NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: air bleeding, key battery, torque, seats, fuse box, ESP inoperative, jacking

Page 2811 of 2898

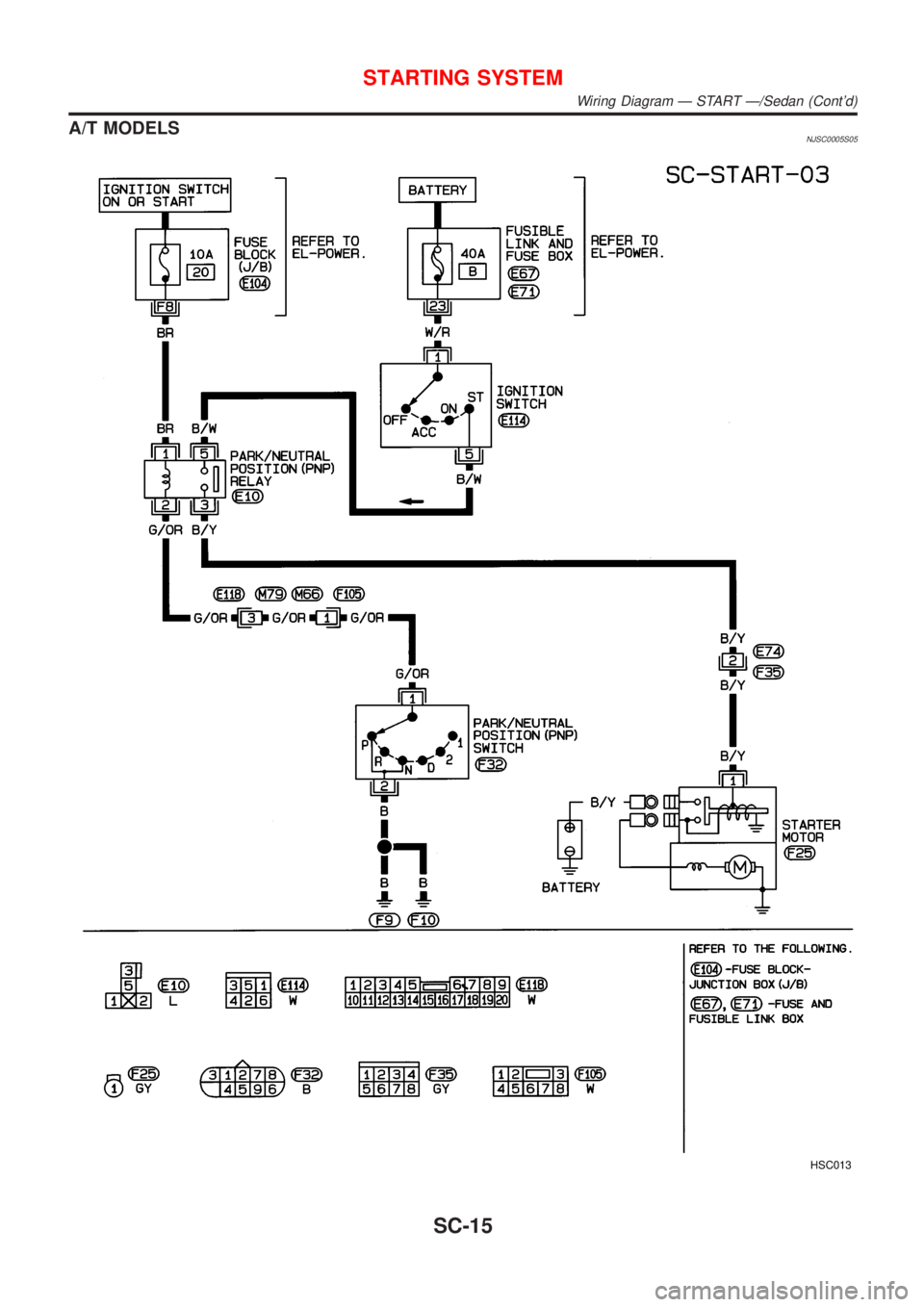

A/T MODELSNJSC0005S05

HSC013

STARTING SYSTEM

Wiring Diagram Ð START Ð/Sedan (Cont'd)

