ABS NISSAN ALMERA 2001 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 596 of 2898

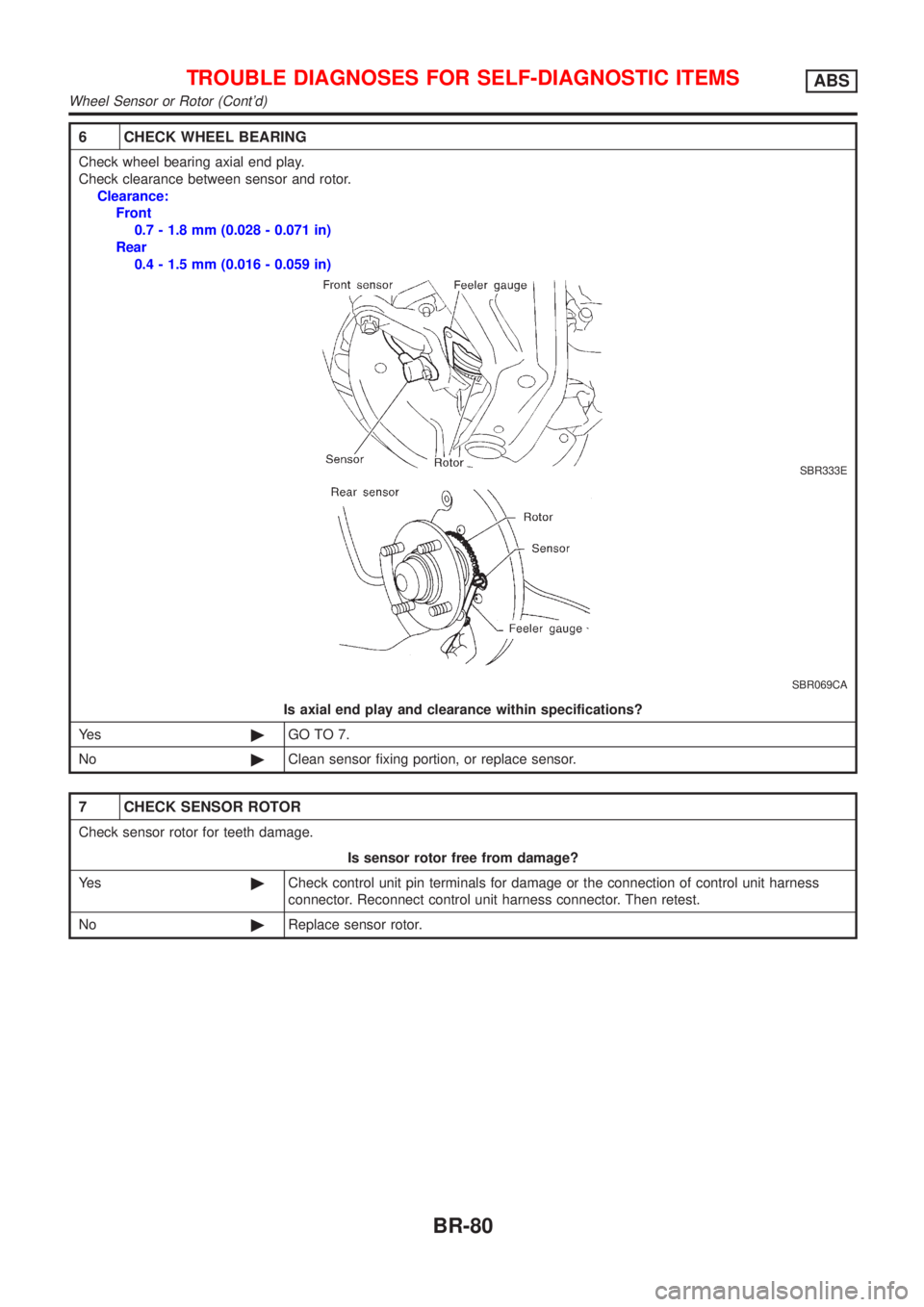

6 CHECK WHEEL BEARING

Check wheel bearing axial end play.

Check clearance between sensor and rotor.

Clearance:

Front

0.7 - 1.8 mm (0.028 - 0.071 in)

Rear

0.4 - 1.5 mm (0.016 - 0.059 in)

SBR333E

SBR069CA

Is axial end play and clearance within specifications?

Ye s©GO TO 7.

No©Clean sensor fixing portion, or replace sensor.

7 CHECK SENSOR ROTOR

Check sensor rotor for teeth damage.

Is sensor rotor free from damage?

Ye s©Check control unit pin terminals for damage or the connection of control unit harness

connector. Reconnect control unit harness connector. Then retest.

No©Replace sensor rotor.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Wheel Sensor or Rotor (Cont'd)

