lock MITSUBISHI MONTERO 1987 1.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 161 of 284

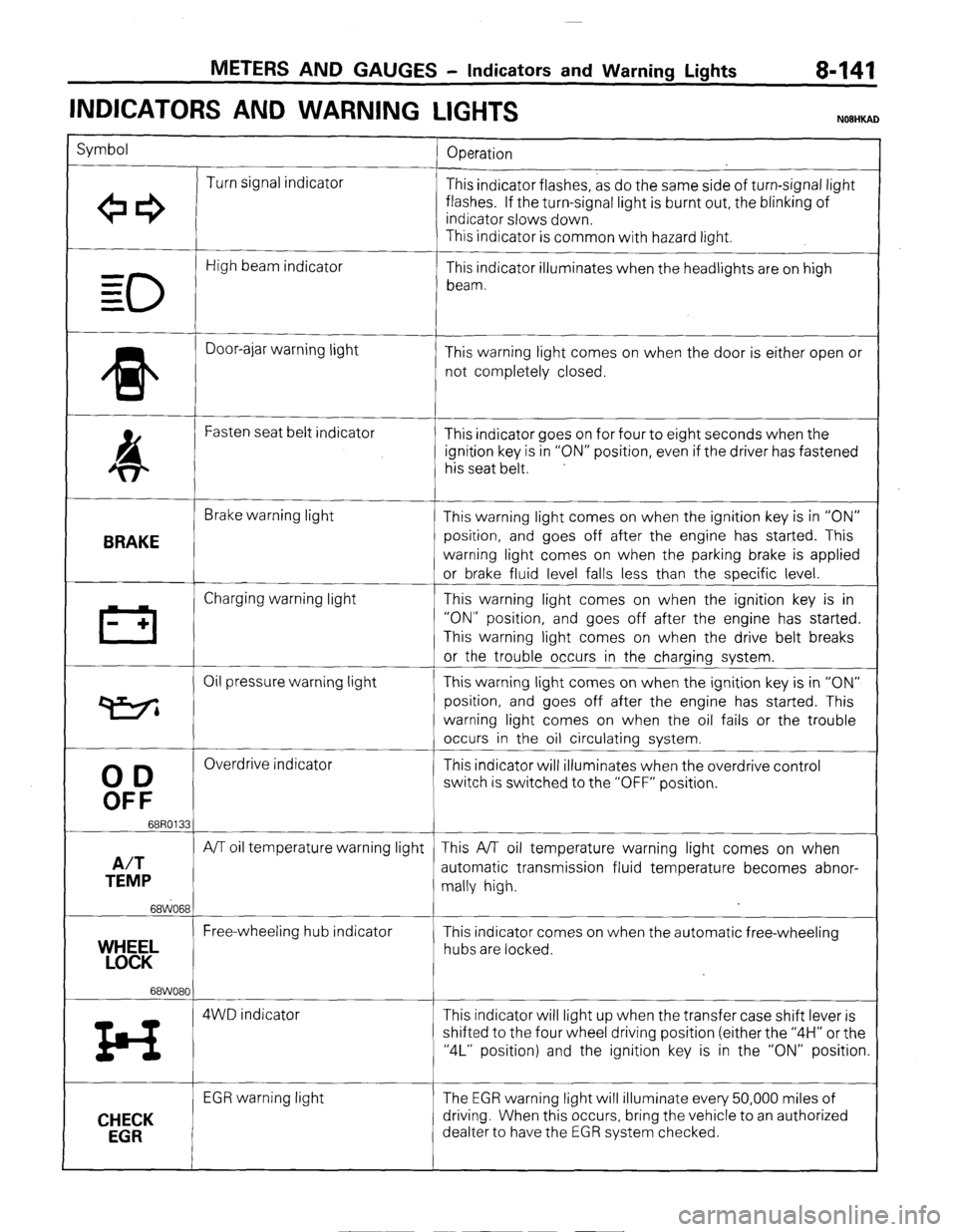

METERS AND GAUGES - Indicators and Warning Lights 8-141

INDICATORS AND WARNING

LIGHTS

Symbol

Operation

Turn signal indicator

+e3 This indicator flashes, as do the same side of turn-signal light

flashes. If the turn-signal light is burnt out, the blinking of

indicator slows down.

This indicator is common with hazard light.

0

High beam indicator

- This indicator illuminates when the headlights are on high

= beam.

=

* Door-ajar warning light

This warning light comes on when the door is either open or

not completely closed.

4 Fasten seat belt indicator

This indicator goes on for four to eight seconds when the

ignition key is in “ON” position, even if the driver has fastened

his seat belt.

BRAKE

Brake warning light

This warning light comes on when the ignition key is in “ON”

position, and goes off after the engine has started. This

warning light comes on when the parking brake is applied

or brake fluid level falls less than the specific level.

III Charging warning light This warning light comes on when the ignition key is in

- + “ON” position, and goes off after the engine has started.

This warning light comes on when the drive belt breaks

or the trouble occurs in the charging system.

Oil pressure warning light This warning light comes on when the ignition key is in “ON”

P position, and goes off after the engine has started. This

warning light comes on when the oil fails or the trouble

occurs in the oil circulating system.

00

Overdrive indicator

This indicator will illuminates when the overdrive control

OFF

switch is switched to the “OFF” position.

68R0133

A/T

A/T oil temperature warning light This A/T oil temperature warning light comes on when

TEMP automatic transmission fluid temperature becomes abnor-

mally high.

68WO68

Free-wheeling hub indicator

YEL This indicator comes on when the automatic free-wheeling

hubs are locked.

68WO80

z4 4WD indicator This indicator will light up when the transfer case shift lever is

shifted to the four wheel driving position (either the “4H” or the

“4L” position) and the ignition key is in the “ON” position.

