Fuel gauge MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 21 of 284

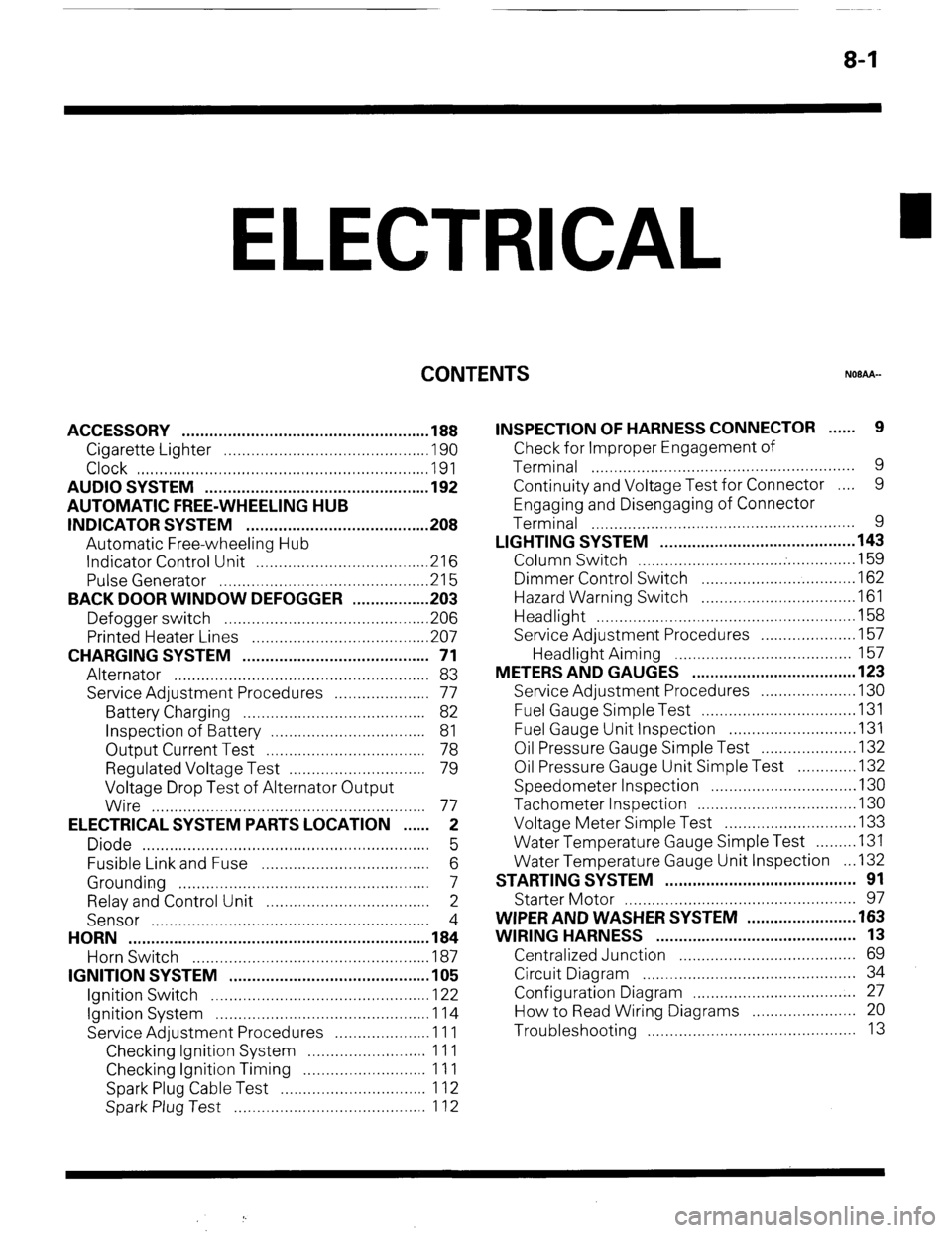

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 51 of 284

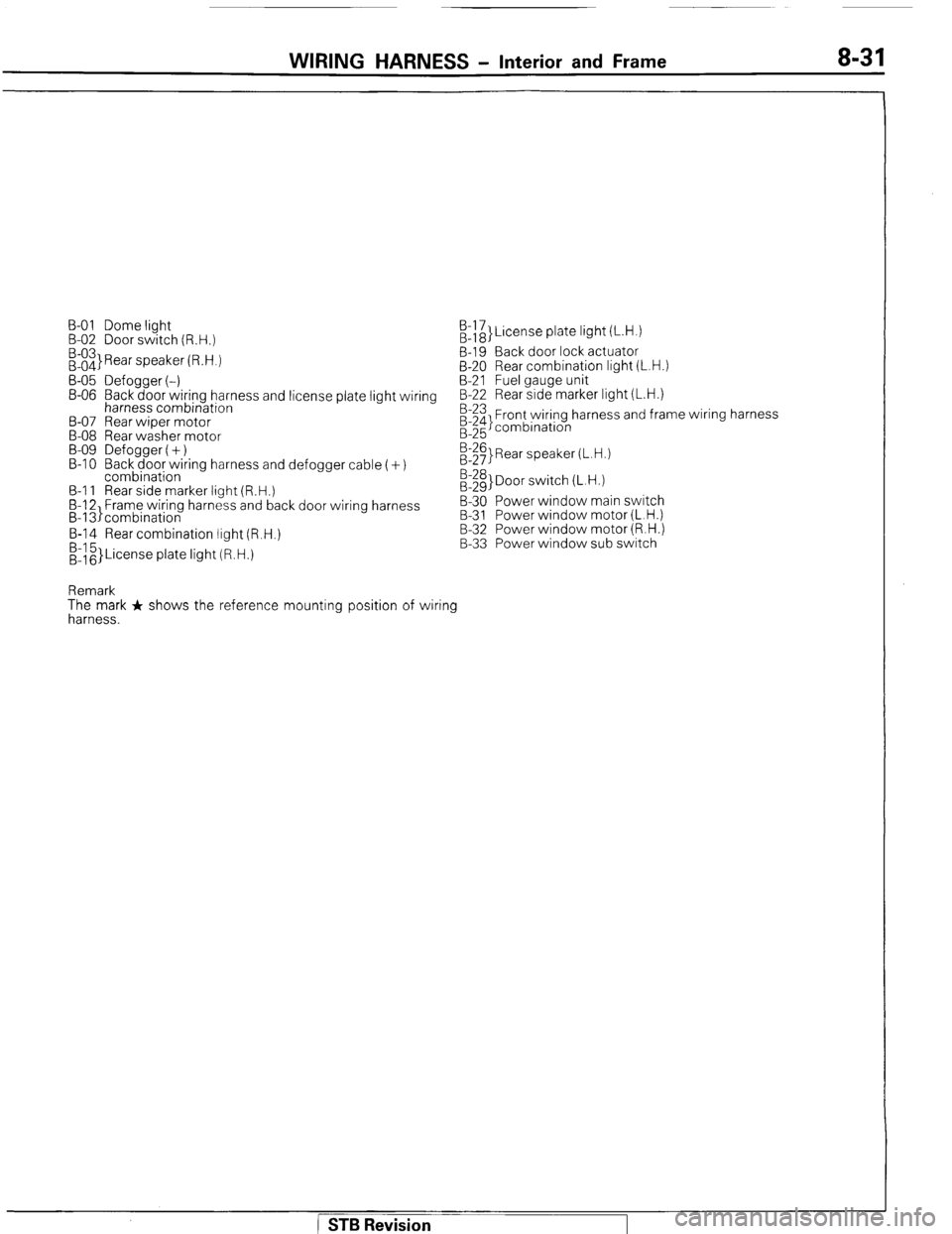

WIRING HARNESS - Interior and Frame 8-31

B-01 Dome light

B-02 Door switch (R.H.)

:::3 Rear speaker (R.H.) /&}License plate light (L.H.)

B-19 Back door lock actuator

B-20 Rear combination light (L.H.)

B-05 Defogger (-) B-21 Fuel gauge unit

B-06 Back door wiring harness and license plate light wiring B-22 Rear side marker light (L.H.)

harness combination

B-07 Rear wiper motor

B-08 Rear washer motor

B-09 Defogger (+)

B-l 0 Back door wiring harness and defogger cable (+)

combination

B-l 1 Rear side marker light (R.H.)

B-12 Frame wiring harness and back door wiring harness

B-13)combination B-23 Front wiring harness and frame wiring harness

