engine NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 896 of 2898

![NISSAN ALMERA 2001 Service Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104* SBSwirl control valve con-

trol solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF)

+ NISSAN ALMERA 2001 Service Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104* SBSwirl control valve con-

trol solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF)

+](/img/5/57348/w960_57348-895.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104* SBSwirl control valve con-

trol solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF)

+Idle speed0-1V

[Engine is running]

+Engine coolant temperature is above 40ÉC

(104ÉF)

+Idle speedBATTERY VOLTAGE

(11 - 14V)

106

108B/Y ECM ground[Engine is running]

+Idle speedEngine ground

11 0

11 2W

WPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

111 R Sensors' power supply[Ignition switch ªONº]Approximately 5V

114 GY/R Adjust switch[Engine is running]

+Idle speed0V

115 LG Data link connector[Engine is running]

+Idle speed (CONSULT-II or GST is discon-

nected)0 - 10V

* If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

ECM Terminals and Reference Value (Cont'd)

EC-172

Page 897 of 2898

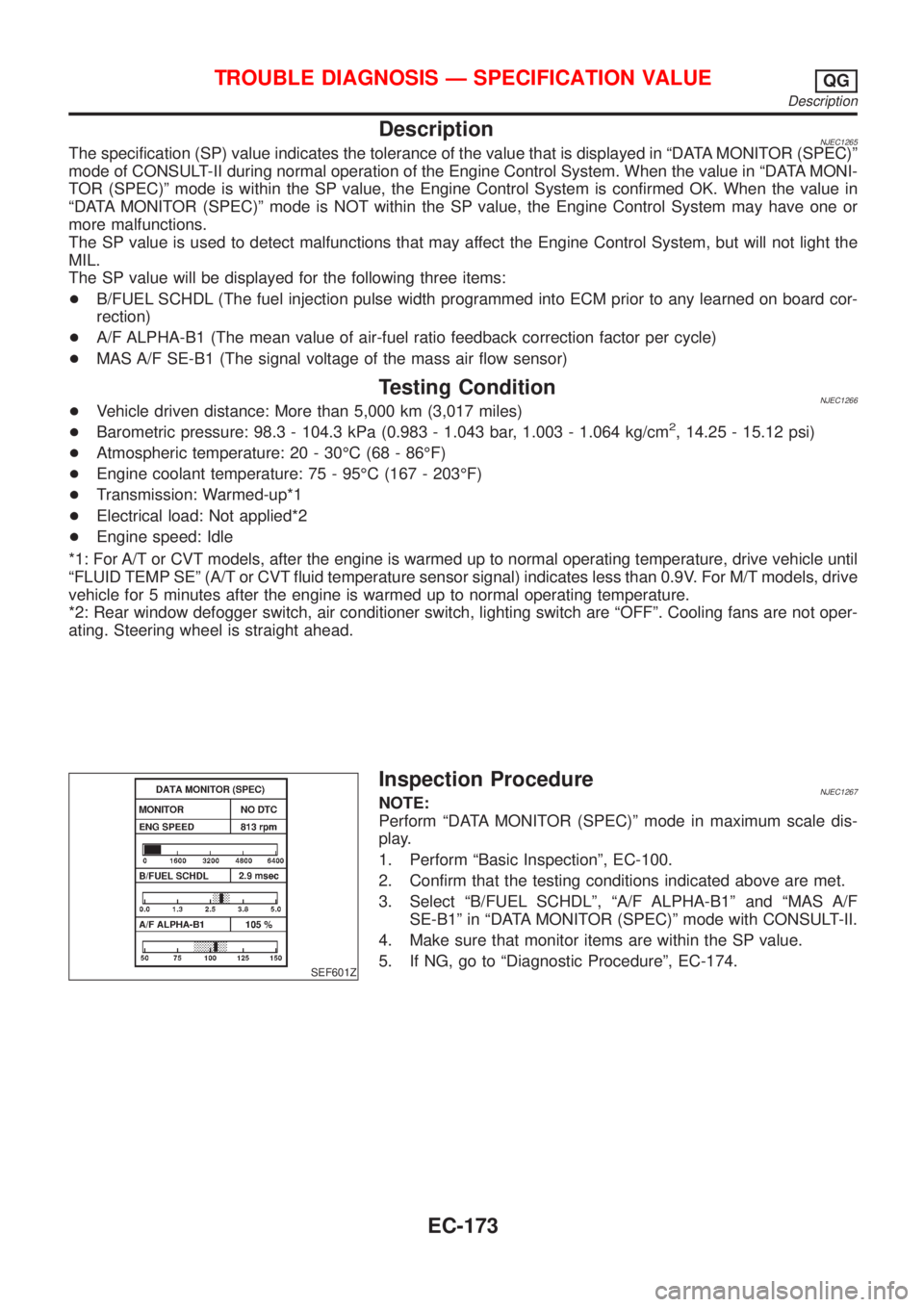

DescriptionNJEC1265The specification (SP) value indicates the tolerance of the value that is displayed in ªDATA MONITOR (SPEC)º

mode of CONSULT-II during normal operation of the Engine Control System. When the value in ªDATA MONI-

TOR (SPEC)º mode is within the SP value, the Engine Control System is confirmed OK. When the value in

ªDATA MONITOR (SPEC)º mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

+B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board cor-

rection)

+A/F ALPHA-B1 (The mean value of air-fuel ratio feedback correction factor per cycle)

+MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionNJEC1266+Vehicle driven distance: More than 5,000 km (3,017 miles)

+Barometric pressure: 98.3 - 104.3 kPa (0.983 - 1.043 bar, 1.003 - 1.064 kg/cm2, 14.25 - 15.12 psi)

+Atmospheric temperature: 20 - 30ÉC (68 - 86ÉF)

+Engine coolant temperature: 75 - 95ÉC (167 - 203ÉF)

+Transmission: Warmed-up*1

+Electrical load: Not applied*2

+Engine speed: Idle

*1: For A/T or CVT models, after the engine is warmed up to normal operating temperature, drive vehicle until

ªFLUID TEMP SEº (A/T or CVT fluid temperature sensor signal) indicates less than 0.9V. For M/T models, drive

vehicle for 5 minutes after the engine is warmed up to normal operating temperature.

