MITSUBISHI MONTERO 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: MONTERO, Model: MITSUBISHI MONTERO 1991Pages: 1333, PDF Size: 24.61 MB

Page 461 of 1333

length of cylinder block at several points.

If warpage exceeds specifications, deck must be resurfaced.

If warpage exceeds manufacturer's maximum tolerance for material

removal, replace block.

DECK HEIGHT

Distance from the crankshaft centerline to the block

deck is termed the deck height. Measure and record front and rear main

journals of crankshaft. To compute this distance, install crankshaft

and retain with center main bearing and cap only. Measure distance

from the crankshaft journal to the block deck, parallel to the

cylinder centerline.

Add one half of the main bearing journal diameter to distance

from crankshaft journal to block deck. This dimension should be

checked at front and rear of cylinder block. Both readings should be

the same.

If difference exceeds specifications, cylinder block must be

repaired or replaced. Deck height and warpage should be corrected at

the same time.

MAIN BEARING BORE & ALIGNMENT

For checking main bearing bore, remove all bearings from

cylinder block and main bearing caps. Install main bearing caps in

original location. Tighten bolts to specification. Using inside

micrometer, measure main bearing bore in 2 areas 90 degrees apart.

Determine bore size and out-of-round. If diameter is not within

specification, block must be align-bored.

For checking alignment, place a straightedge along centerline

of main bearing saddles. Check for clearance between straightedge and

main bearing saddles. Block must be align-bored if clearance is

present.

EXPANSION PLUG REMOVAL & INSTALLATION

Removal

Drill a hole in the center of expansion plug. Remove with

screwdriver or punch. Use care not to damage sealing surface.

Installation

Ensure sealing surface is free of burrs. Coat expansion plug

with sealer. Use a wooden dowel or pipe of slightly smaller diameter,

install expansion plug. Ensure expansion plug is evenly located.

OIL GALLERY PLUG REMOVAL & INSTALLATION

Removal

Remove threaded oil gallery plugs using the appropriate

wrench. Soft, press-in plugs are removed by drilling into plug and

installing a sheet metal screw. Remove plug with slide hammer or

pliers.

Installation

Ensure threads or sealing surface is clean. Coat threaded oil

gallery plugs with sealer and install. Replacement soft press-in plugs

are driven in place with a hammer and drift.

CAMSHAFT

* PLEASE READ THIS FIRST *

Page 462 of 1333

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

CLEANING & INSPECTION

Clean camshaft with solvent. Ensure all oil passages are

clear. Inspect cam lobes and bearing journals for pitting, flaking or

scoring. Using micrometer, measure bearing journal O.D.

Support camshaft at each end with "V" blocks. Position dial

indicator with tip resting on center bearing journal. Rotate camshaft

and note reading. If reading exceeds specification, replace camshaft.

Check cam lobe lift by measuring base circle of camshaft

using micrometer. Measure again at 90 degrees to tip of cam lobe. Cam

lift can be determined by subtracting base circle diameter from tip of

cam lobe measurement.

Different lift dimensions are given for intake and exhaust

cam lobes. Reading must be within specifications. Replace camshaft if

cam lobes or bearing journals are not within specifications.

Inspect camshaft gear for chipped, eroded or damaged teeth.

Replace gear if damaged. On camshafts using thrust plate, measure

distance between thrust plate and camshaft shoulder. Replace thrust

plate if not within specification.

CAMSHAFT BEARINGS

Removal & Installation

Remove the camshaft rear plug. The camshaft bearing remover

is assembled with its shoulder resting on the bearing to be removed

according to manufacturer's instructions. Tighten puller nut until

bearing is removed. Remove remaining bearings, leaving front and rear

bearings until last. These bearings act as guide for camshaft bearing

remover.

To install new bearings, puller is rearranged to pull

bearings toward the center of block. Ensure all lubrication passages

of bearing are aligned with cylinder block. Coat new camshaft rear

plug with sealant. Install camshaft rear plug. Ensure plug is even

in cylinder block.

CAMSHAFT INSTALLATION

Lubricate bearing surfaces and cam lobes with ample amount of

Molykote or camshaft lubricant. Carefully install camshaft. Use care

not to damage bearing journals during installation. Install thrust

plate retaining bolts (if equipped). Tighten bolts to specification.

On overhead camshafts, install bearing caps in original location.

Tighten bolts to specification. Check end play.

CAMSHAFT END PLAY

Using dial indicator, check end play. Position dial indicator

on front of engine block. Position indicator tip against camshaft.

Push camshaft toward rear of engine and adjust indicator to zero.

Move camshaft forward and note reading. Camshaft end play

must be within specification. End play may be adjusted by relocating

gear, shimming thrust plate or replacing thrust plate depending on

manufacturer.

