reset NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 688 of 1701

ON-VEHICLESERVICE

Front Wheel Alignment

Before checking frontwheel alignment, besure tomake apre-

liminary inspection (Unladen*).

*: Fuel, radiator coolantandengine oilfull. Spare tire,jack,

hand tools andmats indesignated positions.

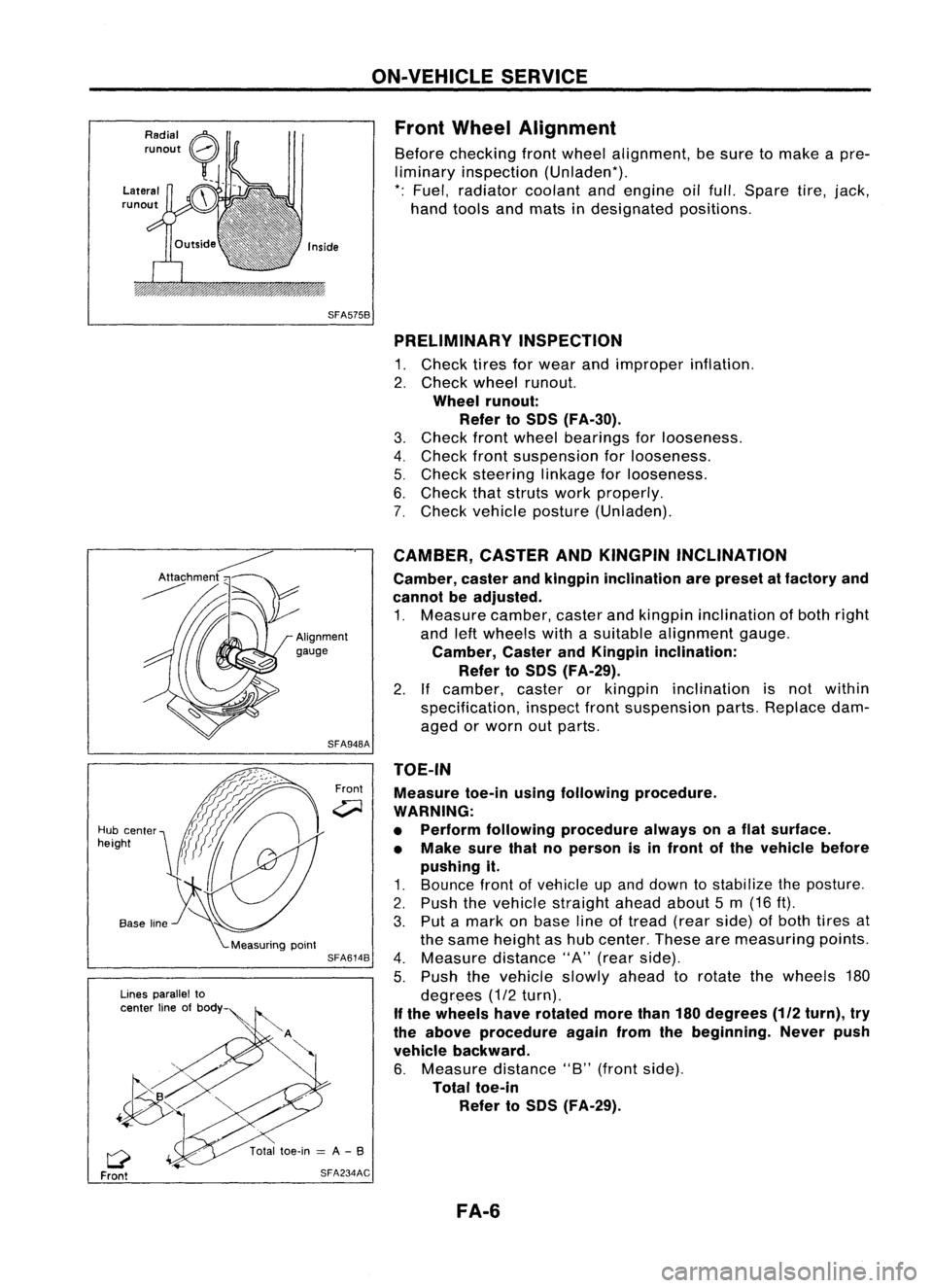

SFA575B PRELIMINARY INSPECTION

1. Check tiresforwear andimproper inflation.

2. Check wheelrunout.

Wheel runout:

Refer toSOS (FA-30).

3. Check frontwheel bearings forlooseness.

4. Check frontsuspension forlooseness.

5. Check steering linkageforlooseness.

6. Check thatstruts workproperly.

7. Check vehicle posture (Unladen).

TOE-IN Measure toe-inusingfollowing procedure.

WARNING:

• Perform following procedure alwaysonaflat surface.

• Make surethatnoperson isin front ofthe vehicle before

pushing it.

1. Bounce frontofvehicle upand down tostabilize theposture.

2. Push thevehicle straight aheadabout5m (16 ft).

3. Put amark onbase lineoftread (rearside) ofboth tires at

the same height ashub center. Thesearemeasuring points.

4. Measure distance"A"(rear side).

5. Push thevehicle slowlyaheadtorotate thewheels 180

degrees (1/2turn).

If the wheels haverotated morethan180degrees

(112

turn), try

the above procedure againfromthebeginning. Neverpush

vehicle backward.

6. Measure distance"B"(front side).

Total toe-in

Refer toSOS (FA-29).

CAMBER,

CASTERANDKINGPIN INCLINATION

Camber, casterandkingpin inclination arepreset atfactory and

cannot beadjusted.

1. Measure camber,casterandkingpin inclination ofboth right

and leftwheels withasuitable alignment gauge.

Camber, CasterandKingpin inclination:

Refer toSOS (FA-29).

2. Ifcamber, casterorkingpin inclination isnot within

specification, inspectfrontsuspension parts.Replace dam-

aged orworn outparts.