;:g combination

E$ Rear speaker (L.H.)

:::g> Door switch (L.H.)

B-30 Power window main switch

B-31 Power window motor (L.H.)

B-14 Rear combination light (R.H.)

&z}License plate light (R.H.) B-32 Power window motor (R.H.)

B-33 Power window sub switch

Remark

The mark + shows the reference mounting position of wiring

harness.

STB Revision

Page 73 of 284

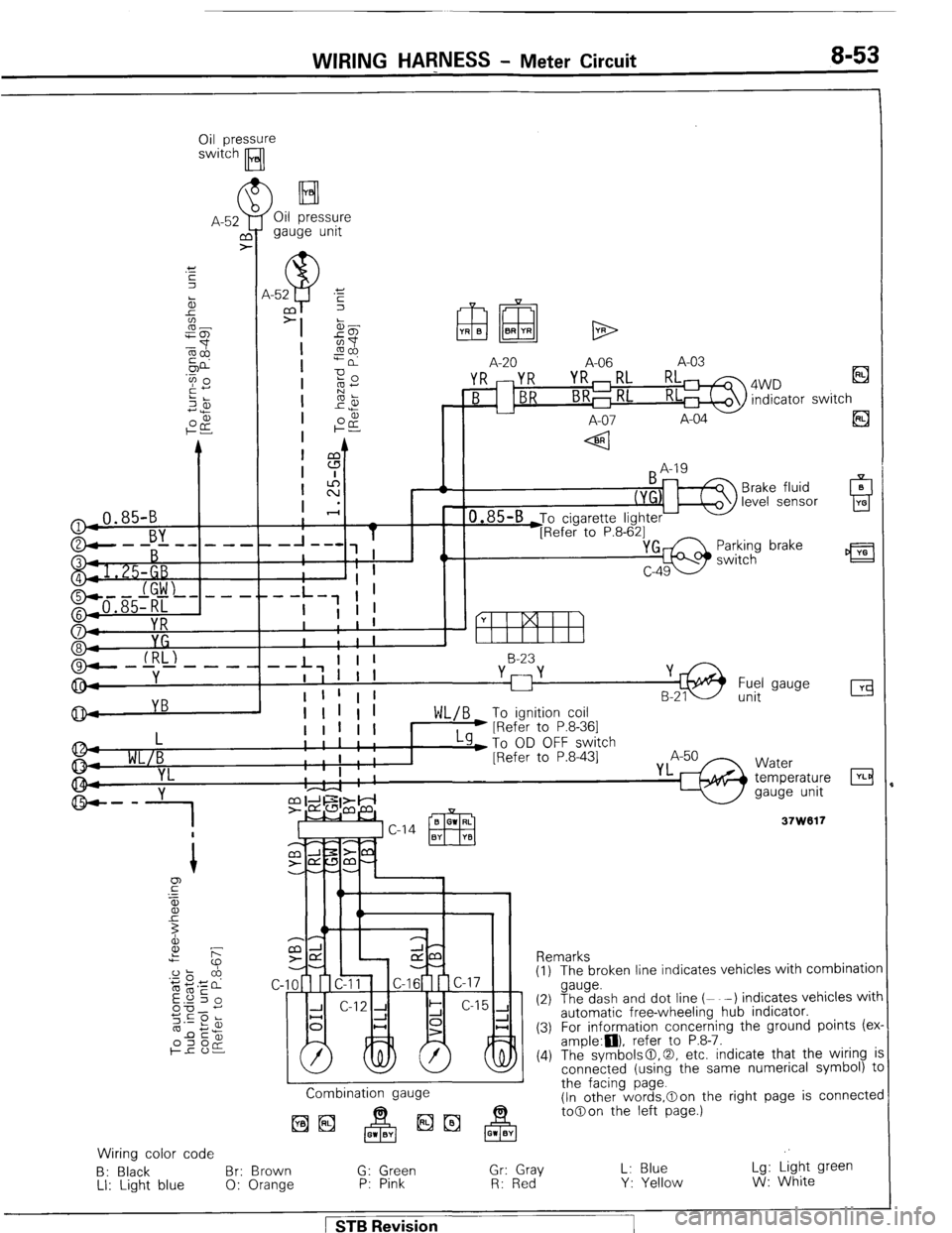

WIRING HAFNESS - Meter Circuit 8-53

O&y-ssure

[Eal

* - -,,- - - - -

YB

> El Oil pressure

gauge unit

ElxQ YR B BR YR

I.+

A-20

A-06 A-03

4WD Ei

indicator switch

A-07 A-04 I r-

’ fs A

I I

I

E

1 ,’

-I T

-- m-w

I ? I

I I ’

k-1 1 I

.- -

I

I ' 1

I I

I I I I 4

0.85-B Jo

cigarette lighter

[Refer to P.8-621 Brake fluid

level sensor

Parking brake

switch

L, I I 1 B-23

-- I , I I I

I !