*2: Rear window defogger switch, air conditioner switch, lighting switch are ªOFFº. Cooling fans are not oper-

ating. Steering wheel is straight ahead.

SEF601Z

Inspection ProcedureNJEC1267NOTE:

Perform ªDATA MONITOR (SPEC)º mode in maximum scale dis-

play.

1. Perform ªBasic Inspectionº, EC-100.

2. Confirm that the testing conditions indicated above are met.

3. Select ªB/FUEL SCHDLº, ªA/F ALPHA-B1º and ªMAS A/F

SE-B1º in ªDATA MONITOR (SPEC)º mode with CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to ªDiagnostic Procedureº, EC-174.

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUEQG

Description

EC-173

Page 902 of 2898

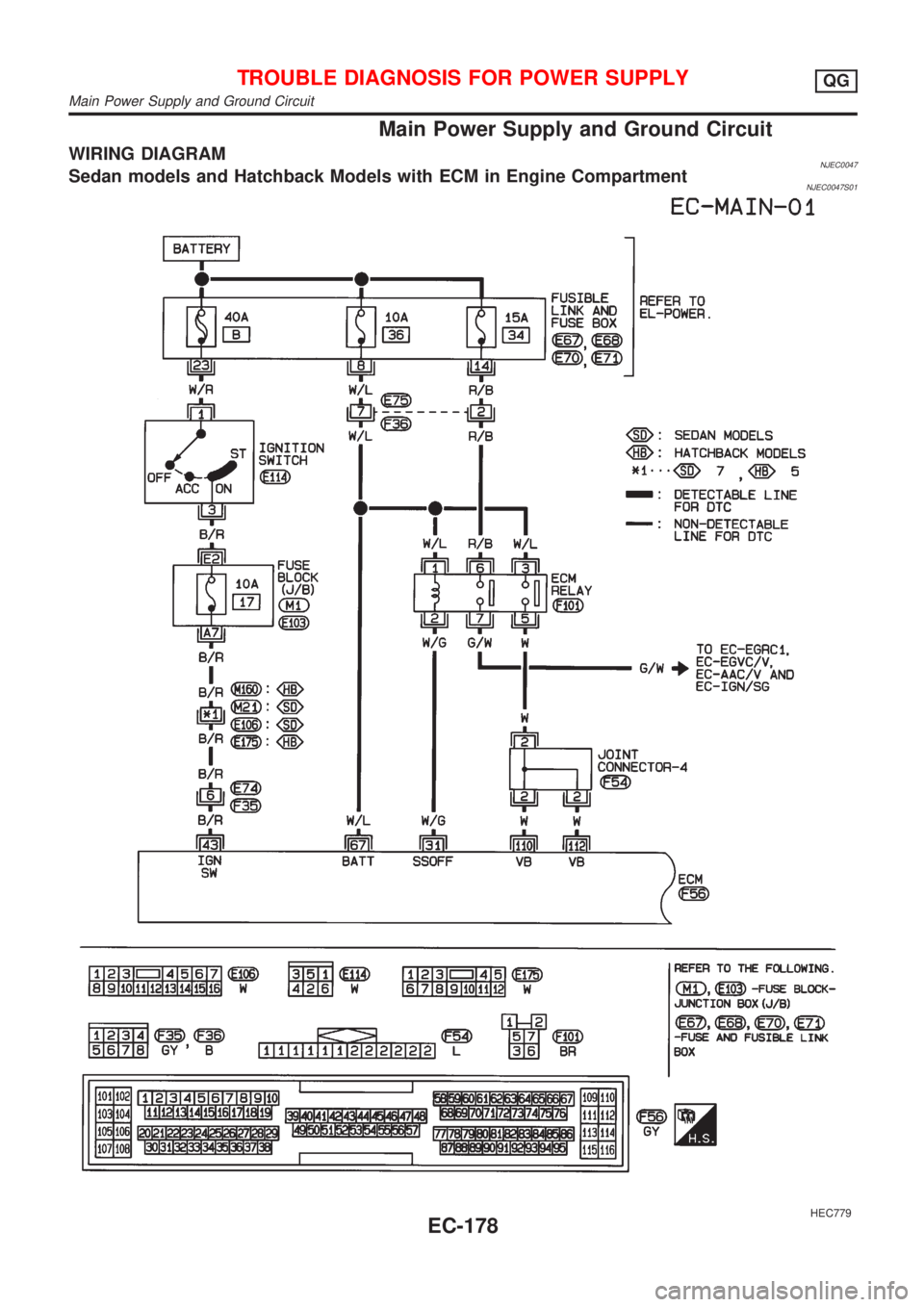

Main Power Supply and Ground Circuit

WIRING DIAGRAMNJEC0047Sedan models and Hatchback Models with ECM in Engine CompartmentNJEC0047S01

