width MITSUBISHI LANCER IX 2006 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 135 of 800

SERVICE SPECIFICATIONS

FRONT AXLE26-3

SERVICE SPECIFICATIONS

M1261000300675

ItemStandard valueLimit

Wheel bearing axial play mm−0.05

Hub starting torque N⋅m−1.8

Protruding length of stabilizer bar mounting bolt mm22 ± 1.5−

Setting of TJ boot length mm1300-RH, 1600-A/T-RH85 ± 3−

1300-LH, 1600-M/T,

1600-A/T-LH, 200090 ± 3−

Opening dimension of the

special tool (MB991561) mmWhen the BJ boot band

(small) is crimped2.9−

When the BJ boot band

(large) is crimped2.9 −

Crimped width of the BJ boot band mm2.4 − 2.8−

LUBRICANTS

M1261000400735

ItemSpecified lubricantQuantity

TJ boot greaseRepair kit grease1300-LH, 1600-LH,

2000-LH120 ± 10 g

1300-RH, 1600-A/T-RH11 0 ± 10 g

1600-M/T-RH, 2000-A/T-RH120 ± 10 g

2000-M/T-RH105 ± 10 g

BJ boot greaseRepair kit grease95 ± 10 g

Page 236 of 800

SERVICE SPECIFICATIONS

POWER STEERING37-6

SERVICE SPECIFICATIONS

M1372000300795

ItemStandard valueLimit

Steering wheel free

play mmWith engine running−30

With engine stopped10 or less−

Steering angleInner wheelInvite39°30' ± 1°30'−

Intense (LH drive vehicles)33°40' +1°00'/-2°00'−

Intense (RH drive vehicles)37°00' +1°00'/-2°00'−

Outer wheel

(reference)Invite32°30'−

Intense (LH drive vehicles)28°46'−

Intense (RH drive vehicles)30°00'−

Toe-inAt the centre of tyre tread mm1 ± 2−

Toe-angle (per wheel)0°03' ± 06'−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5−

Tie rod swing resistance N [Tie rod swing torque N⋅m]8 − 27 [1.5 − 4.9]−

Stationary steering effort N [Fluctuation allowance N]29 or less [5.9 or less]−

Oil pump pressure

MPa (750

± 100 r/min.)

Oil pump relief pressure8.8 − 9.5−

Pressure under no-load conditions0.2 − 0.7−

Steering gear retention hydraulic pressure8.8 − 9.5−

Oil pressure switch operating pressure

MPaOFF → ON1.5 − 2.0−

ON → OFF0.7 − 2.0−

Steering gear total pinion torque N⋅m

[Change in torque N

⋅m]

Invite0.8 − 2.1 [0.6 or less]−

Intense0.7 − 2.1 [0.6 or less]−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9−