CHECK

EGR

EGR warning light The EGR warning light will illuminate every 50,000 miles of

driving. When this occurs, bring the vehicle to an authorized

dealter to have the EGR system checked.

) STB Revision

Page 164 of 284

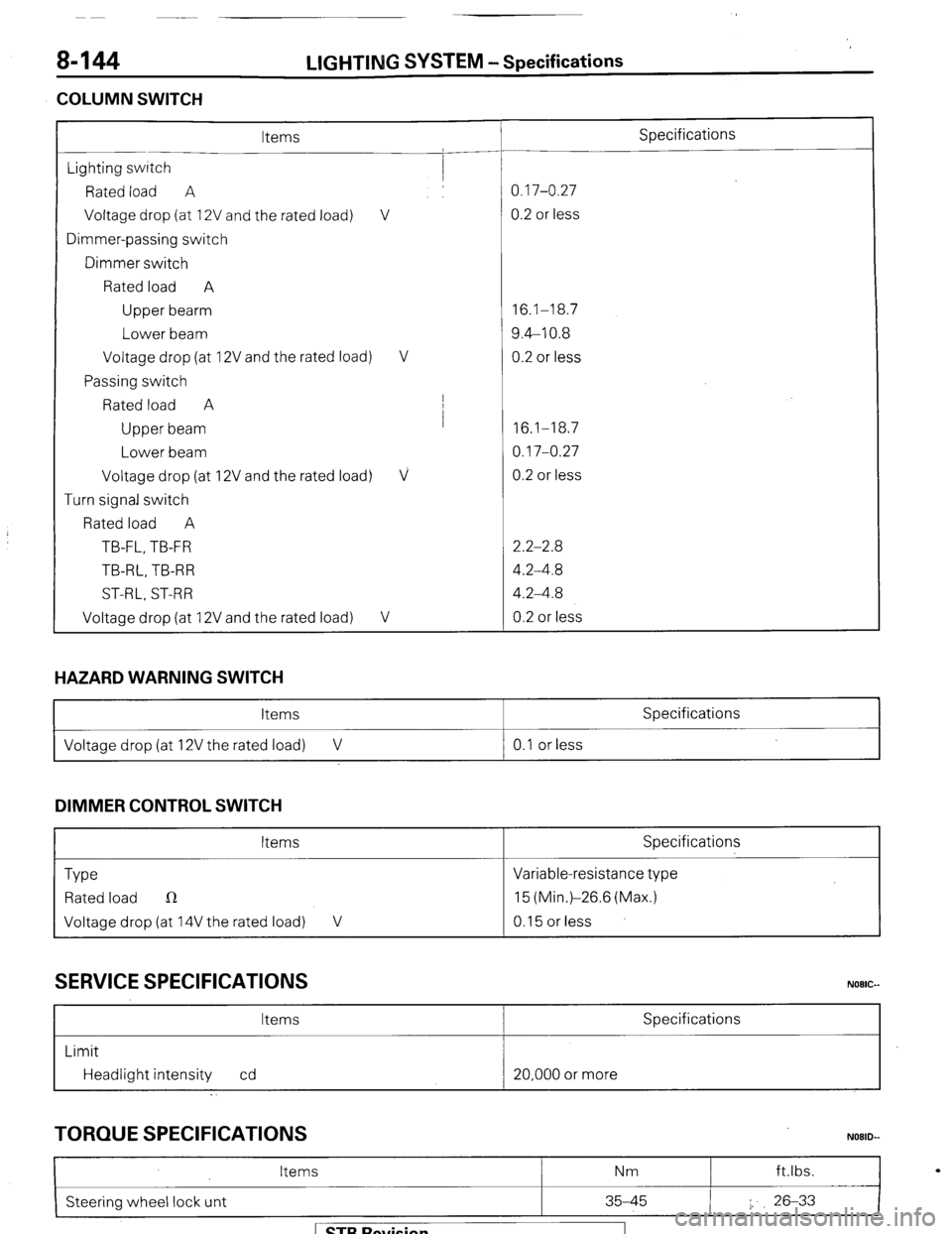

8-144

COLUMN SWITCH LIGHTING

SYSTEM -Specifications

Items Specifications

Lighting switch

Rated load A 0.17-0.27

Voltage drop (at 12V and the rated load) V 0.2 or less

Dimmer-passing switch

Dimmer switch

Rated load A

Upper bearm 16.1-18.7

Lower beam 9.4-10.8

Voltage drop (at 12V and the rated load) V 0.2 or less

Passing switch

Rated load A I

Upper beam I

16.1-18.7

Lower beam 0.17-0.27

Voltage drop (at 12V and the rated load)

V 0.2 or less

Turn signal switch

Rated load A

TB-FL, TB-FR 2.2-2.8

TB-RL, TB-R R 4.2-4.8

ST-RL, ST-RR 4.2-4.8

Voltage drop (at 12V and the rated load)

V 0.2 or less

HAZARD WARNING SWITCH

Items Specifications

I Voltage drop (at 12V the rated load) V 0.1 or less

I

DIMMER CONTROL SWITCH

Items Specifications

Type Variable-resistance type

Rated load n 15 (Min.)-26.6 (Max.)

Voltage drop (at 14V the rated load) V 0.15 or less

SERVICE SPECIFICATIONS

Items Specifications

Limit

Headlight intensity cd 20,000 or more

TORQUE SPECIFICATIONS

I

Items Nm ft.lbs.

