OBD port NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 61 of 2898

![NISSAN ALMERA 2001 Service Manual Item DisplayMonitor item

Description Remarks

ECU input

signalsMain sig-

nals

Throttle position THROTTLE

POSI

[/8]ÐX+Throttle position data,

used for computation by

TCM, is displayed.+A specific value NISSAN ALMERA 2001 Service Manual Item DisplayMonitor item

Description Remarks

ECU input

signalsMain sig-

nals

Throttle position THROTTLE

POSI

[/8]ÐX+Throttle position data,

used for computation by

TCM, is displayed.+A specific value](/img/5/57348/w960_57348-60.png)

Item DisplayMonitor item

Description Remarks

ECU input

signalsMain sig-

nals

Throttle position THROTTLE

POSI

[/8]ÐX+Throttle position data,

used for computation by

TCM, is displayed.+A specific value used for

control is displayed if

fail-safe is activated due

to error.

Line pressure duty LINE PRES DTY

[%]

ÐX+Control value of line

pressure solenoid valve,

computed by TCM from

each input signal, is dis-

played.

Torque converter clutch

solenoid valve dutyTCC S/V DUTY

[%]

ÐX+Control value of torque

converter clutch sole-

noid valve, computed by

TCM from each input

signal, is displayed.

Shift solenoid valve A SHIFT S/V A

[ON/OFF]

ÐX+Control value of shift

solenoid valve A, com-

puted by TCM from

each input signal, is dis-

played.Control value of solenoid is

displayed even if solenoid

circuit is disconnected.

The ªOFFº signal is dis-

played if solenoid circuit is

shorted.

Shift solenoid valve B SHIFT S/V B

[ON/OFF]

ÐX+Control value of shift

solenoid valve B, com-

puted by TCM from

each input signal, is dis-

played.

Overrun clutch solenoid

valveOVERRUN/C S/V

[ON/OFF]

ÐX+Control value of overrun

clutch solenoid valve

computed by TCM from

each input signal is dis-

played.

Self-diagnosis display lamp

(O/D OFF indicator lamp)SELF-D DP LMP

[ON/OFF] Ð X+Control status of O/D

OFF indicator lamp is

displayed.

