brakes NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 272 of 2493

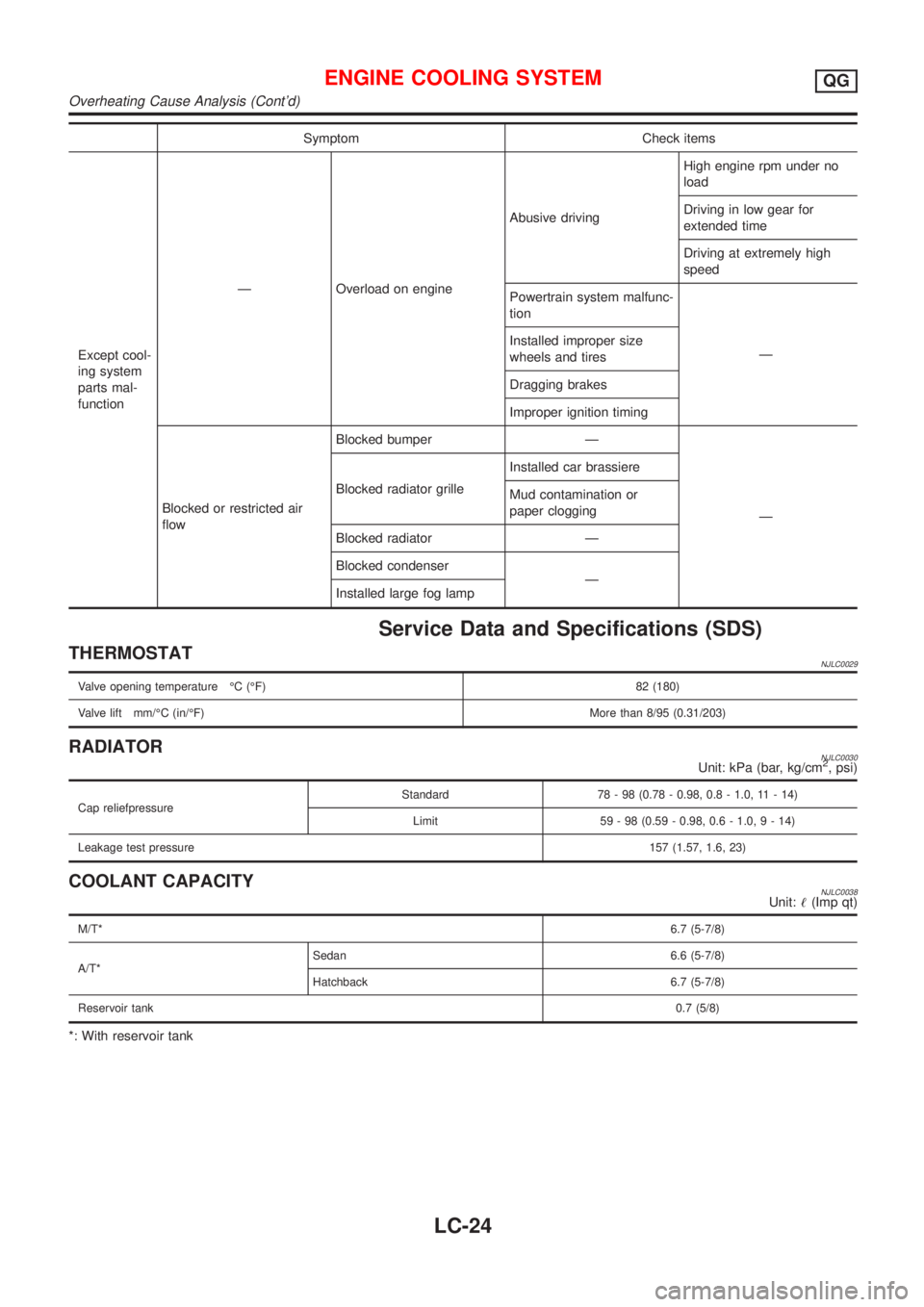

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0029

Valve opening temperature ÉC (ÉF) 82 (180)

Valve lift mm/ÉC (in/ÉF)More than 8/95 (0.31/203)

RADIATORNJLC0030Unit: kPa (bar, kg/cm2, psi)

Cap reliefpressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

COOLANT CAPACITYNJLC0038Unit:!(Imp qt)

M/T*6.7 (5-7/8)

A/T*Sedan 6.6 (5-7/8)

Hatchback 6.7 (5-7/8)

Reservoir tank0.7 (5/8)

*: With reservoir tank

ENGINE COOLING SYSTEMQG

Overheating Cause Analysis (Cont'd)

