check engine NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2565 of 2898

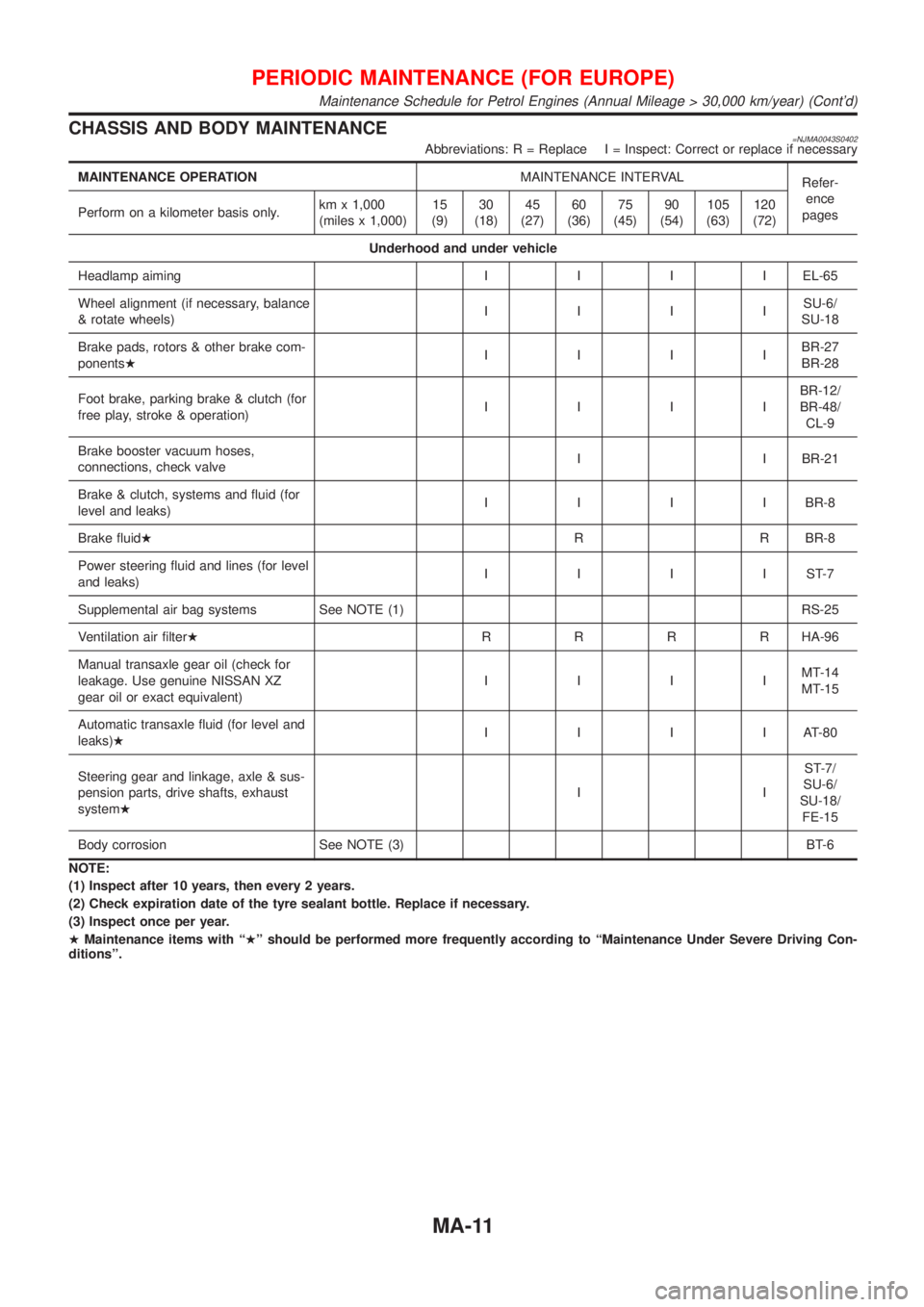

CHASSIS AND BODY MAINTENANCE=NJMA0043S0402Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis only.km x 1,000

(miles x 1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Underhood and under vehicle

Headlamp aimingIIIIEL-65

Wheel alignment (if necessary, balance

& rotate wheels)IIIISU-6/

SU-18

Brake pads, rotors & other brake com-

ponentsHIIIIBR-27

BR-28

Foot brake, parking brake & clutch (for

free play, stroke & operation)IIIIBR-12/

BR-48/

CL-9

Brake booster vacuum hoses,

connections, check valveI I BR-21

Brake & clutch, systems and fluid (for

level and leaks)IIIIBR-8

Brake fluidHR R BR-8

Power steering fluid and lines (for level

and leaks)IIIIST-7

Supplemental air bag systems See NOTE (1) RS-25

Ventilation air filterHRRRRHA-96

Manual transaxle gear oil (check for

leakage. Use genuine NISSAN XZ

gear oil or exact equivalent)IIIIMT-14

MT-15

Automatic transaxle fluid (for level and

leaks)HIIIIAT-80

Steering gear and linkage, axle & sus-

pension parts, drive shafts, exhaust

systemHIIST-7/

SU-6/

SU-18/

FE-15

Body corrosion See NOTE (3) BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage > 30,000 km/year) (Cont'd)