X: Applicable

Ð: Not applicable

SAT998J

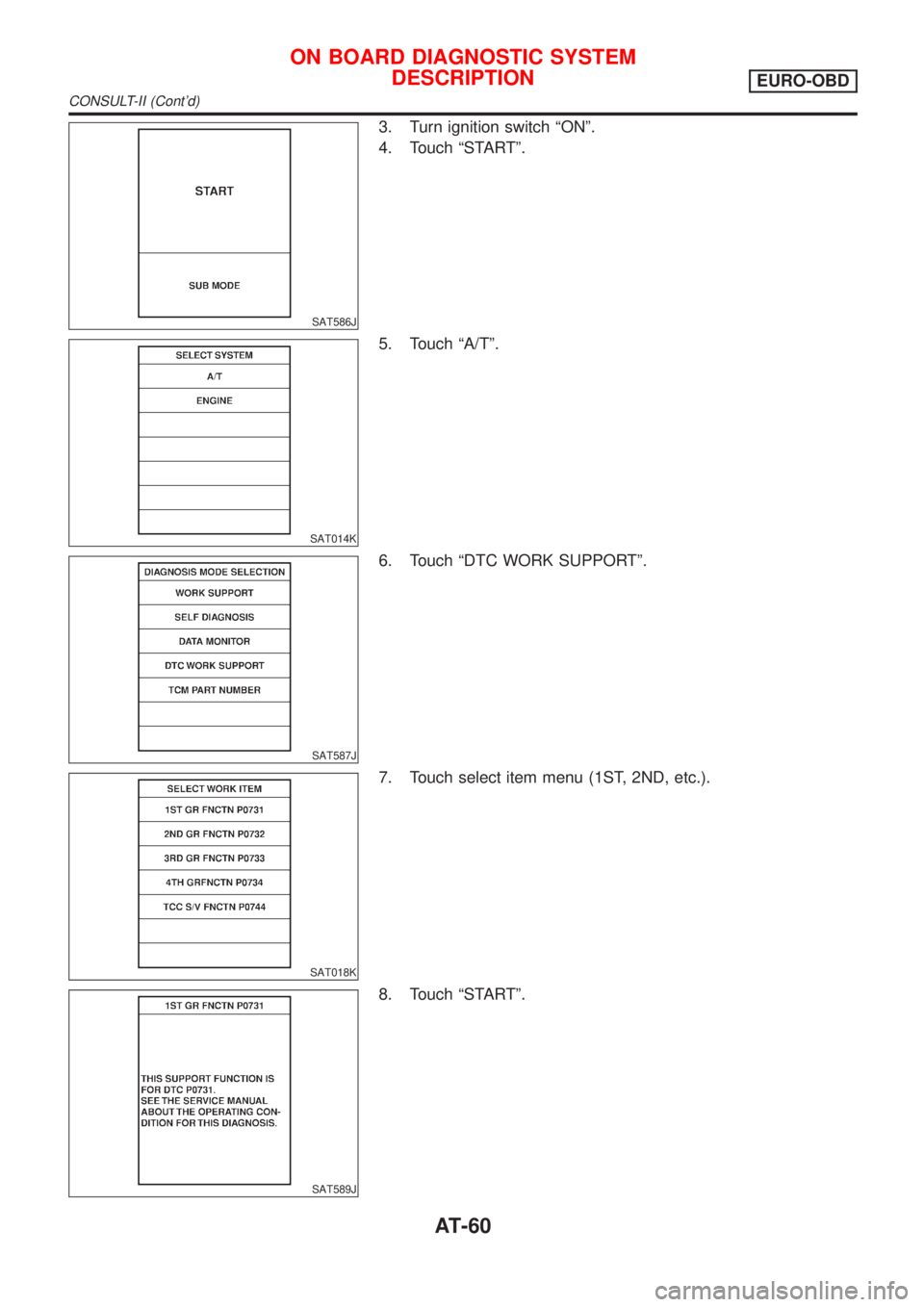

DTC WORK SUPPORT MODE WITH CONSULT-IINJAT0256S04CONSULT-II Setting ProcedureNJAT0256S04011. Turn ignition switch ªOFFº.

2. Connect CONSULT-II to data link connector which is located

in left side lower dash panel.

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

EURO-OBD

CONSULT-II (Cont'd)

AT-59

Page 62 of 2898

SAT586J

3. Turn ignition switch ªONº.

4. Touch ªSTARTº.

SAT014K

5. Touch ªA/Tº.

SAT587J

6. Touch ªDTC WORK SUPPORTº.

SAT018K

7. Touch select item menu (1ST, 2ND, etc.).

SAT589J

8. Touch ªSTARTº.

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

EURO-OBD

CONSULT-II (Cont'd)

AT-60

Page 64 of 2898

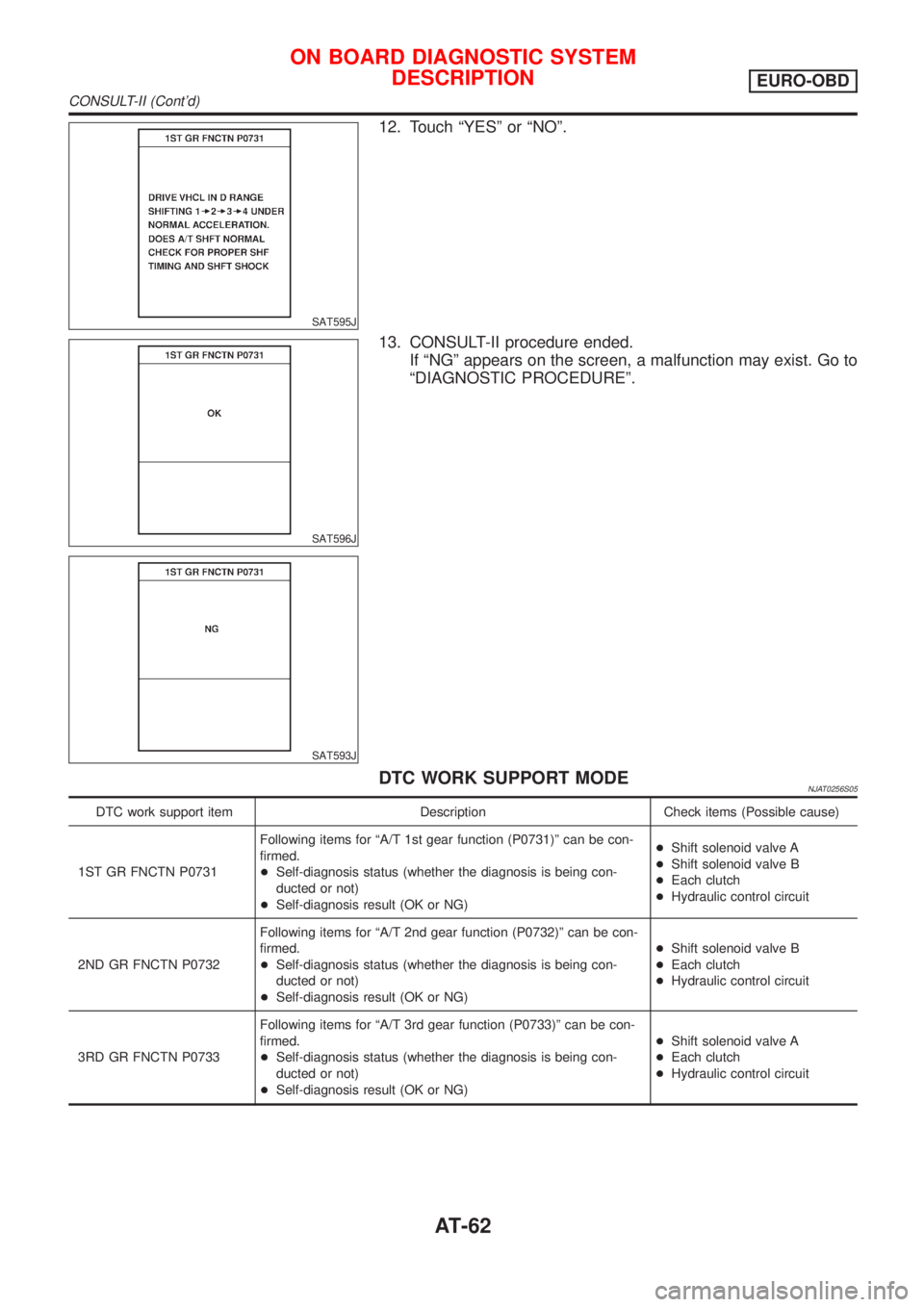

SAT595J

12. Touch ªYESº or ªNOº.

SAT596J

SAT593J

13. CONSULT-II procedure ended.

If ªNGº appears on the screen, a malfunction may exist. Go to

ªDIAGNOSTIC PROCEDUREº.