SC-15

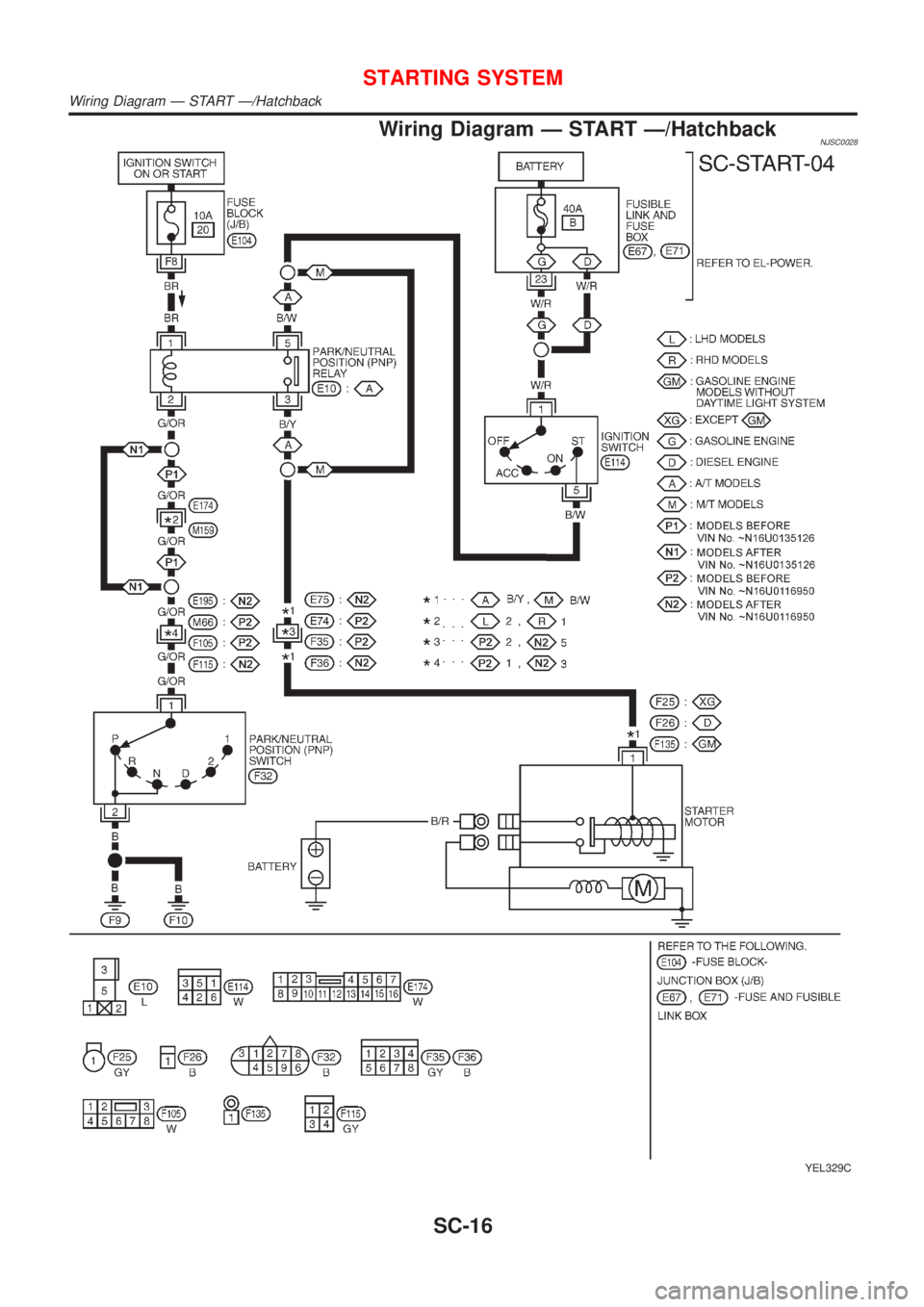

Page 2812 of 2898

Wiring Diagram Ð START Ð/HatchbackNJSC0028

YEL329C

STARTING SYSTEM

Wiring Diagram Ð START Ð/Hatchback

SC-16

Page 2813 of 2898

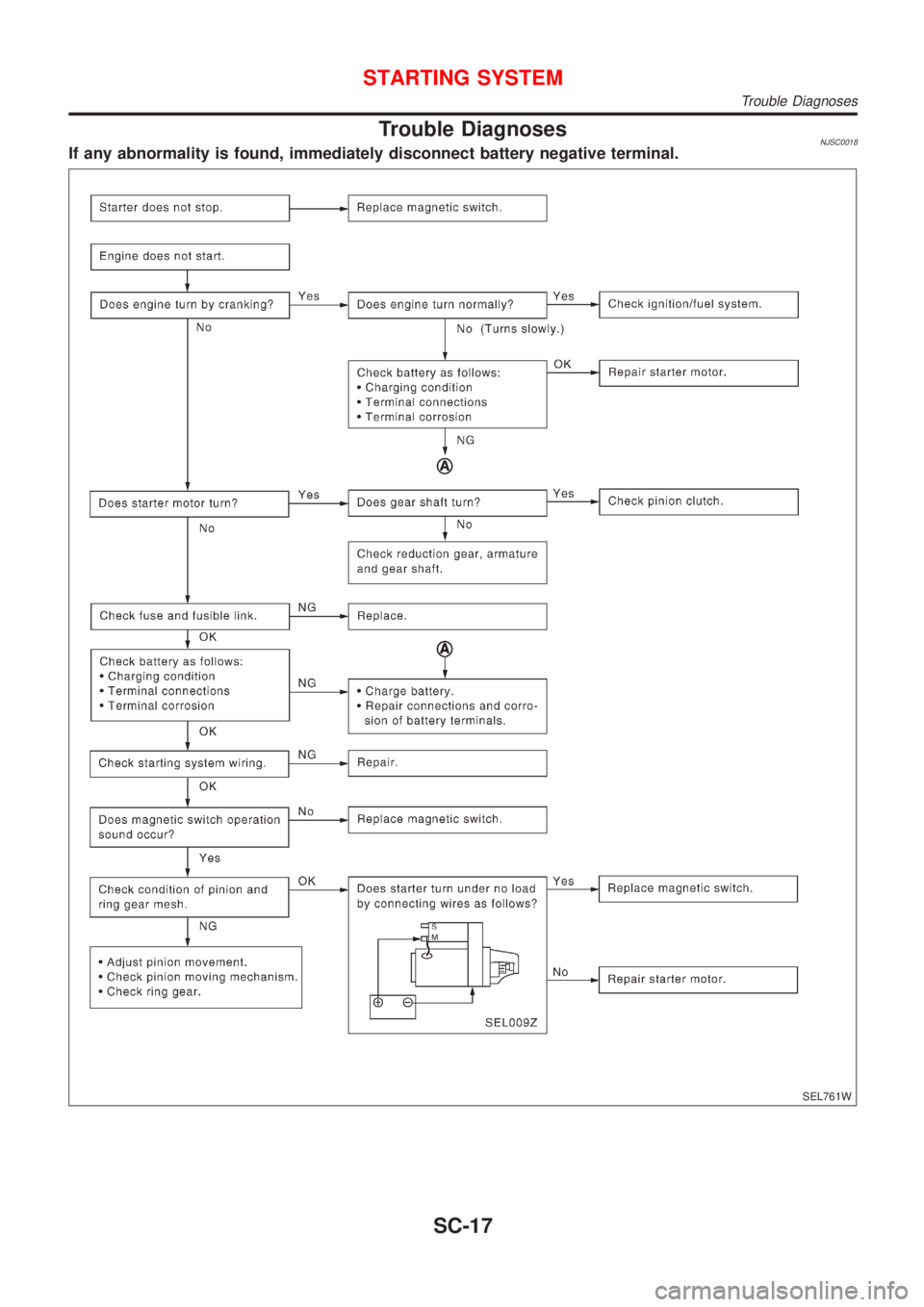

Trouble DiagnosesNJSC0018If any abnormality is found, immediately disconnect battery negative terminal.

