

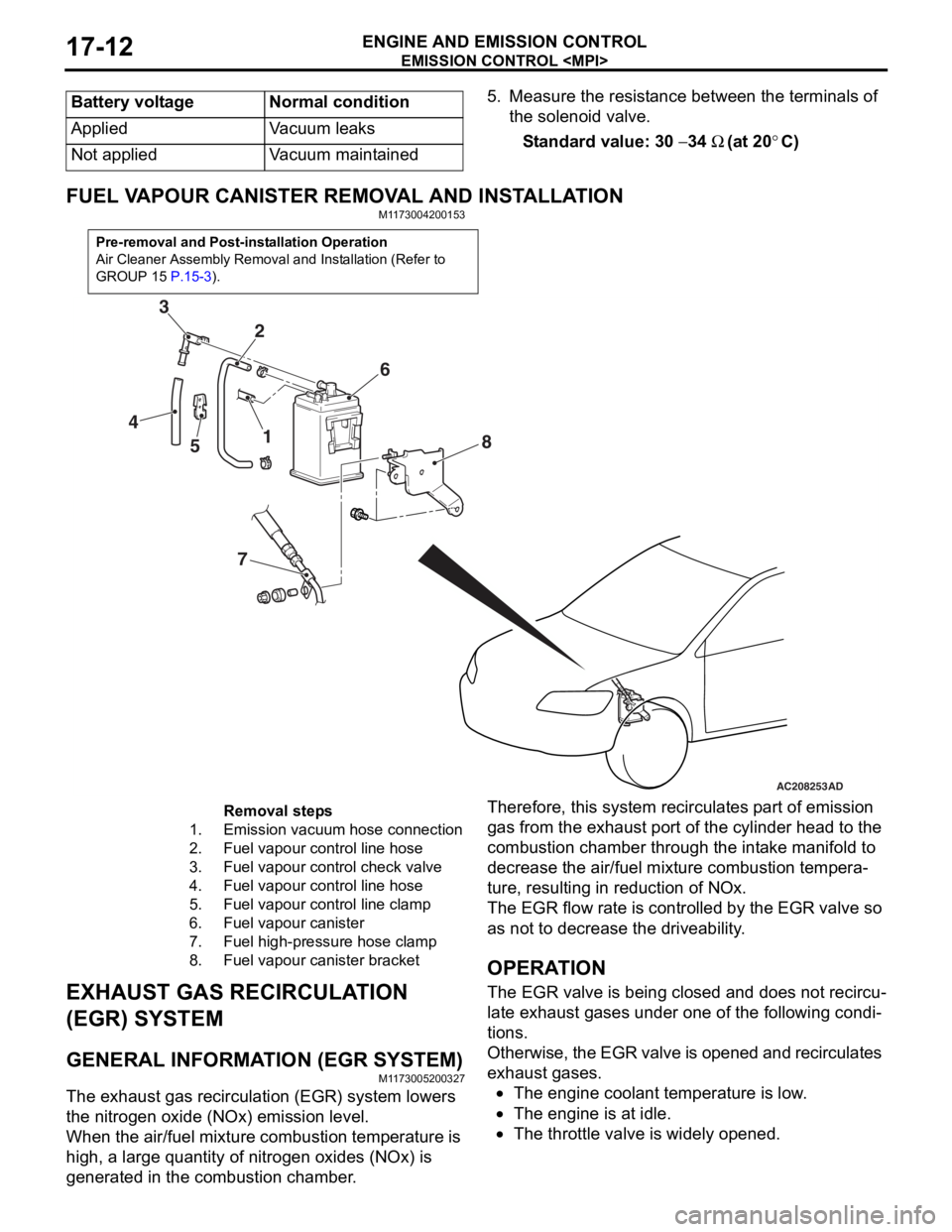

FUEL VAPOUR CANISTER RE MOVAL AND INSTALLATION

M1173004200153

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15

P.15-3).

