air suspension NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1 of 2493

Edition:April 2001

Release :May 2001 (01)

Publicatio nNo. :SM 1E00-1N16E0E

GENERA LINFORMATIONGI

MAINTENANCEMA

ENGIN EMECHANICALEM

ENGIN ELUBRICATIO N&

COOLIN GSYSTEMSLC

ENGIN ECONTRO LSYSTEMEC

ACCELERATO RCONTROL,

FUE L&EXHAUS TSYSTEMSFE

CLUTCHCL

MANUA LTRANSAXLEMT

AUTOMATI CTRANSAXLEAT

FRON T&REA RAXLEAX

FRON T&REA RSUSPENSIONSU

BRAK ESYSTEMBR

STEERIN GSYSTEMST

RESTRAIN TSYSTEMRS

BOD Y&TRIMBT

HEATE R&AIR CONDITIONERHA

STARTIN G&CHARGIN GSYSTEMSSC

ELECTRICA LSYSTEMEL

ALPHABETICA LINDEXIDX

ALMERA

MODE LN16 SERIES

NISSA NEUROP EN.V.

200 1 NISSA NEUROP EN.V.

Produce din Th eNetherlands

No tto be reproduce din whol eor in partwithou tth eprio rwritte npermissio nofNissa nEurop eN.V. ,Amsterdam ,th eNetherlands.

