clock NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 858 of 2898

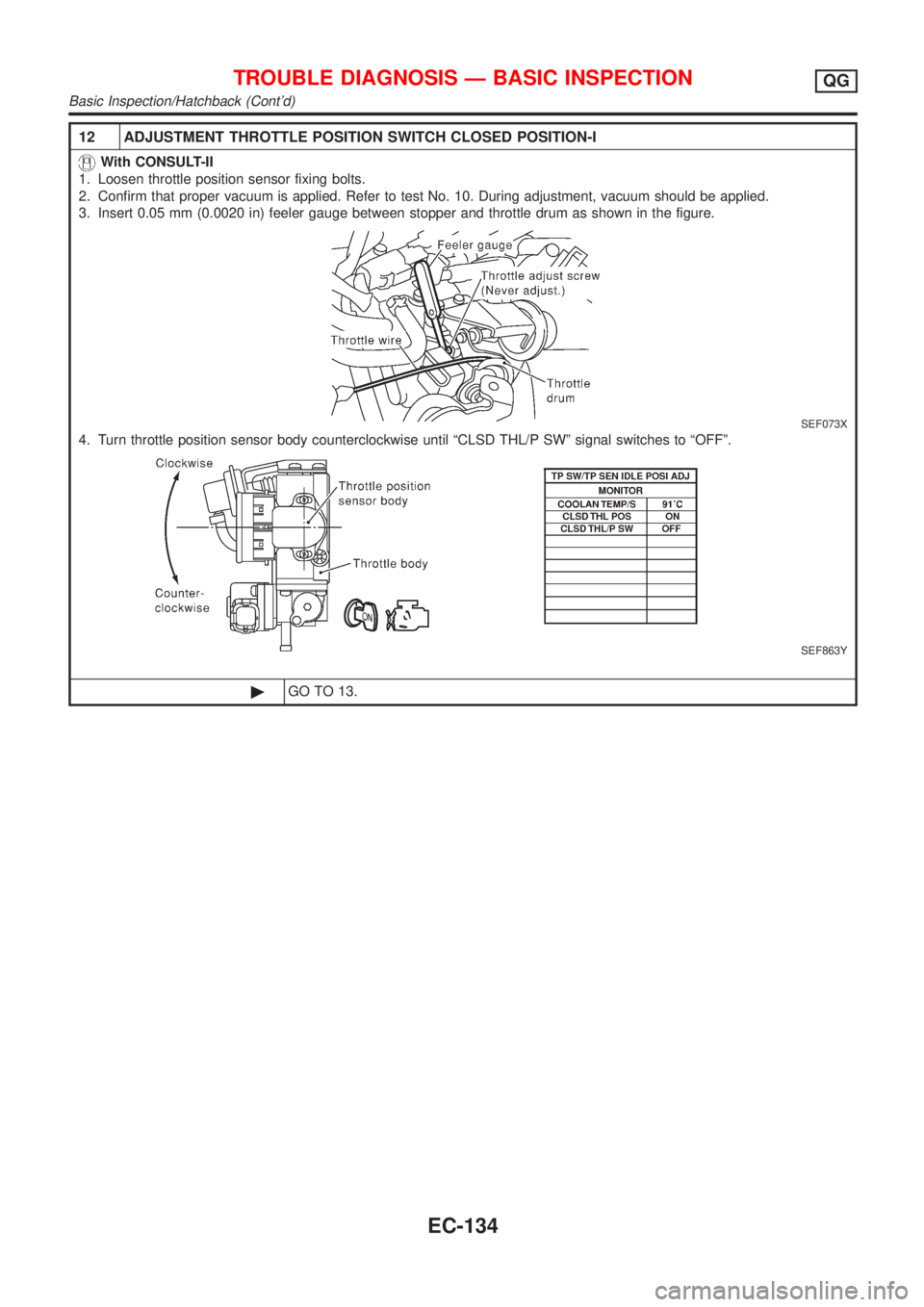

12 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-I

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Confirm that proper vacuum is applied. Refer to test No. 10. During adjustment, vacuum should be applied.

