tow NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 10 of 2898

AAT470A

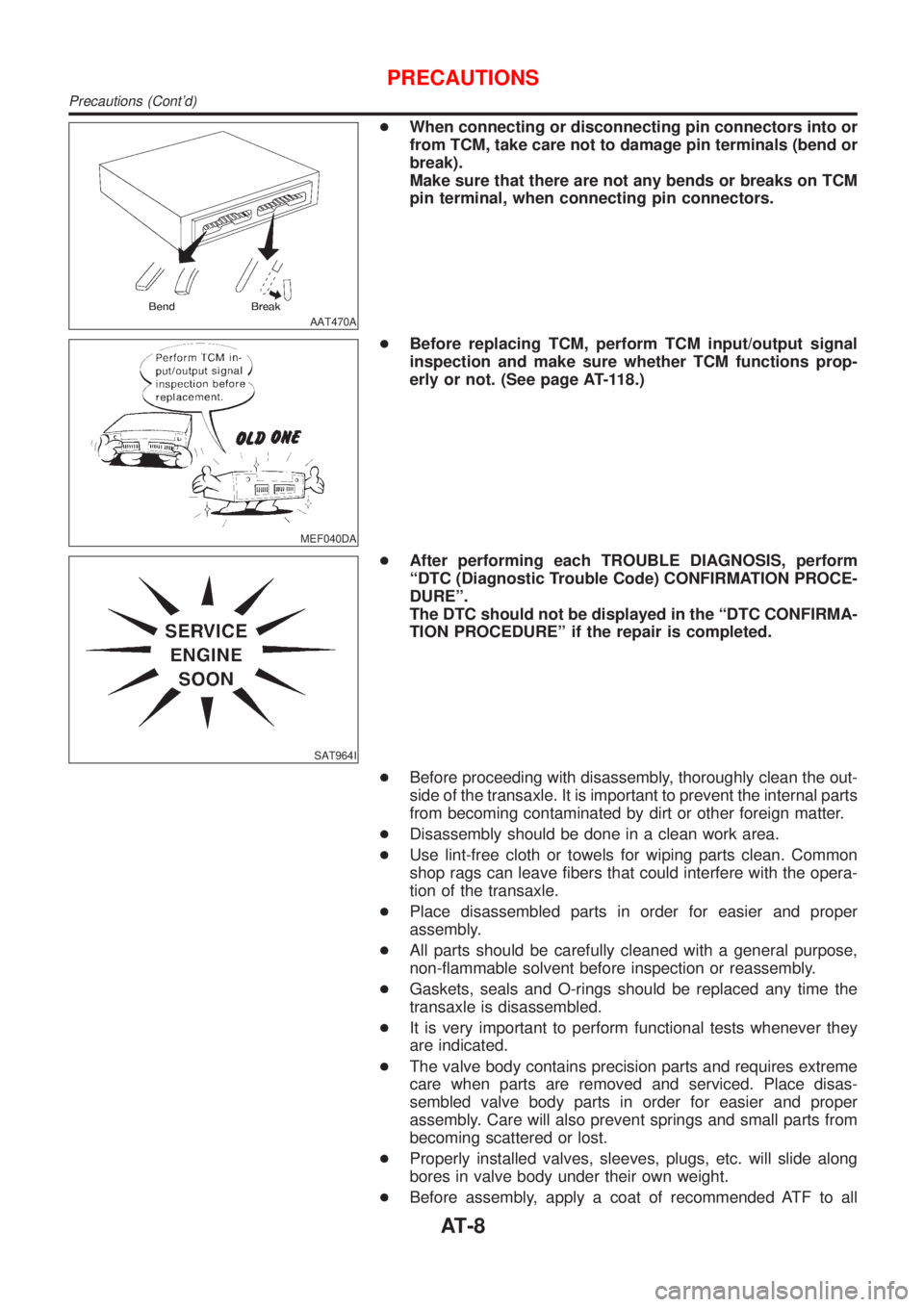

+When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

MEF040DA

+Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions prop-

erly or not. (See page AT-118.)

SAT964I

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is completed.

+Before proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

+Disassembly should be done in a clean work area.

+Use lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the opera-

tion of the transaxle.