Band crimped width mm2.4 − 2.8−

Page 264 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-34

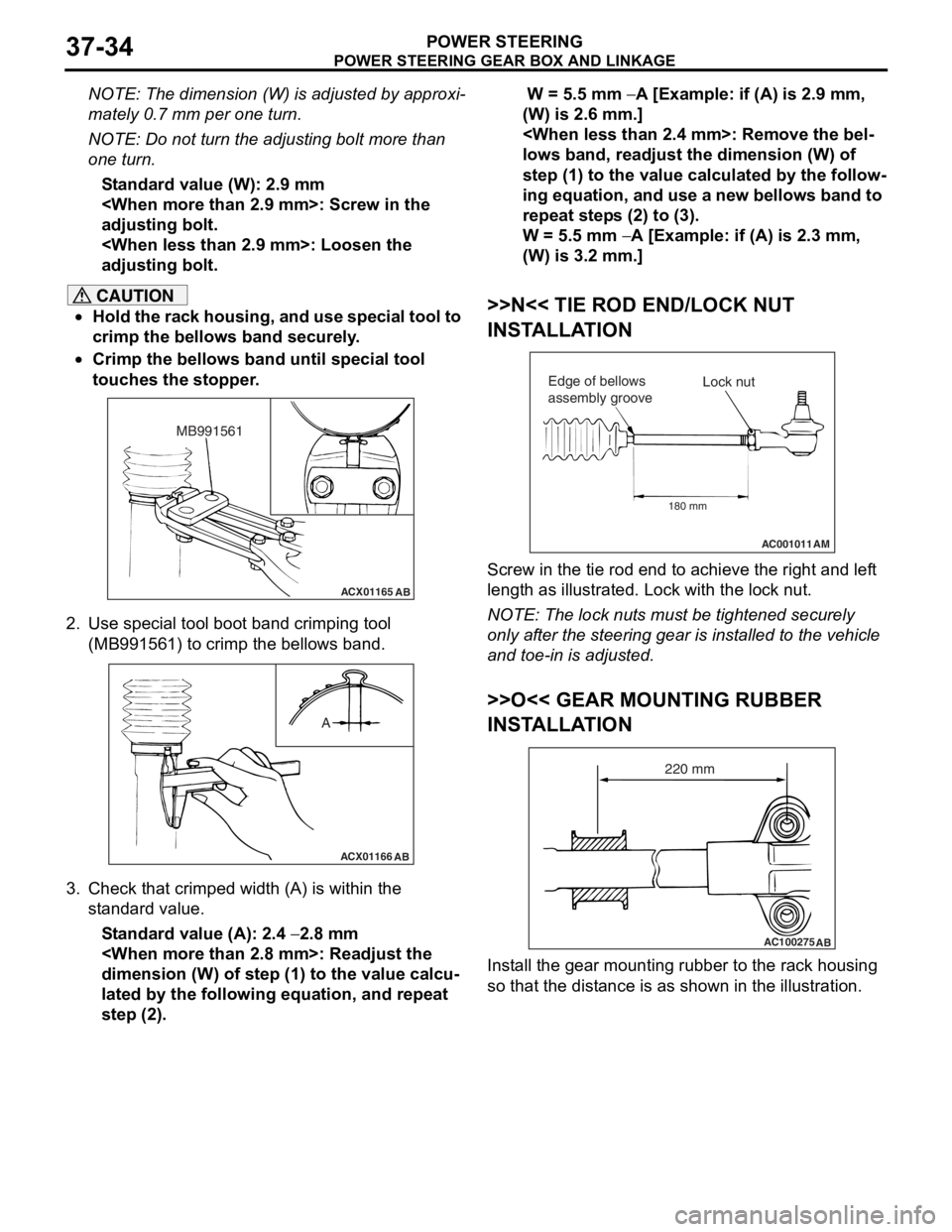

NOTE: The dimension (W) is adjusted by approxi-

mately 0.7 mm per one turn.

NOTE: Do not turn the adjusting bolt more than

one turn.

Standard value (W): 2.9 mm

adjusting bolt.

adjusting bolt.

CAUTION

•Hold the rack housing, and use special tool to

crimp the bellows band securely.

•

ACX01165AB

MB991561

Crimp the bellows band until special tool

touches the stopper.

2. Use special tool boot band crimping tool (MB991561) to crimp the bellows band.

ACX01166 AB

A

3. Check that crimped width (A) is within the

standard value.

Standard value (A): 2.4 − 2.8 mm

dimension (W) of step (1) to the value calcu

-

lated by the following equation, and repeat

step (2).

W = 5.5 mm − A [Example: if (A) is 2.9 mm,

(W) is 2.6 mm.]

lows band, readjust the dimension (W) of

step (1) to the value calculated by the follow

-

ing equation, and use a new bellows band to

repeat steps (2) to (3).

W = 5.5 mm − A [Example: if (A) is 2.3 mm,

(W) is 3.2 mm.]

>>N<< TIE ROD END/LOCK NUT

INSTALLATION

AC001011 AM

Lock nut

Edge of bellows

assembly groove

180 mm

Screw in the tie rod end to achieve the right and left

length as illustrated. Lock with the lock nut.

NOTE: The lock nuts must be tightened securely

only after the steering gear is installed to the vehicle

and toe-in is adjusted.

>>O<< GEAR MOUNTING RUBBER

INSTALLATION

AC100275 AB

220 mm

Install the gear mounting rubber to the rack housing

so that the distance is as shown in the illustration.