MA-11

Page 2566 of 2898

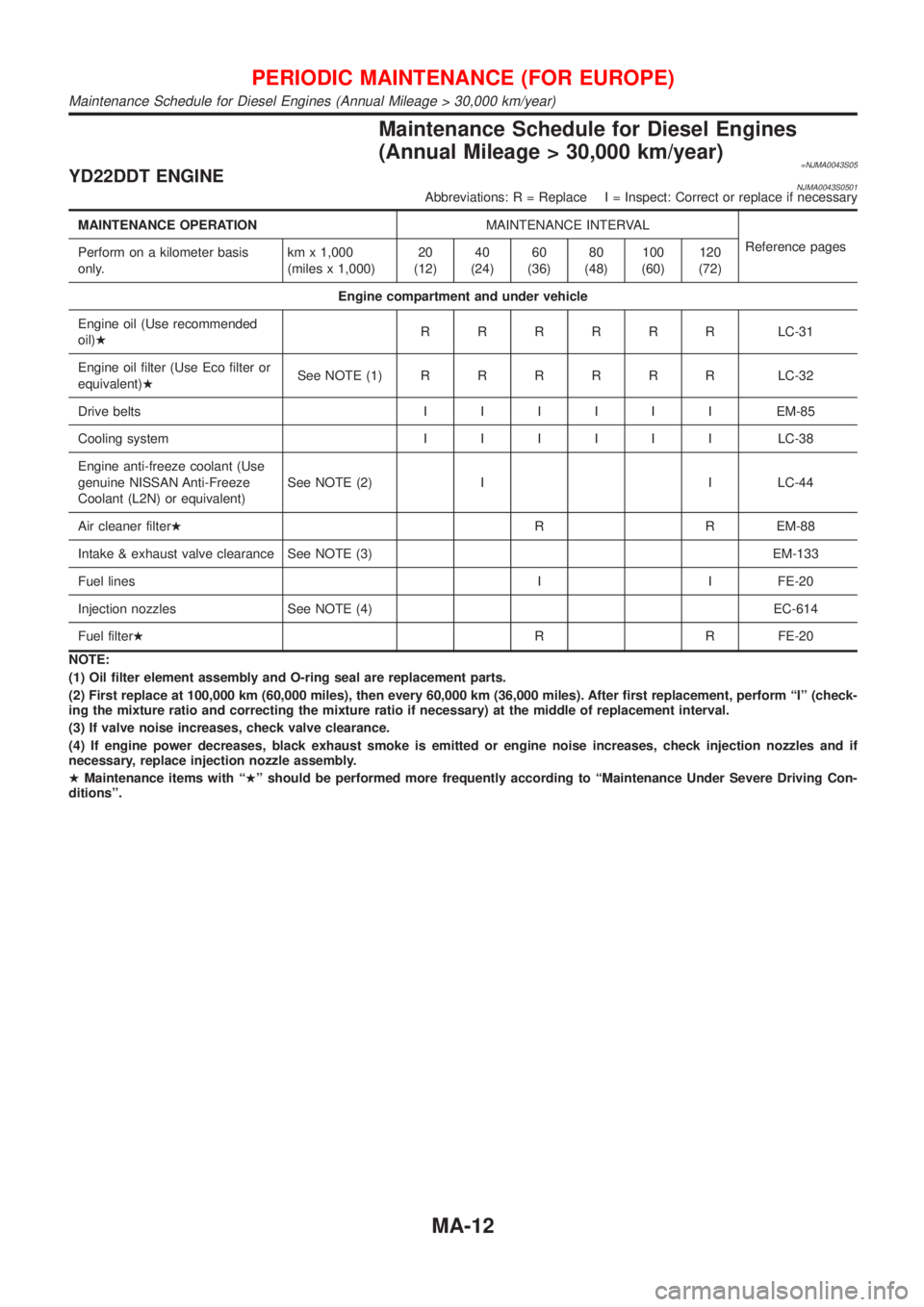

Maintenance Schedule for Diesel Engines

(Annual Mileage > 30,000 km/year)

=NJMA0043S05YD22DDT ENGINENJMA0043S0501Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference pages

Perform on a kilometer basis

only.km x 1,000

(miles x 1,000)20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

Engine compartment and under vehicle

Engine oil (Use recommended

oil)HRRRRRRLC-31

Engine oil filter (Use Eco filter or

equivalent)HSee NOTE (1)RRRRRRLC-32

Drive beltsIIIIIIEM-85

Cooling systemIIIIIILC-38

Engine anti-freeze coolant (Use

genuine NISSAN Anti-Freeze

Coolant (L2N) or equivalent)See NOTE (2) I I LC-44

Air cleaner filterHR R EM-88

Intake & exhaust valve clearance See NOTE (3) EM-133

Fuel lines I I FE-20

Injection nozzles See NOTE (4) EC-614

Fuel filterHR R FE-20

NOTE:

(1) Oil filter element assembly and O-ring seal are replacement parts.

