Valve MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 245 of 284

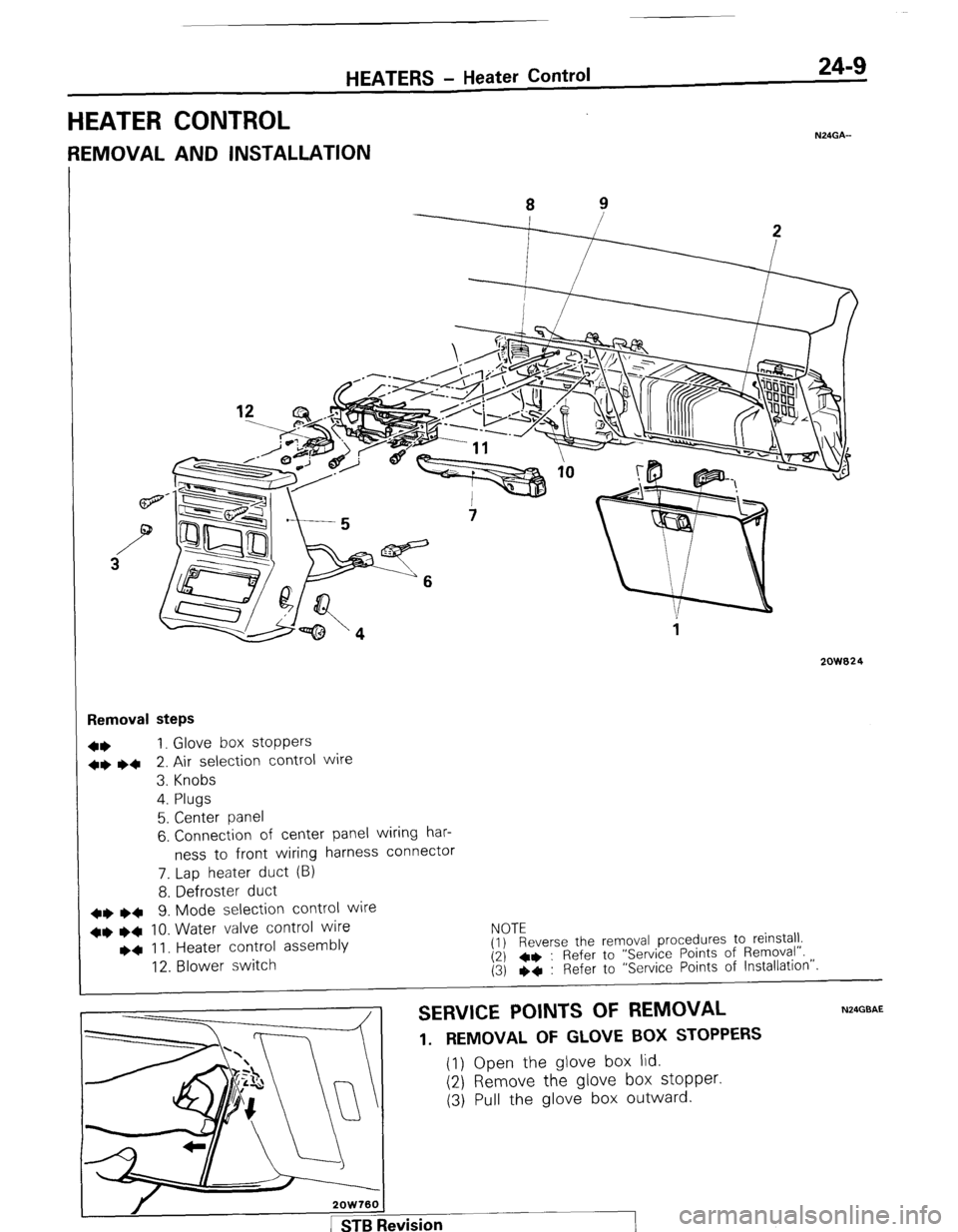

HEATERS - Heater Control 24-9

HEATER CONTROL

N24GA-

REMOVAL AND INSTALLATION

2QW824

Removal steps

4+ 1. Glove box stoppers

++ ~~ 2. Air selection control wire

3. Knobs

4. Plugs

5. Center panel

6. Connection of center panel wiring har-

ness to front wiring harness connector

7. Lap heater duct (B)

8. Defroster duct

++

l + 9. Mode selection control wire

++

l + 10. Water valve control wire

l a II. Heater control assembly

12. Blower switch EyTEeverse the removal procedures to reinstall.

(2) 4+ : Refer to “Service Points of Removal”.

(3) eq : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL N24GBAE

1. REMOVAL OF GLOVE BOX STOPPERS (1) Open the glove box lid.

(2) Remove the glove box stopper. (3) Pull the glove box outward.

Page 246 of 284

24-10 HEATERS I- Heater Control

2ow7a7

VIOVAL OF AIR SELECTION CONTROL WIRE

Use a screwdriver to pry and remove the clip that holds

the outer cable of the air selection control wire.

Disconnect the inner cable of the air selection control

wire from the end of the recirculation/fresh-air change-

over damper lever.

9. REMOVAL OF MODE SELECTION CONTROL WIRE

(1) While using a screwdriver to pry the clip that holds the

outer cable of the mode selection control wire, pull the

/ outer cable to remove it from the clip.

(2) Disconnect the inner cable of the mode selection

control wire from the end of the mode selection

damper lever.

10. REMOVAL OF WATER VALVE CONTROL WIRE

(1) Use a screwdriver to pry and remove the clip that holds

the outer cable of the water valve control wire.

(2) Disconnect the inner cable of the water valve control

wire from the end of the water valve control lever.