Front

SFA948A

SFA614B

SFA234AC

Lines

parallel to

center lineofbody

Q

Front

Hub

center

height

FA-6

Page 743 of 1701

ENGINEANDEMISSION BASICCONTROL SYSTEMDESCRIPTION

Multipart FuelInjection (MFI)System

INPUT/OUTPUT SIGNALLINE

Camshaft positionsensor

Mass airflow sensor

Engine coolant temperature sensor

*1

Oxygen sensor

Throttle position sensor

Neutral position/Inhibitor switch

Vehicle speedsensor

~gnition switch

Air conditioner switch

Power steering oilpressure switch

Battery Engine

speedandpiston position

Amount ofintake air

Engine coolant temperature

Density ofoxygen inexhaust gas

Throttle position

Throttle valveidleposition

Gear position

Vehicle speed

Start signal

Air conditioner operation

Power steering loadsignal

Battery voltage ECM

(ECCS

control module) Injector

*1: Heated oxygen sensor(ForEurope andIsrael, andAustralia A/Tmodels)

Oxygen sensor(Except forEurope andIsrael, andAustralia A/Tmodels)

BASIC MULTIPORT FUELINJECTION

SYSTEM

The amount offuel injected fromthefuel injector

is determined bythe ECM. TheECM controls the

length oftime thevalve remains open(injection

pulse duration). Theamount offuel injected isa

program valueinthe ECM memory. Theprogram

value ispreset byengine operating conditions.

These conditions aredetermined byinput signals

(for engine speedandintake air)from boththe

camshaft positionsensorandthemass airflow

sensor.

VARIOUS

FUELINJECTION

INCREASE/DECREASE COMPENSATION

In addition, theamount offuel injected iscom-

pensated toimprove engineperformance under

various operating conditions aslisted below.

<

Fuel increase>

• During warm-up

• When starting theengine

• During acceleration

• Hot-engine operation

• When selector leverischanged from"N"to

"D"

(AfT

models only)

• High-load, high-speed operation

<

Fuel decrease>

• During deceleration

EC-24

Page 776 of 1701

![NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

CONSULT (Cont'd)

REAL TIMEDIAGNOSIS INDATA MONITOR MODE

CONSULT hastwo kinds oftriggers andthey canbeselected bytouching "SETTING" in"DATA

NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

CONSULT (Cont'd)

REAL TIMEDIAGNOSIS INDATA MONITOR MODE

CONSULT hastwo kinds oftriggers andthey canbeselected bytouching "SETTING" in"DATA](/img/5/57349/w960_57349-775.png)

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

CONSULT (Cont'd)

REAL TIMEDIAGNOSIS INDATA MONITOR MODE

CONSULT hastwo kinds oftriggers andthey canbeselected bytouching "SETTING" in"DATA

MONITOR" mode.

1. "AUTO TRIG"(Automatic trigger):

• The malfunction willbeidentified onthe CONSULT screeninreal time.

In other words, DTCandmalfunction itemwillbedisplayed atthe moment themalfunction is

detected byECM.

DATA MONITOR canbeperformed continuously untilamalfunction isdetected. However, DATA

MONITOR cannotcontinue anylonger afterthemalfunction detection.

2. "MANU TRIG"(Manual trigger):

• DTC andmalfunction itemwillnotbedisplayed automatically onCONSULT screeneventhough

a malfunction isdetected byECM. •

DATA MONITOR canbeperformed continuously eventhough amalfunction isdetected.

Use these triggers asfollows:

1. "AUTO TRIG"

• While trying todetect theDTC byperforming the"DTC CONFIRMATION PROCEDURE",besure

to select to"DATA MONITOR (AUTOTRIG)" mode.Youcanconfirm themalfunction atthe

moment itis detected.

• While narrowing downthepossible causes,CONSULT shouldbeset in"DATA MONITOR (AUTO

TRIG)" mode,especially incase theincident isintermittent.

Inspect thecircuit bygently shaking (ortwisting) suspicious connectors, components andharness

in the "DTC CONFIRMATION PROCEDURE".Themoment amalfunction isfound theDTC willbe

displayed. (RefertoGI section, "Incident Simulation Tests"in"HOW TOPERFORM EFFICIENT

DIAGNOSIS FORANELECTRICAL INCIDENT".)

2. "MANU TRIG"

• Ifthe malfunction isdisplayed assoon as"DATA MONITOR" isselected, resetCONSULT to

"MANU TRIG".Byselecting "MANUTRIG"youcanmonitor andstore thedata. Thedata canbe

utilized forfurther diagnosis, suchasacomparison withthevalue forthe normal operating con-

dition.

HISPEED

AUTO

TRIG

I

~

SELECT MONITOR ITEM

ECM INPUT SIGNALS

MAIN SIGNALS

SELECTION FROMMENU

I

~

SET RECORDING COND

I

MANU TRIG

I

LONG TIME HI

SPEED MANU

TRIG

SETTING

II

START

___ 1__ 1

"SETTIN-G" "AUTOTRIG"

A

malfunction canbe

displayed on"DATA

MONITOR" screen

automatically ifdetected.

EC-57 "MANU

TRIG"

A malfunction cannotbe

displayed on"DATA

MONITOR" screen

automatically evenif

detected.