Fuel gauge

unit

Water

temperature

gauge unit

37W617

les with combinatior

(2) %?zgdeash and dot line (- -) indicates vehicles wit1

automatic free-wheeling hub indicator.

(3) For information concerning the ground points (er

ample:n), refer to P.8-7.

(4) The symbols@,@, etc. indicate that the wiring i

connected (using the same numerical symbol) tl

Combination gauge the facing page.

(In other words,Oon the right page is connecter

to@on the left page.)

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White

1 STB Revision

Page 90 of 284

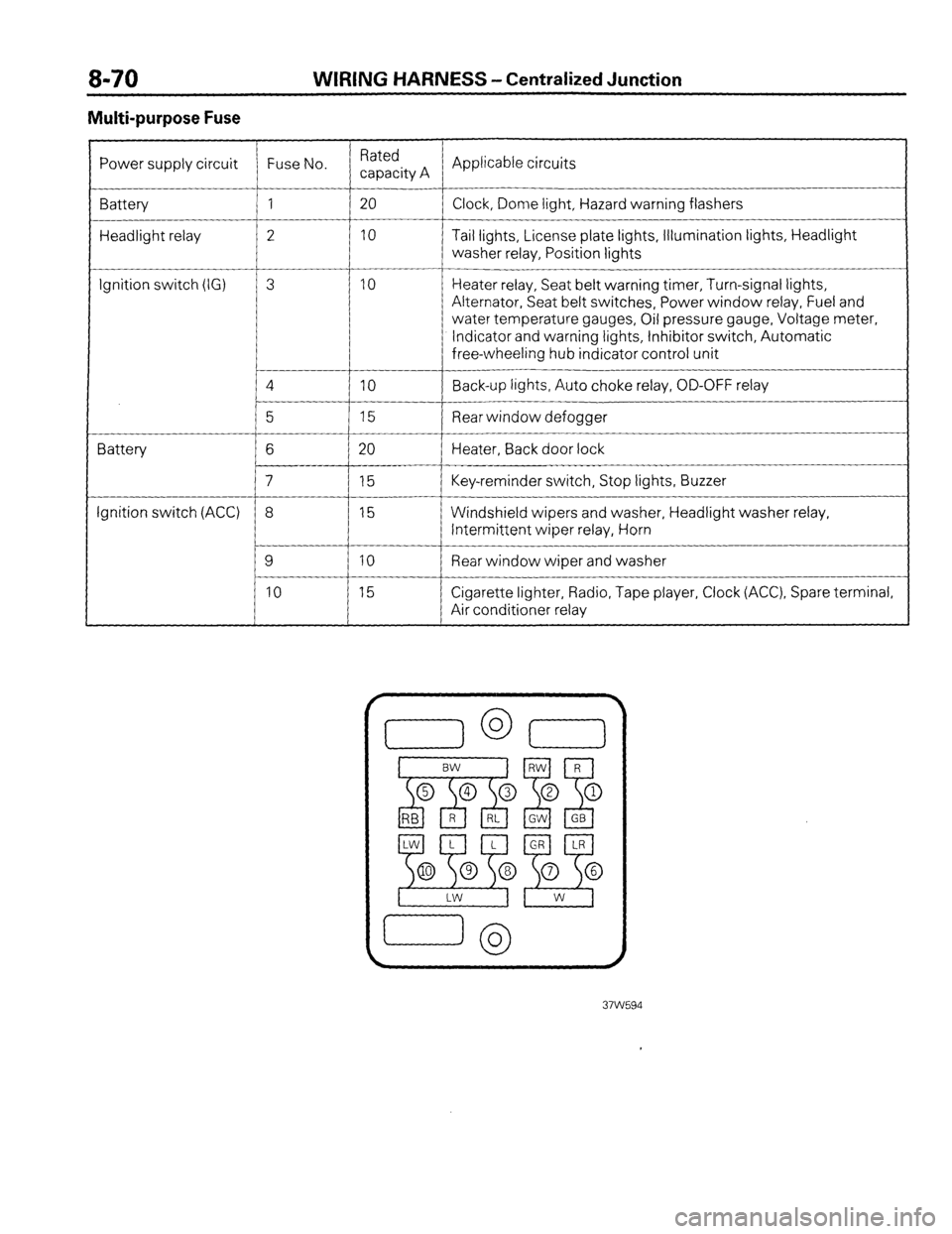

WIRING HARNESS - Centralized Junction

Multi-purpose Fuse

Power supply circuit Fuse No. Rated

capacity A Applicable circuits

Battery 1 20

Clock, Dome light, Hazard warning flashers

Headlight relay 2 10 Tail lights, License plate lights, Illumination lights, Headlight

washer relay, Position lights

__-

Ignition switch (IG) 3 10 Heater relay, Seat belt warning timer, Turn-signal lights,

