catalytic converter MITSUBISHI LANCER IX 2006 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 107 of 800

17-1

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL . . . . . . . . . .17-2

GENERAL INFORMATION . . . . . .17-2

SERVICE SPECIFICATIONS. . . . .17-2

ON-VEHICLE SERVICE. . . . . . . . .17-2

ACCEL CABLE CHECK AND

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 17-2

ACCELERATOR CABLE AND

PEDAL . . . . . . . . . . . . . . . . . . . . . .17-3

REMOVAL AND INSTALLATION . . . . . 17-3

EMISSION CONTROL MPI . . . .17-4

GENERAL INFORMATION . . . . . .17-4

EMISSION CONTROL DEVICE

REFERENCE TABLE . . . . . . . . . .17-4

SERVICE SPECIFICATION(S) . . .17-5

VACUUM HOSE. . . . . . . . . . . . . . .17-5

VACUUM HOSE PIPING DIAGRAM . . . 17-5

VACUUM CIRCUIT DIAGRAM . . . . . . . 17-7

VACUUM HOSE CHECK. . . . . . . . . . . . 17-7

VACUUM HOSE INSTALLATION . . . . . 17-8

CRANKCASE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-8

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-8

COMPONENT LOCATI ON (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-9

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 17-9

POSITIVE CRANKCASE VENTILATION (PCV)

VALVE CHECK . . . . . . . . . . . . . . . . . . . 17-9

EVAPORATIVE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . .17-9

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-9

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-10

PURGE CONTROL SYSTEM CHECK . . 17-10

PURGE PORT VACUUM CHECK . . . . . 17-11

PURGE CONTROL SOLENOID VALVE

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 17-11

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION . . . . . . . . . . . . . . . 17-12

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM . . . . . . . . . . . . . . .17-12

GENERAL INFORMATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-12

COMPONENT LOCATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-14

EGR SYSTEM CHECK . . . . . . . . . . . . . 17-15

EGR VALVE CHECK . . . . . . . . . . . . . . . 17-15

EGR PORT VACUUM CHECK <4G1>. . 17-16

EGR PORT VACUUM CHECK <4G6>. . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G1> . . . . . . . . . . . . . . . . . . . . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G6> . . . . . . . . . . . . . . . . . . . . 17-17

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND I

NSTALLATION . . . . . . . . . . . . . . . . . . . . 17-18

CATALYTIC CONVERTER . . . . . .17-19

REMOVAL AND INSTALLATION

<4G1, 4G6-M/T> . . . . . . . . . . . . . . . . . . 17-19

REMOVAL AND INSTALLATION

<4G6-A/T> . . . . . . . . . . . . . . . . . . . . . . . 17-19

Page 110 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-4

INSTALLATION SERVICE POINT

>>A<< ACCEL PEDAL PAD INSTALLA-

TION

CAUTION

To prevent damages to the accelerator pedal pad,

warm the thumb area of the accelerator pedal

pad with a dryer, etc. prior to assembling it.

NOTE: If it is difficult to assemble, apply soapy water

to the thumb area to enhance the assembling proc

-

ess.

