engine MITSUBISHI MONTERO 1984 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1984, Model line: MONTERO, Model: MITSUBISHI MONTERO 1984 1.GPages: 21, PDF Size: 1.29 MB

Page 1 of 21

. . c-, :

Service Manual

MONTERO

1984

FOREWORD

This Sk-vice Manual has been prepared with the latest

service information available at the time of publi-

cation. It is subdivided into various group categories

-and each section contains diagnosis, disassembly,

repair, and installation procedures along with com-

plete specifications and tightening references. Use of

this manual will aid in properly performing any

servicing necessary to maintain or restore the high

levels of performance and reliability designed into

these outstanding vehicles.

WE SUPPORT l VOLUNTARY TECHNICIAN

CERTIFICATION

THROUGH

.&tsubishi Motors Corporation reserves the right to make changes in

Zesign or to make additions to or improvements in its products without

mposing any obligations upon itself to install them on its products

.reviously manufactured. Introduction . , . .,......,..........

0 Lubrication and Maintenance . . . . . . . . .

2

3

5

6 Front Suspension ..................

RearAxle:. ......................

Brakes - Service and Parking .........

Clutch ..........................

7

8 Cooling ...........................

Electrical System ..................

9

11 Engine ...........................

Exhaust System .....................

13 Body and Frame Alignment . . . . . . . . . .

14 Fuel System . , . . . . . . . . . . .,. . . . . . . . .

16 Propeller Shaft and Universal Joints . . .,.

17 Rear Suspension . . . . . . . . . . . . . . . . . . .

19 Steering - Power . . . . . . . . . . . . . . ., . . .

21 Manual

Transmission - Automatic .,........