3. Insert 0.05 mm (0.0020 in) feeler gauge between stopper and throttle drum as shown in the figure.

SEF073X

4. Turn throttle position sensor body counterclockwise until ªCLSD THL/P SWº signal switches to ªOFFº.

SEF863Y

©GO TO 13.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-134

Page 859 of 2898

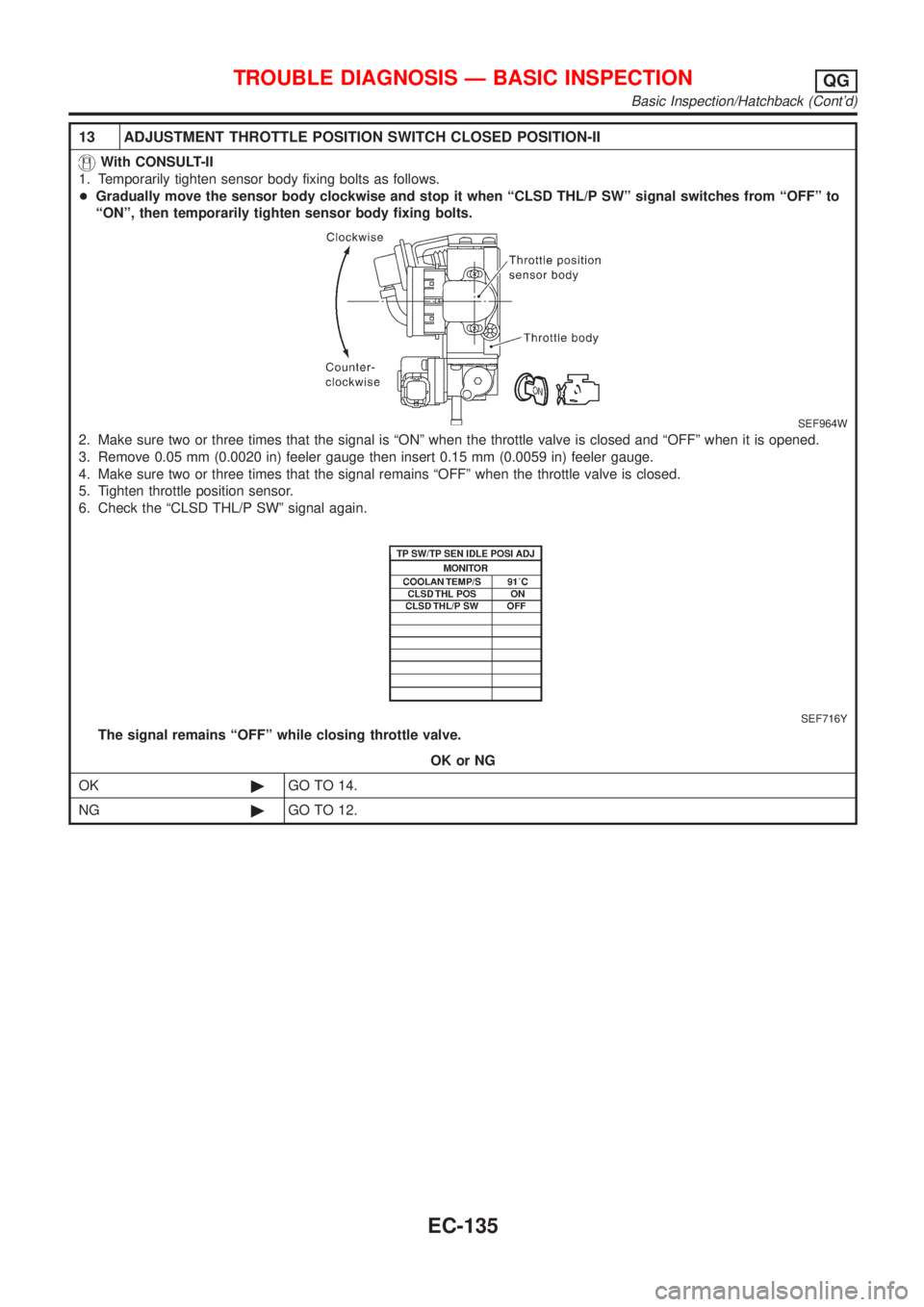

13 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

With CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

+Gradually move the sensor body clockwise and stop it when ªCLSD THL/P SWº signal switches from ªOFFº to

ªONº, then temporarily tighten sensor body fixing bolts.

SEF964W

2. Make sure two or three times that the signal is ªONº when the throttle valve is closed and ªOFFº when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the signal remains ªOFFº when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the ªCLSD THL/P SWº signal again.

SEF716Y

The signal remains ªOFFº while closing throttle valve.

OK or NG

OK©GO TO 14.