LC-24

Page 295 of 2493

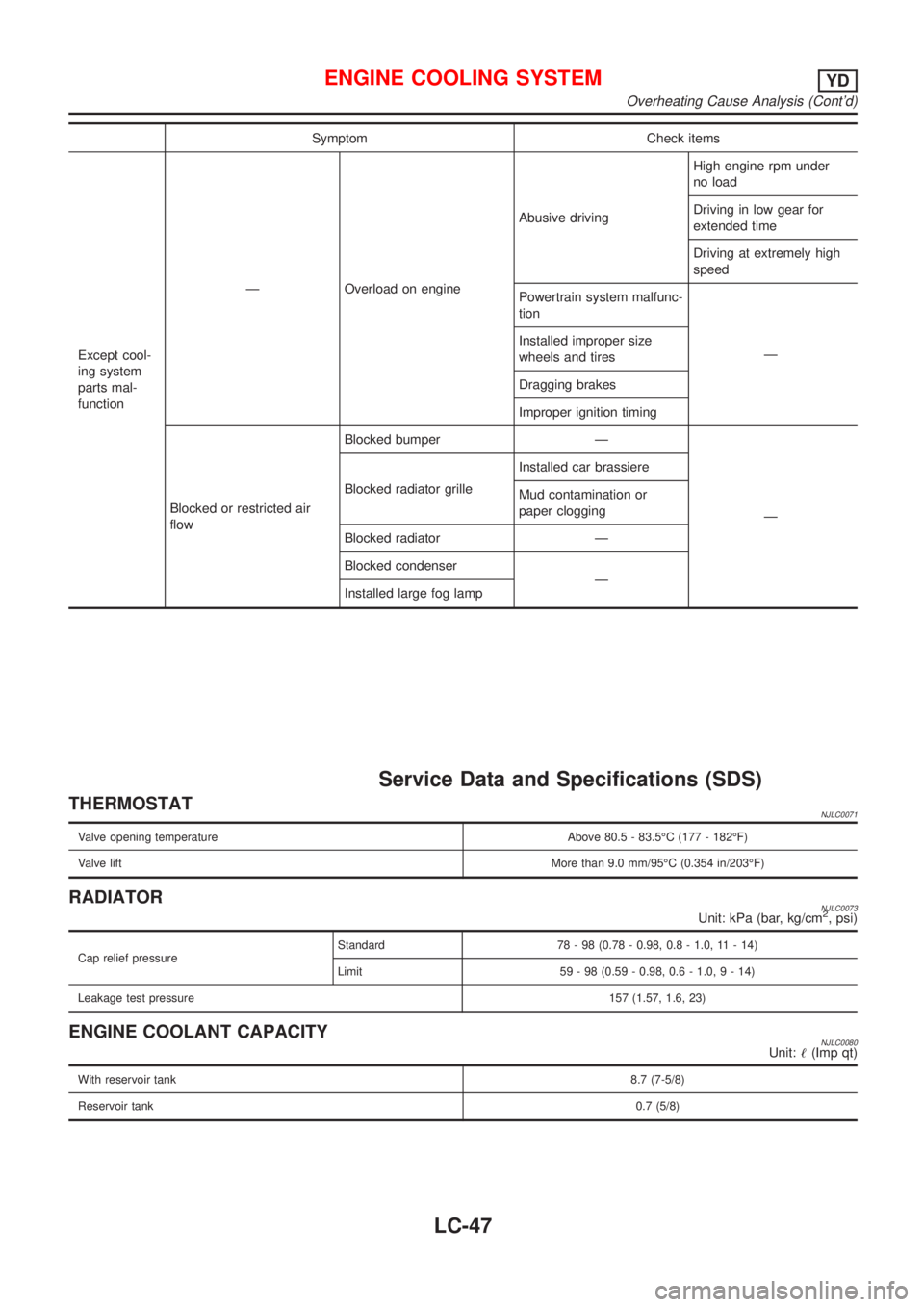

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0071

Valve opening temperature Above 80.5 - 83.5ÉC (177 - 182ÉF)

Valve liftMore than 9.0 mm/95ÉC (0.354 in/203ÉF)

RADIATORNJLC0073Unit: kPa (bar, kg/cm2, psi)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

ENGINE COOLANT CAPACITYNJLC0080Unit:!(Imp qt)

With reservoir tank8.7 (7-5/8)

Reservoir tank0.7 (5/8)

ENGINE COOLING SYSTEMYD

Overheating Cause Analysis (Cont'd)