AC208253

1

2

3

4 5 6

7 8

AD

Removal steps

1.Emission vacuum hose connection

2.Fuel vapour control line hose

3.Fuel vapour control check valve

4.Fuel vapour control line hose

5.Fuel vapour control line clamp

6.Fuel vapour canister

7.Fuel high-pressure hose clamp

8.Fuel vapour canister bracket

EXHAUST GAS RECIRCULA

T ION

(EGR) SYSTEM

GENERAL INFORMAT ION (EGR SYSTEM)

M1173 0052 0032 7

The exhaust gas recircu l atio n (EGR) system lowers

the nitrogen

oxide (NOx) emission level.

When the air/fuel mixture combus tio n temp erature is

high,

a larg e qua ntity of nitrogen oxides (NOx) is

generat

ed in the comb ustion chamb e r .

Therefor e, this syst em re circulat es p a rt o f emission

gas fro

m the e x ha ust po rt of the cylinder h ead to th e

combust

i on chamber thro ugh th e int a ke ma nifold to

decre

ase the air/fuel mixture combust i on te mpera

-

ture, resulting in redu ctio n of NOx.

The EGR flow rate is cont rolle d by the EGR valve so

as no

t to de crease the driveability .

OPERAT ION

The EGR valve is being clos ed an d does not re circu-

late ex hau st ga ses unde r one o f the fo llo wing condi-

tions.

Otherwise, th e EGR va lve is opene d an d recircul ates

exha

ust g a ses.

•The engine coolan t temperature is low .

•The engine is at idle.

•The throttle va lve is widely ope ned.