NG©GO TO 12.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-135

Page 862 of 2898

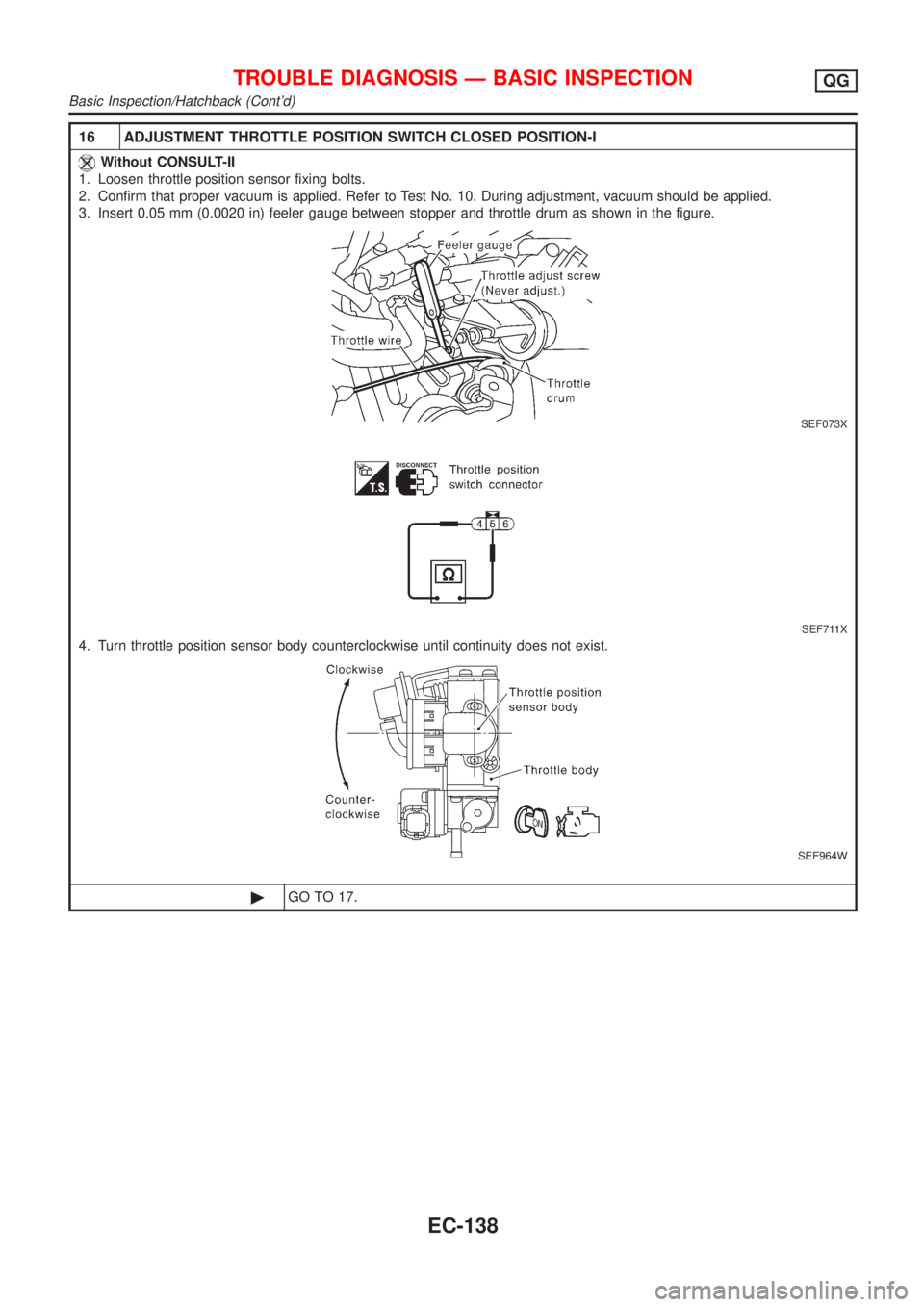

16 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-I

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Confirm that proper vacuum is applied. Refer to Test No. 10. During adjustment, vacuum should be applied.

3. Insert 0.05 mm (0.0020 in) feeler gauge between stopper and throttle drum as shown in the figure.

SEF073X

SEF711X

4. Turn throttle position sensor body counterclockwise until continuity does not exist.

SEF964W

©GO TO 17.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-138

Page 863 of 2898

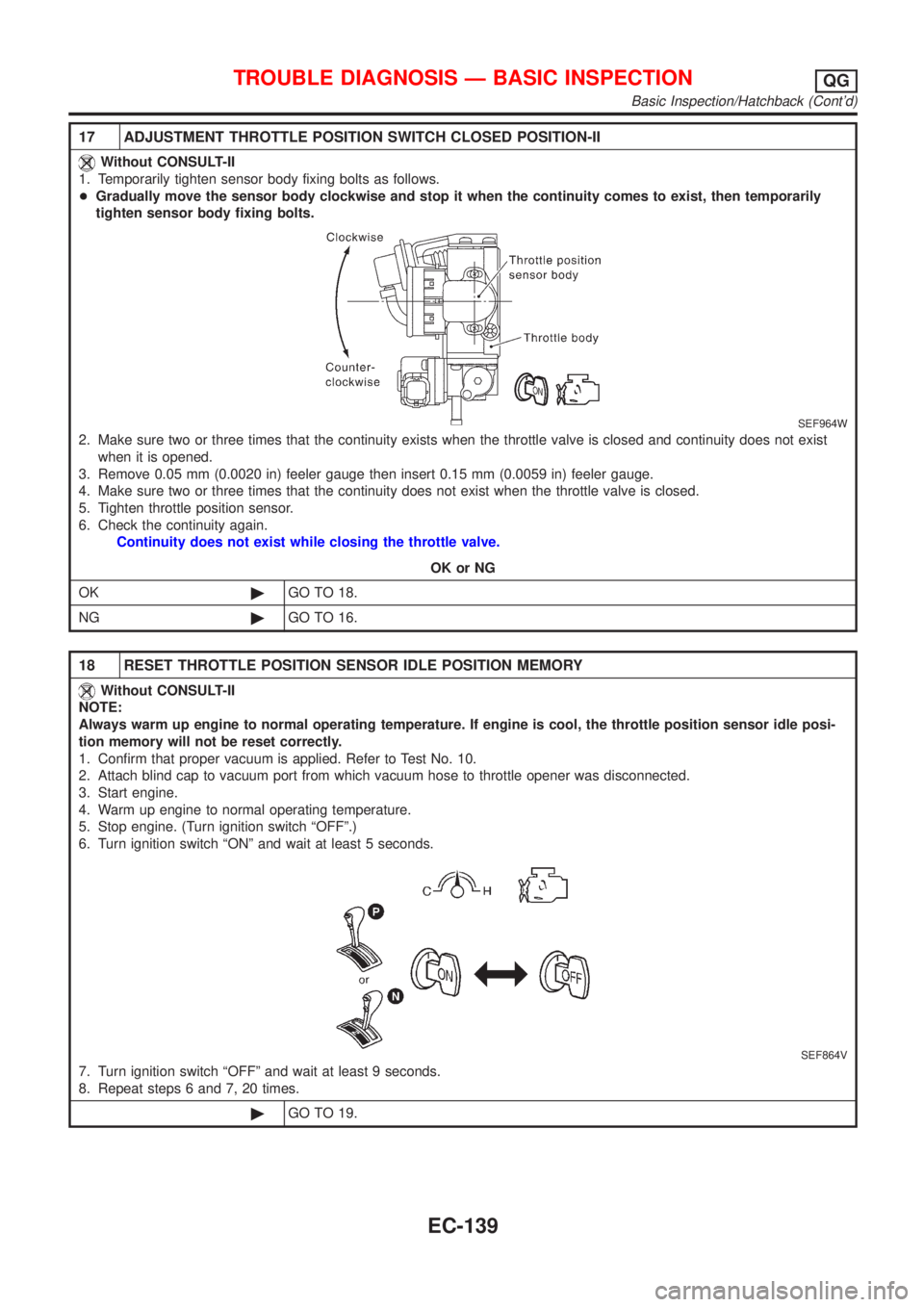

17 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

Without CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

+Gradually move the sensor body clockwise and stop it when the continuity comes to exist, then temporarily

tighten sensor body fixing bolts.

SEF964W

2. Make sure two or three times that the continuity exists when the throttle valve is closed and continuity does not exist

when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the continuity does not exist when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the continuity again.

Continuity does not exist while closing the throttle valve.

OK or NG

OK©GO TO 18.

NG©GO TO 16.

18 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Confirm that proper vacuum is applied. Refer to Test No. 10.