BR-80

Page 597 of 2898

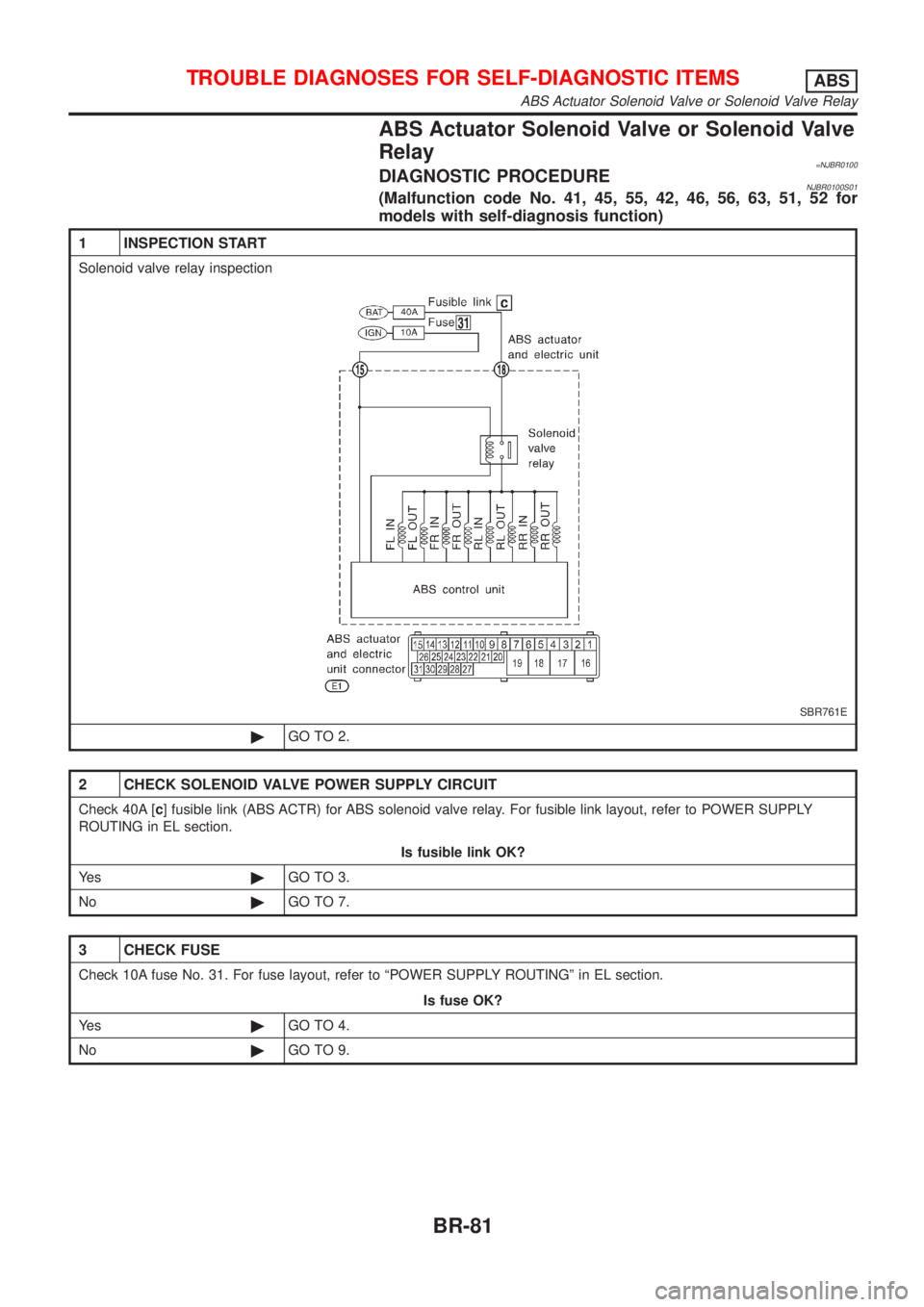

ABS Actuator Solenoid Valve or Solenoid Valve

Relay

=NJBR0100DIAGNOSTIC PROCEDURENJBR0100S01(Malfunction code No. 41, 45, 55, 42, 46, 56, 63, 51, 52 for

models with self-diagnosis function)

1 INSPECTION START

Solenoid valve relay inspection

SBR761E

©GO TO 2.

2 CHECK SOLENOID VALVE POWER SUPPLY CIRCUIT

Check 40A [c] fusible link (ABS ACTR) for ABS solenoid valve relay. For fusible link layout, refer to POWER SUPPLY

ROUTING in EL section.

Is fusible link OK?

Ye s©GO TO 3.

No©GO TO 7.

3 CHECK FUSE

Check 10A fuse No. 31. For fuse layout, refer to ªPOWER SUPPLY ROUTINGº in EL section.

Is fuse OK?

Ye s©GO TO 4.

No©GO TO 9.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

ABS Actuator Solenoid Valve or Solenoid Valve Relay

BR-81

Page 598 of 2898

4 CHECK CONNECTOR

1. Disconnect ABS actuator and electric unit connector. Check terminals for damage or loose connection. Then reconnect

connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s©GO TO 5.

No©INSPECTION END

5 CHECK GROUND CIRCUIT

Refer to ABS ACTUATOR AND ELECTRIC UNIT in Ground Circuit Check, BR-75.

Is ground circuit OK?

Ye s©GO TO 6.

No©Repair harness and connectors.