SEF674Q

Page 783 of 1701

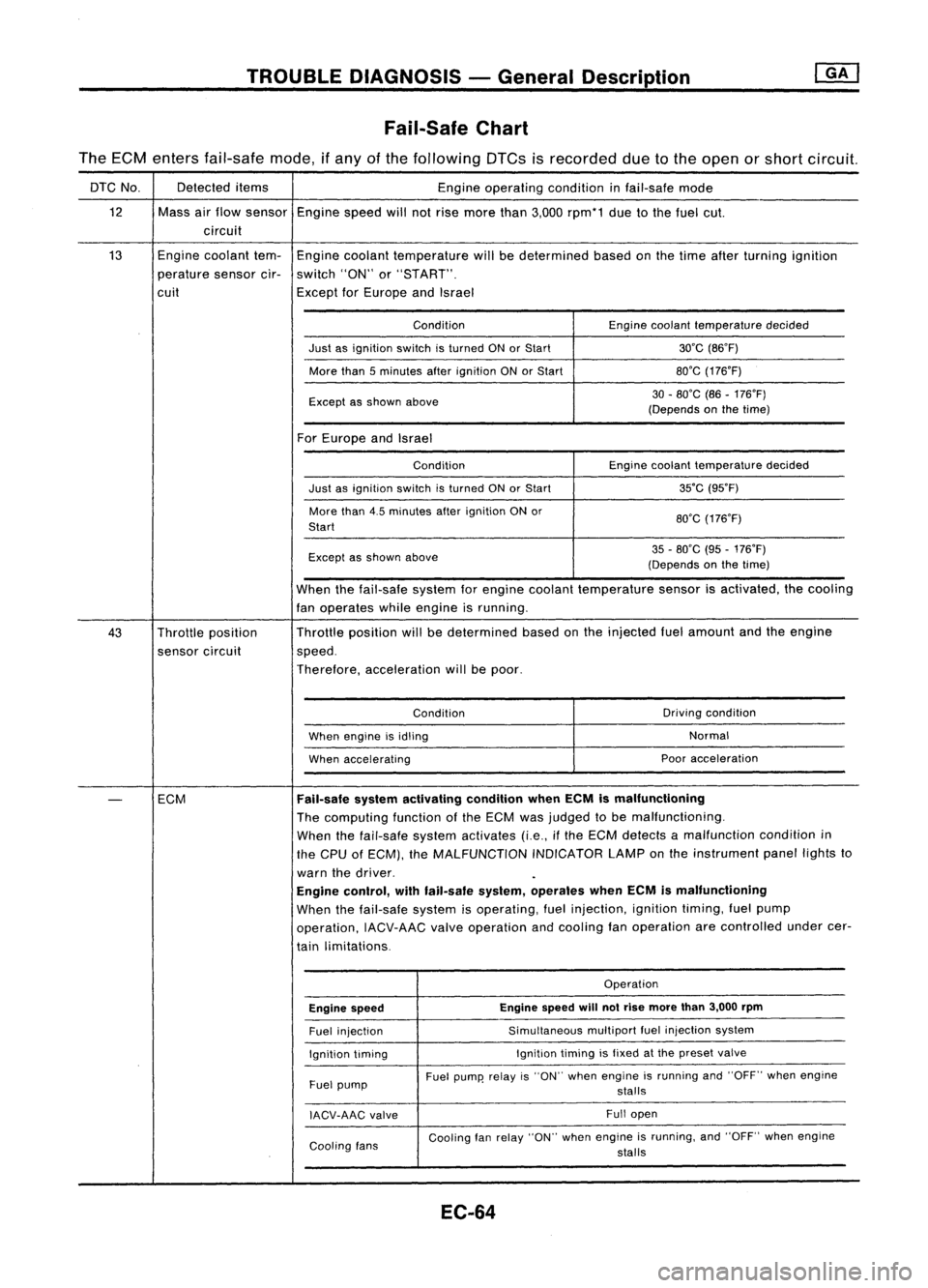

TROUBLEDIAGNOSIS -General Description

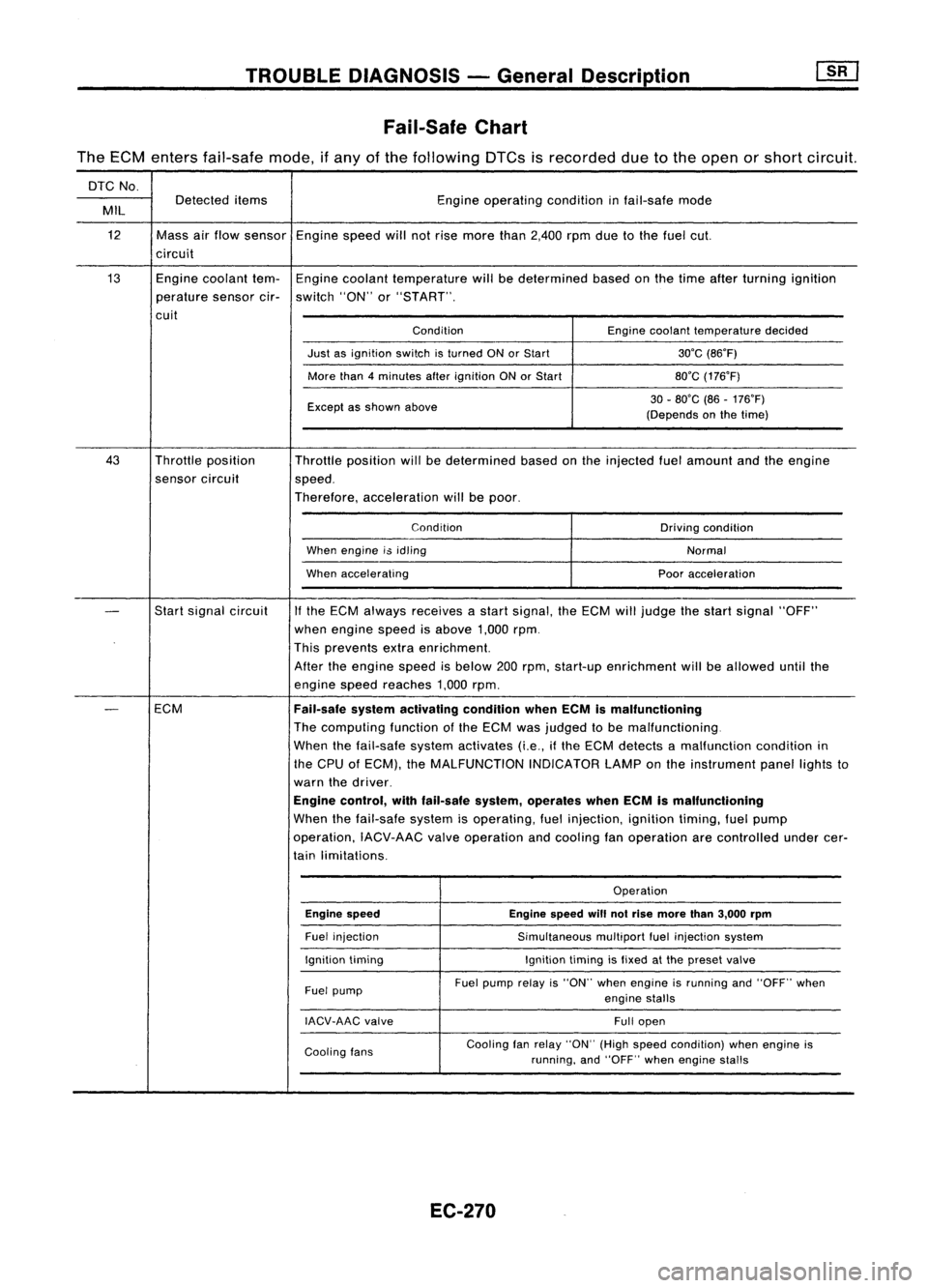

Fail-Safe Chart

The ECM enters fail-safe mode,ifany ofthe following DTCsisrecorded duetothe open orshort circuit.

DTC No. Detected

items

Engineoperating conditioninfail-safe mode

12 Massairflow sensor

Enginespeedwillnotrise more than3,000 rpm*1 duetothe fuel cut.

circuit

13 Engine

coolant tem-

Engine coolant temperature willbedetermined basedonthe time after turning ignition

perature sensorcir-switch "ON"or"START".

cuit ExceptforEurope andIsrael

Condition Enginecoolant temperature decided

Just asignition switchisturned ONorStart 30'C(B6'F)

More than5minutes afterignition ONorStart BO'G

(176'F)

Except asshown above 30

-BO'C (B6-176'F)

(Depends onthe time)

For Europe andIsrael

Condition Enginecoolant temperature decided

Just asignition switchisturned ONorStart 35'C

(95'F)

More than4.5minutes afterignition ONor

BO'G(176'F)

Start

Except asshown above 35

-BO'C (95-176'F)

(Depends onthe time)

When thefail-safe systemforengine coolant temperature sensorisactivated, thecooling

fan operates whileengine isrunning.

43 Throttle position Throttle

position willbedetermined basedonthe injected fuelamount andtheengine

sensor circuit speed.

Therefore, acceleration willbepoor.

Condition Driving

condition

When engine isidling Normal

When accelerating Poor

acceleration

-

ECM

Fail-safe

systemactivating conditionwhenECMismalfunctioning

The computing functionofthe ECM wasjudged tobe malfunctioning.

When thefail-safe systemactivates (i.e.,ifthe ECM detects amalfunction conditionin

the CPU ofECM), theMALFUNCTION INDICATORLAMPonthe instrument panellightsto

warn thedriver.

Engine control, withfail-safe system,operates whenECMismalfunctioning

When thefail-safe systemisoperating, fuelinjection, ignitiontiming,fuelpump

operation, IACV-AACvalveoperation andcooling fanoperation arecontrolled undercer-

