EC-163 NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 306 of 2493

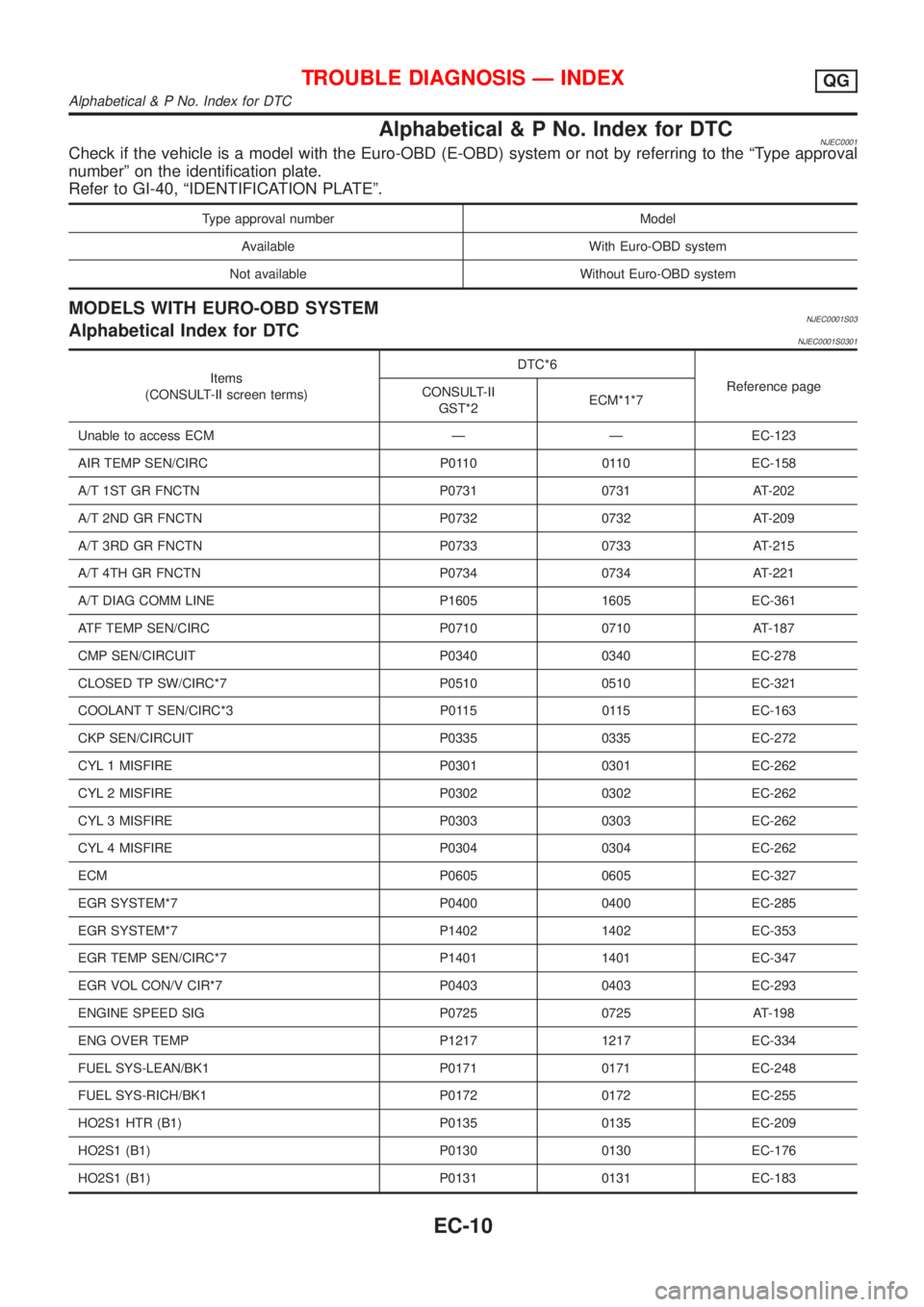

Alphabetical & P No. Index for DTCNJEC0001Check if the vehicle is a model with the Euro-OBD (E-OBD) system or not by referring to the ªType approval

numberº on the identification plate.

Refer to GI-40, ªIDENTIFICATION PLATEº.