TIMING CHAINS & BELTS

Page 463 of 1333

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

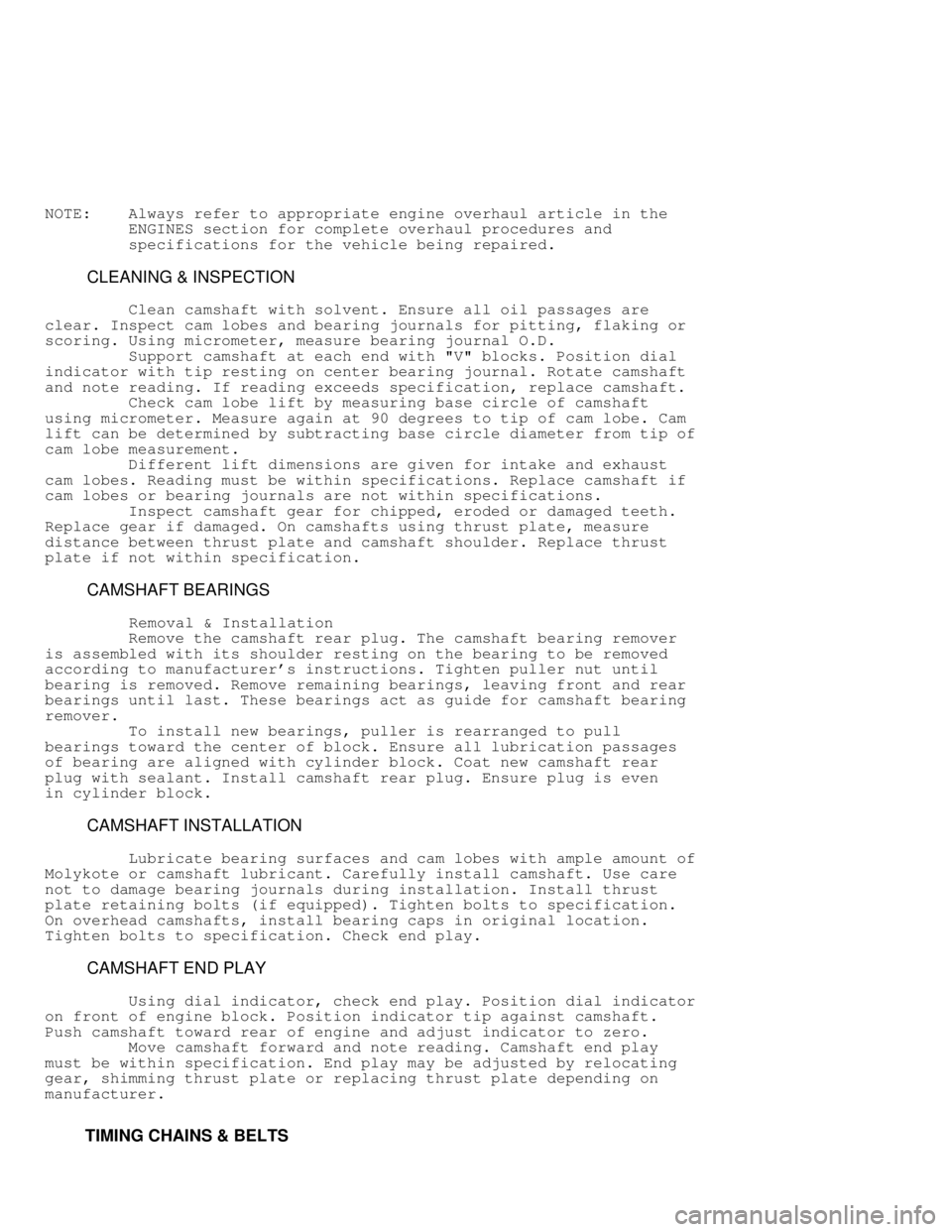

TIMING CHAINS

Timing chains will stretch during operation. Limits are

placed upon amount of stretch before replacement is required. Timing

chain stretch will alter ignition timing and valve timing.

To check timing chain stretch, rotate crankshaft to eliminate

slack from one side of timing chain. Mark reference point on cylinder

block. Rotate crankshaft in opposite direction to eliminate slack from

remaining side of timing chain. Force other side of chain outward

and measure distance between reference point and timing chain. See

Fig. 23 . Replace timing chain and gears if not within specification.

