alternator NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 80 of 2493

REPLACEMENT OF CONNECTING ROD

BUSHING (SMALL END)

..........................................60

FLYWHEEL/DRIVE PLATE RUNOUT........................60

Assembly ...................................................................60

PISTON..................................................................60

CRANKSHAFT.........................................................61

SERVICE DATA AND SPECIFICATIONS (SDS).........64

General Specifications ...............................................64

Compression Pressure ..............................................64

Belt Deflection............................................................64

Spark Plug .................................................................65

Cylinder Head ............................................................65

Valve ..........................................................................66

VALVE....................................................................66

VALVE SPRING.......................................................66

VALVE LIFTER........................................................66

VALVE CLEARANCE................................................67

VALVE GUIDE.........................................................67

AVAILABLE SHIMS..................................................67

VALVE SEAT...........................................................70

VALVE SEAT RESURFACE LIMIT.............................71

Camshaft and Camshaft Bearing ..............................71

Cylinder Block ............................................................72

Piston, Piston Ring and Piston Pin ...........................73

PISTON..................................................................73

PISTON RING.........................................................73

PISTON PIN............................................................73

Connecting Rod .........................................................74

Crankshaft..................................................................74

Main Bearing..............................................................74

STANDARD.............................................................74

UNDERSIZE............................................................74

Connecting Rod Bearing ...........................................75

STANDARD SIZE....................................................75

UNDERSIZE............................................................75

Bearing Clearance .....................................................75

Miscellaneous Components.......................................75

YD

PRECAUTIONS.............................................................76

Parts Requiring Angular Tightening ...........................76

Liquid Gasket Application Procedure ........................76

PREPARATION.............................................................77

Special Service Tools ................................................77

Commercial Service Tools .........................................79

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING...................................................81

NVH Troubleshooting - Engine Noise .......................81

MEASUREMENT OF COMPRESSION PRESSURE....82

DRIVE BELTS................................................................84

Inspection...................................................................84

Adjustment .................................................................84

AIR CONDITIONER COMPRESSOR BELT................85

ALTERNATOR & WATER PUMP BELT.....................85

Removal .....................................................................85

Installation ..................................................................86

AIR CLEANER...............................................................87

Changing Air Cleaner Filter .......................................87

VISCOUS PAPER TYPE...........................................87

OIL PAN.........................................................................88

Components...............................................................88

Removal .....................................................................88

Installation ..................................................................90

TIMING CHAIN..............................................................93

Secondary Timing Chain ...........................................93

REMOVAL...............................................................93

INSPECTION...........................................................95

INSTALLATION........................................................95

Primary Timing Chain ................................................98

REMOVAL...............................................................99

INSPECTION.........................................................101

INSTALLATION......................................................101

INTAKE MANIFOLD....................................................106

Removal and Installation .........................................106

PREPARATIVE WORK...........................................106

FUEL PIPING........................................................107

INTAKE MANIFOLD...............................................107

EGR VOLUME CONTROL VALVE...........................107

WATER HOSE.......................................................107

Inspection.................................................................108

INTAKE MANIFOLD...............................................108

CATALYST..................................................................109

Removal and Installation .........................................109

PREPARATIVE WORK...........................................109

CATALYST............................................................109

GUSSET............................................................... 110

EXHAUST MANIFOLD, TURBOCHARGER............... 111

Removal and Installation ......................................... 111

PREPARATIVE WORK........................................... 111

EXHAUST MANIFOLD AND TURBOCHARGER....... 111

EXHAUST MANIFOLD GASKET............................. 112

Disassembly and Assembly ..................................... 112

TURBOCHARGER................................................. 112

Inspection................................................................. 113

EXHAUST MANIFOLD........................................... 113

TURBOCHARGER................................................. 113

ROCKER COVER........................................................ 116

Removal and Installation ......................................... 116

PREPARATIVE WORK........................................... 116

ROCKER COVER.................................................. 116

CYLINDER HEAD........................................................ 118

Components............................................................. 118

Removal ................................................................... 119

PREPARATIVE WORK........................................... 119

CAMSHAFT........................................................... 119

CYLINDER HEAD..................................................120

Disassembly.............................................................120

Inspection.................................................................121

CONTENTS(Cont'd)