tain limitations.

Operation

Engine speed Engine

speed

will

notrise more than3,000 rpm

Fuel injection Simultaneous

multipartfuelinjection system

Ignition timing Ignition

timingisfixed atthe preset valve

Fuel pump Fuel

pump' relayis"ON" when engine isrunning and"OFF" whenengine

stalls

IACV-AAG valve Full

open

Cooling fans Cooling

fanrelay "ON" whenengine isrunning, and"OFF" whenengine

stalls

EC-64

Page 785 of 1701

![NISSAN ALMERA N15 1995 Service Manual @

(Go tonext page)

(;]

1

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

~

RPM.

turning

idleadjusting

Base idlespeed: RefertoEC-36.

screw.

II

t

K

CHECK THROTTLE POSITIONSENSOR

NG

NISSAN ALMERA N15 1995 Service Manual @

(Go tonext page)

(;]

1

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

~

RPM.

turning

idleadjusting

Base idlespeed: RefertoEC-36.

screw.

II

t

K

CHECK THROTTLE POSITIONSENSOR

NG](/img/5/57349/w960_57349-784.png)

@

(Go tonext page)

(;]

1

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

~

RPM.

turning

idleadjusting

Base idlespeed: RefertoEC-36.

screw.

II

t

K

CHECK THROTTLE POSITIONSENSOR

NG

Adjust output

voltage

to

~

IDLE POSITION.

0.50

:l:

0.1V byrotating

00

1.

Perform ''THRTlPOSSEN throttle

position sensor

ADJ" in"WORK SUPPORT" body.

mode.

2. Check thatoutput

voltage

of

throttle position sensoris

approx. 0.35to0.65V (Throttle

valve

fullycloses.) and"ClSD

THlIP SW"stays "ON".

OR

00

Measure

output

voltage

ofthrot-

tle position sensorusing

voltmeter,

andcheck thatitis

approx. 0.35to0.65V. (Throttle

valve

fullyclosed.)

OK

RESETIDLEPOSITION

MEMORY.

1. Warm upengine suffi-

ciently.

2. Turn ignition switch

"OFF" andwait at

least 5seconds.

3. Disconnect

throttle

position sensorhar-

ness connector.

4.

Start

engine andwait

at least 5seconds in

"N" position .

5. Reconnect throttle

position sensorhar-

ness connector while

running engine.