SEL761W

STARTING SYSTEM

Trouble Diagnoses

SC-17

Page 2814 of 2898

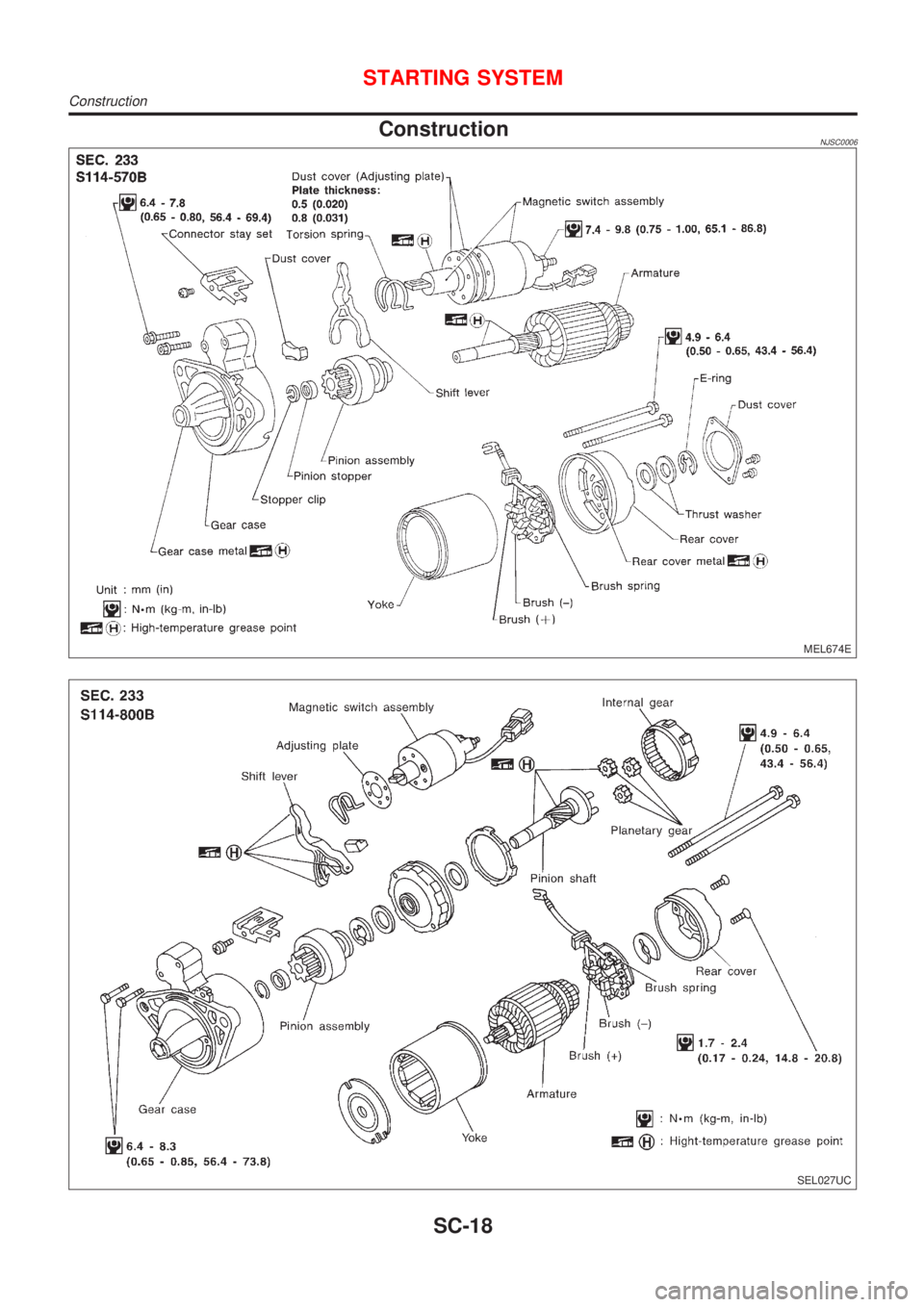

ConstructionNJSC0006

MEL674E

SEL027UC

STARTING SYSTEM

Construction

SC-18

Page 2815 of 2898