N08lb

Steering wheel lock unt 35-45 I. 26-33

I

1 STB Revision

Page 184 of 284

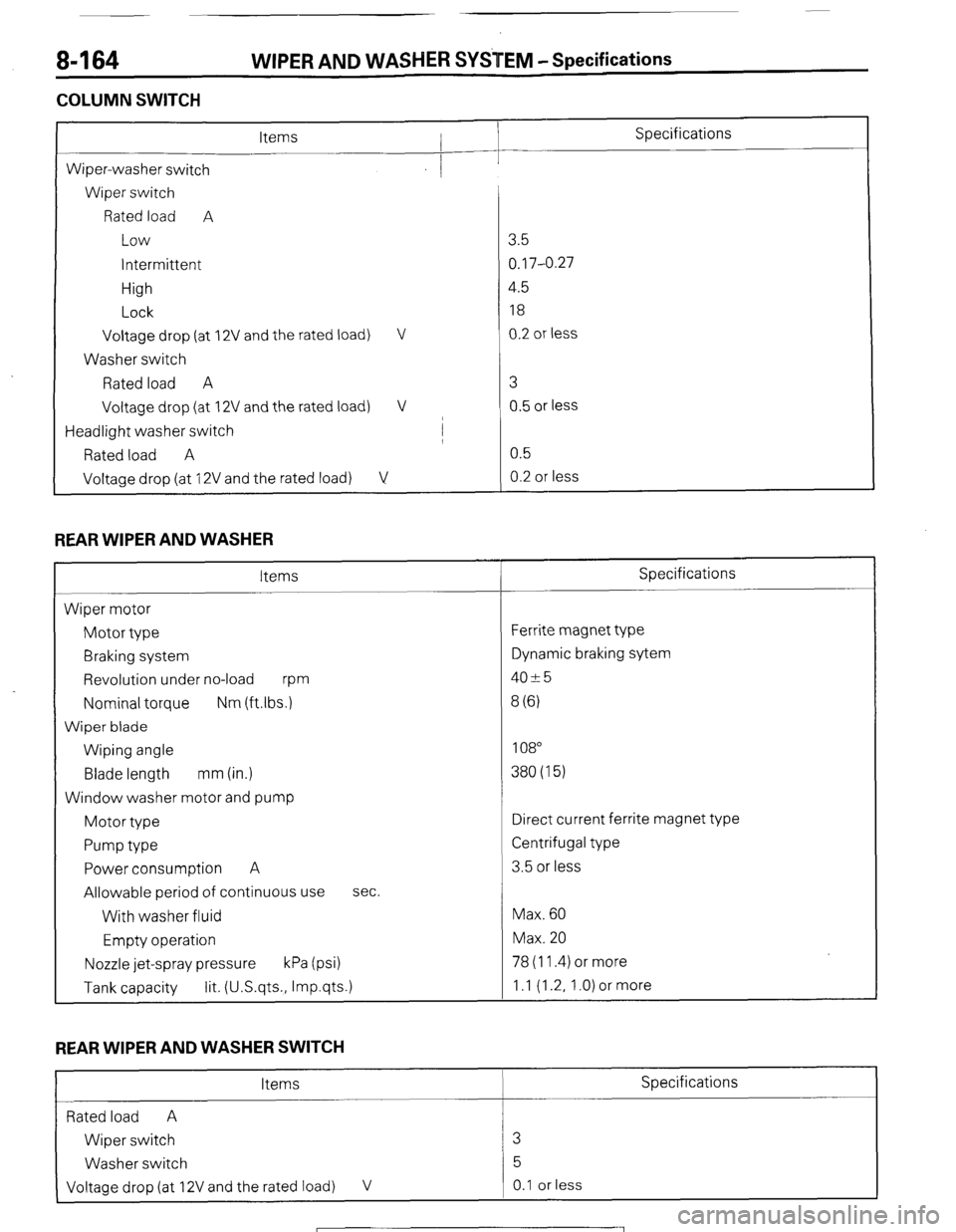

8-164 WIPER AND WASHER SYSTEM -Specifications

COLUMN SWITCH

L

Specifications

Wiper-washer switch

Wiper switch

Rated load A

Low

intermittent

High

Lock

Voltage drop (at

Washer switch

Rated load A

Voltage drop (at 2V and the rated load) V

2V and the rated load) V

/

Headlight washer switch I

Rated load A

Voltage drop (at 12V and the rated load) V

REAR WIPER AND WASHER

Items

Wiper motor

Motor type

Braking system

Revolution under no-load

m

Nominal torque Nm (ftlbs.)

Wiper blade

Wiping angle

Blade length mm (in.)

Window washer motor and pump

Motor type

Pump type

Power consumption A

Allowable period of continuous use

With washer fluid

Empty operation sec.

Nozzle jet-spray pressure kPa (psi) 78 (11.4) or more

Tank capacity lit. (U.S.qts., Imp.qts.) 1 .I (1.2, 1 .O) or more 3.5

0.17-0.27

4.5

18

0.2 or less

3

0.5 or less

0.5

0.2 or less

Specifications

Ferrite magnet type

Dynamic braking sytem

4025

8 (6)

108

380(15)