2. Attach blind cap to vacuum port from which vacuum hose to throttle opener was disconnected.

3. Start engine.

4. Warm up engine to normal operating temperature.

5. Stop engine. (Turn ignition switch ªOFFº.)

6. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

7. Turn ignition switch ªOFFº and wait at least 9 seconds.

8. Repeat steps 6 and 7, 20 times.

©GO TO 19.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-139

Page 870 of 2898

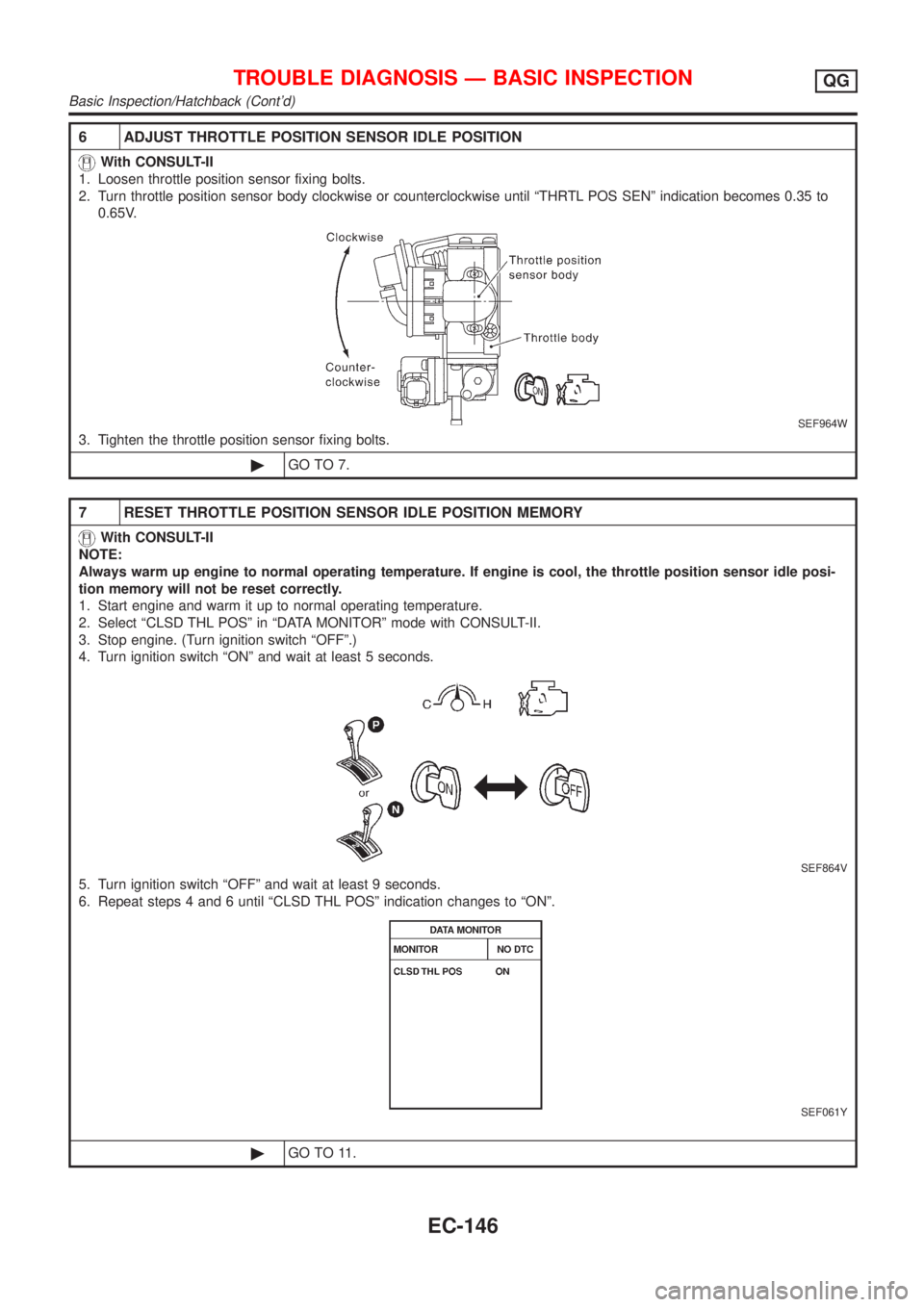

6 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to

0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

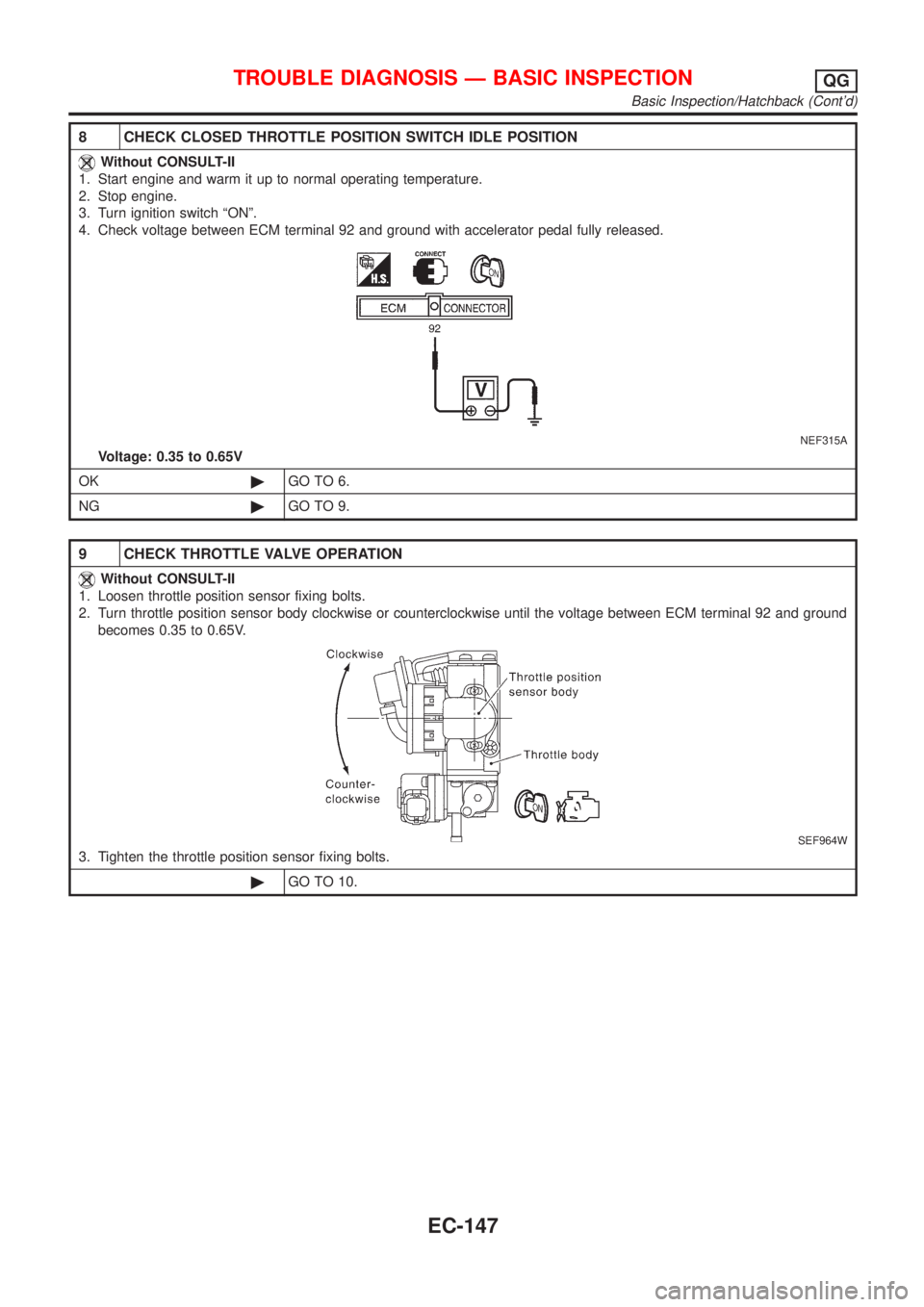

7 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Select ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

3. Stop engine. (Turn ignition switch ªOFFº.)

4. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

5. Turn ignition switch ªOFFº and wait at least 9 seconds.

6. Repeat steps 4 and 6 until ªCLSD THL POSº indication changes to ªONº.

SEF061Y

©GO TO 11.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-146

Page 871 of 2898

8 CHECK CLOSED THROTTLE POSITION SWITCH IDLE POSITION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Check voltage between ECM terminal 92 and ground with accelerator pedal fully released.

NEF315A

Voltage: 0.35 to 0.65V

OK©GO TO 6.

NG©GO TO 9.

9 CHECK THROTTLE VALVE OPERATION

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until the voltage between ECM terminal 92 and ground

becomes 0.35 to 0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 10.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Hatchback (Cont'd)

