specifications MITSUBISHI MONTERO 1987 1.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 204 of 284

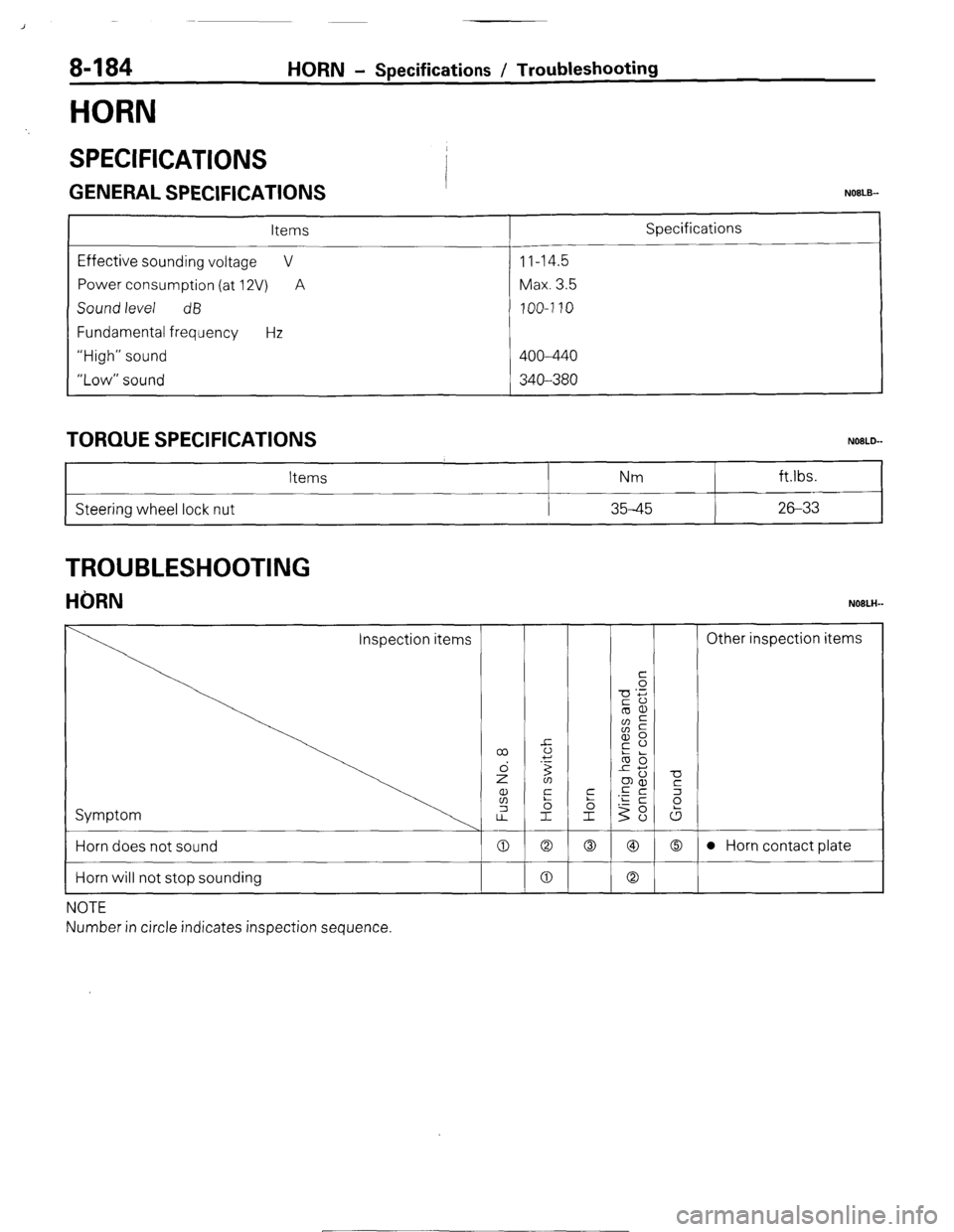

8-184

HORN

HORN - Specifications / Troubleshooting

SPECIFICATIONS

GENERAL SPECIFICATIONS I NOBLE--

Items

Effective sounding voltage V

Power consumption (at 12V) A

Sound level dB

Fundamental frequency Hz

“High” sound

“Low” sound 11-14.5

Max. 3.5

100-7 10

400--440

340--380 Specifications

TORQUE SPECIFICATIONS

Steering wheel lock nut Items

i Nm ft.lbs.