Direct current ferrite magnet type

Centrifugal type

3.5 or less

Max. 60

Max. 20

REAR WIPER AND WASHER SWITCH

Items Specifications

Rated load A

Wiper switch 3

Washer switch 5

Voltage drop (at 12V and the rated load) V 0.1 or less

1 STB Revision

Page 185 of 284

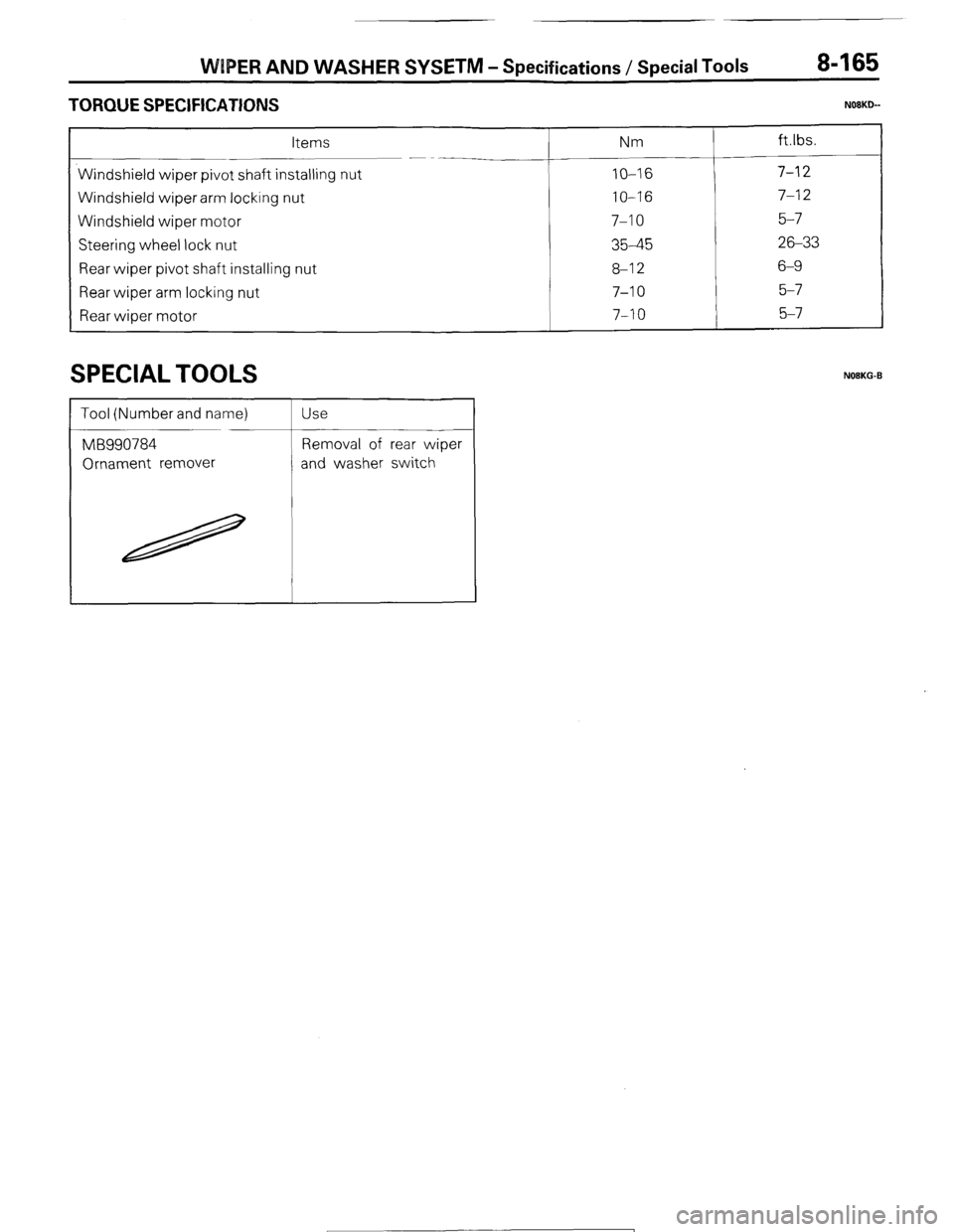

WIPER AND WASHER SYSETM - Specifications / Special TOOIS 8-165

TORQUE SPECIFICATIONS N08KLb-

Items Nm

Windshield wiper pivot shaft installing nut

IO-16 Windshield wiper arm locking nut

IO-16 Windshield wiper motor

7-10 Steering wheel lock nut

35-45 Rear wiper pivot shaft installing nut

8-12 Rear wiper arm locking nut

7-10 Rear wioer motor

7-10

SPECIAL TOOLS NOEKG-B

1 STB Revision

Page 194 of 284

a-174 WIPER AND WASHER $YSTEM - Windshield Wipers / Rear Wiper

REAR WIPtER

7

-est light

16K1920

t

REMOVAL AND INSTALLATION

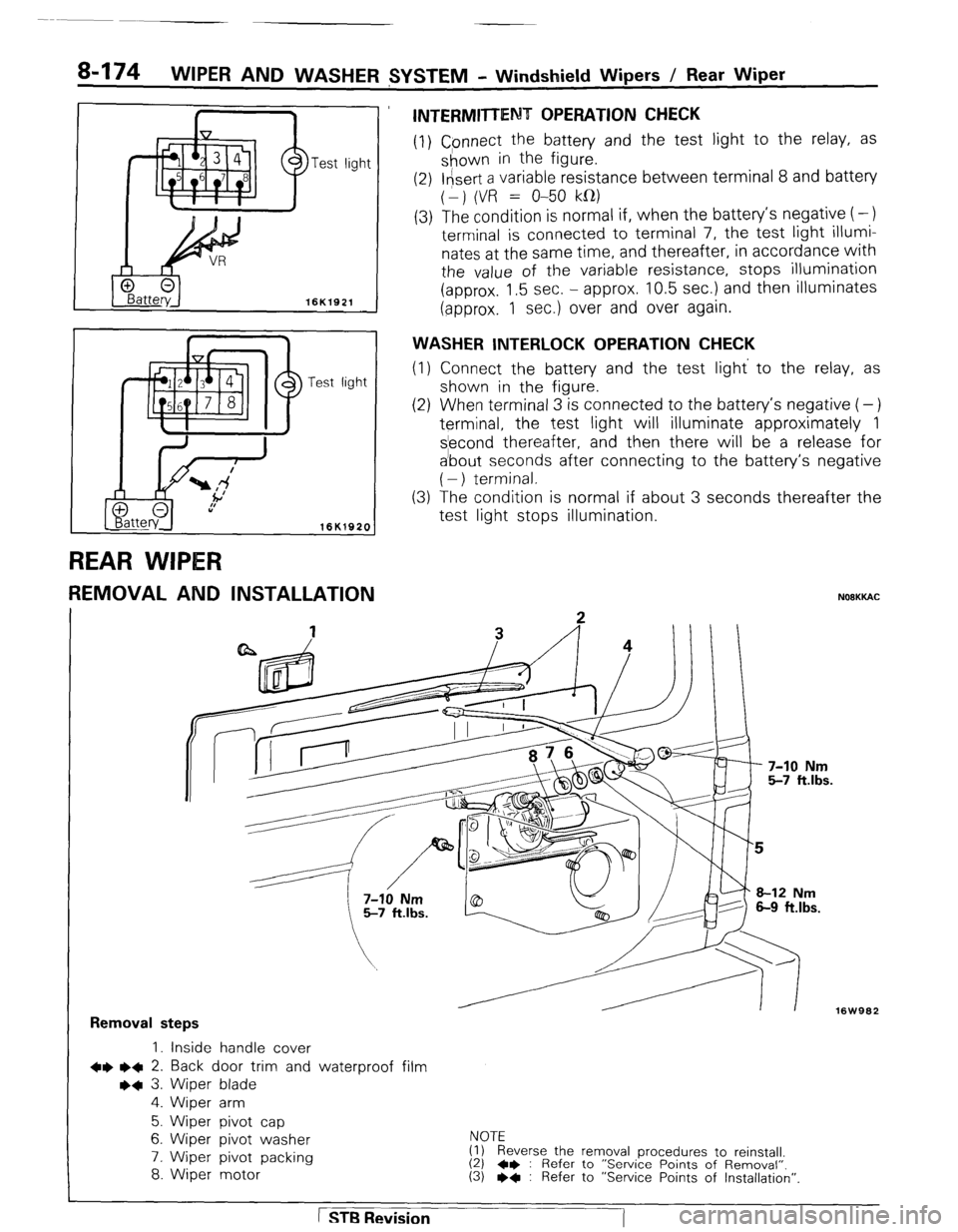

INTERMITTENT OPERATION CHECK

(1) Cpnnect the battery and the test light to the relay, as

shown in the figure.

(2) l&ert a variable resistance between terminal 8 and battery

(1) (VR = O-50 kfl)

(3) The condition is normal if, when the battery’s negative (-)

terminal is connected to terminal 7, the test light illumi-

nates at the same time, and thereafter, in accordance with

the value of the variable resistance, stops illumination

(approx. 1.5 sec. - approx. 10.5 sec.) and then illuminates

(approx. 1 sec.) over and over again.

WASHER INTERLOCK OPERATION CHECK

(1) Connect the battery and the test light’ to the relay, as

shown in the .figure.

(2) When terminal 3 is connected to the battery’s negative (-)

terminal, the test light will illuminate approximately 1

s’econd thereafter, and then there will be a release for

a’bout seconds after connecting to the battery’s negative

( - ) terminal.

The condition is normal if about 3 seconds thereafter the

test light stops illumination. (3

NOOKKAC

16W962

Removal steps

1. inside handle cover

+e l + 2. Back door trim and waterproof film

++ 3. Wiper blade

4. Wiper arm

5. Wiper pivot cap

6. Wiper pivot washer

7. Wiper pivot packing

8. Wiper motor NOTE

(1) Reverse the removal procedures to reinstall.

(2) 4* : Refer to “Service Points of Removal”. (3) l * : Refer to “Service Points of Installation”.