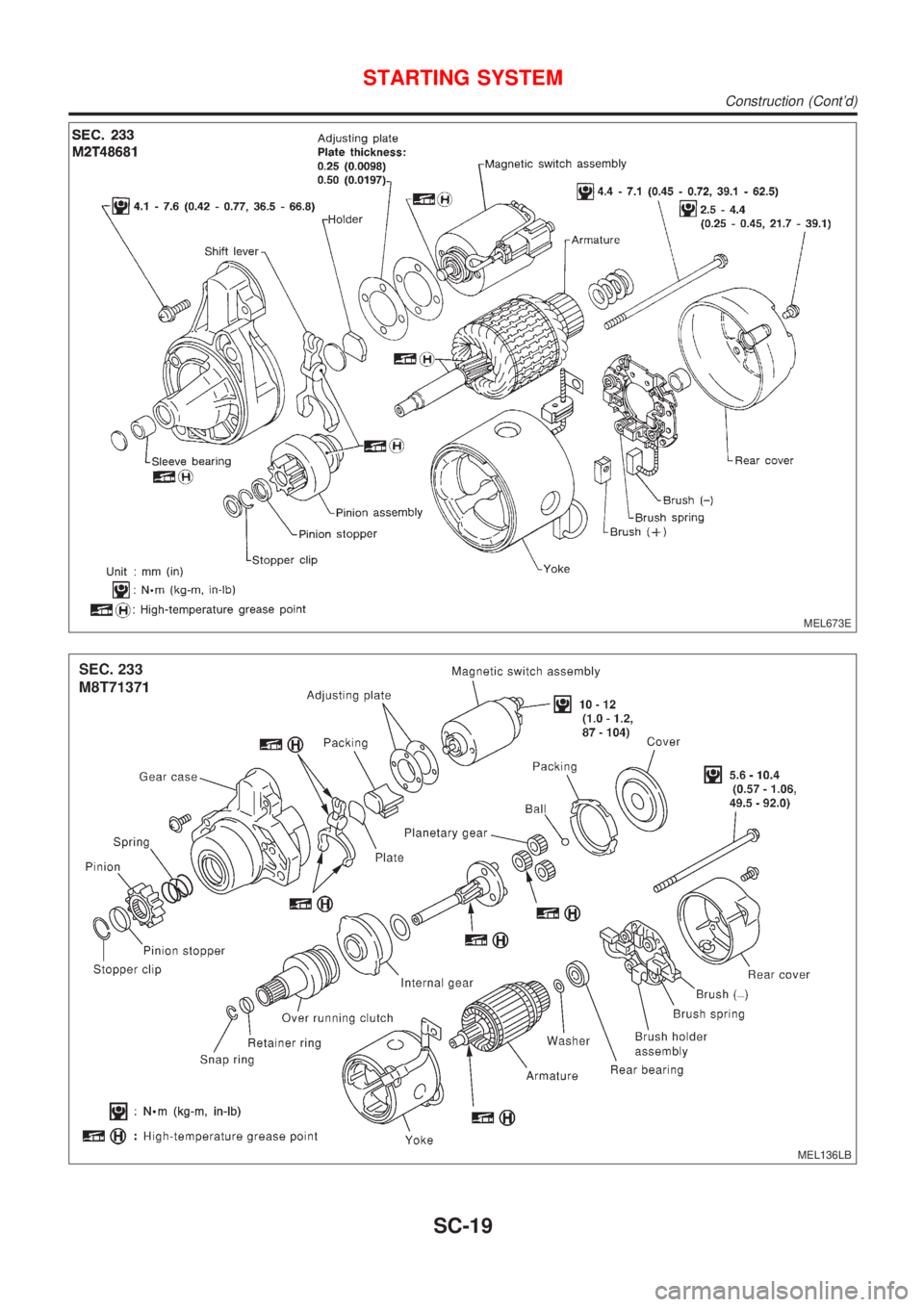

MEL673E

MEL136LB

STARTING SYSTEM

Construction (Cont'd)

SC-19

Page 2816 of 2898

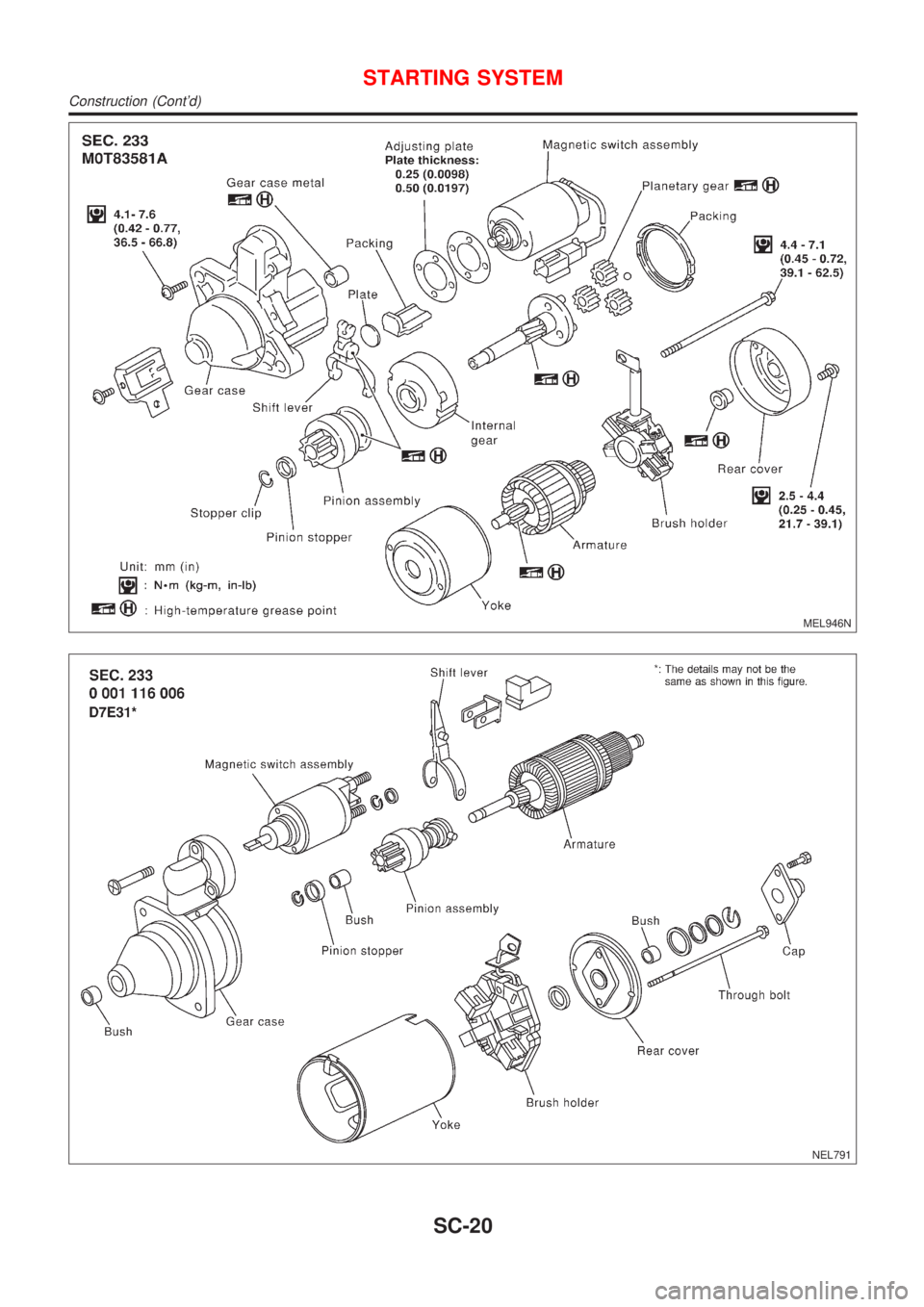

MEL946N

NEL791

STARTING SYSTEM

Construction (Cont'd)