Alternator, Seat belt switches, Power window relay, Fuel and

water temperature gauges, Oil pressure gauge, Voltage meter,

Indicator and warning lights, Inhibitor switch, Automatic

free-wheeling hub indicator control unit

4

IO Back-up lights, Auto choke relay, OD-OFF relay

__-

5 15 Rear window defogger

Battery 6 20 Heater, Back door lock

7 15 Key-reminder switch, Stop lights, Buzzer

Ignition switch (ACC) 8 15 Windshield wipers and washer, Headlight washer relay,

Intermittent wiper relay, Horn

9 10 Rear window wiper and washer

10 15 Cigarette lighter, Radio, Tape player, Clock (ACC), Spare terminal,

Air conditioner relay

Page 143 of 284

METERS AND GAUGES-Specifications

METERS AND GAUGES

8-123

SPECIFICATIONS

GENERAL SPECIFICATIONS

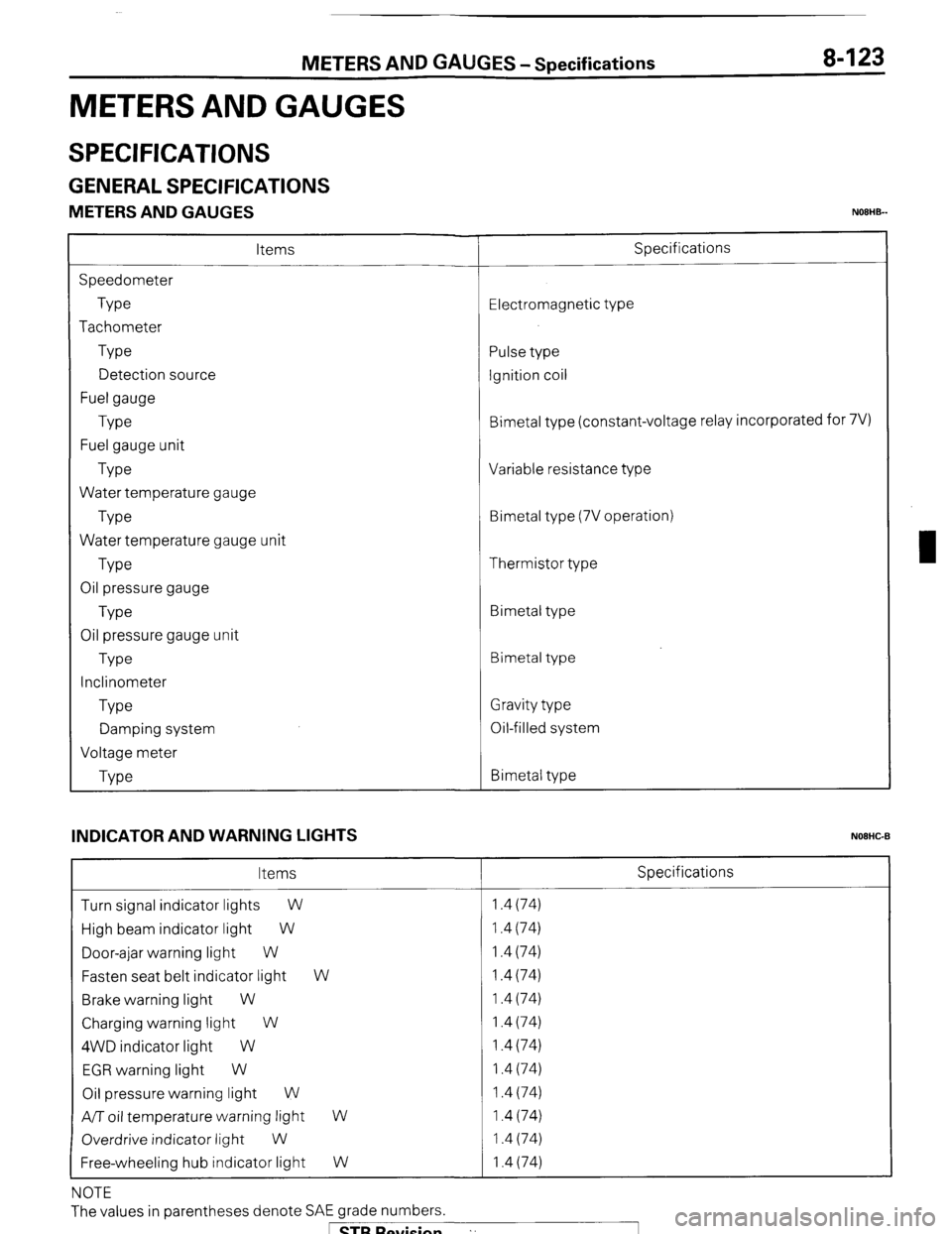

METERS AND GAUGES NOEHB-

Items

Speedometer

Type

Tachometer

Type

Detection source

Fuel gauge

Type

Fuel gauge unit

Type

Water temperature gauge

Type

Water temperature gauge unit

Type

Oil pressure gauge

Type

Oil pressure gauge unit

Type

Inclinometer

Type

Damping system

Voltage meter

Type Specifications

Electromagnetic type

Pulse type

Ignition coil

Bimetal type (constant-voltage relay incorporated for 7V)

Variable resistance type

Bimetal type (7V operation)

Thermistor type

Bimetal type

Bimetal type

Gravity type

Oil-filled system

Bimetal type

INDICATOR AND WARNING LIGHTS

NOEHC-B

Items Specifications

Turn signal indicator lights

W 1.4 (74)

High beam indicator light W 1.4 (74)

Door-ajar warning light W 1.4 (74)

Fasten seat belt indicator light W 1.4 (74)

Brake warning light W 1.4 (74)

Charging warning light W 1.4 (74)

4WD indicator light W 1.4 (74)

EGR warning light W 1.4 (74)

Oil pressure warning light W 1.4 (74)

A/T oil temperature warning light

W 1.4 (74)

Overdrive indicator light

W 1.4 (74)

Free-wheeling hub indicator light W 1.4 (74)

NOTE

The values in parentheses denote SAE grade numbers.