Fig. 23: Measuring Timing Chain Stretch - Typical

This Graphic For General Information Only

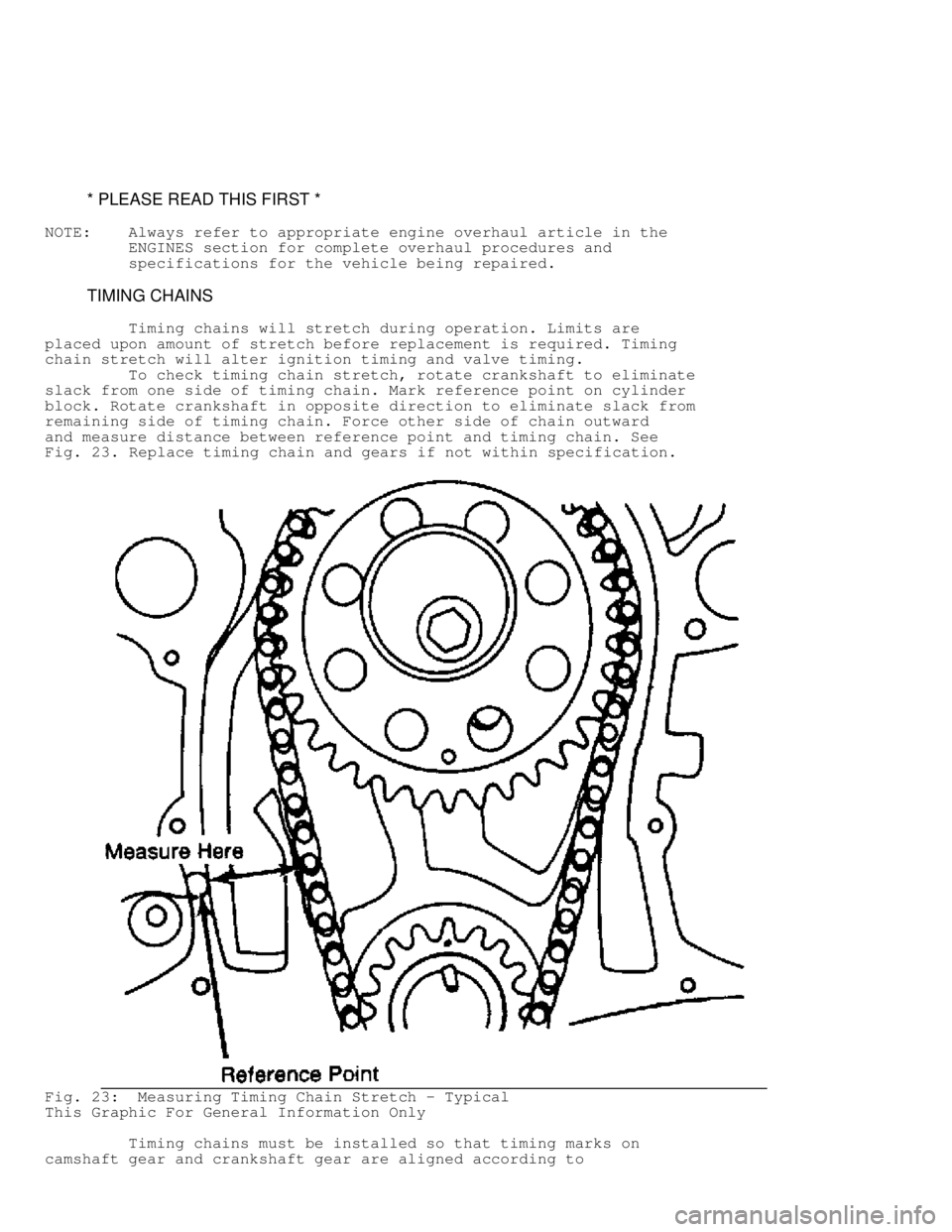

Timing chains must be installed so that timing marks on

camshaft gear and crankshaft gear are aligned according to

Page 464 of 1333

manufacturer. See Fig. 24.