SC-20

Page 2817 of 2898

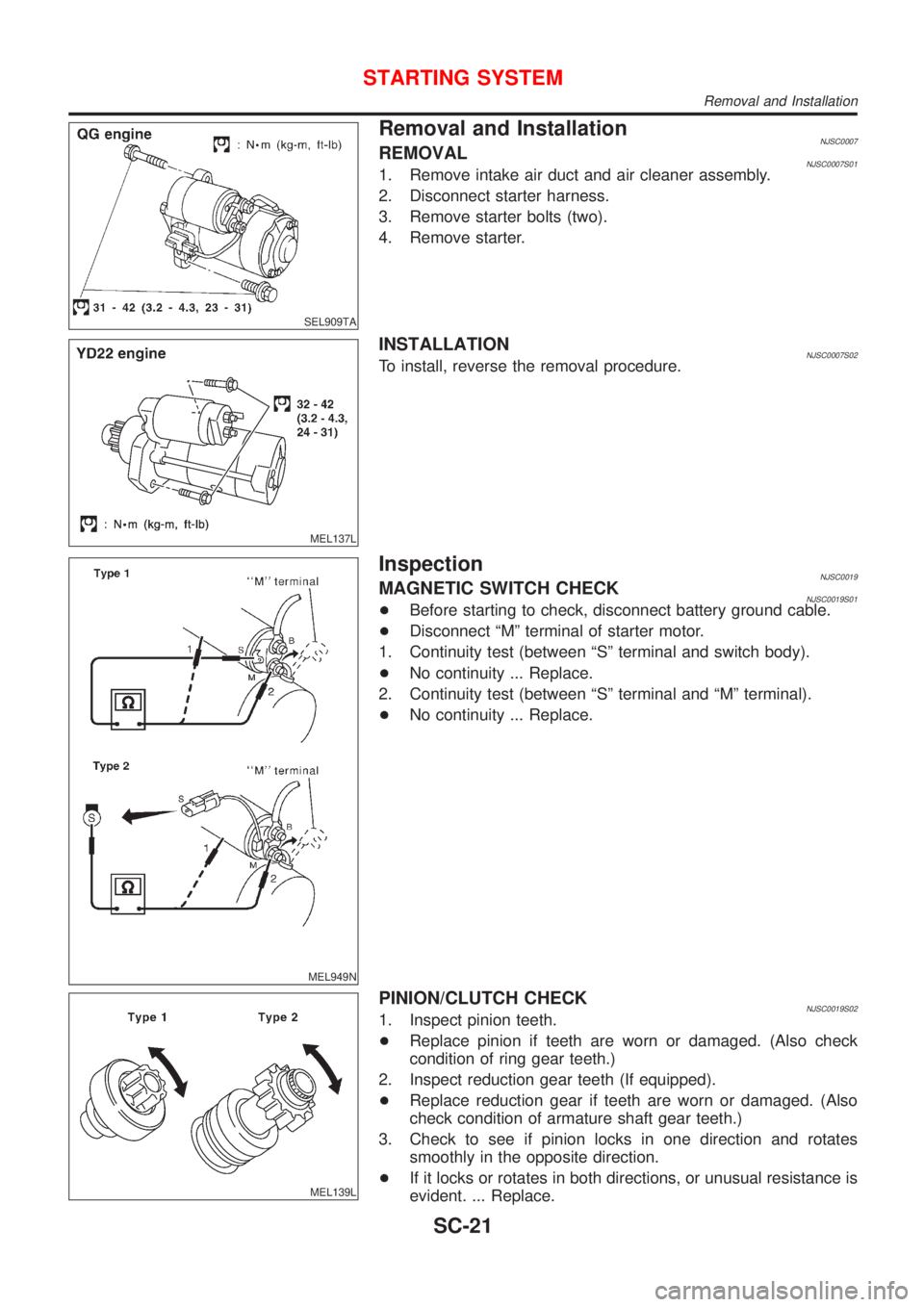

SEL909TA

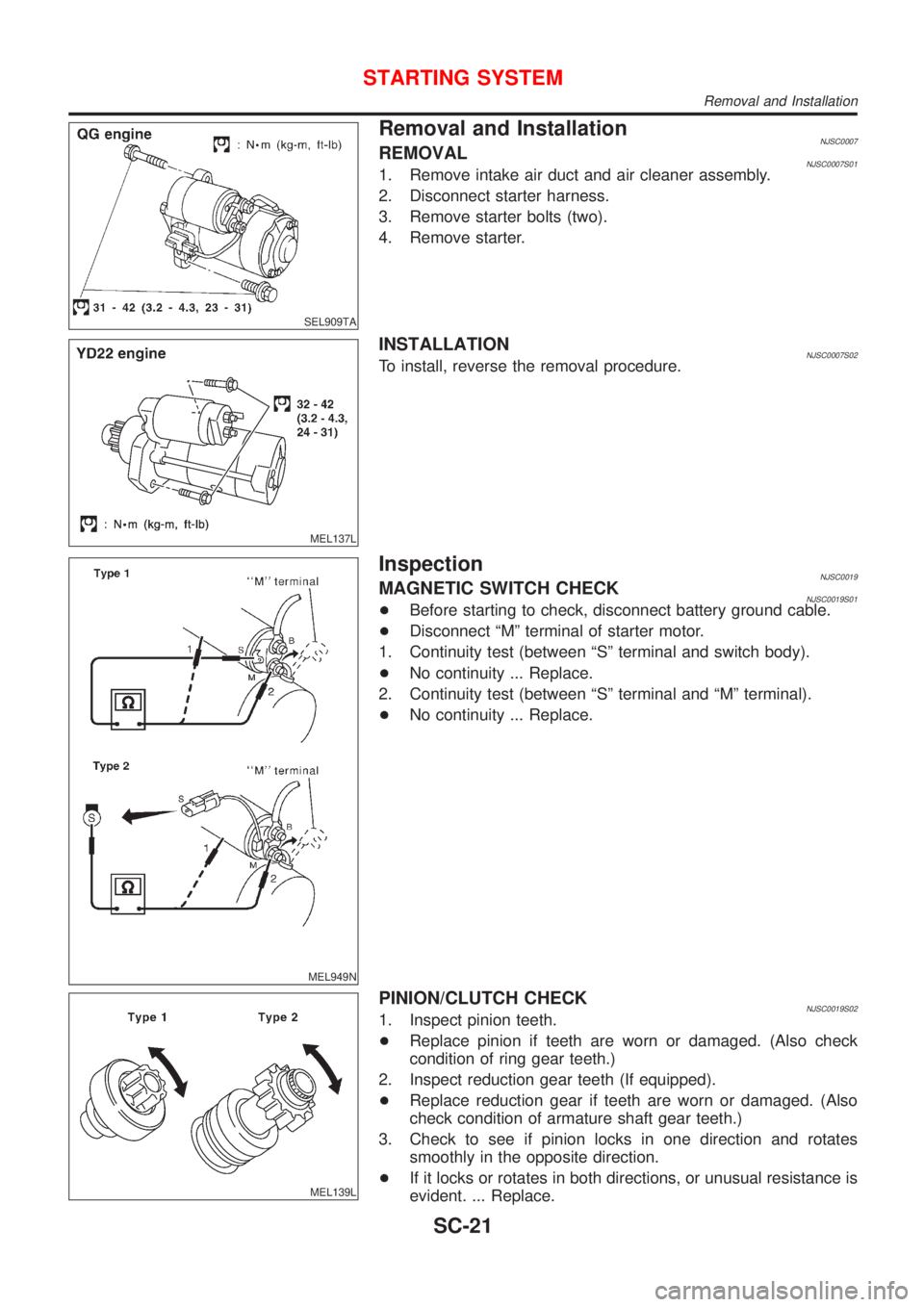

Removal and InstallationNJSC0007REMOVALNJSC0007S011. Remove intake air duct and air cleaner assembly.

2. Disconnect starter harness.

3. Remove starter bolts (two).

4. Remove starter.

MEL137L

INSTALLATIONNJSC0007S02To install, reverse the removal procedure.

MEL949N

InspectionNJSC0019MAGNETIC SWITCH CHECKNJSC0019S01+Before starting to check, disconnect battery ground cable.

+Disconnect ªMº terminal of starter motor.

1. Continuity test (between ªSº terminal and switch body).

+No continuity ... Replace.

2. Continuity test (between ªSº terminal and ªMº terminal).

+No continuity ... Replace.

MEL139L

PINION/CLUTCH CHECKNJSC0019S021. Inspect pinion teeth.

+Replace pinion if teeth are worn or damaged. (Also check

condition of ring gear teeth.)

2. Inspect reduction gear teeth (If equipped).

+Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

+If it locks or rotates in both directions, or unusual resistance is

evident. ... Replace.