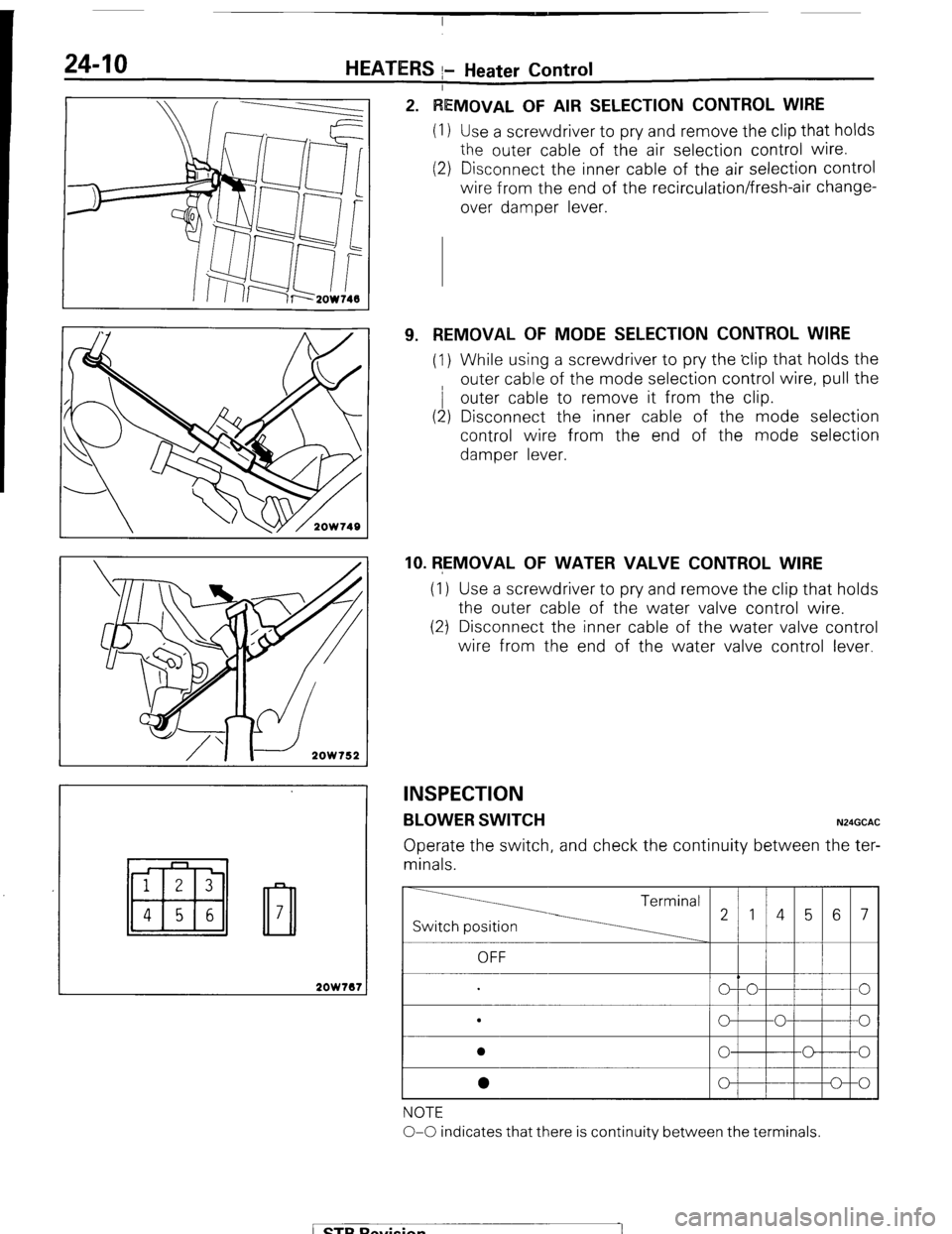

INSPECTION

BLOWER SWITCH N24GCAC

Operate the switch, and check the continuity between the ter-

minals.

Switch position

OFF

. Terminal

214567

o--O

0

0

0 0

NOTE

O-O indicates that there is continuity between the terminals.