DTC WORK SUPPORT MODENJAT0256S05

DTC work support item Description Check items (Possible cause)

1ST GR FNCTN P0731Following items for ªA/T 1st gear function (P0731)º can be con-

firmed.

+Self-diagnosis status (whether the diagnosis is being con-

ducted or not)

+Self-diagnosis result (OK or NG)+Shift solenoid valve A

+Shift solenoid valve B

+Each clutch

+Hydraulic control circuit

2ND GR FNCTN P0732Following items for ªA/T 2nd gear function (P0732)º can be con-

firmed.

+Self-diagnosis status (whether the diagnosis is being con-

ducted or not)

+Self-diagnosis result (OK or NG)+Shift solenoid valve B

+Each clutch

+Hydraulic control circuit

3RD GR FNCTN P0733Following items for ªA/T 3rd gear function (P0733)º can be con-

firmed.

+Self-diagnosis status (whether the diagnosis is being con-

ducted or not)

+Self-diagnosis result (OK or NG)+Shift solenoid valve A

+Each clutch

+Hydraulic control circuit

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

EURO-OBD

CONSULT-II (Cont'd)

AT-62

Page 65 of 2898

DTC work support item Description Check items (Possible cause)

4TH GR FNCTN P0734Following items for ªA/T 4th gear function (P0734)º can be con-

firmed.

+Self-diagnosis status (whether the diagnosis is being con-

ducted or not)

+Self-diagnosis result (OK or NG)+Shift solenoid valve A

+Shift solenoid valve B

+Overrun clutch solenoid valve

+Line pressure solenoid valve

+Each clutch

+Hydraulic control circuit

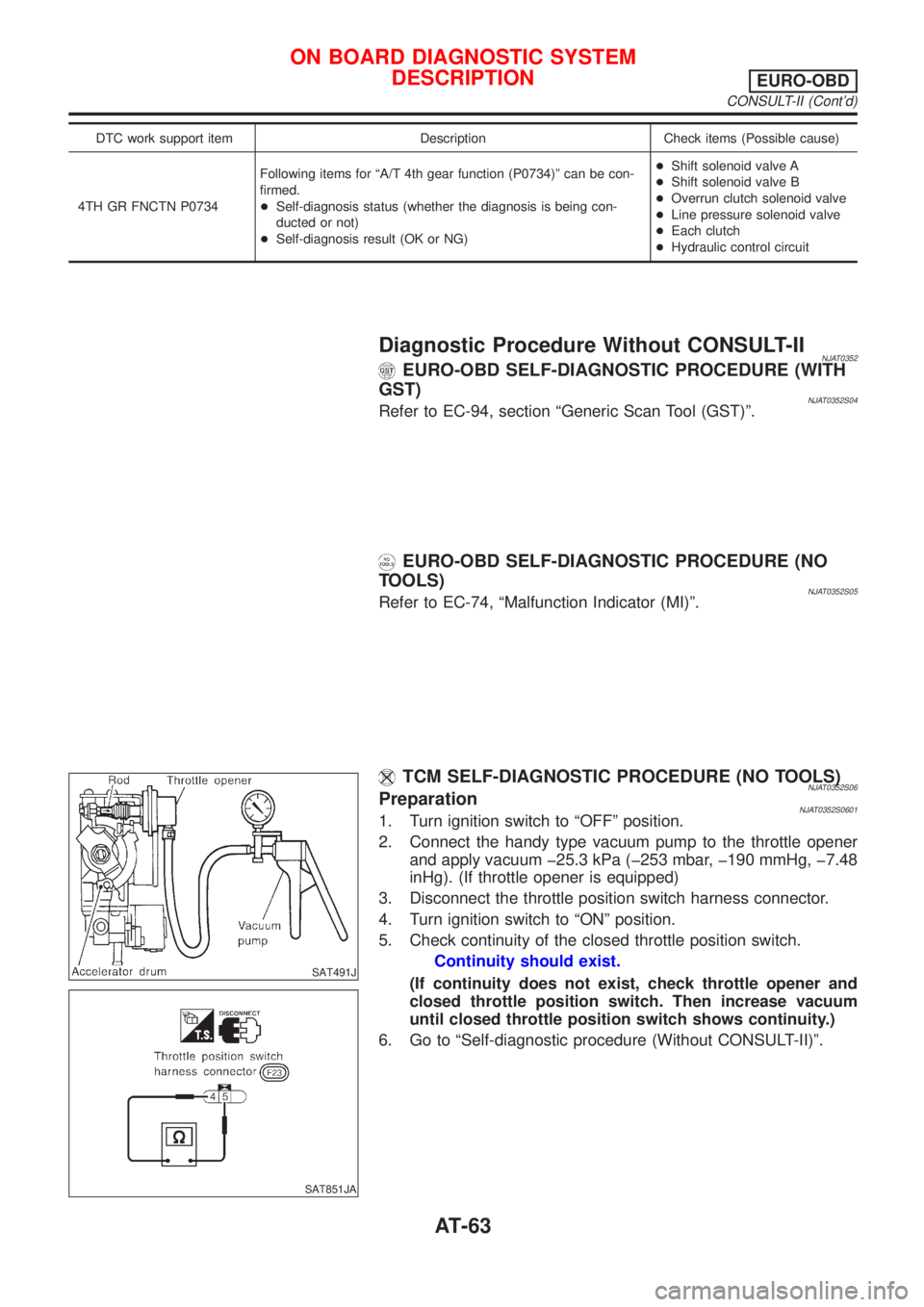

Diagnostic Procedure Without CONSULT-IINJAT0352EURO-OBD SELF-DIAGNOSTIC PROCEDURE (WITH