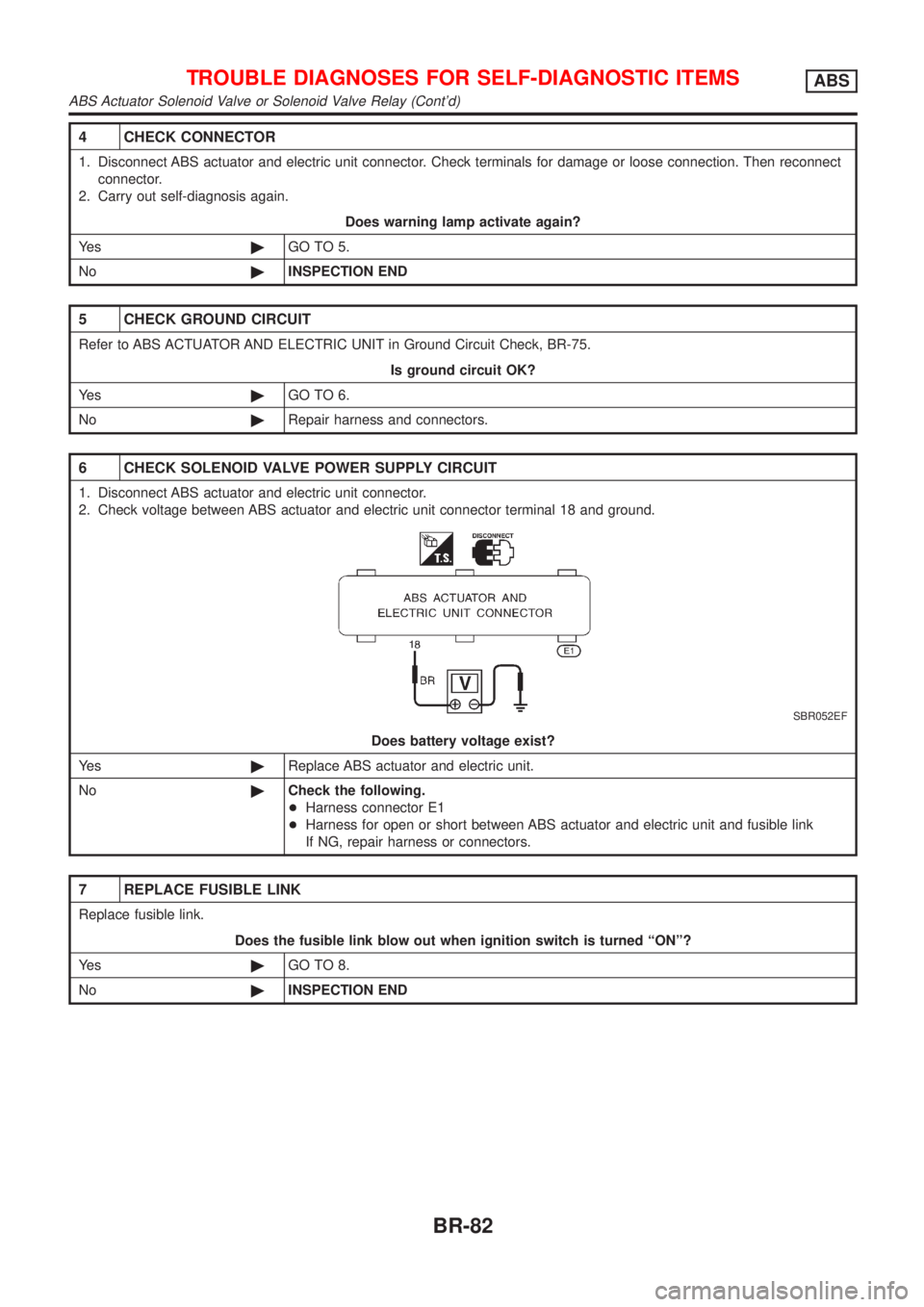

6 CHECK SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector terminal 18 and ground.

SBR052EF

Does battery voltage exist?

Ye s©Replace ABS actuator and electric unit.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fusible link

If NG, repair harness or connectors.

7 REPLACE FUSIBLE LINK

Replace fusible link.

Does the fusible link blow out when ignition switch is turned ªONº?

Ye s©GO TO 8.

No©INSPECTION END

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

ABS Actuator Solenoid Valve or Solenoid Valve Relay (Cont'd)