/ STB Revision

-7

Page 247 of 284

HEATERS - Heater Control 24-11

Top view

Bottom view

I

2OW553

2OW534

2OW750

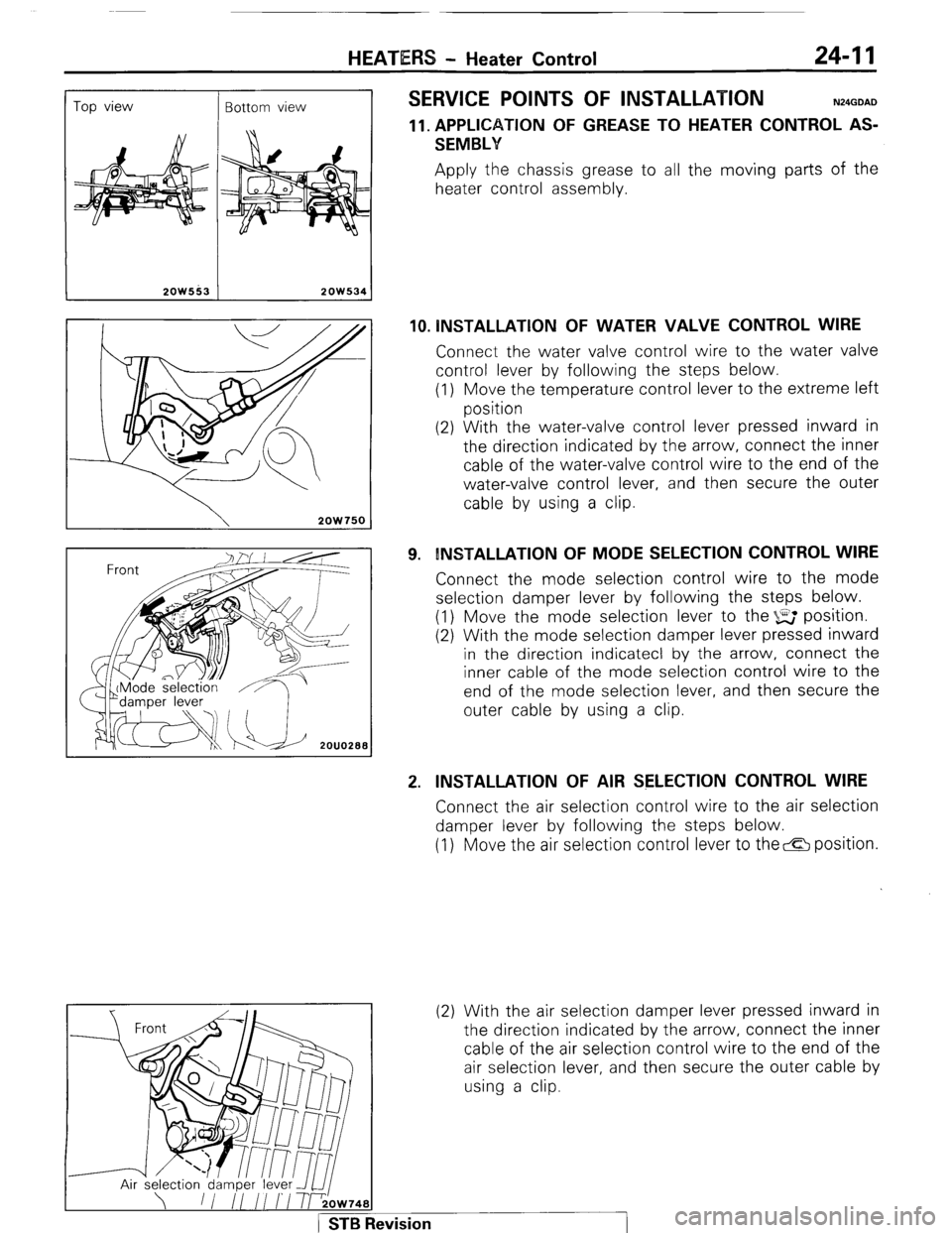

SERVICE POINTS OF INSTALLATION N24GDAD

11. APPLICATION OF GREASE TO HEATER CONTROL AS-

SEMBLY Apply the chassis grease to all the moving parts of the

heater control assembly.

10. lNSTALLATlON OF WATER VALVE CONTROL WIRE Connect the water valve control wire to the water valve

control lever by following the steps below.

(1) Move the temperature control lever to the extreme left

position

(2) With the water-valve control lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the water-valve control wire to the end of the

water-valve control lever, and then secure the outer

cable by using a clip.

9. INSTALLATION OF MODE SELECTION CONTROL WIRE Connect the mode selection control wire to the mode

selection damper lever by following the steps below.

(1) Move the mode selection lever to the %E position.

(2) With the mode selection damper lever pressed inward

in the direction indicatecl by the arrow, connect the

inner cable of the mode selection control wire to the

end of the mode selection lever, and then secure the

outer cable by using a clip.

2. INSTALLATION OF AIR SELECTION CONTROL WIRE Connect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the& position.

(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection lever, and then secure the outer cable by

using a clip.

1 STB Revision

Page 249 of 284

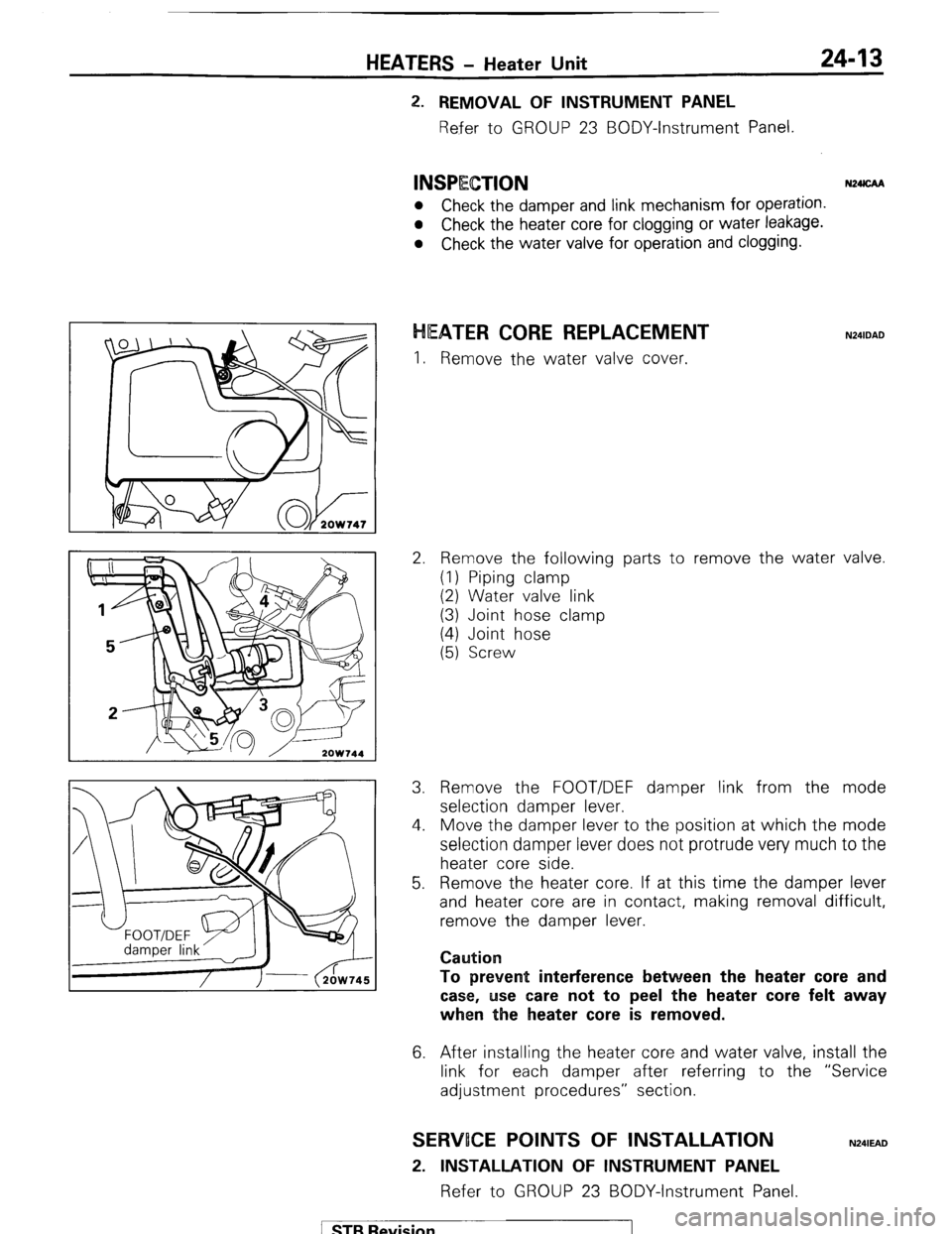

HEATERS - Heater Unit 24-13

2. REMOVAL OF INSTRUMENT PANEL

Refer to GROUP 23 BODY-Instrument Panel.