Page 242 of 800

ON-VEHICLE SERVICE

POWER STEERING37-12

TIE ROD END BALL JOINT TURNING

TORQUE CHECK

M1372001500554

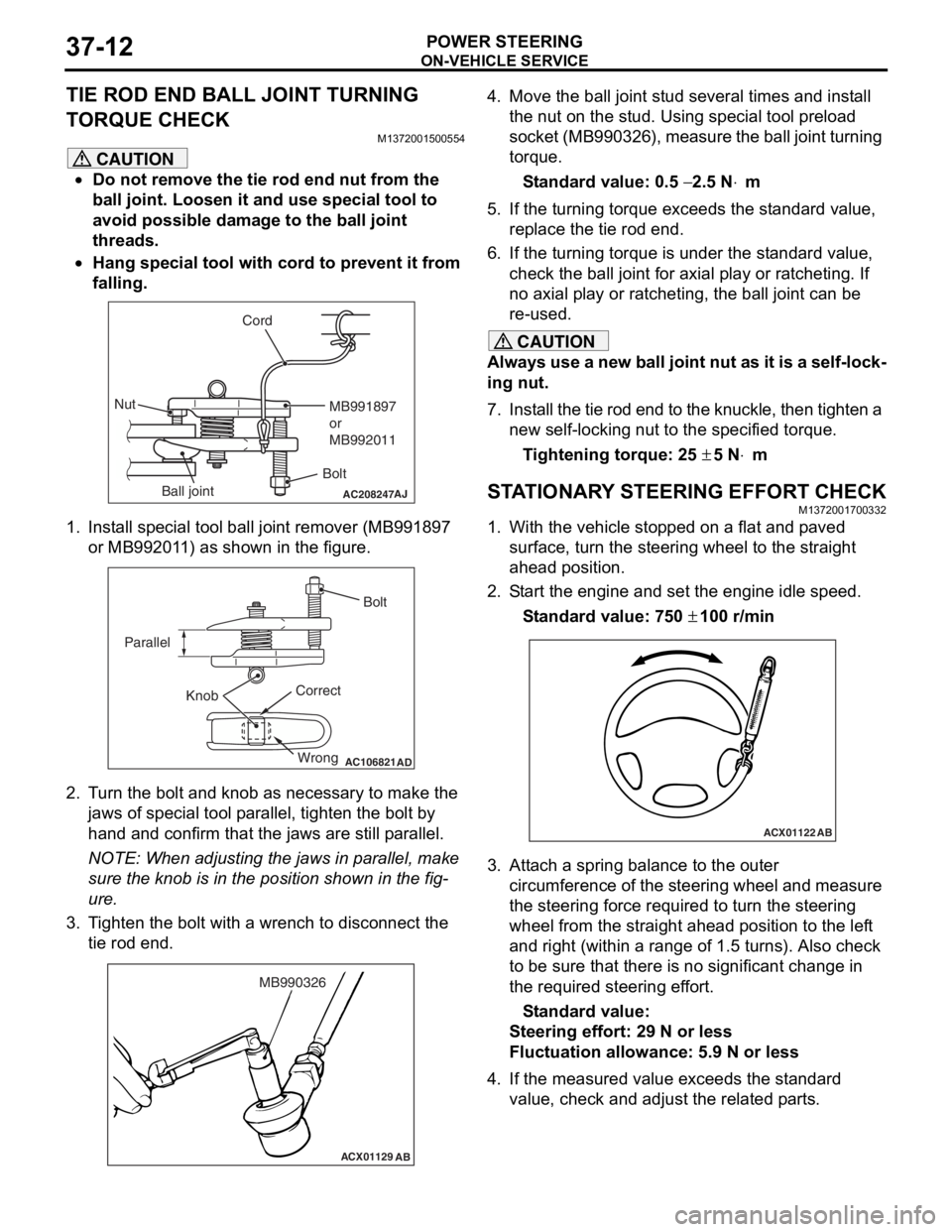

CAUTION

•Do not remove the tie rod end nut from the

ball joint. Loosen it and use special tool to

avoid possible damage to the ball joint

threads.

•

AC208247AJ

CordBoltMB991897

or

MB992011

Nut

Ball joint

Hang special tool with cord to prevent it from

falling.

1. Install special tool ball joint remover (MB991897 or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Correct Wrong

AD

2. Turn the bolt and knob as necessary to make the jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the fig

-

ure.

3. Tighten the bolt with a wrench to disconnect the tie rod end.

ACX01129 AB

MB990326

4. Move the ball joint stud several times and install

the nut on the stud. Using special tool preload

socket (MB990326), measure the ball joint turning

torque.

Standard value: 0.5 − 2.5 N⋅m

5. If the turning torque exceeds the standard value, replace the tie rod end.

6. If the turning torque is under the standard value, check the ball joint for axial play or ratcheting. If

no axial play or ratcheting, the ball joint can be

re-used.

CAUTION

Always use a new ball joint nut as it is a self-lock-

ing nut.

7. Install the tie rod end to the knuckle, then tighten a new self-locking nut to the specified torque.

Tightening torque: 25 ± 5 N⋅m

STATIONARY STEERING EFFORT CHECKM1372001700332

1. With the vehicle stopped on a flat and paved

surface, turn the steering wheel to the straight

ahead position.

2. Start the engine and set the engine idle speed.

Standard value: 750 ± 100 r/min

ACX01122 AB

3. Attach a spring balance to the outer

circumference of the steering wheel and measure

the steering force required to turn the steering

wheel from the straight ahead position to the left

and right (within a range of 1.5 turns). Also check

to be sure that there is no significant change in

the required steering effort.

Standard value:

Steering effort: 29 N or less

Fluctuation allowance: 5.9 N or less

4. If the measured value exceeds the standard value, check and adjust the related parts.

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

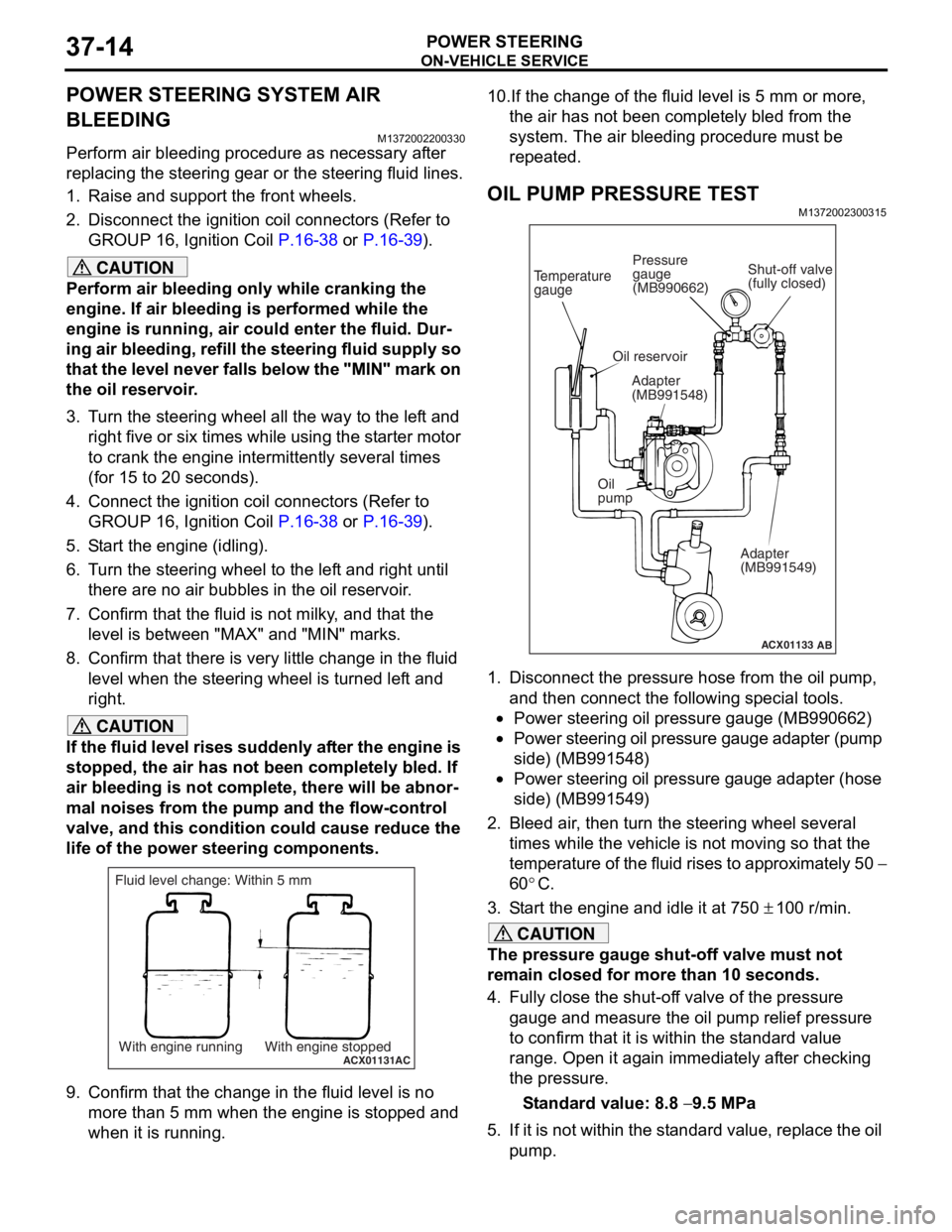

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 398 of 800

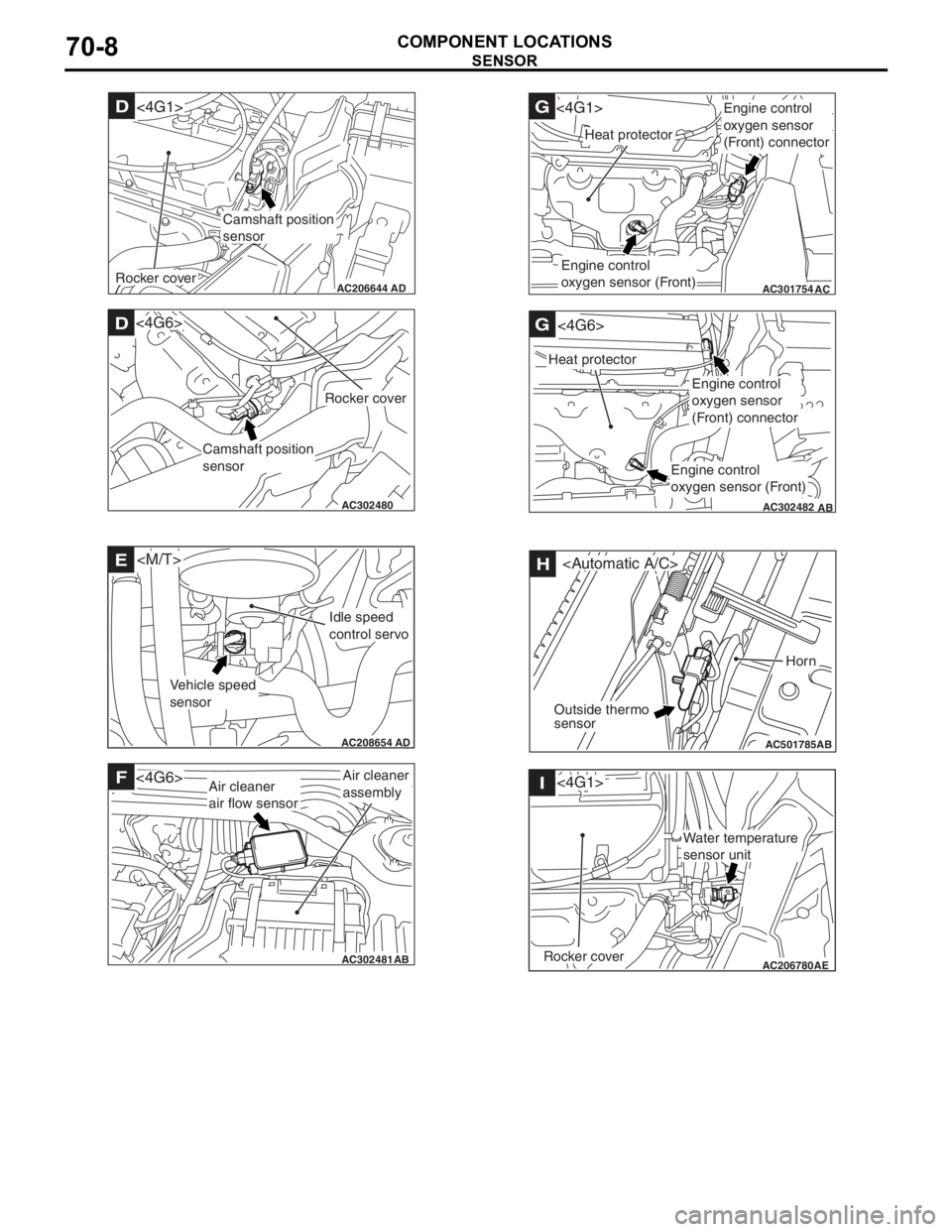

AC206644AD

Camshaft position

sensor

D<4G1>

Rocker cover

AC302480AB

D

Camshaft position

sensor

Rocker cover

<4G6>

AC208654

AD

E

Vehicle speed

sensor

Idle speed

control servo

AC302481AB

FAir cleaner

assembly<4G6>Air cleaner

air flow sensor

AB

AC301754

G<4G1>

AC

Heat protector

Engine control

oxygen sensor (Front)

Engine control

oxygen sensor

(Front) connector

AC302482

G

AB

Heat protector

<4G6>

Engine control

oxygen sensor

(Front) connector

Engine control

oxygen sensor (Front)