(2) First replace at 100,000 km (60,000 miles), then every 60,000 km (36,000 miles). After first replacement, perform ªIº (check-

ing the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(3) If valve noise increases, check valve clearance.

(4) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check injection nozzles and if

necessary, replace injection nozzle assembly.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Diesel Engines (Annual Mileage > 30,000 km/year)

MA-12

Page 2567 of 2898

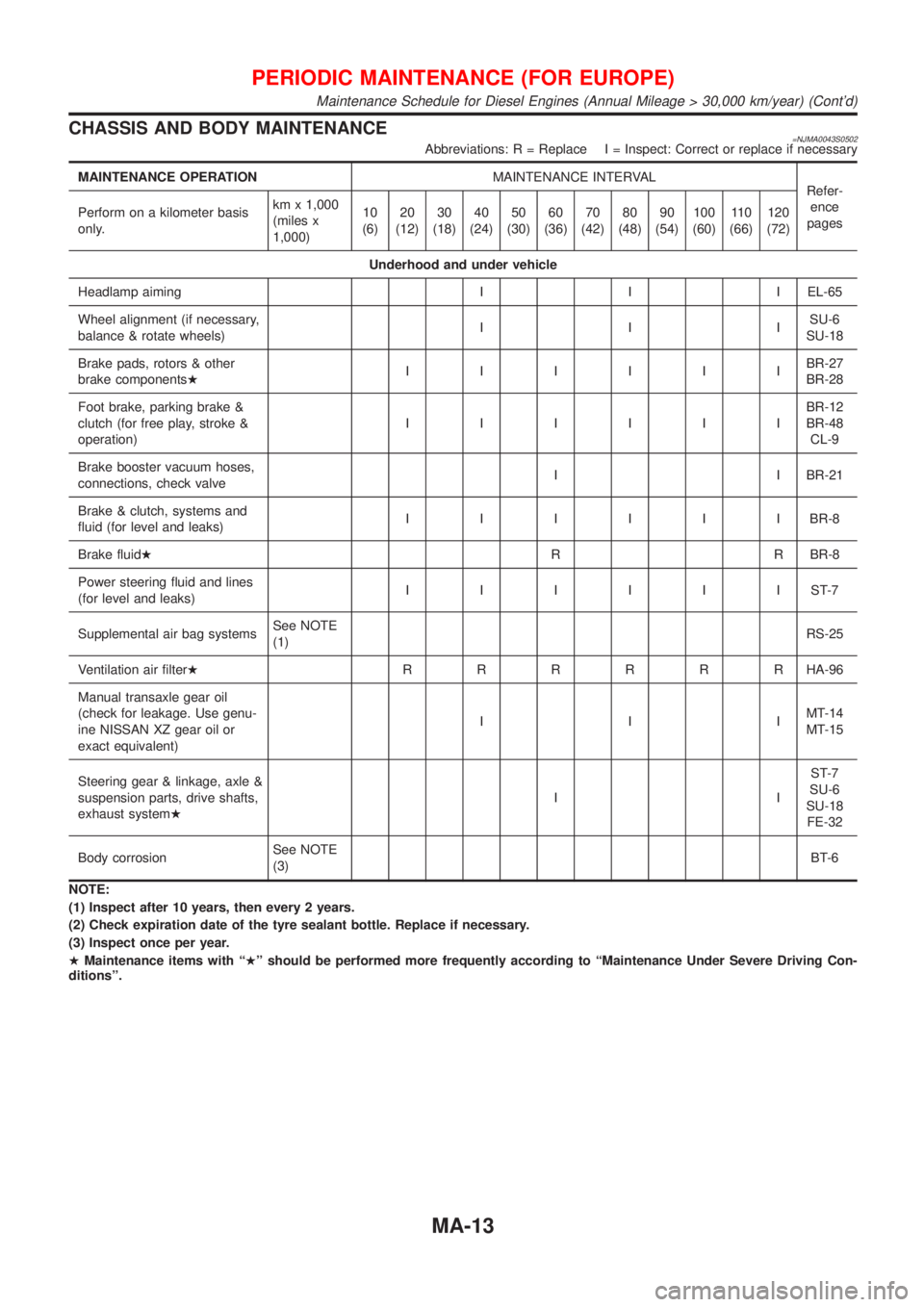

CHASSIS AND BODY MAINTENANCE=NJMA0043S0502Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis

only.km x 1,000

(miles x

1,000)10

(6)20

(12)30

(18)40

(24)50

(30)60

(36)70

(42)80

(48)90

(54)100

(60)11 0

(66)120

(72)