EMISSION CONTROL

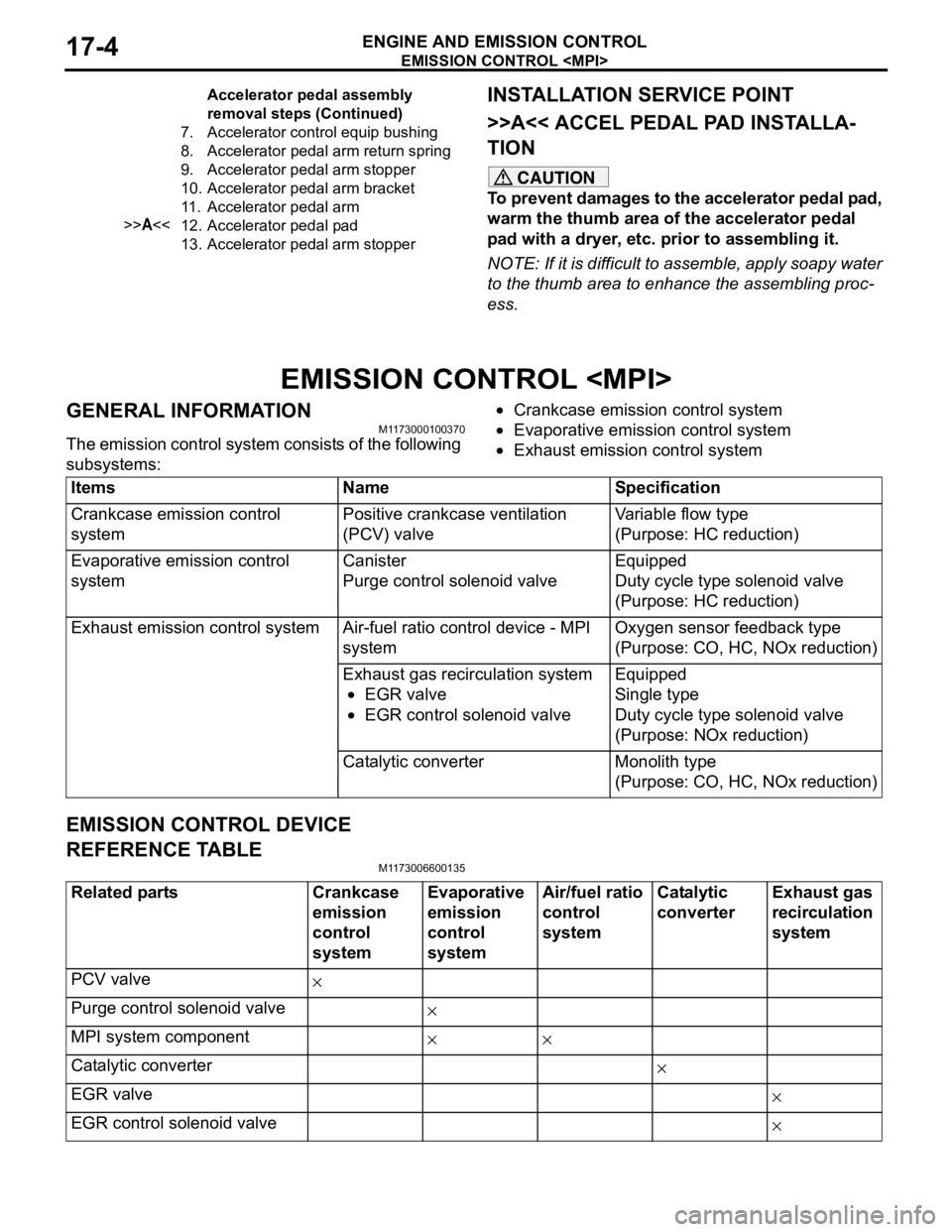

GENERAL INFORMATION

M1173000100370

The emission control system consists of the following

subsystems:

•Crankcase emission control system

•Evaporative emission control system

•

ItemsNameSpecification

Crankcase emission control

systemPositive crankcase ventilation

(PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission control

systemCanister

Purge control solenoid valve

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission control systemAir-fuel ratio control device - MPI

systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

•EGR valve

•EGR control solenoid valve

Equipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

Catalytic converterMonolith type

(Purpose: CO, HC, NOx reduction)

Exhaust emission control system

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006600135

Related partsCrankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel ratio

control

systemCatalytic

converterExhaust gas

recirculation

system

PCV valve×

Purge control solenoid valve×

MPI system component××

Catalytic converter×

EGR valve×

EGR control solenoid valve×

7.Accelerator control equip bushing

8.Accelerator pedal arm return spring

9.Accelerator pedal arm stopper

10.Accelerator pedal arm bracket

11 .Accelerator pedal arm

>>A<<12.Accelerator pedal pad

13.Accelerator pedal arm stopper

Accelerator pedal assembly

removal steps (Continued)