QUIC KREFERENC EINDEX

Page 58 of 2493

NJMA0036

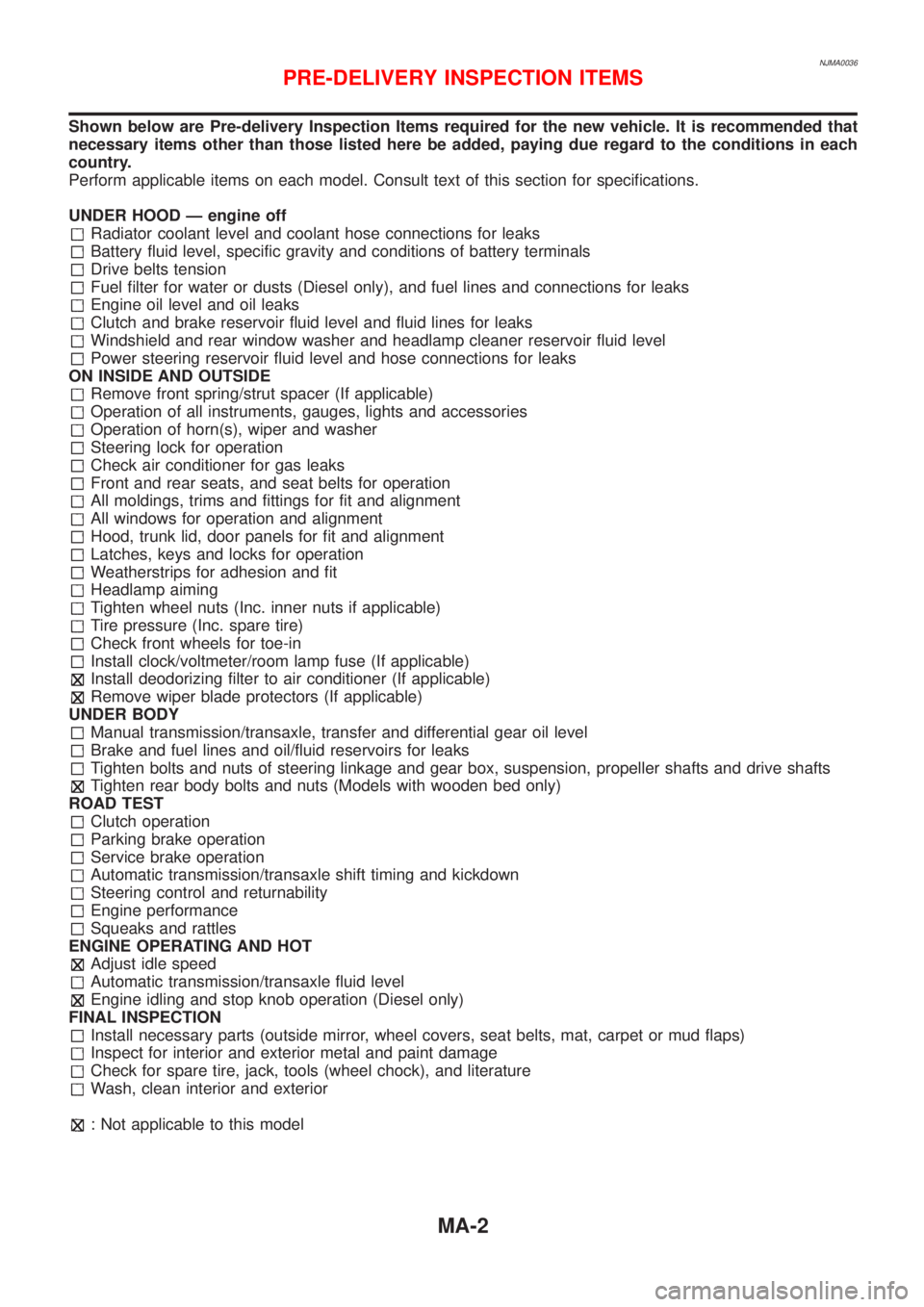

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 63 of 2493

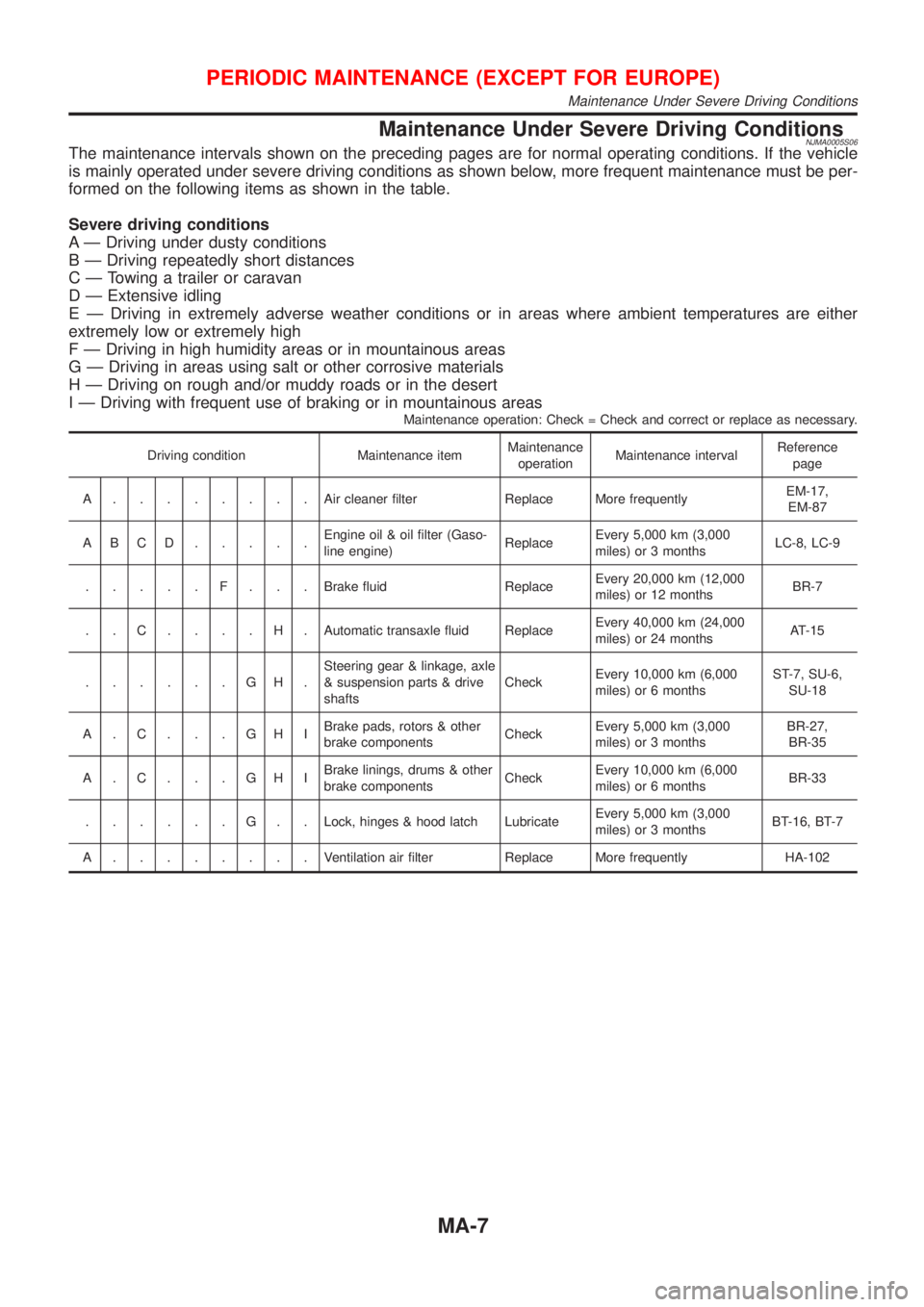

Maintenance Under Severe Driving ConditionsNJMA0005S06The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

Maintenance operation: Check = Check and correct or replace as necessary.

Driving condition Maintenance itemMaintenance

operationMaintenance intervalReference

page

A........Aircleaner filter Replace More frequentlyEM-17,

EM-87

ABCD.....Engine oil & oil filter (Gaso-

line engine)ReplaceEvery 5,000 km (3,000

miles) or 3 monthsLC-8, LC-9

.....F...Brake fluid ReplaceEvery 20,000 km (12,000

miles) or 12 monthsBR-7

. . C . . . . H . Automatic transaxle fluid ReplaceEvery 40,000 km (24,000

miles) or 24 monthsAT-15

......GH.Steering gear & linkage, axle

& suspension parts & drive

shaftsCheckEvery 10,000 km (6,000

miles) or 6 monthsST-7, SU-6,

SU-18

A.C...GHIBrake pads, rotors & other

brake componentsCheckEvery 5,000 km (3,000

miles) or 3 monthsBR-27,

BR-35

A.C...GHIBrake linings, drums & other

brake componentsCheckEvery 10,000 km (6,000

miles) or 6 monthsBR-33

......G..Lock, hinges & hood latch LubricateEvery 5,000 km (3,000

miles) or 3 monthsBT-16, BT-7

A........Ventilation air filter Replace More frequently HA-102

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Maintenance Under Severe Driving Conditions