Type approval number Model

Available With Euro-OBD system

Not available Without Euro-OBD system

MODELS WITH EURO-OBD SYSTEMNJEC0001S03Alphabetical Index for DTCNJEC0001S0301

Items

(CONSULT-II screen terms)DTC*6

Reference page

CONSULT-II

GST*2ECM*1*7

Unable to access ECM Ð Ð EC-123

AIR TEMP SEN/CIRC P0110 0110 EC-158

A/T 1ST GR FNCTN P0731 0731 AT-202

A/T 2ND GR FNCTN P0732 0732 AT-209

A/T 3RD GR FNCTN P0733 0733 AT-215

A/T 4TH GR FNCTN P0734 0734 AT-221

A/T DIAG COMM LINE P1605 1605 EC-361

ATF TEMP SEN/CIRC P0710 0710 AT-187

CMP SEN/CIRCUIT P0340 0340 EC-278

CLOSED TP SW/CIRC*7 P0510 0510 EC-321

COOLANT T SEN/CIRC*3 P0115 0115 EC-163

CKP SEN/CIRCUIT P0335 0335 EC-272

CYL 1 MISFIRE P0301 0301 EC-262

CYL 2 MISFIRE P0302 0302 EC-262

CYL 3 MISFIRE P0303 0303 EC-262

CYL 4 MISFIRE P0304 0304 EC-262

ECM P0605 0605 EC-327

EGR SYSTEM*7 P0400 0400 EC-285

EGR SYSTEM*7 P1402 1402 EC-353

EGR TEMP SEN/CIRC*7 P1401 1401 EC-347

EGR VOL CON/V CIR*7 P0403 0403 EC-293

ENGINE SPEED SIG P0725 0725 AT-198

ENG OVER TEMP P1217 1217 EC-334

FUEL SYS-LEAN/BK1 P0171 0171 EC-248

FUEL SYS-RICH/BK1 P0172 0172 EC-255

HO2S1 HTR (B1) P0135 0135 EC-209

HO2S1 (B1) P0130 0130 EC-176

HO2S1 (B1) P0131 0131 EC-183

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC

EC-10

Page 308 of 2493

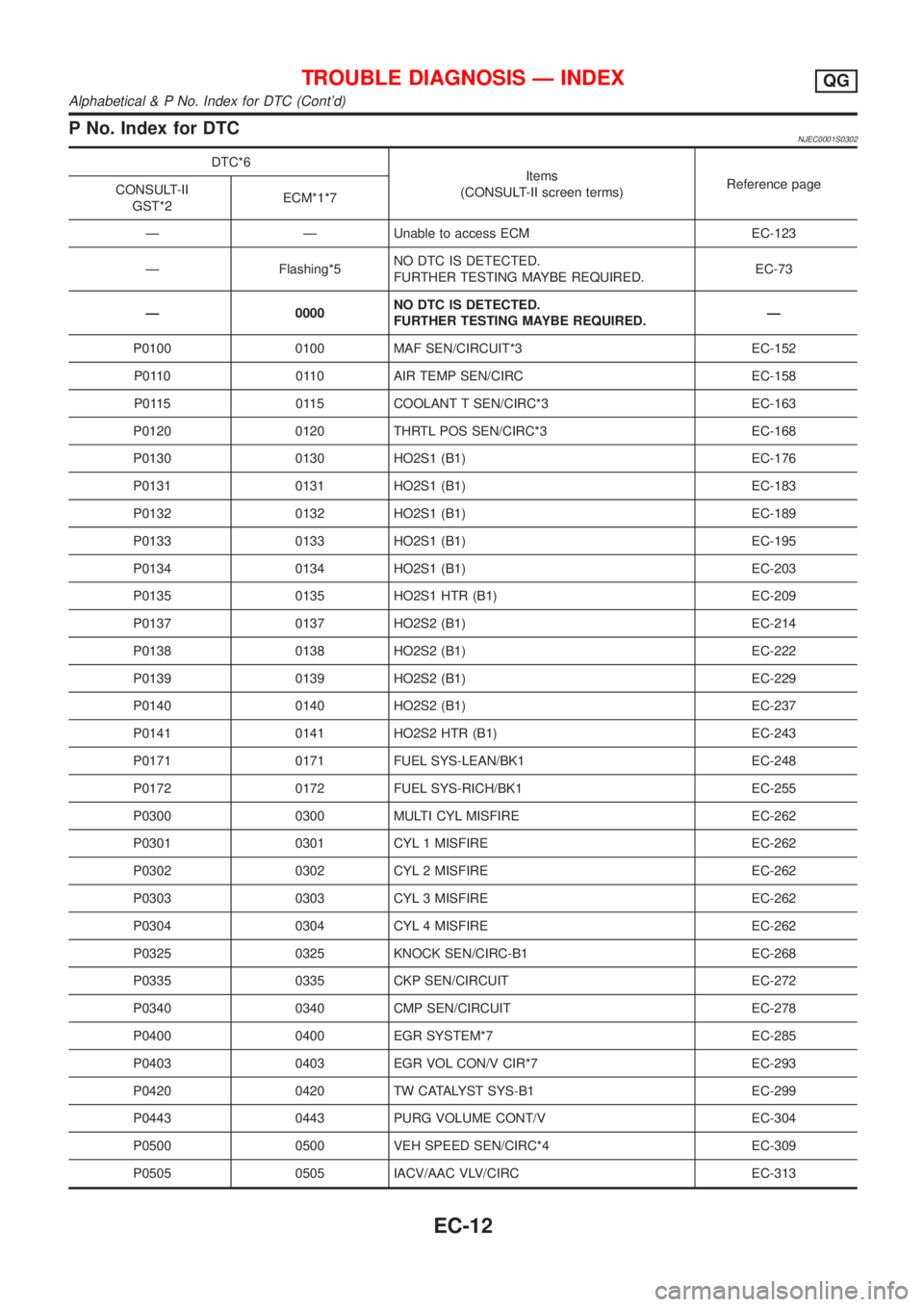

P No. Index for DTCNJEC0001S0302

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1*7

Ð Ð Unable to access ECM EC-123

Ð Flashing*5NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.EC-73

Ð 0000NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.Ð

P0100 0100 MAF SEN/CIRCUIT*3 EC-152

P0110 0110 AIR TEMP SEN/CIRC EC-158

P0115 0115 COOLANT T SEN/CIRC*3 EC-163

P0120 0120 THRTL POS SEN/CIRC*3 EC-168

P0130 0130 HO2S1 (B1) EC-176

P0131 0131 HO2S1 (B1) EC-183

P0132 0132 HO2S1 (B1) EC-189

P0133 0133 HO2S1 (B1) EC-195

P0134 0134 HO2S1 (B1) EC-203

P0135 0135 HO2S1 HTR (B1) EC-209

P0137 0137 HO2S2 (B1) EC-214

P0138 0138 HO2S2 (B1) EC-222

P0139 0139 HO2S2 (B1) EC-229

P0140 0140 HO2S2 (B1) EC-237

P0141 0141 HO2S2 HTR (B1) EC-243

P0171 0171 FUEL SYS-LEAN/BK1 EC-248

P0172 0172 FUEL SYS-RICH/BK1 EC-255

P0300 0300 MULTI CYL MISFIRE EC-262

P0301 0301 CYL 1 MISFIRE EC-262

P0302 0302 CYL 2 MISFIRE EC-262