LC-47

Page 1190 of 2493

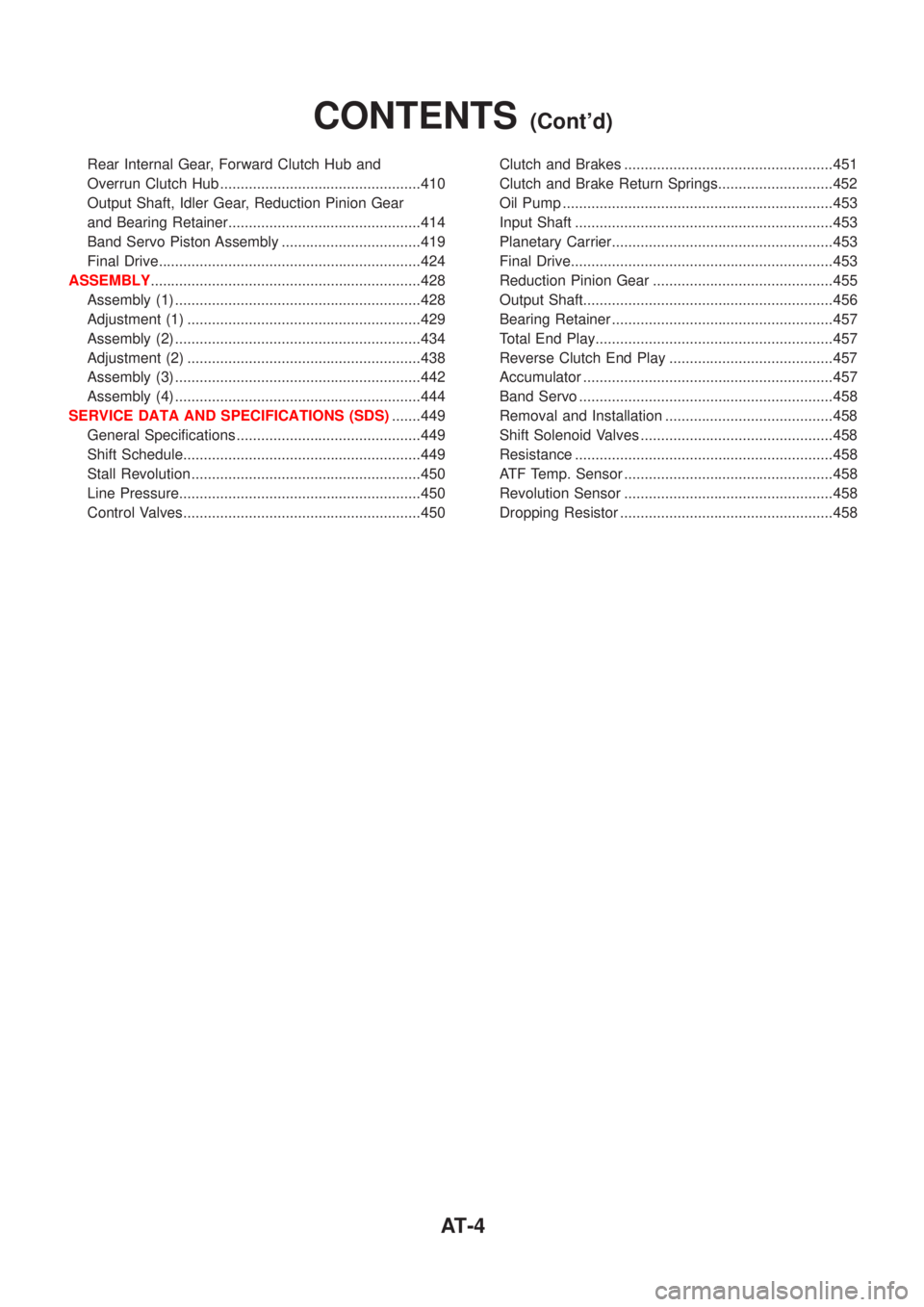

Rear Internal Gear, Forward Clutch Hub and

Overrun Clutch Hub .................................................410

Output Shaft, Idler Gear, Reduction Pinion Gear

and Bearing Retainer...............................................414

Band Servo Piston Assembly ..................................419

Final Drive................................................................424

ASSEMBLY..................................................................428

Assembly (1) ............................................................428

Adjustment (1) .........................................................429

Assembly (2) ............................................................434

Adjustment (2) .........................................................438

Assembly (3) ............................................................442

Assembly (4) ............................................................444

SERVICE DATA AND SPECIFICATIONS (SDS).......449

General Specifications .............................................449

Shift Schedule..........................................................449

Stall Revolution ........................................................450

Line Pressure...........................................................450

Control Valves..........................................................450Clutch and Brakes ...................................................451

Clutch and Brake Return Springs............................452

Oil Pump ..................................................................453

Input Shaft ...............................................................453

Planetary Carrier......................................................453

Final Drive................................................................453

Reduction Pinion Gear ............................................455

Output Shaft.............................................................456

Bearing Retainer ......................................................457

Total End Play..........................................................457

Reverse Clutch End Play ........................................457

Accumulator .............................................................457

Band Servo ..............................................................458

Removal and Installation .........................................458

Shift Solenoid Valves ...............................................458

Resistance ...............................................................458

ATF Temp. Sensor ...................................................458

Revolution Sensor ...................................................458

Dropping Resistor ....................................................458

CONTENTS(Cont'd)