Underhood and under vehicle

Headlamp aiming I I I EL-65

Wheel alignment (if necessary,

balance & rotate wheels)IIISU-6

SU-18

Brake pads, rotors & other

brake componentsHIIIIIIBR-27

BR-28

Foot brake, parking brake &

clutch (for free play, stroke &

operation)IIIIIIBR-12

BR-48

CL-9

Brake booster vacuum hoses,

connections, check valveI I BR-21

Brake & clutch, systems and

fluid (for level and leaks)IIIIIIBR-8

Brake fluidHR R BR-8

Power steering fluid and lines

(for level and leaks)IIIIIIST-7

Supplemental air bag systemsSee NOTE

(1)RS-25

Ventilation air filterHRRRRRRHA-96

Manual transaxle gear oil

(check for leakage. Use genu-

ine NISSAN XZ gear oil or

exact equivalent)IIIMT-14

MT-15

Steering gear & linkage, axle &

suspension parts, drive shafts,

exhaust systemHIIST-7

SU-6

SU-18

FE-32

Body corrosionSee NOTE

(3)BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Diesel Engines (Annual Mileage > 30,000 km/year) (Cont'd)

MA-13

Page 2572 of 2898

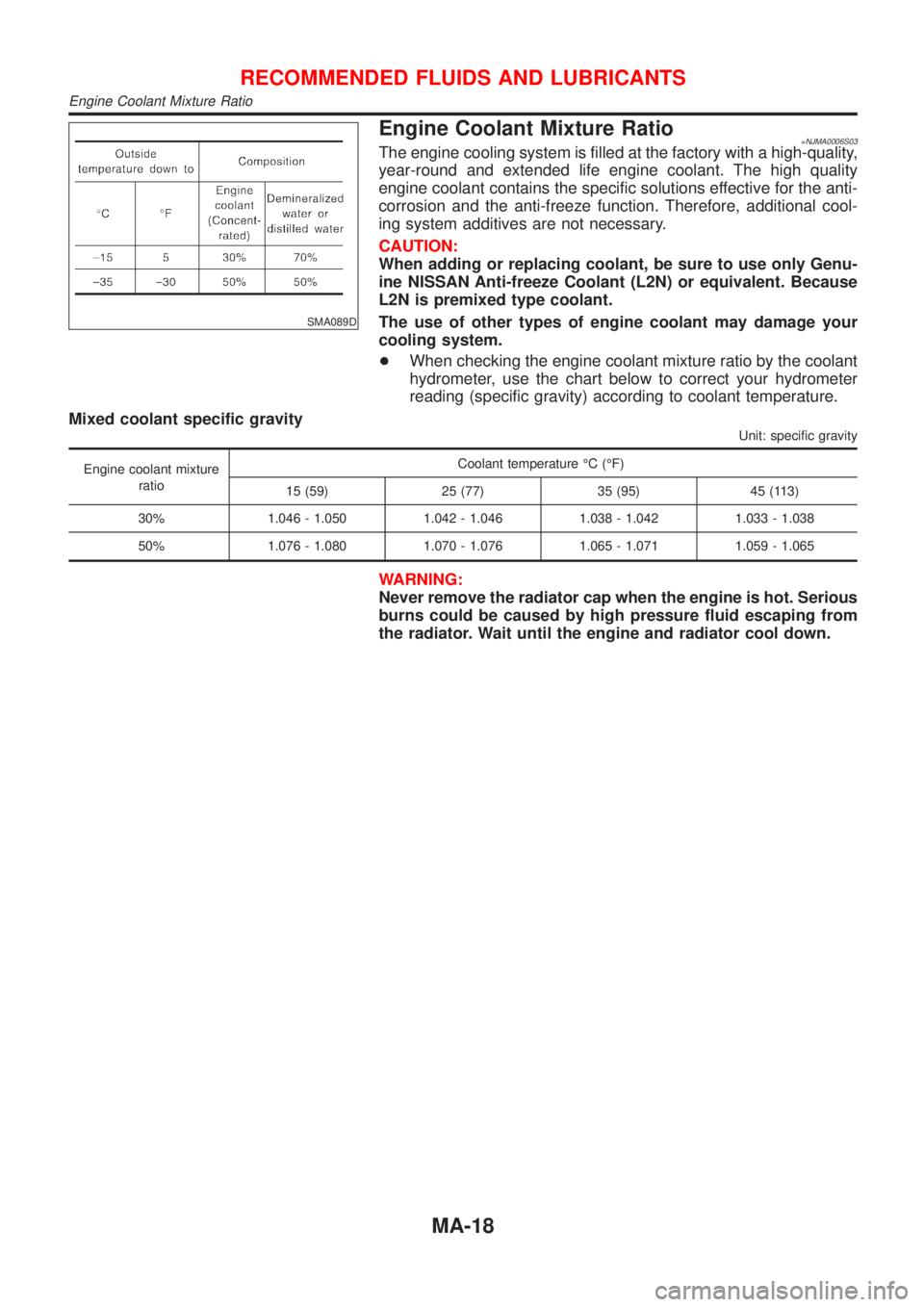

SMA089D

Engine Coolant Mixture Ratio=NJMA0006S03The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality

engine coolant contains the specific solutions effective for the anti-

corrosion and the anti-freeze function. Therefore, additional cool-

ing system additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genu-

ine NISSAN Anti-freeze Coolant (L2N) or equivalent. Because

L2N is premixed type coolant.

The use of other types of engine coolant may damage your

cooling system.