INSPEGTION N24cAa

l

Check the damper and link mechanism for operation.

l Check the heater core for clogging or water leakage.

l Check the water valve for operation and clogging.

EATER CORE REPLACEMENT

I. Remove the water valve cover.

2. Remove the following parts to remove the water valve.

(1) Piping clamp

(2) Water valve link

(3) Joint hose clamp

(4) Joint hose

(5) Screw

3. Remove the FOOT/DEF damper link from the mode

selection damper lever.

4. Move the damper lever to the position at which the mode

selection damper lever does not protrude very much to the

heater core side.

5. Remove the heater core. If at this time the damper lever

and heater core are in contact, making removal difficult,

remove the damper lever.

Caution

To prevent interference between the heater

core and

case, use care not to peel the heater

core felt away

when the heater core is removed.

6. After installing the heater core and water valve, install the

link for each damper after referring to the “Service

adjustment procedures” section.

SERWOCE POINTS OF INSTALLATION

2. INSTALLATION OF INSTRUMENT PANEL

Refer to GROUP 23 BODY-Instrument Panel.

N241EAD

1 STB Revision

Page 256 of 284

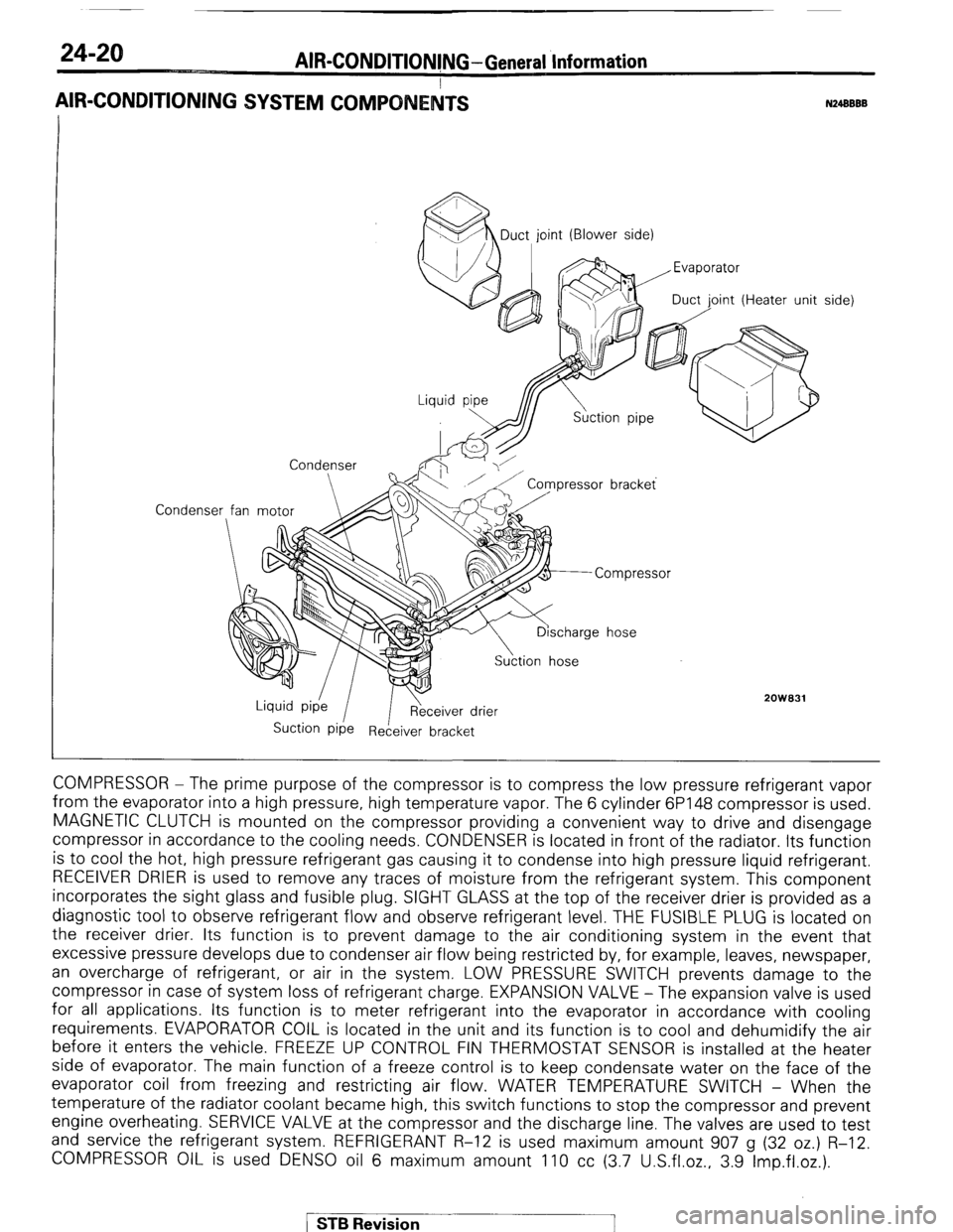

24-20 AIR-CONDITION!NG-General Information

I

AIR-CONDITIONING SYSTEM COMPO

N24BBBB

Condenser MDuct, joint (Blower side)

oint (Heater unit

Condenser

2OWB31

Suction Pipe Receiver bracket side)

COMPRESSOR - The prime purpose of the compressor is to compress the low pressure refrigerant vapor

from the evaporator into a high pressure, high temperature vapor. The 6 cylinder 6P148 compressor is used.