Fig. 24: Timing Gear Mark Alignment - Typical

This Graphic For General Information Only

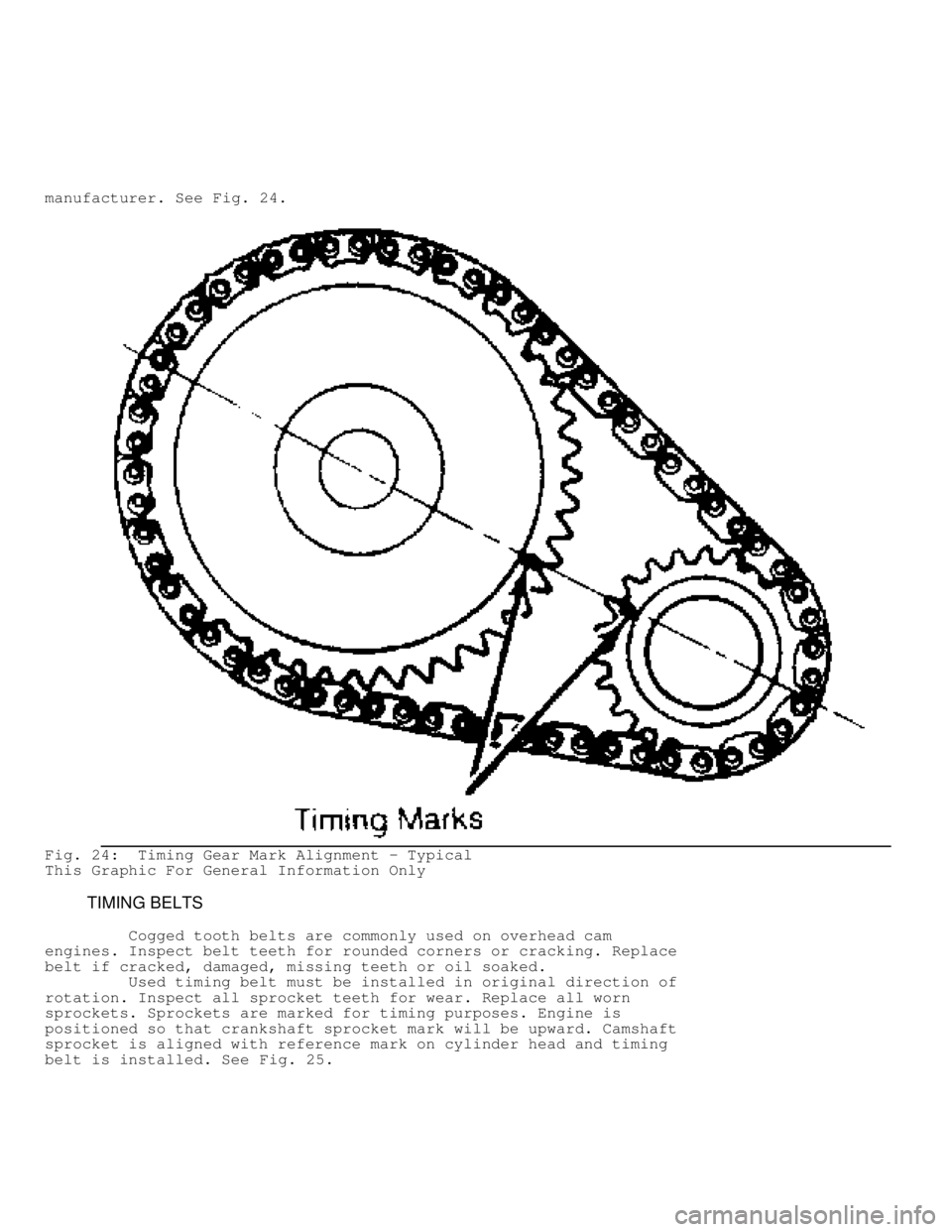

TIMING BELTS

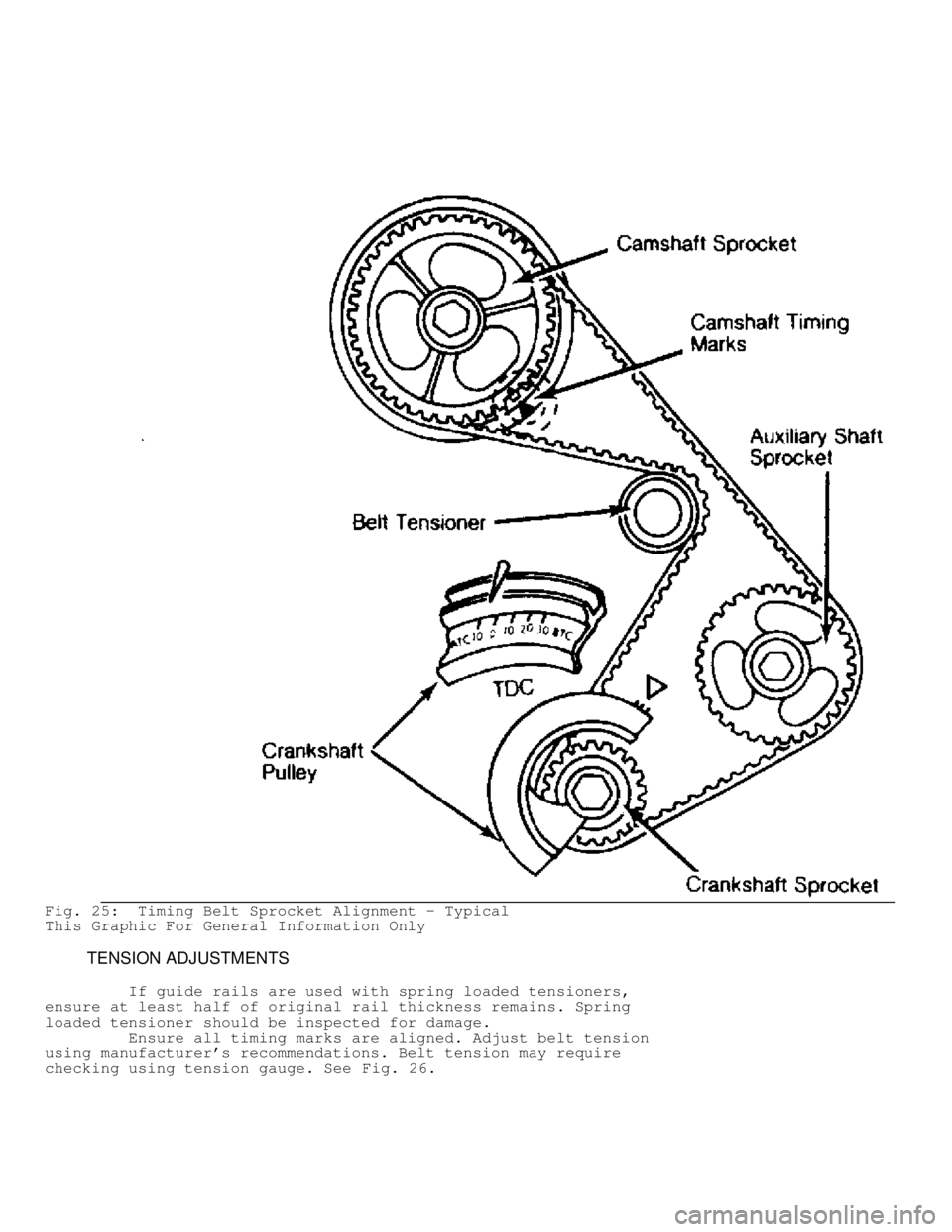

Cogged tooth belts are commonly used on overhead cam

engines. Inspect belt teeth for rounded corners or cracking. Replace

belt if cracked, damaged, missing teeth or oil soaked.

Used timing belt must be installed in original direction of

rotation. Inspect all sprocket teeth for wear. Replace all worn

sprockets. Sprockets are marked for timing purposes. Engine is

positioned so that crankshaft sprocket mark will be upward. Camshaft

sprocket is aligned with reference mark on cylinder head and timing

belt is installed. See Fig. 25.