MA-7

Page 1077 of 2493

SMT940D

SMT951D

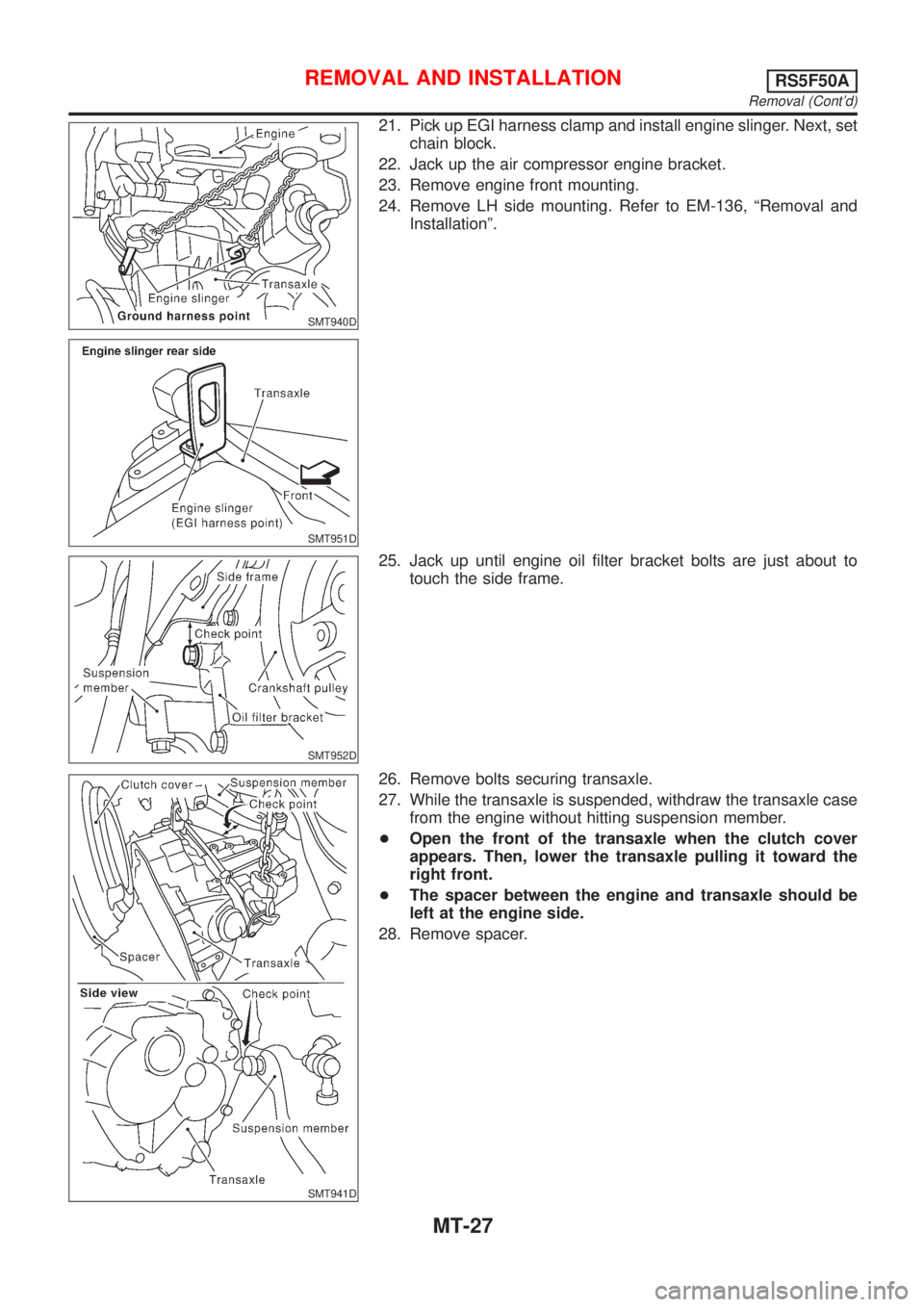

21. Pick up EGI harness clamp and install engine slinger. Next, set

chain block.

22. Jack up the air compressor engine bracket.

23. Remove engine front mounting.

24. Remove LH side mounting. Refer to EM-136, ªRemoval and

Installationº.

SMT952D

25. Jack up until engine oil filter bracket bolts are just about to

touch the side frame.

SMT941D

26. Remove bolts securing transaxle.

27. While the transaxle is suspended, withdraw the transaxle case

from the engine without hitting suspension member.

+Open the front of the transaxle when the clutch cover

appears. Then, lower the transaxle pulling it toward the

right front.