AC501785AB

H

Horn

Outside thermo

sensor

AC206780 AE

I

Rocker cover

<4G1>

Water temperature

sensor unit

SE

NSOR

COMPONENT LOCA TIONS70-8

Page 404 of 800

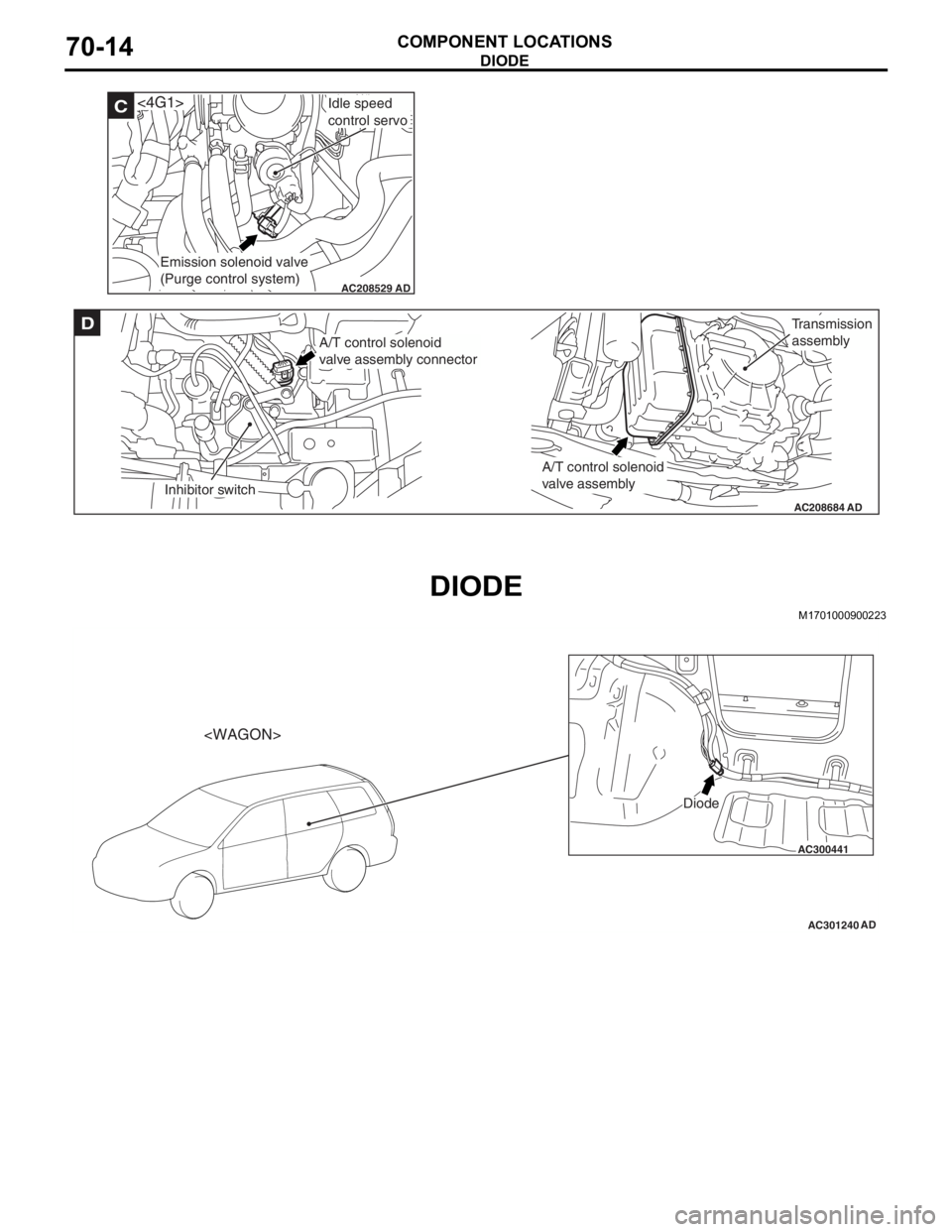

AC208529AD

C<4G1>Idle speed

control servo

Emission solenoid valve

(Purge control system)