Page 269 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-39

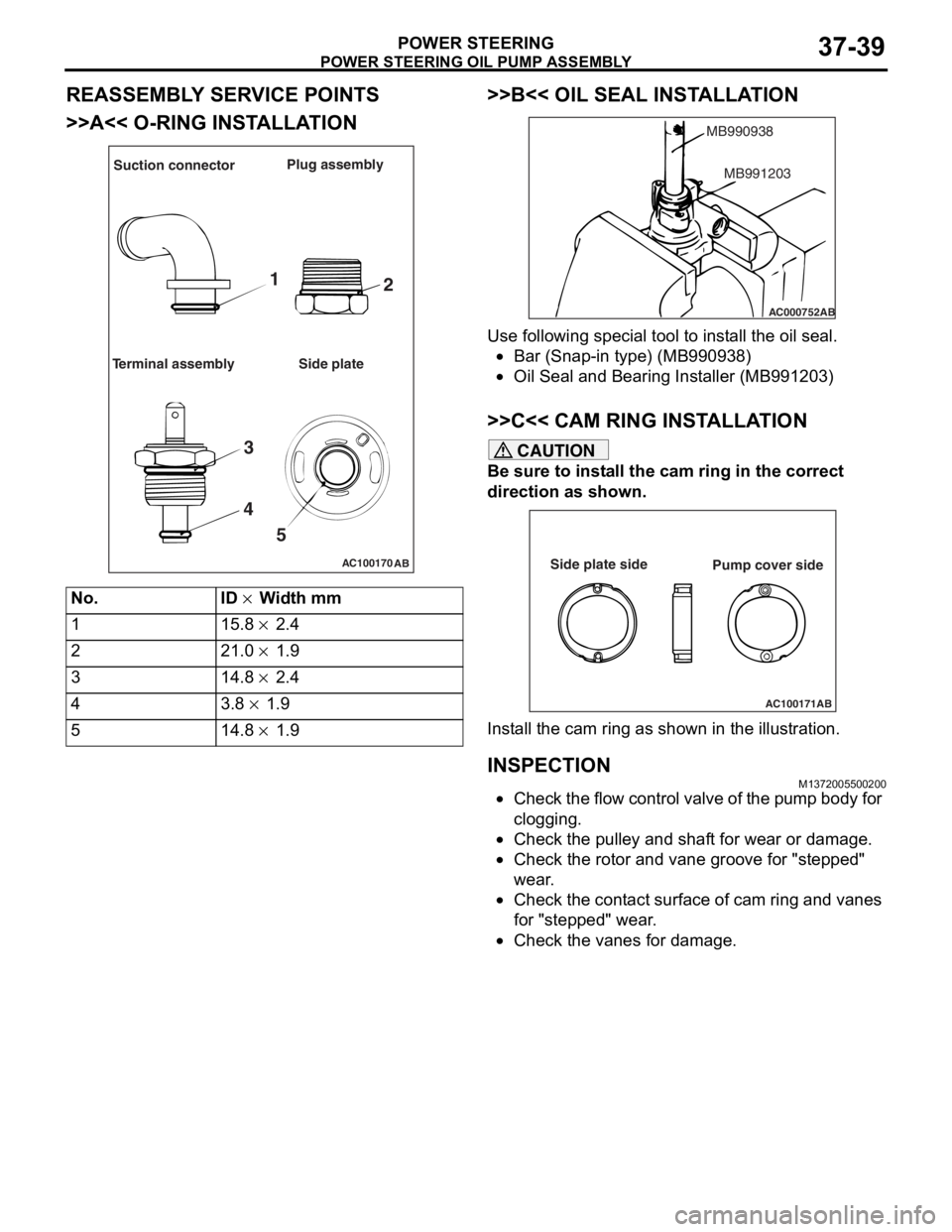

REASSEMBLY SERVICE POINTS

>>A<< O-RING INSTALLATION

AC100170AB

Suction connector Plug assembly

Terminal assembly Side plate

1 2

3

4 5

No.ID × Width mm

115.8 × 2.4

221.0 × 1.9

314.8 × 2.4

43.8 × 1.9

514.8 × 1.9

>>B<< OIL SEAL INST ALLA TION

AC000752

MB990938

AB

MB991203

Use following spe c ia l too l to inst all the oil seal.

•Bar (Snap-in type) (MB9909 38)

•Oil Seal and Bearin g Inst aller (MB9912 03)

>>C<< CAM RING INSTALLA TION

CAUTION

Be sure to install the cam ring in the correct

direction as shown.

AC100171AB

Side plate side

Pump cover side

Install the cam ring as shown in the illustration.

INSPECTION

M1372005500200

•Check the flow control valve of the pump body for

clogging.

•Check the pulley and shaft for wear or damage.

•Check the rotor and vane groove for "stepped"

wear.

•Check the contact surface of cam ring and vanes

for "stepped" wear.

•Check the vanes for damage.