1 STB Revision

-7

Page 204 of 284

8-184

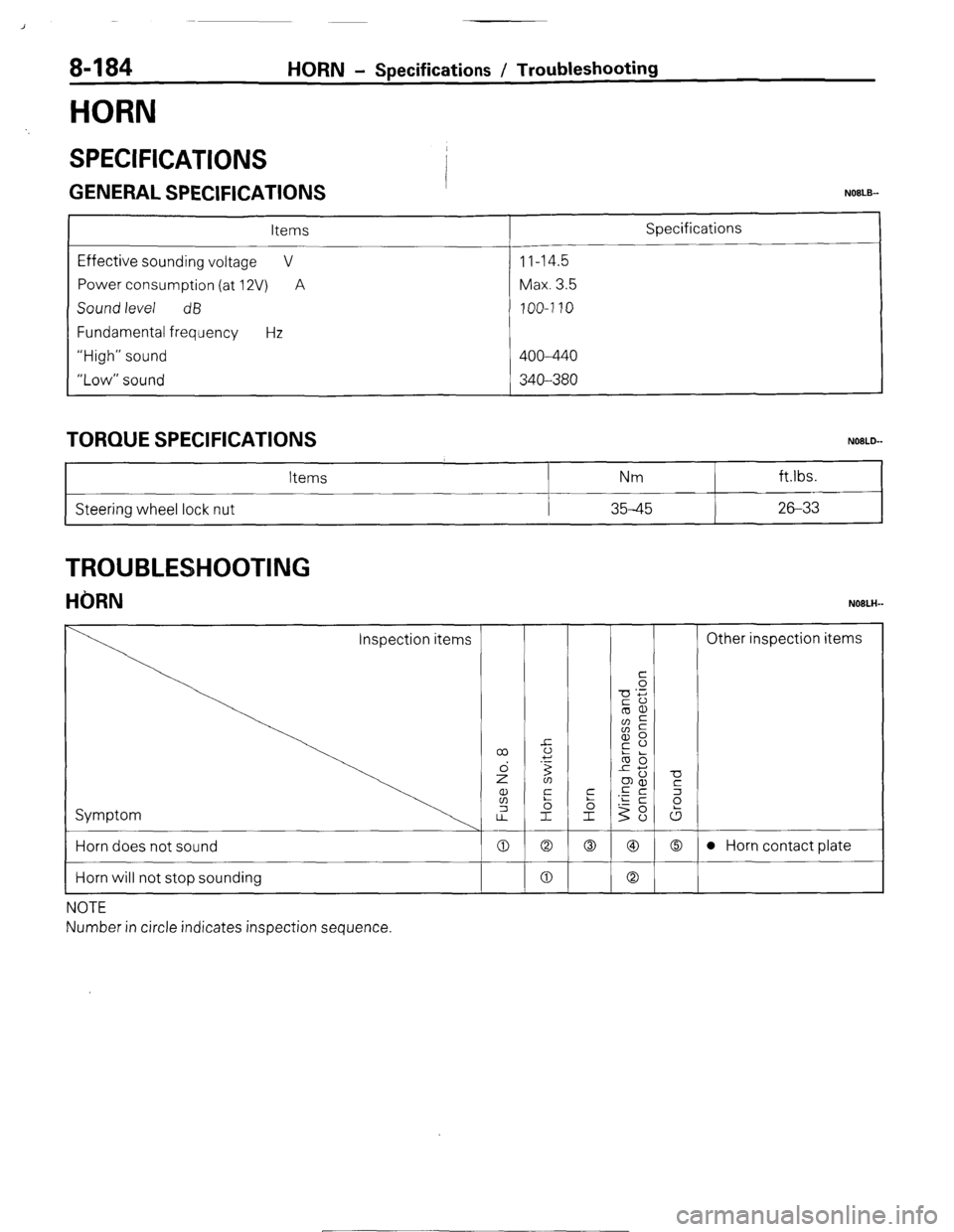

HORN

HORN - Specifications / Troubleshooting

SPECIFICATIONS

GENERAL SPECIFICATIONS I NOBLE--

Items

Effective sounding voltage V

Power consumption (at 12V) A

Sound level dB

Fundamental frequency Hz

“High” sound

“Low” sound 11-14.5

Max. 3.5

100-7 10

400--440

340--380 Specifications

TORQUE SPECIFICATIONS

Steering wheel lock nut Items

i Nm ft.lbs.

35-45 26-33

TROUBLESHOOTING

HORN NOBLH-

Horn does not sound

Horn will not stop sounding

NOTE

Number in circle indicates inspection sequence. 0 Q 0 @I 0 l Horn contact plate

0 0

1 STB Revision

~-1

Page 208 of 284

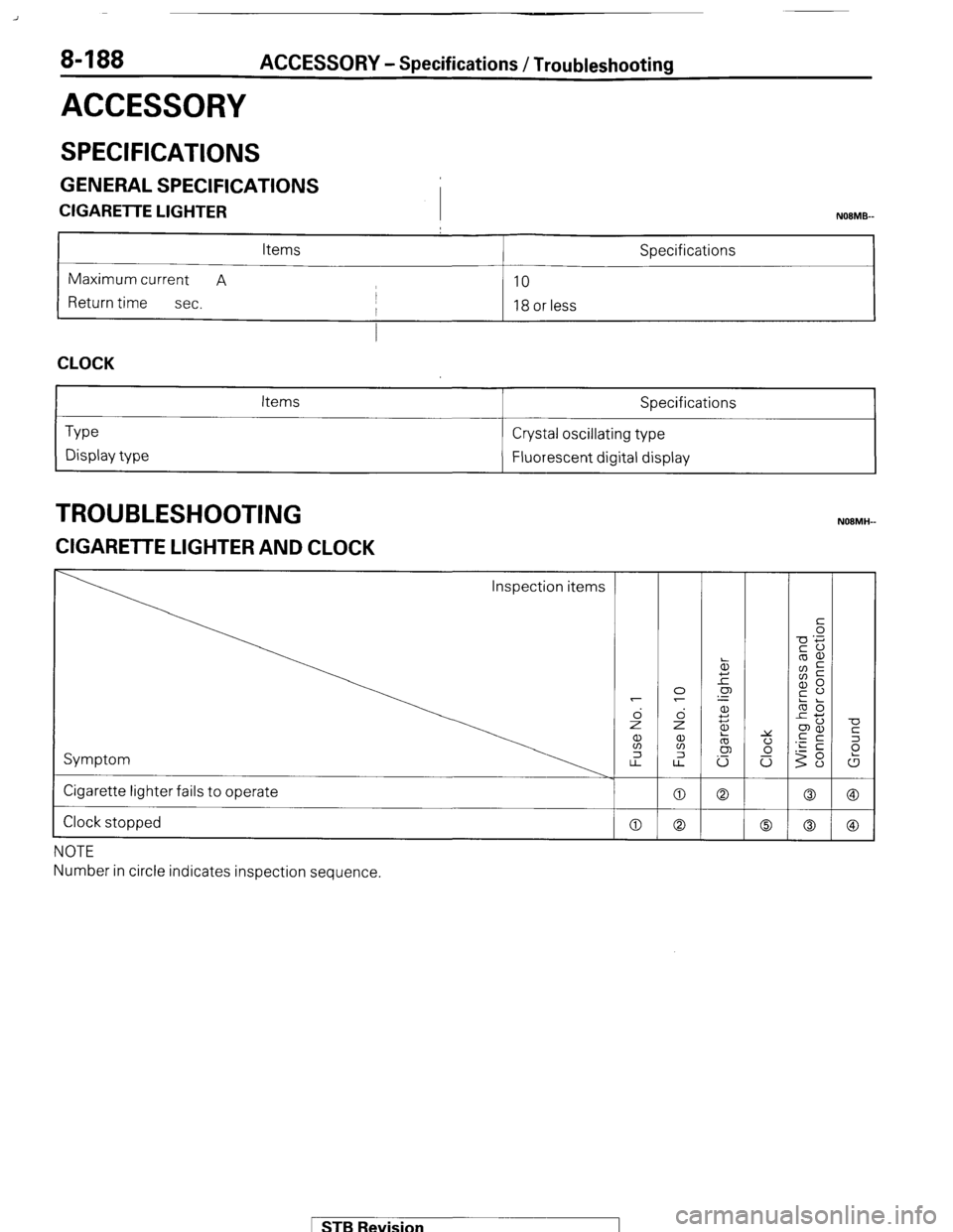

8-188 ACCESSORY - Specifications / Troubleshooting

ACCESSORY

SPECIFICATIONS

GENERAL SPECIFICATIONS

CIGARETTE LIGHTER

I NOBMB-

Items Specifications

Maximum current A

10

Return time

sec. I

I 18 or less

I

CLOCK

Type

Display type Items Specifications

Crystal oscillating type

Fluorescent digital display

TROUBLESHOOTING

ZIGARETTE LIGHTER AND CLOCK

Inspection items

Symptom

Cigarette lighter fails to operate

Clock stopped

NOTE

Number in circle indicates inspection sequence.