BR-82

Page 599 of 2898

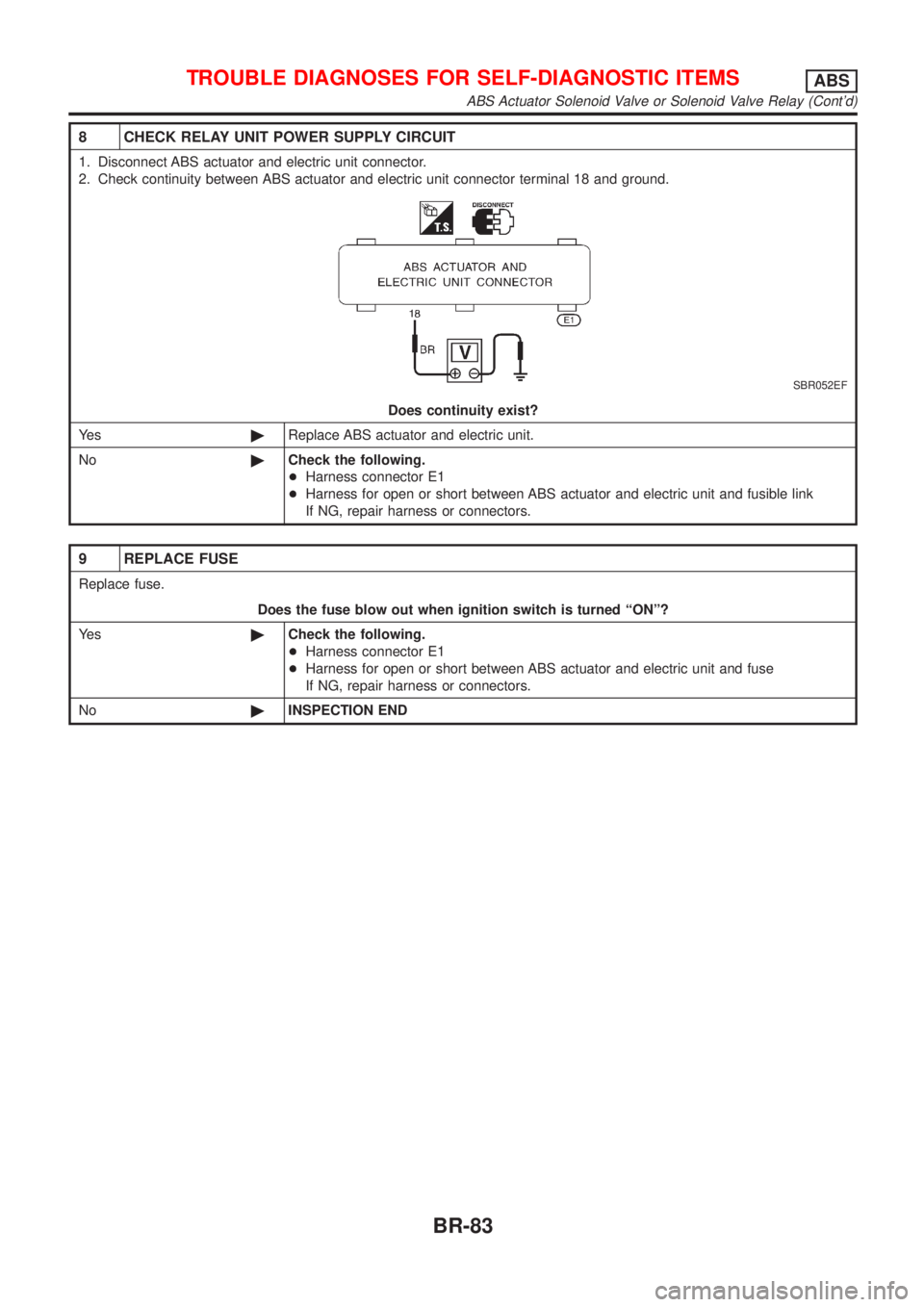

8 CHECK RELAY UNIT POWER SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric unit connector.

2. Check continuity between ABS actuator and electric unit connector terminal 18 and ground.

SBR052EF

Does continuity exist?

Ye s©Replace ABS actuator and electric unit.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fusible link

If NG, repair harness or connectors.

9 REPLACE FUSE

Replace fuse.

Does the fuse blow out when ignition switch is turned ªONº?

Ye s©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fuse

If NG, repair harness or connectors.

No©INSPECTION END

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

ABS Actuator Solenoid Valve or Solenoid Valve Relay (Cont'd)

BR-83

Page 600 of 2898

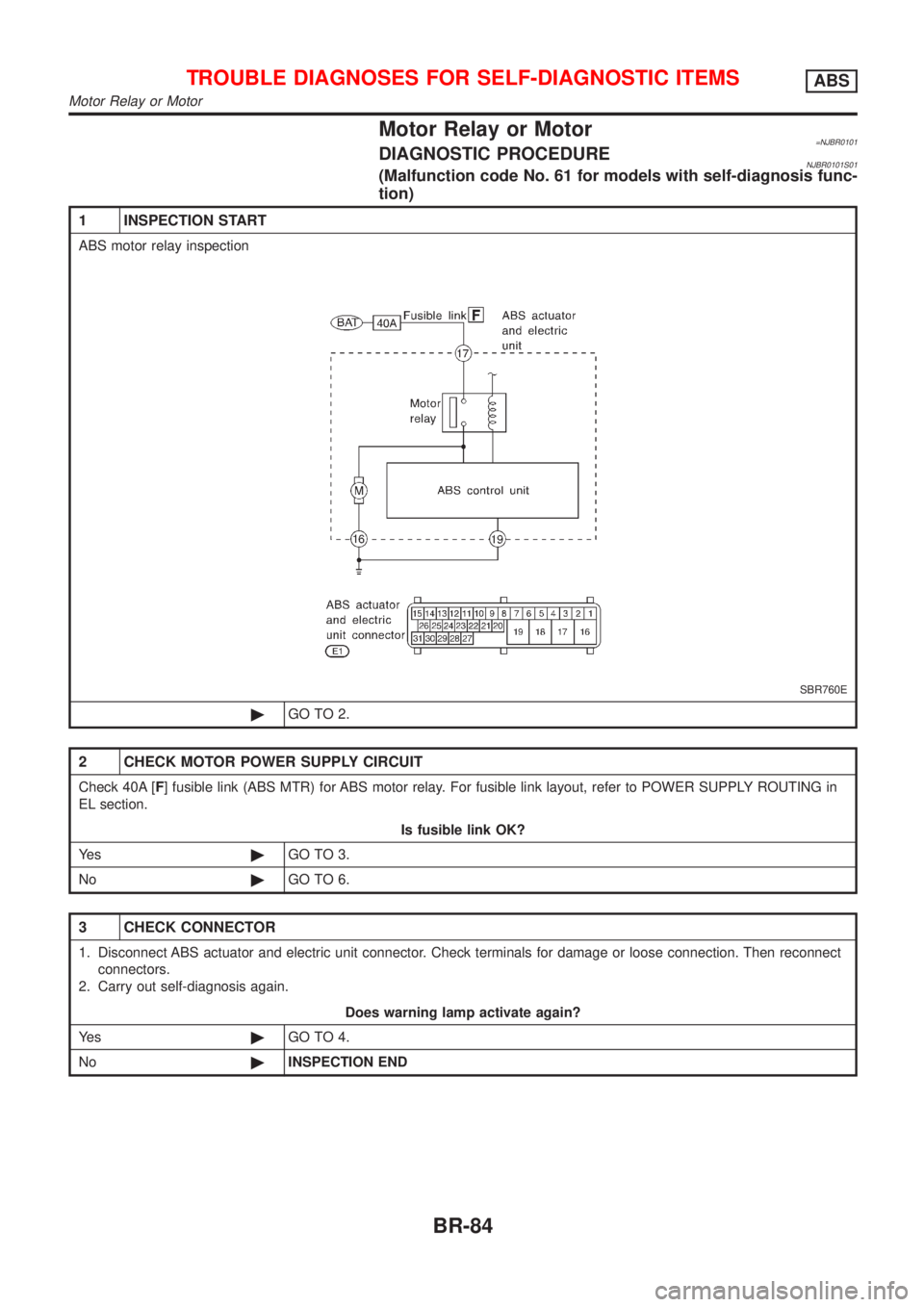

Motor Relay or Motor=NJBR0101DIAGNOSTIC PROCEDURENJBR0101S01(Malfunction code No. 61 for models with self-diagnosis func-

tion)