EM-2

Page 94 of 2493

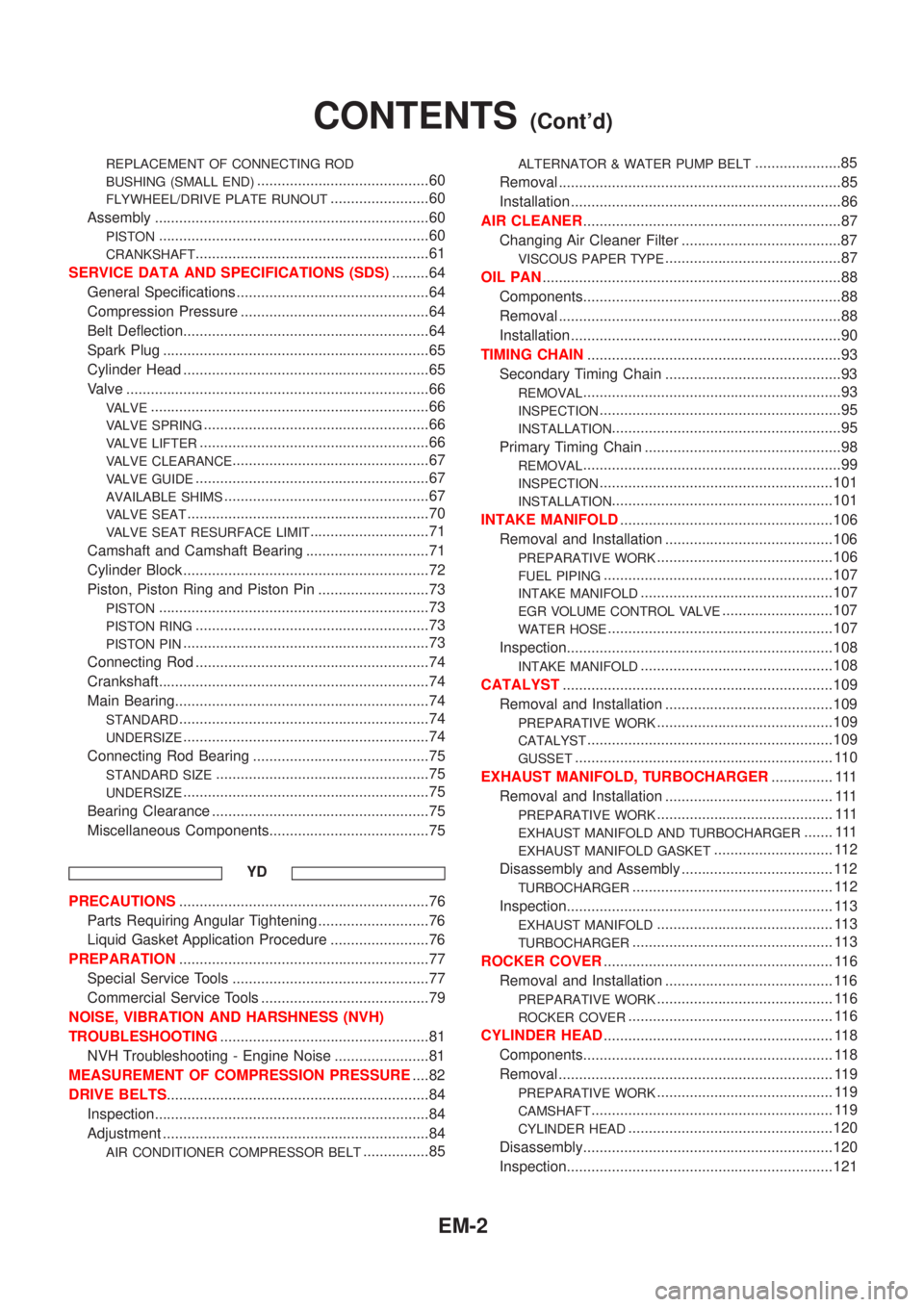

Belt deflection:

Unit: mm (in)

Applied engineUsed belt deflection

Deflection

of new belt

LimitDeflection

after

adjustment

AlternatorWith air

conditioner

compressorQG15´18DE 8.1 (0.319)5.3 - 5.7

(0.209 -

0.224)4.5 - 5.0

(0.177 -

0.197)

Without air

conditioner

compressorQG15´18DE10.2

(0.402)6.5 - 7.0

(0.256 -

0.276)5.5 - 6.1

(0.217 -

0.240)

Power steering oil

pumpQG15DE 8.5 (0.335)5.2 - 5.8

(0.205 -

0.228)4.6 - 5.2

(0.181 -

0.205)

QG18DE 7.1 (0.280)4.4 - 4.9

(0.173 -

0.193)3.9 - 4.4

(0.154 -

0.173)

Applied pushing force 98 N (10 kg, 22 lb)

Inspect drive belt deflections when engine is cold.

DRIVE BELTSQG

Checking (Cont'd)