Page 341 of 800

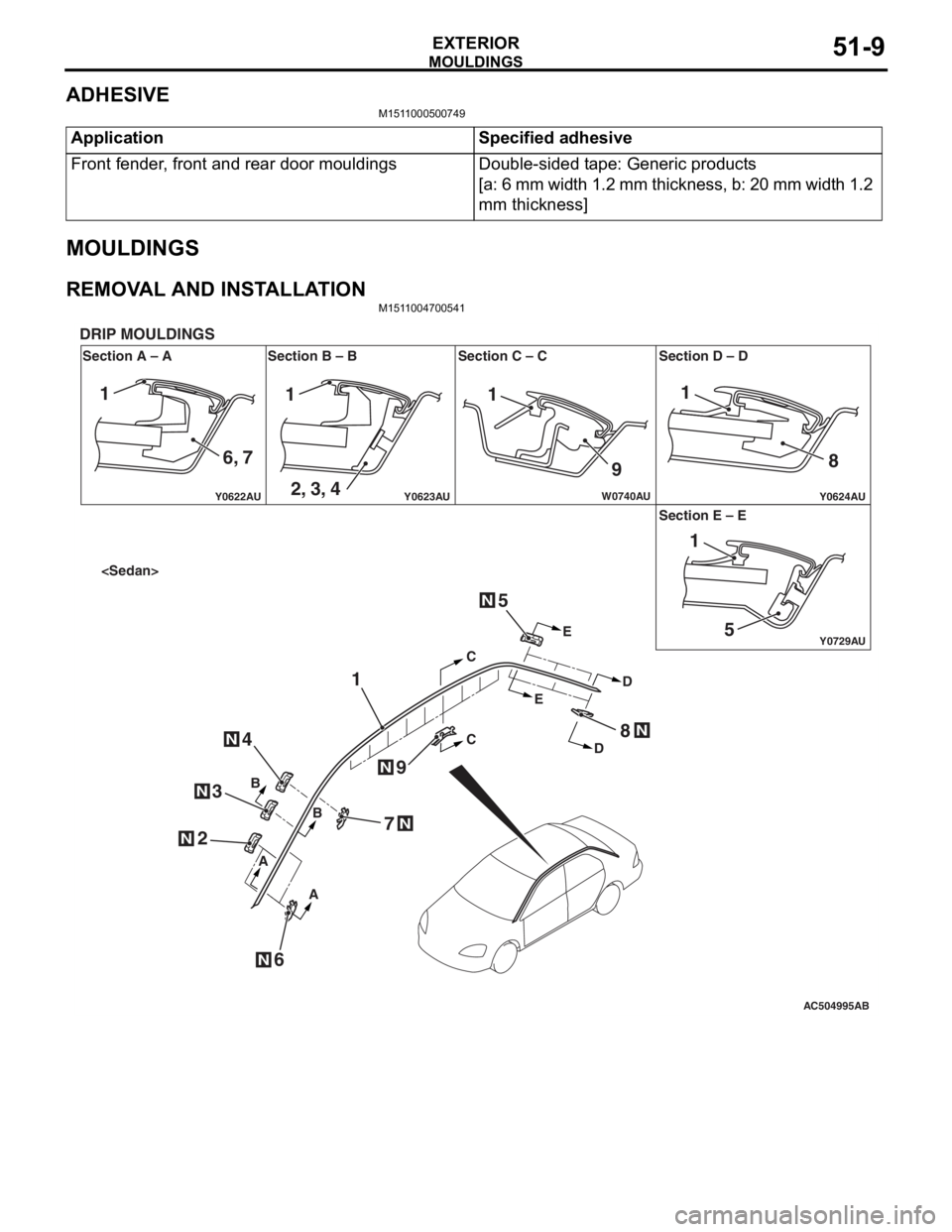

MOULDINGS

EXTERIOR51-9

ADHESIVE

M1511000500749

ApplicationSpecified adhesive

Front fender, front and rear door mouldingsDouble-sided tape: Generic products

[a: 6 mm width 1.2 mm thickness, b: 20 mm width 1.2

mm thickness]