EC-147

Page 1340 of 2898

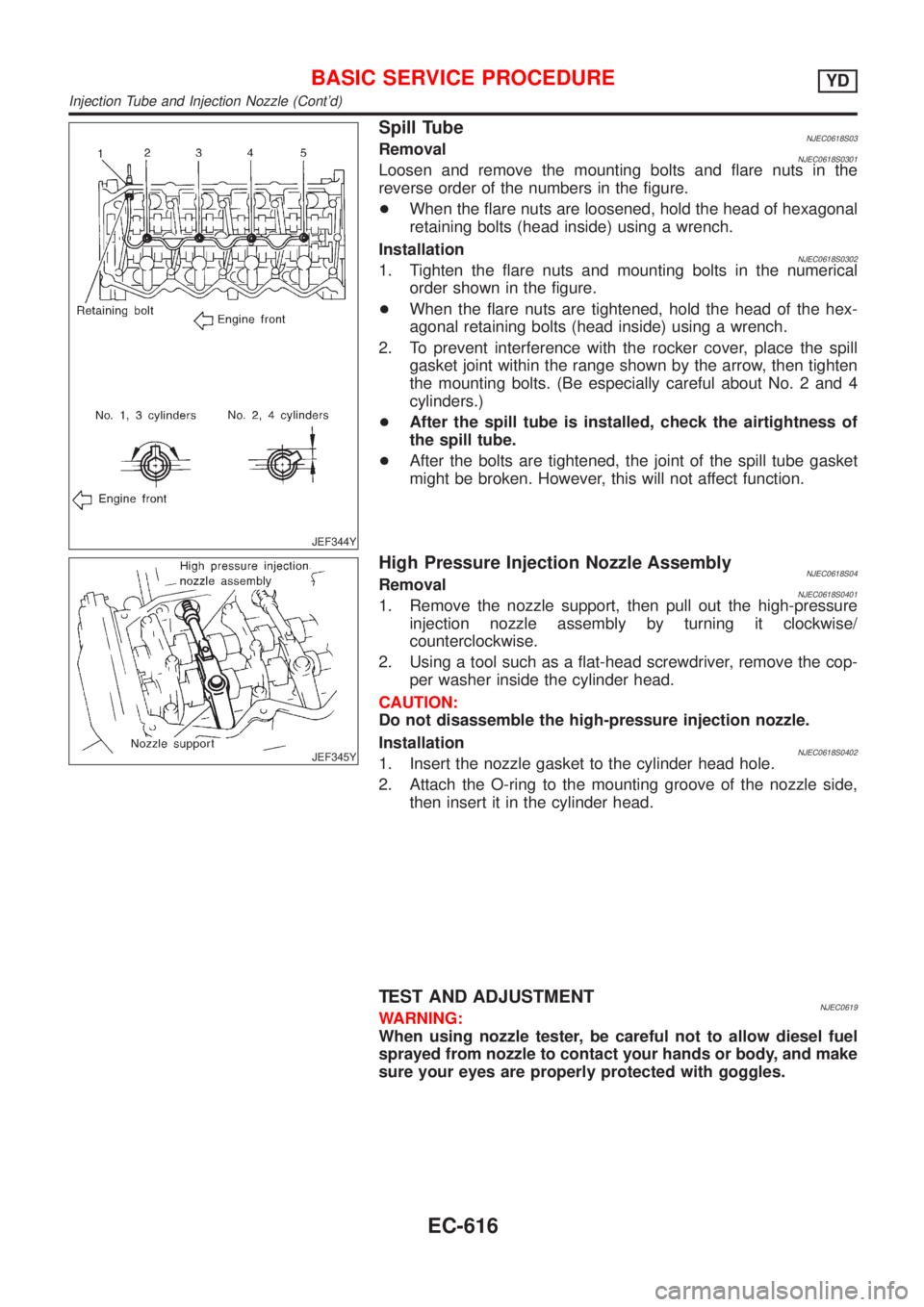

JEF344Y

Spill TubeNJEC0618S03RemovalNJEC0618S0301Loosen and remove the mounting bolts and flare nuts in the

reverse order of the numbers in the figure.

+When the flare nuts are loosened, hold the head of hexagonal

retaining bolts (head inside) using a wrench.

Installation

NJEC0618S03021. Tighten the flare nuts and mounting bolts in the numerical

order shown in the figure.

+When the flare nuts are tightened, hold the head of the hex-

agonal retaining bolts (head inside) using a wrench.

2. To prevent interference with the rocker cover, place the spill

gasket joint within the range shown by the arrow, then tighten

the mounting bolts. (Be especially careful about No. 2 and 4

cylinders.)

+After the spill tube is installed, check the airtightness of

the spill tube.

+After the bolts are tightened, the joint of the spill tube gasket

might be broken. However, this will not affect function.

JEF345Y