1 INSPECTION START

ABS motor relay inspection

SBR760E

©GO TO 2.

2 CHECK MOTOR POWER SUPPLY CIRCUIT

Check 40A [F] fusible link (ABS MTR) for ABS motor relay. For fusible link layout, refer to POWER SUPPLY ROUTING in

EL section.

Is fusible link OK?

Ye s©GO TO 3.

No©GO TO 6.

3 CHECK CONNECTOR

1. Disconnect ABS actuator and electric unit connector. Check terminals for damage or loose connection. Then reconnect

connectors.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s©GO TO 4.

No©INSPECTION END

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Motor Relay or Motor

BR-84

Page 601 of 2898

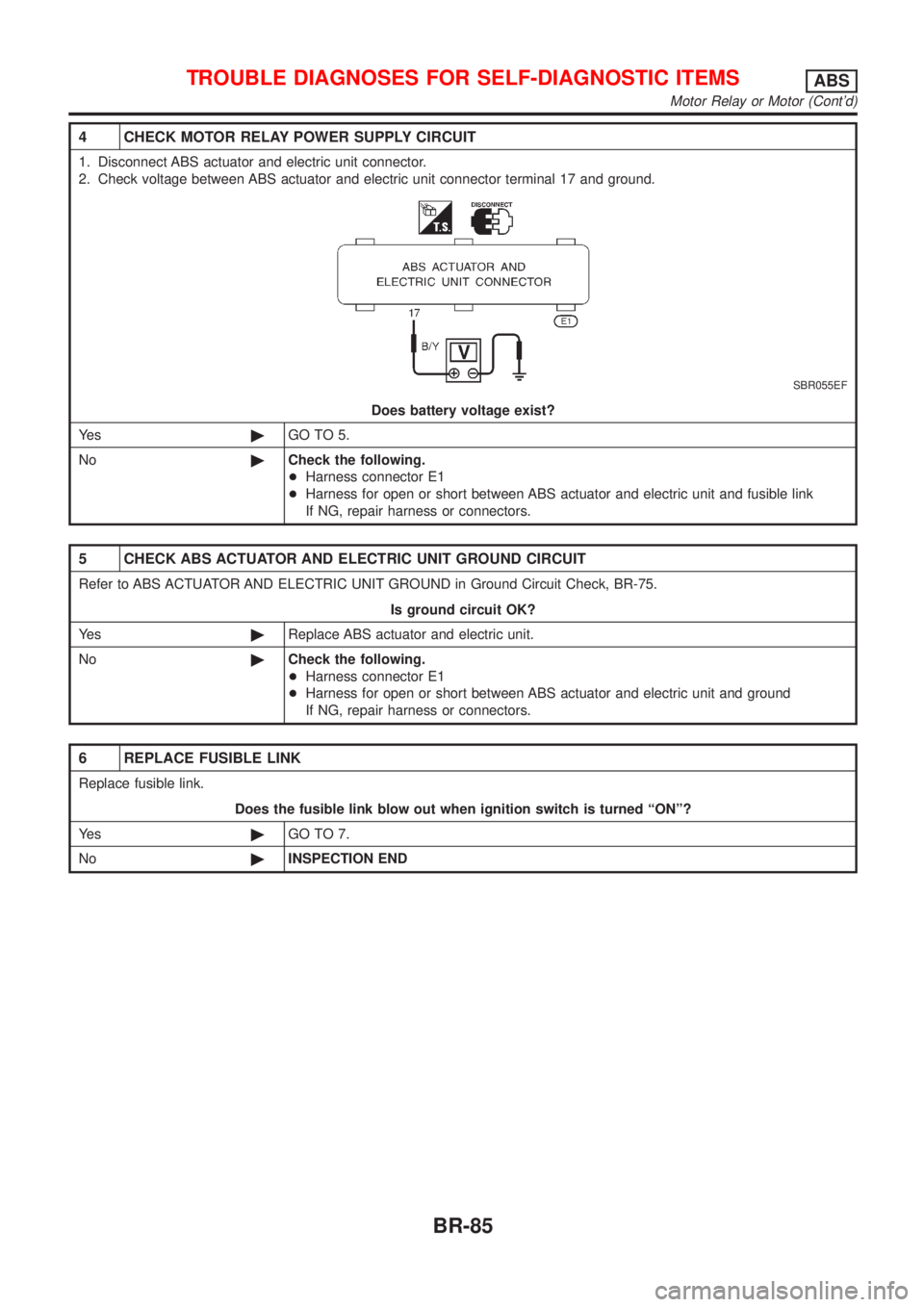

4 CHECK MOTOR RELAY POWER SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector terminal 17 and ground.

SBR055EF

Does battery voltage exist?

Ye s©GO TO 5.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fusible link

If NG, repair harness or connectors.