HEC779

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit

EC-178

Page 905 of 2898

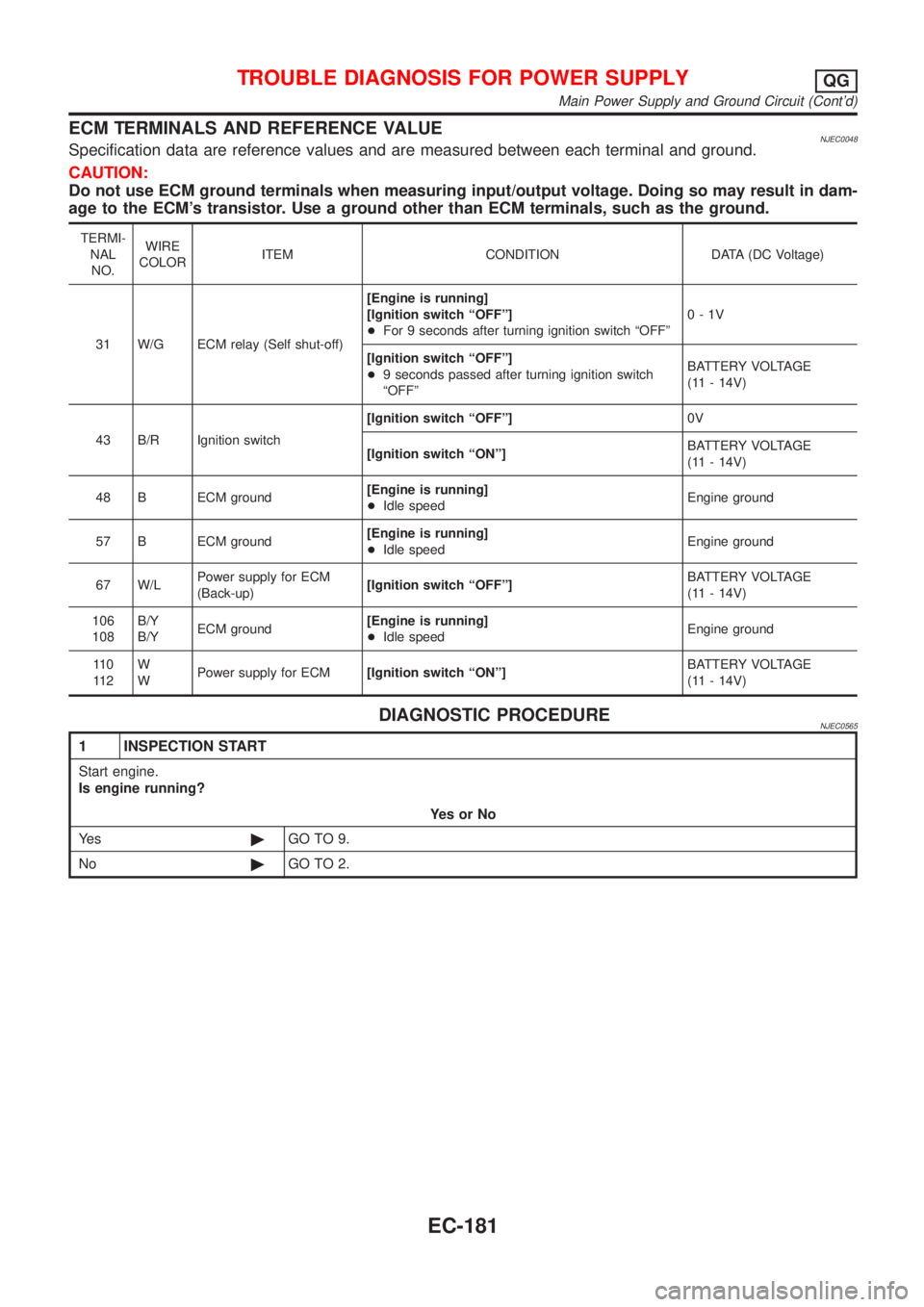

ECM TERMINALS AND REFERENCE VALUENJEC0048Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

31 W/G ECM relay (Self shut-off)[Engine is running]

[Ignition switch ªOFFº]

+For 9 seconds after turning ignition switch ªOFFº0-1V

[Ignition switch ªOFFº]

+9 seconds passed after turning ignition switch

ªOFFºBATTERY VOLTAGE

(11 - 14V)

43 B/R Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

48 B ECM ground[Engine is running]

+Idle speedEngine ground

57 B ECM ground[Engine is running]

+Idle speedEngine ground

67 W/LPower supply for ECM

(Back-up)[Ignition switch ªOFFº]BATTERY VOLTAGE

(11 - 14V)

106

108B/Y

B/YECM ground[Engine is running]

+Idle speedEngine ground

11 0

11 2W

WPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

DIAGNOSTIC PROCEDURENJEC0565

1 INSPECTION START

Start engine.

Is engine running?

YesorNo

Ye s©GO TO 9.

