jump start MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 409 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual Scan tool 16

General scan tool A/C Clutch Relay Circuit ,.

33

[Comment]Coinpressor clutch relay shortedBackgroundl control circuit defectivel The PCM provides a switched groun MITSUBISHI SPYDER 1990 Service Repair Manual Scan tool 16

General scan tool A/C Clutch Relay Circuit ,.

33

[Comment]Coinpressor clutch relay shortedBackgroundl control circuit defectivel The PCM provides a switched groun](/img/19/57345/w960_57345-408.png)

Scan tool 16

General scan tool A/C Clutch Relay Circuit ,.

33

[Comment]Coinpressor clutch relay shortedBackgroundl control circuit defectivel The PCM provides a switched ground to the clutch relay.

l circuit driver in PCMlThe PCM can prevent operation of the clutch in selected situations such as duringwide-open or for a period at start-up.l This DTC indicates an open or short-circuit conditi on in the circuit.Range of Checkl Ignition ONl Battery voltage: or morel 30 seconds or more after starting engineSet ConditionlOpen or short circuit is detected in the A/C clutch relay control circuit for 3 seconds.

N G relay. Replace

. .

. 55 On-vehicle Service) me (Refer to GROUF

OK

Measure at the PCM connectors and lDisconnect the connector, and measure at the harnes s side.

l Voltage between 36 and ground, and 64 and ground

(Ignition switch: ON)

switch: ON)

OK: Battery positive

l Connect a jumper wire between and the ground.

(Ignition switch: ON)

(A/C switch: ON)

OK:

compressor clutch is turned on

N G

Check the system (Refer to GROUP 55 Troubleshooting) Check trouble symptom.