TROUBLE

DIAGNOSIS -General Description

Basic Inspection (Coni'd)

@

• THRTl POSSEN ADJ.

0

* **

ADJ MONITOR

***

THRTL POSSEN 0.52V

==========

MONITOR

==========

CMPS.RPM (REF)Orpm

CLSD THLIPOSI ON

SEF516Q

SEF12BR EC-66

Page 952 of 1701

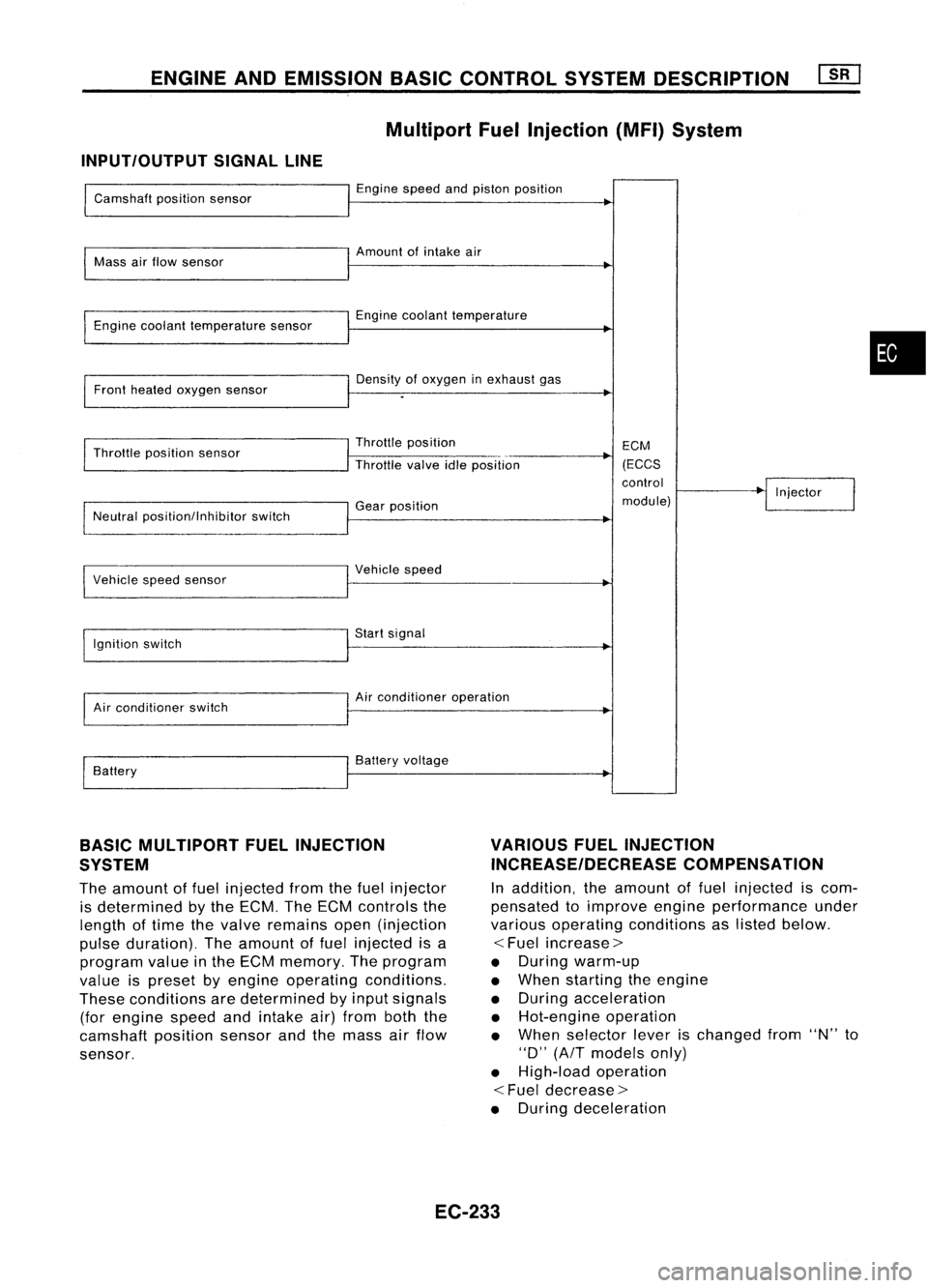

ENGINEANDEMISSION BASICCONTROL SYSTEMDESCRIPTION

Multiport FuelInjection (MFI)System

INPUT/OUTPUT SIGNALLINE

Camshaft positionsensor

Mass airflow sensor

Engine coolant temperature sensor

Front heated oxygen sensor

Throttle position sensor

Neutral position/lnhibitor switch

I

Vehicle speedsensor

Ignition switch

Air conditioner switch

Battery Engine

speedandpiston position

Amount ofintake air

Engine coolant temperature

Density ofoxygen inexhaust gas

Throttle position

Throttle valveidleposition

Gear position

I

Vehicle speed

Start signal

Air conditioner operation

Battery voltage ECM

(ECCS

control

module) Injector

•

BASIC MULTIPORT FUELINJECTION

SYSTEM

The amount offuel injected fromthefuel injector

is determined bythe ECM. TheECM controls the

length oftime thevalve remains open(injection

pulse duration). Theamount offuel injected isa

program valueinthe ECM memory. Theprogram

value ispreset byengine operating conditions.

These conditions aredetermined byinput signals

(for engine speedandintake air)from boththe

camshaft positionsensorandthemass airflow

sensor.

VARIOUS

FUELINJECTION

INCREASE/DECREASE COMPENSATION

In addition, theamount offuel injected iscom-

pensated toimprove engineperformance under

various operating conditions aslisted below.