35-45 26-33

TROUBLESHOOTING

HORN NOBLH-

Horn does not sound

Horn will not stop sounding

NOTE

Number in circle indicates inspection sequence. 0 Q 0 @I 0 l Horn contact plate

0 0

1 STB Revision

~-1

Page 208 of 284

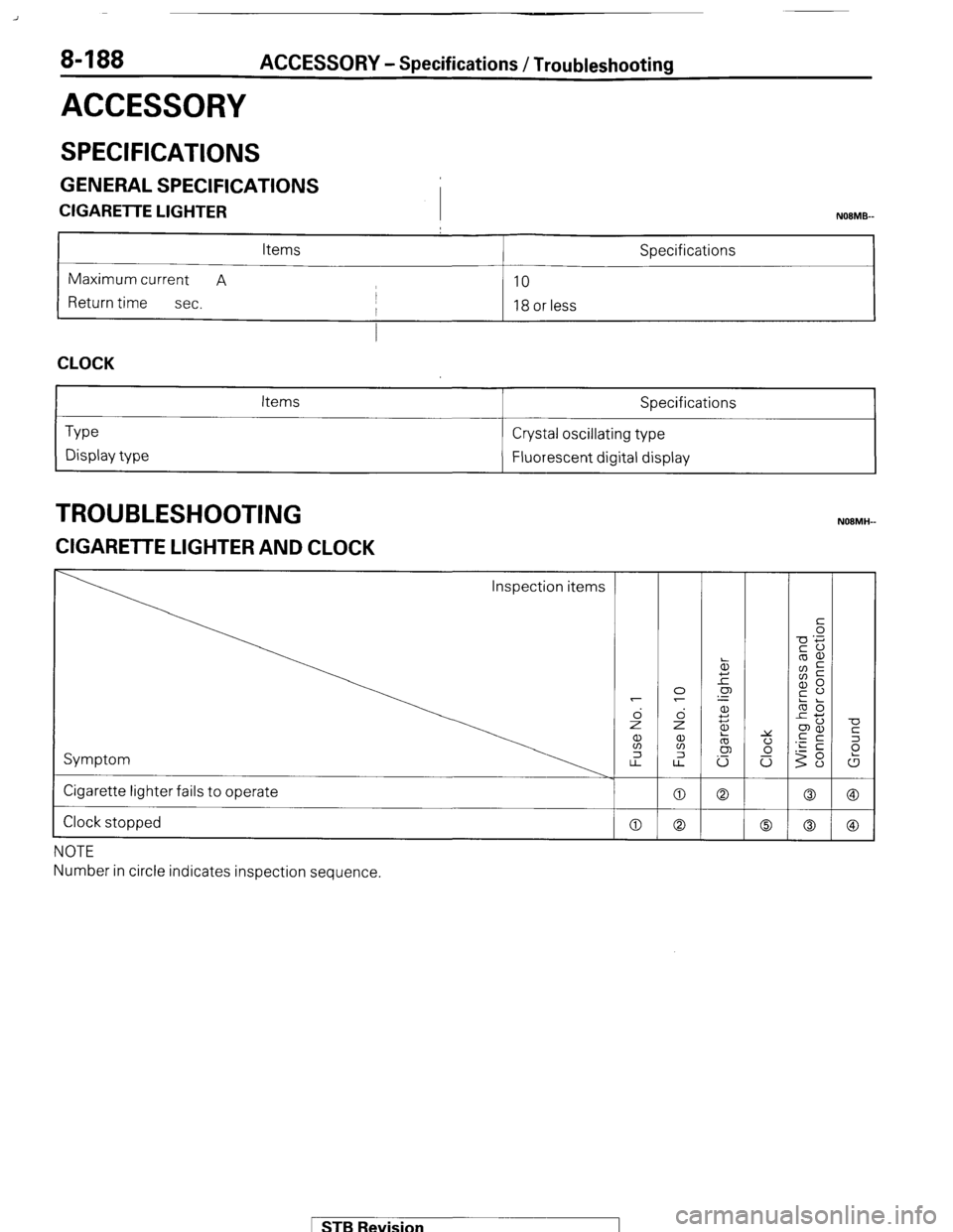

8-188 ACCESSORY - Specifications / Troubleshooting

ACCESSORY

SPECIFICATIONS

GENERAL SPECIFICATIONS

CIGARETTE LIGHTER

I NOBMB-

Items Specifications

Maximum current A

10

Return time

sec. I

I 18 or less

I

CLOCK

Type

Display type Items Specifications

Crystal oscillating type

Fluorescent digital display

TROUBLESHOOTING

ZIGARETTE LIGHTER AND CLOCK

Inspection items

Symptom

Cigarette lighter fails to operate

Clock stopped

NOTE

Number in circle indicates inspection sequence.