AT-4

Page 1255 of 2493

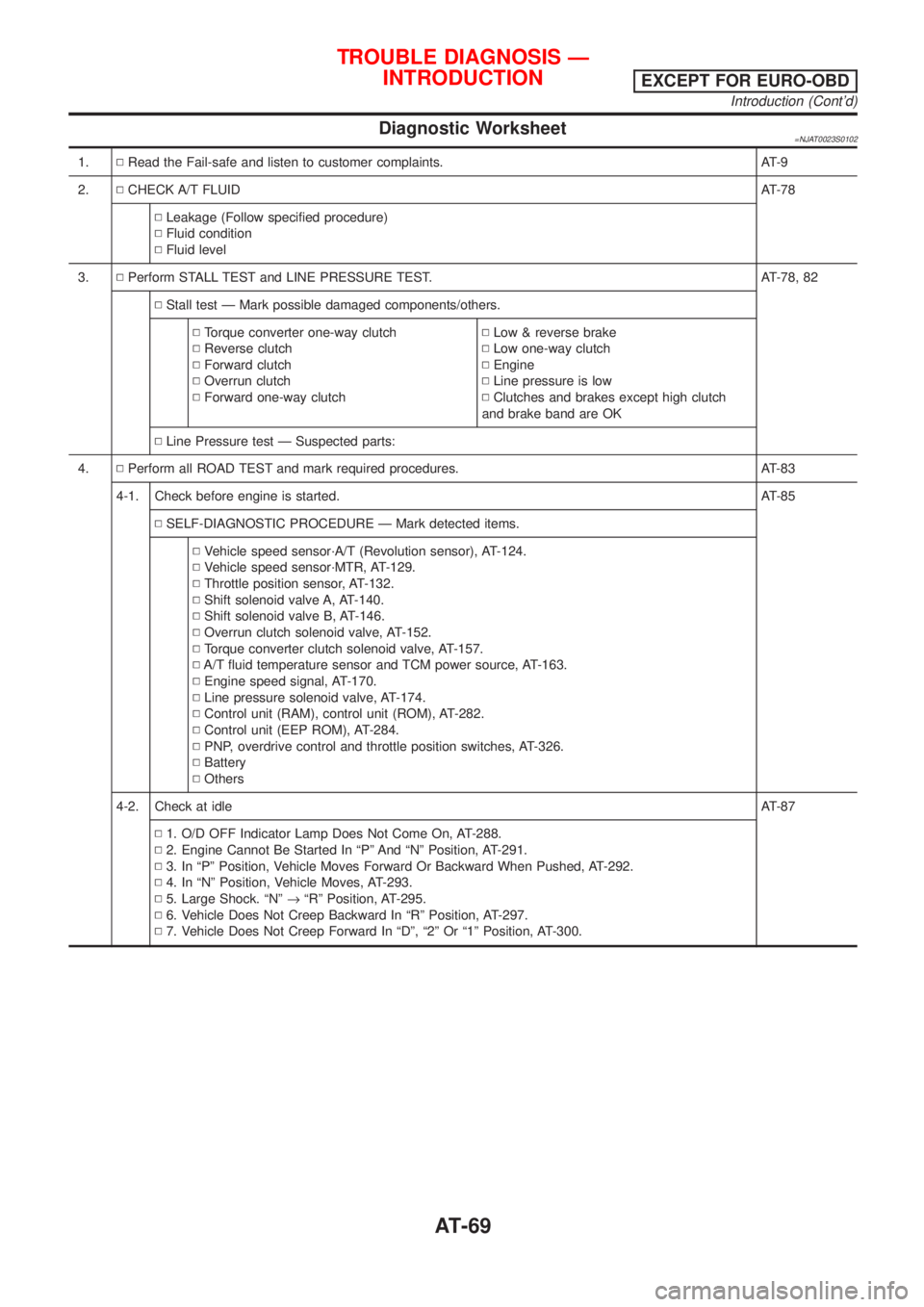

Diagnostic Worksheet=NJAT0023S0102

1.NRead the Fail-safe and listen to customer complaints. AT-9

2.NCHECK A/T FLUIDAT-78

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-78, 82

NStall test Ð Mark possible damaged components/others.

NTorque converter one-way clutch

NReverse clutch

NForward clutch

NOverrun clutch

NForward one-way clutchNLow & reverse brake

NLow one-way clutch

NEngine

NLine pressure is low

NClutches and brakes except high clutch

and brake band are OK

NLine Pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-83

4-1. Check before engine is started. AT-85

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NVehicle speed sensor´A/T (Revolution sensor), AT-124.

NVehicle speed sensor´MTR, AT-129.

NThrottle position sensor, AT-132.

NShift solenoid valve A, AT-140.

NShift solenoid valve B, AT-146.

NOverrun clutch solenoid valve, AT-152.

NTorque converter clutch solenoid valve, AT-157.

NA/T fluid temperature sensor and TCM power source, AT-163.

NEngine speed signal, AT-170.

NLine pressure solenoid valve, AT-174.

NControl unit (RAM), control unit (ROM), AT-282.

NControl unit (EEP ROM), AT-284.

NPNP, overdrive control and throttle position switches, AT-326.

NBattery

NOthers

4-2. Check at idleAT-87

N1. O/D OFF Indicator Lamp Does Not Come On, AT-288.

N2. Engine Cannot Be Started In ªPº And ªNº Position, AT-291.

N3. In ªPº Position, Vehicle Moves Forward Or Backward When Pushed, AT-292.

N4. In ªNº Position, Vehicle Moves, AT-293.

N5. Large Shock. ªNº®ªRº Position, AT-295.

N6. Vehicle Does Not Creep Backward In ªRº Position, AT-297.

N7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position, AT-300.

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

Introduction (Cont'd)