22 Wheels and Tires. . . , . . . , , . . . . . . . . . .

23 Body and Sheet Metal , . . . . . . . . . . . . .

24 Heaters and Air-conditioning . . . . . . . . .

25 Emission Control Systems . . . . . . . . . . .

GROUP INDEX Alphabetical Index

0 1983 Mitsubishi Motors Corporation Printed in Japan

Page 3 of 21

VEHICLE IDENTIf~CATlON

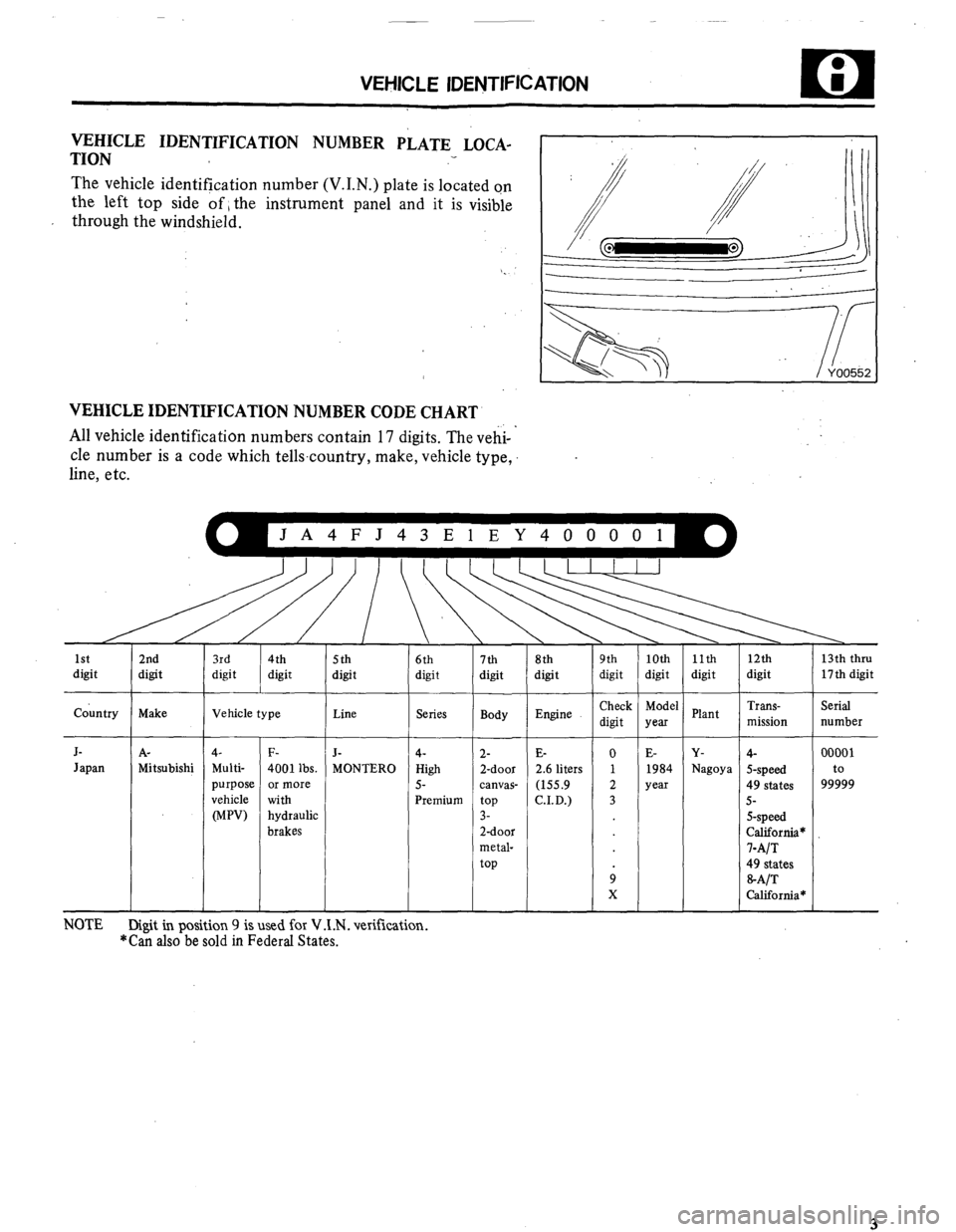

VEHICLE IDENTIFICATION NUMBER PLATE LOCA-

TION

The vehicle identification number (V.I.N.) plate is located on

the left top side of 1 the instrument panel and it is visible

through the windshield.

VEHICLE IDENTIFICATION NUMBER CODE CHART

All vehicle identification numbers contain 17 digits. The vehi- ’

cle number is a code which tellscountry, make, vehicle type,

line, etc.

JA4FJ43ElEY400001

I

5th

digit

I

1st

digit 2nd

digit

country Make

J- A-

Japan Mitsubishi 6th

digit 7th 8th

digit digit

Series

Body

4-

High

5-

Premium 2-

2-door

canvas-

top

3-

2-door

metal-

top 11th

digit 9th

digit

Check

digit Vehicle type : 10th

digit

Model

yea

E-

1984

year 12th

digit

Trans-

mission

4-

S-speed

49 states

5-

S-speed

California*

l-A/T

49 states

&A/T

California* 13th thru

17th digit

Serial

number

00001

to

99999 Plant

Y-

Nagoya Line Engine ,

J-

MONTERO E-

2.6 liters

(155.9

CID.) 4-

Multi-

purpose

vehicle

WV) F-

4001 lbs.

or more

with

hydraulic

brakes NOTE

Digit in position 9 is used for V .1 .N . verification. *Can also be sold in Federal States.