EM-16

Page 101 of 2493

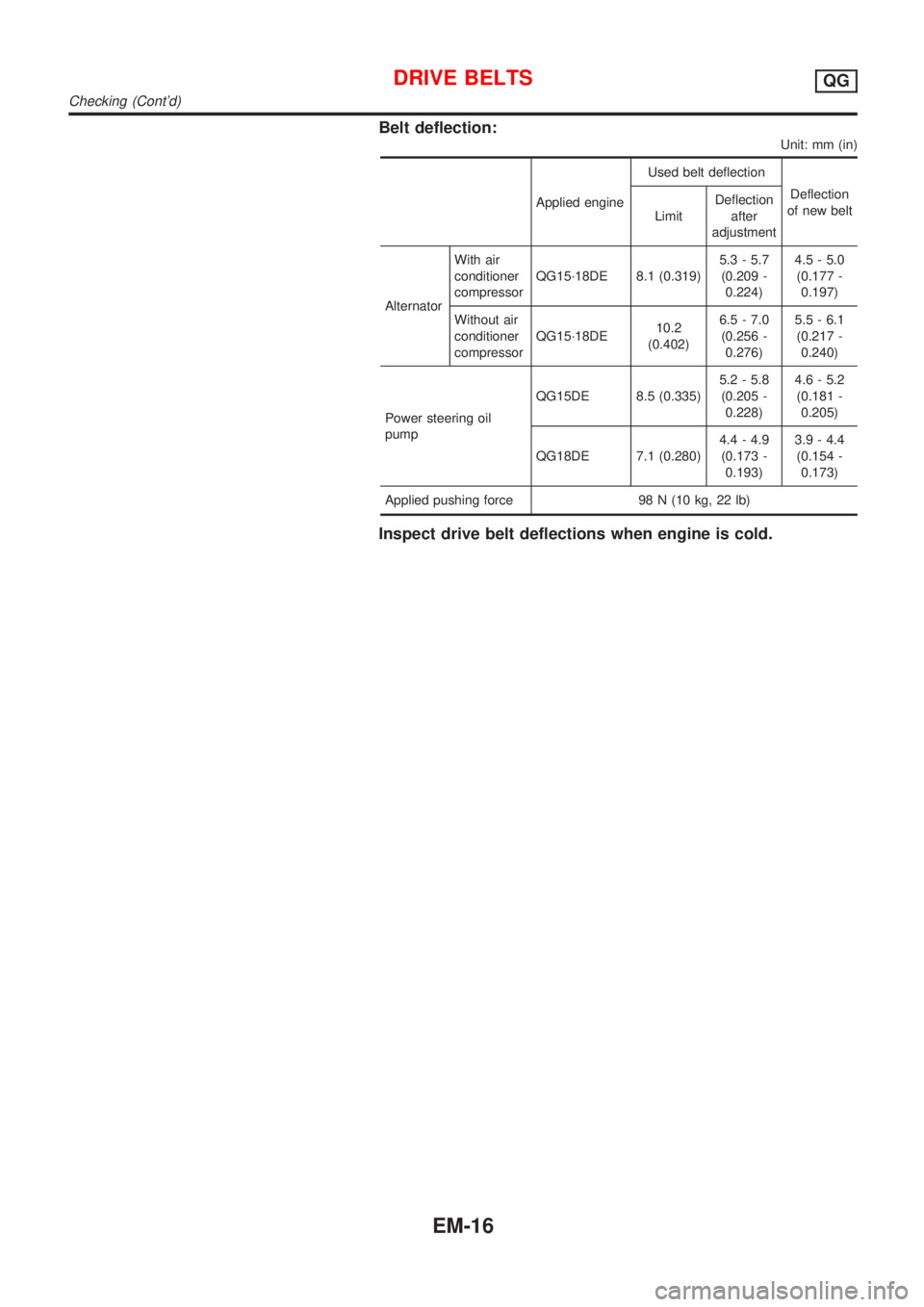

CAUTION:

+After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

+When installing chain tensioner, oil seats, or other sliding

parts, lubricate contacting surfaces with new engine oil.

+Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

+When removing oil pump assembly, remove camshaft

position sensor (PHASE), then remove timing chain from

engine.

+Be careful not to damage sensor edges.

SEM869F

RemovalNJEM01051. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Remove reservoir tank.

3. Release fuel pressure.

Refer to EC-38, ªFuel Pressure Releaseº.

4. Remove the following belts.

+Power steering pump drive belt

+Alternator drive belt

5. Remove front right-side wheel.

6. Remove front/right splash undercover.

7. Remove front exhaust tube.

SEM870F

8. Remove vacuum hoses, fuel hoses, and so on.

9. Remove ignition coils.

10. Remove spark plugs.

SEM102G

11. Remove rocker cover bolts in numerical order as shown in the

figure.

TIMING CHAINQG

Components (Cont'd)

EM-23

Page 109 of 2493

SEM909F

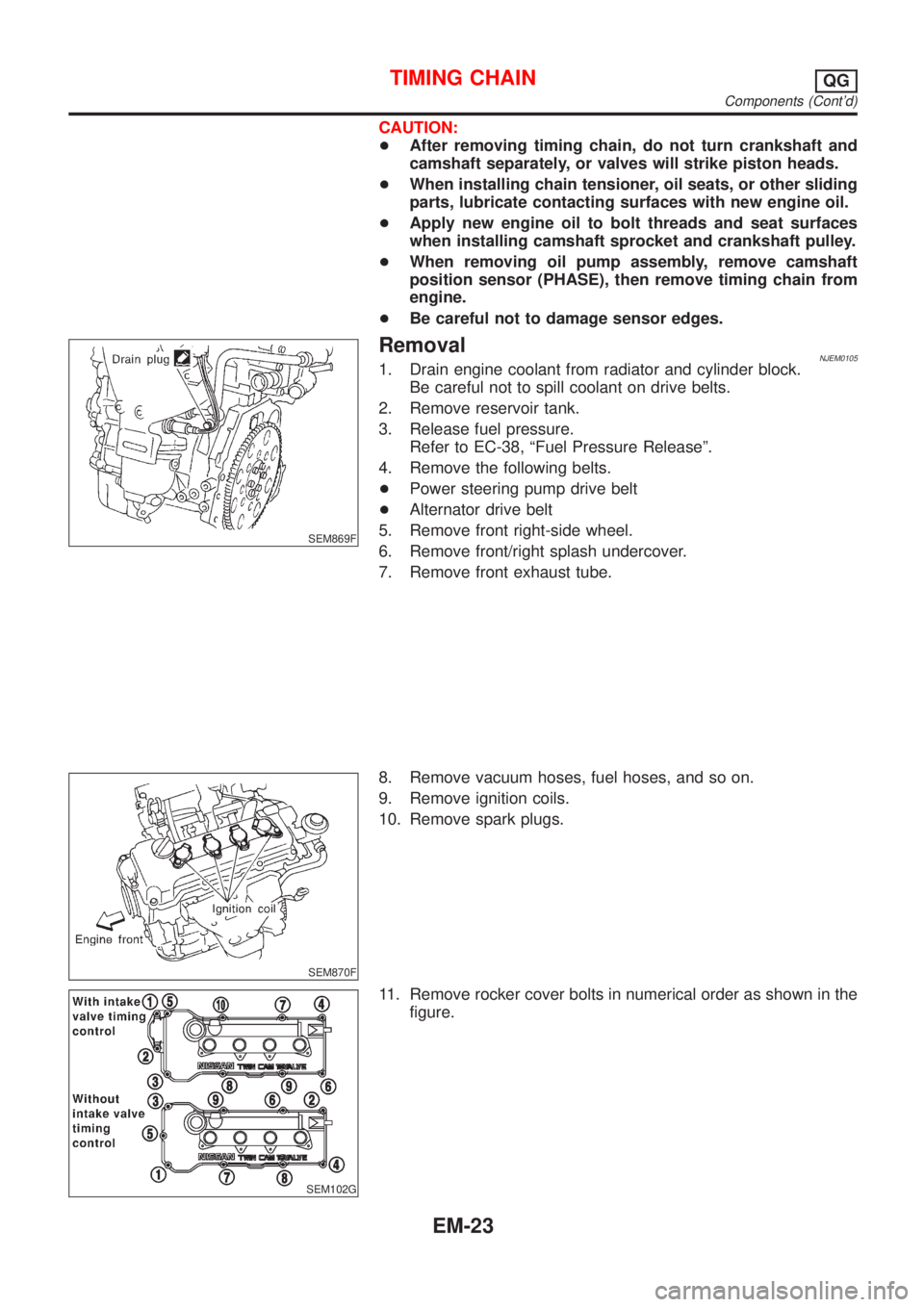

ReplacementNJEM0015VALVE OIL SEALNJEM0015S011. Remove rocker cover.