Page 111 of 800

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-5

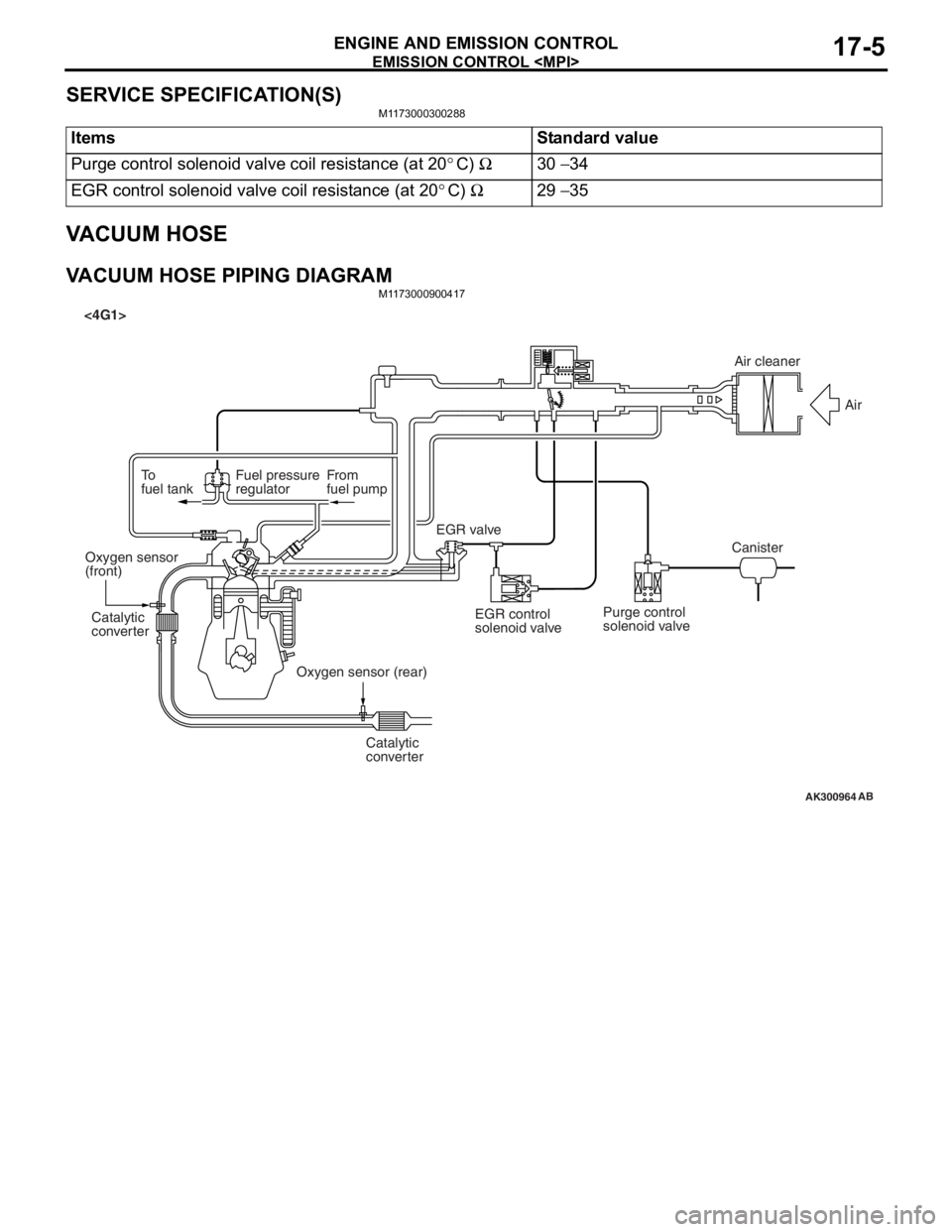

SERVICE SPECIFICATION(S)

M1173000300288

ItemsStandard value

Purge control solenoid valve coil resistance (at 20°C) Ω30 − 34

EGR control solenoid valve coil resistance (at 20°C) Ω29 − 35

VACUUM HOSE

VACUUM HOSE PIPING DIAGRAMM1173000900417

AK300964

To

fuel tankFuel pressure

regulatorFrom

fuel pump

Catalytic

converter Catalytic

converter

Oxygen sensor

(front)