P0303 0303 CYL 3 MISFIRE EC-262

P0304 0304 CYL 4 MISFIRE EC-262

P0325 0325 KNOCK SEN/CIRC-B1 EC-268

P0335 0335 CKP SEN/CIRCUIT EC-272

P0340 0340 CMP SEN/CIRCUIT EC-278

P0400 0400 EGR SYSTEM*7 EC-285

P0403 0403 EGR VOL CON/V CIR*7 EC-293

P0420 0420 TW CATALYST SYS-B1 EC-299

P0443 0443 PURG VOLUME CONT/V EC-304

P0500 0500 VEH SPEED SEN/CIRC*4 EC-309

P0505 0505 IACV/AAC VLV/CIRC EC-313

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-12

Page 310 of 2493

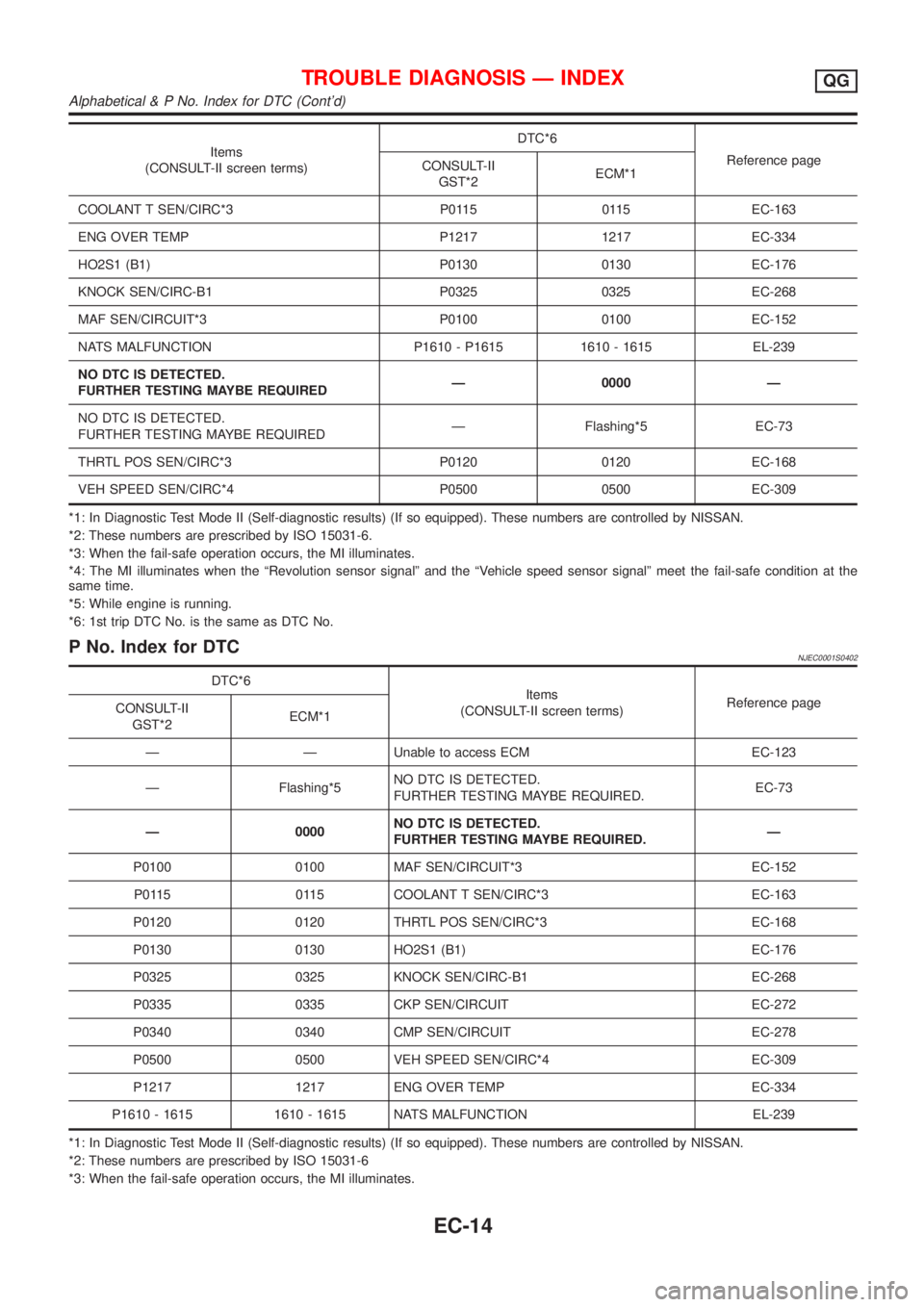

Items

(CONSULT-II screen terms)DTC*6

Reference page

CONSULT-II

GST*2ECM*1

COOLANT T SEN/CIRC*3 P0115 0115 EC-163

ENG OVER TEMP P1217 1217 EC-334

HO2S1 (B1) P0130 0130 EC-176

KNOCK SEN/CIRC-B1 P0325 0325 EC-268

MAF SEN/CIRCUIT*3 P0100 0100 EC-152

NATS MALFUNCTION P1610 - P1615 1610 - 1615 EL-239

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ 0000 Ð

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ Flashing*5 EC-73

THRTL POS SEN/CIRC*3 P0120 0120 EC-168

VEH SPEED SEN/CIRC*4 P0500 0500 EC-309

*1: In Diagnostic Test Mode II (Self-diagnostic results) (If so equipped). These numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO 15031-6.

*3: When the fail-safe operation occurs, the MI illuminates.

*4: The MI illuminates when the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at the

same time.

*5: While engine is running.

*6: 1st trip DTC No. is the same as DTC No.

P No. Index for DTCNJEC0001S0402

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1

Ð Ð Unable to access ECM EC-123

Ð Flashing*5NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.EC-73

Ð 0000NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.Ð

P0100 0100 MAF SEN/CIRCUIT*3 EC-152

P0115 0115 COOLANT T SEN/CIRC*3 EC-163

P0120 0120 THRTL POS SEN/CIRC*3 EC-168

P0130 0130 HO2S1 (B1) EC-176

P0325 0325 KNOCK SEN/CIRC-B1 EC-268

P0335 0335 CKP SEN/CIRCUIT EC-272

P0340 0340 CMP SEN/CIRCUIT EC-278

P0500 0500 VEH SPEED SEN/CIRC*4 EC-309

P1217 1217 ENG OVER TEMP EC-334

P1610 - 1615 1610 - 1615 NATS MALFUNCTION EL-239

*1: In Diagnostic Test Mode II (Self-diagnostic results) (If so equipped). These numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO 15031-6

*3: When the fail-safe operation occurs, the MI illuminates.