NG

Replace the . ,

I ,

TSB Revision

Page 636 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

Analyzer

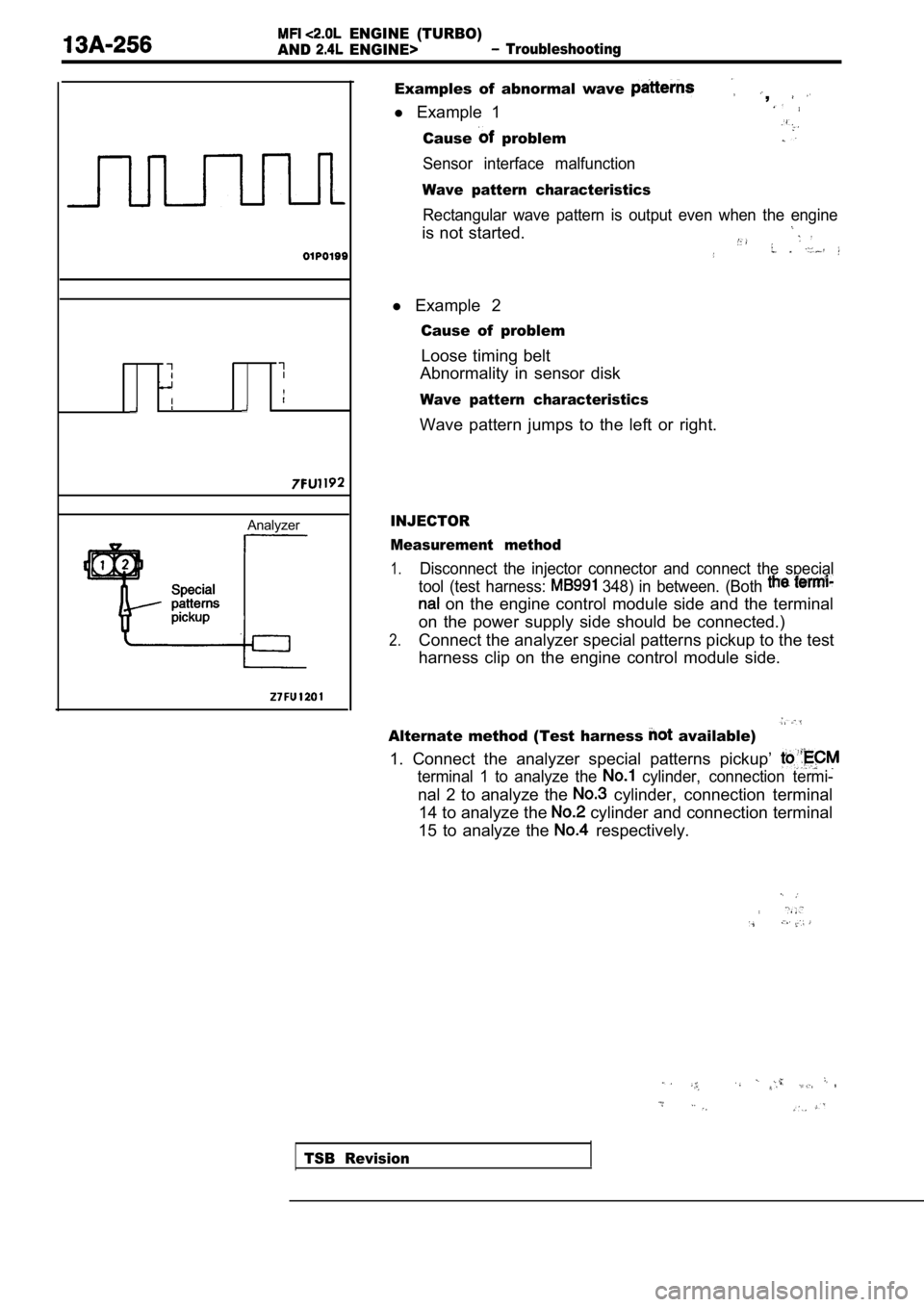

Examples of abnormal wave ,

l Example 1

Cause problem

Sensor interface malfunction

Wave pattern characteristics

Rectangular wave pattern is output even when the en gine

is not started.

l Example 2

Cause of problem

Loose timing belt

Abnormality in sensor disk

Wave pattern characteristics

Wave pattern jumps to the left or right.

INJECTOR

Measurement method

1.Disconnect the injector connector and connect the s pecial

tool (test harness:

348) in between. (Both

on the engine control module side and the terminal

on the power supply side should be connected.)

2.Connect the analyzer special patterns pickup to the test

harness clip on the engine control module side.

Alternate method (Test harness available)

1. Connect the analyzer special patterns pickup’

terminal 1 to analyze the cylinder, connection termi-

nal 2 to analyze the cylinder, connection terminal

14 to analyze the

cylinder and connection terminal

15 to analyze the

respectively.