MB Revision

Page 212 of 284

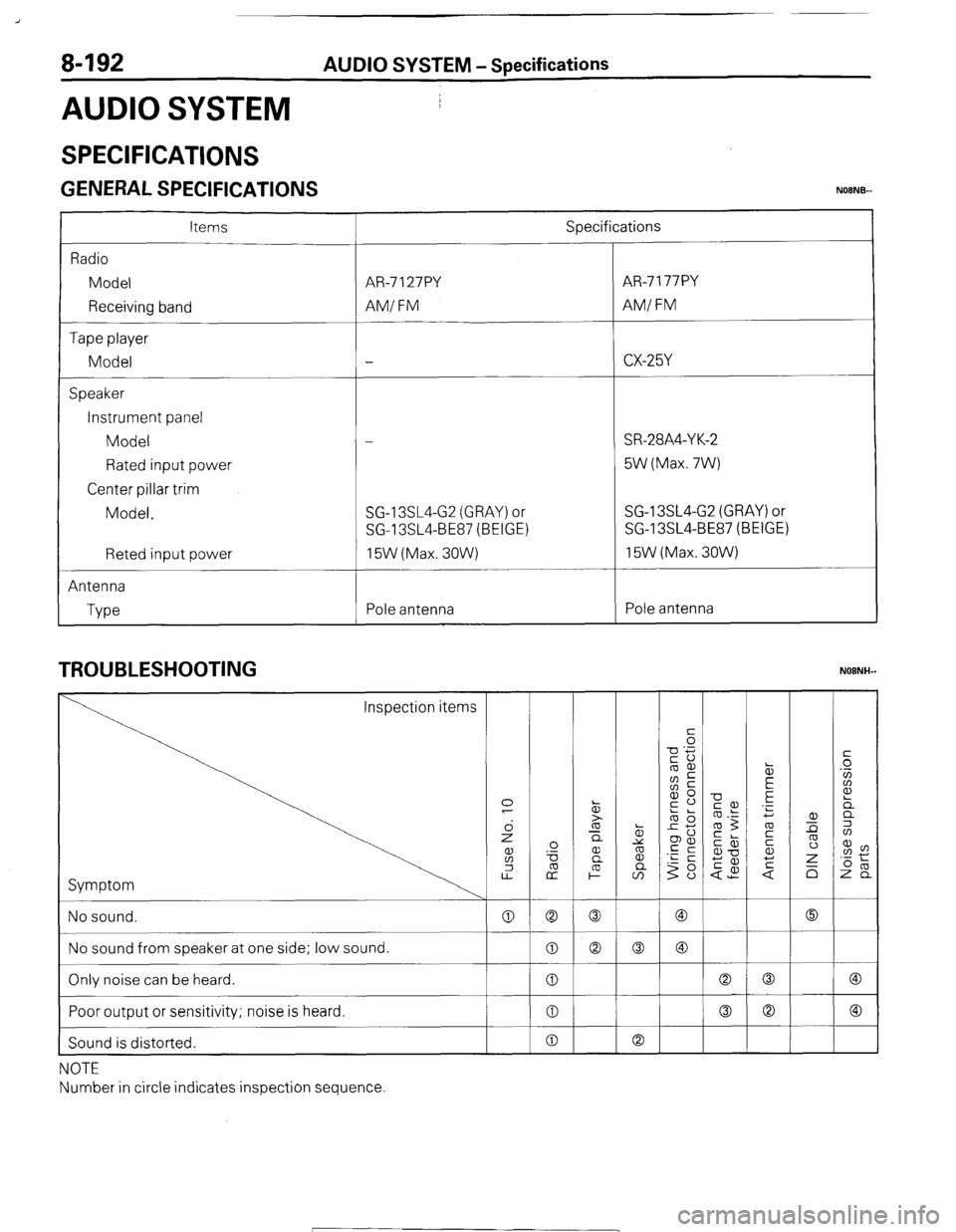

8-192 AUDIO SYSTEM - Specifications

AUDIO SYSTEM I

/

SPECIFICATIONS

GENERAL SPECIFICATIONS NOENB-

Items

Radio

Model

Receiving band

Tape player

Model

Speaker

Instrument panel

Model

Rated input power

Center pillar trim

Model.

Reted input power

Antenna

Type Spe,cifications

AR-7 127PY AR-7 177PY

AM/ FM AMI FM

-

CX-25Y

-_-

-

SR-28A4-Y K-2

5W (Max. 7W)

SG-13SL4-G2 (GRAY) or SG-13SL4-G2 (GRAY) or

SG-13SL4-BE87 (BEIGE) SG-13SL4-BE87 (BEIGE)

15W (Max. 30W) 15W (Max. 3OW)