+When checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer

reading (specific gravity) according to coolant temperature.

Mixed coolant specific gravity

Unit: specific gravity

Engine coolant mixture

ratioCoolant temperature ÉC (ÉF)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator. Wait until the engine and radiator cool down.

RECOMMENDED FLUIDS AND LUBRICANTS

Engine Coolant Mixture Ratio

MA-18

Page 2573 of 2898

MANUAL TRANSAXLE

SECTION

MT

CONTENTS

RS5F30A

PREPARATION...............................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

RS5F70A

PREPARATION...............................................................7

Special Service Tools ..................................................7

Commercial Service Tools ...........................................9

RS5F50A

PREPARATION.............................................................10

Special Service Tools ................................................10

Commercial Service Tools .........................................12

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING...................................................13

NVH Troubleshooting Chart.......................................13

MANUAL TRANSAXLE.............................................13

RS5F30A, RS5F70A

M/T OIL..........................................................................14

Changing M/T Oil.......................................................14

Checking ....................................................................14

OIL LEAK AND OIL LEVEL.......................................14

RS5F50A

M/T OIL..........................................................................15

Changing M/T Oil.......................................................15

Checking ....................................................................15

OIL LEAK AND OIL LEVEL.......................................15

DESCRIPTION...............................................................16

Cross-sectional View - RS5F30A ..............................16Cross-sectional View - RS5F70A ..............................17

Cross-sectional View - RS5F50A ..............................18

DOUBLE-CONE SYNCHRONIZER............................19

ON-VEHICLE SERVICE................................................20

Replacing Oil Seal .....................................................20

DIFFERENTIAL OIL SEAL........................................20

STRIKING ROD OIL SEAL.......................................21

Position Switch Check ...............................................21

BACK-UP LAMP SWITCH........................................21

PNP SWITCH..........................................................22

BACK-UP LAMP SWITCH AND PNP SWITCH...........22

RS5F30A, RS5F70A

REMOVAL AND INSTALLATION.................................23

Removal .....................................................................23

Installation ..................................................................24

MODEL QG15DE ENGINE.......................................24

MODEL QG18DE ENGINE.......................................25

RS5F50A

REMOVAL AND INSTALLATION.................................26

Removal .....................................................................26

Installation ..................................................................28