No©GO TO 2.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-181

Page 906 of 2898

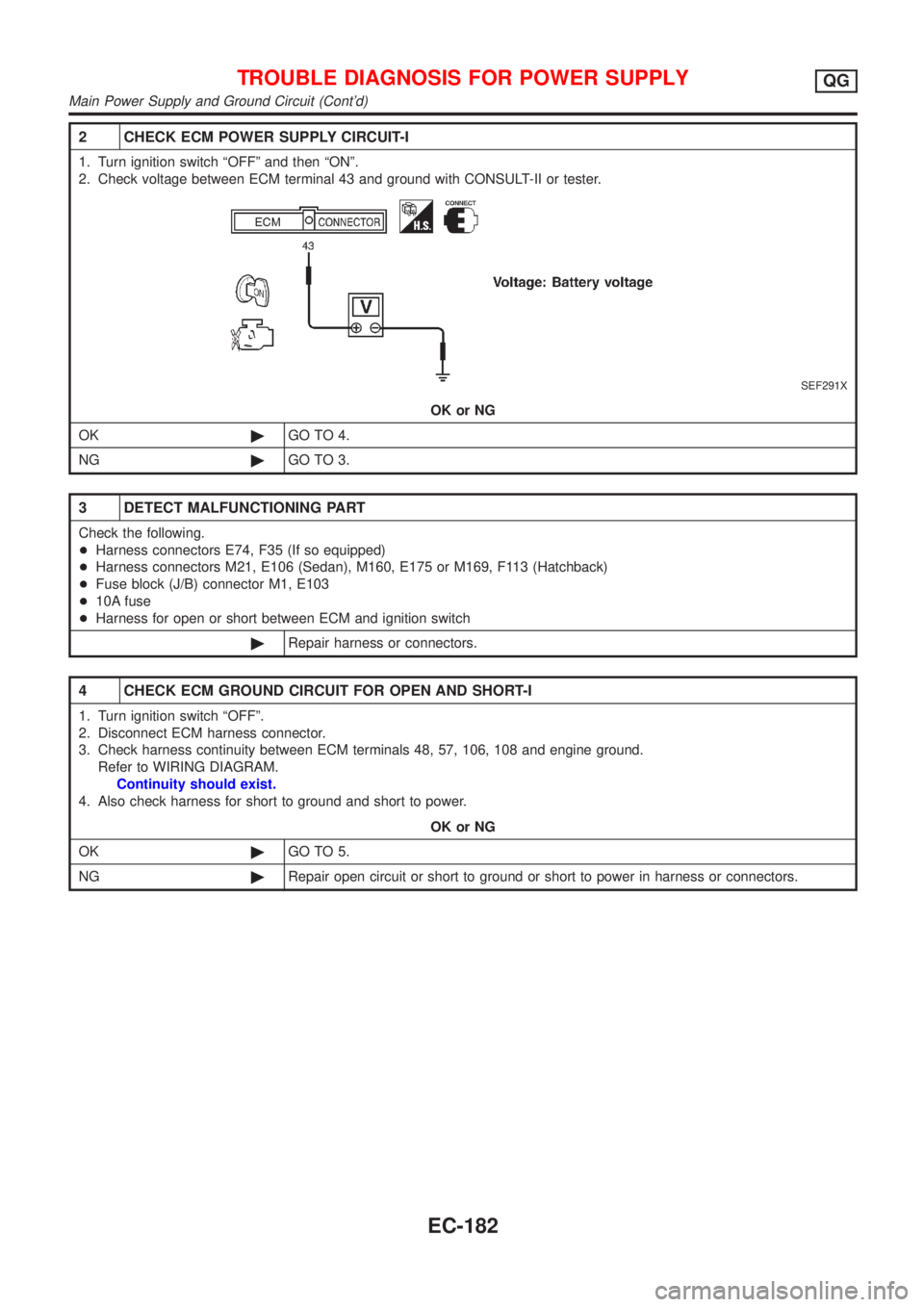

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between ECM terminal 43 and ground with CONSULT-II or tester.

SEF291X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E74, F35 (If so equipped)

+Harness connectors M21, E106 (Sedan), M160, E175 or M169, F113 (Hatchback)