5 CHECK ABS ACTUATOR AND ELECTRIC UNIT GROUND CIRCUIT

Refer to ABS ACTUATOR AND ELECTRIC UNIT GROUND in Ground Circuit Check, BR-75.

Is ground circuit OK?

Ye s©Replace ABS actuator and electric unit.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and ground

If NG, repair harness or connectors.

6 REPLACE FUSIBLE LINK

Replace fusible link.

Does the fusible link blow out when ignition switch is turned ªONº?

Ye s©GO TO 7.

No©INSPECTION END

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Motor Relay or Motor (Cont'd)

BR-85

Page 602 of 2898

7 CHECK ABS ACTUATOR MOTOR POWER SUPPLY CIRCUIT

1. Disconnect battery cable and ABS actuator and electric unit connector.

2. Check continuity between ABS actuator and electric unit connector terminal 17 and ground.

SBR055EF

Does continuity exist?

Ye s©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fusible link

If NG, repair harness or connectors.

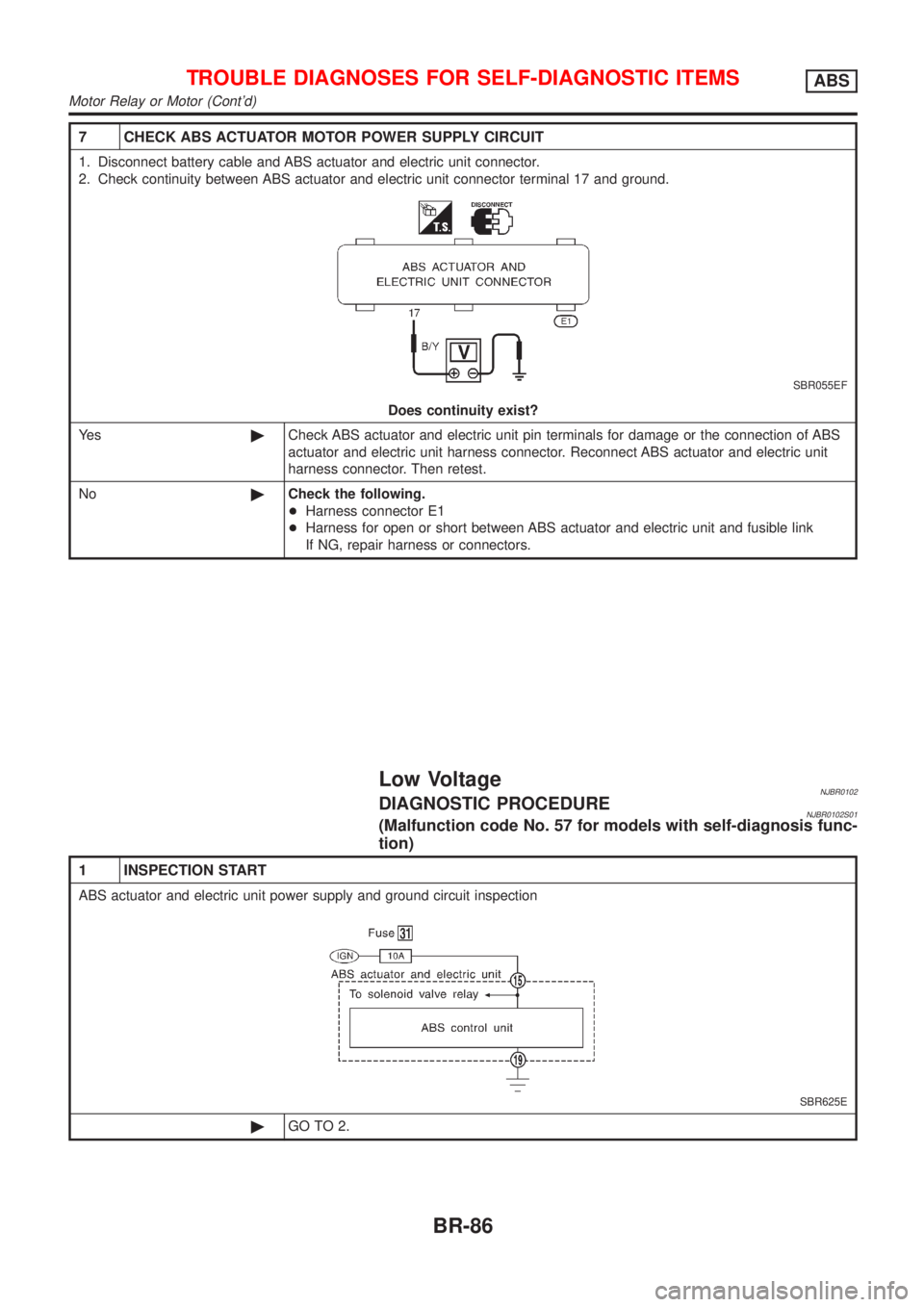

Low VoltageNJBR0102DIAGNOSTIC PROCEDURENJBR0102S01(Malfunction code No. 57 for models with self-diagnosis func-

tion)

1 INSPECTION START

ABS actuator and electric unit power supply and ground circuit inspection

SBR625E

©GO TO 2.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Motor Relay or Motor (Cont'd)

BR-86

Page 603 of 2898

2 CHECK CONNECTOR

1. Disconnect ABS actuator and electric unit connector. Check terminals for damage or loose connections. Then recon-

nect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s©GO TO 3.