+The spacer between the engine and transaxle should be

left at the engine side.

28. Remove spacer.

REMOVAL AND INSTALLATIONRS5F50A

Removal (Cont'd)

MT-27

Page 1647 of 2493

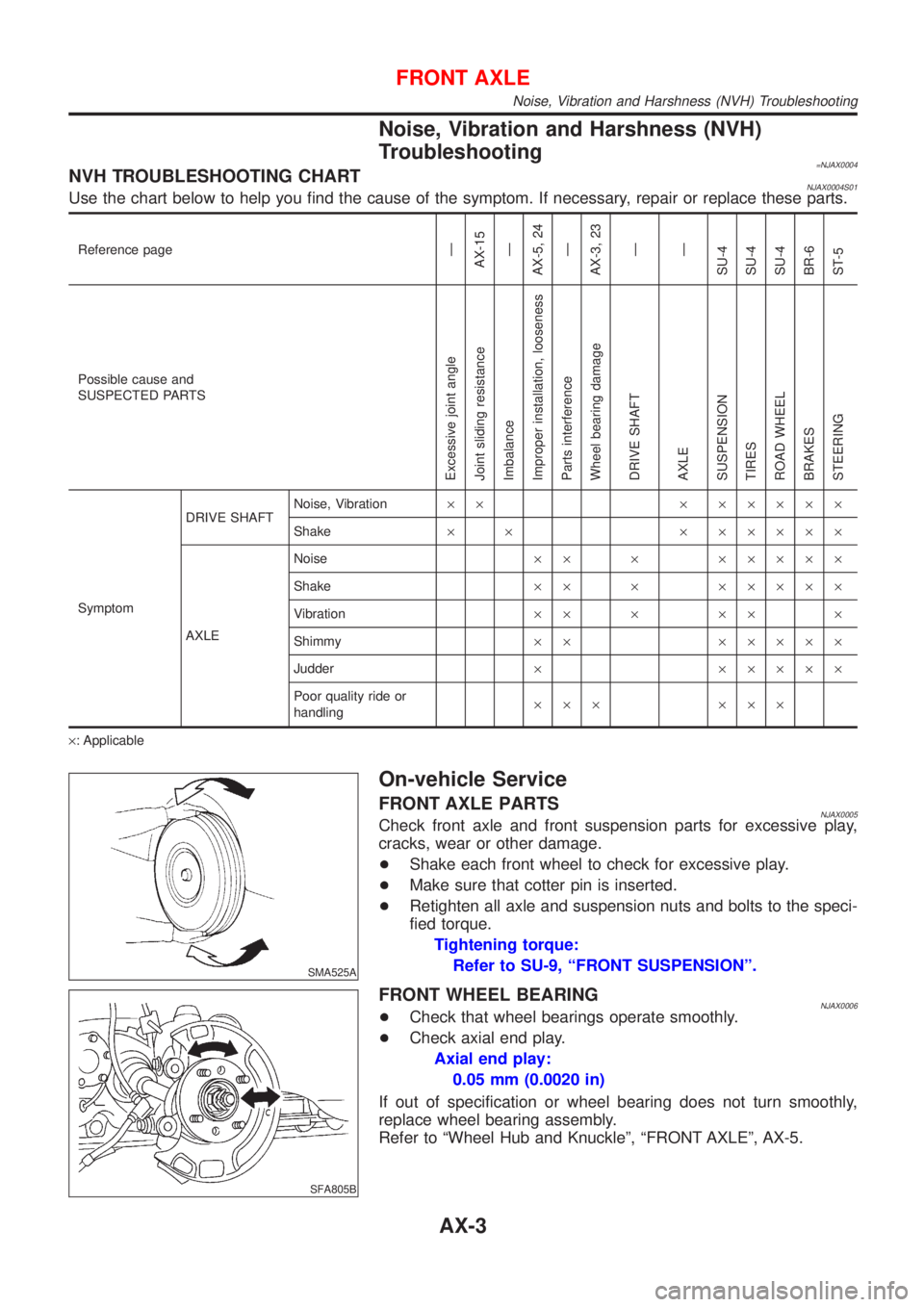

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NJAX0004NVH TROUBLESHOOTING CHARTNJAX0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-15

Ð

AX-5, 24

Ð

AX-3, 23

Ð

Ð

SU-4

SU-4

SU-4

BR-6

ST-5

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´ ´´´´´

Shake´ ´ ´ ´´´´´

AXLENoise´´ ´ ´´´´´

Shake´´ ´ ´´´´´

Vibration´´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNJAX0005Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

+Shake each front wheel to check for excessive play.

+Make sure that cotter pin is inserted.

+Retighten all axle and suspension nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to SU-9, ªFRONT SUSPENSIONº.

SFA805B

FRONT WHEEL BEARINGNJAX0006+Check that wheel bearings operate smoothly.

+Check axial end play.