+Place disassembled parts in order for easier and proper

assembly.

+All parts should be carefully cleaned with a general purpose,

non-flammable solvent before inspection or reassembly.

+Gaskets, seals and O-rings should be replaced any time the

transaxle is disassembled.

+It is very important to perform functional tests whenever they

are indicated.

+The valve body contains precision parts and requires extreme

care when parts are removed and serviced. Place disas-

sembled valve body parts in order for easier and proper

assembly. Care will also prevent springs and small parts from

becoming scattered or lost.

+Properly installed valves, sleeves, plugs, etc. will slide along

bores in valve body under their own weight.

+Before assembly, apply a coat of recommended ATF to all

PRECAUTIONS

Precautions (Cont'd)

AT-8

Page 494 of 2898

SFA898A

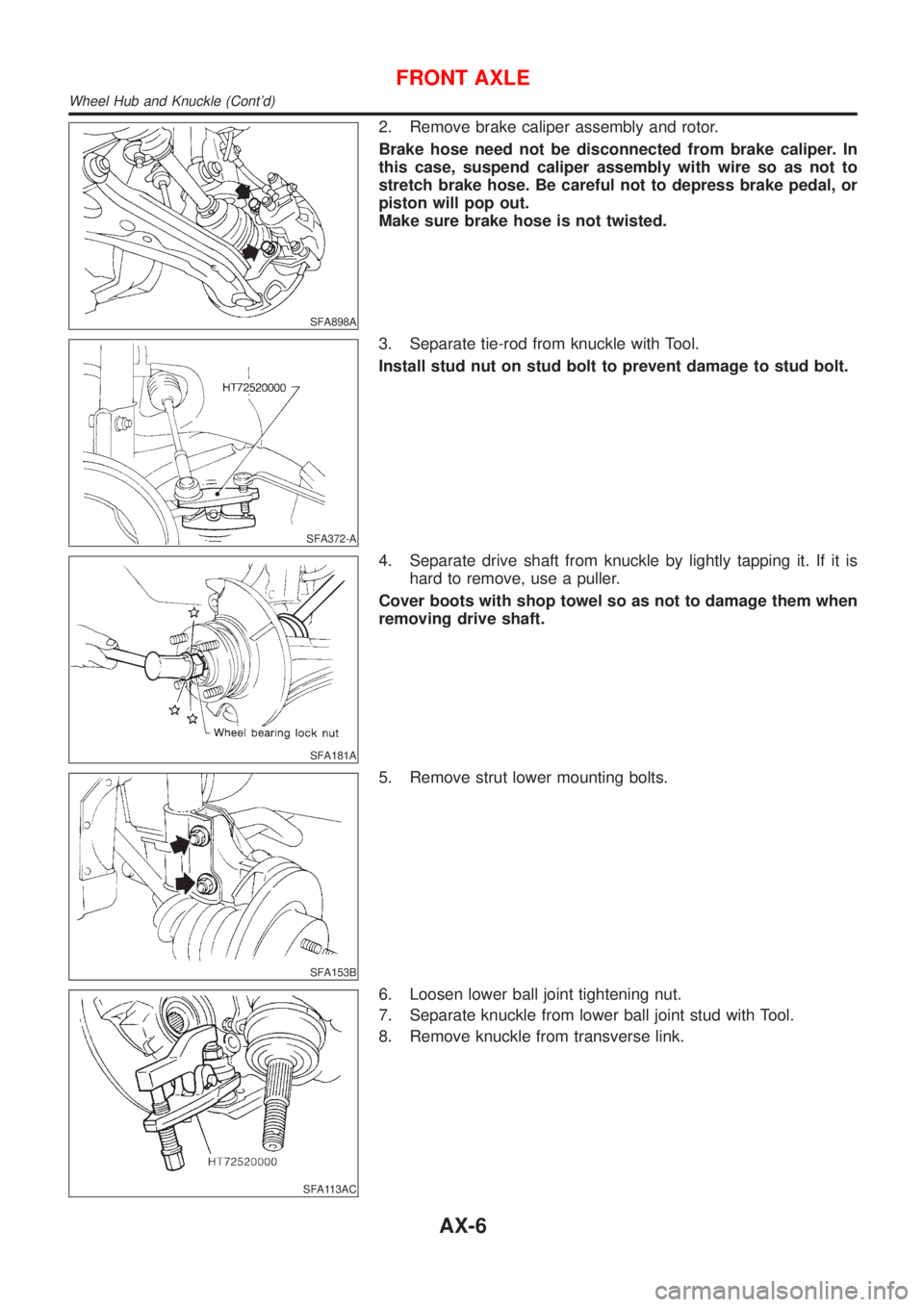

2. Remove brake caliper assembly and rotor.

Brake hose need not be disconnected from brake caliper. In

this case, suspend caliper assembly with wire so as not to

stretch brake hose. Be careful not to depress brake pedal, or

piston will pop out.

Make sure brake hose is not twisted.

SFA372-A

3. Separate tie-rod from knuckle with Tool.

Install stud nut on stud bolt to prevent damage to stud bolt.

SFA181A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA153B

5. Remove strut lower mounting bolts.

SFA113AC

6. Loosen lower ball joint tightening nut.

7. Separate knuckle from lower ball joint stud with Tool.

8. Remove knuckle from transverse link.

FRONT AXLE

Wheel Hub and Knuckle (Cont'd)