TSB Revision

Page 770 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise Control

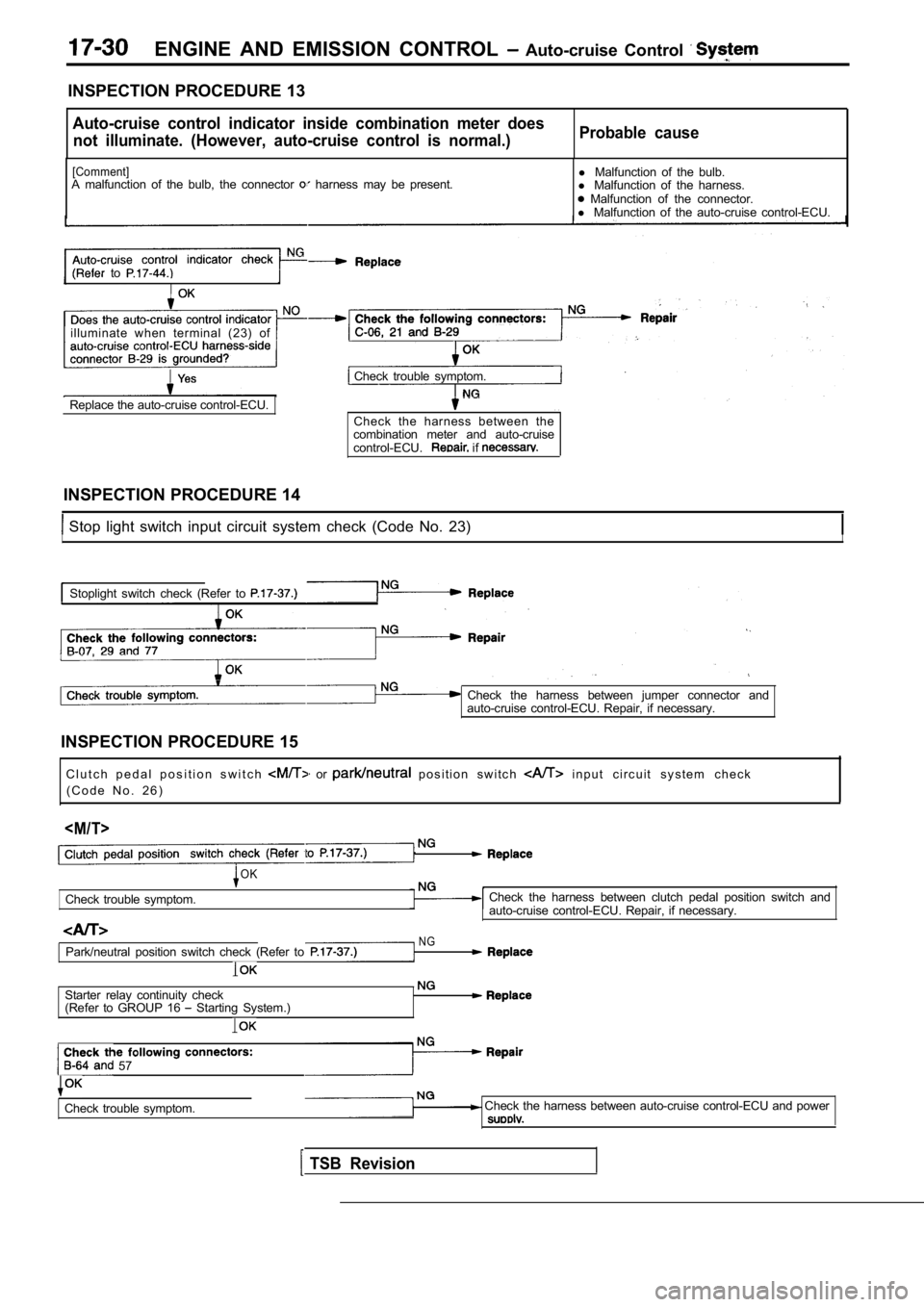

INSPECTION PROCEDURE 13

Auto-cruise control indicator inside combination meter does

not illuminate. (However, auto-cruise control is no rmal.)Probable cause

[Comment]A malfunction of the bulb, the connector harness may be present. l

Malfunction of the bulb.

l Malfunction of the harness. Malfunction of the connector.

l Malfunction of the auto-cruise control-ECU.

to

illuminate when terminal (23) of

Check trouble symptom.

Replace the auto-cruise control-ECU. Check the harness between the

combination meter and auto-cruise

control-ECU.

if

INSPECTION PROCEDURE 14

Stop light switch input circuit system check (Code No. 23)II

Stoplight switch check (Refer to

Check the harness between jumper connector and

auto-cruise control-ECU. Repair, if necessary.

INSPECTION PROCEDURE 15 C l u t c h p e d a l p o s i t i o n s w i t c h

or p o s i t i o n s w i t c h i n p u t c i r c u i t s y s t e m c h e c k

( C o d e N o . 2 6 )

Check trouble symptom.

OK

NG

Check the harness between clutch pedal position swi tch and

auto-cruise control-ECU. Repair, if necessary.

Park/neutral position switch check (Refer to

Starter relay continuity check

(Refer to GROUP 16 Starting System.)

57

Check trouble symptom. Check the harness between auto-cruise control-ECU and power