Page 4 of 21

I

I

cl ; VElfICLE IDENTIFICATION

/

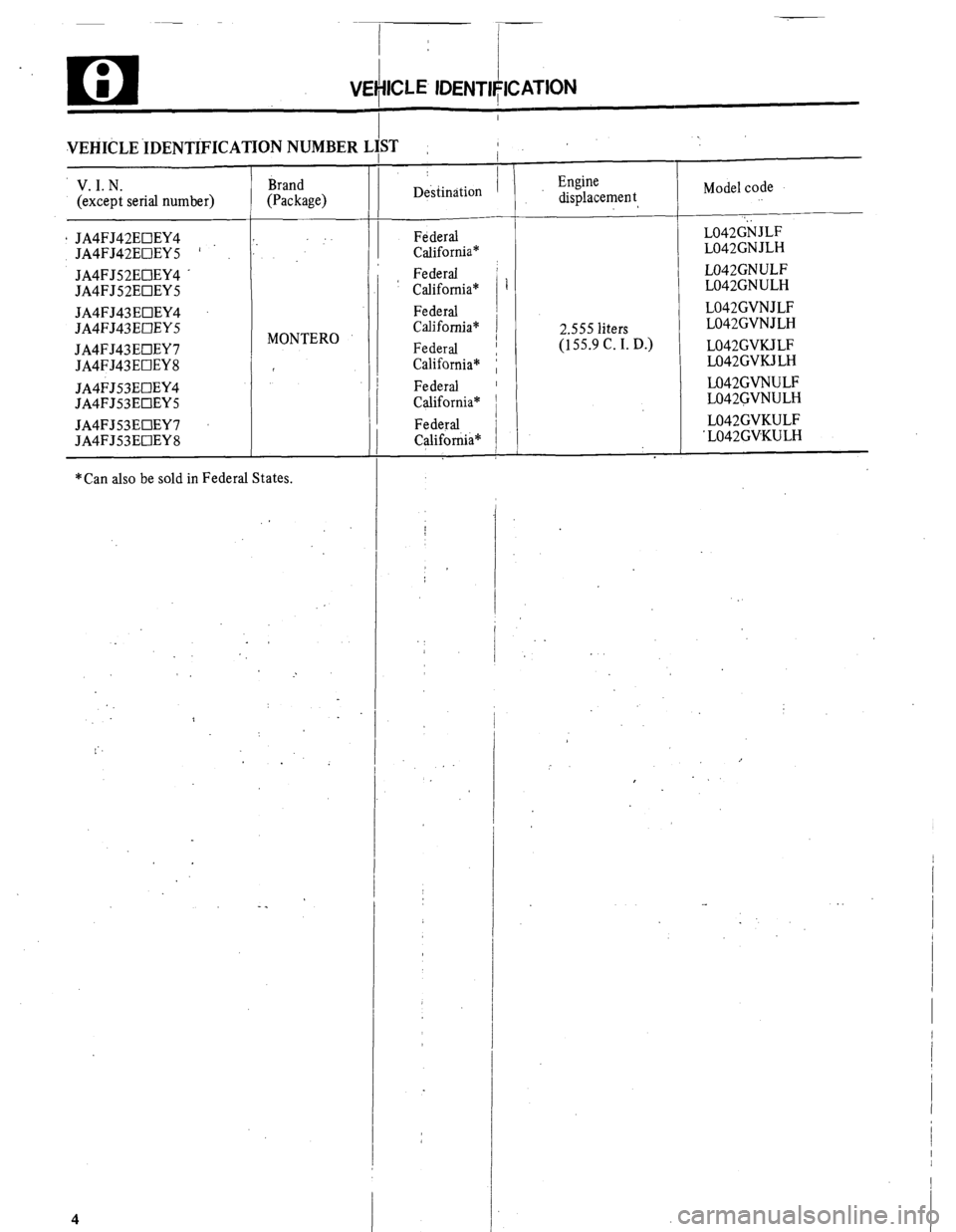

VEHICLE .IDENTiFICATION NUMBER L;ST

V. I. N.

(except serial number)

* JA4FJ42EOEY4

JA4FJ42EOEYS ’

JA4FJ52EUEY4 .

JA4FJ52EOEYS

JA4FJ43EOEY4

JA4FJ43EUEYS

JA4FJ43EUEY7

JA4FJ43EOEY8

JA4FJ53EClEY4

JA4FJ53EOEYS

JA4FJ53EOEY7

JA4FJ53EClEY8 Brand

(Package)