AX-6

Page 499 of 2898

SFA090A

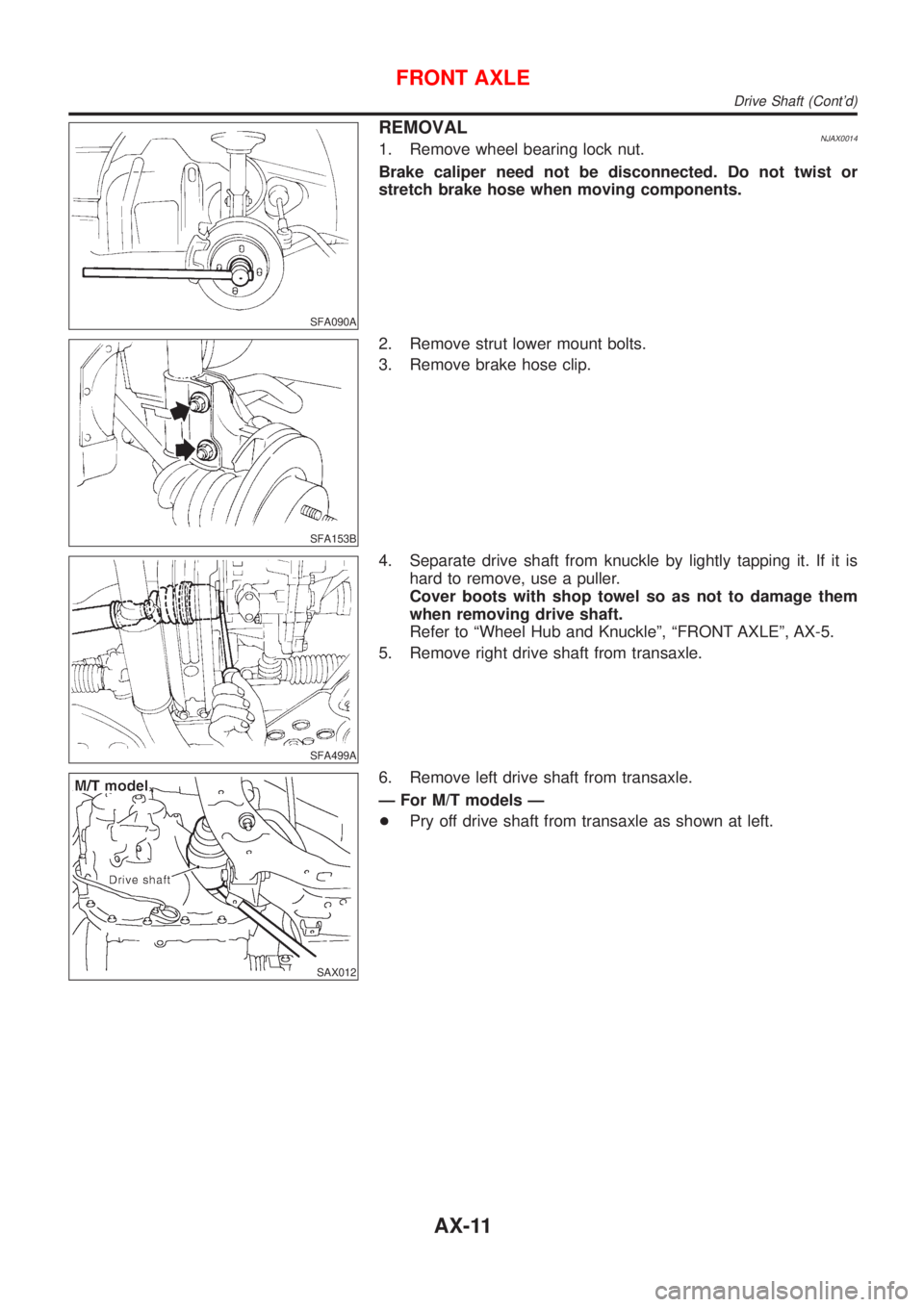

REMOVALNJAX00141. Remove wheel bearing lock nut.

Brake caliper need not be disconnected. Do not twist or

stretch brake hose when moving components.

SFA153B

2. Remove strut lower mount bolts.

3. Remove brake hose clip.

SFA499A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them

when removing drive shaft.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

5. Remove right drive shaft from transaxle.

SAX012

6. Remove left drive shaft from transaxle.

Ð For M/T models Ð

+Pry off drive shaft from transaxle as shown at left.

FRONT AXLE

Drive Shaft (Cont'd)

AX-11

Page 555 of 2898

Pin and Pin BootNJBR0041S0104Check for wear, cracks or other damage.

Replace if any of the above conditions are observed.