Page 465 of 1333

Fig. 25: Timing Belt Sprocket Alignment - Typical

This Graphic For General Information Only

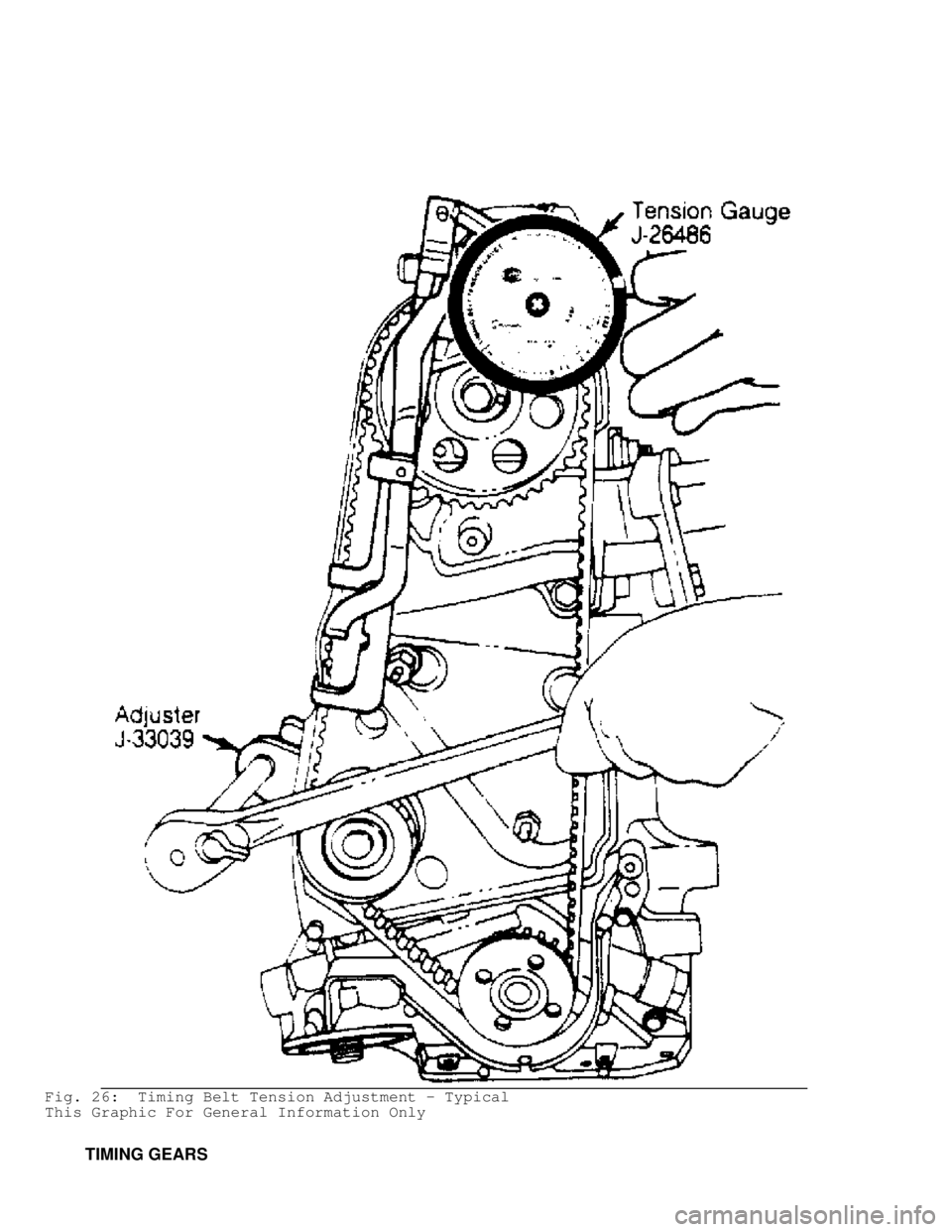

TENSION ADJUSTMENTS

If guide rails are used with spring loaded tensioners,

ensure at least half of original rail thickness remains. Spring

loaded tensioner should be inspected for damage.

Ensure all timing marks are aligned. Adjust belt tension

using manufacturer's recommendations. Belt tension may require

checking using tension gauge. See Fig. 26.

Page 466 of 1333

Fig. 26: Timing Belt Tension Adjustment - Typical

This Graphic For General Information Only

TIMING GEARS

Page 467 of 1333

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

TIMING GEAR BACKLASH & RUNOUT

On engines where camshaft gear operates directly on

crankshaft gear, gear backlash and runout must be checked. To check

backlash, install dial indicator with tip resting on tooth of camshaft

gear. Rotate camshaft gear as far as possible. Adjust indicator to

zero. Rotate camshaft gear in opposite direction as far as possible

and note reading.

To determine timing gear runout, mount dial indicator with

tip resting on face edge of camshaft gear. Adjust indicator to zero.

Rotate camshaft gear 360 degrees and note reading. If backlash or

runout exceed specifications, replace camshaft and/or crankshaft

gear.