MONTERO

*Can also be sold in Federal States. Destination I

FdderaJ

California*

Federal

California*

Federal

California*

Federal

California*

Federal

California*

Federal

Califorrh” i

T

-

T

Engine

displacement

2.555 liters

(155.9 C. I. D.) Model code

‘. LO42GN JLF

L042GNJLH

L042GNULF

L042GNULH

L042GVNJLF

L042GVNJLH

L042GVKJLF

L042GVKJLH

LO42GVNULF

L042GVNULH

L042GVKULF

‘L042GVKULH

Page 5 of 21

VEHICLE IDENTIFICATION

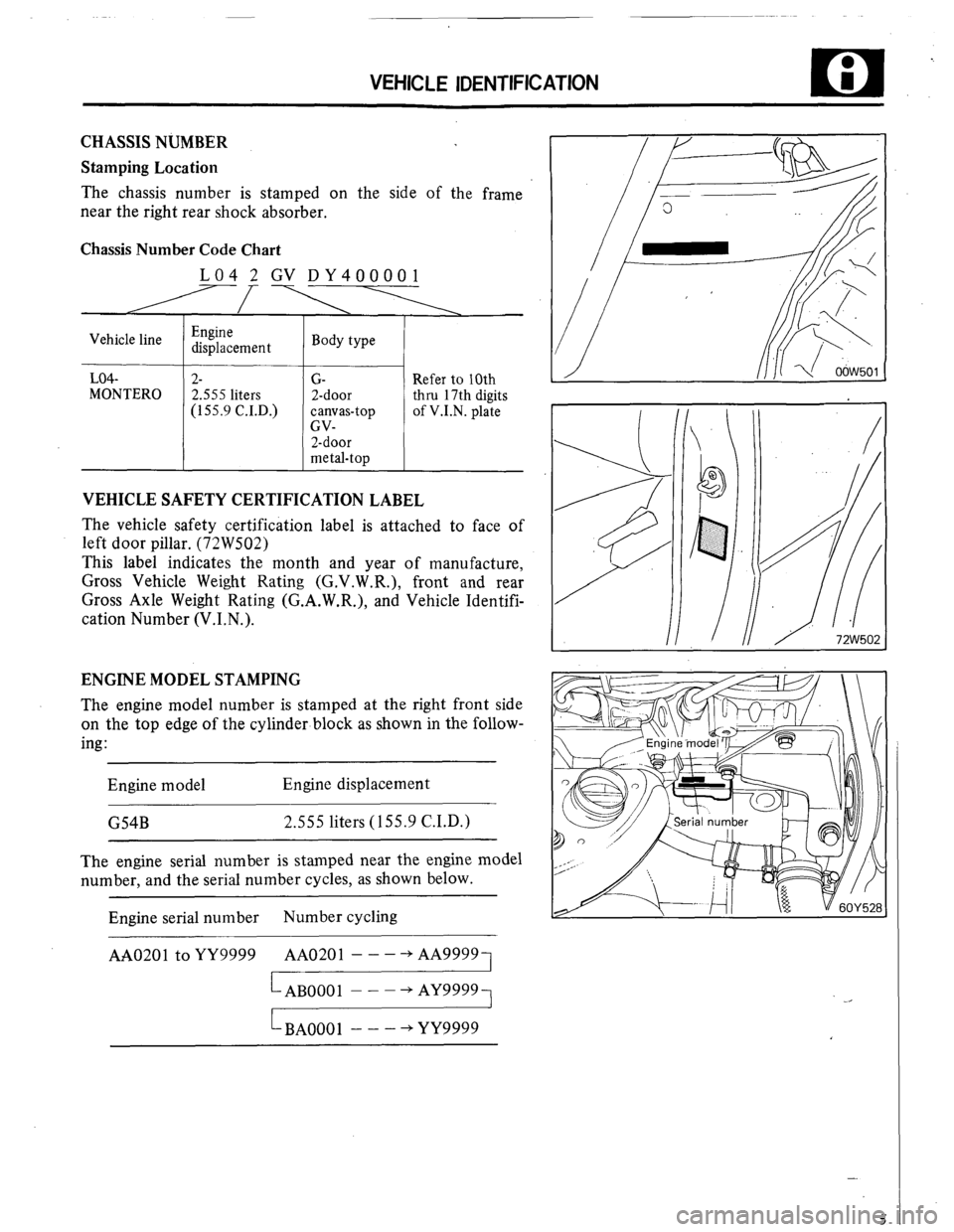

CHASSIS NUMBER

Stamping Location

The chassis number is stamped on the side of the frame

near the right rear shock absorber.

Chassis Number Code Chart

LO4 2 GV DY400001

Vehicle line

LO4-

7

MONTERO

I

Engine

displacement

2-

2.555 liters

(155.9 C.I.D.) Body type

G-

2-door

canvas-top

GV-

2-door

metal-top

1

Refer to 10th

thru 17th digits

of V.I.N. plate

VEHICLE SAFETY CERTIFICATION LABEL

The vehicle safety certification label is attached to face of

left door pillar. (72W502)

This label indicates the month and year of manufacture,

Gross Vehicle Weight Rating (G.V.W.R.), front and rear

Gross Axle Weight Rating (G.A.W.R.), and Vehicle Identifi-

cation Number (V.I.N.).

ENGINE MODEL STAMPING

The engine model number is stamped at the right front side

on the top edge of the cylinder block as shown in the follow-

ing :

Engine model Engine displacement

G54B 2.555 liters (155.9 C.I.D.)

The engine serial number is stamped near the engine model

number, and the serial number cycles, as shown below.