MOULDINGS

REMOVAL AND INSTALLATIONM1511004700541

AC504995

Y0622AU

Y0624AUY0623AU

Y0729AU

W0740AU

Section A – A

DRIP MOULDINGS

Section B – B Section C – C Section D – D

Section E – E

AB

N

N

N

N

N

CC

E E

D

D

B

B

A

A

1

2

6

4

3

5

7

8

9

N

N

N

111

9 8

51

1

6, 7 2, 3, 4

Page 344 of 800

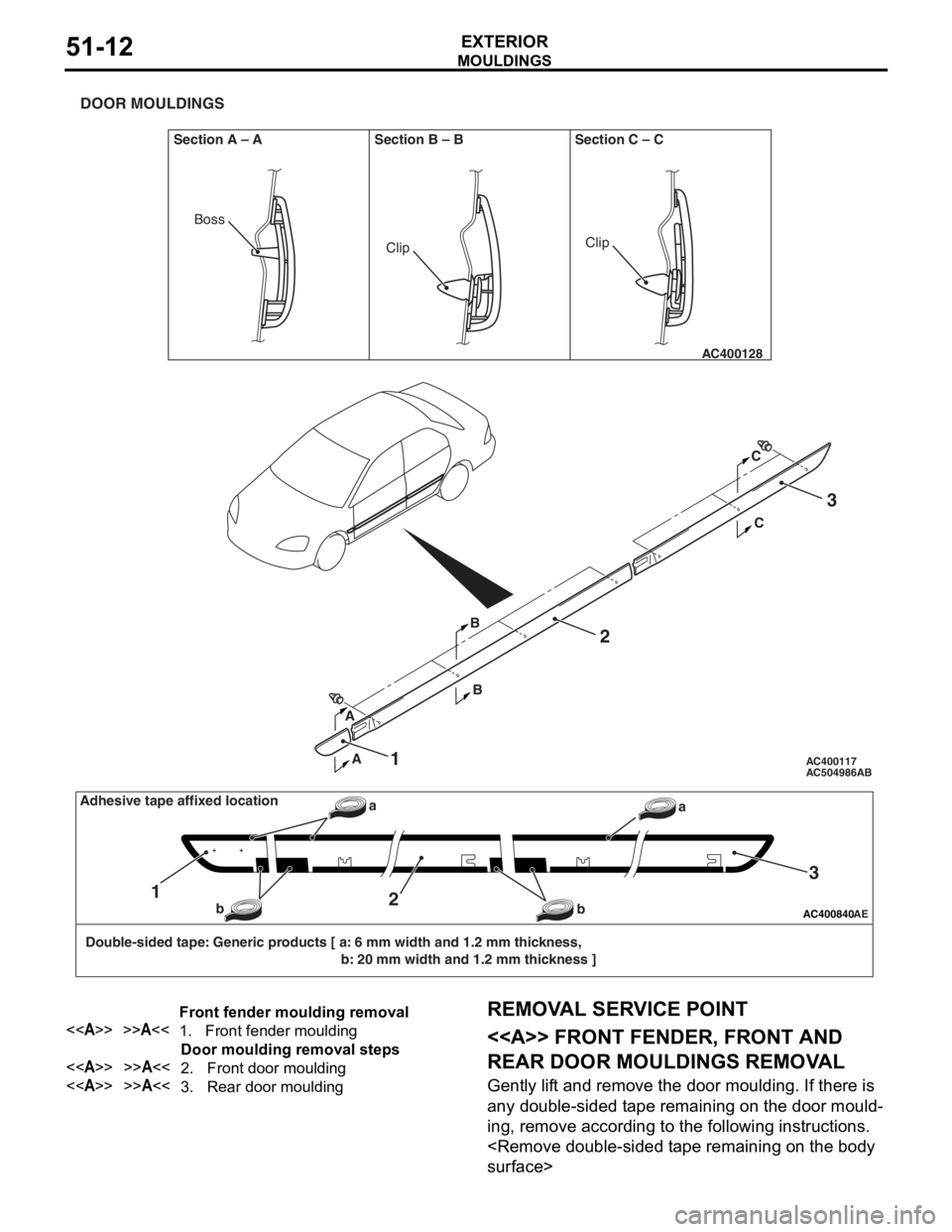

AC504986 AC400117

AC400128

Section A – A

DOOR MOULDINGS

Section B – B Section C – C

AB

AA C

C

BB2

1

3

ClipClip

Boss

AC400840AE

Double-sided tape: Generic products [ a: 6 mm width and 1.2 mm thickness, b: 20 mm width and 1.2 mm thickness ]

12

3

a

b

baAdhesive tape affixed location

Front fender moulding removal

<>>>A<<1.Front fender moulding

Door moulding removal steps

<>>>A<<2.Front door moulding

<>>>A<<3.Rear door moulding

MO

UL DI N G S

EXTERIOR51-12

REMOVA L SER VICE POINT

<> FRONT FENDER, FRONT AND

REAR DOOR MOULDINGS REMOV

A L

Gently lif t and remo ve th e door moulding . If the r e is

any d

ouble-sided t ape remainin g on th e door mould

-

ing, remove accord ing to the fo llowing in struction s .