STARTING SYSTEM

Removal and Installation

SC-21

Page 2818 of 2898

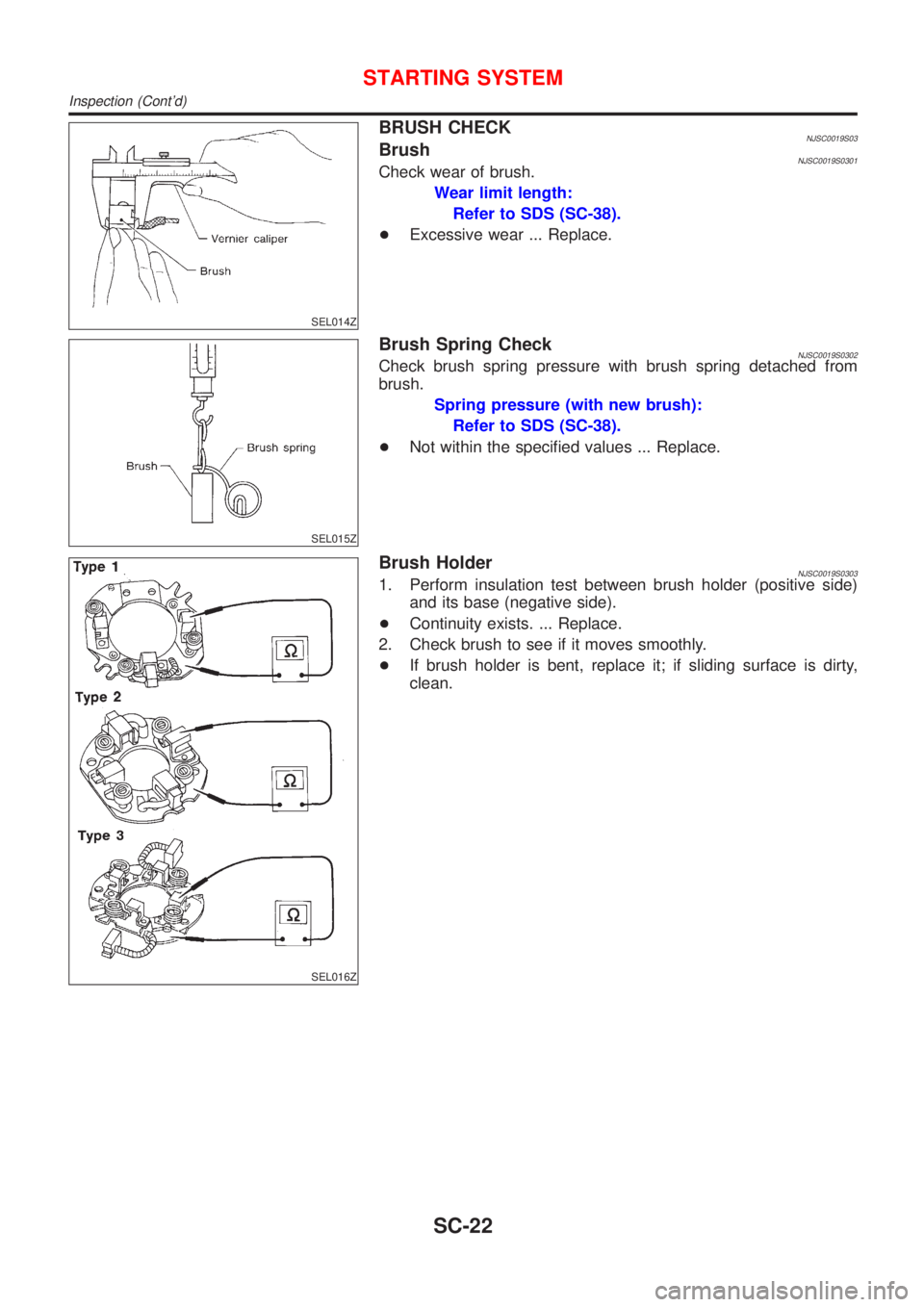

SEL014Z

BRUSH CHECKNJSC0019S03BrushNJSC0019S0301Check wear of brush.

Wear limit length:

Refer to SDS (SC-38).

+Excessive wear ... Replace.

SEL015Z

Brush Spring CheckNJSC0019S0302Check brush spring pressure with brush spring detached from

brush.

Spring pressure (with new brush):

Refer to SDS (SC-38).

+Not within the specified values ... Replace.

SEL016Z

Brush HolderNJSC0019S03031. Perform insulation test between brush holder (positive side)