GST)

NJAT0352S04Refer to EC-94, section ªGeneric Scan Tool (GST)º.

EURO-OBD SELF-DIAGNOSTIC PROCEDURE (NO

TOOLS)

NJAT0352S05Refer to EC-74, ªMalfunction Indicator (MI)º.

SAT491J

SAT851JA

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)NJAT0352S06PreparationNJAT0352S06011. Turn ignition switch to ªOFFº position.

2. Connect the handy type vacuum pump to the throttle opener

and apply vacuum þ25.3 kPa (þ253 mbar, þ190 mmHg, þ7.48

inHg). (If throttle opener is equipped)

3. Disconnect the throttle position switch harness connector.

4. Turn ignition switch to ªONº position.

5. Check continuity of the closed throttle position switch.

Continuity should exist.

(If continuity does not exist, check throttle opener and

closed throttle position switch. Then increase vacuum

until closed throttle position switch shows continuity.)

6. Go to ªSelf-diagnostic procedure (Without CONSULT-II)º.

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

EURO-OBD

CONSULT-II (Cont'd)

AT-63

Page 75 of 2898

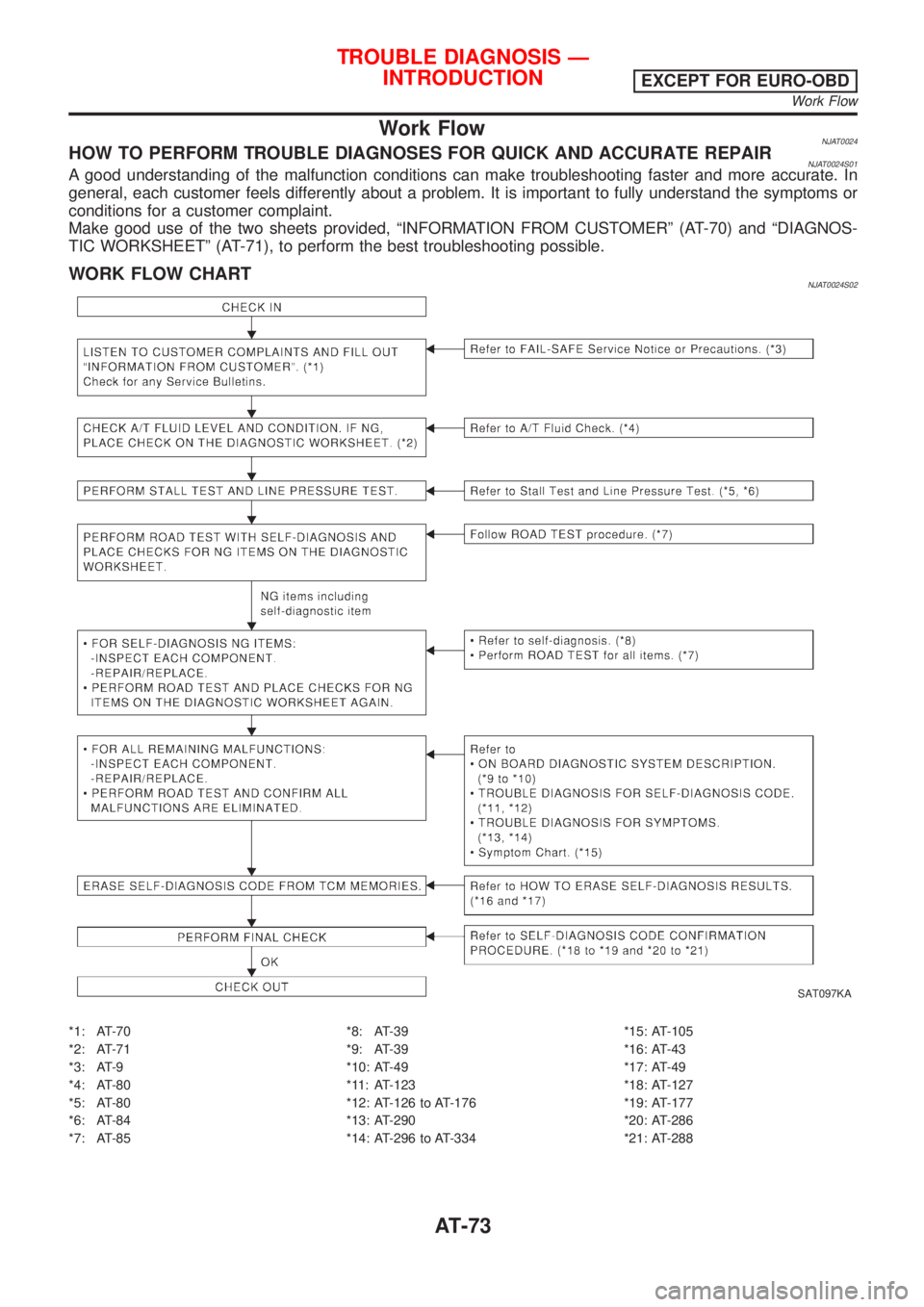

Work FlowNJAT0024HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIRNJAT0024S01A good understanding of the malfunction conditions can make troubleshooting faster and more accurate. In

general, each customer feels differently about a problem. It is important to fully understand the symptoms or

conditions for a customer complaint.