Pole antenna Pole antenna

TROUBLESHOOTING

Symptom

NOTE

Number in circle indicates inspection sequence

( STB Revision

Page 213 of 284

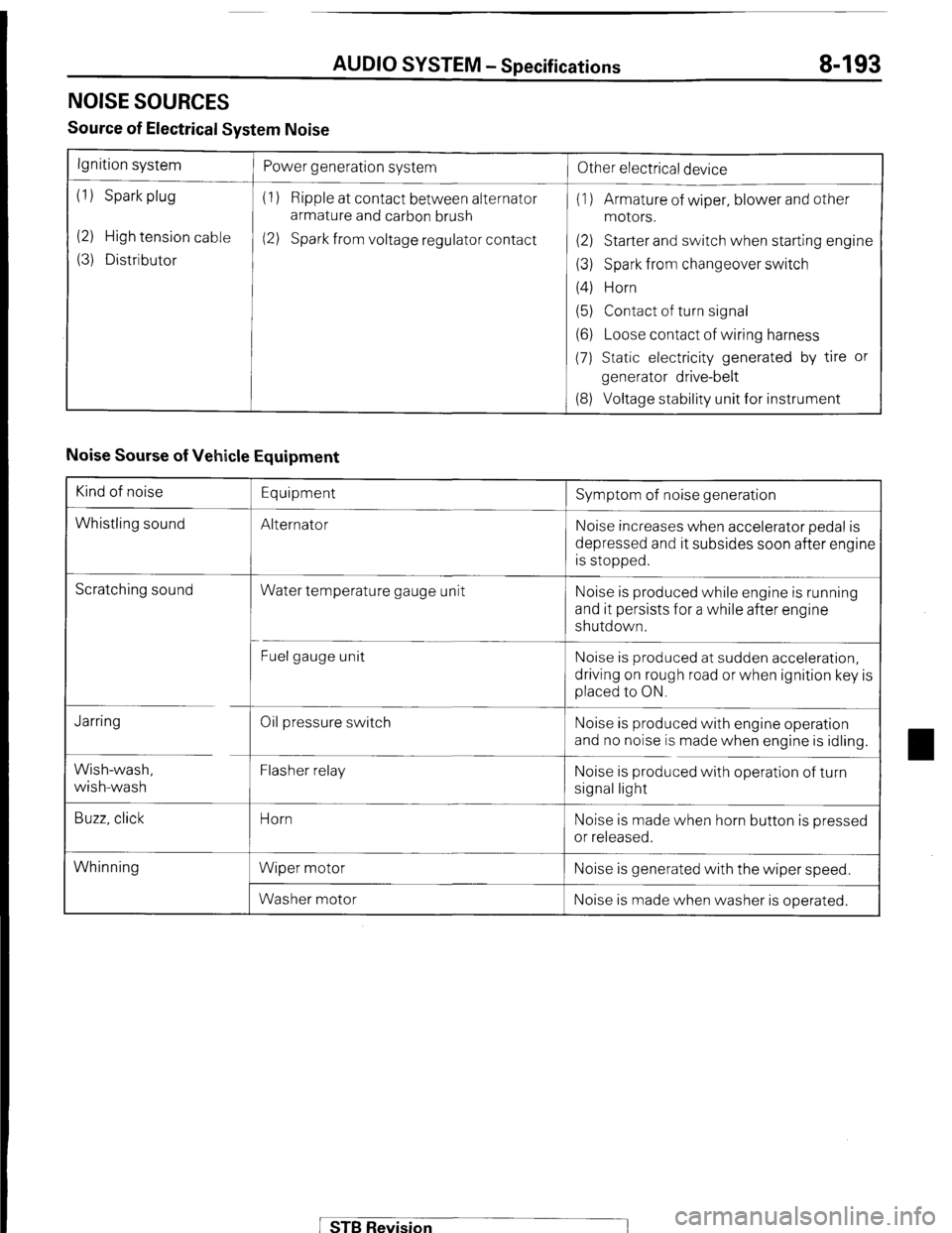

AUDIO SYSTEM - Specifications 8-193

NOISE SOURCES

Source of Electrical System Noise

Ignition system

(1) Spark plug

(2) High tension cable

(3) Distributor Power generation system

(1) Ripple at contact between alternator

armature and carbon brush

(2) Spark from voltage regulator contact

!

Other electrical device

(1) Armature of wiper, blower and other

motors.

(2) Starter and switch when starting engine

(3) Spark from changeover switch

(4) Horn

(5) Contact of turn signal

(6) Loose contact of wiring harness

(7) Static electricity generated by tire or

generator drive-belt

(8) Voltage stability unit for instrument

Noise Sourse of Vehicle Equipment

Kind of noise

Whistling sound Equipment

Alternator Symptom of noise generation

Noise increases when accelerator pedal is

depressed and it subsides soon after engine

is stopped.

Scratching sound

Water temperature gauge unit Noise is produced while engine is running

and it persists for a while after engine

shutdown.