SBR219C

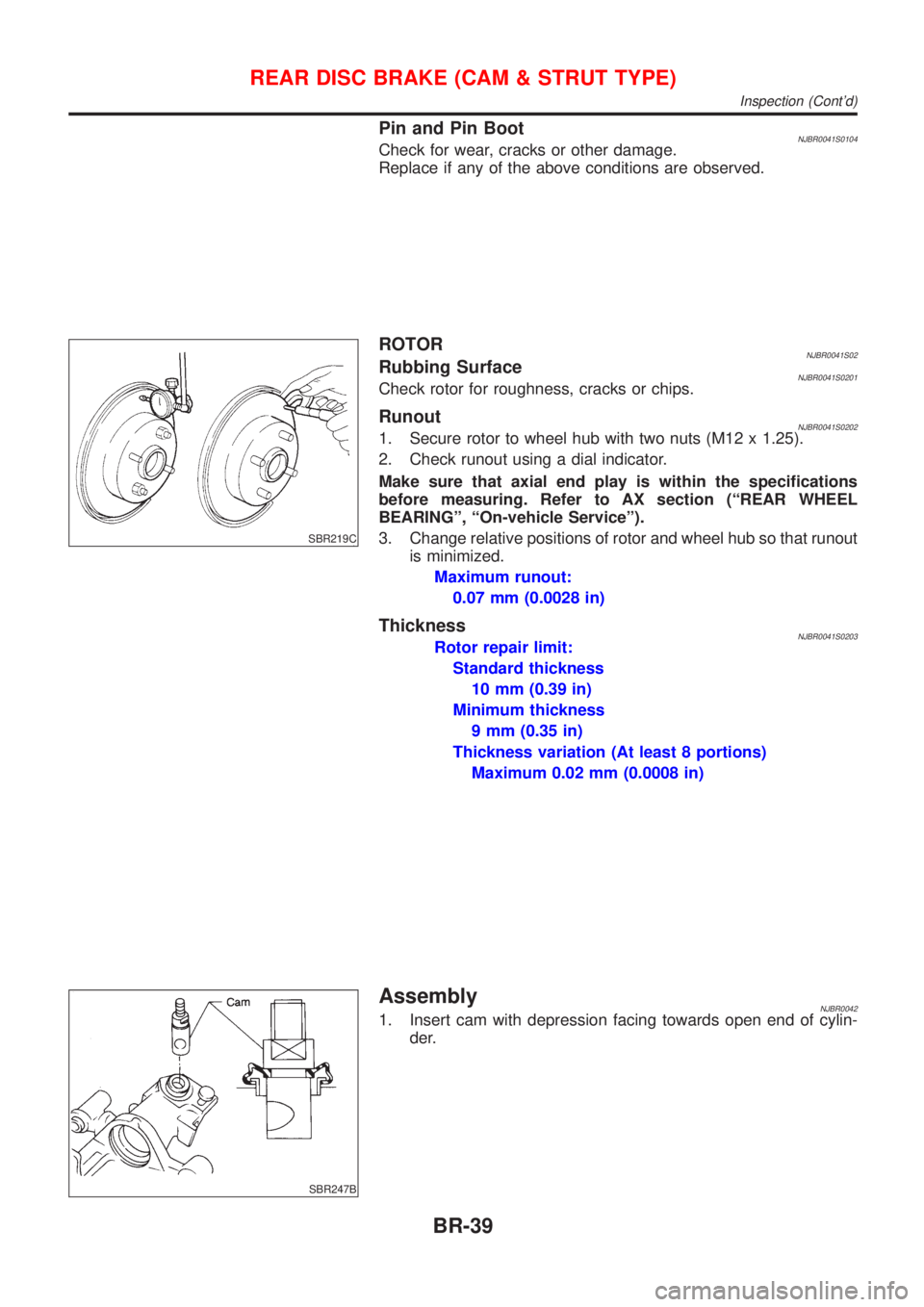

ROTORNJBR0041S02Rubbing SurfaceNJBR0041S0201Check rotor for roughness, cracks or chips.

RunoutNJBR0041S02021. Secure rotor to wheel hub with two nuts (M12 x 1.25).

2. Check runout using a dial indicator.

Make sure that axial end play is within the specifications

before measuring. Refer to AX section (ªREAR WHEEL

BEARINGº, ªOn-vehicle Serviceº).

3. Change relative positions of rotor and wheel hub so that runout

is minimized.

Maximum runout:

0.07 mm (0.0028 in)

ThicknessNJBR0041S0203Rotor repair limit:

Standard thickness

10 mm (0.39 in)

Minimum thickness

9 mm (0.35 in)

Thickness variation (At least 8 portions)

Maximum 0.02 mm (0.0008 in)

SBR247B

AssemblyNJBR00421. Insert cam with depression facing towards open end of cylin-

der.

REAR DISC BRAKE (CAM & STRUT TYPE)

Inspection (Cont'd)

BR-39

Page 624 of 2898

Checking Body CorrosionNJBT0033Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE (FOR EUROPE)

Checking Body Corrosion

BT-6

Page 677 of 2898

Heated SeatNJBT0036HFor Wiring Diagram, refer to EL-288, ªHEATED SEATº for details.

SBT014A

Active Head RestraintNJBT0032The active head restraint system is designed so that the headrest

instantaneously moves towards the front upper direction by utiliz-

ing the force at the seatback during a rear-end collision.

As a result, the occupant's head is protected from being

overextended, reducing the chance for neck injury as much as

possible.

Seat with active head restraint have the labels shown in figures at

left.

SBT888

OPERATION OUTLINENJBT0032S01When the seatback receives a sharp backward force during a rear-

end collision, the input plate moves with the link rotating center as

a pivot. The headrest will then move towards the front upper direc-

tion with the center of the sliding roller as a pivot.

As the backward force on the seat back is eliminated, spring ten-

sion returns the headrest to its original position.