AT-69

Page 1260 of 2493

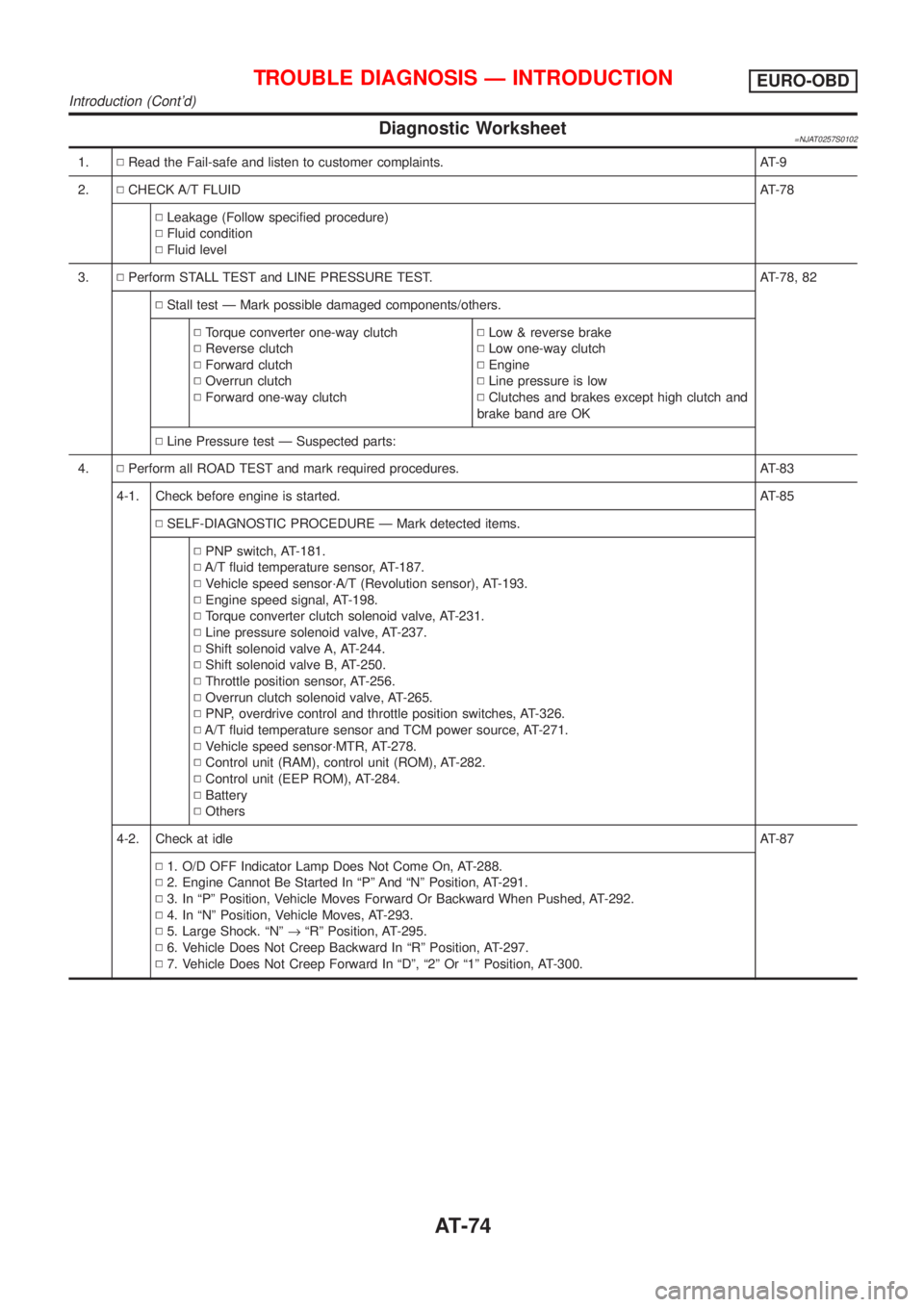

Diagnostic Worksheet=NJAT0257S0102

1.NRead the Fail-safe and listen to customer complaints. AT-9

2.NCHECK A/T FLUIDAT-78

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-78, 82

NStall test Ð Mark possible damaged components/others.

NTorque converter one-way clutch

NReverse clutch

NForward clutch

NOverrun clutch

NForward one-way clutchNLow & reverse brake

NLow one-way clutch

NEngine

NLine pressure is low

NClutches and brakes except high clutch and

brake band are OK

NLine Pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-83

4-1. Check before engine is started. AT-85

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NPNP switch, AT-181.

NA/T fluid temperature sensor, AT-187.

NVehicle speed sensor´A/T (Revolution sensor), AT-193.

NEngine speed signal, AT-198.

NTorque converter clutch solenoid valve, AT-231.

NLine pressure solenoid valve, AT-237.

NShift solenoid valve A, AT-244.

NShift solenoid valve B, AT-250.

NThrottle position sensor, AT-256.

NOverrun clutch solenoid valve, AT-265.

NPNP, overdrive control and throttle position switches, AT-326.

NA/T fluid temperature sensor and TCM power source, AT-271.

NVehicle speed sensor´MTR, AT-278.

NControl unit (RAM), control unit (ROM), AT-282.

NControl unit (EEP ROM), AT-284.

NBattery

NOthers

4-2. Check at idleAT-87

N1. O/D OFF Indicator Lamp Does Not Come On, AT-288.

N2. Engine Cannot Be Started In ªPº And ªNº Position, AT-291.

N3. In ªPº Position, Vehicle Moves Forward Or Backward When Pushed, AT-292.

N4. In ªNº Position, Vehicle Moves, AT-293.

N5. Large Shock. ªNº®ªRº Position, AT-295.

N6. Vehicle Does Not Creep Backward In ªRº Position, AT-297.

N7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position, AT-300.

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Introduction (Cont'd)

AT-74

Page 1291 of 2493

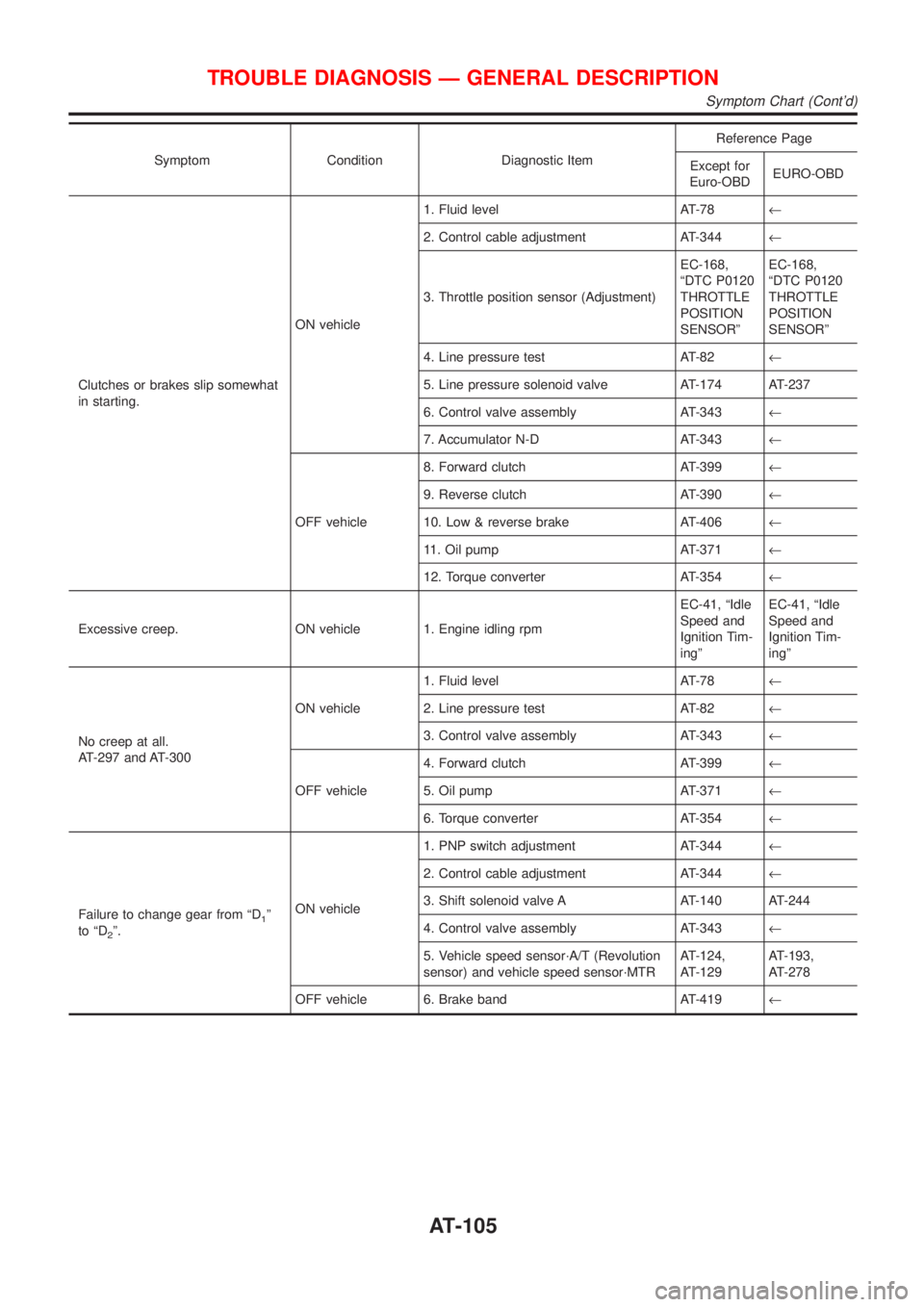

Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Clutches or brakes slip somewhat