No©INSPECTION END

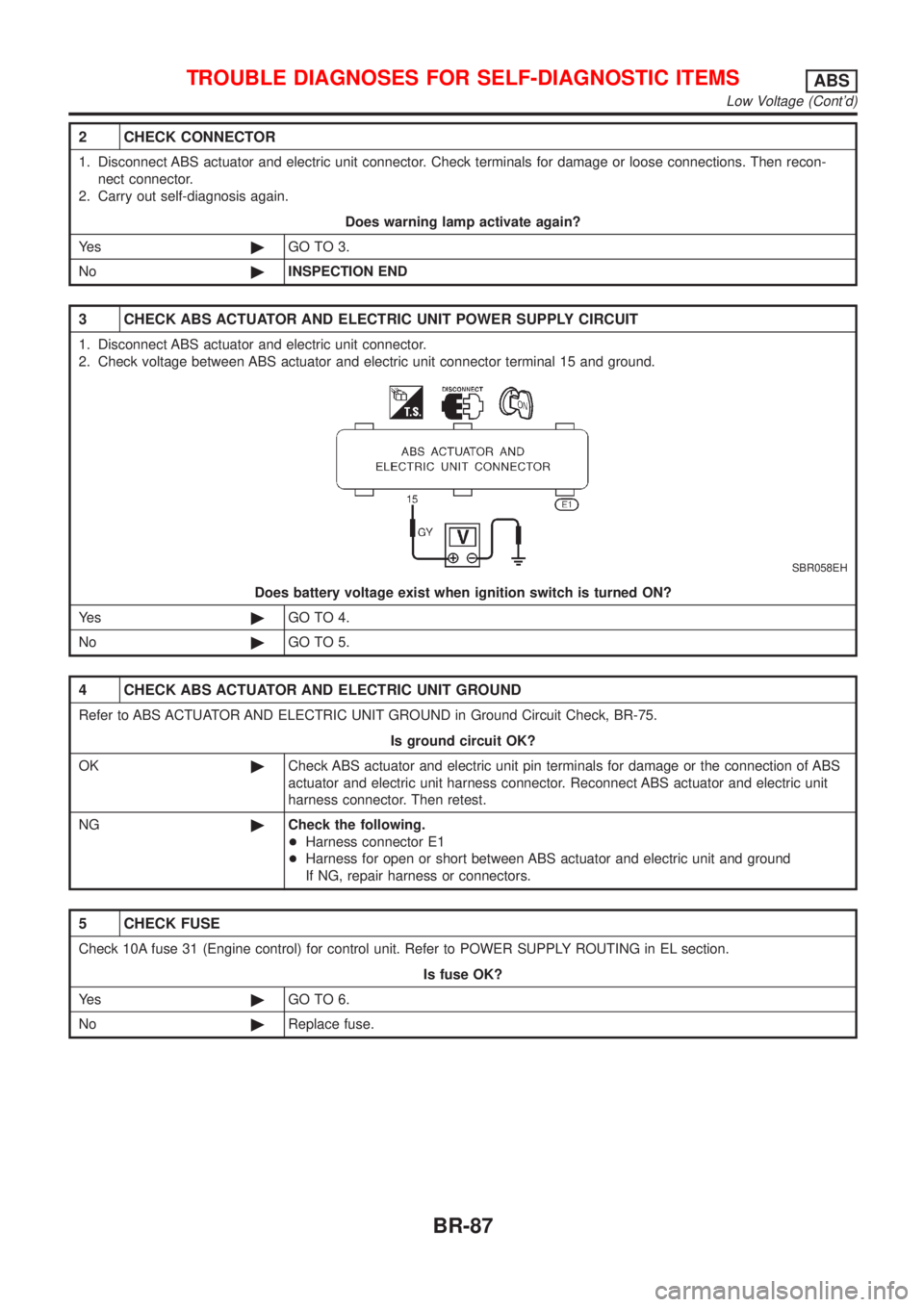

3 CHECK ABS ACTUATOR AND ELECTRIC UNIT POWER SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector terminal 15 and ground.

SBR058EH

Does battery voltage exist when ignition switch is turned ON?

Ye s©GO TO 4.

No©GO TO 5.

4 CHECK ABS ACTUATOR AND ELECTRIC UNIT GROUND

Refer to ABS ACTUATOR AND ELECTRIC UNIT GROUND in Ground Circuit Check, BR-75.

Is ground circuit OK?

OK©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

NG©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and ground

If NG, repair harness or connectors.

5 CHECK FUSE

Check 10A fuse 31 (Engine control) for control unit. Refer to POWER SUPPLY ROUTING in EL section.

Is fuse OK?

Ye s©GO TO 6.

No©Replace fuse.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Low Voltage (Cont'd)

BR-87

Page 604 of 2898

6 CHECK ABS ACTUATOR AND ELECTRIC UNIT POWER SUPPLY CIRCUIT

Check continuity between battery and ABS actuator and electric unit connector terminal 15.

Does continuity exist?

Ye s©Check battery. Refer to BATTERY in EL section.

No©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fuse

If NG, repair harness or connectors.