2. Remove camshaft.

3. Remove valve spring. Refer to EM-36.

4. Remove valve oil seal with Tool.

Piston concerned should be set at TDC to prevent valve from

falling.

SEM910F

5. Apply new engine oil to new valve oil seal and install it with

Tool.

SEM911F

FRONT OIL SEALNJEM0015S021. Remove the following parts:

+Engine under cover

+RH engine side cover

+Alternator and power steering drive belts

+Crankshaft pulley

2. Remove front oil seal from front cover.

+Be careful not to scratch front cover.

SEM715A

SEM912F

3. Apply new engine oil to new oil seal and install it using a suit-

able tool.

+Install new oil seal in the direction shown.

OIL SEALQG

Replacement

EM-31

Page 128 of 2493

WARNING:

+Position vehicle on a flat and solid surface.

+Place chocks at front and back of rear wheels.

+Do not remove engine until exhaust system has com-

pletely cooled off, otherwise, you may burn yourself

and/or fire may break out in fuel line.

+Before disconnecting fuel hose, release pressure.

Refer to EC-38, ªFuel Pressure Releaseº.

+Be sure to lift engine and transaxle in a safe manner.

+For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

+When lifting engine, be sure to clear surrounding parts.

Use special care near accelerator wire casing, brake lines

and brake master cylinder.

+When lifting the engine, always use engine slingers in a

safe manner.

+When removing drive shaft, be careful not to damage

grease seal of transaxle.

+Before separating engine and transaxle, remove crank-

shaft position sensor (POS) from the cylinder block

assembly.

+Always be extra careful not to damage edge of crankshaft

position sensor (POS), or signal plate teeth.

Engine cannot be removed separately from transaxle. Remove

engine with transaxle as an assembly.

REMOVALNJEM0022S011. Drain coolant from radiator and cylinder block. Refer to LC-17,

ªChanging Engine Coolantº.

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from

engine.

8. Remove power steering oil pump from engine and position

aside.

Power steering oil pump does not need to be disconnected

from power steering tubes.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-50

Page 142 of 2493

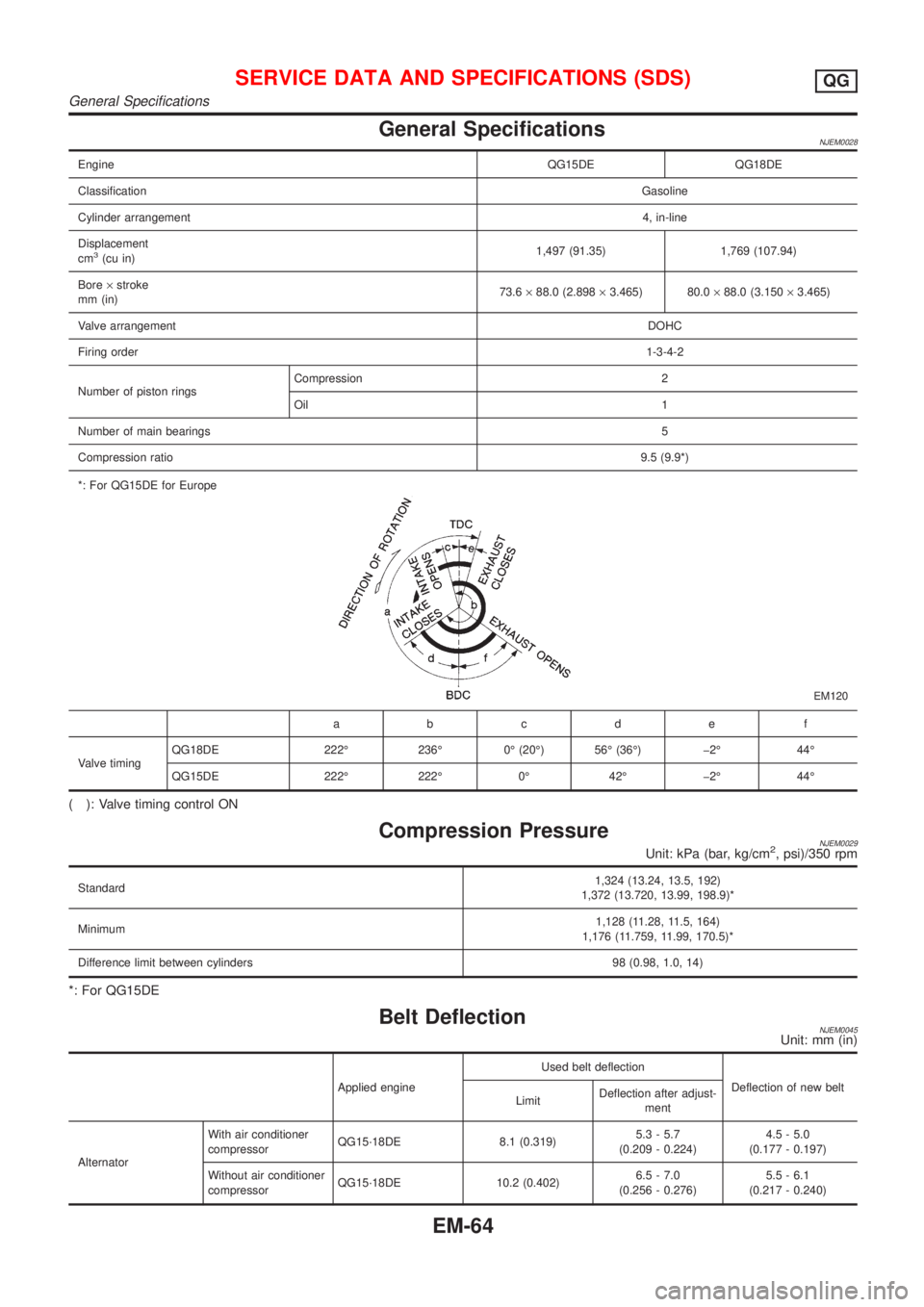

General SpecificationsNJEM0028

EngineQG15DE QG18DE

ClassificationGasoline

Cylinder arrangement4, in-line

Displacement

cm

3(cu in)1,497 (91.35) 1,769 (107.94)