MB Revision

Page 209 of 284

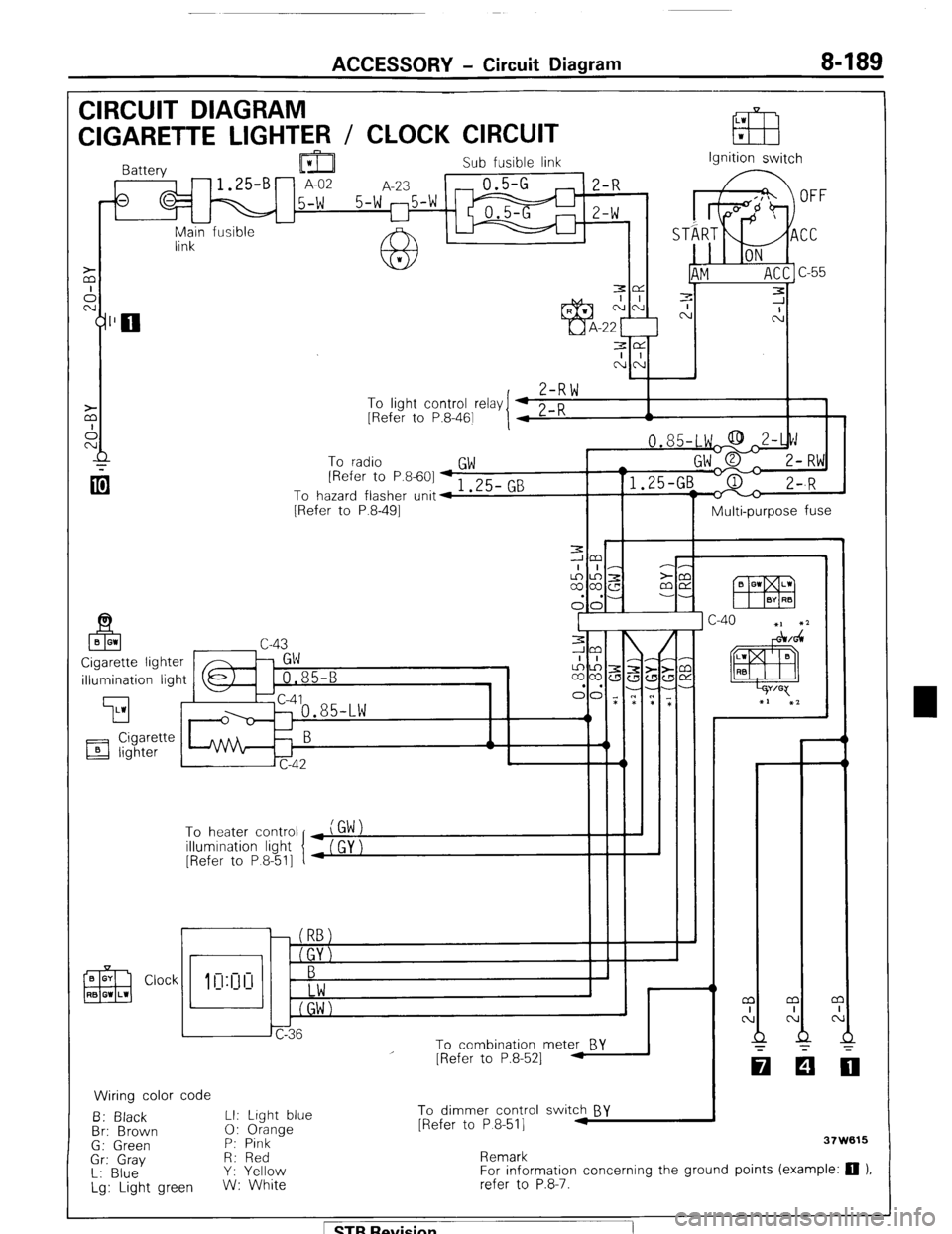

ACCESSORY - Circuit Diagram 8-189

CIRCUIT DIAGRAM

LW

CIGARETTE LIGHTER / CLOCK CIRCUIT EB w

Sub fusible link

,-fs q M 15-W 5-W 25-W m ;I;

I I

-

Main fusible -

link Ignition switch

3e

I I

NN

,

Z-RW To

linht cnntrnl r&v I 4 0 n

I 1 - .J . __._ - -., [Refer to P.8-461

I 4 L-K A

To radio

GW [Refer to P.8-601 + 1 .25- GB

To hazard flasher unit4

[Refer to P.8-491

Multi-purpose fuse

illumination light

’ To heater control

illumination light

[Refer to P 8-511

r

i I

To combination meter BY

Wiring color code

B: Black LI: Light blue

Br: Brown 0: Orange

G: Green P: Pink

Gr: Gray R: Red

L: Blue Y: Yellow

Lg: Light green W: White

I

I - - m

I

N

Q

-

[Refer to P.8-521 -

To dimmer control switch BY

[Refer to P 8-511 .I

Remark 37W615

For information concerning the ground points (example: 0 ).

refer to P.8-7.