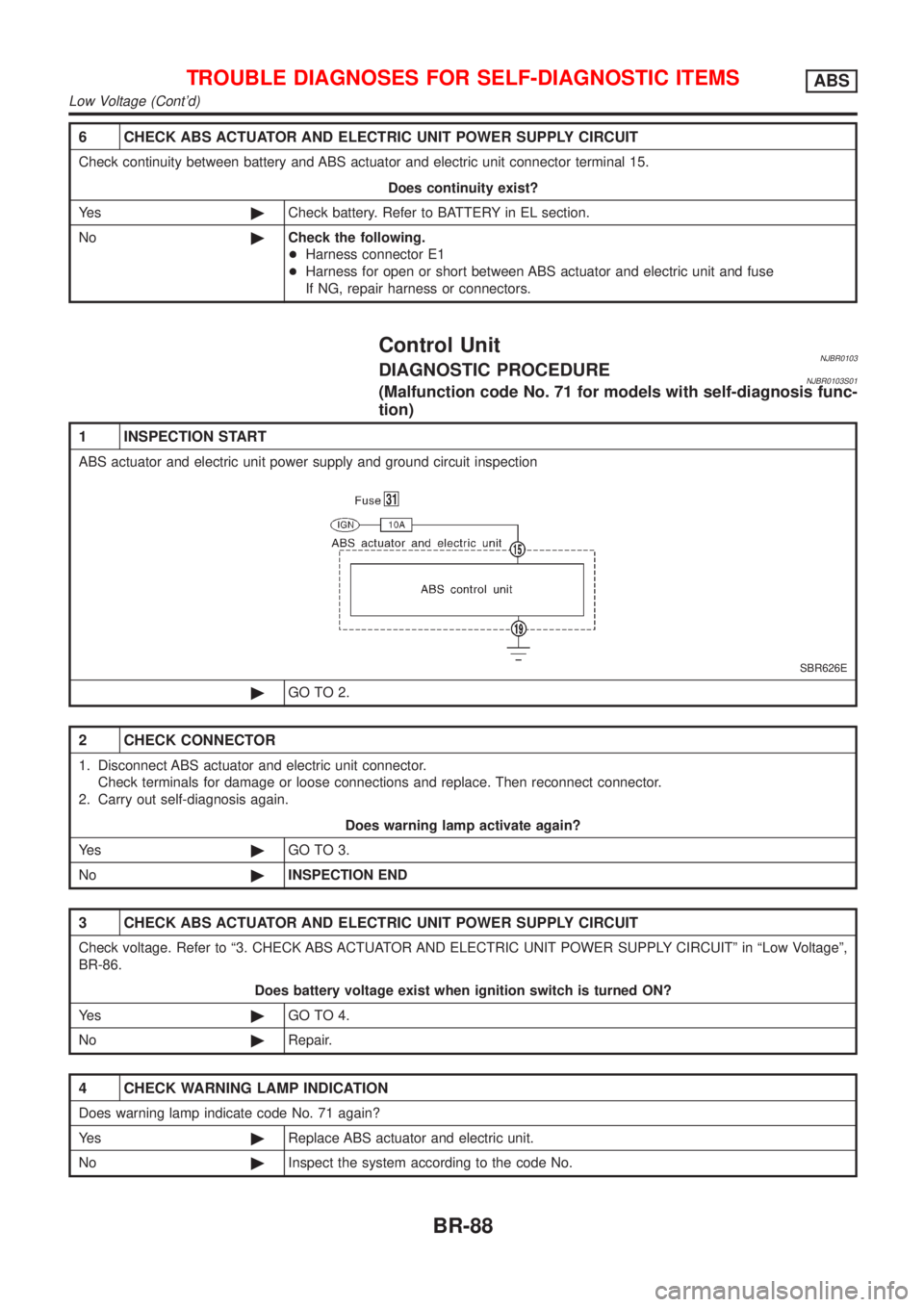

Control UnitNJBR0103DIAGNOSTIC PROCEDURENJBR0103S01(Malfunction code No. 71 for models with self-diagnosis func-

tion)

1 INSPECTION START

ABS actuator and electric unit power supply and ground circuit inspection

SBR626E

©GO TO 2.

2 CHECK CONNECTOR

1. Disconnect ABS actuator and electric unit connector.

Check terminals for damage or loose connections and replace. Then reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s©GO TO 3.

No©INSPECTION END

3 CHECK ABS ACTUATOR AND ELECTRIC UNIT POWER SUPPLY CIRCUIT

Check voltage. Refer to ª3. CHECK ABS ACTUATOR AND ELECTRIC UNIT POWER SUPPLY CIRCUITº in ªLow Voltageº,

BR-86.

Does battery voltage exist when ignition switch is turned ON?

Ye s©GO TO 4.

No©Repair.

4 CHECK WARNING LAMP INDICATION

Does warning lamp indicate code No. 71 again?

Ye s©Replace ABS actuator and electric unit.

No©Inspect the system according to the code No.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Low Voltage (Cont'd)

BR-88

Page 605 of 2898

1. ABS Works FrequentlyNJBR0104

1 CHECK BRAKE FLUID PRESSURE

Check brake fluid pressure distribution.

Is brake fluid pressure distribution normal?

Ye s©GO TO 2.

No©Perform Preliminary Check. Refer to BR-72.

2 CHECK WHEEL SENSOR

1. Check wheel sensor connector for terminal damage or loose connections.

2. Perform wheel sensor mechanical check.

Refer to ªWheel Sensor or Rotorº, BR-78.

Are wheel sensors functioning properly?

Ye s©GO TO 3.

No©Repair.

3 CHECK FRONT AXLE

Check front and rear axles for excessive looseness. Refer to AX section, ªFront Wheel Bearingº, ªON-VEHICLE SERVICEº

and ªRear Wheel Bearingº, ªON-VEHICLE SERVICEº.

Is front axle installed properly?

Ye s©Go to ª3. CHECK WARNING LAMP INDICATIONº in ª2. Unexpected Pedal Actionº,

BR-89.

No©Repair.

2. Unexpected Pedal ActionNJBR0105

1 CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Is stroke excessively large?

SBR540A

Ye s©Perform Preliminary Check. Refer to BR-72.

No©GO TO 2.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

1. ABS Works Frequently

BR-89