and its base (negative side).

+Continuity exists. ... Replace.

2. Check brush to see if it moves smoothly.

+If brush holder is bent, replace it; if sliding surface is dirty,

clean.

STARTING SYSTEM

Inspection (Cont'd)

SC-22

Page 2819 of 2898

SEL018Z

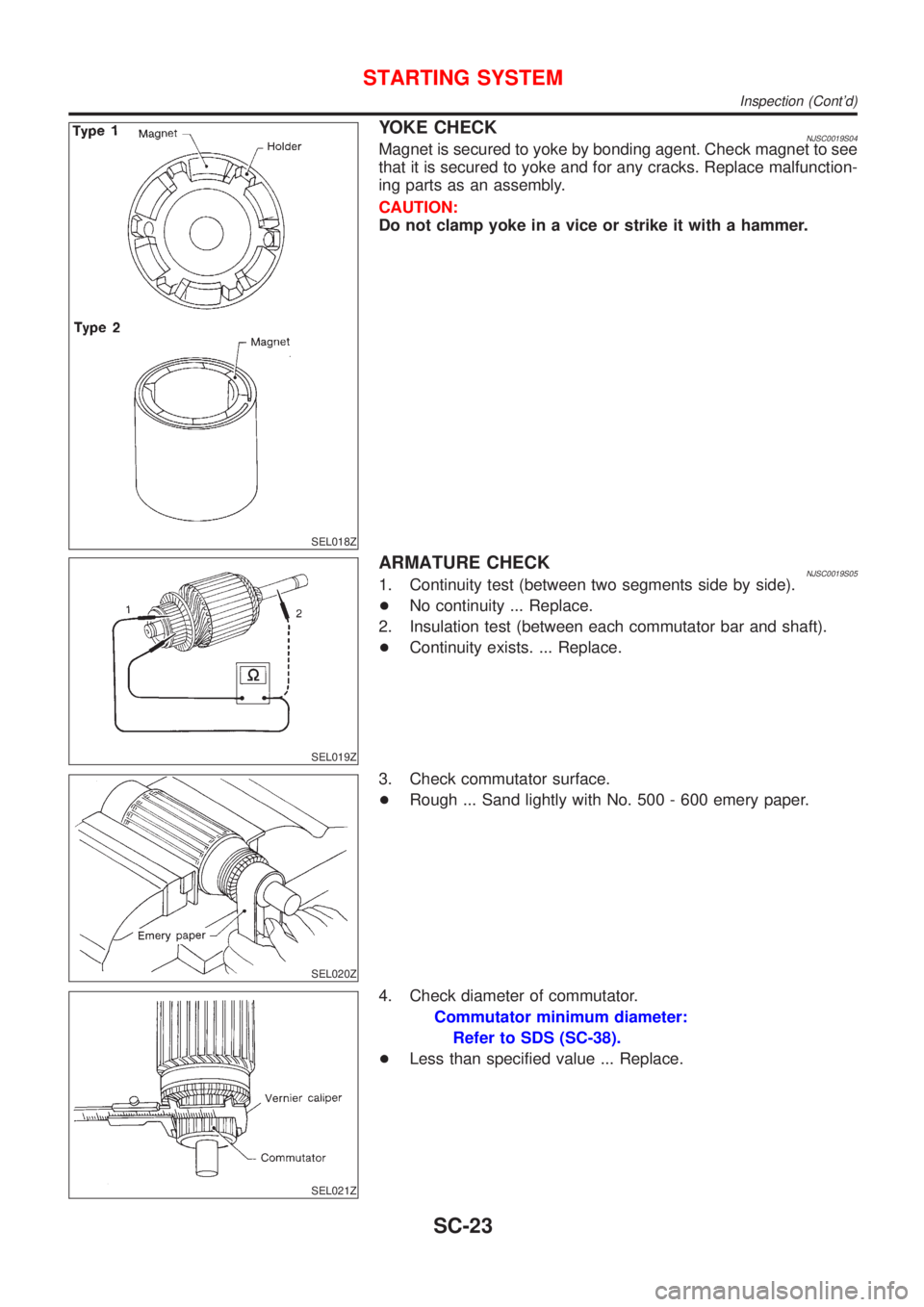

YOKE CHECKNJSC0019S04Magnet is secured to yoke by bonding agent. Check magnet to see

that it is secured to yoke and for any cracks. Replace malfunction-

ing parts as an assembly.