Oxygen sensor (rear)EGR valve

<4G1>

EGR control

solenoid valvePurge control

solenoid valve CanisterAir

AB

Air cleaner

Page 112 of 800

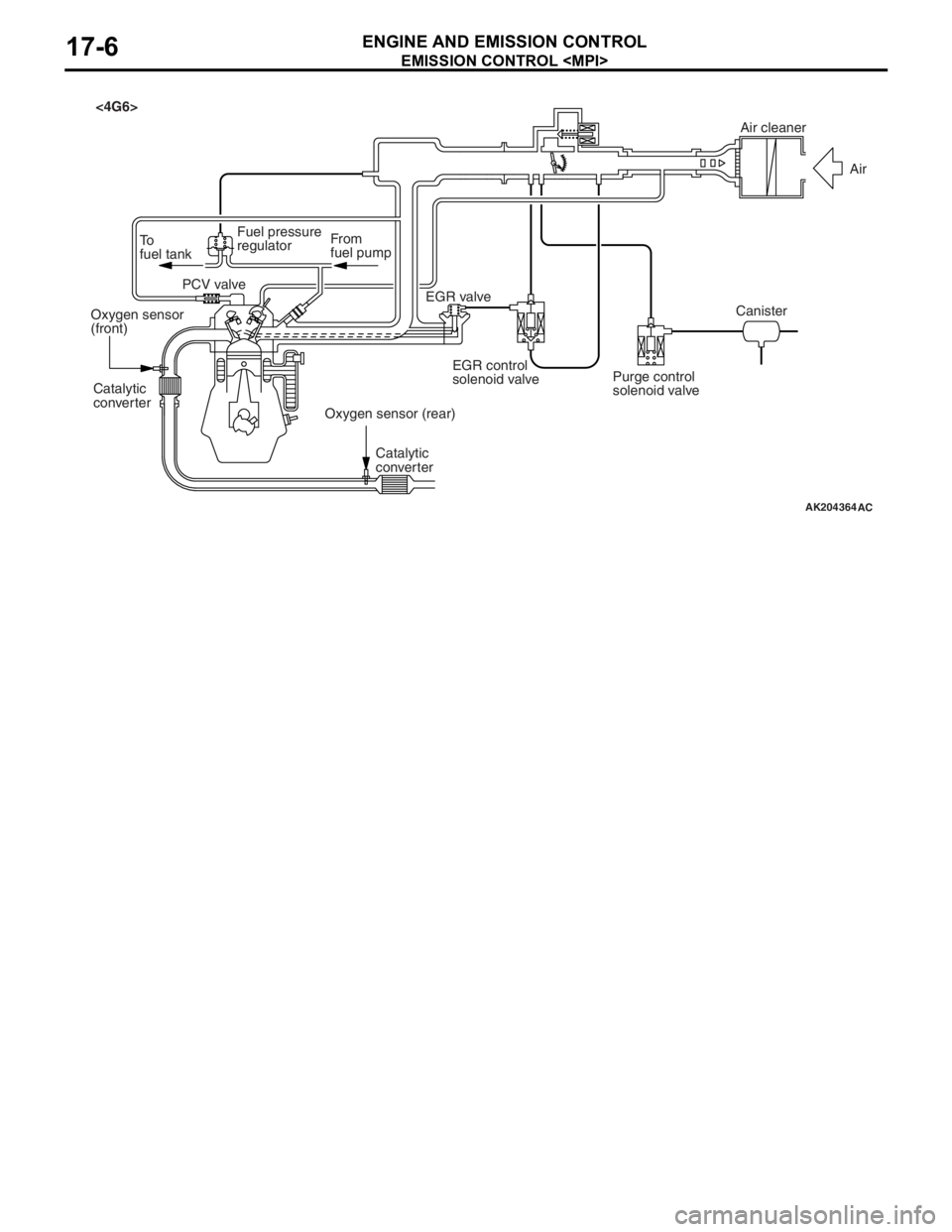

AK204364AC

Air cleaner

Air

Canister

Purge control

solenoid valve

EGR control

solenoid valve

EGR valve

From

fuel pump

To

fuel tank Fuel pressure

regulator

PCV valve

Oxygen sensor

(front)

Oxygen sensor (rear)