AC208684

D

AD

A/T control solenoid

valve assembly connector

Inhibitor switch

A/T control solenoid

valve assembly

Transmission

assembly

DIOD E

COMPONENT LOCA TIONS70-14

DIODE

M1701 0009 0022 3

AC300441

AC301240

Diode

AD

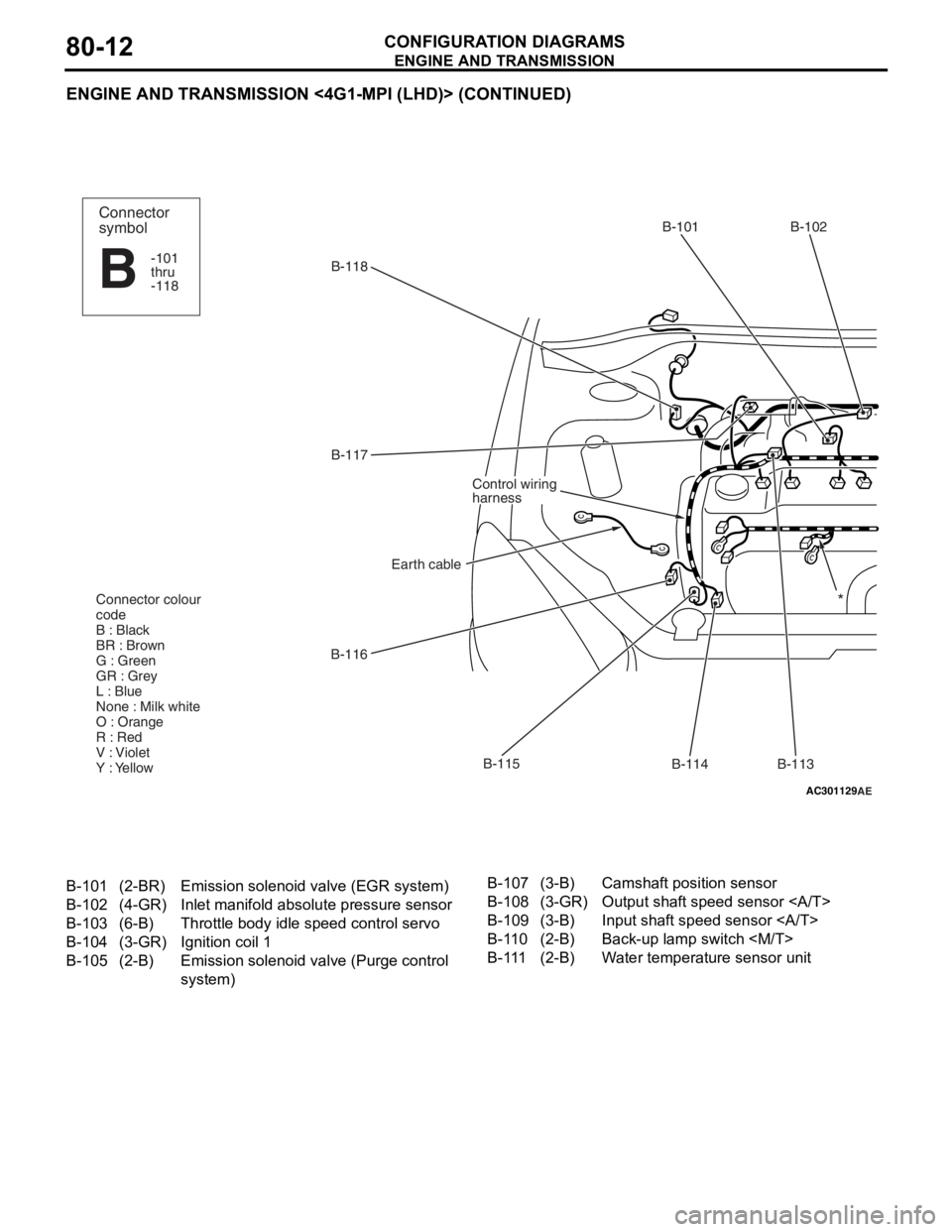

Page 422 of 800

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-12

ENGINE AND TRANSMISSION <4G1-MPI (LHD)> (CONTINUED)

AC301129AE

B-118B-101 B-102

B-113

B-114

B-115

B-116 B-117

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118

B

*

B-101(2-BR)Emission solenoid valve (EGR system)

B-102(4-GR)Inlet manifold absolu te pressure sensor

B-103(6-B)Throttle body idle speed control servo

B-104(3-GR)Ignition coil 1

B-105(2-B)Emission solenoid va lve (Purge control

system)