FRONT SEAT

Heated Seat

BT-59

Page 694 of 2898

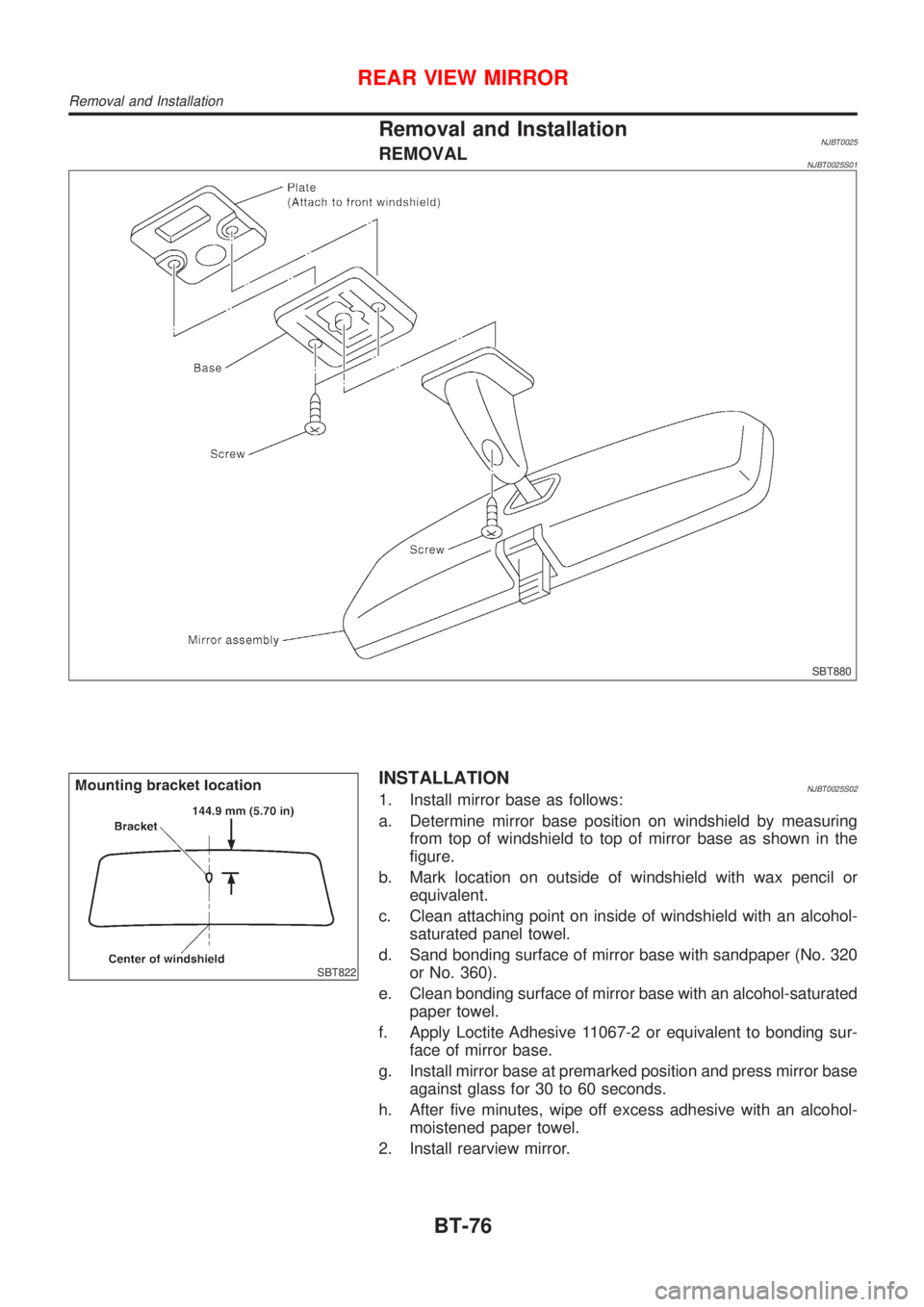

Removal and InstallationNJBT0025REMOVALNJBT0025S01

SBT880

SBT822

INSTALLATIONNJBT0025S021. Install mirror base as follows:

a. Determine mirror base position on windshield by measuring

from top of windshield to top of mirror base as shown in the

figure.

b. Mark location on outside of windshield with wax pencil or

equivalent.

c. Clean attaching point on inside of windshield with an alcohol-

saturated panel towel.

d. Sand bonding surface of mirror base with sandpaper (No. 320

or No. 360).

e. Clean bonding surface of mirror base with an alcohol-saturated

paper towel.

f. Apply Loctite Adhesive 11067-2 or equivalent to bonding sur-

face of mirror base.

g. Install mirror base at premarked position and press mirror base

against glass for 30 to 60 seconds.

h. After five minutes, wipe off excess adhesive with an alcohol-

moistened paper towel.

2. Install rearview mirror.

REAR VIEW MIRROR

Removal and Installation

BT-76

Page 719 of 2898

SCL738

6. Make sure each sliding part operates smoothly when with-

drawal lever is moved.