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-14

Page 347 of 2493

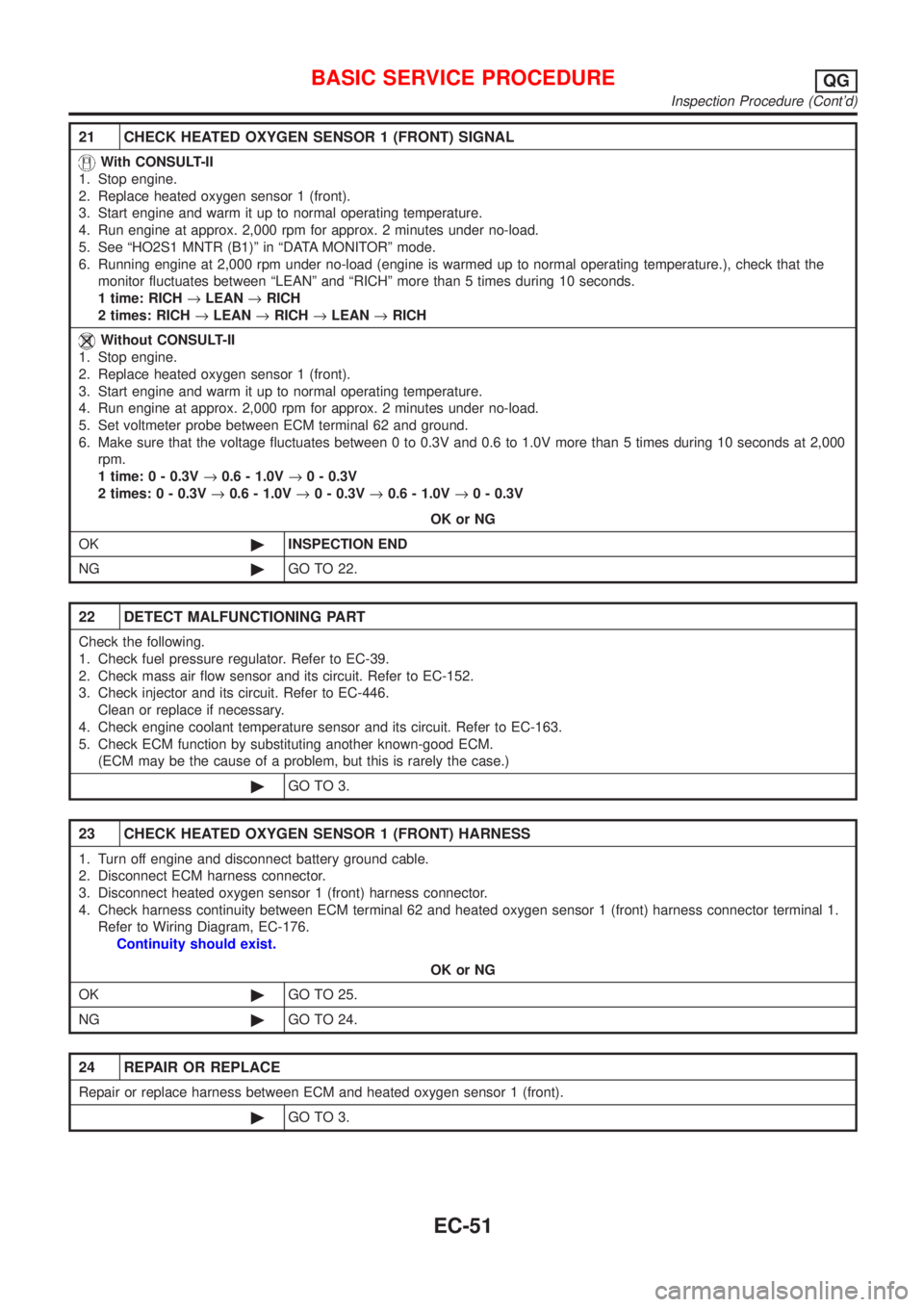

21 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

6. Running engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. Set voltmeter probe between ECM terminal 62 and ground.

6. Make sure that the voltage fluctuates between 0 to 0.3V and 0.6 to 1.0V more than 5 times during 10 seconds at 2,000

rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©INSPECTION END

NG©GO TO 22.

22 DETECT MALFUNCTIONING PART

Check the following.

1. Check fuel pressure regulator. Refer to EC-39.

2. Check mass air flow sensor and its circuit. Refer to EC-152.

3. Check injector and its circuit. Refer to EC-446.

Clean or replace if necessary.

4. Check engine coolant temperature sensor and its circuit. Refer to EC-163.

5. Check ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

23 CHECK HEATED OXYGEN SENSOR 1 (FRONT) HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) harness connector.

4. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 1.

Refer to Wiring Diagram, EC-176.

Continuity should exist.

OK or NG

OK©GO TO 25.

NG©GO TO 24.

24 REPAIR OR REPLACE

Repair or replace harness between ECM and heated oxygen sensor 1 (front).

©GO TO 3.

BASIC SERVICE PROCEDUREQG

Inspection Procedure (Cont'd)