B-107(3-B)Camshaft position sensor

B-108(3-GR)Output shaft speed sensor

B-109(3-B)Input shaft speed sensor

B-110(2-B)Back-up lamp switch

B-111(2-B)Water temperature sensor unit

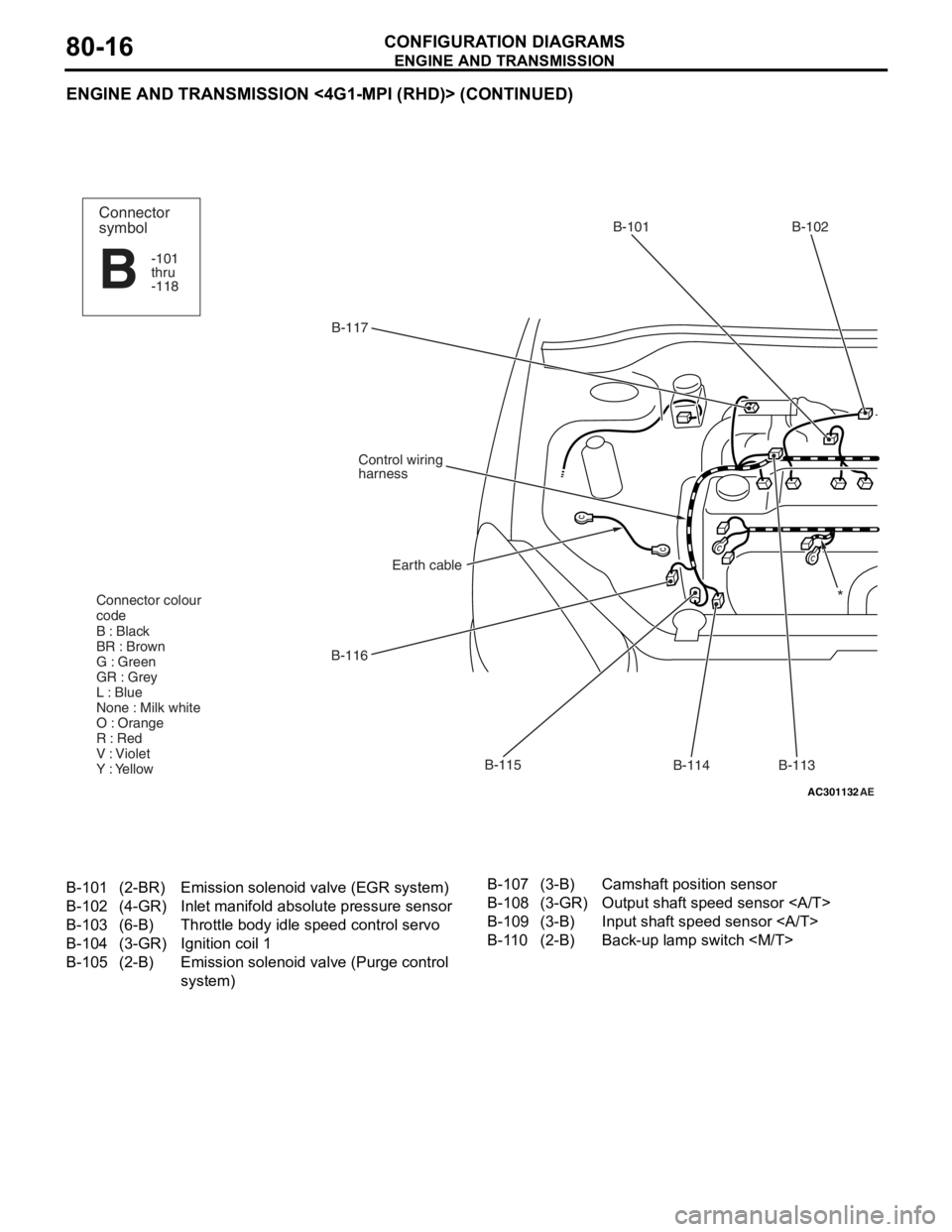

Page 426 of 800

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-16

ENGINE AND TRANSMISSION <4G1-MPI (RHD)> (CONTINUED)

AC301132AE

B-117B-101 B-102

B-113

B-114

B-115

B-116

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Grey

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118

B

*

B-101(2-BR)Emission solenoid valve (EGR system)

B-102(4-GR)Inlet manifold absolu te pressure sensor

B-103(6-B)Throttle body idle speed control servo

B-104(3-GR)Ignition coil 1

B-105(2-B)Emission solenoid va lve (Purge control

system)

B-107(3-B)Camshaft position sensor

B-108(3-GR)Output shaft speed sensor

B-109(3-B)Input shaft speed sensor

B-110(2-B)Back-up lamp switch