Catalytic

converter

Catalytic

converter

<4G6>

EMISSION CONTROL

ENGINE AND E M ISSION CON T ROL17-6

Page 125 of 800

EMISSION CONTROL

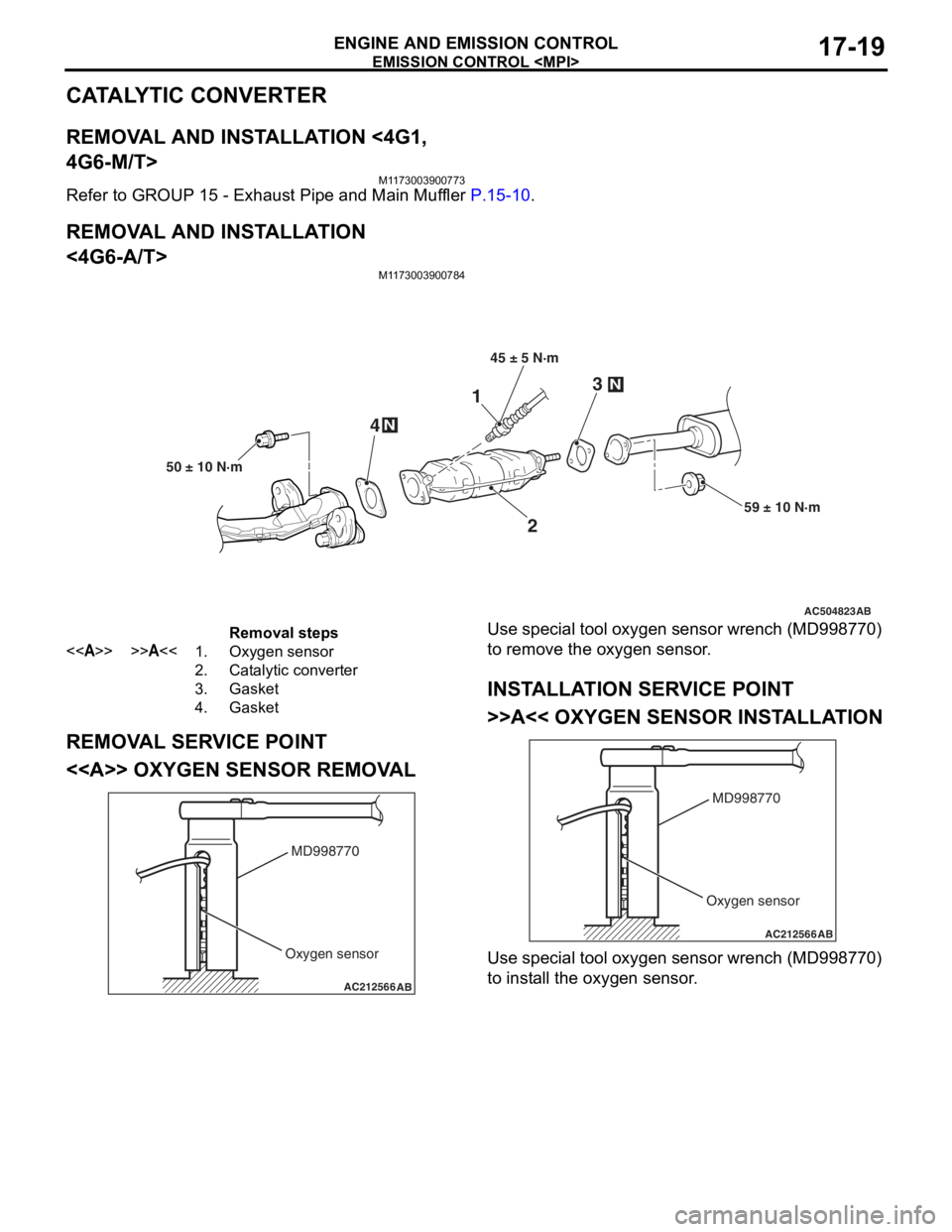

ENGINE AND EMISSION CONTROL17-19

CATALYTIC CONVERTER

REMOVAL AND INSTALLATION <4G1,

4G6-M/T>

M1173003900773

Refer to GROUP 15 - Exhaust Pipe and Main Muffler P.15-10.

REMOVAL AND INSTALLATION

<4G6-A/T>

M1173003900784

AC504823

2

3N

N4

59 ± 10 N·m

50 ± 10 N·m

1

45 ± 5 N·m

AB

Removal steps

<>>>A<<1.Oxygen sensor

2.Catalytic converter

3.Gasket

4.Gasket

REMOVA L SER V ICE POINT

<> OXYGEN SENSOR REMOV A L

AC212566AB

MD998770

Oxygen sensor

Use spec ia l tool oxyg en sen s or wrench (MD9987 70)

to remove

the oxyge n sen s or .

INSTALLA T ION SER VICE POINT

>>A<< OXYGEN SENSOR INST ALL A TION

AC212566AB

MD998770

Oxygen sensor

Use spec ia l tool oxyg en sen s or wrench (MD9987 70)

to inst

all the oxyge n sen s or .