<

Fuel increase>

• During warm-up

• When starting theengine

• During acceleration

• Hot-engine operation

• When selector leverischanged from"N"to

"0" (AfT models only)

• High-load operation

<

Fuel decrease>

• During deceleration

EC-233

Page 982 of 1701

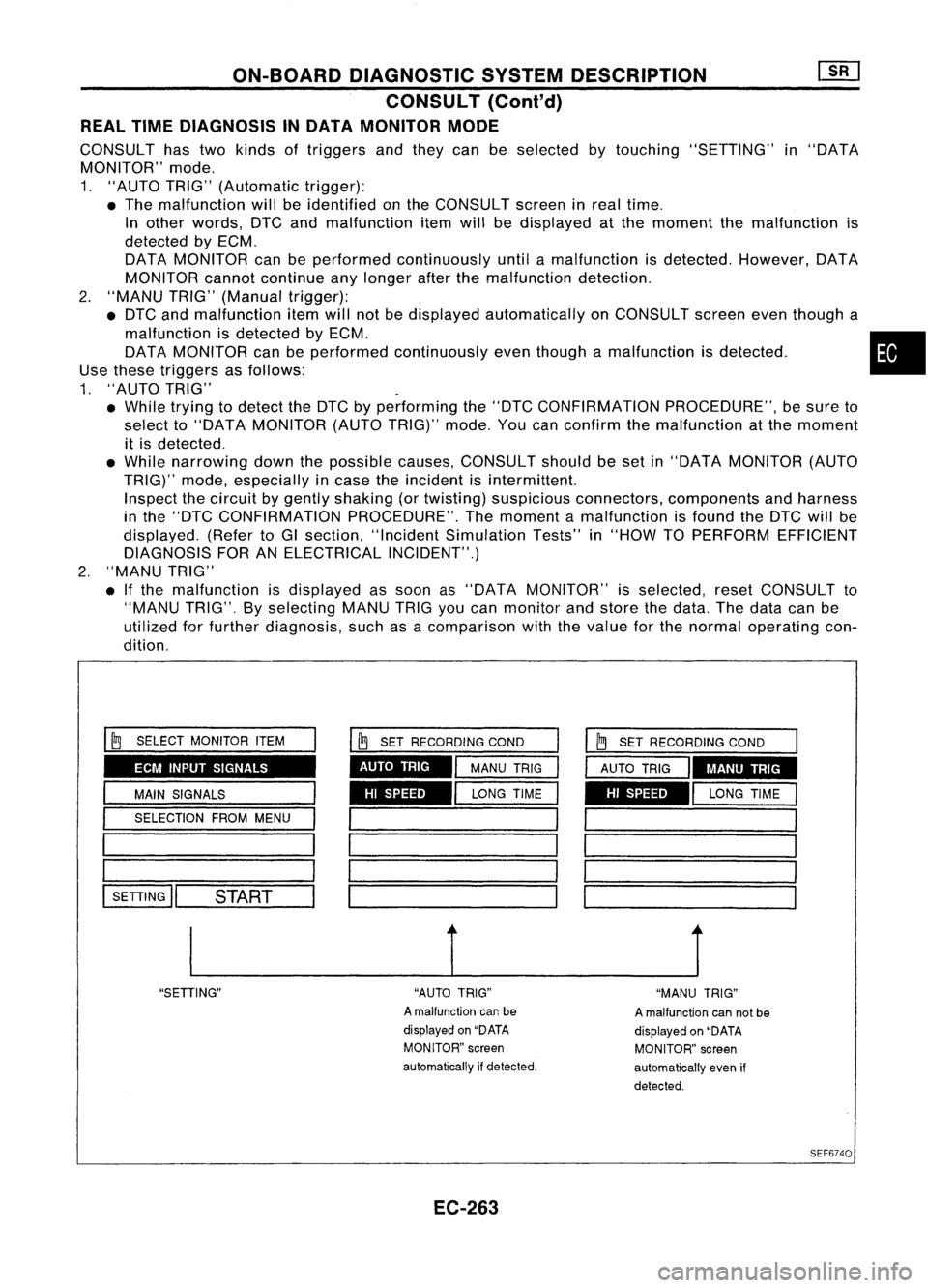

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

REAL TIMEDIAGNOSIS INDATA MONITOR MODE

CONSULT hastwo kinds oftriggers andthey canbeselected bytouching "SETTING" in"DATA

MONITOR" mode.

1. "AUTO TRIG"(Automatic trigger):

• The malfunction willbeidentified onthe CONSULT screeninreal time.

In other words, DTCandmalfunction itemwillbedisplayed atthe moment themalfunction is

detected byECM.

DATA MONITOR canbeperformed continuously untilamalfunction isdetected. However, DATA

MONITOR cannotcontinue anylonger afterthemalfunction detection.

2. "MANU TRIG"(Manual trigger):

• DTC andmalfunction itemwillnotbedisplayed automatically onCONSULT screeneventhough a

malfunction isdetected byECM. •

DATA MONITOR canbeperformed continuously eventhough amalfunction isdetected.

Use these triggers asfollows:

1. "AUTO TRIG"

• While trying todetect theDTC byperforming the"DTC CONFIRMATION PROCEDURE",besure to

select to"DATA MONITOR (AUTOTRIG)" mode.Youcanconfirm themalfunction atthe moment

it is detected .

• While narrowing downthepossible causes,CONSULT shouldbeset in"DATA MONITOR (AUTO

TRIG)" mode,especially incase theincident isintermittent.

Inspect thecircuit bygently shaking (ortwisting) suspicious connectors, components andharness

in the "DTC CONFIRMATION PROCEDURE".Themoment amalfunction isfound theDTC willbe

displayed. (RefertoGI section, "Incident Simulation Tests"in"HOW TOPERFORM EFFICIENT

DIAGNOSIS FORANELECTRICAL INCIDENT".)