1 STB Revision

Page 211 of 284

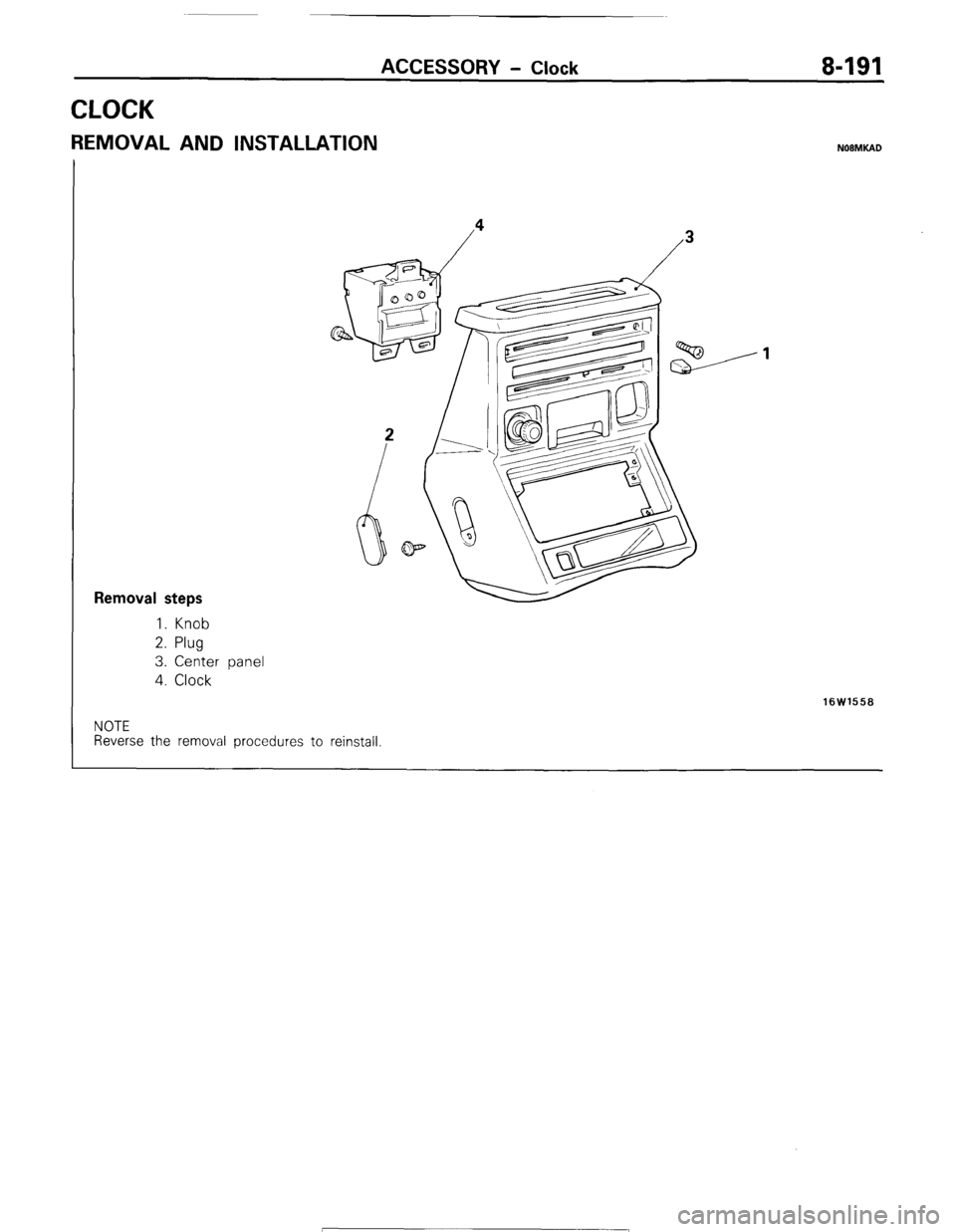

ACCESSORY - Clock 8-191

CLOCK

REMOVAL AND INSTALLATION NOBMKAD

Removal steps

1. Knob

2. Plug

3. Center panel

4. Clock

16W1558

NOTE

Reverse the removal procedures to reinstall 1 STB Revision

Page 216 of 284

8-196 AUDIO SYSTEM - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

ANTkNNA TRUMMER NOBNIAA

70R0351

1.

2.

3.

1.

2.

3.

4.

5. The antenna trimmer is essential for matching the antenna

with the radio in order to obtain the maximum sensitivity of

the radio.

It must be adjusted with the antenna actually mounted on

the vehicle. If the trimmer is not adjusted properly, the

radio suffers from not only low sensitivity but also noises,

su’ch as external noise and noise from passing vehicles.

In the following cases, therefore, adjust it as described

below.

(1) When radio is installed.

(2) If antenna is replaced.

(3) If radio has low sensitivity.

(4) If radio is noisy.

AkTENNA TRIMMER ADJUSTMENT

Mgke the following preparations for adjustment:

(1)’ Turn the ignition key to the “ACC” position.

(2) Extend the antenna all the way.

(3) Tune accurately to a station near 1,400 kHz in order to

receive a broadcast in as weak an electric field as can

be barely received. If there is no station near 1,400 kHz,

tune to any high-frequency station (above 1,000 kHz)

available. If there are two or more stations near 1,400

kHz, choose the louder one.

(4) Set the volume control to the proper volume.

(5) Set the tone ccontrol to treble position.

Be sure that preparations 1 through 5 have been correctly

made.

Insert a screwdriver into the trimmer adjusting hole.

Tumrn the screwdriver clockwise or counterclockwise for

maximum sensitivity (maximum broadcast wave sound).

If the optimum sensitivity point cannot be found, check for

an antenna malfunction or a broken wire.

NOTE

The antenna trimmer of an electronic tuning radio does not

require adjustment.

/ STB Revision