Bore´stroke

mm (in)73.6´88.0 (2.898´3.465) 80.0´88.0 (3.150´3.465)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil 1

Number of main bearings5

Compression ratio9.5 (9.9*)

*: For QG15DE for Europe

EM120

abcde f

Valve timingQG18DE 222É 236É 0É (20É) 56É (36É) þ2É 44É

QG15DE 222É 222É 0É 42É þ2É 44É

( ): Valve timing control ON

Compression PressureNJEM0029Unit: kPa (bar, kg/cm2, psi)/350 rpm

Standard1,324 (13.24, 13.5, 192)

1,372 (13.720, 13.99, 198.9)*

Minimum1,128 (11.28, 11.5, 164)

1,176 (11.759, 11.99, 170.5)*

Difference limit between cylinders 98 (0.98, 1.0, 14)

*: For QG15DE

Belt DeflectionNJEM0045Unit: mm (in)

Applied engineUsed belt deflection

Deflection of new belt

LimitDeflection after adjust-

ment

AlternatorWith air conditioner

compressorQG15´18DE 8.1 (0.319)5.3 - 5.7

(0.209 - 0.224)4.5 - 5.0

(0.177 - 0.197)

Without air conditioner

compressorQG15´18DE 10.2 (0.402)6.5 - 7.0

(0.256 - 0.276)5.5 - 6.1

(0.217 - 0.240)

SERVICE DATA AND SPECIFICATIONS (SDS)QG

General Specifications

EM-64

Page 162 of 2493

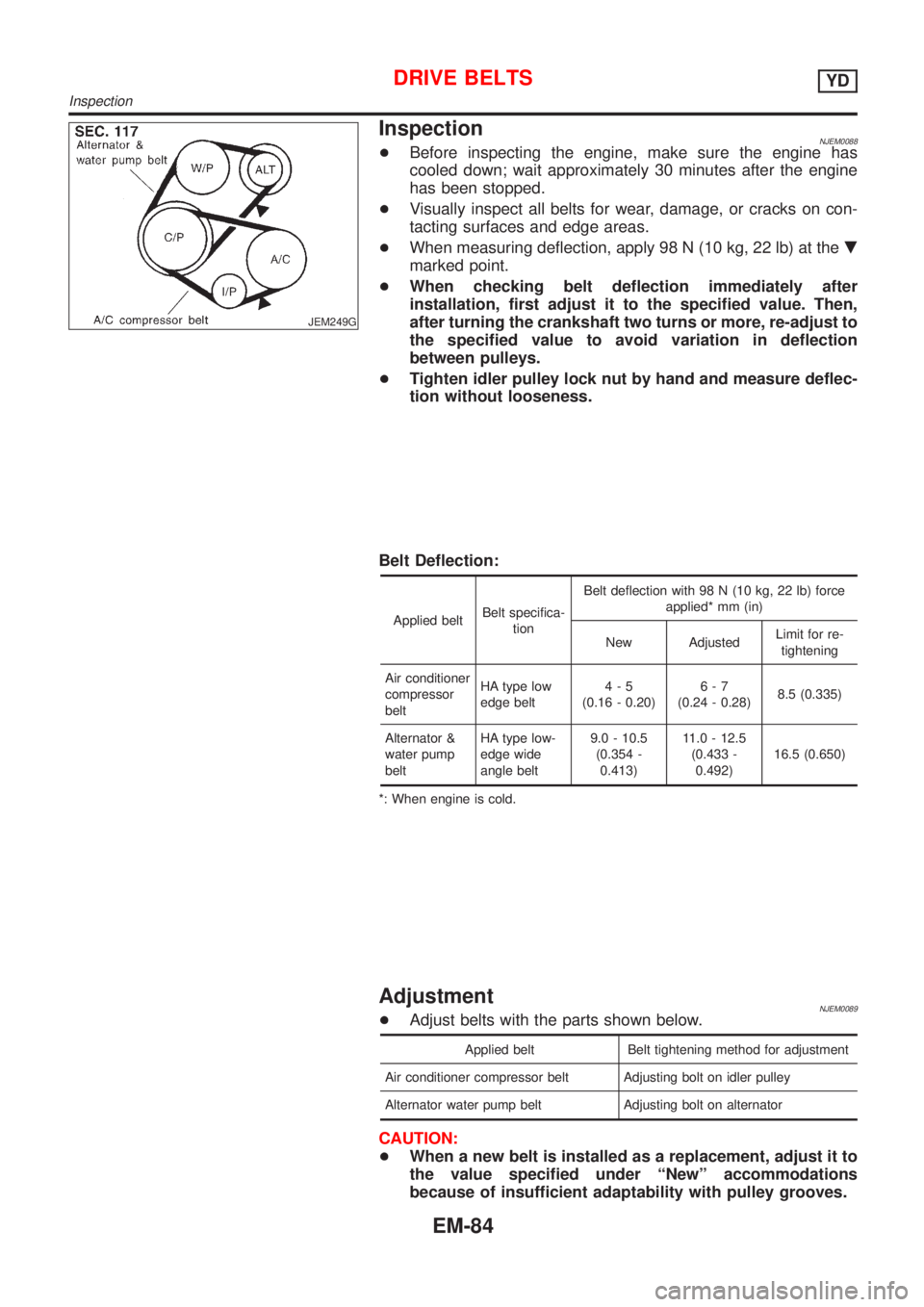

JEM249G

InspectionNJEM0088+Before inspecting the engine, make sure the engine has

cooled down; wait approximately 30 minutes after the engine

has been stopped.