Axial end play:

0.05 mm (0.0020 in)

If out of specification or wheel bearing does not turn smoothly,

replace wheel bearing assembly.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

Page 1676 of 2493

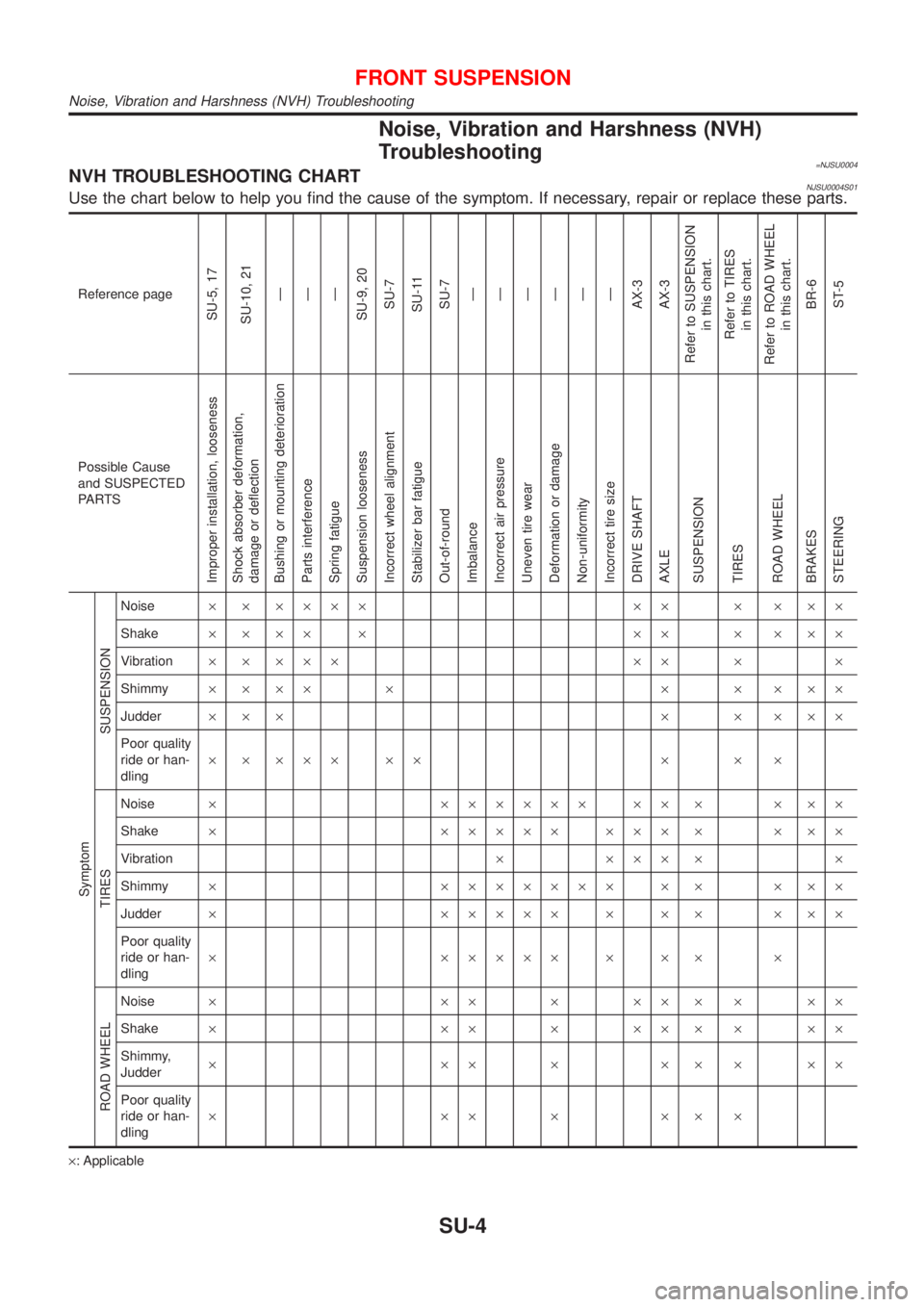

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NJSU0004NVH TROUBLESHOOTING CHARTNJSU0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

SU-5, 17

SU-10, 21

Ð

Ð

Ð

SU-9, 20

SU-7

SU-11

SU-7

Ð

Ð

Ð

Ð

Ð

Ð

AX-3

AX-3

Refer to SUSPENSION

in this chart.

Refer to TIRES

in this chart.

Refer to ROAD WHEEL

in this chart.