REAR MAIN OIL SEAL

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

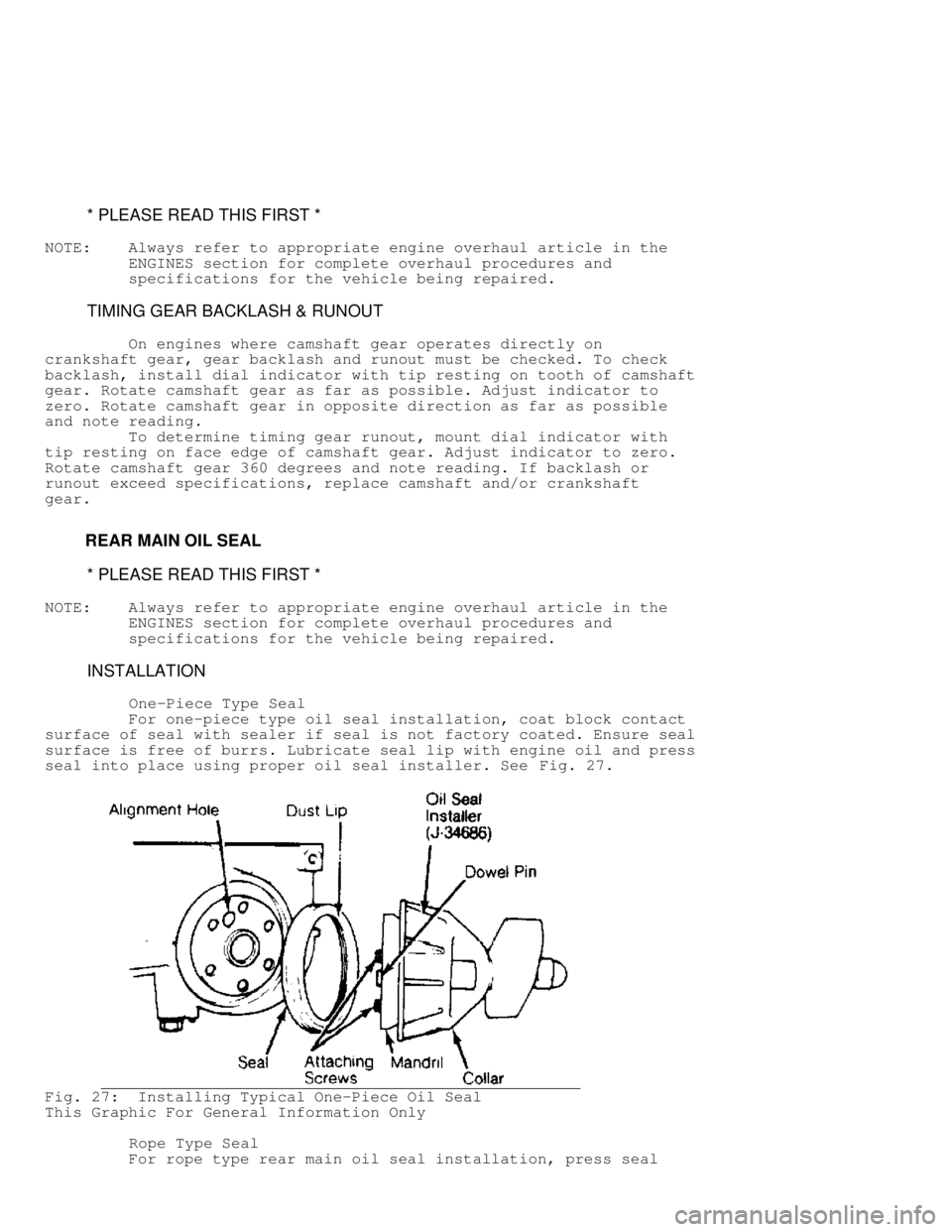

INSTALLATION

One-Piece Type Seal

For one-piece type oil seal installation, coat block contact

surface of seal with sealer if seal is not factory coated. Ensure seal

surface is free of burrs. Lubricate seal lip with engine oil and press

seal into place using proper oil seal installer. See Fig. 27.