2. "MANU TRIG"

• Ifthe malfunction isdisplayed assoon as"DATA MONITOR" isselected, resetCONSULT to

"MANU TRIG".Byselecting MANUTRIGyoucan monitor andstore thedata. Thedata canbe

utilized forfurther diagnosis, suchasacomparison withthevalue forthe normal operating con-

dition.

ECM INPUT SIGNALS

HISPEED

AUTO

TRIG

I

~

SELECT MONITOR ITEM

I

MAIN SIGNALS

I

SELECTION FROMMENU

1 _

1========

l-SE-TI-IN-G

ll--S-T.-AR-T--

I

~

SET RECORDING COND

I

MANU TRIG

I

LONG TIME HI

SPEED MANU

TRIG

__ 1__ J

"SETIING" "AUTOTRIG"

A malfunction canbe

displayed on"DATA

MONITOR" screen

automatically ifdetected.

EC-263 "MANU

TRIG"

A malfunction cannotbe

displayed on"DATA

MONITOR" screen

automatically evenif

detected.

SEF6740

Page 989 of 1701

TROUBLEDIAGNOSIS -General Description

Fail-Safe Chart

The ECM enters fail-safe mode,ifany ofthe following DTCsisrecorded duetothe open orshort circuit.

DTC No.

Detected items Engineoperating conditioninfail-safe mode

MIL

12 Massairflow sensor Enginespeedwillnotrise more than2,400 rpmduetothe fuel cut.

circuit

13 Enginecoolant tem-Engine coolant temperature willbedetermined basedonthe time after turning ignition

perature sensorcir-switch "ON"or"START".

cuit ConditionEnginecoolant temperature decided

Just asignition switchisturned ONorStart 30'C(86'F)

More than4minutes afterignition ONorStart 80'C(176'F)

Except asshown above 30

-80'C (86-176'F)

(Depends onthe time)

43 Throttle position

Throttleposition willbedetermined basedonthe injected fuelamount andtheengine

sensor circuit

speed.

Therefore, acceleration willbepoor.

Condition Drivingcondition

When engine i$idling

Normal

When accelerating Pooracceleration

-

Start

signal circuit

If

the ECM always receives astart signal, theECM willjudge thestart signal "OFF"

when engine speedisabove 1,000rpm.

This prevents extraenrichment.

After theengine speedisbelow 200rpm, start-up enrichment willbeallowed untilthe

engine speedreaches 1,000rpm.

-

ECM

Fail-safesystemactivating conditionwhenECMismalfunctioning

The computing functionofthe ECM wasjudged tobe malfunctioning.

When thefail-safe systemactivates (i.e.,ifthe ECM detects amalfunction conditionin

the CPU ofECM), theMALFUNCTION INDICATORLAMPonthe instrument panellightsto

warn thedriver.

Engine control, withfail-safe system,operates whenECMismalfunctioning

When thefail-safe systemisoperating, fuelinjection, ignitiontiming,fuelpump

operation, IACV-AACvalveoperation andcooling fanoperation arecontrolled undercer-

tain limitations.

Operation

Engine speed Enginespeedwillnotrise more than3,000 rpm

Fuel injection

Simultaneousmultiportfuelinjection system

Ignition timing Ignitiontimingisfixed atthe preset valve

Fuel pump Fuel

pump relayis"ON" whenengine isrunning and"OFF" when

engine stalls

IACV-AAC valve

Fullopen

Cooling fans Cooling

fanrelay "ON" (Highspeed condition) whenengine is

running, and"OFF" whenengine stalls

EC-270

Page 991 of 1701

![NISSAN ALMERA N15 1995 Service Manual

I!]

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

---..

RPM.

turningidleadjusting

00

1.

Select "IGNTIMING ADJ"in screw.

"WORK SUPPORT" mode.

2. When touching "STAR NISSAN ALMERA N15 1995 Service Manual

I!]

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

---..

RPM.

turningidleadjusting

00

1.

Select "IGNTIMING ADJ"in screw.

"WORK SUPPORT" mode.

2. When touching "STAR](/img/5/57349/w960_57349-990.png)

I!]

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

---..

RPM.

turningidleadjusting

00

1.

Select "IGNTIMING ADJ"in screw.

"WORK SUPPORT" mode.

2. When touching "START",

does engine speedfallto

750:!: 50rpm

(AfT

in

"N"

posi-

tion)?

OR

00

Does

engine runat750:!: 50rpm

(AfT

In

"N"

position)?

OK

Reconnect throttleposition sensorhar-

ness connector.

Ii

CHECK THROTTLE POSITIONSENSOR

NG

Adjust outputvoltage to

IDLE POSITION.

---..

0.50Vbyrotating throttle

00

1.

Perform ''THRTLPOSSEN

positionsensorbody.

ADJ" in"WORK SUPPORT"

1

mode.

2. Check thatoutput voltage of

RESETIDLEPOSITION

throttle position sensoris

MEMORY.

approx. 0.35to0.65V (Throttle

1.Warm upengine suffi-

valve fullycloses.) and"CLSD ciently.

2. Turn ignition switch

THLIPOSI" stays"ON".

"OFF"andwait at

OR least5seconds.

00

Measure

outputvoltage ofthrot- 3.

Disconnect throttle

position sensorhar-

tie position sensorusing

nessconnector.

voltmeter, andcheck thatitis

4.

Start engine andwait

approx. 0.35toO.65V. (Throttle at

least 5seconds in

"N" position.

valve fullyclosed.)

5.Reconnect throttle

OK • position

sensorhar-

ness connector while

running engine.

~

1

,

THRTL

POSSEN O,52V

SEF165P

•••

ADJMONITOR •••

TROUBLE

DIAGNOSIS -General Description

Basic Inspection (Cont'd)

@

========

MONITOR

========

CMPS.RPM (REF)Orpm

CLSDTHUP ON

Ii

•

THRTL POSSENADJ

.0

I!]

•IGN TIMING ADJ.