in starting.ON vehicle1. Fluid level AT-78¬

2. Control cable adjustment AT-344¬

3. Throttle position sensor (Adjustment)EC-168,

ªDTC P0120

THROTTLE

POSITION

SENSORºEC-168,

ªDTC P0120

THROTTLE

POSITION

SENSORº

4. Line pressure test AT-82¬

5. Line pressure solenoid valve AT-174 AT-237

6. Control valve assembly AT-343¬

7. Accumulator N-D AT-343¬

OFF vehicle8. Forward clutch AT-399¬

9. Reverse clutch AT-390¬

10. Low & reverse brake AT-406¬

11. Oil pump AT-371¬

12. Torque converter AT-354¬

Excessive creep. ON vehicle 1. Engine idling rpmEC-41, ªIdle

Speed and

Ignition Tim-

ingºEC-41, ªIdle

Speed and

Ignition Tim-

ingº

No creep at all.

AT-297 and AT-300ON vehicle1. Fluid level AT-78¬

2. Line pressure test AT-82¬

3. Control valve assembly AT-343¬

OFF vehicle4. Forward clutch AT-399¬

5. Oil pump AT-371¬

6. Torque converter AT-354¬

Failure to change gear from ªD

1º

to ªD

2º.ON vehicle1. PNP switch adjustment AT-344¬

2. Control cable adjustment AT-344¬

3. Shift solenoid valve A AT-140 AT-244

4. Control valve assembly AT-343¬

5. Vehicle speed sensor´A/T (Revolution

sensor) and vehicle speed sensor´MTRAT-124,

AT-129AT-193,

AT-278

OFF vehicle 6. Brake band AT-419¬

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-105

Page 1637 of 2493

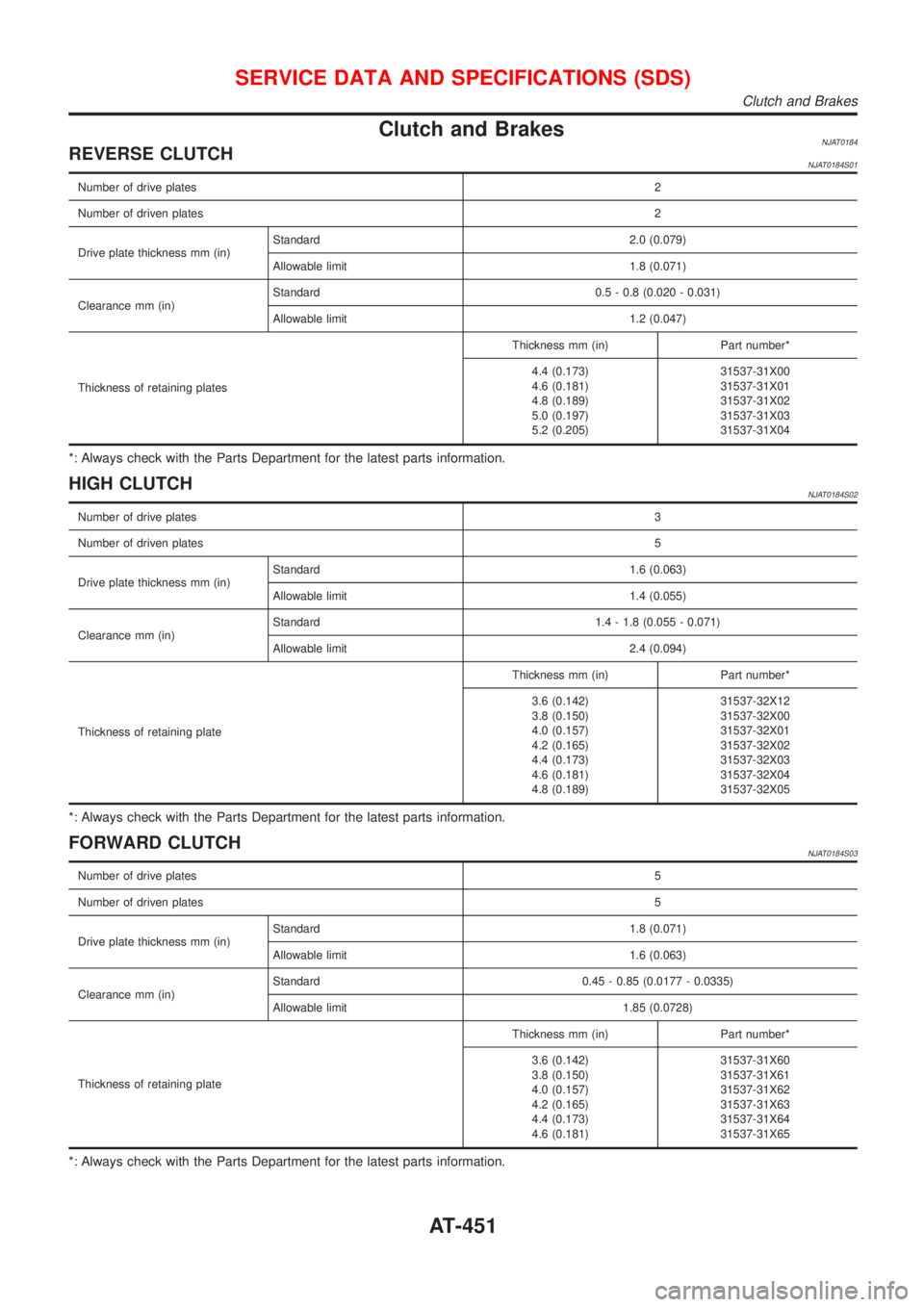

Clutch and BrakesNJAT0184REVERSE CLUTCHNJAT0184S01

Number of drive plates2

Number of driven plates2

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)

Thickness of retaining platesThickness mm (in) Part number*

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)31537-31X00

31537-31X01

31537-31X02

31537-31X03

31537-31X04

*: Always check with the Parts Department for the latest parts information.