EC-51

Page 350 of 2493

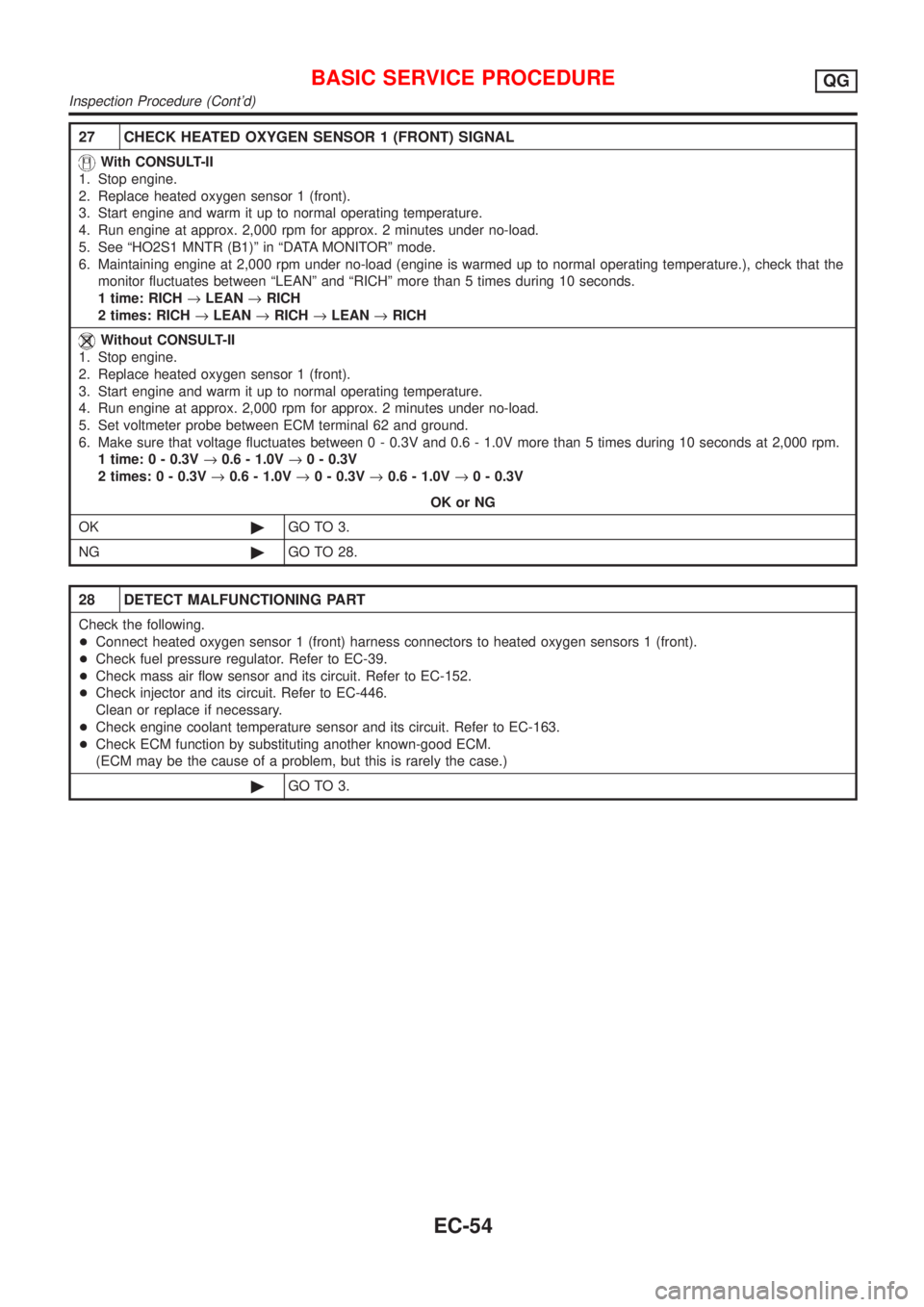

27 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

6. Maintaining engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. Set voltmeter probe between ECM terminal 62 and ground.

6. Make sure that voltage fluctuates between 0 - 0.3V and 0.6 - 1.0V more than 5 times during 10 seconds at 2,000 rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©GO TO 3.

NG©GO TO 28.

28 DETECT MALFUNCTIONING PART

Check the following.

+Connect heated oxygen sensor 1 (front) harness connectors to heated oxygen sensors 1 (front).

+Check fuel pressure regulator. Refer to EC-39.

+Check mass air flow sensor and its circuit. Refer to EC-152.

+Check injector and its circuit. Refer to EC-446.

Clean or replace if necessary.

+Check engine coolant temperature sensor and its circuit. Refer to EC-163.

+Check ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

BASIC SERVICE PROCEDUREQG

Inspection Procedure (Cont'd)

EC-54

Page 362 of 2493

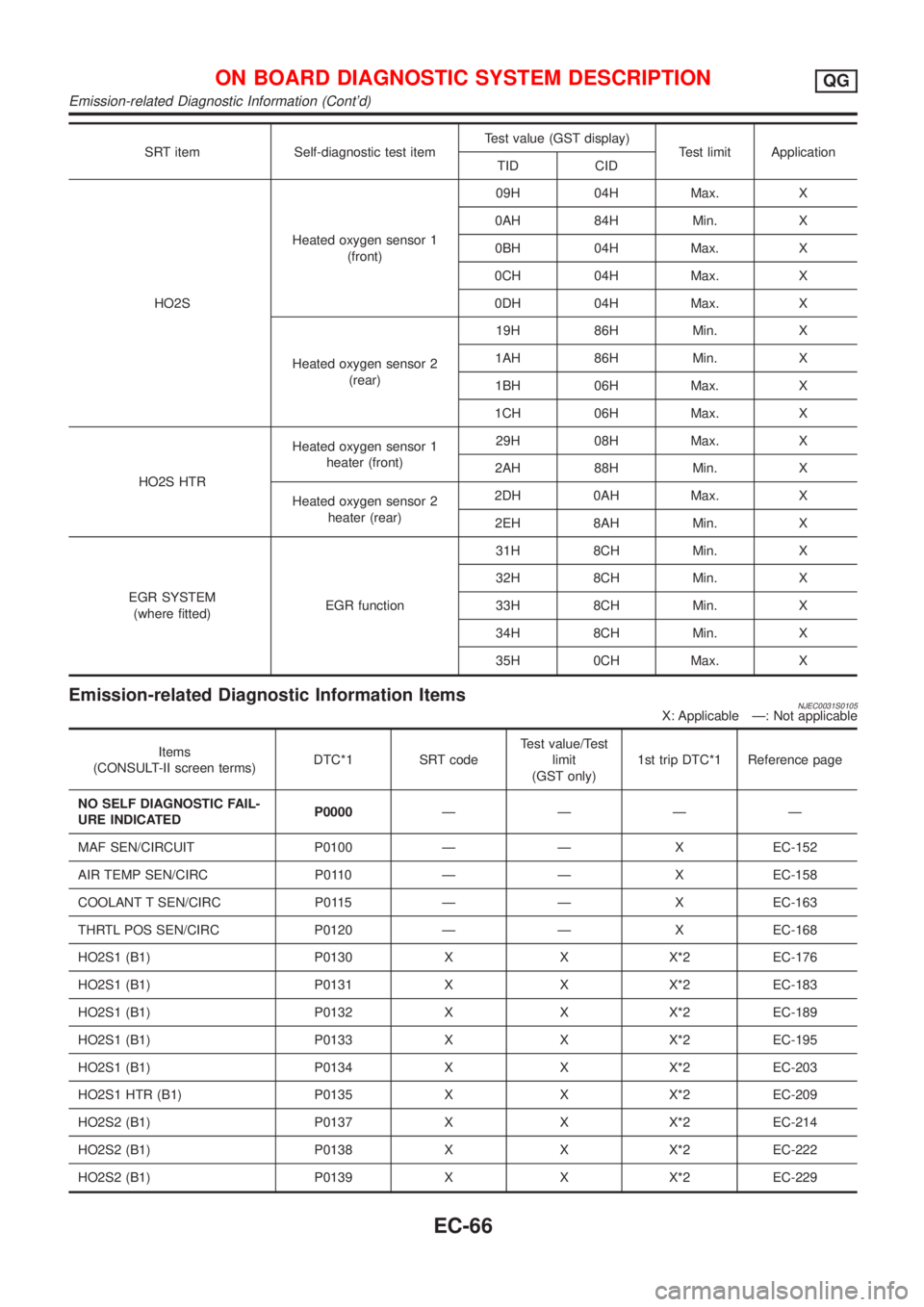

SRT item Self-diagnostic test itemTest value (GST display)