BR-6

ST-5

Possible Cause

and SUSPECTED

PA R T S

Improper installation, looseness

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

Out-of-round

Imbalance

Incorrect air pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING Symptom

SUSPENSION

Noise´ ´ ´´´´ ´´ ´ ´ ´´

Shake´ ´ ´´ ´ ´´ ´ ´ ´´

Vibration´ ´ ´´´ ´´ ´ ´

Shimmy´´´´ ´ ´ ´ ´´´

Judder´´´ ´ ´ ´´´

Poor quality

ride or han-

dling´ ´ ´´´ ´´ ´ ´ ´

TIRES

Noise´ ´´´´´´ ´´ ´ ´ ´´

Shake´ ´´´´´ ´´´ ´ ´ ´´

Vibration´ ´´´ ´ ´

Shimmy´ ´´´´´´´ ´ ´ ´ ´´

Judder´ ´´´´´ ´ ´ ´ ´ ´´

Poor quality

ride or han-

dling´ ´´´´´ ´ ´ ´ ´

ROAD WHEEL

Noise´ ´´´´´´´´´

Shake´ ´´´´´´´´´

Shimmy,

Judder´´´´´´´´´

Poor quality

ride or han-

dling´´´´´´´

´: Applicable

FRONT SUSPENSION

Noise, Vibration and Harshness (NVH) Troubleshooting

SU-4

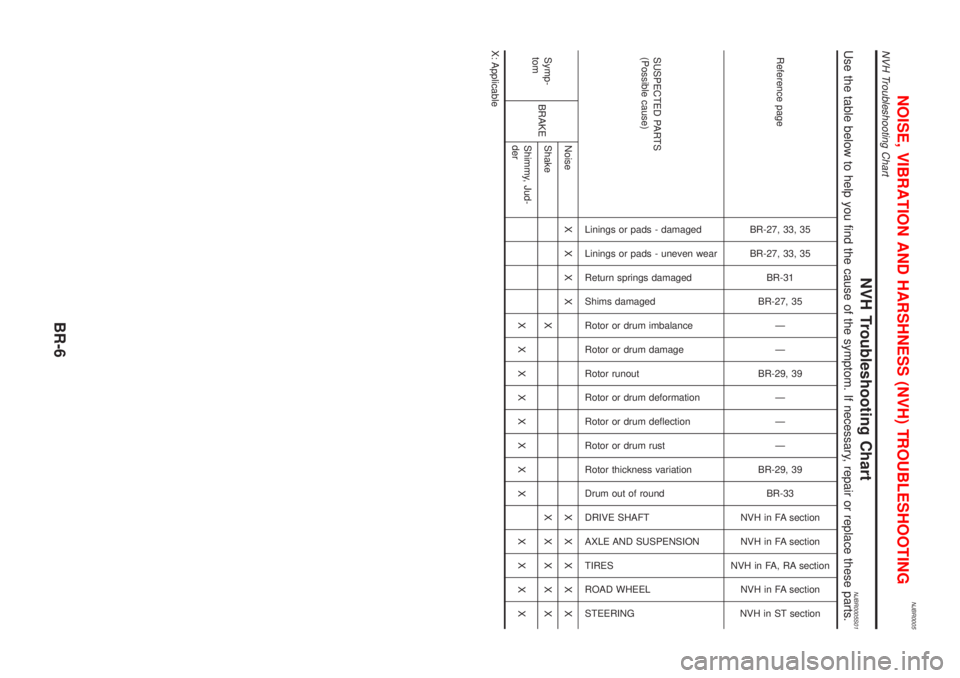

Page 1704 of 2493

NJBR0005

NVH Troubleshooting ChartNJBR0005S01Use the table below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

BR-27, 33, 35

BR-27, 33, 35

BR-31

BR-27, 35

Ð

Ð

BR-29, 39

Ð

Ð

Ð

BR-29, 39

BR-33

NVH in FA section

NVH in FA section

NVH in FA, RA section

NVH in FA section

NVH in ST section

SUSPECTED PARTS

(Possible cause)