1 STB Revision ”

Page 144 of 284

8-124

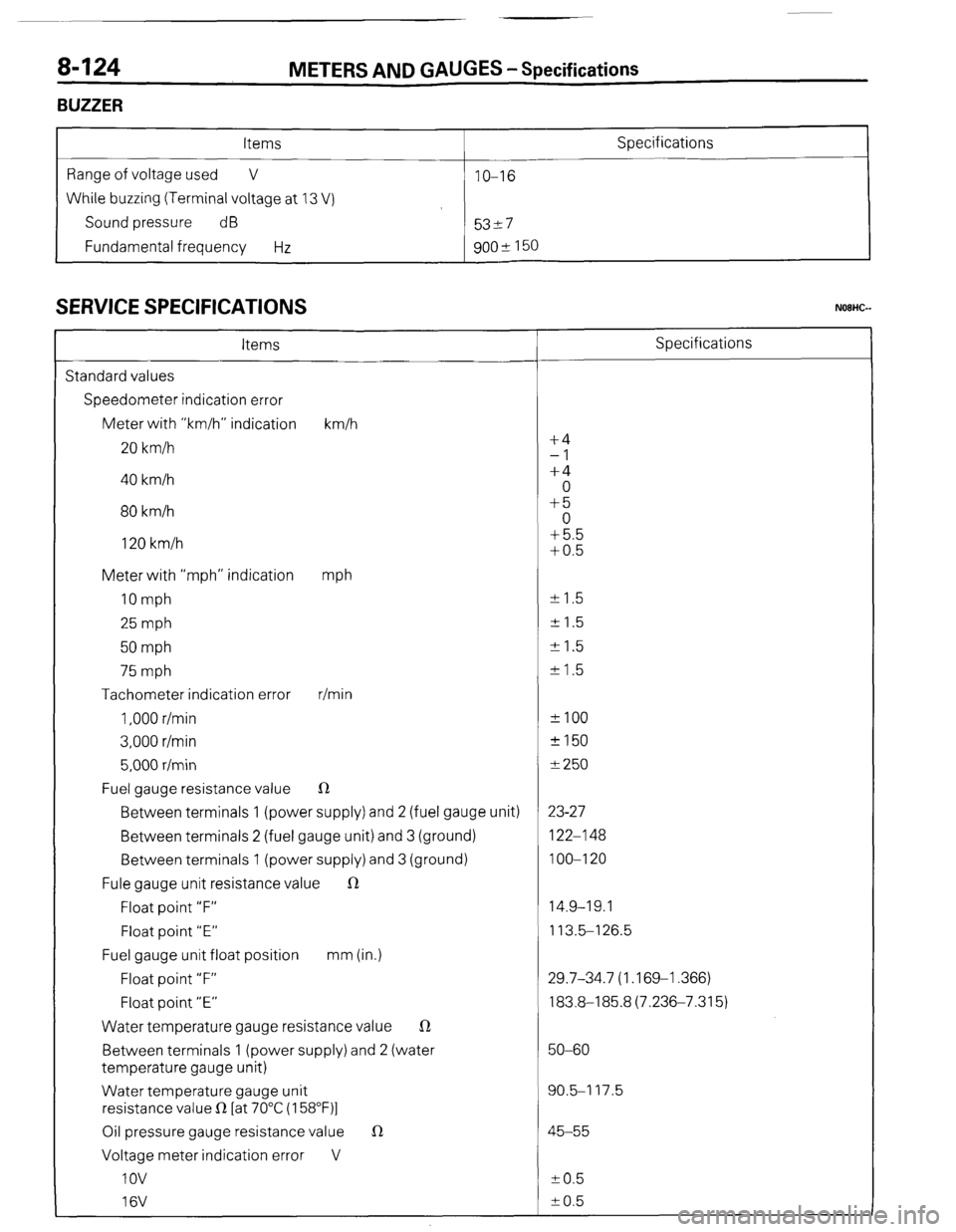

BUZZER METERS AND

GAUGES - Specifications

Items

Range of voltage used V

While buzzing (Terminal voltage at 13 V)

Sound pressure dB

Fundamental frequency Hz IO-16

53-7

goo* 150 Specifications

SERVICE SPECIFICATIONS

Items Specifications

Standard values

Speedometer indication error

Meter with “km/h” indication km/h

20 km/h f4

-1

40 km/h +4

0

80 km/h +5

0

120 km/h +5.5

+0.5

Meter with “mph” indication

mph

10 mph +- 1.5

25 mph + 1.5

50 mph +I.5

75 mph k 1.5

Tachometer indication error r/min

1,000 r/min *IO0

3,000 r/min +150

5,000 r/min f 250

Fuel gauge resistance value R

Between terminals 1 (power supply) and 2 (fuel gauge unit) 23-27

Between terminals 2 (fuel gauge unit) and 3 (ground) 122-l 48

Between terminals 1 (power supply) and 3 (ground) 100-l 20

Fule gauge unit resistance value R

Float point “F” 14.9-19.1

Float point “E” 113.5-l 26.5

Fuel gauge unit float position mm (in.)

Float point “F” 29.7-34.7 (1.169-l .366)

Float point “E” 183.8-185.8(7.236-7.315)

Water temperature gauge resistance value R

Between terminals 1 (power supply) and 2 (water 50-60

temperature gauge unit)