CAUTION:

Do not clamp yoke in a vice or strike it with a hammer.

SEL019Z

ARMATURE CHECKNJSC0019S051. Continuity test (between two segments side by side).

+No continuity ... Replace.

2. Insulation test (between each commutator bar and shaft).

+Continuity exists. ... Replace.

SEL020Z

3. Check commutator surface.

+Rough ... Sand lightly with No. 500 - 600 emery paper.

SEL021Z

4. Check diameter of commutator.

Commutator minimum diameter:

Refer to SDS (SC-38).

+Less than specified value ... Replace.

STARTING SYSTEM

Inspection (Cont'd)

SC-23

Page 2820 of 2898

SEL022Z

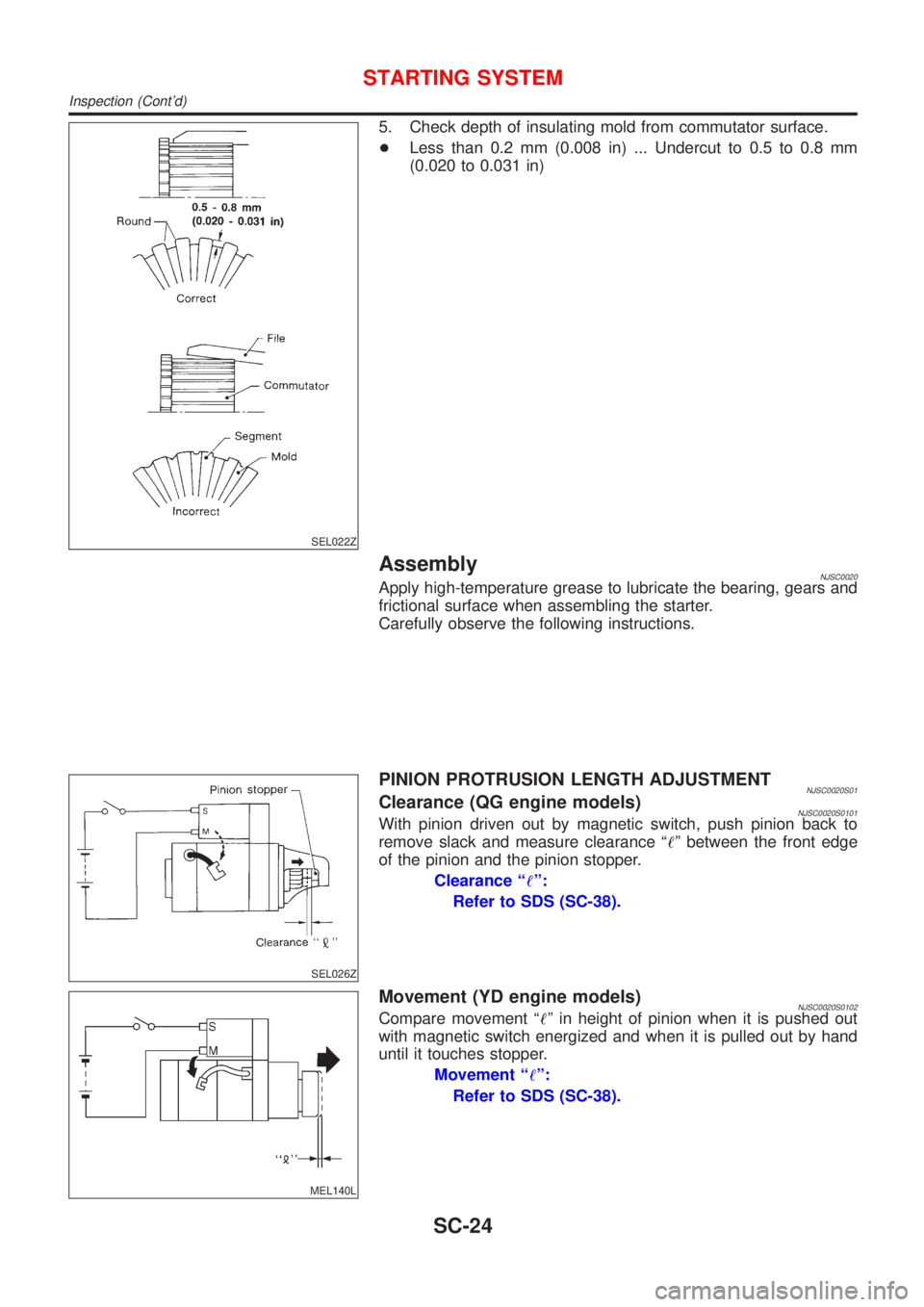

5. Check depth of insulating mold from commutator surface.

+Less than 0.2 mm (0.008 in) ... Undercut to 0.5 to 0.8 mm

(0.020 to 0.031 in)

AssemblyNJSC0020Apply high-temperature grease to lubricate the bearing, gears and

frictional surface when assembling the starter.

Carefully observe the following instructions.

SEL026Z

PINION PROTRUSION LENGTH ADJUSTMENTNJSC0020S01Clearance (QG engine models)NJSC0020S0101With pinion driven out by magnetic switch, push pinion back to

remove slack and measure clearance ª!º between the front edge

of the pinion and the pinion stopper.

Clearance ª!º:

Refer to SDS (SC-38).

MEL140L

Movement (YD engine models)NJSC0020S0102Compare movement ª!º in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

Movement ª!º:

Refer to SDS (SC-38).

STARTING SYSTEM

Inspection (Cont'd)

SC-24

Trending: Front brakes, coolant reservoir, mirror, ECU, ESP, high beam, wiper fluid