MAGNETIC CLUTCH is mounted on the compressor providing a convenient way to drive and disengage

compressor in accordance to the cooling needs. CONDENSER is located in front of the radiator. Its function

is to cool the hot, high pressure refrigerant gas causing it to condense into high pressure liquid refrigerant.

RECEIVER DRIER is used to remove any traces of moisture from the refrigerant system. This component

incorporates the sight glass and fusible plug. SIGHT GLASS at the top of the receiver drier is provided as a

diagnostic tool to observe refrigerant flow and observe refrigerant level. THE FUSIBLE PLUG is located on

the receiver drier. Its function is to prevent damage to the air conditioning system in the event that

excessive pressure develops due to condenser air flow being restricted by, for example, leaves, newspaper,

an overcharge of refrigerant, or air in the system. LOW PRESSURE SWITCH prevents damage to the

compressor in case of system loss of refrigerant charge. EXPANSION VALVE - The expansion valve is used

for all applications. Its function is to meter refrigerant into the evaporator in accordance with cooling

requirements. EVAPORATOR COIL is located in the unit and its function is to cool and dehumidify the air

before it enters the vehicle. FREEZE UP CONTROL FIN THERMOSTAT SENSOR is installed at the heater

side of evaporator. The main function of a freeze control is to keep condensate water on the face of the

evaporator coil from freezing and restricting air flow. WATER TEMPERATURE SWITCH - When the

temperature of the radiator coolant became high, this switch functions to stop the compressor and prevent

engine overheating. SERVICE VALVE at the compressor and the discharge line. The valves are used to test

and service the refrigerant system. REFRIGERANT R-12 is used maximum amount 907 g (32 oz.) R-12.

COMPRESSOR OIL is used DENS0 oil 6 maximum amount 110 cc (3.7 U.S.fl.oz., 3.9 Imp.fl.oz.).

/ STB Revision

Page 259 of 284

![MITSUBISHI MONTERO 1987 1.G User Guide AIR-CONDITIONING-Troubleshooting 24-23

1 CONTINUED FROM PREVIOUS PAGE] i

--) 2lnsufficient refrigerant

?

--) 3.Receiver drier clogged o Check the refrigerant amount _1 Supply

(P.24-29) refrigeran MITSUBISHI MONTERO 1987 1.G User Guide AIR-CONDITIONING-Troubleshooting 24-23

1 CONTINUED FROM PREVIOUS PAGE] i

--) 2lnsufficient refrigerant

?

--) 3.Receiver drier clogged o Check the refrigerant amount _1 Supply

(P.24-29) refrigeran](/img/19/7559/w960_7559-258.png)

AIR-CONDITIONING-Troubleshooting 24-23

1 CONTINUED FROM PREVIOUS PAGE] i

--) 2lnsufficient refrigerant

?

--) 3.Receiver drier clogged o Check the refrigerant amount _1 Supply

(P.24-29) refrigerant

. Check the receiver drier

.--+ Replace

(P.24-29)