MODEL YD ENGINE................................................28

TRANSAXLE GEAR CONTROL...................................29

Components...............................................................29

RS5F30A

OVERHAUL...................................................................30

Case Components .....................................................30

Gear Components .....................................................31

Shift Control Components .........................................32

DISASSEMBLY..............................................................33

REPAIR FOR COMPONENT PARTS...........................36

Input Shaft and Gears ...............................................36

DISASSEMBLY........................................................36

Page 2586 of 2898

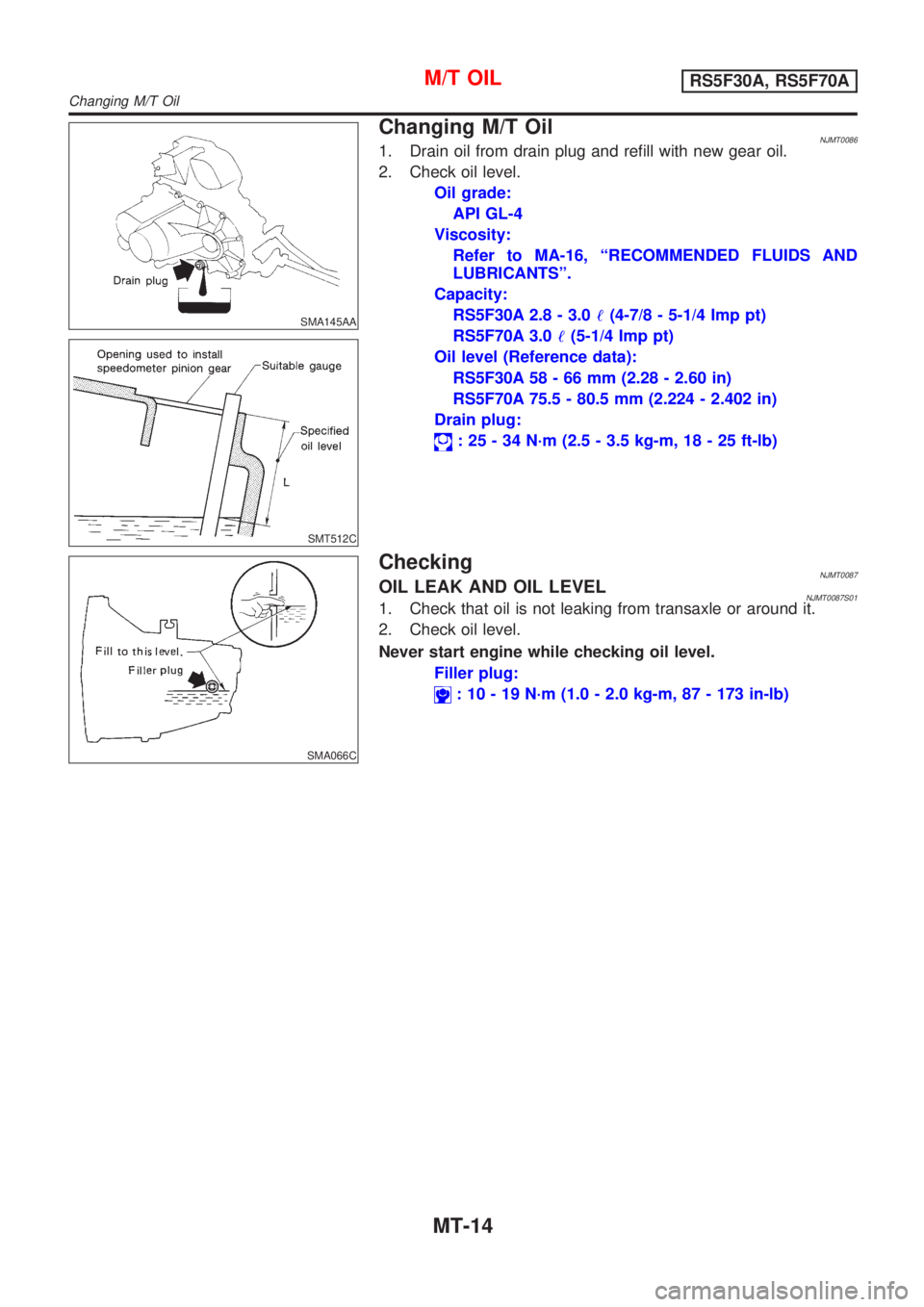

SMA145AA

SMT512C

Changing M/T OilNJMT00861. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade:

API GL-4

Viscosity:

Refer to MA-16, ªRECOMMENDED FLUIDS AND

LUBRICANTSº.

Capacity:

RS5F30A 2.8 - 3.0!(4-7/8 - 5-1/4 Imp pt)

RS5F70A 3.0!(5-1/4 Imp pt)

Oil level (Reference data):

RS5F30A 58 - 66 mm (2.28 - 2.60 in)

RS5F70A 75.5 - 80.5 mm (2.224 - 2.402 in)

Drain plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

SMA066C

CheckingNJMT0087OIL LEAK AND OIL LEVELNJMT0087S011. Check that oil is not leaking from transaxle or around it.

2. Check oil level.

Never start engine while checking oil level.

Filler plug:

: 10 - 19 N´m (1.0 - 2.0 kg-m, 87 - 173 in-lb)