CAUTION:

Remove any excess grease with a shop towel.

CLUTCH RELEASE MECHANISMRS5F30A, RS5F70A

Installation (Cont'd)

CL-19

Page 811 of 2898

![NISSAN ALMERA 2001 Service Manual Freeze frame data

item*Description

S-FUEL TRIM-B1 [%]+ªShort-term fuel trimº at the moment a malfunction is detected is displayed.

+The short-term fuel trim indicates dynamic or instantaneous feedba NISSAN ALMERA 2001 Service Manual Freeze frame data

item*Description

S-FUEL TRIM-B1 [%]+ªShort-term fuel trimº at the moment a malfunction is detected is displayed.

+The short-term fuel trim indicates dynamic or instantaneous feedba](/img/5/57348/w960_57348-810.png)

Freeze frame data

item*Description

S-FUEL TRIM-B1 [%]+ªShort-term fuel trimº at the moment a malfunction is detected is displayed.

+The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel

schedule.

ENGINE SPEED

[rpm]+The engine speed at the moment a malfunction is detected is displayed.

VEHICL SPEED

[km/h] or [mph]+The vehicle speed at the moment a malfunction is detected is displayed.

ABSOL TH´P/S [%]+The throttle valve opening angle at the moment a malfunction is detected is displayed.

B/FUEL SCHDL

[msec]+The base fuel schedule at the moment a malfunction is detected is displayed.

INT/A TEMP SE [ÉC]

or [ÉF]+The intake air temperature at the moment a malfunction is detected is displayed.

*: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODENJEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]jj+Indicates the engine speed computed from

the POS signal of the crankshaft position

sensor.+Accuracy becomes poor if engine

speed drops below the idle rpm.

+If the signal is interrupted while the

engine is running, an abnormal

value may be indicated.

MAS A/F SE-B1 [V]jj+The signal voltage of the mass air flow sen-

sor is displayed.+When the engine is stopped, a cer-

tain value is indicated.

B/FUEL SCHDL

[msec]+ªBase fuel scheduleº indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board correc-

tion.

A/F ALPHA-B1 [%]j+Indicates the mean value of the air-fuel

ratio feedback correction factor per cycle.+When the engine is stopped, a cer-

tain value is indicated.

+This data also includes the data for

the air-fuel ratio learning control.

COOLAN TEMP/S

[ÉC] or [ÉF]jj+The engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.+When the engine coolant tempera-

ture sensor is open or short-

circuited, ECM enters fail-safe

mode. The engine coolant tempera-

ture determined by the ECM is dis-

played.

HO2S1 (B1) [V]jj+The signal voltage of the heated oxygen

sensor 1 (front) is displayed.

HO2S2 (B1) [V]j+The signal voltage of the heated oxygen

sensor 2 (rear) is displayed.

HO2S1 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 1 (front)

signal during air-fuel ratio feedback control:

RICH ... means the mixture became ªrichº,

and control is being affected toward a

leaner mixture.

LEAN ... means the mixture became ªleanº,

and control is being affected toward a rich

mixture.+After turning ON the ignition switch,

ªRICHº is displayed until air-fuel

mixture ratio feedback control

begins.

+When the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continuously.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG

CONSULT-II (Cont'd)