High Pressure Injection Nozzle AssemblyNJEC0618S04RemovalNJEC0618S04011. Remove the nozzle support, then pull out the high-pressure

injection nozzle assembly by turning it clockwise/

counterclockwise.

2. Using a tool such as a flat-head screwdriver, remove the cop-

per washer inside the cylinder head.

CAUTION:

Do not disassemble the high-pressure injection nozzle.

Installation

NJEC0618S04021. Insert the nozzle gasket to the cylinder head hole.

2. Attach the O-ring to the mounting groove of the nozzle side,

then insert it in the cylinder head.

TEST AND ADJUSTMENTNJEC0619WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and make

sure your eyes are properly protected with goggles.

BASIC SERVICE PROCEDUREYD

Injection Tube and Injection Nozzle (Cont'd)

EC-616

Page 1343 of 2898

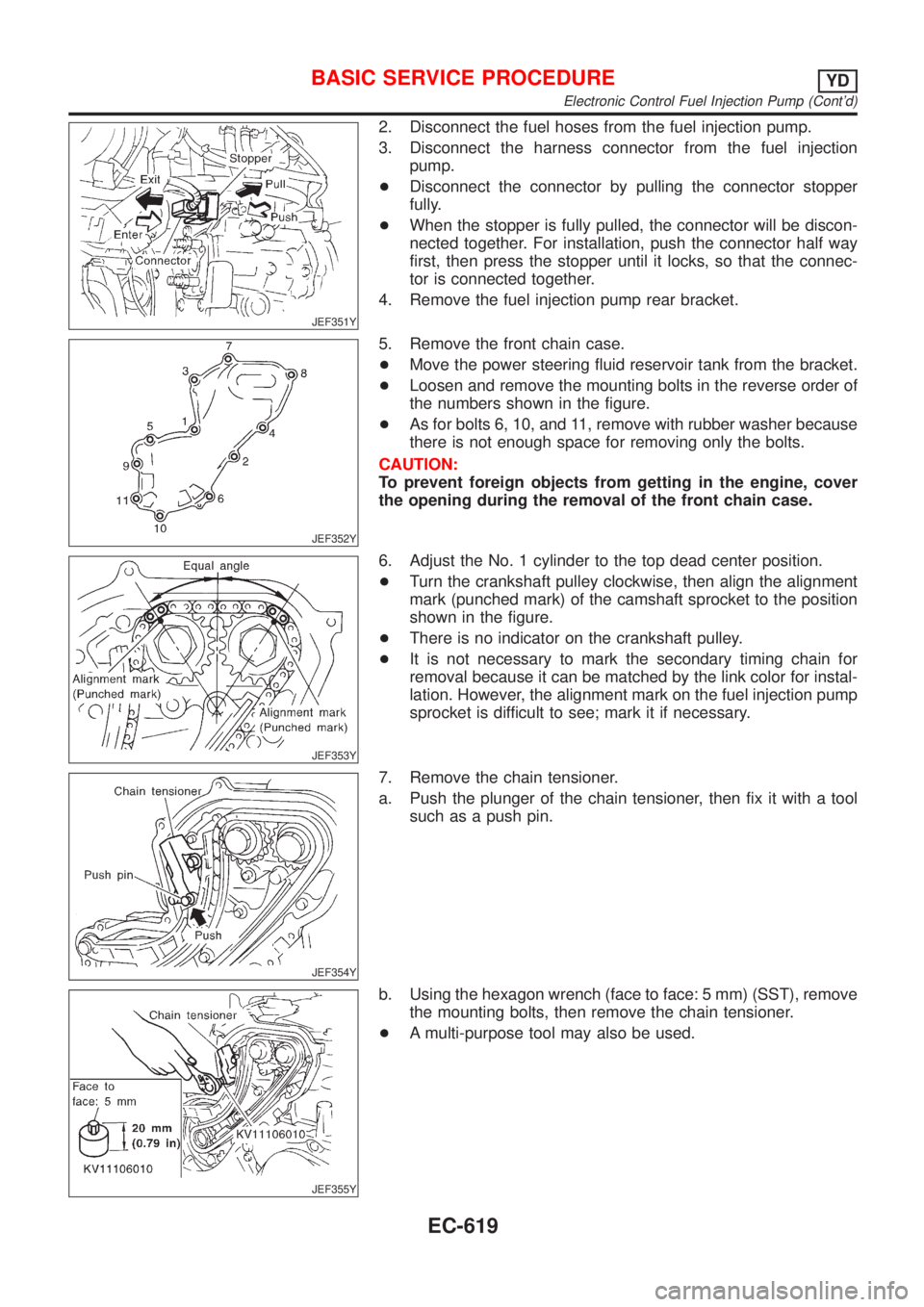

JEF351Y

2. Disconnect the fuel hoses from the fuel injection pump.

3. Disconnect the harness connector from the fuel injection

pump.