Fuel gauge unit Noise is produced at sudden acceleration,

driving on rough road or when ignition key is

placed to ON.

Jarring

Wish-wash,

wish-wash

Buzz, click Oil pressure switch

Flasher relay

Horn

Wiper motor

Washer motor Noise is produced with engine operation

and no noise is made when engine is idling.

Noise is produced with operation of turn

signal light

Noise is made when horn button is pressed

or released.

Whinning Noise is generated with the wiper speed.

Noise is made when washer is operated.

STB Revision

Page 223 of 284

BACK DOOR WINDOW DEFOGGER - Specifications / Special Tools

BACK DOOR WINDOW DEFOGGER

8-203

SPECIFICATIONS

( ;ENERAL SPECIFICATIONS NOOPB-B

Items

Back door window defogger switch

Type Seesaw type Specifications

Rated current

Back door window defogger timer

Timer

Back door window glass with defogger

No. of printed heater lines

Power consumption [2O”C (68”F)] 20A

-

11

112-148W

SPECIAL TOOLS

Tool (Number and name)

MB990784

Ornament remover Use

Removal of back door

window defogger

switch

NOBPG-B

1 STB Revision

Page 232 of 284

8-212 AUTOMATIC FREE-WHEELING HUB lNCDlCATOR SYSTEM - $%%60n’~at’on’