Test limit Application

TID CID

HO2SHeated oxygen sensor 1

(front)09H 04H Max. X

0AH 84H Min. X

0BH 04H Max. X

0CH 04H Max. X

0DH 04H Max. X

Heated oxygen sensor 2

(rear)19H 86H Min. X

1AH 86H Min. X

1BH 06H Max. X

1CH 06H Max. X

HO2S HTRHeated oxygen sensor 1

heater (front)29H 08H Max. X

2AH 88H Min. X

Heated oxygen sensor 2

heater (rear)2DH 0AH Max. X

2EH 8AH Min. X

EGR SYSTEM

(where fitted)EGR function31H 8CH Min. X

32H 8CH Min. X

33H 8CH Min. X

34H 8CH Min. X

35H 0CH Max. X

Emission-related Diagnostic Information ItemsNJEC0031S0105X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC*1 SRT codeTest value/Test

limit

(GST only)1st trip DTC*1 Reference page

NO SELF DIAGNOSTIC FAIL-

URE INDICATEDP0000ÐÐÐÐ

MAF SEN/CIRCUIT P0100 Ð Ð X EC-152

AIR TEMP SEN/CIRC P0110 Ð Ð X EC-158

COOLANT T SEN/CIRC P0115 Ð Ð X EC-163

THRTL POS SEN/CIRC P0120 Ð Ð X EC-168

HO2S1 (B1) P0130 X X X*2 EC-176

HO2S1 (B1) P0131 X X X*2 EC-183

HO2S1 (B1) P0132 X X X*2 EC-189

HO2S1 (B1) P0133 X X X*2 EC-195

HO2S1 (B1) P0134 X X X*2 EC-203

HO2S1 HTR (B1) P0135 X X X*2 EC-209

HO2S2 (B1) P0137 X X X*2 EC-214

HO2S2 (B1) P0138 X X X*2 EC-222

HO2S2 (B1) P0139 X X X*2 EC-229

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG

Emission-related Diagnostic Information (Cont'd)

EC-66

Page 421 of 2493

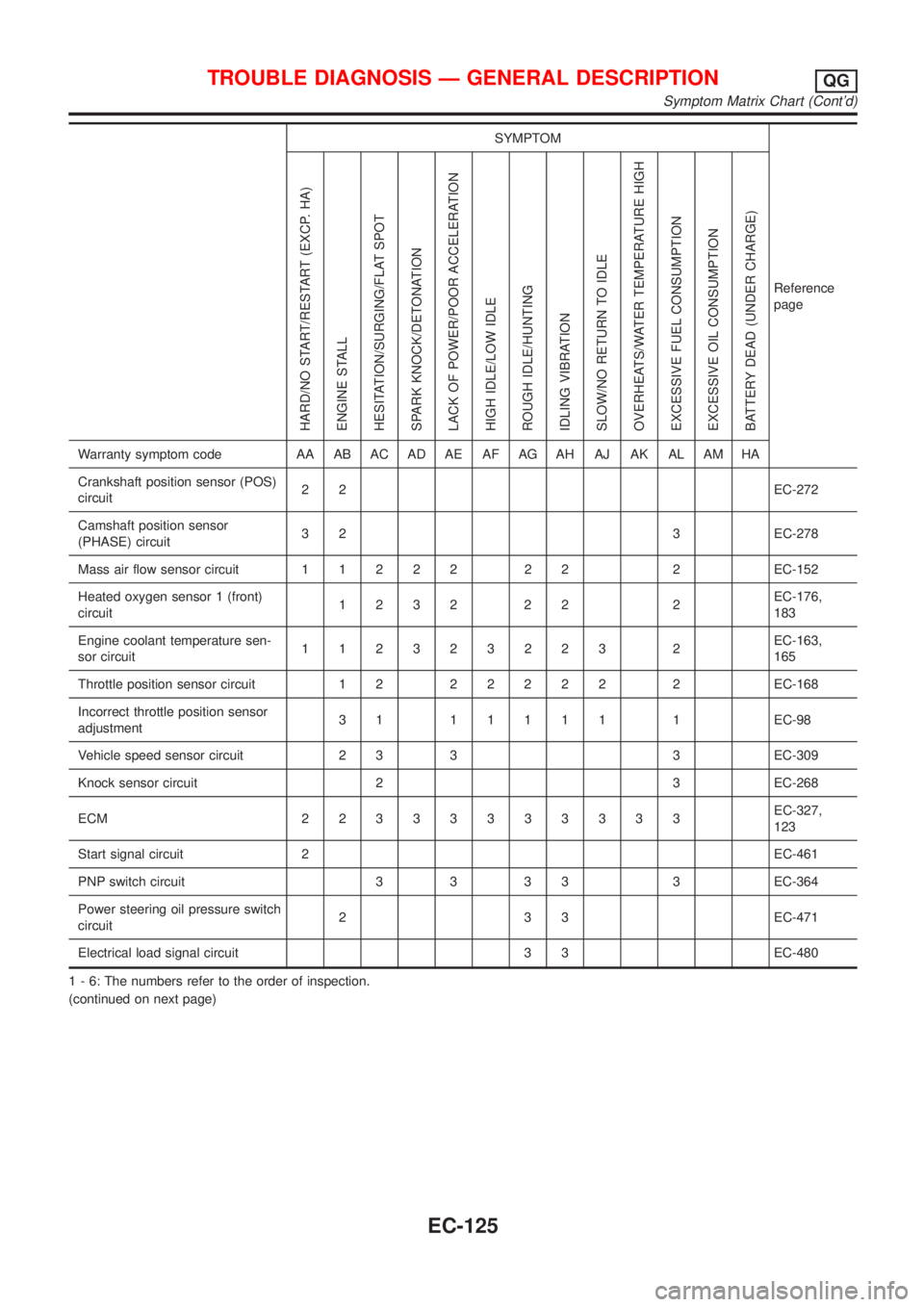

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Crankshaft position sensor (POS)

circuit22EC-272

Camshaft position sensor

(PHASE) circuit3 2 3 EC-278

Mass air flow sensor circuit11222 22 2EC-152

Heated oxygen sensor 1 (front)

circuit1232 22 2EC-176,

183

Engine coolant temperature sen-

sor circuit112323223 2EC-163,

165

Throttle position sensor circuit 1 222222 2EC-168

Incorrect throttle position sensor

adjustment31 11111 1EC-98

Vehicle speed sensor circuit 2 3 3 3 EC-309

Knock sensor circuit 2 3 EC-268

ECM 22333333333EC-327,

123

Start signal circuit 2EC-461

PNP switch circuit 3 3 3 3 3 EC-364

Power steering oil pressure switch

circuit2 3 3 EC-471

Electrical load signal circuit 3 3 EC-480

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart (Cont'd)