+Fuse block (J/B) connector M1, E103

+10A fuse

+Harness for open or short between ECM and ignition switch

©Repair harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-182

Page 907 of 2898

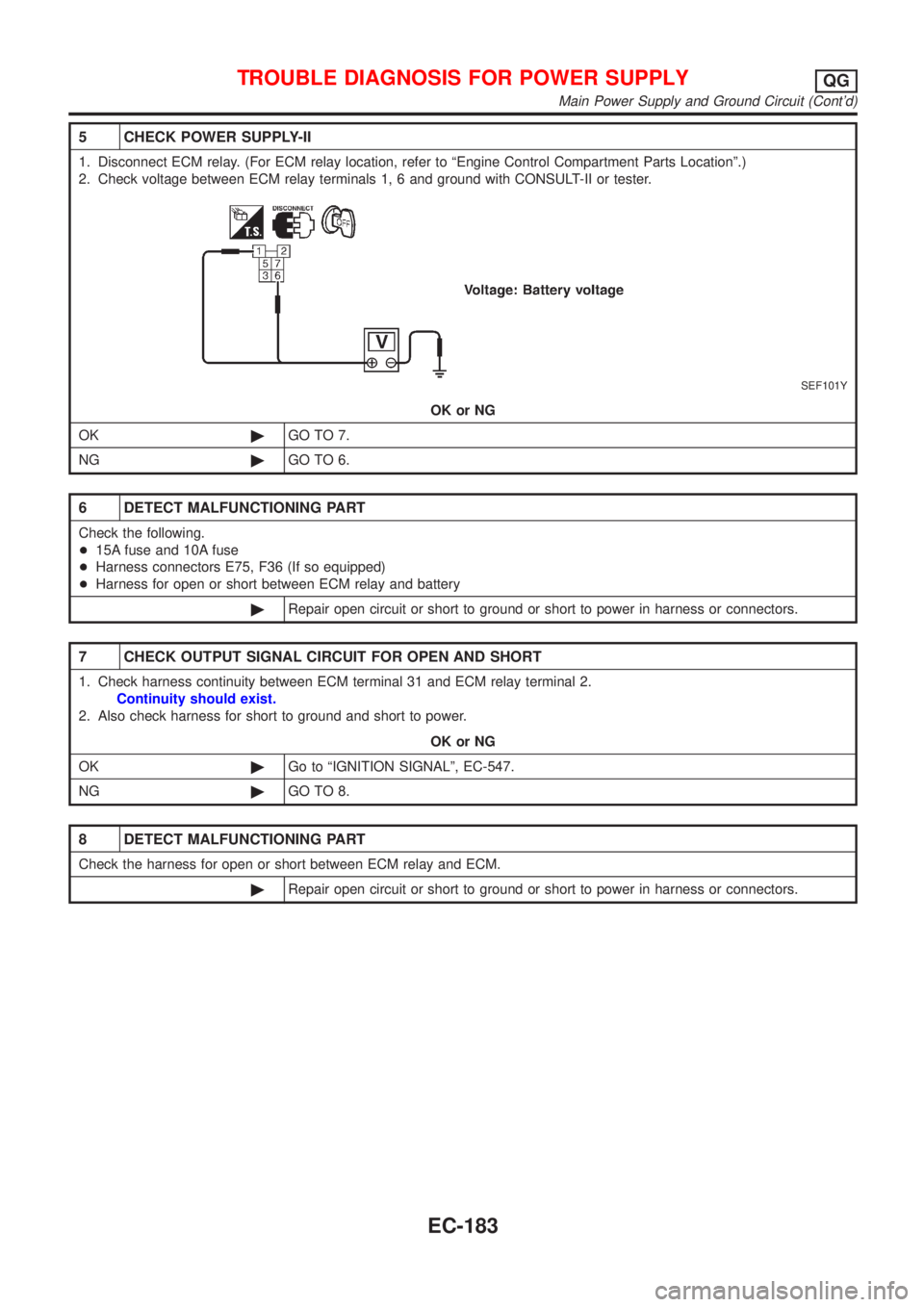

5 CHECK POWER SUPPLY-II

1. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Compartment Parts Locationº.)

2. Check voltage between ECM relay terminals 1, 6 and ground with CONSULT-II or tester.

SEF101Y

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse and 10A fuse

+Harness connectors E75, F36 (If so equipped)

+Harness for open or short between ECM relay and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 31 and ECM relay terminal 2.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©Go to ªIGNITION SIGNALº, EC-547.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM relay and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-183