TSB Revision

Page 779 of 2103

C o n t r o l

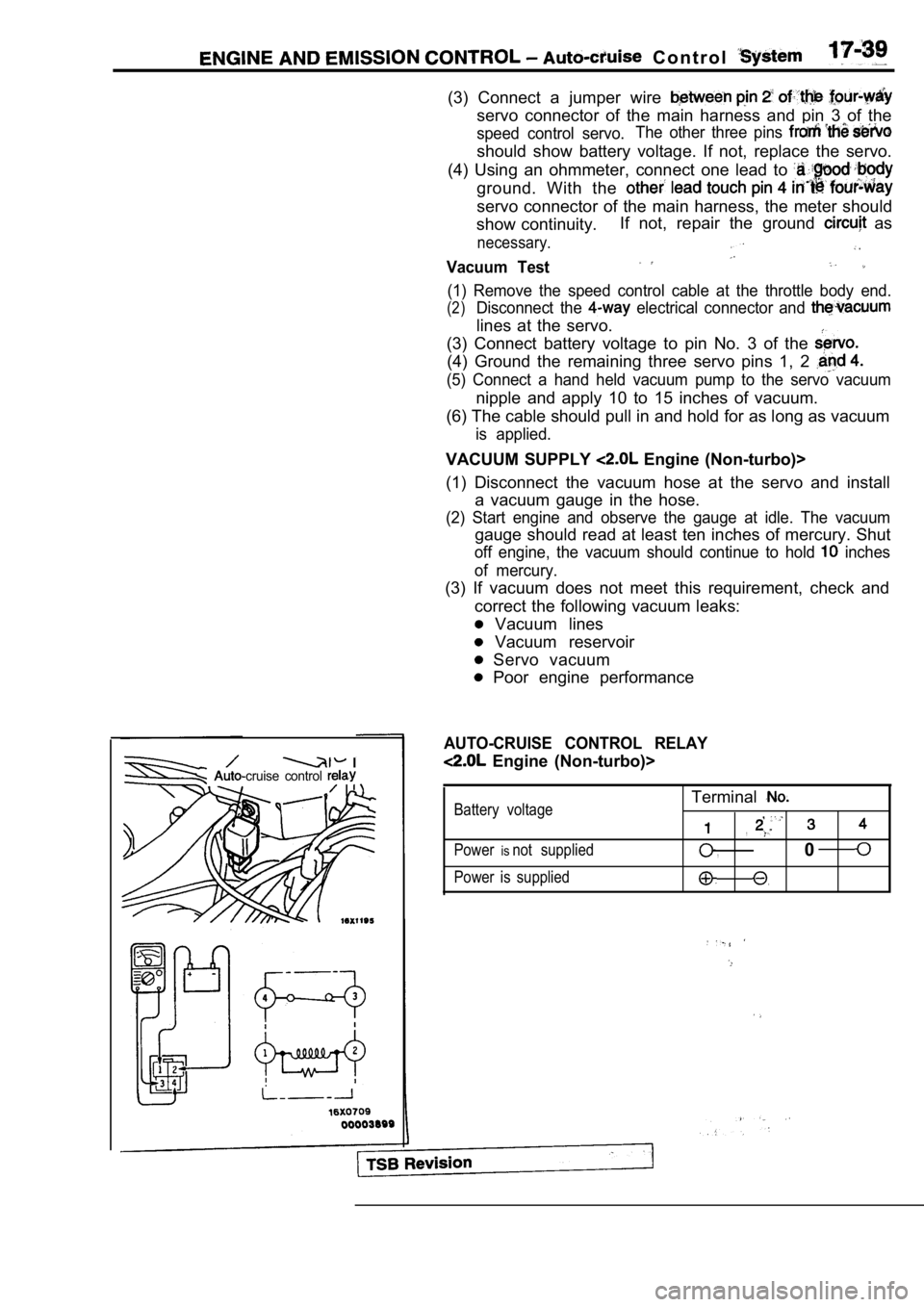

(3) Connect a jumper wire

servo connector of the main harness and pin 3 of the

speed control servo.The other three pins

should show battery voltage. If not, replace the se

rvo.

(4) Using an ohmmeter, connect one lead to

ground. With the

servo connector of the main harness, the meter shou ld

show continuity. If not, repair the ground

as

necessary. .

Vacuum Test

(1) Remove the speed control cable at the throttle

body end.

(2)Disconnect the electrical connector and

lines at the servo.

(3) Connect battery voltage to pin No. 3 of the

(4) Ground the remaining three servo pins 1, 2

(5) Connect a hand held vacuum pump to the servo va cuum

nipple and apply 10 to 15 inches of vacuum.

(6) The cable should pull in and hold for as long a s vacuum

is applied.

VACUUM SUPPLY Engine (Non-turbo)>

(1) Disconnect the vacuum hose at the servo and ins tall

a vacuum gauge in the hose.

(2) Start engine and observe the gauge at idle. The vacuum

gauge should read at least ten inches of mercury. Shut

off engine, the vacuum should continue to hold inches

of mercury.

(3) If vacuum does not meet this requirement, check and

correct the following vacuum leaks:

Vacuum lines

Vacuum reservoir

Servo vacuum

Poor engine performance

I-cruise control

AUTO-CRUISE CONTROL RELAY

Engine (Non-turbo)>

Battery voltage

Power

isnot supplied

Power is supplied

Terminal

,

,

,0

Page 796 of 2103

ENGINE AND

Emission Control System

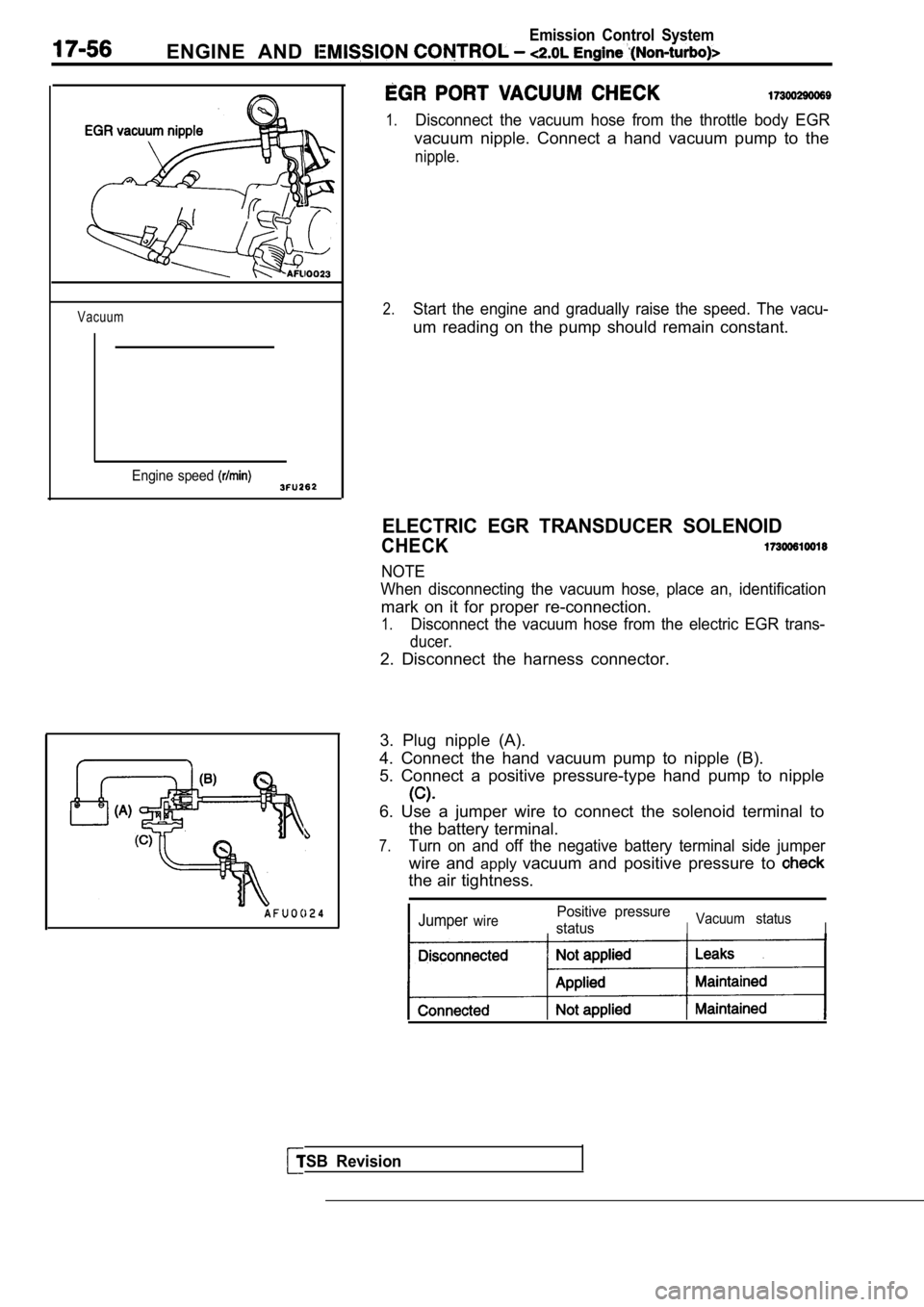

Vacuum

Engine speed

TSB Revision

4I

1.Disconnect the vacuum hose from the throttle body EGR

vacuum nipple. Connect a hand vacuum pump to the

nipple.

2.Start the engine and gradually raise the speed. The vacu-

um reading on the pump should remain constant.

ELECTRIC EGR TRANSDUCER SOLENOID

CHECK

NOTE

When disconnecting the vacuum hose, place an, ident ification

mark on it for proper re-connection.

1.Disconnect the vacuum hose from the electric EGR trans-

ducer.

2. Disconnect the harness connector.

3. Plug nipple (A).

4. Connect the hand vacuum pump to nipple (B).

5. Connect a positive pressure-type hand pump to ni pple

6. Use a jumper wire to connect the solenoid terminal to

the battery terminal.

7.Turn on and off the negative battery terminal side jumper

wire and applyvacuum and positive pressure to

the air tightness.

JumperwirePositive pressure

status

IVacuum statusI