EC-125

Page 458 of 2493

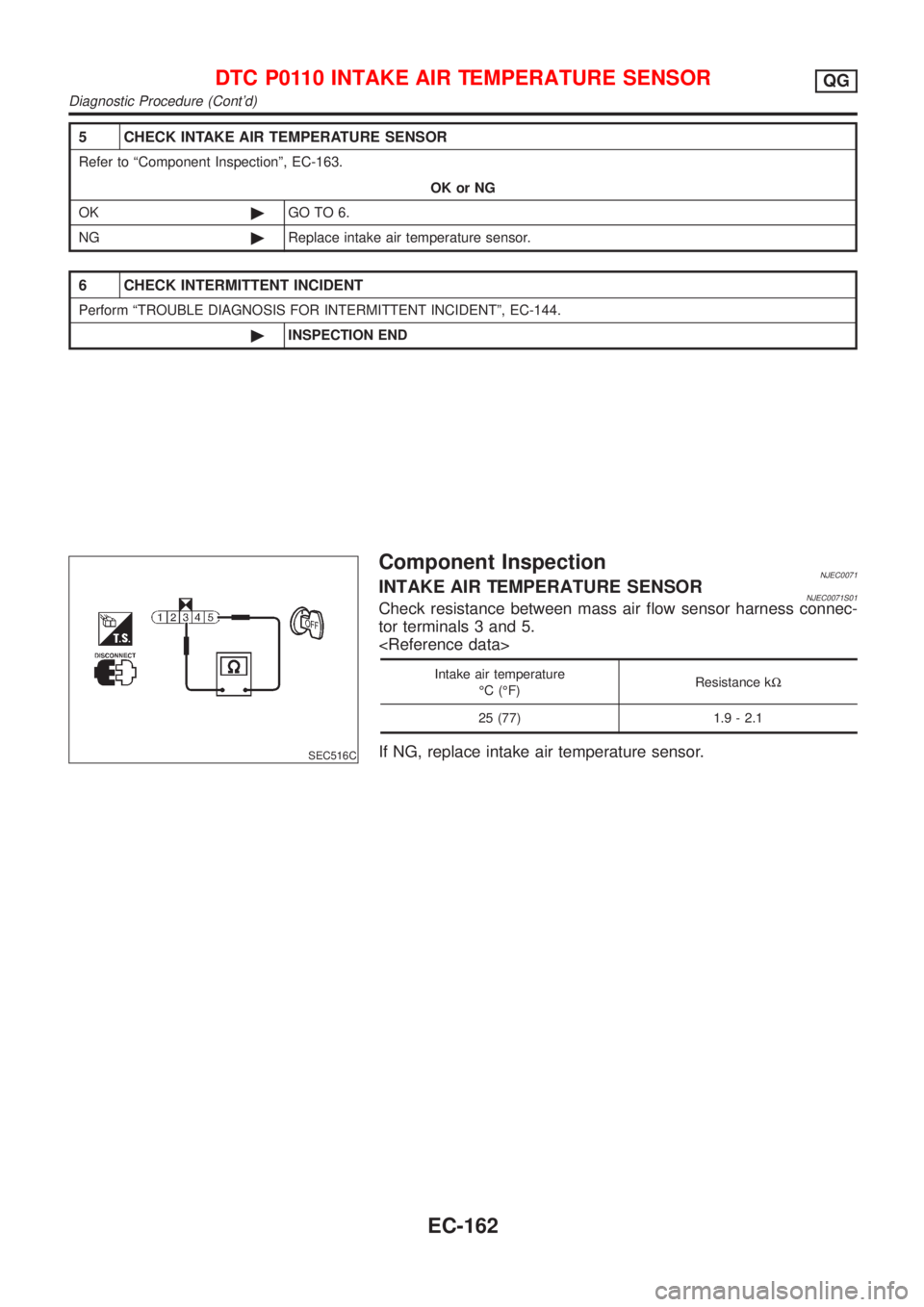

5 CHECK INTAKE AIR TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-163.

OK or NG

OK©GO TO 6.

NG©Replace intake air temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

SEC516C

Component InspectionNJEC0071INTAKE AIR TEMPERATURE SENSORNJEC0071S01Check resistance between mass air flow sensor harness connec-

tor terminals 3 and 5.

Intake air temperature

ÉC (ÉF)Resistance kW

25 (77) 1.9 - 2.1

If NG, replace intake air temperature sensor.

DTC P0110 INTAKE AIR TEMPERATURE SENSORQG

Diagnostic Procedure (Cont'd)