Fig. 27: Installing Typical One-Piece Oil Seal

This Graphic For General Information Only

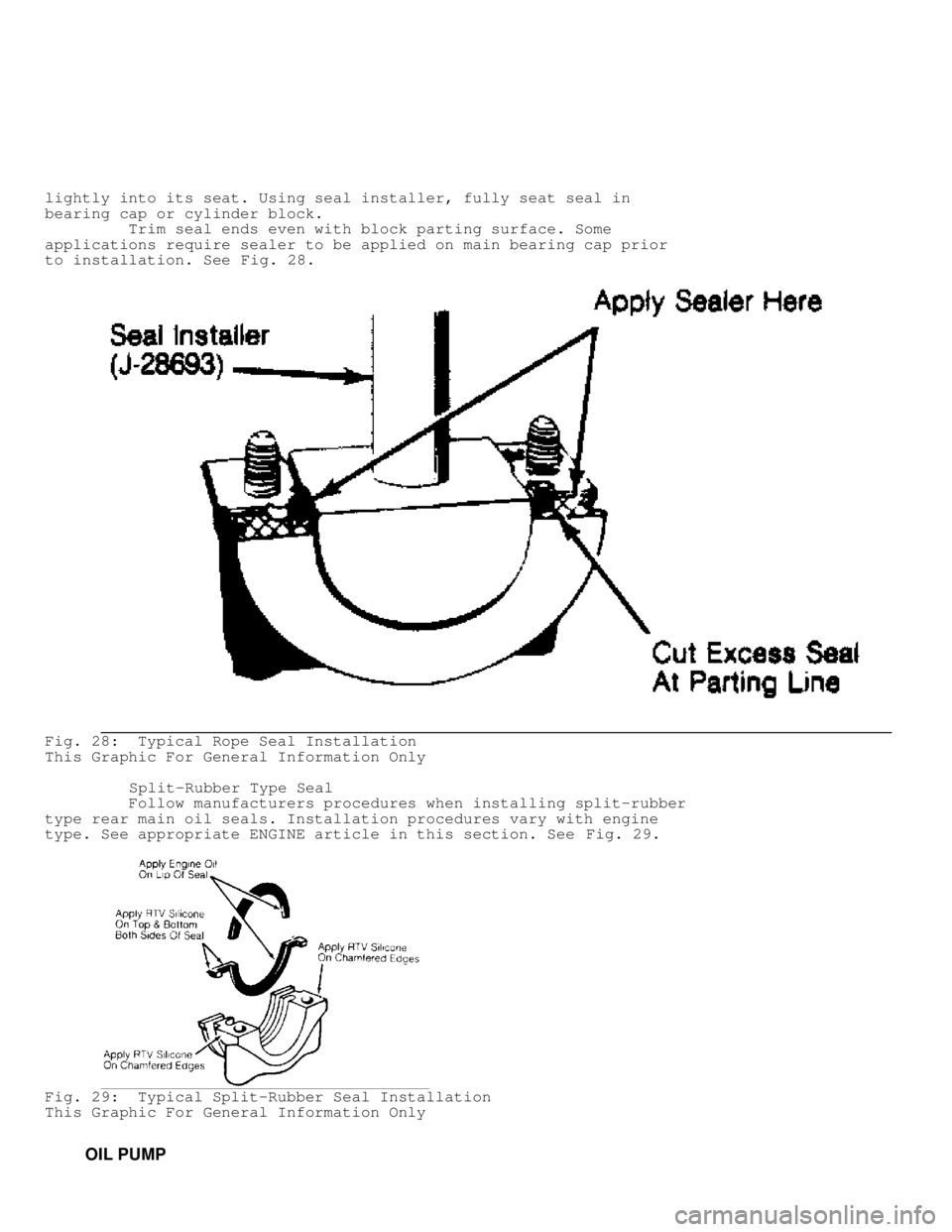

Rope Type Seal

For rope type rear main oil seal installation, press seal

Page 468 of 1333

lightly into its seat. Using seal installer, fully seat seal in

bearing cap or cylinder block.

Trim seal ends even with block parting surface. Some

applications require sealer to be applied on main bearing cap prior

to installation. See Fig. 28.

Fig. 28: Typical Rope Seal Installation

This Graphic For General Information Only

Split-Rubber Type Seal

Follow manufacturers procedures when installing split-rubber

type rear main oil seals. Installation procedures vary with engine

type. See appropriate ENGINE article in this section. See Fig. 29.

Fig. 29: Typical Split-Rubber Seal Installation

This Graphic For General Information Only

OIL PUMP

Page 469 of 1333

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

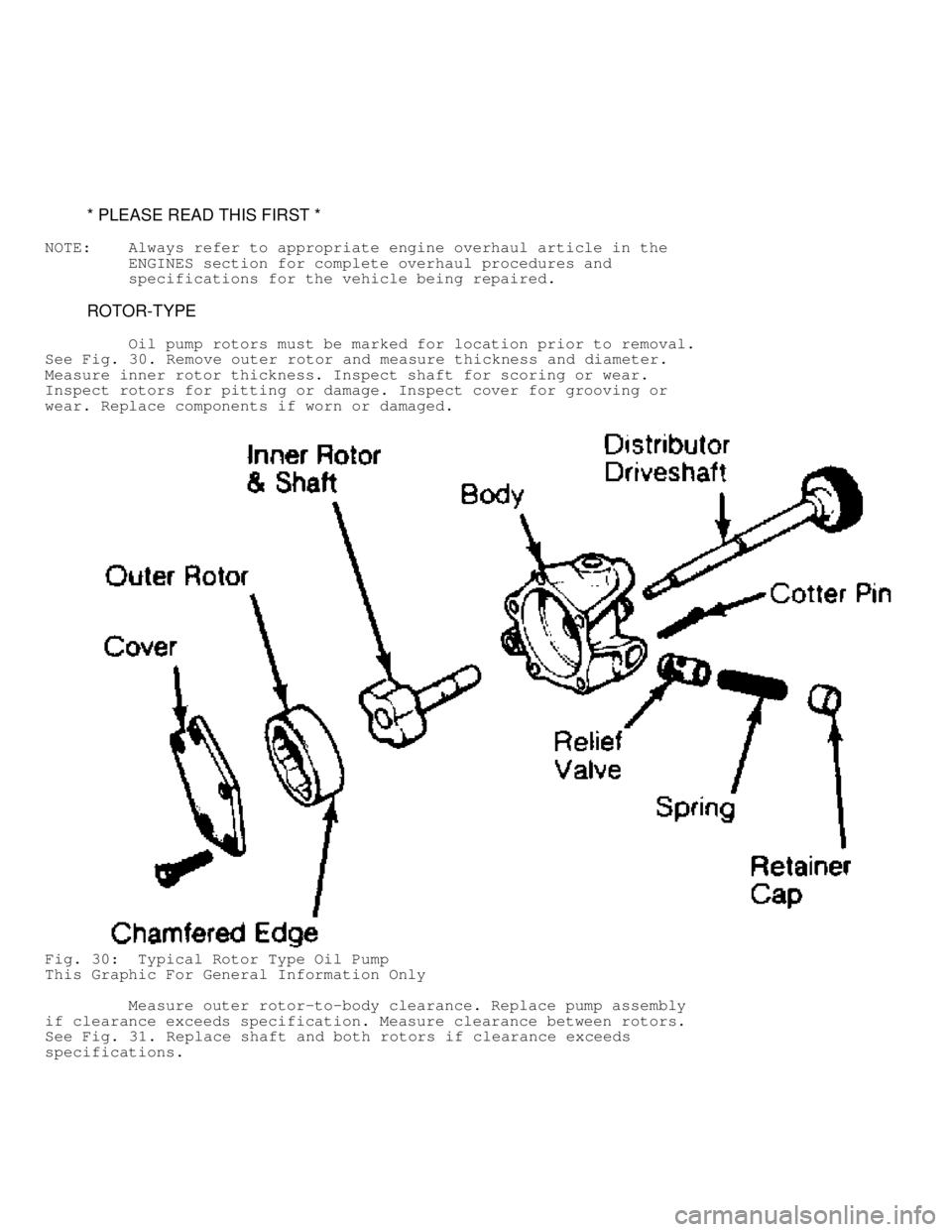

ROTOR-TYPE

Oil pump rotors must be marked for location prior to removal.