Page 346 of 800

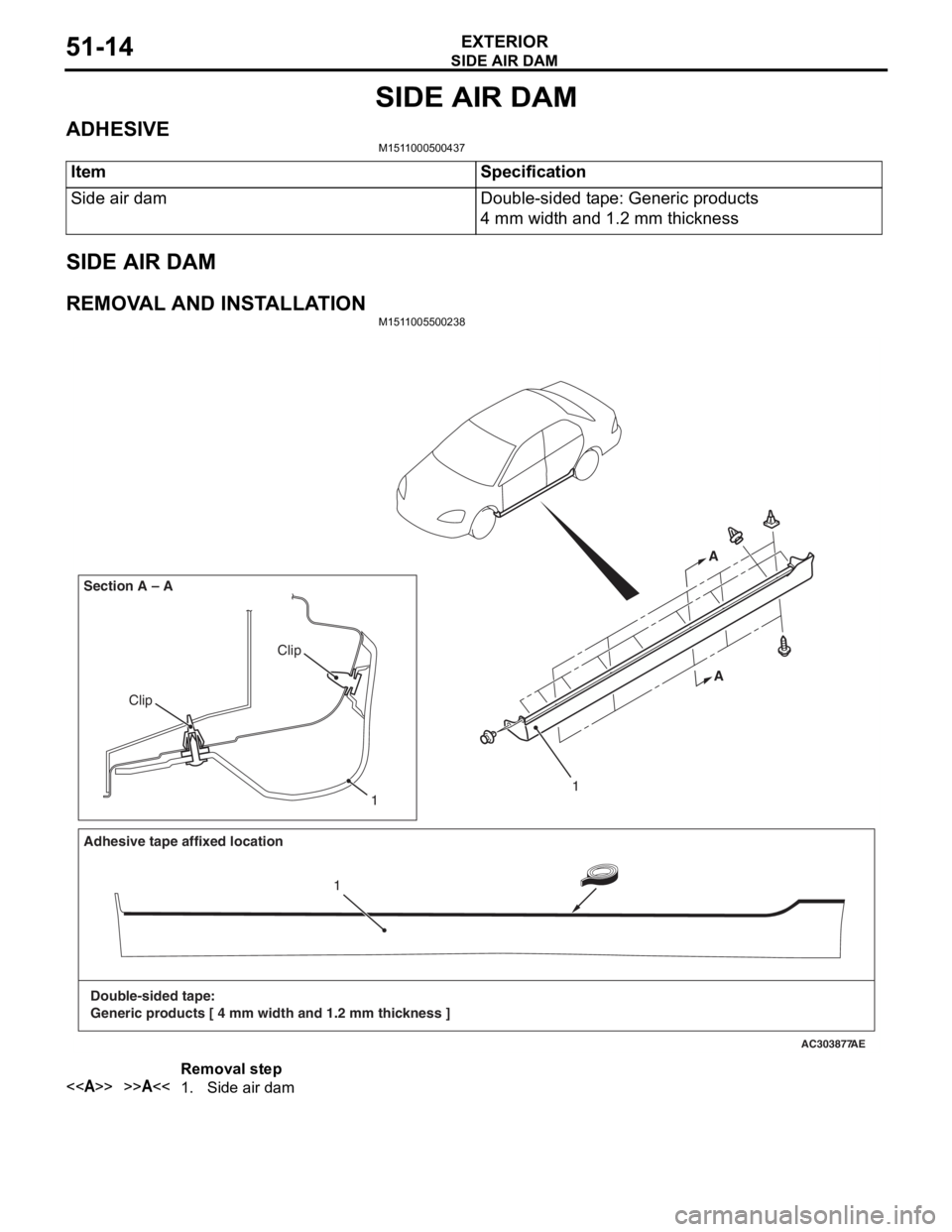

SIDE AIR DAM

EXTERIOR51-14

SIDE AIR DAM

ADHESIVEM1511000500437

ItemSpecification

Side air damDouble-sided tape: Generic products

4 mm width and 1.2 mm thickness

SIDE AIR DAM

REMOVAL AND INSTALLATIONM1511005500238

AC303877

Clip

Clip

Section A – A

AE

1

A

A

Adhesive tape affixed location

Double-sided tape:

Generic products [ 4 mm width and 1.2 mm thickness ] 1

1

Removal step

<>>>A<<1.Side air dam