M/T OILRS5F30A, RS5F70A

Changing M/T Oil

MT-14

Page 2587 of 2898

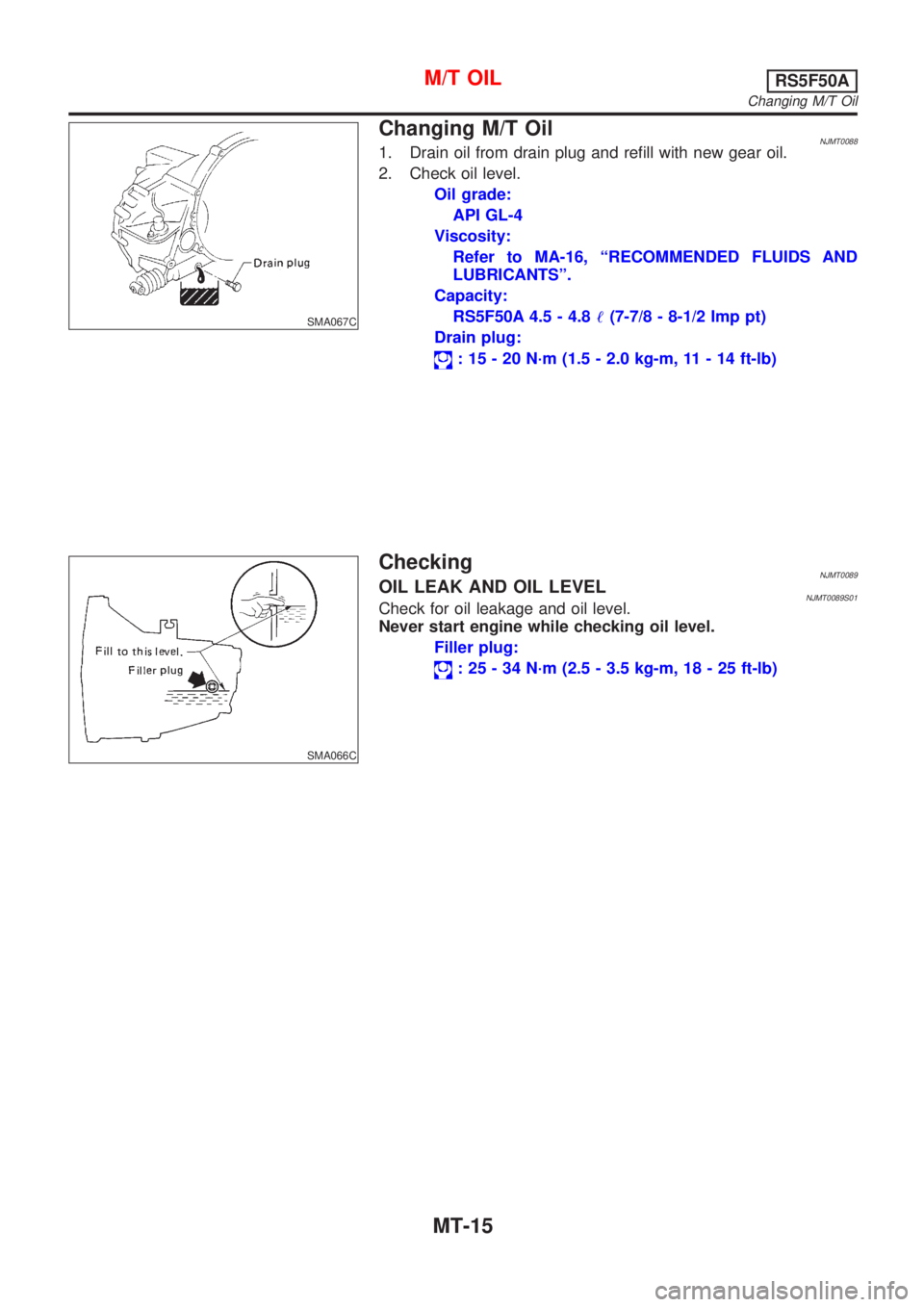

SMA067C

Changing M/T OilNJMT00881. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade:

API GL-4

Viscosity:

Refer to MA-16, ªRECOMMENDED FLUIDS AND

LUBRICANTSº.

Capacity:

RS5F50A 4.5 - 4.8!(7-7/8 - 8-1/2 Imp pt)

Drain plug:

: 15 - 20 N´m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

SMA066C

CheckingNJMT0089OIL LEAK AND OIL LEVELNJMT0089S01Check for oil leakage and oil level.

Never start engine while checking oil level.

Filler plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

M/T OILRS5F50A

Changing M/T Oil

MT-15

Page 2797 of 2898

STARTING & CHARGING SYSTEMS

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY.........................................................................3

How to Handle Battery ................................................3

METHODS OF PREVENTING OVER-DISCHARGE......3

CHECKING ELECTROLYTE LEVEL............................3

SPECIFIC GRAVITY CHECK......................................4

Battery Test and Charging Chart .................................6

CHART I...................................................................6

CHART II..................................................................7

A: SLOW CHARGE....................................................8

B: STANDARD CHARGE..........................................10

C: QUICK CHARGE................................................. 11

STARTING SYSTEM.....................................................13

System Description ....................................................13

M/T MODELS..........................................................13

A/T MODELS...........................................................13

Wiring Diagram - START -/Sedan .............................14

M/T MODELS..........................................................14

A/T MODELS...........................................................15

Wiring Diagram - START -/Hatchback.......................16

Trouble Diagnoses.....................................................17

Construction ...............................................................18

Removal and Installation ...........................................21

REMOVAL...............................................................21

INSTALLATION........................................................21

Inspection...................................................................21

MAGNETIC SWITCH CHECK...................................21

PINION/CLUTCH CHECK.........................................21

BRUSH CHECK.......................................................22

YOKE CHECK.........................................................23

ARMATURE CHECK................................................23

Assembly ...................................................................24

PINION PROTRUSION LENGTH ADJUSTMENT........24

CHARGING SYSTEM....................................................26

System Description ....................................................26

SEDAN...................................................................26

HATCHBACK...........................................................26

Wiring Diagram - CHARGE -/Sedan .........................27

GASOLINE ENGINE MODELS..................................27

DIESEL ENGINE MODELS.......................................28

Wiring Diagram - CHARGE -/Hatchback...................29

Trouble Diagnoses.....................................................30

WITH IC REGULATOR.............................................30

MALFUNCTION INDICATOR....................................30

Construction ...............................................................31

Removal and Installation ...........................................34

REMOVAL (QG ENGINE).........................................34

REMOVAL (YD ENGINE)..........................................34

INSTALLATION........................................................35

Disassembly...............................................................35

REAR COVER.........................................................35

REAR BEARING......................................................35

Inspection...................................................................35

ROTOR CHECK......................................................35

BRUSH CHECK.......................................................36

STATOR CHECK.....................................................36

Assembly ...................................................................36

RING FITTING IN REAR BEARING...........................36

REAR COVER INSTALLATION.................................37

SERVICE DATA AND SPECIFICATIONS (SDS).........38

Battery........................................................................38

Starter ........................................................................38

Alternator ...................................................................39

Page 2799 of 2898

How to Handle BatteryNJSC0003CAUTION:

If it becomes necessary to start the engine with a booster

battery and jumper cables,

1) Use a 12-volt booster battery.

2) After connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

MEL040F

METHODS OF PREVENTING OVER-DISCHARGENJSC0003S01The following precautions must be taken to prevent over-discharg-

ing a battery.

+The battery surface (particularly its top) should always be kept

clean and dry.

+The terminal connections should be clean and tight.