+Disconnect the connector by pulling the connector stopper

fully.

+When the stopper is fully pulled, the connector will be discon-

nected together. For installation, push the connector half way

first, then press the stopper until it locks, so that the connec-

tor is connected together.

4. Remove the fuel injection pump rear bracket.

JEF352Y

5. Remove the front chain case.

+Move the power steering fluid reservoir tank from the bracket.

+Loosen and remove the mounting bolts in the reverse order of

the numbers shown in the figure.

+As for bolts 6, 10, and 11, remove with rubber washer because

there is not enough space for removing only the bolts.

CAUTION:

To prevent foreign objects from getting in the engine, cover

the opening during the removal of the front chain case.

JEF353Y

6. Adjust the No. 1 cylinder to the top dead center position.

+Turn the crankshaft pulley clockwise, then align the alignment

mark (punched mark) of the camshaft sprocket to the position

shown in the figure.

+There is no indicator on the crankshaft pulley.

+It is not necessary to mark the secondary timing chain for

removal because it can be matched by the link color for instal-

lation. However, the alignment mark on the fuel injection pump

sprocket is difficult to see; mark it if necessary.

JEF354Y

7. Remove the chain tensioner.

a. Push the plunger of the chain tensioner, then fix it with a tool

such as a push pin.

JEF355Y

b. Using the hexagon wrench (face to face: 5 mm) (SST), remove

the mounting bolts, then remove the chain tensioner.

+A multi-purpose tool may also be used.

BASIC SERVICE PROCEDUREYD

Electronic Control Fuel Injection Pump (Cont'd)

EC-619

Page 1424 of 2898

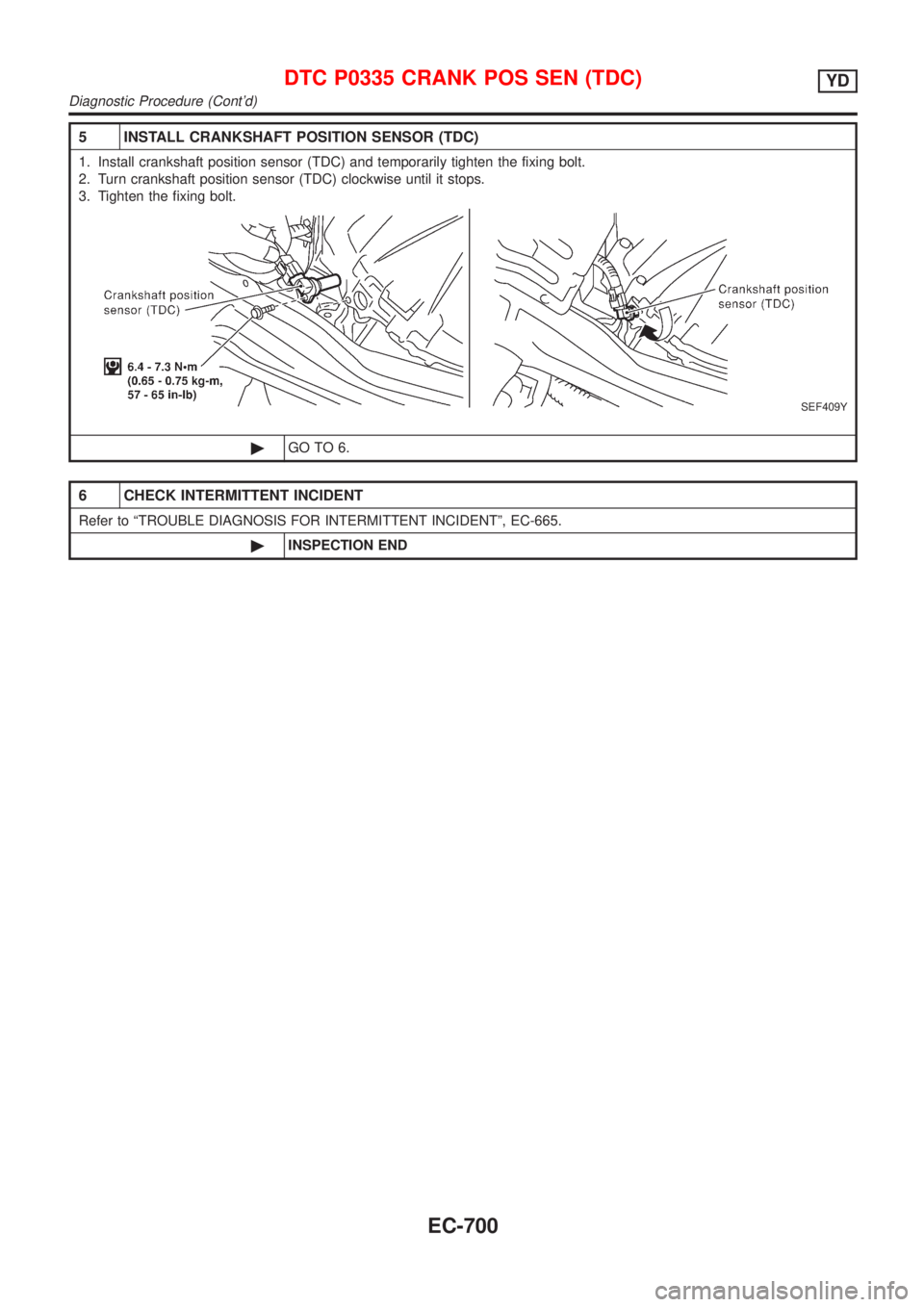

5 INSTALL CRANKSHAFT POSITION SENSOR (TDC)

1. Install crankshaft position sensor (TDC) and temporarily tighten the fixing bolt.

2. Turn crankshaft position sensor (TDC) clockwise until it stops.

3. Tighten the fixing bolt.

SEF409Y

©GO TO 6.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-665.