Make good use of the two sheets provided, ªINFORMATION FROM CUSTOMERº (AT-70) and ªDIAGNOS-

TIC WORKSHEETº (AT-71), to perform the best troubleshooting possible.

WORK FLOW CHARTNJAT0024S02

SAT097KA

*1: AT-70

*2: AT-71

*3: AT-9

*4: AT-80

*5: AT-80

*6: AT-84

*7: AT-85*8: AT-39

*9: AT-39

*10: AT-49

*11: AT-123

*12: AT-126 to AT-176

*13: AT-290

*14: AT-296 to AT-334*15: AT-105

*16: AT-43

*17: AT-49

*18: AT-127

*19: AT-177

*20: AT-286

*21: AT-288

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

Work Flow

AT-73

Page 80 of 2898

Work FlowNJAT0258HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIRNJAT0258S01A good understanding of the malfunction conditions can make troubleshooting faster and more accurate. In

general, each customer feels differently about a problem. It is important to fully understand the symptoms or

conditions for a customer complaint.

Make good use of the two sheets provided, ªINFORMATION FROM CUSTOMERº (AT-75) and ªDIAGNOS-

TIC WORKSHEETº (AT-76), to perform the best troubleshooting possible.

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Work Flow

AT-78

Page 207 of 2898

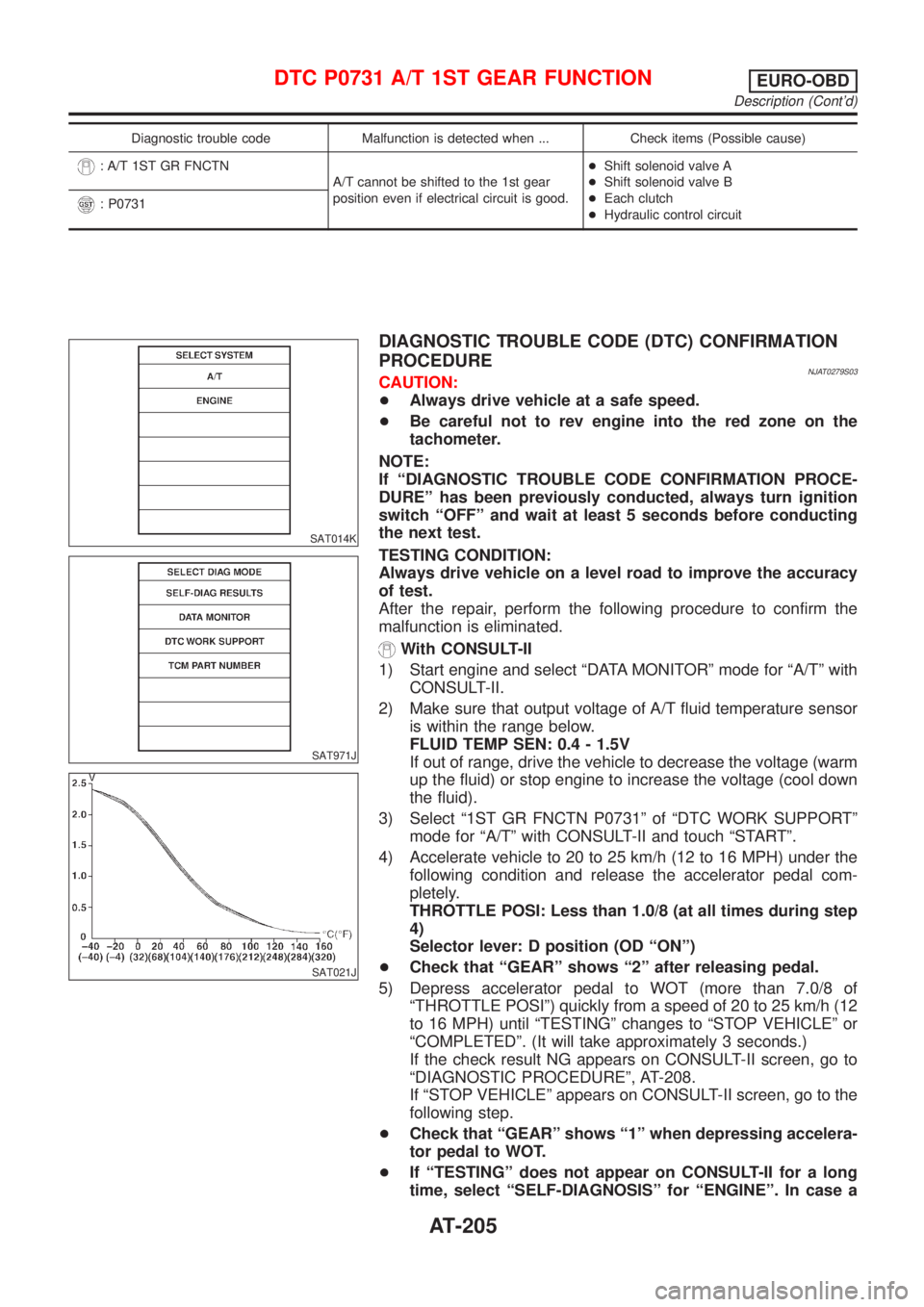

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: A/T 1ST GR FNCTN