Engine serial number Number cycling i

AA0201 to YY9999 AA0201 - - - -+ AA99991

LAB0001 - - - + AY9999

LBAOOOl - - - += YY9999

5

Page 6 of 21

i 1

I

VEHICLE IDENTIFICATION

I

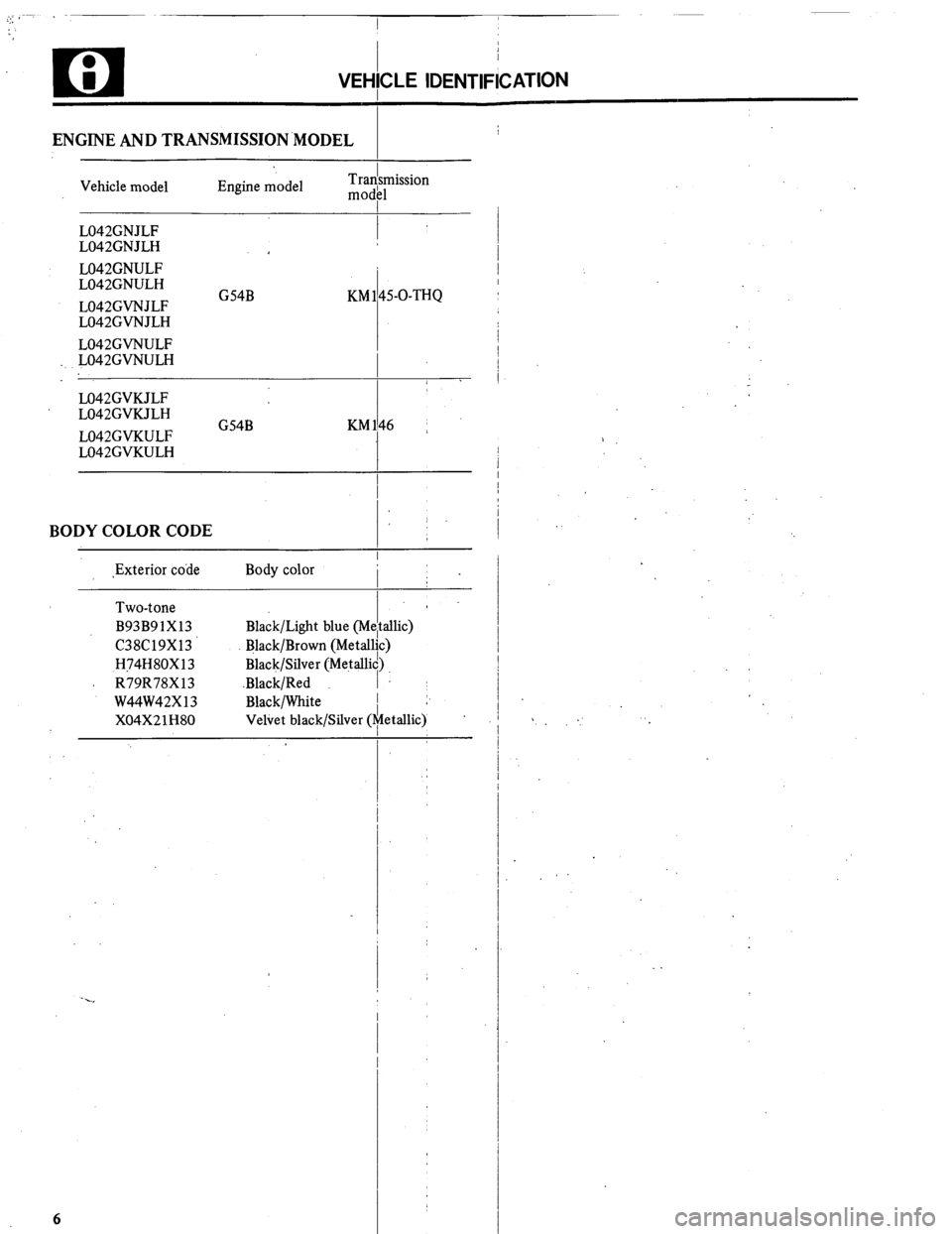

ENGINE AND TRANSMISSION.MODEL

Vehicle model Engine model Tradsmission

mod11

L042GNJLF

I

L042GNJLH

L042GNULF

L042GNULH

L042GVNJLF G54B KM 145-O-THQ

L042GVNJLH

L042GVNULF

L042GVNULH

1 .

M42GVKJLF

L042GVKJLH

L042GVKULF G54B KM146 ~

L042GVKULH

I

BODY COLOR CODE

,Exterior code Body color

Two-tone

B93B91X13

C38C19X13

H74H80X13

A R79R78X13

W44W42X13

X04X21H80 Black/Light blue (M

Black/Brown (Metal

Black/Silver (Metalk

.Black/Red

Black/White

Veliet black/Silver (

6

i

efi

lit

id)

I

:“:

T sllic)

>

etallic) :