Page 908 of 2898

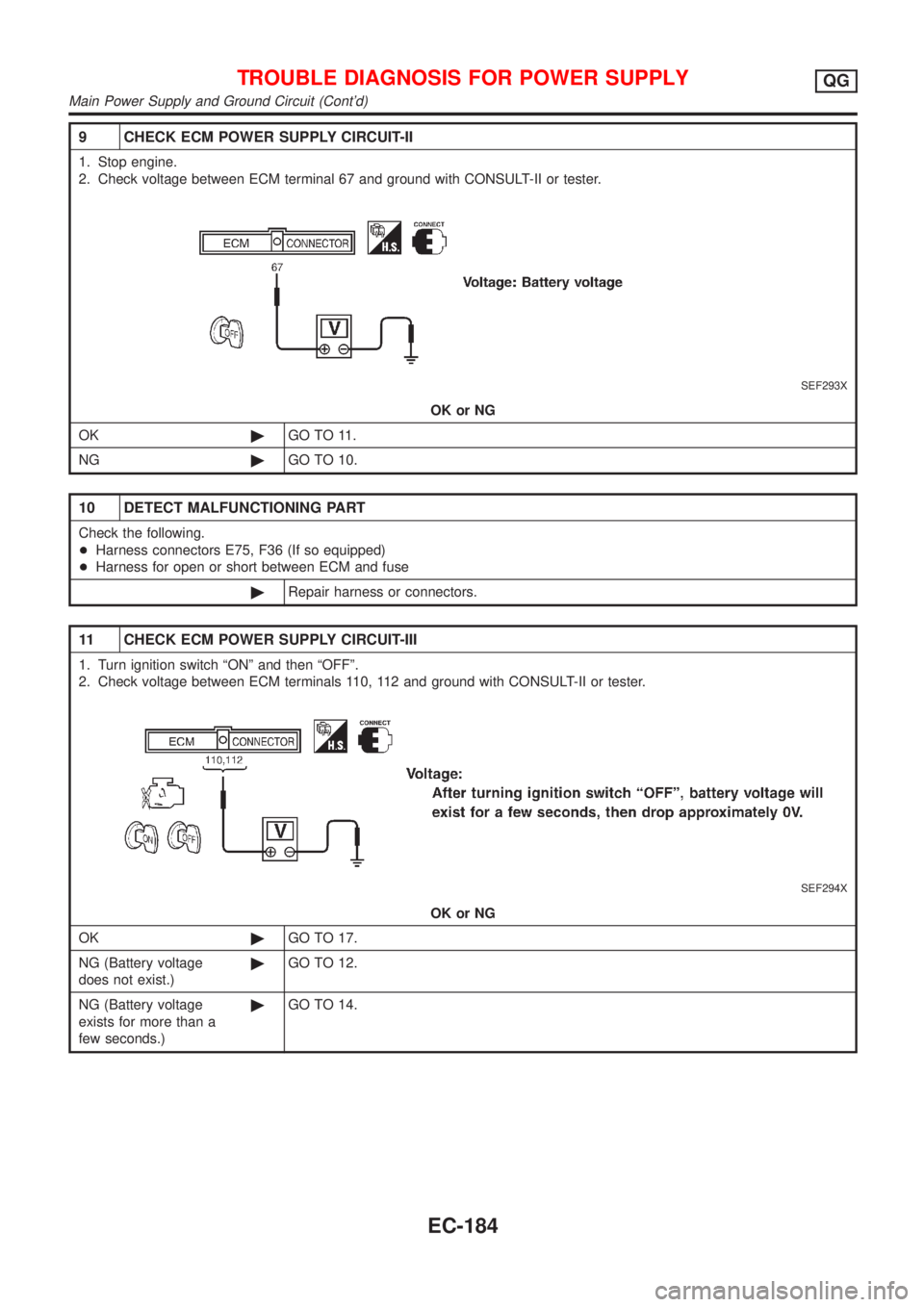

9 CHECK ECM POWER SUPPLY CIRCUIT-II

1. Stop engine.

2. Check voltage between ECM terminal 67 and ground with CONSULT-II or tester.

SEF293X

OK or NG

OK©GO TO 11.

NG©GO TO 10.

10 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36 (If so equipped)

+Harness for open or short between ECM and fuse

©Repair harness or connectors.

11 CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch ªONº and then ªOFFº.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF294X

OK or NG

OK©GO TO 17.

NG (Battery voltage

does not exist.)©GO TO 12.

NG (Battery voltage

exists for more than a

few seconds.)©GO TO 14.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-184

Page 909 of 2898

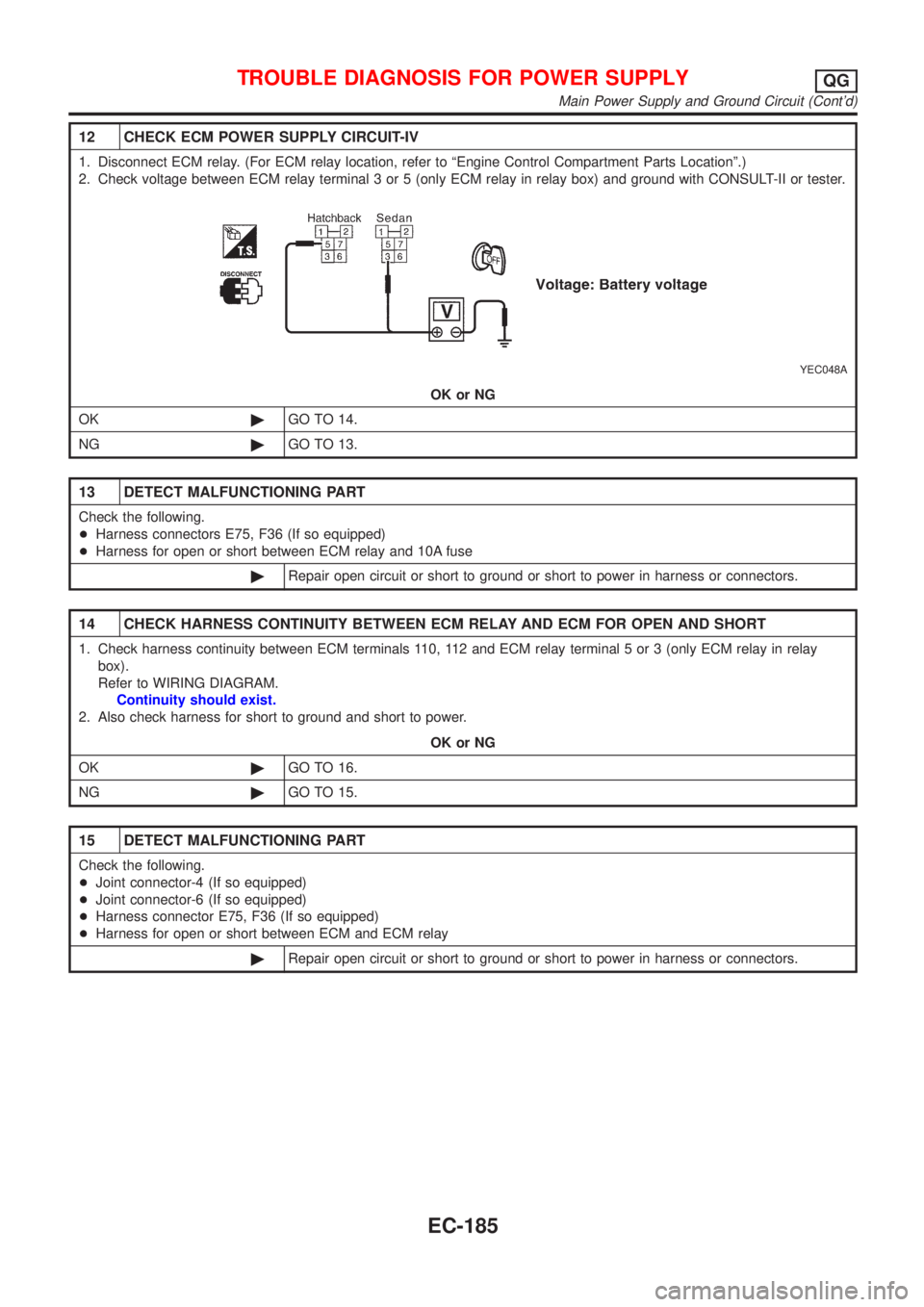

12 CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Compartment Parts Locationº.)

2. Check voltage between ECM relay terminal 3 or 5 (only ECM relay in relay box) and ground with CONSULT-II or tester.

YEC048A

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36 (If so equipped)