Water temperature gauge unit 90.5-I 17.5

resistance value R [at 70°C (158”F)l

Oil pressure gauge resistance value 1R 45-55

Voltage meter indication error V

IOV to.5

16V k 0.5

( ST6 Revision

-7

Page 145 of 284

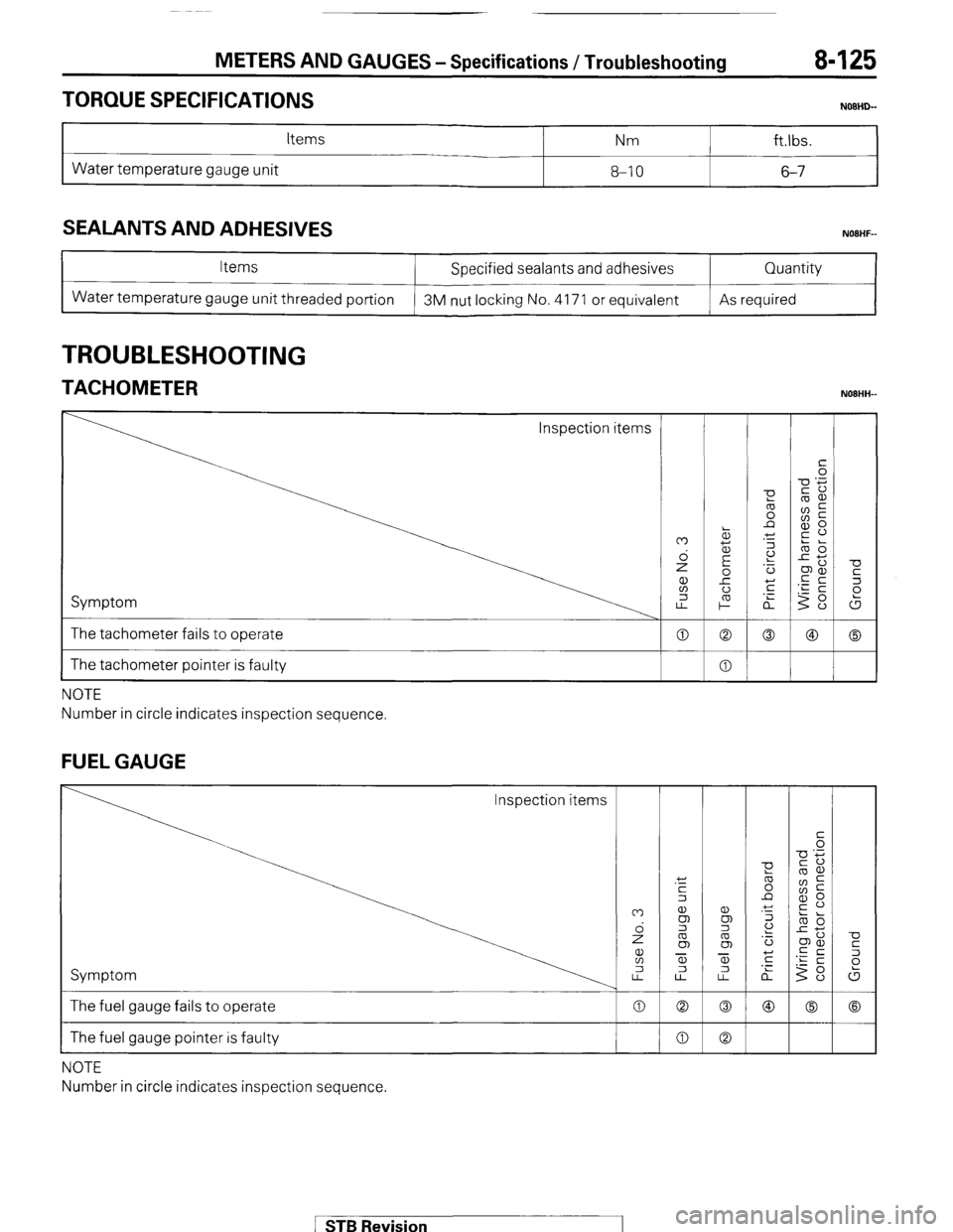

METERS AND GAUGES-Specifications /Troubleshooting 8425

TORQUE SPECIFICATIONS

Items Nm ft.lbs.

Water temperature gauge unit 8-10 6-7

SEALANTS AND ADHESIVES

Items

Water temperature gauge unit threaded portion Specified sealants and adhesives

3M nut locking No. 4171 or equivalent Quantity

As required

TROUBLESHOOTING

TACHOMETER NOBHH-

Inspection items

Symptom

The tachometer fails to operate

I The tachometer pointer is faulty

NOTE

Number in circle indicates inspection sequence.

FUEL GAUGE

Inspection items

Symptom

The fuel gauge fails to operate

The fuel gauge pointer is faulty

NOTE

Number in circle indicates inspection sequence.

1 STB Revision

Page 149 of 284

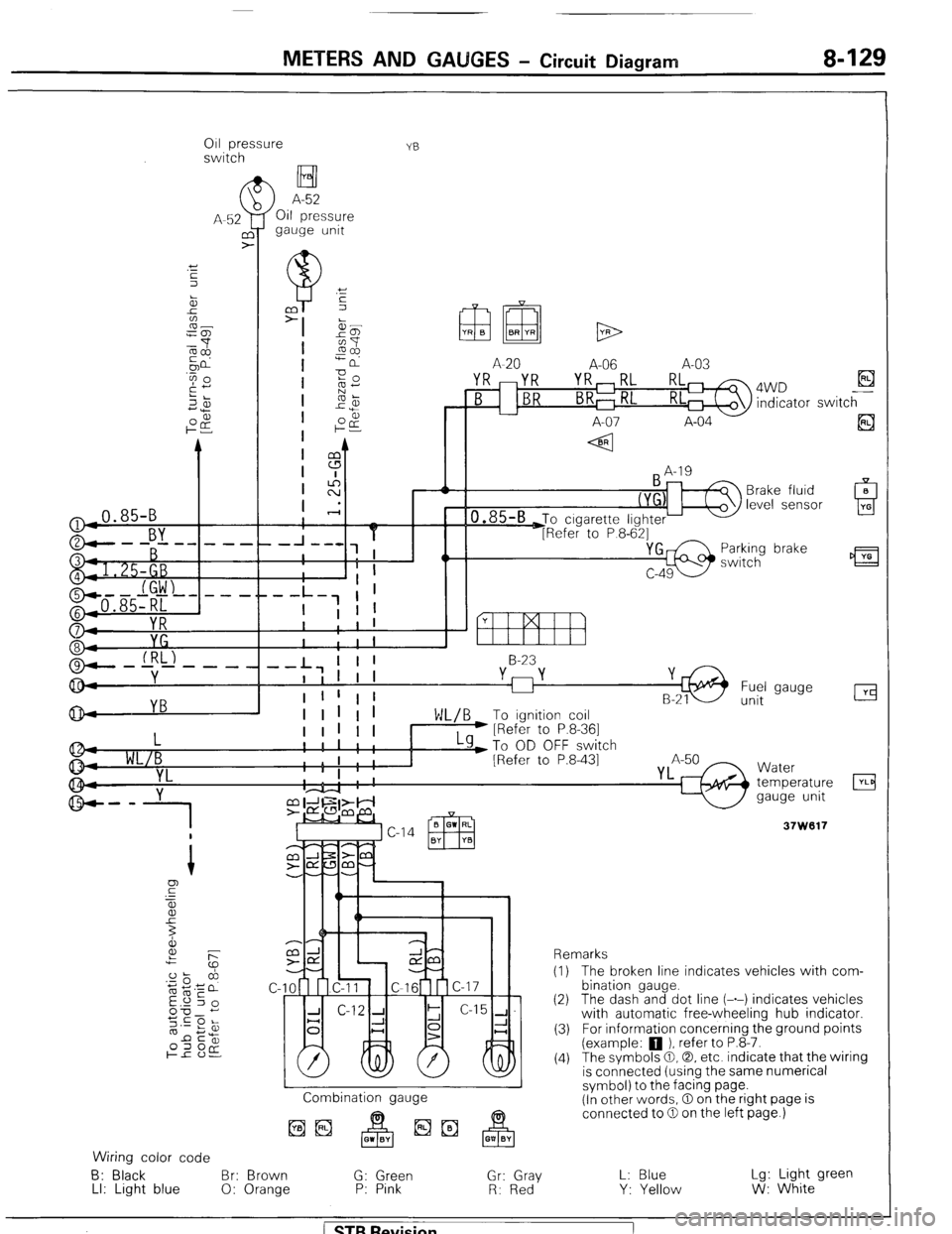

METERS AND GAUGES - Circuit Diagram 8-129

011 pressure

switch YB

H I

>

A-52

Oil pressure

gauge unit

(

A-52

UY

>

-0.85-B

r.., !