EC-162

Page 459 of 2493

SEF594K

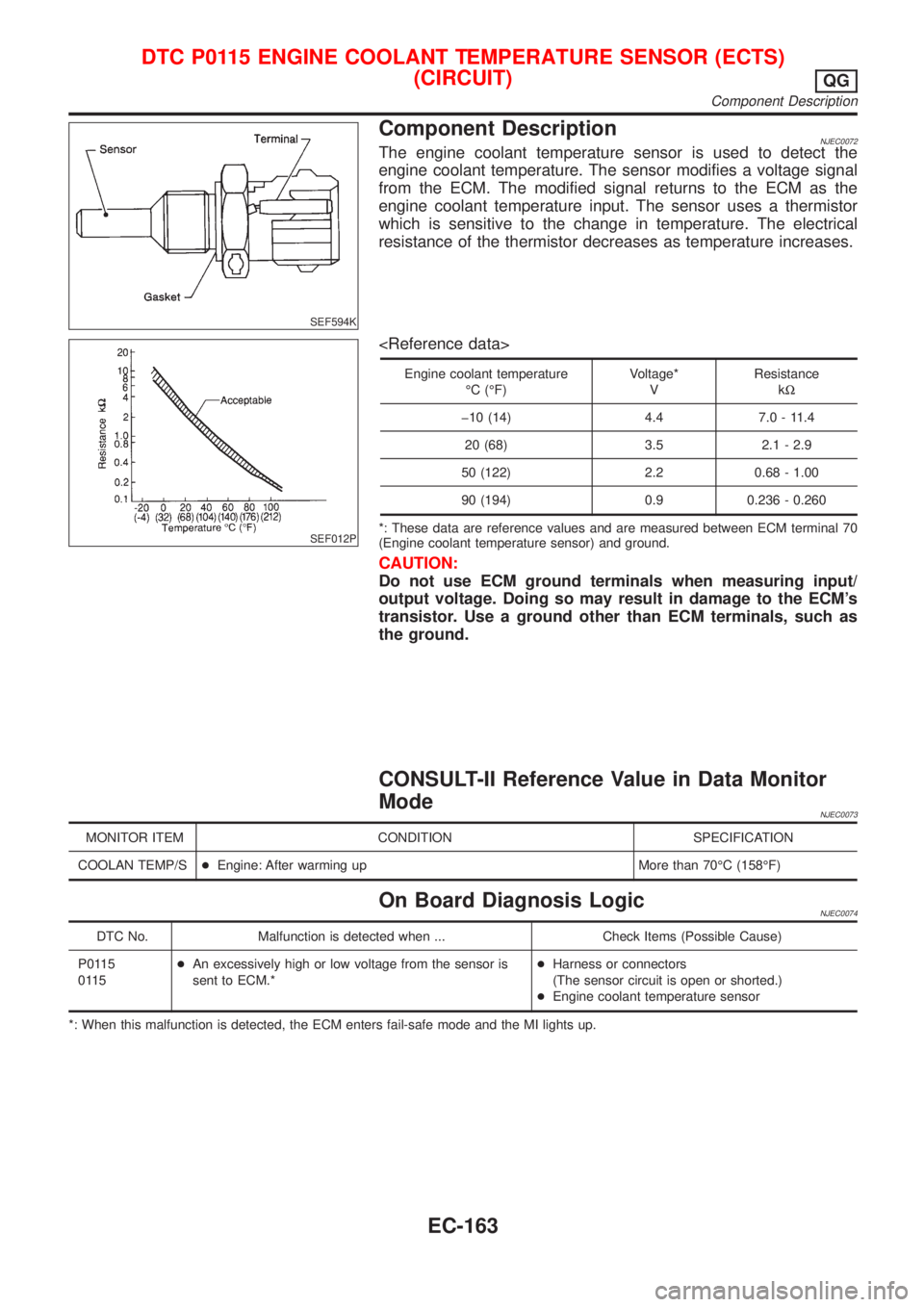

Component DescriptionNJEC0072The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature increases.

SEF012P

Engine coolant temperature

ÉC (ÉF)Voltage*

VResistance

kW

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.2 0.68 - 1.00

90 (194) 0.9 0.236 - 0.260

*: These data are reference values and are measured between ECM terminal 70

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0073

MONITOR ITEM CONDITION SPECIFICATION

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

On Board Diagnosis LogicNJEC0074

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0115

0115+An excessively high or low voltage from the sensor is

sent to ECM.*+Harness or connectors

(The sensor circuit is open or shorted.)

+Engine coolant temperature sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR (ECTS)

(CIRCUIT)

QG

Component Description

EC-163

Page 2484 of 2493

Engine control module (ECM) ....... EC-327, 554,

604, 664, 666, 670, 672

Engine control system diagram and

chart .............................................. EC-26, 503

Engine coolant temperature sensor

(ECTS) ........................................ EC-163, 572

Engine fail-safe system ........................... EC-123

Engine oil precautions .................................. GI-7

Engine outer component parts ................. EM-11

Engine removal ................................ EM-49, 136

Engine room - See Engine

compartment .......................................... BT-75

Engine serial number ................................. GI-41

Evaporative emission (EVAP)

system ................................................... EC-33

Exhaust gas recirculation (EGR)

valve .................................... EC-285, 353, 400

Exhaust system ................................... FE-11, 27

Exterior ...................................................... BT-47

F

F/PUMP - Wiring diagram ....................... EC-466

FR02 - Wiring diagram ... EC-179, 198, 205, 374

FR02/H - Wiring diagram ................ EC-211, 380

FUEL - Wiring diagram ................... EC-250, 257

Fan switch ................................................. HA-60

Final drive (FF A/T) .................................. AT-424

Final drive (FF M/T) .............. MT-43, 77, 93, 107

Finisher, interior - See Trim ....................... BT-31

Finisher, trunk lid ....................................... BT-45

Floor trim ................................................... BT-31

Fluid temperature sensor (A/T) ................ AT-192

Fluids ........................................................ MA-20

Flywheel (clutch) ....................................... CL-22

Flywheel runout ................................ EM-60, 153

Fog lamp, front, removal and

installation ................................................ BT-7

Fog lamp, front .......................................... EL-60

Fork rod (M/T) .............................. MT-32, 56, 94

Forward clutch ......................................... AT-399

Freeze frame data .............................. EC-59, 70

Front axle .................................................... AX-2

Front bumper ............................................... BT-7

Front combination lamp removal and

installation ................................................ BT-7

Front disc brake ........................................ BR-27

Front door .................................................. BT-16

Front fog lamp removal and

installation ................................................ BT-7

Front fog lamp ........................................... EL-60

Front heated oxygen sensor (HO2S)

heater .......................................... EC-209, 379

Front heated oxygen sensor (HO2S) ..... EC-176,

183, 189, 195, 203, 373

Front seat belt ............................................. RS-5

Front seat .................................................. BT-56

Front suspension ........................................ SU-2

Front washer ............................................ EL-123Front wiper ............................................... EL-123

Fuel cut control (at no load & high

engine speed) ............................... EC-33, 507

Fuel gauge ................................................. EL-89

Fuel injection system .............. EC-248, 255, 505

Fuel injector ............................................ EC-446

Fuel precautions ........................................... GI-8

Fuel pressure check ................................. EC-38

Fuel pressure regulator ............................. EC-39

Fuel pressure release ............................... EC-38

Fuel pump relay ...................................... EC-464

Fuel pump ............................................... EC-464

Fuel system ........................................... FE-5, 16

Fuel tank vacuum relief valve ................... EC-34

Fuse block ............................................... EL-369

Fuse ........................................................... EL-22

Fusible link ................................................. EL-22

G

GLOW - Wiring diagram ......................... EC-677

Garage jack and safety stand .................... GI-45

Gauges ...................................................... EL-89

Gear components (M/T) ............... MT-31, 55, 93

Generator - See Alternator ....................... SC-27

Generic scan tool (GST) ........................... EC-92

Glass .......................................................... BT-17

Glow plug ................................................ EC-677

Glow relay ............................................... EC-677

Grease ...................................................... MA-20

Ground distribution .................................... EL-23

H

H/LAMP - Wiring diagram .......................... EL-40

HEATER - Wiring diagram ........................ HA-24

HFC134a (R134a) system

recaution .................................................. HA-2

HFC134a (R134a) system service

procedure .............................................. HA-84

HFC134a (R134a) system service

tools ....................................................... HA-11

HFC134a system service equipment

precaution ................................................ HA-6

HORN - Wiring diagram .......................... EL-135

HSEAT - Wiring diagram ......................... EL-163

Harness connector ...................................... EL-5

Harness layout ......................................... EL-324

Hazard warning lamp ................................ EL-65

Headlamp removal and installation ............. BT-7

Headlamp washer .................................... EL-133

Headlamp .................................................. EL-40

Headlining - See Roof trim ........................ BT-43

Heated oxygen sensor (HO2S)

(front) .......... EC-176, 183, 189, 195, 203, 373

Heated oxygen sensor (HO2S) heater

(front) ........................................... EC-209, 379

ALPHABETICAL INDEX

IDX-4