+Visually inspect all belts for wear, damage, or cracks on con-

tacting surfaces and edge areas.

+When measuring deflection, apply 98 N (10 kg, 22 lb) at the.

marked point.

+When checking belt deflection immediately after

installation, first adjust it to the specified value. Then,

after turning the crankshaft two turns or more, re-adjust to

the specified value to avoid variation in deflection

between pulleys.

+Tighten idler pulley lock nut by hand and measure deflec-

tion without looseness.

Belt Deflection:

Applied beltBelt specifica-

tionBelt deflection with 98 N (10 kg, 22 lb) force

applied* mm (in)

New AdjustedLimit for re-

tightening

Air conditioner

compressor

beltHA type low

edge belt4-5

(0.16 - 0.20)6-7

(0.24 - 0.28)8.5 (0.335)

Alternator &

water pump

beltHA type low-

edge wide

angle belt9.0 - 10.5

(0.354 -

0.413)11.0 - 12.5

(0.433 -

0.492)16.5 (0.650)

*: When engine is cold.

AdjustmentNJEM0089+Adjust belts with the parts shown below.

Applied belt Belt tightening method for adjustment

Air conditioner compressor belt Adjusting bolt on idler pulley

Alternator water pump belt Adjusting bolt on alternator

CAUTION:

+When a new belt is installed as a replacement, adjust it to

the value specified under ªNewº accommodations

because of insufficient adaptability with pulley grooves.

DRIVE BELTSYD

Inspection

EM-84

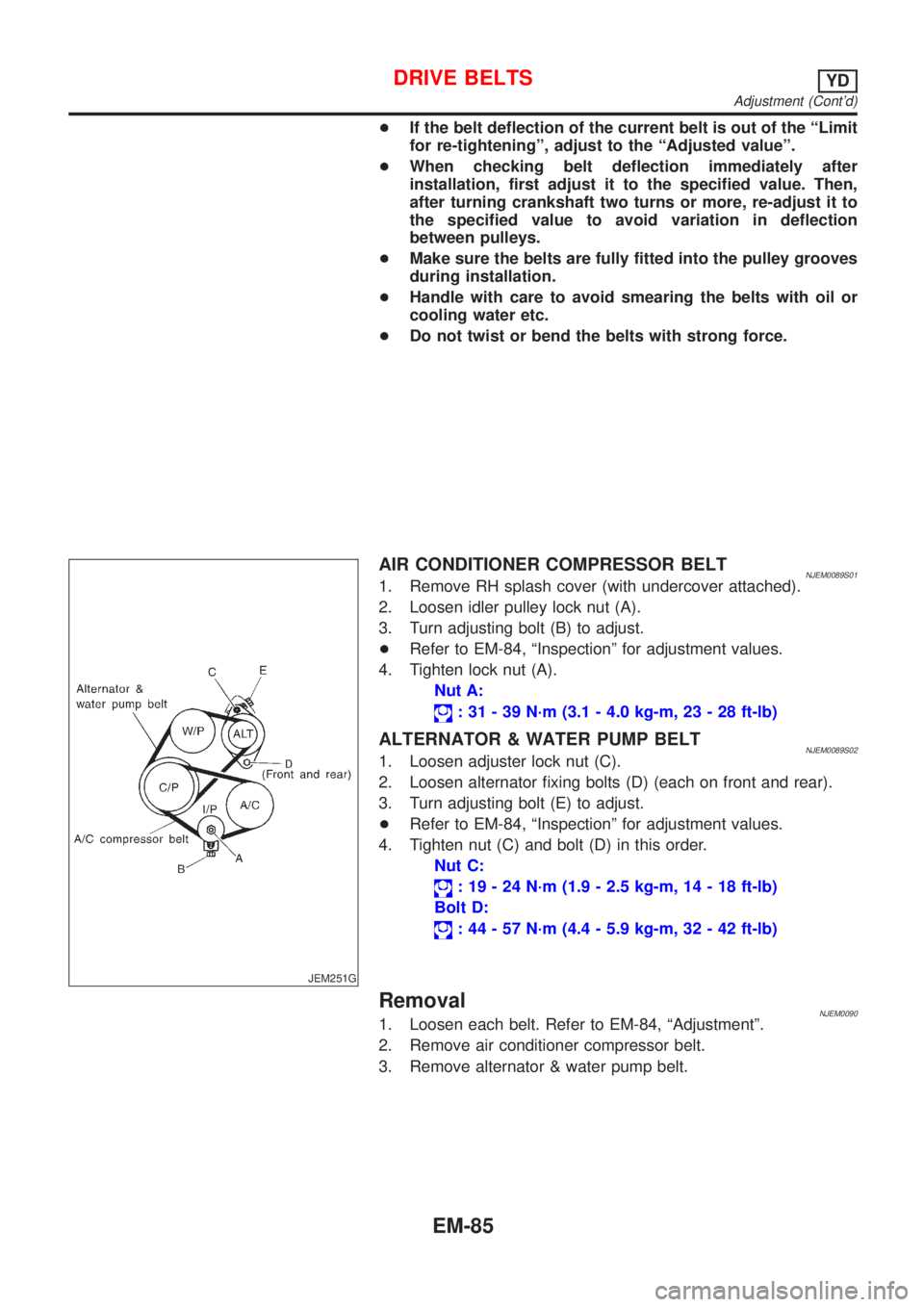

Page 163 of 2493

+If the belt deflection of the current belt is out of the ªLimit

for re-tighteningº, adjust to the ªAdjusted valueº.