+Harness for open or short between ECM relay and 10A fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

14 CHECK HARNESS CONTINUITY BETWEEN ECM RELAY AND ECM FOR OPEN AND SHORT

1. Check harness continuity between ECM terminals 110, 112 and ECM relay terminal 5 or 3 (only ECM relay in relay

box).

Refer to WIRING DIAGRAM.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©GO TO 15.

15 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-4 (If so equipped)

+Joint connector-6 (If so equipped)

+Harness connector E75, F36 (If so equipped)

+Harness for open or short between ECM and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-185

Page 910 of 2898

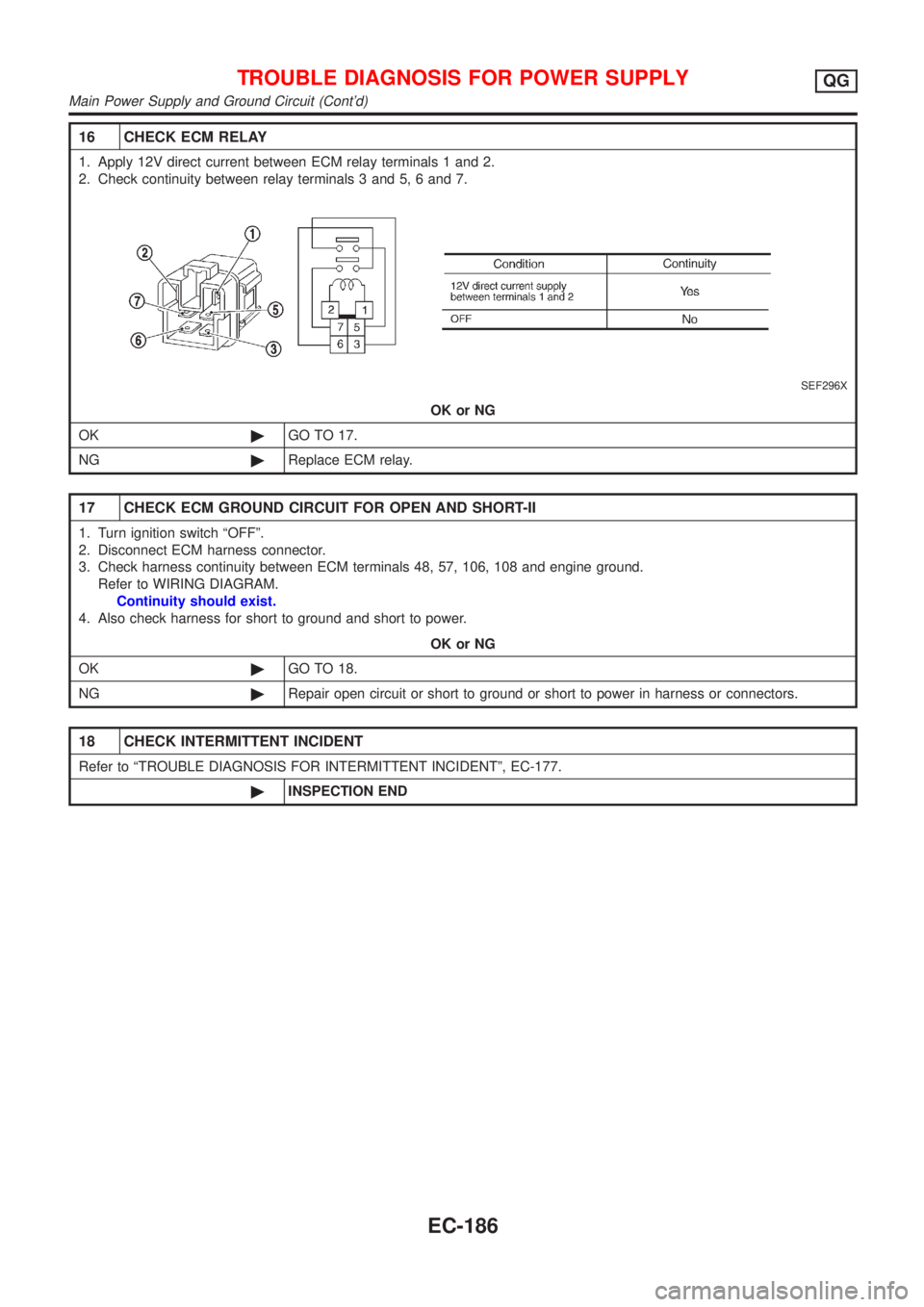

16 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK©GO TO 17.

NG©Replace ECM relay.