--. 4.Abnormal rotation of Drive belt loose

compresspor

* (P.24-40) __) Adjust the

belt

1

- 5.Expansion valve clogged ) Check the expansion valve - Replace

(P.24-44) t

- 6.Poor compression of

compressor c Check the compressor

(P.24-32)) - Replace

1 STB Revision

Page 260 of 284

AIR-CONDITIONING-Service Adjustment Procedures

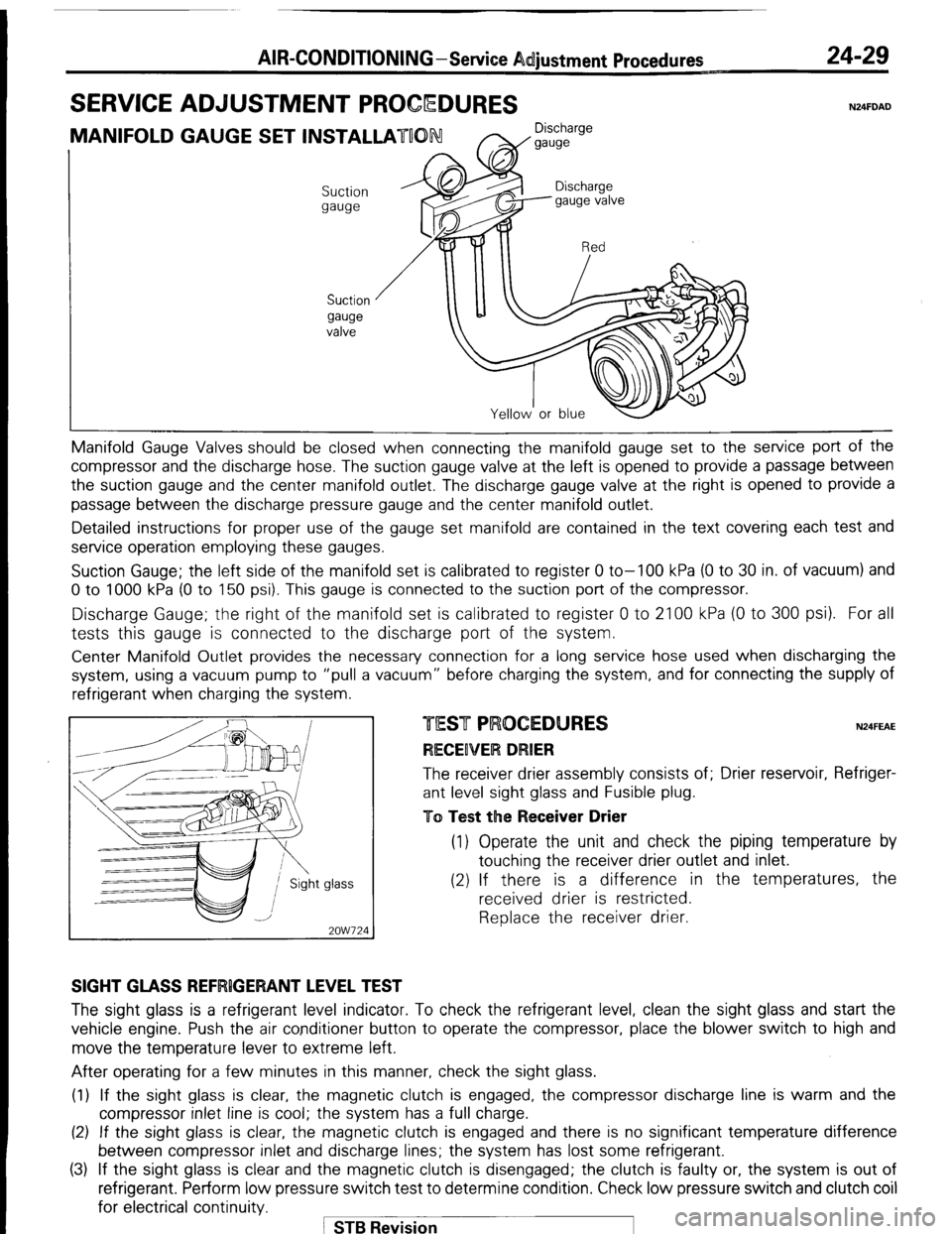

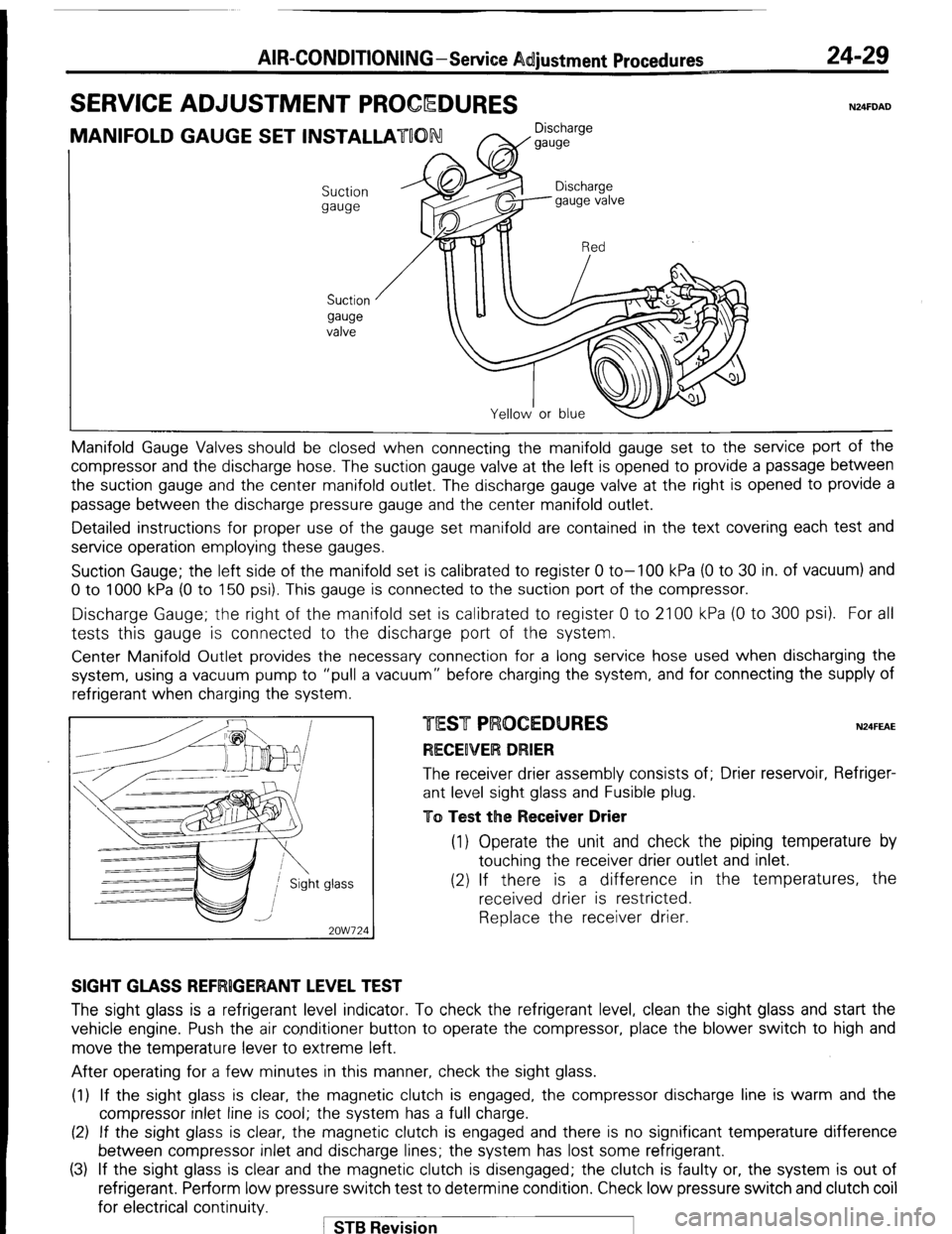

SERVICE ADJUSTMENT PROCQDURES 24-29 N24FDAD

MANIFOLD GAUGE SET INSTALLATUON Discharge

W gauge

Suction

gauge

Suction

gauge

valve Manifold Gauge Valves should be closed

when connecting the manifold gauge set to the service port of the

compressor and the discharge hose. The suction gauge valve at the left is opened to provide a passage between

the suction gauge and the center manifold outlet. The discharge gauge valve at the right is opened to provide a

passage between the discharge pressure gauge and the center manifold outlet.

Detailed instructions for proper use of the gauge set manifold are contained in the text covering each test and

service operation employing these gauges.

Suction Gauge; the left side of the manifold set is calibrated to register 0 to-100 kPa (0 to 30 in. of vacuum) and

0 to 1000 kPa (0 to 150 psi). This gauge is connected to the suction port of the compressor.

Discharge Gauge; the right of the manifold set is calibrated to register 0 to 2100 kPa (0 to 300 psi). For all

tests this gauge is connected to the discharge port of the system.

Center Manifold Outlet provides the necessary connection for a long service hose used when discharging the

system, using a vacuum pump to “pull a vacuum” before charging the system, and for connecting the supply of

refrigerant when charging the system

glass -

2OW724 N24FEAE The receiver drier assembly consists of; Drier reservoir, Refriger-

ant level sight glass and Fusible plug.