©INSPECTION END

DTC P0335 CRANK POS SEN (TDC)YD

Diagnostic Procedure (Cont'd)

EC-700

Page 1560 of 2898

Wiring Diagram - ROOM/L -/Sedan With Interior

Room Lamp Timer ................................................... 117

Trouble Diagnoses/Sedan With Interior Room

Lamp Timer .............................................................. 119

System Description/Hatchback With Interior

Room Lamp Timer ...................................................127

Wiring Diagram - ROOM/L -/Hatchback With

Interior Room Lamp Timer.......................................129

Trouble Diagnoses/Hatchback With Interior

Room Lamp Timer ...................................................131

Wiring Diagram - ROOM/L -/Sedan Without

Timer ........................................................................139

Wiring Diagram - ROOM/L -/Hatchback Without

Timer ........................................................................140

SPOT AND TRUNK ROOM LAMPS...........................141

Wiring Diagram - INT/L -/Sedan ..............................141

Wiring Diagram - INT/L -/Hatchback .......................143

METERS AND GAUGES.............................................144

Component Parts and Harness Connector

Location/Sedan ........................................................144

System Description/Sedan ......................................144

Combination Meter/Sedan With Tachometer...........146

Schematic/Sedan With Tachometer ........................147

Combination Meter/Without Tachometer .................148

Schematic/Without Tachometer ...............................149

Construction/Sedan .................................................150

Wiring Diagram - METER -/Without Tachometer ....151

Wiring Diagram - METER -/Sedan ..........................152

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode/Sedan.............153

Trouble Diagnoses/Sedan .......................................154

Electrical Components Inspection/Sedan ................162

Component Parts and Harness Connector

Location/Hatchback .................................................164

System Description/Hatchback ................................164

Combination Meter/Hatchback (Models before

VIN No. - N16U0135126) ........................................166

Combination Meter/Hatchback (Models after VIN

No. - N16U0135126) ...............................................167

Schematic/Hatchback (Models before VIN No. -

N160135126) ...........................................................168

Schematic/Hatchback (Models after VIN No. -

N16U0135126).........................................................169

Construction/Hatchback ...........................................170

Wiring Diagram - METER -/Hatchback ...................171

Combination Meter Self-Diagnosis/Hatchback ........173

Trouble Diagnoses/Hatchback.................................176

Electrical Components Inspection/Hatchback .........183

WARNING LAMPS......................................................184

Schematic/Sedan .....................................................184

Wiring Diagram - WARN -/Sedan ............................185

Schematic/Hatchback ..............................................189Wiring Diagram - WARN -/Hatchback .....................190

Electrical Components Inspection ...........................194

A/T INDICATOR...........................................................195

Wiring Diagram - AT/IND -/With Tachometer...........195

Wiring Diagram - AT/IND -/Without Tachometer......196

WARNING CHIME.......................................................197

Component Parts and Harness Connector

Location/Sedan ........................................................197

System Description/Sedan ......................................198

Wiring Diagram - CHIME -/Sedan ...........................199

Trouble Diagnoses/Sedan .......................................200

Component Parts and Harness Connector

Location/Hatchback .................................................205

System Description/Hatchback ................................206

Wiring Diagram - CHIME -/Hatchback ....................207

Trouble Diagnoses/Hatchback.................................209

FRONT WIPER AND WASHER..................................215

System Description/Sedan ......................................215

Wiring Diagram - WIPER -/Sedan ...........................217

System Description/Hatchback ................................218

Wiring Diagram - WIPER -/Hatchback ....................220

Removal and Installation .........................................222

Washer Nozzle Adjustment .....................................223

Washer Tube Layout ...............................................224

REAR WIPER AND WASHER....................................225

Wiring Diagram - WIP/R -/Sedan ............................225

Wiring Diagram - WIP/R -/Hatchback......................227

Removal and Installation .........................................229

Washer Nozzle Adjustment .....................................229

Washer Tube Layout ...............................................230

HEADLAMP WASHER................................................231

Wiring Diagram - HLC -/Sedan ...............................231

Wiring Diagram - HLC -/Hatchback .........................232

Washer Tube Layout ...............................................233

HORN...........................................................................234

Wiring Diagram - HORN -/Sedan ............................234

Wiring Diagram - HORN -/Hatchback .....................235

CIGARETTE LIGHTER................................................236

Wiring Diagram - CIGAR -/Sedan ...........................236

Wiring Diagram - CIGAR -/Hatchback.....................237

CLOCK.........................................................................238

Wiring Diagram - CLOCK -/Sedan ..........................238

Wiring Diagram - CLOCK -/Hatchback....................239

REAR WINDOW DEFOGGER.....................................240

System Description/Sedan ......................................240

Wiring Diagram - DEF -/Sedan ...............................242

Trouble Diagnoses/Sedan .......................................246

System Description/Hatchback ................................249

Wiring Diagram - DEF -/Hatchback .........................250

Trouble Diagnoses/Hatchback.................................252

Electrical Components Inspection ...........................255

Filament Check ........................................................256

CONTENTS(Cont'd)

EL-2