Page 9 of 21

PRECAUTIONS BEFORE SERVICE

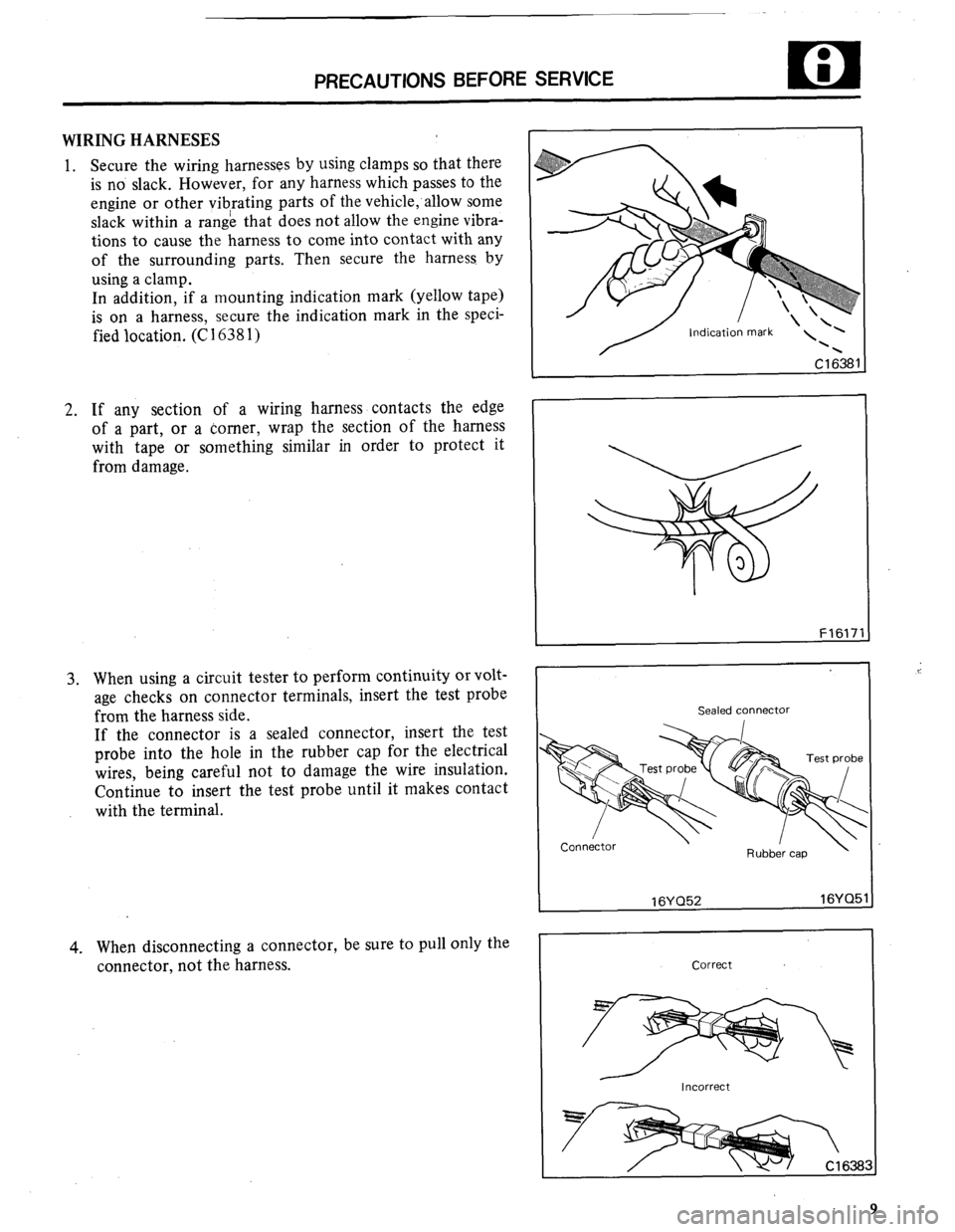

WIRING HARNESES

1. Secure the wiring harnesses by using clamps so that there

is no slack. However, for any harness which passes to the

engine or other vibrating parts of the vehicle;allow some

slack within a range that does not allow the engine vibra-

tions to cause the harness to come into contact with any

of the surrounding parts. Then secure the harness. by

using a clamp.

In addition, if a mounting indication mark (yellow tape)

is on a harness, secure the indication mark in the speci-

fied location. (C 1638 1)

2. If any section of a wiring harness contacts the edge

of a part, or a corner, wrap the section of the harness

with tape or something similar in order to protect it

from damage.

3. When using a circuit tester to perform continuity or volt-

age checks on connector terminals, insert the test probe

from the harness side.

If the connector is a sealed connector, insert the test

probe into the hole in the rubber cap for the electrical

wires, being careful not to damage the wire insulation.

Continue to insert the test probe until it makes contact

with the terminal.

4. When disconnecting a connector, be sure to pull only the

connector, not the harness.

F1617

Sealed connector

I 16YQ52 16YQ5

Correct

I Incorrect 1

Page 11 of 21

. . .