Linings or pads - damaged

Linings or pads - uneven wear

Return springs damaged

Shims damaged

Rotor or drum imbalance

Rotor or drum damage

Rotor runout

Rotor or drum deformation

Rotor or drum deflection

Rotor or drum rust

Rotor thickness variation

Drum out of round

DRIVE SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

STEERING

Symp-

tomBRAKENoiseXXXX XXXXX

Shake XXXXXX

Shimmy, Jud-

derXXXXXXXX XXXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

BR-6

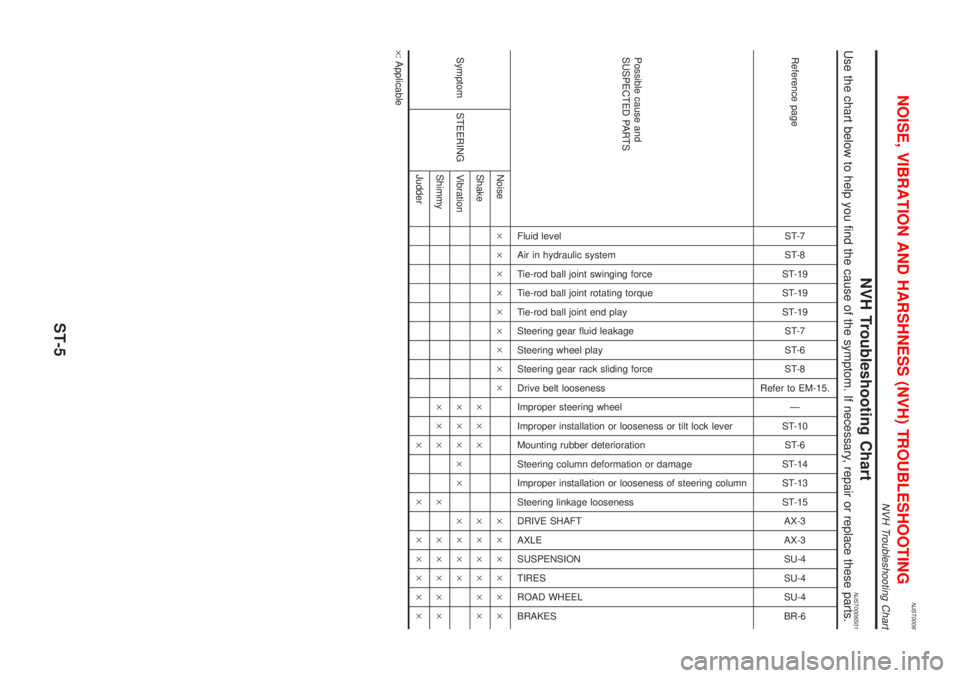

Page 1795 of 2493

NJST0006

NVH Troubleshooting ChartNJST0006S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-7

ST-8

ST-19

ST-19

ST-19

ST-7

ST-6

ST-8

Refer to EM-15.