A/T cannot be shifted to the 1st gear

position even if electrical circuit is good.+Shift solenoid valve A

+Shift solenoid valve B

+Each clutch

+Hydraulic control circuit

: P0731

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0279S03CAUTION:

+Always drive vehicle at a safe speed.

+Be careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª1ST GR FNCTN P0731º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 20 to 25 km/h (12 to 16 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

+Check that ªGEARº shows ª2º after releasing pedal.

5) Depress accelerator pedal to WOT (more than 7.0/8 of

ªTHROTTLE POSIº) quickly from a speed of 20 to 25 km/h (12

to 16 MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-208.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to the

following step.

+Check that ªGEARº shows ª1º when depressing accelera-

tor pedal to WOT.

+If ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAGNOSISº for ªENGINEº. In case a

DTC P0731 A/T 1ST GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-205

Page 214 of 2898

SAT014K

SAT971J

SAT021J

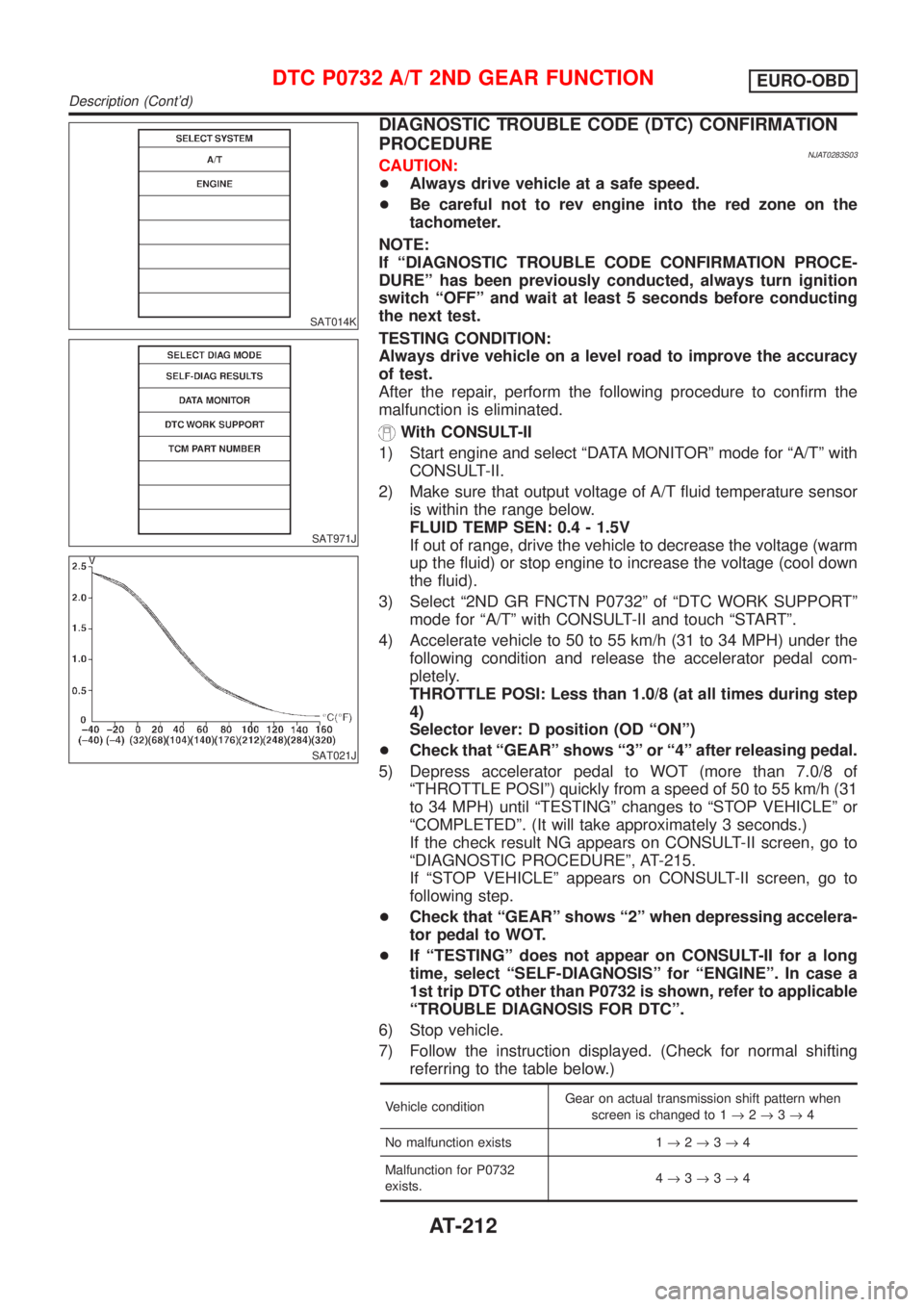

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0283S03CAUTION:

+Always drive vehicle at a safe speed.