HIGH CLUTCHNJAT0184S02

Number of drive plates3

Number of driven plates5

Drive plate thickness mm (in)Standard 1.6 (0.063)

Allowable limit 1.4 (0.055)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.4 (0.094)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)31537-32X12

31537-32X00

31537-32X01

31537-32X02

31537-32X03

31537-32X04

31537-32X05

*: Always check with the Parts Department for the latest parts information.

FORWARD CLUTCHNJAT0184S03

Number of drive plates5

Number of driven plates5

Drive plate thickness mm (in)Standard 1.8 (0.071)

Allowable limit 1.6 (0.063)

Clearance mm (in)Standard 0.45 - 0.85 (0.0177 - 0.0335)

Allowable limit 1.85 (0.0728)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)31537-31X60

31537-31X61

31537-31X62

31537-31X63

31537-31X64

31537-31X65

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch and Brakes

AT-451

Page 1638 of 2493

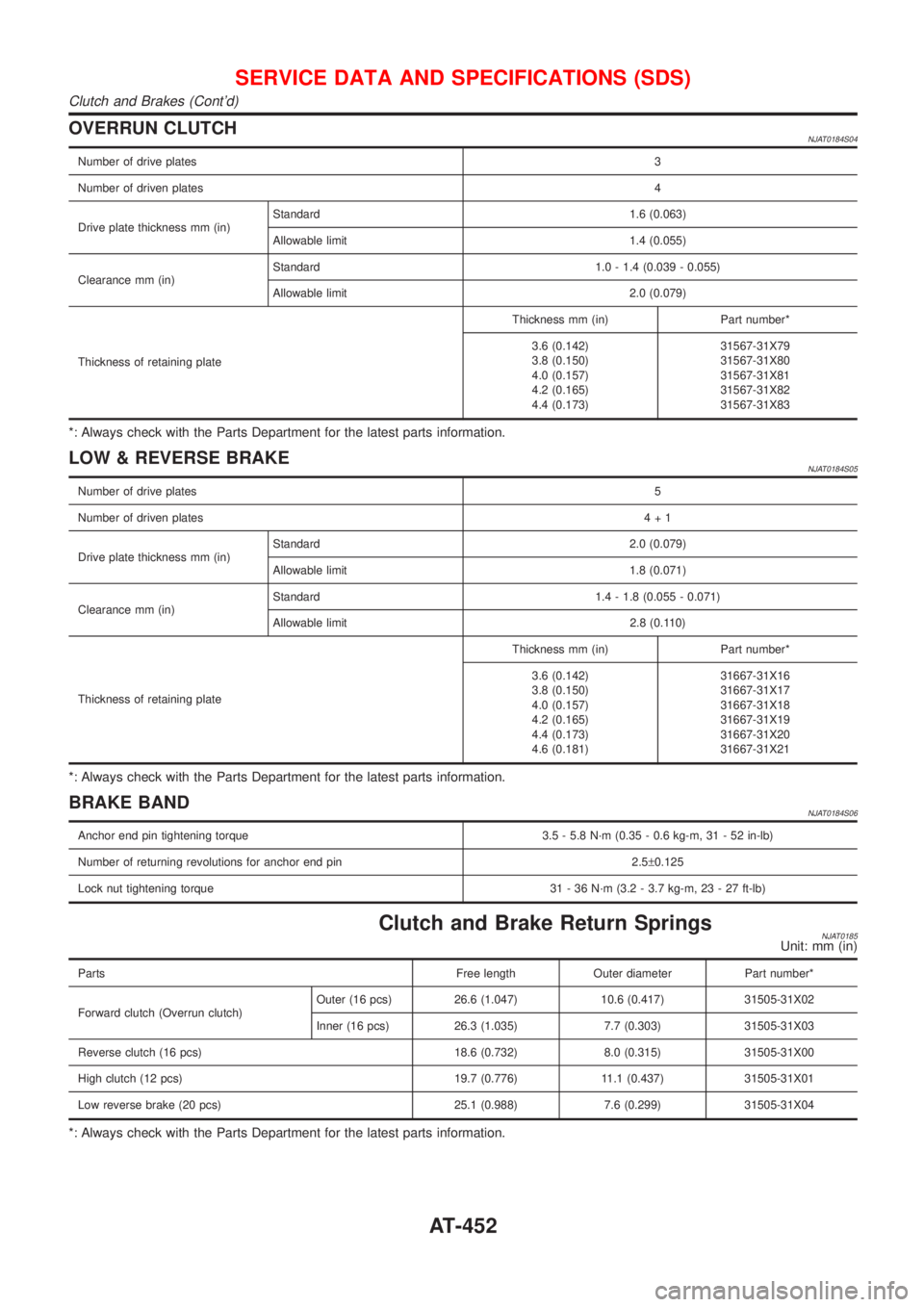

OVERRUN CLUTCHNJAT0184S04

Number of drive plates3

Number of driven plates4

Drive plate thickness mm (in)Standard 1.6 (0.063)

Allowable limit 1.4 (0.055)

Clearance mm (in)Standard 1.0 - 1.4 (0.039 - 0.055)

Allowable limit 2.0 (0.079)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)31567-31X79

31567-31X80

31567-31X81

31567-31X82

31567-31X83

*: Always check with the Parts Department for the latest parts information.