PRECAUTIONS BEFORE SERVICE

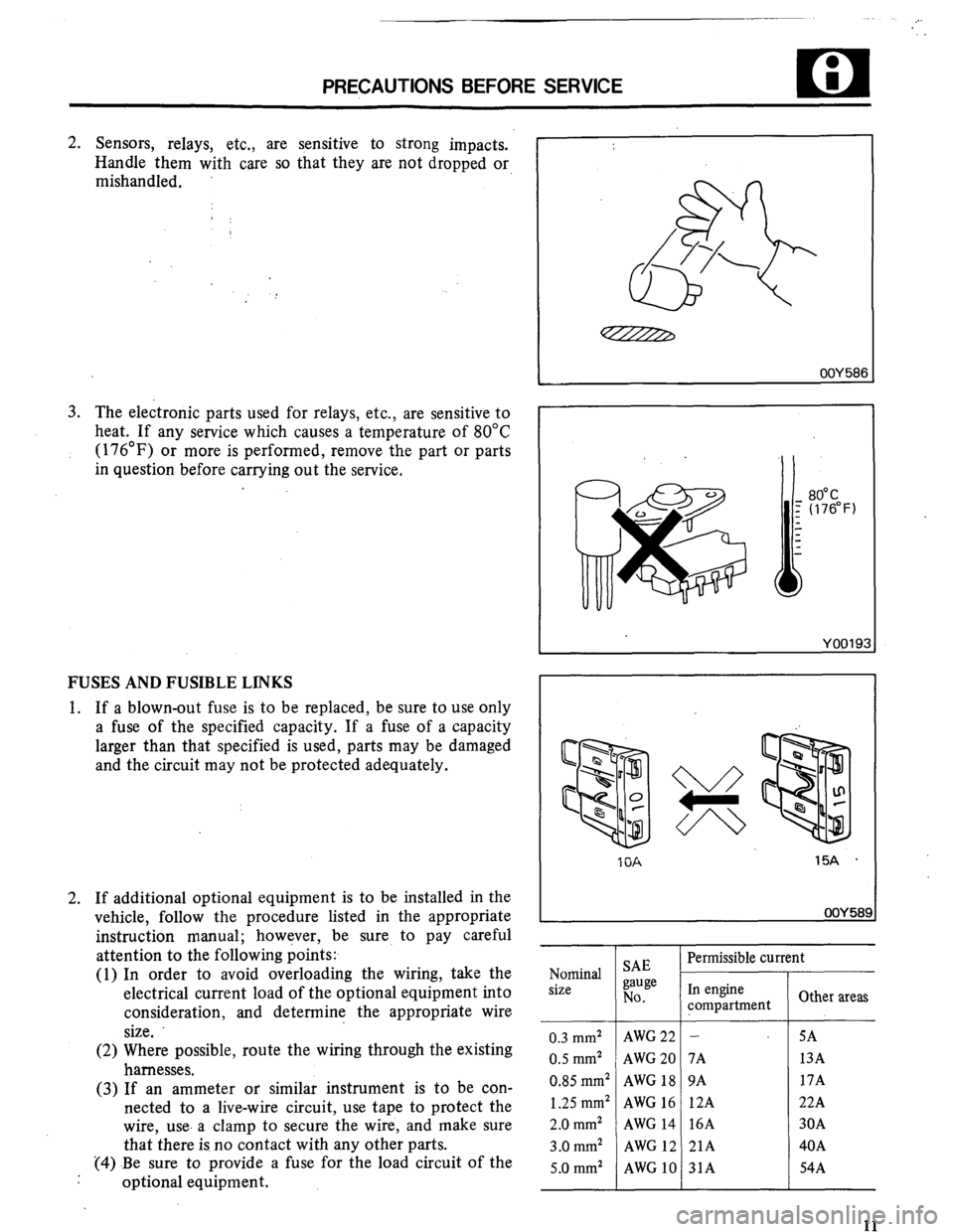

2. Sensors, relays, etc., are sensitive to strong impacts.

Handle them with care so that they are not dropped or,

mishandled.

3. The electronic parts used for relays, etc., are sensitive to

heat. If any service which causes a temperature of 80°C

(176’F) or more is performed, remove the part or parts

in question before carrying out the service,

FUSES AND FUSIBLE LINKS

1. If a blown-out fuse is to be replaced, be sure to use only

a fuse of the specified capacity. If a fuse of a capacity

larger than that specified is used, parts may be damaged

and the circuit may not be protected adequately.

2. If additional optional equipment is to be installed in the

vehicle, follow the procedure listed in the appropriate

instruction manual; however, be sure to pay careful

attention to the following points:

(1) In order to avoid overloading the wiring, take the

electrical current load of the optional equipment into

consideration, and determine the appropriate wire

size.

(2) Where possible, route the wiring through the existing

harnesses.

(3) If an ammeter or similar instrument is to be con-

nected to a live-wire circuit, use tape to protect the

wire, use. a clamp to secure the wire, and make sure

that there is no contact with any other parts.

(4) Be sure to provide a fuse for the load circuit of the

optional equipment.

OOY 58E

15A .

OOY 582

Nominal

size

0.3 mm2

0.5 mm2

0.85 mm2

1.25 mm2 2.0

mm2 3.0

mm2

5.0 mm2 SAE

gauge

No.