YB

A-20 A-06 A-03

YR mYR YR,RL RL 4WD El B indicator switch

-- L7 I I 1 8-23

I I I I I

I 1 !

Fuel 1 1 gauge

unit

L

WL/B

YL

g-- y

1

I

I I I I I I LY)T~ OD OFF switch

1 1 I

I ' ; [Refer to P.8-431 I I

I . . I

'4 8.

Combination gauge

Wiring color code

6: Black Br: Brown G: Green Gr: Gray

LI: Light blue 0: Orange P: Pink

R: Red

Y Water

temperature

gauge unit

Remarks

(I) The broken line indicates vehicles with com-

bination gauge.

(2) The dash and dot line (-.-) indicates vehicles

with automatic free-wheeling hub indicator.

(3) For information concerning the ground points

(example: 0 ). refer to P.8-7.

(4) The symbols @I,@, etc. indicate that the wiring

is connected (using the same numerical

symbol) to the facing page.

(In other words, 0 on the right page is

connected to 0 on the left page.)

L: Blue

Y: Yellow Lg: Light green

W: White

/ STB Revision

Page 151 of 284

METERS AND GAUGES - Service Adiustment Procedures 8-131

r

(harness side) 16W834

Stopper (upper)

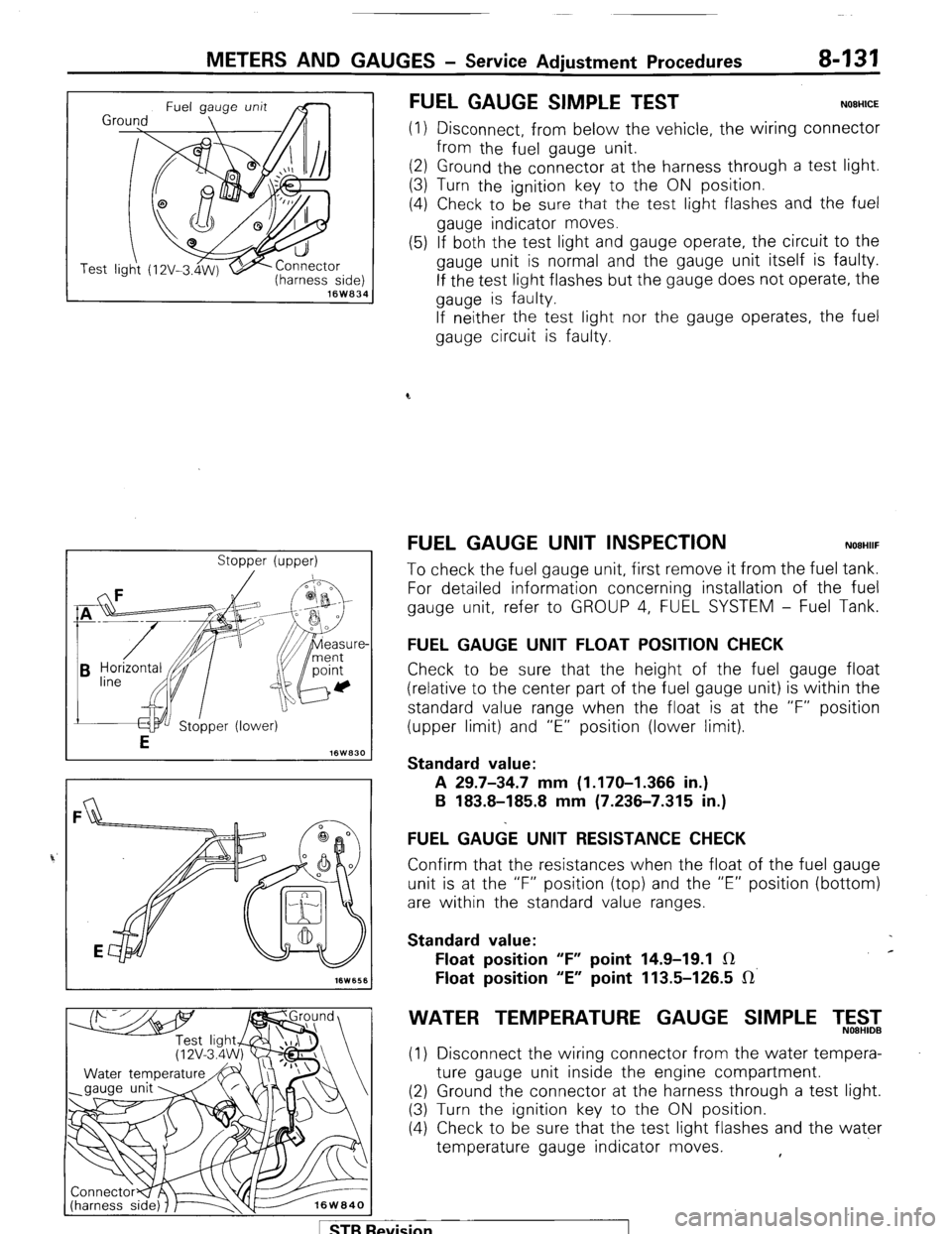

FUEL GAUGE SIMPLE TEST NOEHICE

(1) Disconnect, from below the vehicle, the wiring connector

from the fuel gauge unit.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be

sure that the test light flashes and the fuel

gauge indicator moves.

(5) If both the test light and gauge operate, the circuit to the

gauge unit is normal and the gauge unit itself is faulty.

If the test light flashes but the gauge does not operate, the

gauge is faulty.