To Test the Receiver Drier (1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the

received drier is restricted.

Replace the receiver drier.

SIGHT GLASS REFRlGERANT LEVEL TEST The sight glass is a refrigerant level indicator. To check the refrigerant level, clean the sight glass and start the

vehicle engine. Push the air conditioner button to operate the compressor, place the blower switch to high and

move the temperature lever to extreme left.

After operating for a few minutes in this manner, check the sight glass.

(1) If the sight glass is clear, the magnetic clutch is engaged, the compressor discharge line is warm and the

compressor inlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged and there is no significant temperature difference

between compressor inlet and discharge lines; the system has lost some refrigerant.

(3) If the sight glass is clear and the magnetic clutch is disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine condition. Check low pressure switch and clutch coil

for electrical continuity.

1 STB Revision

Page 261 of 284

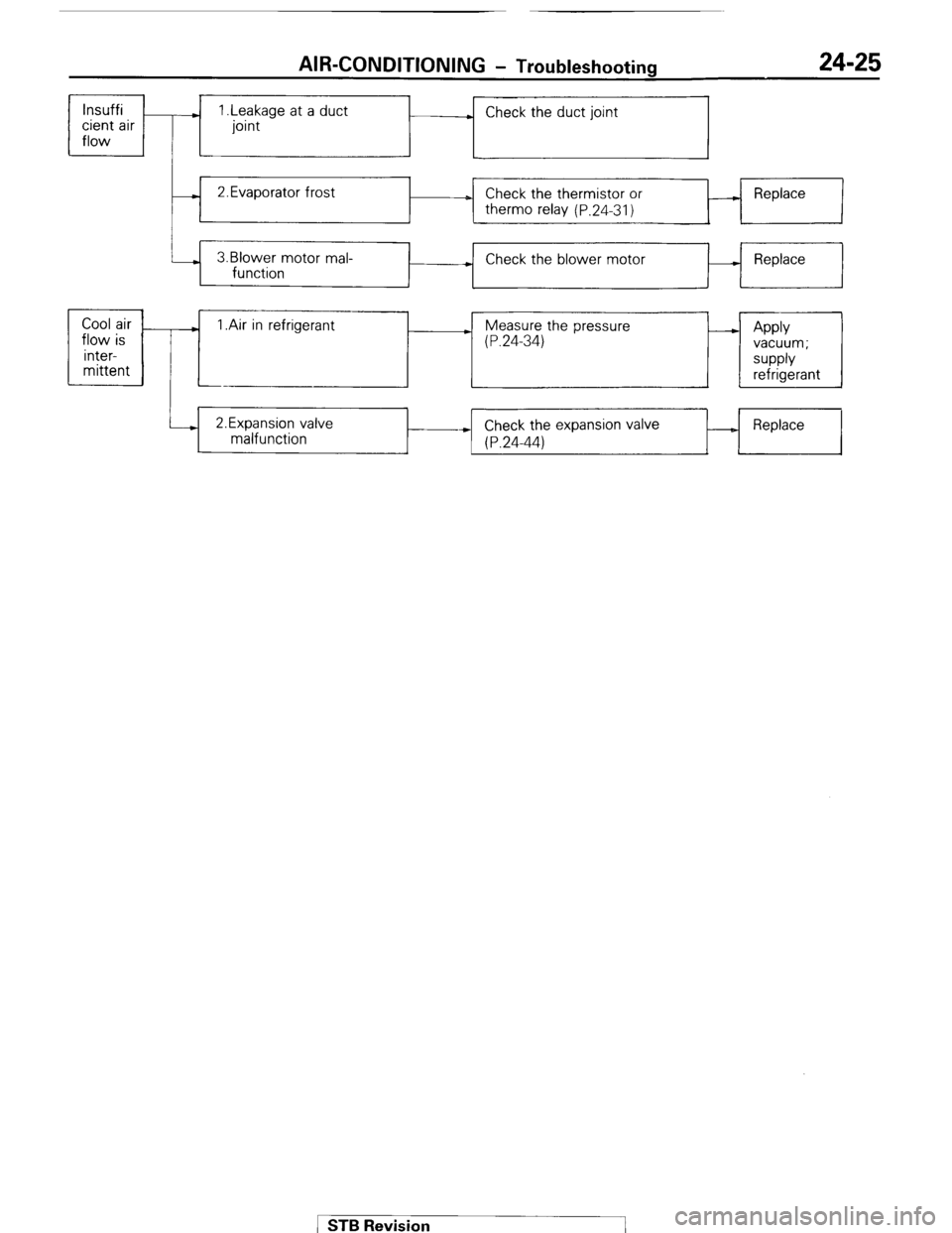

AIR-CONDITIONING - Troubleshooting 24-25

lnsuffi

cient air

flow ) 1 .Leakage at a duct

joint . Check the duct joint

- 2.Evaporator frost

D Check the thermistor or

therm0 relay (P.24-31) A Replace

3.Blower motor mal-

function + Check the blower motor - Replace

+

Cool air

.

flow is 1 .Air in refrigerant ) Measure the pressure

(P.24-34) - Apply

inter- vacuum;