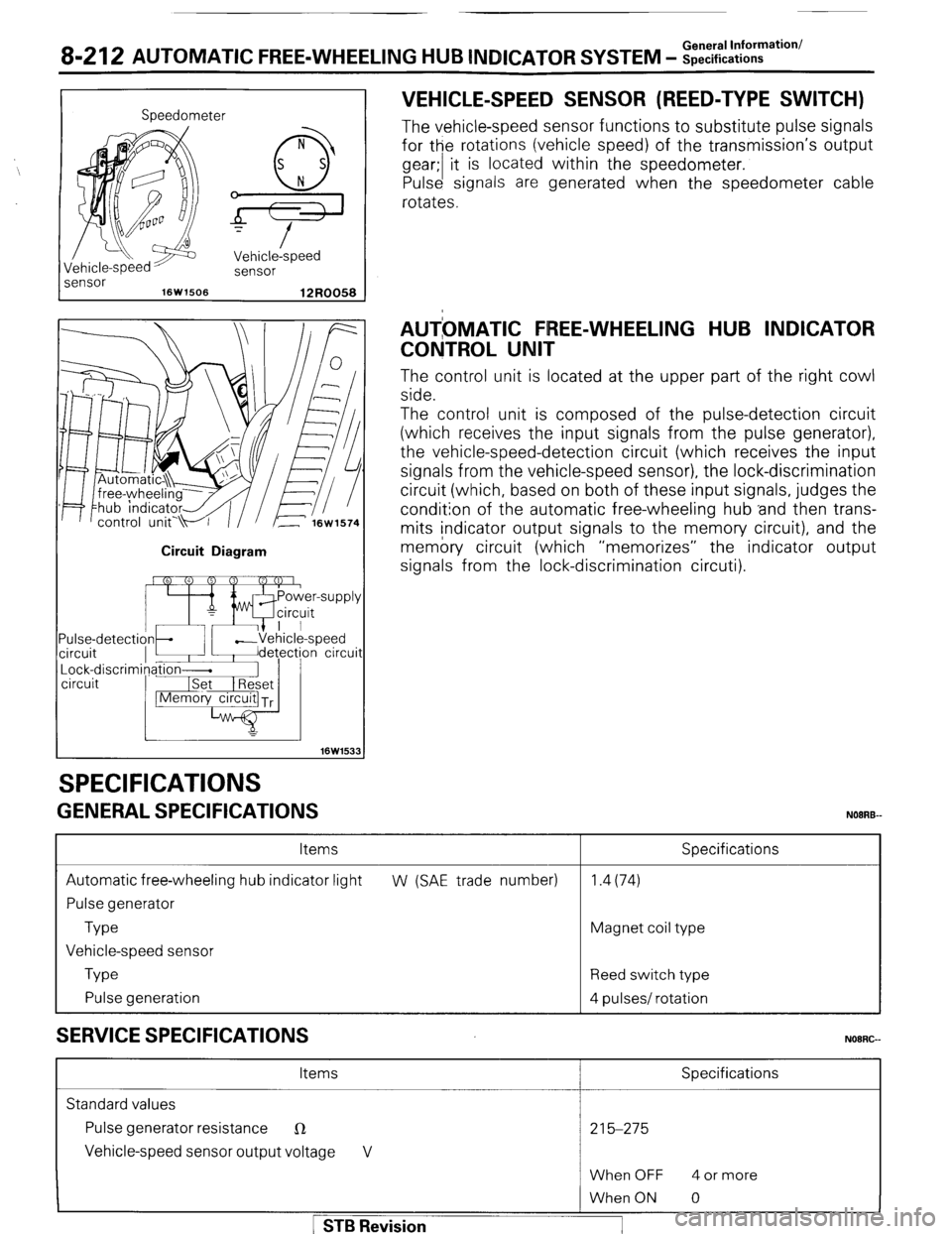

Speedometer

I

iensor Vehicle-speed

sensor

16W1506

12R0058

Circuit Diagram

16W153

SPECIFICATIONS

GENERAL SPECIFICATIONS VEHICLE-SPEED SENSOR (REED-TYPE SWITCH)

The vehicle-speed sensor functions to substitute pulse signals

for the rotations (vehicle speed) of the transmission’s output

gear;/ t i is located within the speedometer.

Pulse signals are generated when the speedometer cable

rotates.

AUTbMATlC FREE-WHEELING HUB INDICATOR

CONTROL UNIT

The control unit is located at the upper part of the right cowl

side.