+When checking belt deflection immediately after

installation, first adjust it to the specified value. Then,

after turning crankshaft two turns or more, re-adjust it to

the specified value to avoid variation in deflection

between pulleys.

+Make sure the belts are fully fitted into the pulley grooves

during installation.

+Handle with care to avoid smearing the belts with oil or

cooling water etc.

+Do not twist or bend the belts with strong force.

JEM251G

AIR CONDITIONER COMPRESSOR BELTNJEM0089S011. Remove RH splash cover (with undercover attached).

2. Loosen idler pulley lock nut (A).

3. Turn adjusting bolt (B) to adjust.

+Refer to EM-84, ªInspectionº for adjustment values.

4. Tighten lock nut (A).

Nut A:

: 31 - 39 N´m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

ALTERNATOR & WATER PUMP BELTNJEM0089S021. Loosen adjuster lock nut (C).

2. Loosen alternator fixing bolts (D) (each on front and rear).

3. Turn adjusting bolt (E) to adjust.

+Refer to EM-84, ªInspectionº for adjustment values.

4. Tighten nut (C) and bolt (D) in this order.

Nut C:

: 19 - 24 N´m (1.9 - 2.5 kg-m, 14 - 18 ft-lb)

Bolt D:

: 44 - 57 N´m (4.4 - 5.9 kg-m, 32 - 42 ft-lb)

RemovalNJEM00901. Loosen each belt. Refer to EM-84, ªAdjustmentº.

2. Remove air conditioner compressor belt.

3. Remove alternator & water pump belt.

DRIVE BELTSYD

Adjustment (Cont'd)

EM-85

Page 215 of 2493

crankshaft position sensor (TDC sensor) from the assem-

bly.

+Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-43, ªChanging Engine Coolantº.

3. Remove the following parts:

+Battery

+RH and LH front wheels

+RH and LH splash covers (combined with undercover)

+Auxiliary belts

+Alternator

+Alternator brackets

+Radiator and cooling fan

+Engine cover

+Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

+Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

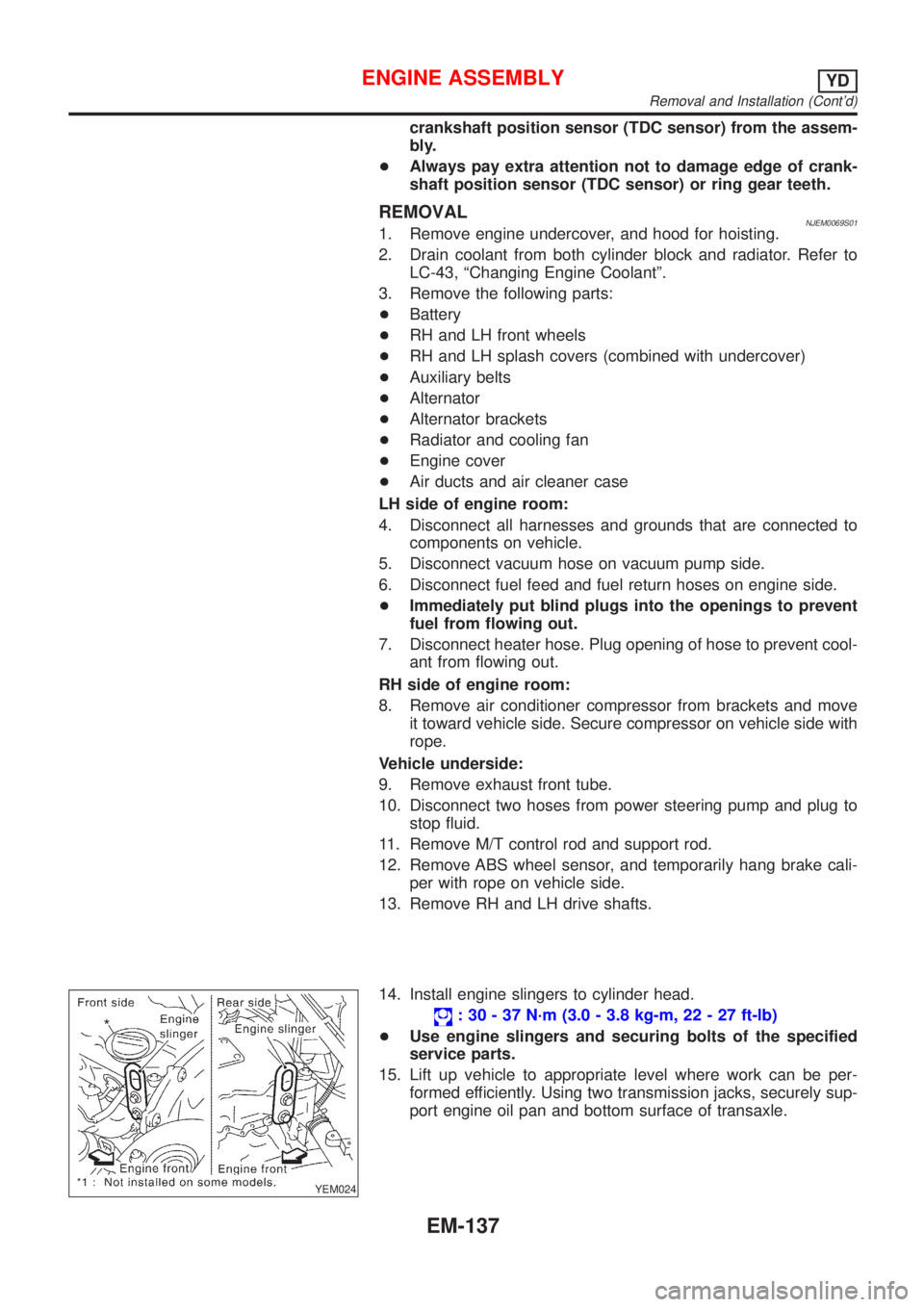

YEM024

14. Install engine slingers to cylinder head.

: 30 - 37 N´m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

+Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont'd)