+Be careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª2ND GR FNCTN P0732º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 50 to 55 km/h (31 to 34 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

+Check that ªGEARº shows ª3º or ª4º after releasing pedal.

5) Depress accelerator pedal to WOT (more than 7.0/8 of

ªTHROTTLE POSIº) quickly from a speed of 50 to 55 km/h (31

to 34 MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-215.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

+Check that ªGEARº shows ª2º when depressing accelera-

tor pedal to WOT.

+If ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAGNOSISº for ªENGINEº. In case a

1st trip DTC other than P0732 is shown, refer to applicable

ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1®2®3®4

No malfunction exists 1®2®3®4

Malfunction for P0732

exists.4®3®3®4

DTC P0732 A/T 2ND GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-212

Page 220 of 2898

SAT014K

SAT971J

SAT021J

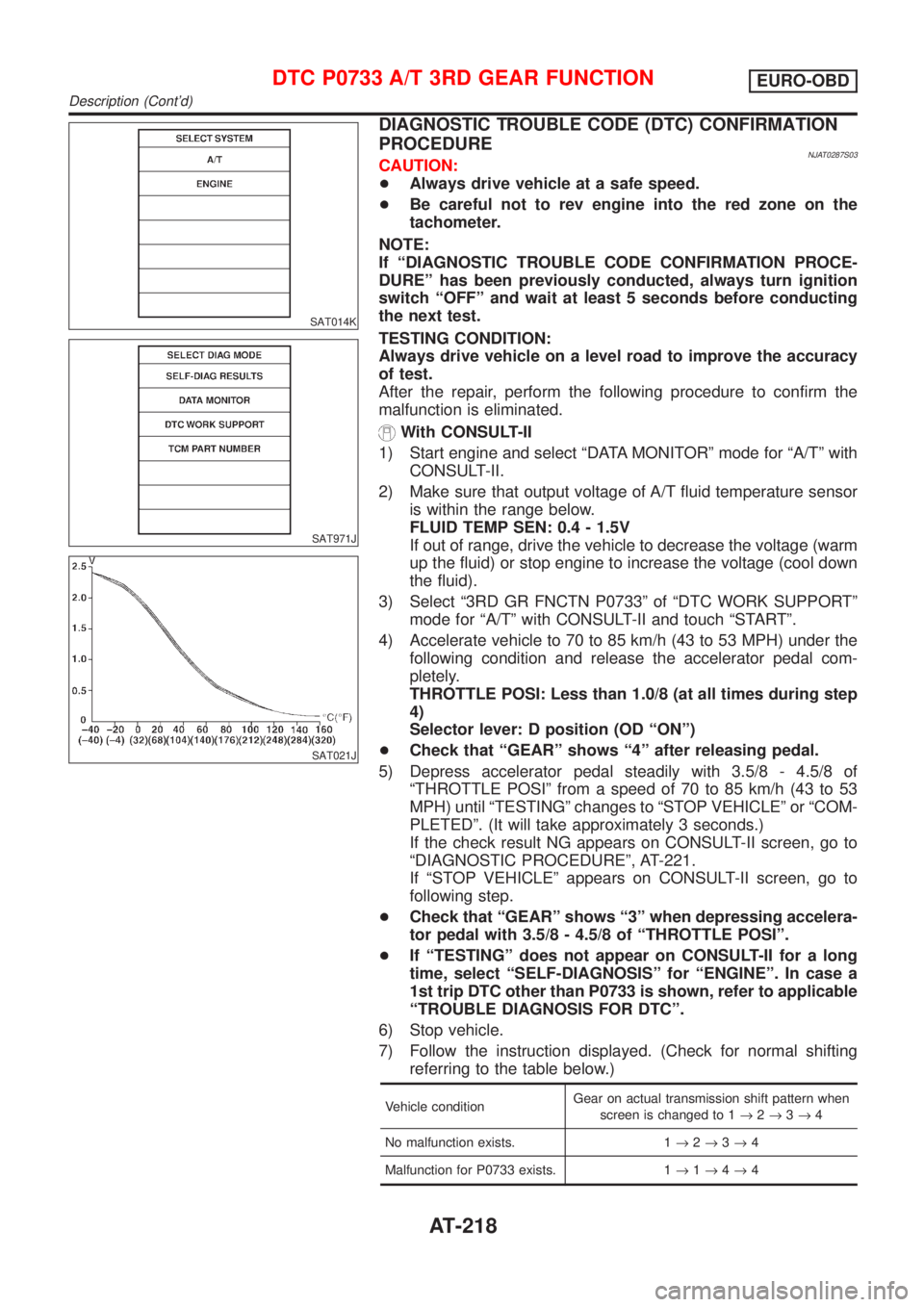

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0287S03CAUTION:

+Always drive vehicle at a safe speed.

+Be careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª3RD GR FNCTN P0733º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 70 to 85 km/h (43 to 53 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

+Check that ªGEARº shows ª4º after releasing pedal.

5) Depress accelerator pedal steadily with 3.5/8 - 4.5/8 of

ªTHROTTLE POSIº from a speed of 70 to 85 km/h (43 to 53

MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or ªCOM-

PLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-221.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

+Check that ªGEARº shows ª3º when depressing accelera-

tor pedal with 3.5/8 - 4.5/8 of ªTHROTTLE POSIº.