17 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 18.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

18 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-186

Page 911 of 2898

SEF987W

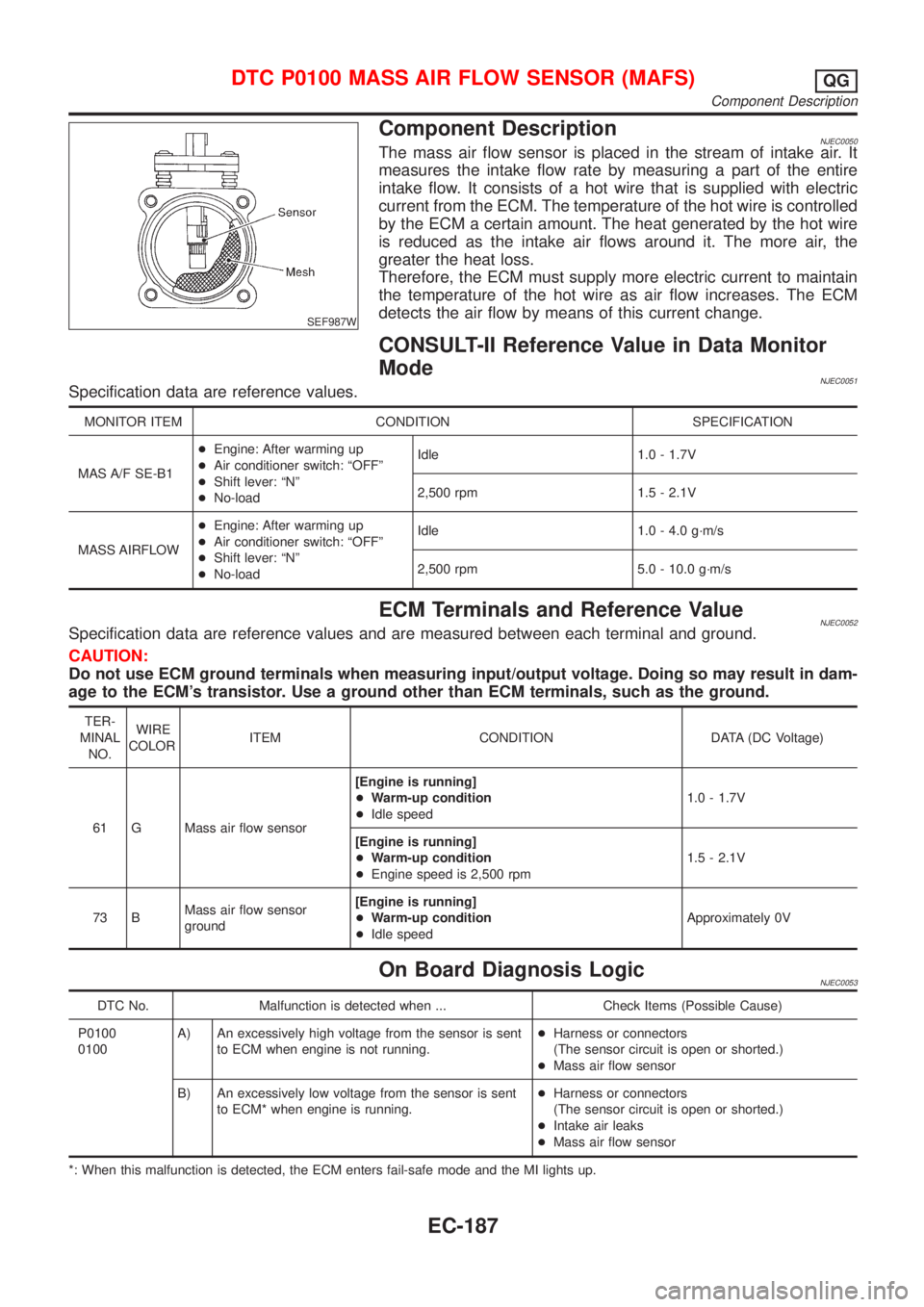

Component DescriptionNJEC0050The mass air flow sensor is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. It consists of a hot wire that is supplied with electric

current from the ECM. The temperature of the hot wire is controlled

by the ECM a certain amount. The heat generated by the hot wire

is reduced as the intake air flows around it. The more air, the

greater the heat loss.

Therefore, the ECM must supply more electric current to maintain

the temperature of the hot wire as air flow increases. The ECM

detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0051Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

MAS A/F SE-B1+Engine: After warming up

+Air conditioner switch: ªOFFº

+Shift lever: ªNº

+No-loadIdle 1.0 - 1.7V

2,500 rpm 1.5 - 2.1V

MASS AIRFLOW+Engine: After warming up

+Air conditioner switch: ªOFFº

+Shift lever: ªNº

+No-loadIdle 1.0 - 4.0 g´m/s

2,500 rpm 5.0 - 10.0 g´m/s

ECM Terminals and Reference ValueNJEC0052Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

61 G Mass air flow sensor[Engine is running]

+Warm-up condition

+Idle speed1.0 - 1.7V

[Engine is running]

+Warm-up condition

+Engine speed is 2,500 rpm1.5 - 2.1V

73 BMass air flow sensor

ground[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

On Board Diagnosis LogicNJEC0053

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0100

0100A) An excessively high voltage from the sensor is sent

to ECM when engine is not running.+Harness or connectors

(The sensor circuit is open or shorted.)

+Mass air flow sensor

B) An excessively low voltage from the sensor is sent

to ECM* when engine is running.+Harness or connectors

(The sensor circuit is open or shorted.)

+Intake air leaks

+Mass air flow sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

DTC P0100 MASS AIR FLOW SENSOR (MAFS)QG

Component Description

EC-187