EM-137

Page 235 of 2493

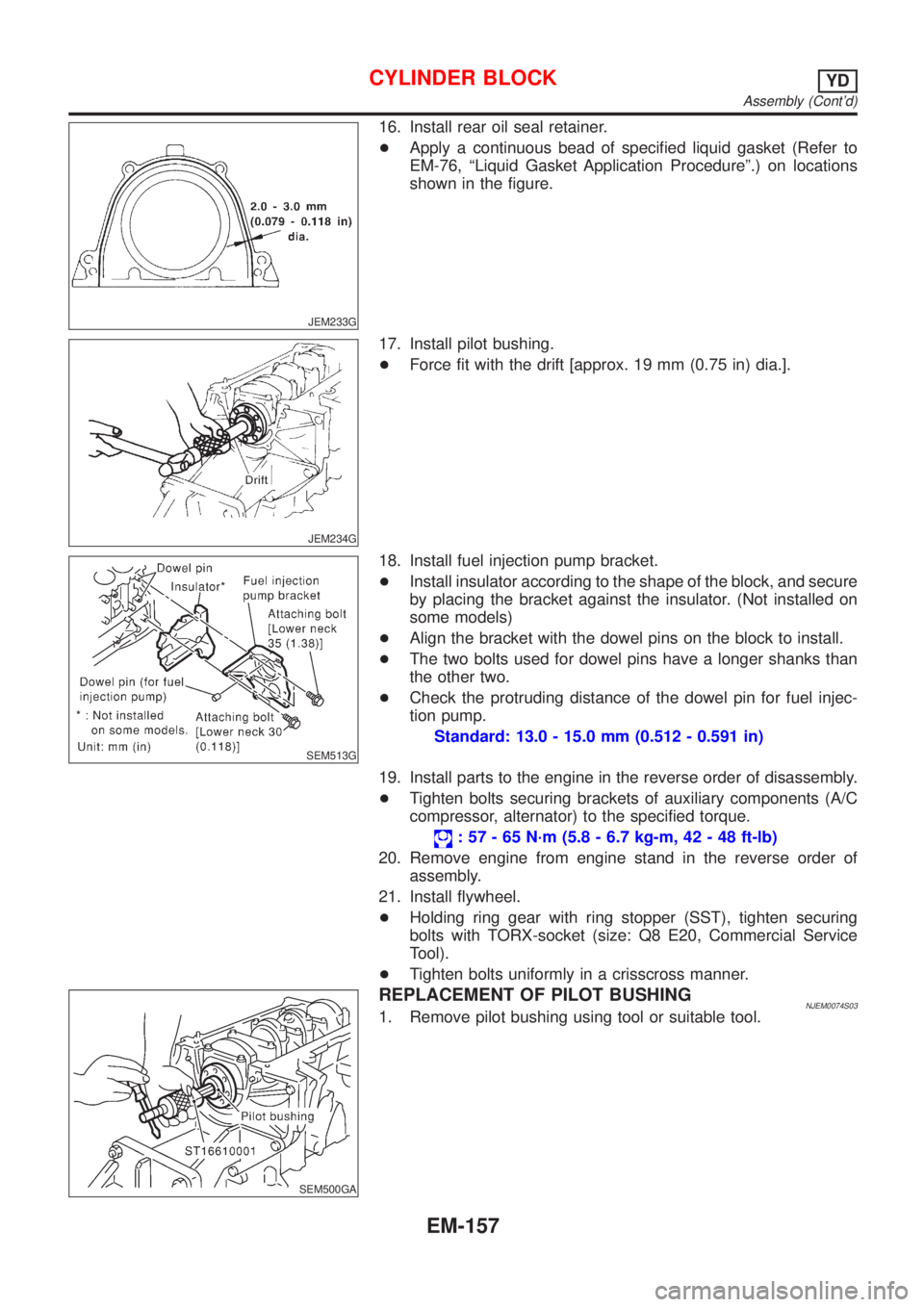

JEM233G

16. Install rear oil seal retainer.

+Apply a continuous bead of specified liquid gasket (Refer to

EM-76, ªLiquid Gasket Application Procedureº.) on locations

shown in the figure.

JEM234G

17. Install pilot bushing.

+Force fit with the drift [approx. 19 mm (0.75 in) dia.].

SEM513G

18. Install fuel injection pump bracket.

+Install insulator according to the shape of the block, and secure

by placing the bracket against the insulator. (Not installed on

some models)

+Align the bracket with the dowel pins on the block to install.

+The two bolts used for dowel pins have a longer shanks than

the other two.

+Check the protruding distance of the dowel pin for fuel injec-

tion pump.

Standard: 13.0 - 15.0 mm (0.512 - 0.591 in)

19. Install parts to the engine in the reverse order of disassembly.

+Tighten bolts securing brackets of auxiliary components (A/C

compressor, alternator) to the specified torque.

: 57 - 65 N´m (5.8 - 6.7 kg-m, 42 - 48 ft-lb)

20. Remove engine from engine stand in the reverse order of

assembly.

21. Install flywheel.

+Holding ring gear with ring stopper (SST), tighten securing

bolts with TORX-socket (size: Q8 E20, Commercial Service

Tool).

+Tighten bolts uniformly in a crisscross manner.

SEM500GA

REPLACEMENT OF PILOT BUSHINGNJEM0074S031. Remove pilot bushing using tool or suitable tool.

CYLINDER BLOCKYD

Assembly (Cont'd)

EM-157