+If ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAGNOSISº for ªENGINEº. In case a

1st trip DTC other than P0733 is shown, refer to applicable

ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1®2®3®4

No malfunction exists. 1®2®3®4

Malfunction for P0733 exists. 1®1®4®4

DTC P0733 A/T 3RD GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-218

Page 227 of 2898

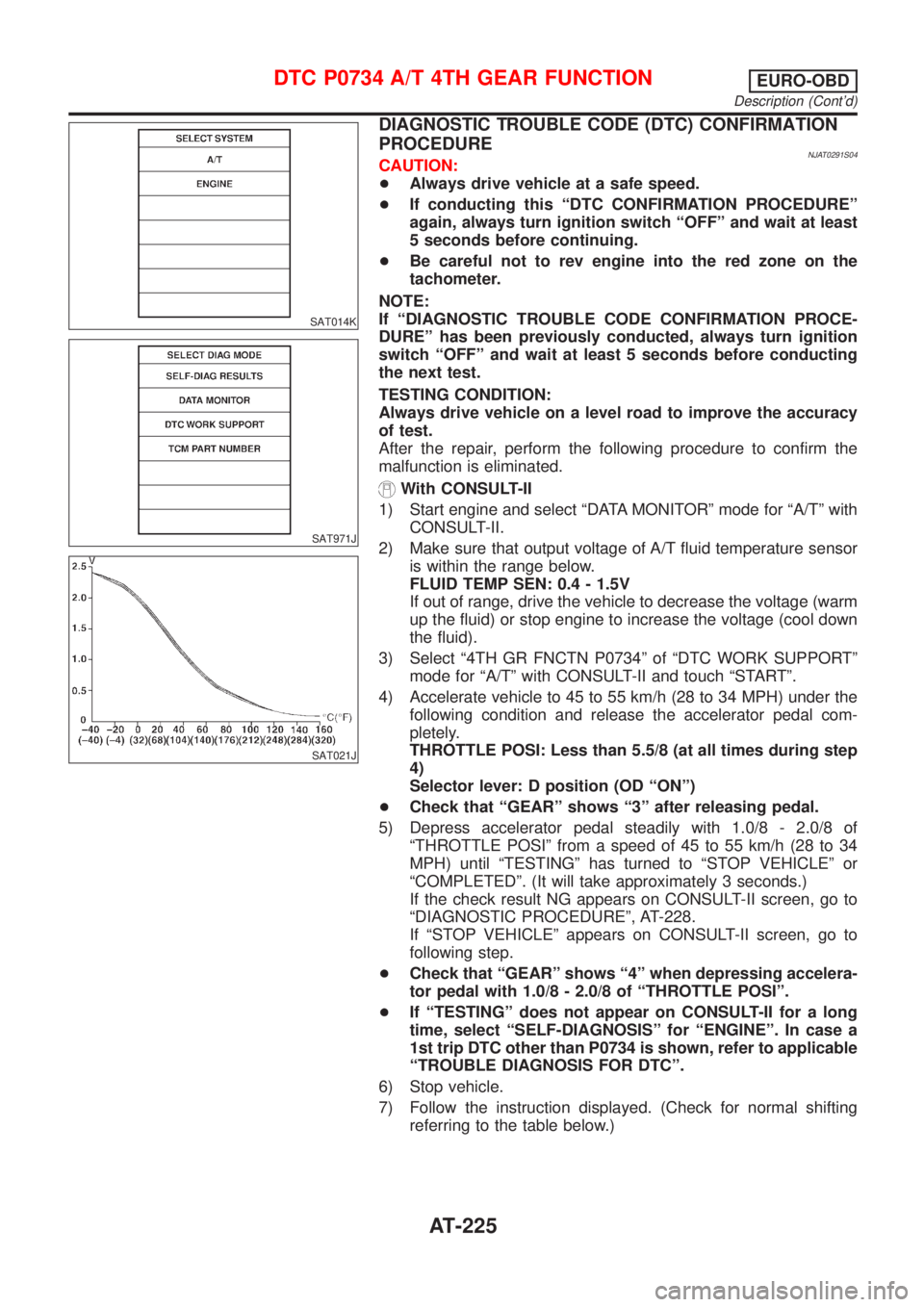

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0291S04CAUTION:

+Always drive vehicle at a safe speed.

+If conducting this ªDTC CONFIRMATION PROCEDUREº

again, always turn ignition switch ªOFFº and wait at least

5 seconds before continuing.

+Be careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª4TH GR FNCTN P0734º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 45 to 55 km/h (28 to 34 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 5.5/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

+Check that ªGEARº shows ª3º after releasing pedal.

5) Depress accelerator pedal steadily with 1.0/8 - 2.0/8 of

ªTHROTTLE POSIº from a speed of 45 to 55 km/h (28 to 34

MPH) until ªTESTINGº has turned to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-228.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

+Check that ªGEARº shows ª4º when depressing accelera-

tor pedal with 1.0/8 - 2.0/8 of ªTHROTTLE POSIº.

+If ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAGNOSISº for ªENGINEº. In case a

1st trip DTC other than P0734 is shown, refer to applicable

ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

DTC P0734 A/T 4TH GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-225