Ð

ST-10

ST-6

ST-14

ST-13

ST-15

AX-3

AX-3

SU-4

SU-4

SU-4

BR-6

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

Symptom STEERINGNoise´´´´´´´´´ ´´´´´´

Shake´´´ ´´´´´´

Vibration´´´´´ ´´´´

Shimmy´´´ ´ ´´´´´

Judder´ ´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

ST-5

Page 2486 of 2493

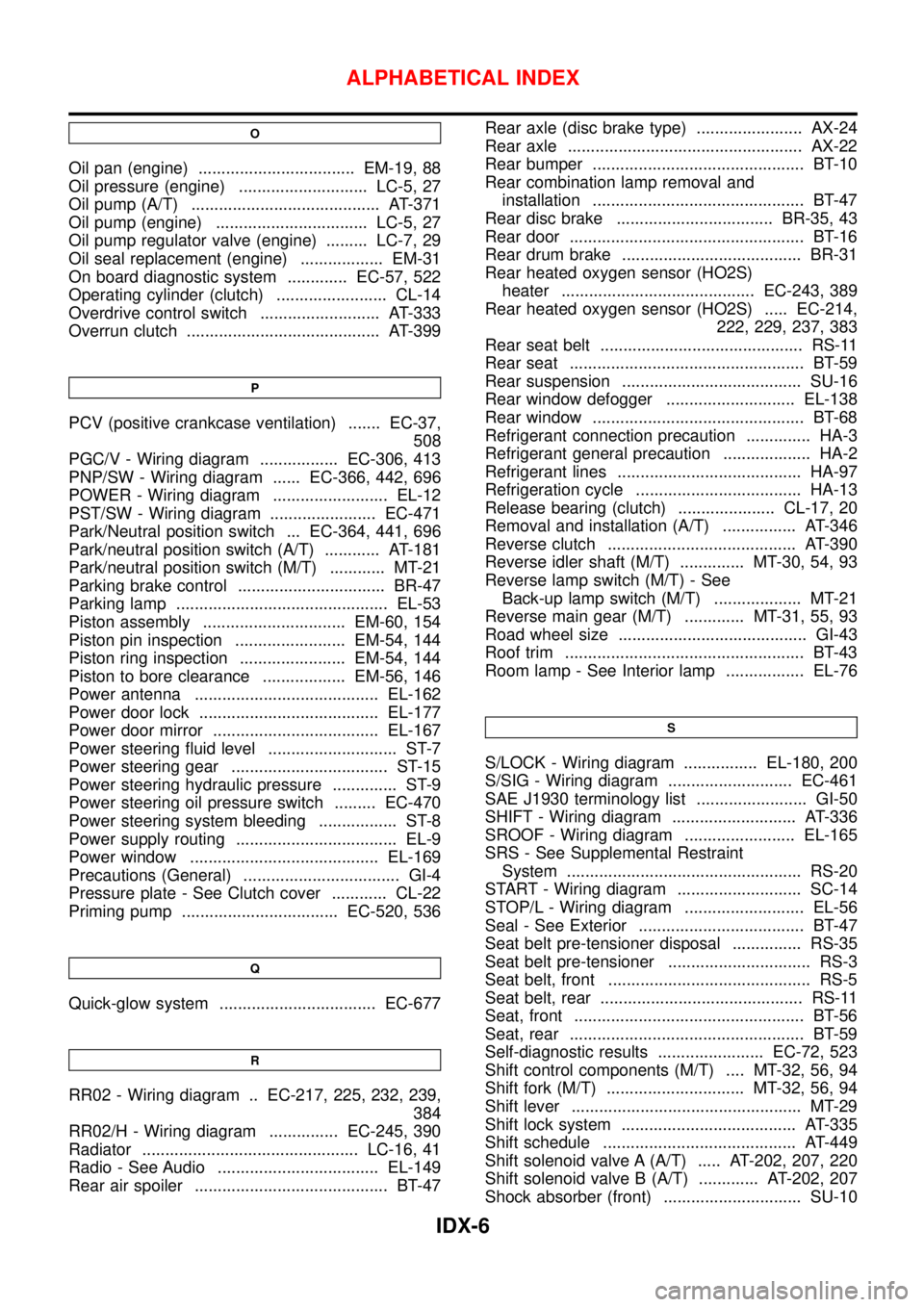

O

Oil pan (engine) .................................. EM-19, 88

Oil pressure (engine) ............................ LC-5, 27

Oil pump (A/T) ......................................... AT-371

Oil pump (engine) ................................. LC-5, 27

Oil pump regulator valve (engine) ......... LC-7, 29

Oil seal replacement (engine) .................. EM-31

On board diagnostic system ............. EC-57, 522

Operating cylinder (clutch) ........................ CL-14

Overdrive control switch .......................... AT-333

Overrun clutch .......................................... AT-399

P

PCV (positive crankcase ventilation) ....... EC-37,

508

PGC/V - Wiring diagram ................. EC-306, 413

PNP/SW - Wiring diagram ...... EC-366, 442, 696

POWER - Wiring diagram ......................... EL-12

PST/SW - Wiring diagram ....................... EC-471

Park/Neutral position switch ... EC-364, 441, 696

Park/neutral position switch (A/T) ............ AT-181

Park/neutral position switch (M/T) ............ MT-21

Parking brake control ................................ BR-47

Parking lamp .............................................. EL-53

Piston assembly ............................... EM-60, 154

Piston pin inspection ........................ EM-54, 144

Piston ring inspection ....................... EM-54, 144

Piston to bore clearance .................. EM-56, 146

Power antenna ........................................ EL-162

Power door lock ....................................... EL-177

Power door mirror .................................... EL-167

Power steering fluid level ............................ ST-7

Power steering gear .................................. ST-15

Power steering hydraulic pressure .............. ST-9

Power steering oil pressure switch ......... EC-470

Power steering system bleeding ................. ST-8

Power supply routing ................................... EL-9

Power window ......................................... EL-169

Precautions (General) .................................. GI-4

Pressure plate - See Clutch cover ............ CL-22

Priming pump .................................. EC-520, 536

Q

Quick-glow system .................................. EC-677

R

RR02 - Wiring diagram .. EC-217, 225, 232, 239,

384

RR02/H - Wiring diagram ............... EC-245, 390

Radiator ............................................... LC-16, 41

Radio - See Audio ................................... EL-149

Rear air spoiler .......................................... BT-47Rear axle (disc brake type) ....................... AX-24

Rear axle ................................................... AX-22

Rear bumper .............................................. BT-10

Rear combination lamp removal and

installation .............................................. BT-47

Rear disc brake .................................. BR-35, 43

Rear door ................................................... BT-16

Rear drum brake ....................................... BR-31

Rear heated oxygen sensor (HO2S)

heater .......................................... EC-243, 389

Rear heated oxygen sensor (HO2S) ..... EC-214,

222, 229, 237, 383

Rear seat belt ............................................ RS-11

Rear seat ................................................... BT-59

Rear suspension ....................................... SU-16

Rear window defogger ............................ EL-138

Rear window .............................................. BT-68

Refrigerant connection precaution .............. HA-3

Refrigerant general precaution ................... HA-2

Refrigerant lines ........................................ HA-97

Refrigeration cycle .................................... HA-13

Release bearing (clutch) ..................... CL-17, 20

Removal and installation (A/T) ................ AT-346

Reverse clutch ......................................... AT-390

Reverse idler shaft (M/T) .............. MT-30, 54, 93

Reverse lamp switch (M/T) - See

Back-up lamp switch (M/T) ................... MT-21

Reverse main gear (M/T) ............. MT-31, 55, 93

Road wheel size ......................................... GI-43

Roof trim .................................................... BT-43

Room lamp - See Interior lamp ................. EL-76

S

S/LOCK - Wiring diagram ................ EL-180, 200

S/SIG - Wiring diagram ........................... EC-461

SAE J1930 terminology list ........................ GI-50

SHIFT - Wiring diagram ........................... AT-336

SROOF - Wiring diagram ........................ EL-165

SRS - See Supplemental Restraint

System ................................................... RS-20

START - Wiring diagram ........................... SC-14

STOP/L - Wiring diagram .......................... EL-56

Seal - See Exterior .................................... BT-47

Seat belt pre-tensioner disposal ............... RS-35

Seat belt pre-tensioner ............................... RS-3

Seat belt, front ............................................ RS-5

Seat belt, rear ............................................ RS-11

Seat, front .................................................. BT-56

Seat, rear ................................................... BT-59

Self-diagnostic results ....................... EC-72, 523

Shift control components (M/T) .... MT-32, 56, 94

Shift fork (M/T) .............................. MT-32, 56, 94

Shift lever .................................................. MT-29

Shift lock system ...................................... AT-335

Shift schedule .......................................... AT-449

Shift solenoid valve A (A/T) ..... AT-202, 207, 220

Shift solenoid valve B (A/T) ............. AT-202, 207

Shock absorber (front) .............................. SU-10

ALPHABETICAL INDEX

IDX-6