EC-87

Page 888 of 2898

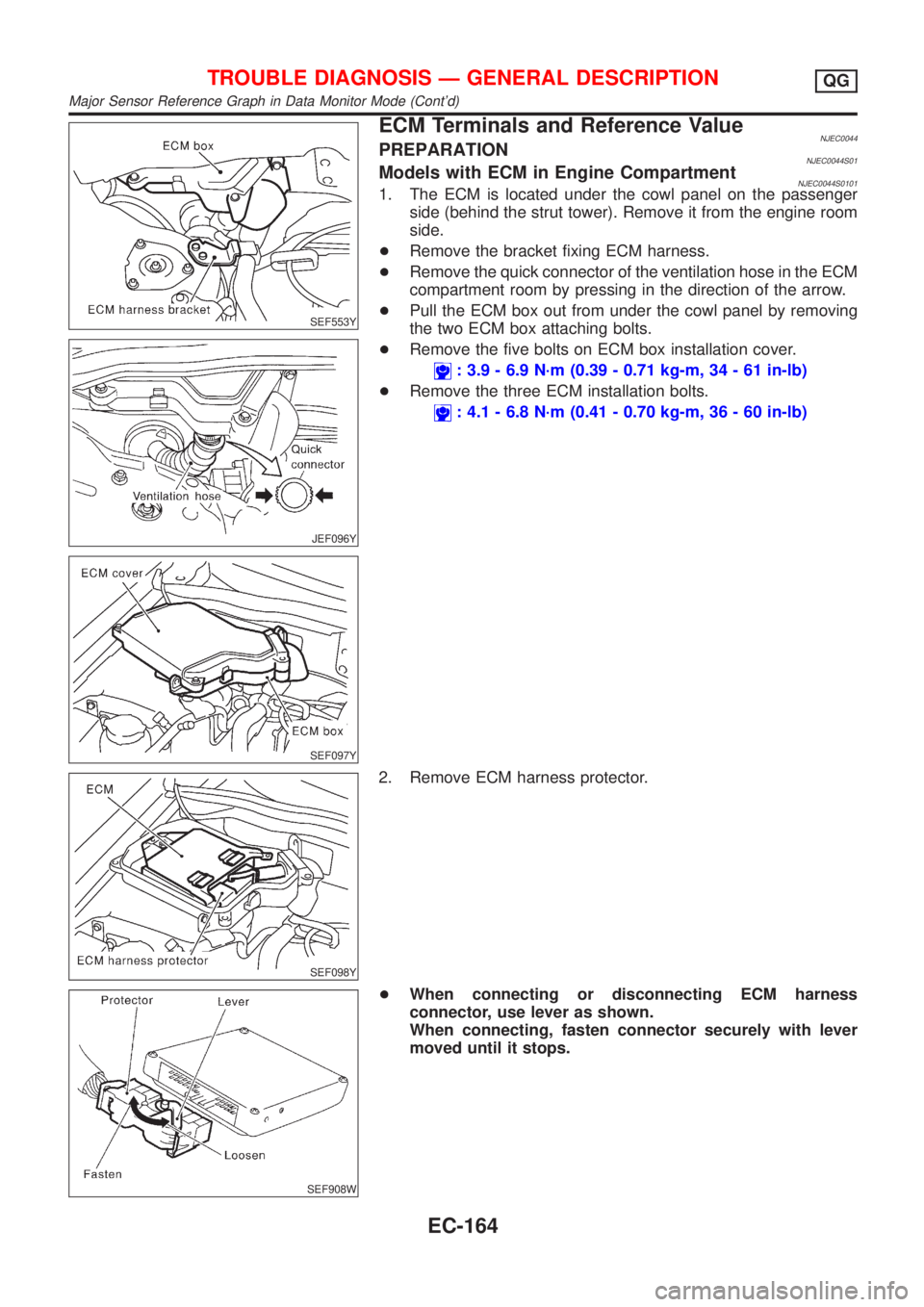

SEF553Y

JEF096Y

SEF097Y

ECM Terminals and Reference ValueNJEC0044PREPARATIONNJEC0044S01Models with ECM in Engine CompartmentNJEC0044S01011. The ECM is located under the cowl panel on the passenger

side (behind the strut tower). Remove it from the engine room

side.

+Remove the bracket fixing ECM harness.

+Remove the quick connector of the ventilation hose in the ECM

compartment room by pressing in the direction of the arrow.

+Pull the ECM box out from under the cowl panel by removing

the two ECM box attaching bolts.

+Remove the five bolts on ECM box installation cover.

: 3.9 - 6.9 N´m (0.39 - 0.71 kg-m, 34 - 61 in-lb)

+Remove the three ECM installation bolts.

: 4.1 - 6.8 N´m (0.41 - 0.70 kg-m, 36 - 60 in-lb)

SEF098Y

2. Remove ECM harness protector.

SEF908W

+When connecting or disconnecting ECM harness

connector, use lever as shown.

When connecting, fasten connector securely with lever

moved until it stops.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Major Sensor Reference Graph in Data Monitor Mode (Cont'd)

EC-164