See Fig. 30 . Remove outer rotor and measure thickness and diameter.

Measure inner rotor thickness. Inspect shaft for scoring or wear.

Inspect rotors for pitting or damage. Inspect cover for grooving or

wear. Replace components if worn or damaged.

Fig. 30: Typical Rotor Type Oil Pump

This Graphic For General Information Only

Measure outer rotor-to-body clearance. Replace pump assembly

if clearance exceeds specification. Measure clearance between rotors.

See Fig. 31 . Replace shaft and both rotors if clearance exceeds

specifications.

Page 470 of 1333

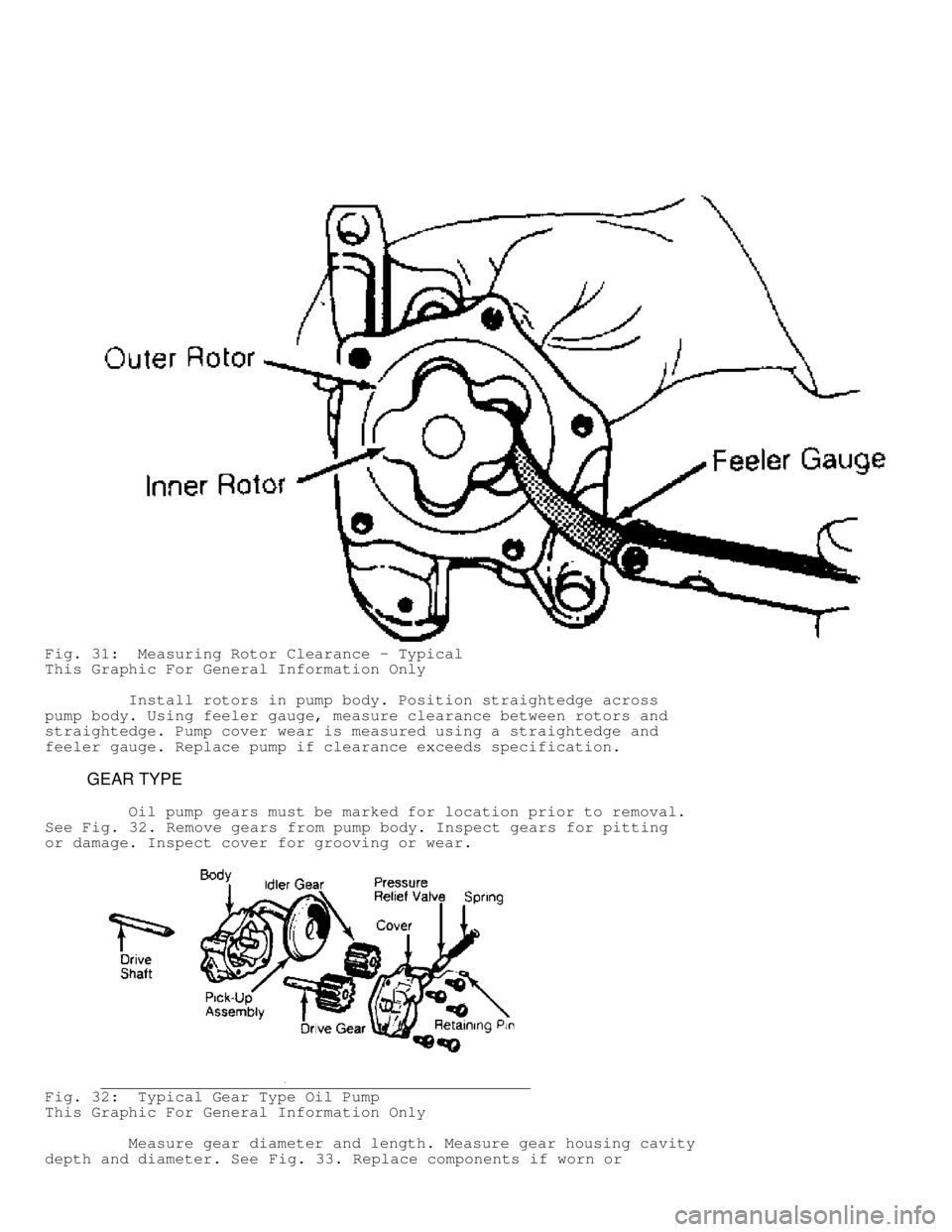

Fig. 31: Measuring Rotor Clearance - Typical

This Graphic For General Information Only

Install rotors in pump body. Position straightedge across

pump body. Using feeler gauge, measure clearance between rotors and

straightedge. Pump cover wear is measured using a straightedge and

feeler gauge. Replace pump if clearance exceeds specification.

GEAR TYPE

Oil pump gears must be marked for location prior to removal.

See Fig. 32 . Remove gears from pump body. Inspect gears for pitting

or damage. Inspect cover for grooving or wear.

Fig. 32: Typical Gear Type Oil Pump

This Graphic For General Information Only

Measure gear diameter and length. Measure gear housing cavity

depth and diameter. See Fig. 33. Replace components if worn or