0

IGNITION TIMINGFEEDBACK

CONTROL WILLBEHELD BY

TOUCHING START

AFTER DOING SO,ADJUST

IGNITION TIMINGWITHA

TIMING LIGHTBYTURNING

THE CAMSHAFT POSITION

SENSOR

I

START

I

SEF546N

CID

(Go tonext page)

EC-272

Page 1270 of 1701

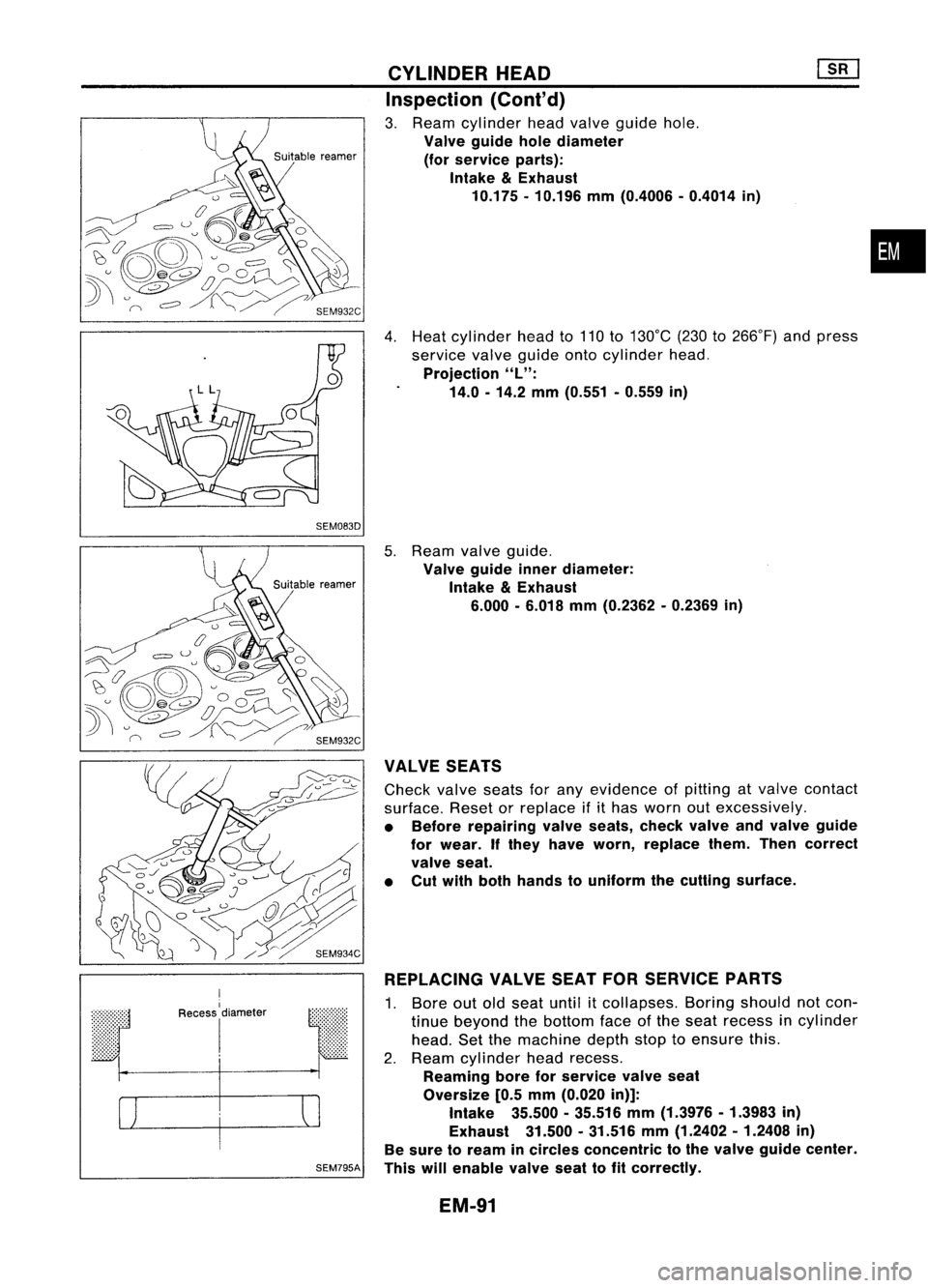

SEM083DCYLINDER

HEAD

Inspection (Cont'd)

3. Ream cylinder headvalve guide hole.

Valve guide holediameter

(for service parts):

Intake

&

Exhaust

10.175 -10.196 mm(0.4006 -0.4014 in)

4. Heat cylinder headto110 to130°C (230to266°F) andpress

service valveguide ontocylinder head.

Projection

"L":

14.0 -14.2 mm(0.551 -0.559 in)

•

r

I

Recess

I

diameter

I

SEM795A

5.

Ream valveguide.

Valve guide innerdiameter:

Intake

&

Exhaust

6.000 -6.018 mm(0.2362 -0.2369 in)

VALVE SEATS

Check valveseatsforany evidence ofpitting atvalve contact

surface. Resetorreplace ifithas worn outexcessively.

• Before repairing valveseats, checkvalveandvalve guide

for wear. Ifthey have worn, replace them.Thencorrect

valve seat.

• Cut with both hands touniform thecutting surface.

REPLACING VALVESEATFORSERVICE PARTS

1. Bore outoldseat until

it

collapses. Boringshould notcon-

tinue beyond thebottom faceofthe seat recess incylinder

head. Setthemachine depthstoptoensure this.

2. Ream cylinder headrecess.

Reaming boreforservice valveseat

Oversize [0.5mm (0.020 in)]:

Intake 35.500-35.516 mm(1.3976 -1.3983 in)

Exhaust 31.500.31.516 mm(1.2402 -1.2408 in)

Be sure toream incircles concentric tothe valve guide center.

This willenable valveseattofit correctly.

EM-91