The control unit is composed of the pulse-detection circuit

(which receives the input signals from the pulse generator),

the vehicle-speed-detection circuit (which receives the input

signals from the vehicle-speed sensor), the lock-discrimination

circuit (which, based on both of these input signals, judges the

condition of the automatic free-wheeling hub ‘and then trans-

mits indicator output signals to the memory circuit), and the

memory circuit (which “memorizes” the indicator output

signals from the lock-discrimination circuti).

Items

Automatic free-wheeling hub indicator light

Pulse generator

Type

Vehicle-speed sensor

Type

Pulse generation

SERVICE SPECIFICATIONS

Specifications

W (SAE trade number) 1.4(74)

Magnet coil type

Reed switch type

4 pulses/ rotation

NOORG-

Items Specifications

Standard values

Pulse generator resistance

R 215-275

Vehicle-speed sensor output voltage V

When OFF 4 or more 1 STB Revision

When ON 0

Page 237 of 284

24-1

AIR-CO IONING

CONTENTS

AIR-CONDITIONING

AIR CONDITIONER SWITCH ......................... 42

CIRCUIT DIAGRAM ...................................... . . 26

COMPRESSOR ............................................... 46

EVAPORATOR ............................................ . ... 43

GENERAL INFORMATION .............. . ....... . . . .... 19

RECEIVER DRIER, CONDENSER,

COMPRESSOR CLUTCH ASSEMBLY .......... 45

SAFETY PRECAUTIONS ................................ 28

SERVICE ADJUSTMENT PROCEDURES ...... 29

Compressor Drive Belt Adjustment ...........

40

Compressor Noise ..................................... 41

Handling Tubing and Fittings ..................... 39

Manifold Gauge Set Installation ................ 29

Performance Test ...................................... 34

Refrigerant Leak Repair Procedure ........... 34

Test Procedures ......................................... 29

Testing System for Leaks .......................... 33

SPECIAL TOOLS ............................................ 22

SPECIFICATIONS ...... . .

.. . ................................ 21

General Specifications ...............................

21

Service Specifications ................................

21

Torque Specifications ................................

21

TROUBLESHOOTING .................................... 22 Air is Emitted but Is Not Cool

Cool Air Flow Is Intermittent

Insufficient Air Flow

Insufficient Cooling

HEATERS

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . . . ..a............... 14

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

HEATER CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SERVICE ADJUSTMENT PROCEDURES . . . . . . 5

Temperature Control System

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Blower Motor Inoperative

Blower Motor Operates on High

Speed Only

Improper Heat

No Ventilation Even When Mode

Selection Lever Is Operated

VENTILATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a..... . . . . . . . . . . . .