+At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as ªlow maintenanceº

and ªmaintenance-freeº.

MEL041F

+When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal.

MEL042F

+Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVELNJSC0003S02WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

BATTERY

How to Handle Battery

SC-3

Page 2820 of 2898

SEL022Z

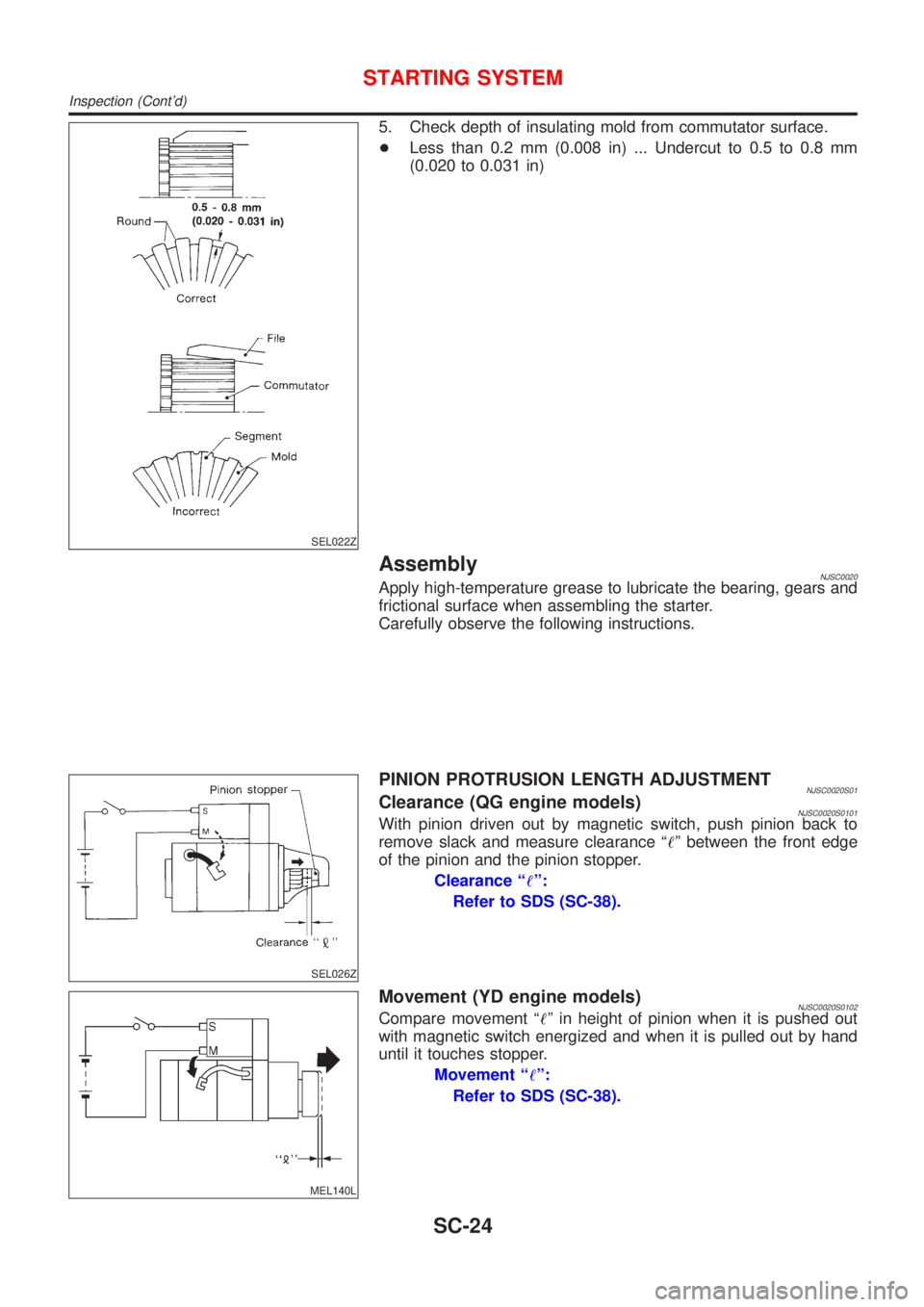

5. Check depth of insulating mold from commutator surface.

+Less than 0.2 mm (0.008 in) ... Undercut to 0.5 to 0.8 mm

(0.020 to 0.031 in)

AssemblyNJSC0020Apply high-temperature grease to lubricate the bearing, gears and

frictional surface when assembling the starter.

Carefully observe the following instructions.

SEL026Z

PINION PROTRUSION LENGTH ADJUSTMENTNJSC0020S01Clearance (QG engine models)NJSC0020S0101With pinion driven out by magnetic switch, push pinion back to

remove slack and measure clearance ª!º between the front edge

of the pinion and the pinion stopper.

Clearance ª!º:

Refer to SDS (SC-38).

MEL140L

Movement (YD engine models)NJSC0020S0102Compare movement ª!º in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

Movement ª!º:

Refer to SDS (SC-38).

STARTING SYSTEM

Inspection (Cont'd)

SC-24