AWG 22

AWG 20

AWG 18

AWG 16

AWG 14

AWG 12

AWG 10

Permissible current

In engine

compartment

-

7A

9A

12A

16A

21A

31A Other areas

SA

13A

17A

22A

30A

40A

54A 11

Page 17 of 21

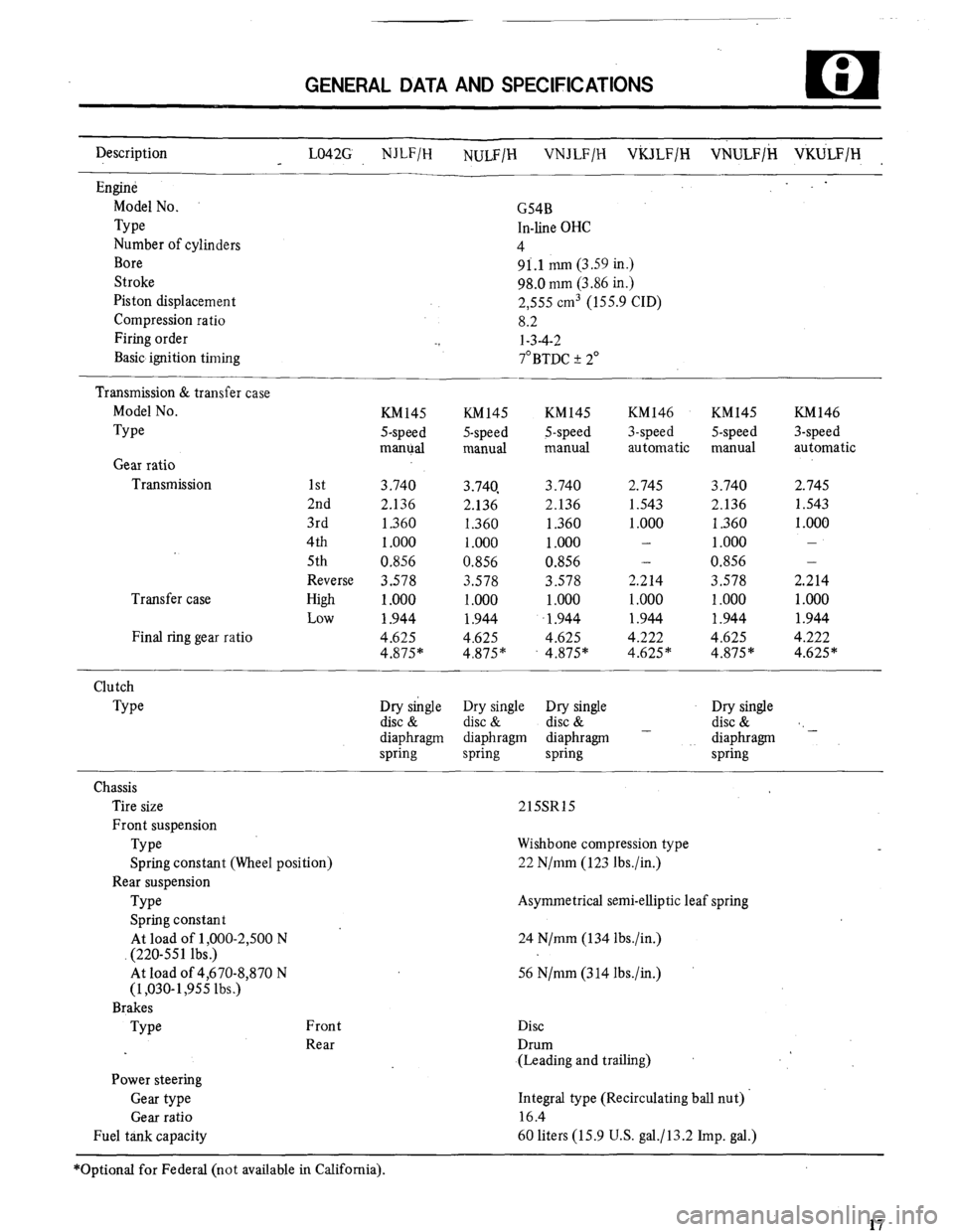

GENERAL DATA AND SPECIFICATIONS

Description

LO42G NJLF/H

NULFIH VNJLF/H ViULF/H VNULF/H VKULF/H

Engine

Model No.

Type

Number of cylinders

Bore

Stroke

Piston displacement

Compression ratio

Firing order

Basic ignition timing

Transmission & transfer case

Model No.

Type

Gear ratio

Transmission

Transfer case

Final ring gear ratio G54B

In-line OHC

4

9i.l mm (3.59 in.)

98.0 mm (3.86 in.)

2,555 cm3 (155.9 CID)

8.2

-3 l-3-4-2

7”BTDC + 2”

KM145 KM145

S-speed 5-speed

manual manual KM145

5-speed

manual KM146 KM145 KM146

3-speed 5-speed 3-speed

automatic manual automatic

1st 3.740 3.740, 3.740 2.745 3.740 2.745

2nd 2.136 2.136 2.136 1.543 2.136 1.543

3rd 1.360 1.360 1.360 1 .ooo 1.360 1 .OOO

4th 1 .ooo 1 .ooo 1.000 - 1 .ooo

5th 0.856 0.856 0.856 - 0.856 -

Reverse 3.578 3.578 3.578 2.214 3.578 2.214

High

Low 1 .ooo 1 .ooo 1 .ooo 1 .ooo 1 .ooo 1 .ooo

1.944 1.944 1.944 1.944 1.944 1.944

4.625 4.625 4.625 4.222 4.625 4.222

4.875* 4.875” 4.875* 4.625* 4.875” 4.625*

Clutch

Type

Chassis

Tire size

Front suspension

Type

Spring constant (Wheel position)

Rear suspension

Type

Spring constant

At load of 1 ,OOO-2,500 N

(220-551 lbs.)

At load of 4,670-8,870 N

(1,030-1,955 lbs.)

Brakes

Type Front

Rear

Power steering

Gear type

Gear ratio

Fuel tank capacity Dry single Dry single Dry single

disc & disc & disc &

diaphragm diaphragm diaphragm -

spring spring spring Dry single

disc & ‘,

diaphragm -

spring

215SR15

Wishbone compression type

22 N/mm (123 lbs./in.)

Asymmetrical semi-elliptic leaf spring

24 N/mm (134 lbs ./in.)

56 N/mm (3 14 Ibs./in.)

Disc

Drum

(Leading and trailing)

Integral type (Recirculating ball nut).

16.4

60 liters (15.9 U.S. ga.lJ13.2 Imp. gal.)

*Optional for Federal (not available in California).

17