16

Page 257 of 284

AIR-CONDITIONING -Specifications

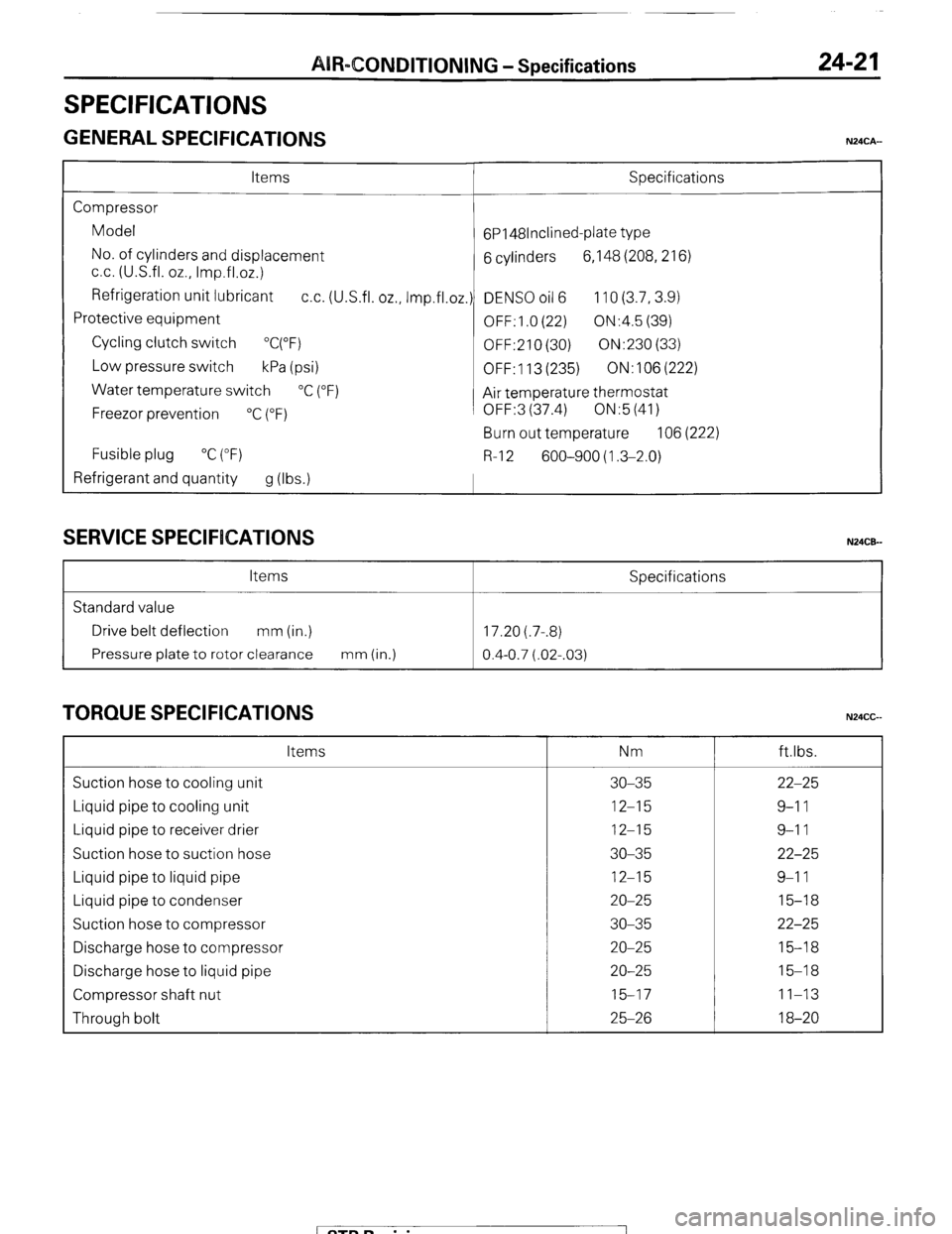

SPECIFICATIONS

GENERAL SPECIFICATIONS

24-2 1

N24CA-

Items Specifications

Compressor

Model

6P148lnclined-plate type

No. of cylinders and displacement

6 cylinders 6,148 (208,216)

cc. (U.S.fl. oz., Imp.fl.02.)

Refrigeration unit lubricant

cc. (U.S.fl. oz., Imp.fl.oz.) DENS0 oil 6 110 (3.7,3.9)

Protective equipment

OFF: 1 .O (22) ON:4.5 (39)

Cycling clutch switch

“C(“F)

OFF:210 (30) ON:230 (33)

Low pressure switch

kPa (psi)

OFF: 113 (235) ON:106(222)

Water temperature switch

“C (“F)

Air temperature thermostat

Freezor prevention

“C (“F) OFF:3 (37.4) ON:5 (41)

Burn out temperature 106 (222)

Fusible plug “C (“F)

R-l 2 600-900 (1.3-2.0)

Refrigerant and quantity

g (Ibs.1

SERVICE SPECIFICATIONS N24CE-

Items Specifications

Standard value

Drive belt deflection mm (in.) 17.20 (.7-.8)

Pressure plate to rotor clearance mm (in.)

0.4-0.7 (.02-.03)

TORQUE SPECIFICATIONS N24CG Items Nm ftlbs.

Suction hose to cooling unit 30-35 22-25

Liquid pipe to cooling unit 12-15 9-l 1

Liquid pipe to receiver drier 12-15 9-l 1

Suction hose to suction hose 30-35 22-25

Liquid pipe to liquid pipe 12-15 9-l 1

Liquid pipe to condenser 20-25 15-18

Suction hose to compressor 30-35 22-25

Discharge hose to compressor 20-25 15-18

Discharge hose to liquid pipe 20-25 15-18

Compressor shaft nut 15-17 11-13

Through bolt 25-26 18-20

/ STB Revision I