If neither the test light nor the gauge operates, the fuel

gauge circuit is faulty.

FUEL GAUGE UNIT INSPECTION NOEHIIF

To check the fuel gauge unit, first remove it from the fuel tank.

For detailed information concerning installation of the fuel

gauge unit, refer to GROUP 4, FUEL SYSTEM - Fuel Tank.

FUEL GAUGE UNIT FLOAT POSITION CHECK

Check to be sure that the height of the fuel gauge float

(relative to the center part of the fuel gauge unit) is within the

standard value range when the float is at the “F” position

(upper limit) and “E” position (lower limit).

Standard value:

A 29.7-34.7 mm (1.170-I .366 in.)

B 183.8-185.8 mm (7.236-7.315 in.)

FUEL GA&E UNIT RESISTANCE CHECK

Confirm that the resistances when the float of the fuel gauge

unit is at the “F” position (top) and the “E” position (bottom)

are within the standard value ranges.

Standard value:

Float position “F” point 14.9-19.1 IR c

Float position “E” point 113.5-126.5 IR’

WATER TEMPERATURE GAUGE SIMPLE T,5$2

(1) Disconnect the wiring connector from the water tempera-

ture gauge unit inside the engine compartment.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be sure that the test light flashes and the water

temperature gauge indicator moves. ,

1 STB Revision

Page 155 of 284

METERS AND GAUGES - Combination Meter 8-135

.3

16WQ25

16W925

10W926

16F554

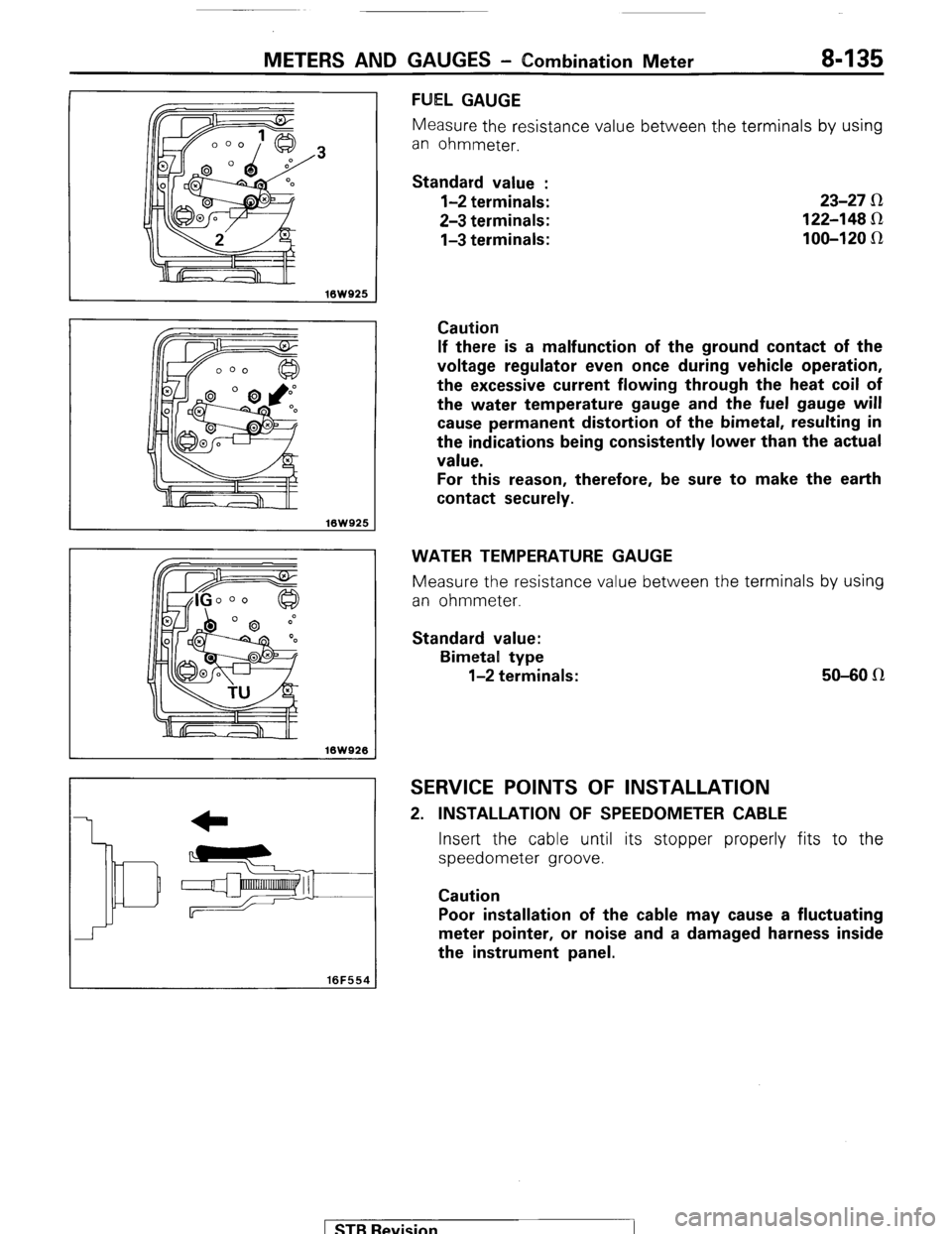

FUEL GAUGE

Measure the resistance value between t.he terminals by using

an ohmmeter.

Standard value :

l-2 terminals:

2-3 terminals:

l-3 terminals: 23-27 R

122-148 Sz

100-120 IR

Caution

If there is a malfunction of the ground contact of the

voltage regulator even once during vehicle operation,

the excessive current flowing through the heat coil of

the water temperature gauge and the fuel gauge will

cause permanent distortion of the bimetal, resulting in

the indications being consistently lower than the actual

value.

For this reason, therefore, be sure to make the earth

contact securely.

WATER TEMPERATURE GAUGE

Measure the resistance value between the terminals by using

an ohmmeter.

Standard value:

Bimetal type

l-2 terminals: 50-80 n

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF SPEEDOMETER CABLE

Insert the cable until its stopper properly fits to the

speedometer groove.

Caution

Poor installation of the cable may cause a fluctuating

meter pointer, or noise and a damaged harness inside

the instrument panel.

) STB Revision