mittent supply

refrigerant

i--) 2.Expansion valve

malfunction Check the expansion valve

* (P.24-44) _ Replace STB Revision

Page 263 of 284

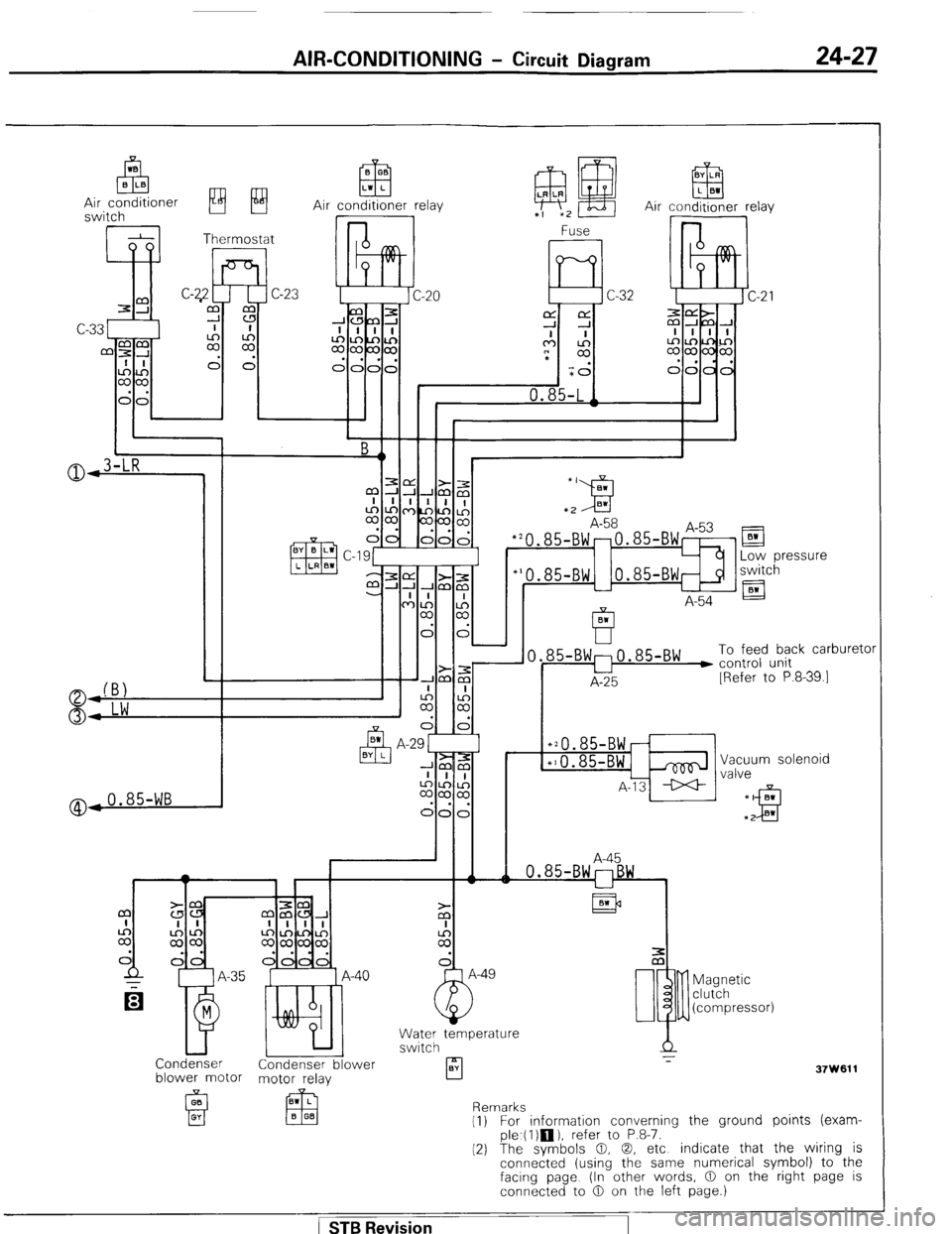

AIR-CONDITIONING - Circuit Diagram 24-27

Air conditioner relay

@,0.85-WB

El

Low pressure

switch

A-54 El

85-BW:0.85-BW ) To feed back carburetc

u control unit

A-25 [Refer to P.8-39.1

*20.85-BWr

*10.85-BWi& Vacuum solenoid

A-13 ++ valve

A-45

Condenser Condenser blower

blower motor motor relay

A

rl z-

BY

37W611 Magnetic

clutch

(compressor)

Remarks

(1) For information converning the ground points (exam-

ple.(l)m), refer to P.8-7.

(2) The symbols 0, 0, etc indicate that the wiring is

connected (using the same numerical symbol) to the

facing page (In other words, 0 on the right page is

connected to 0 on the left page.)

( STB Revision

Page 265 of 284

AIR-CONDITIONING-Service Adjustment Procedures

SERVICE ADJUSTMENT PROCQDURES 24-29 N24FDAD

MANIFOLD GAUGE SET INSTALLATUON Discharge

W gauge

Suction

gauge

Suction

gauge

valve Manifold Gauge Valves should be closed

when connecting the manifold gauge set to the service port of the

compressor and the discharge hose. The suction gauge valve at the left is opened to provide a passage between

the suction gauge and the center manifold outlet. The discharge gauge valve at the right is opened to provide a

passage between the discharge pressure gauge and the center manifold outlet.

Detailed instructions for proper use of the gauge set manifold are contained in the text covering each test and

service operation employing these gauges.

Suction Gauge; the left side of the manifold set is calibrated to register 0 to-100 kPa (0 to 30 in. of vacuum) and

0 to 1000 kPa (0 to 150 psi). This gauge is connected to the suction port of the compressor.

Discharge Gauge; the right of the manifold set is calibrated to register 0 to 2100 kPa (0 to 300 psi). For all

tests this gauge is connected to the discharge port of the system.

Center Manifold Outlet provides the necessary connection for a long service hose used when discharging the

system, using a vacuum pump to “pull a vacuum” before charging the system, and for connecting the supply of

refrigerant when charging the system

glass -

2OW724 N24FEAE The receiver drier assembly consists of; Drier reservoir, Refriger-

ant level sight glass and Fusible plug.

To Test the Receiver Drier (1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the

received drier is restricted.

Replace the receiver drier.

SIGHT GLASS REFRlGERANT LEVEL TEST The sight glass is a refrigerant level indicator. To check the refrigerant level, clean the sight glass and start the

vehicle engine. Push the air conditioner button to operate the compressor, place the blower switch to high and

move the temperature lever to extreme left.

After operating for a few minutes in this manner, check the sight glass.

(1) If the sight glass is clear, the magnetic clutch is engaged, the compressor discharge line is warm and the

compressor inlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged and there is no significant temperature difference

between compressor inlet and discharge lines; the system has lost some refrigerant.

(3) If the sight glass is clear and the magnetic clutch is disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine condition. Check low pressure switch and clutch coil

for electrical continuity.

1 STB Revision