LOW & REVERSE BRAKENJAT0184S05

Number of drive plates5

Number of driven plates4+1

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.8 (0.110)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)31667-31X16

31667-31X17

31667-31X18

31667-31X19

31667-31X20

31667-31X21

*: Always check with the Parts Department for the latest parts information.

BRAKE BANDNJAT0184S06

Anchor end pin tightening torque 3.5 - 5.8 N´m (0.35 - 0.6 kg-m, 31 - 52 in-lb)

Number of returning revolutions for anchor end pin 2.5±0.125

Lock nut tightening torque 31 - 36 N´m (3.2 - 3.7 kg-m, 23 - 27 ft-lb)

Clutch and Brake Return SpringsNJAT0185Unit: mm (in)

Parts Free length Outer diameter Part number*

Forward clutch (Overrun clutch)Outer (16 pcs) 26.6 (1.047) 10.6 (0.417) 31505-31X02

Inner (16 pcs) 26.3 (1.035) 7.7 (0.303) 31505-31X03

Reverse clutch (16 pcs) 18.6 (0.732) 8.0 (0.315) 31505-31X00

High clutch (12 pcs) 19.7 (0.776) 11.1 (0.437) 31505-31X01

Low reverse brake (20 pcs) 25.1 (0.988) 7.6 (0.299) 31505-31X04

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch and Brakes (Cont'd)

AT-452

Page 1647 of 2493

Noise, Vibration and Harshness (NVH)

Troubleshooting

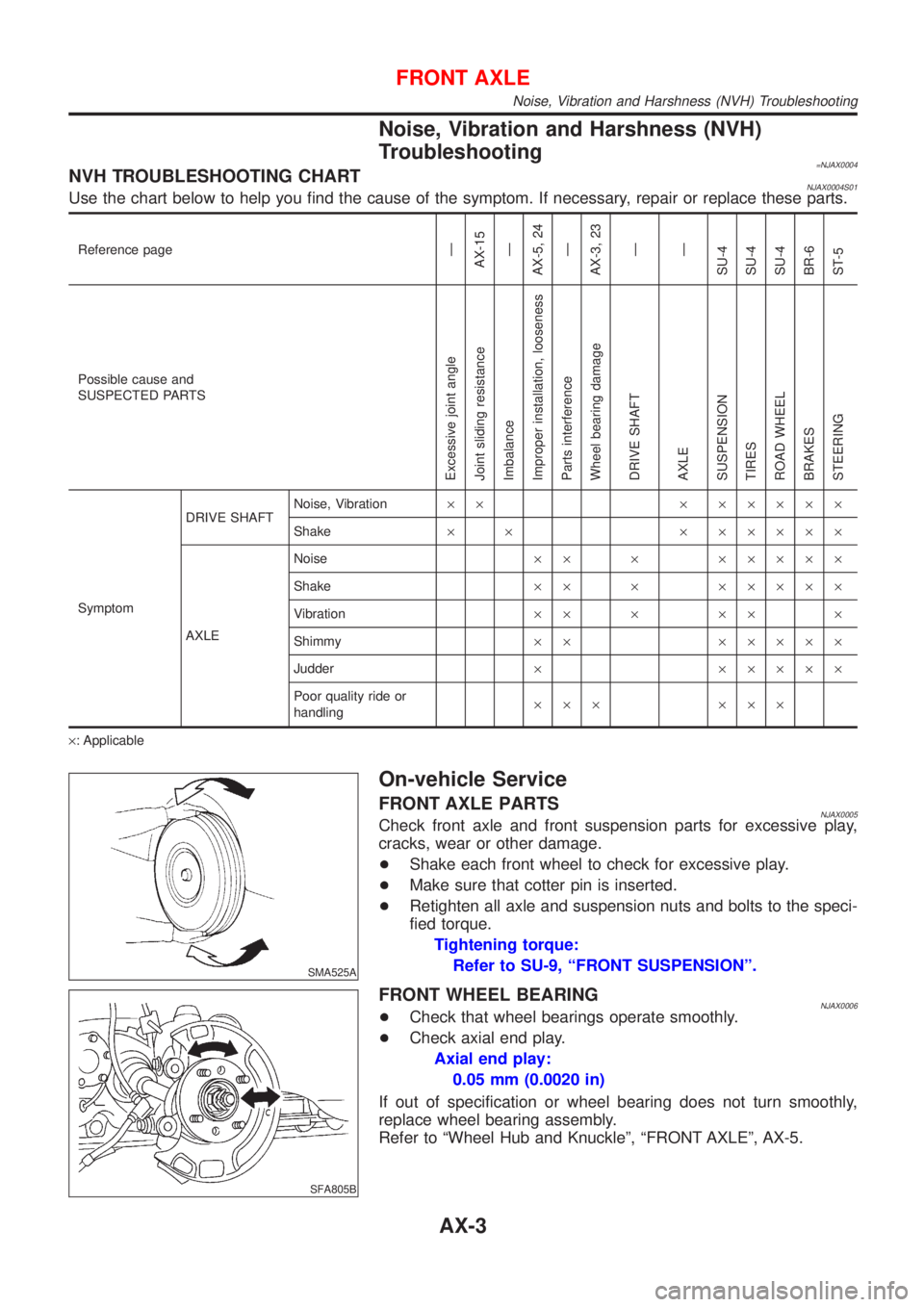

=NJAX0004NVH TROUBLESHOOTING CHARTNJAX0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-15

Ð

AX-5, 24

Ð

AX-3, 23

Ð

Ð

SU-4

SU-4

SU-4

BR-6

ST-5

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´ ´´´´´

Shake´ ´ ´ ´´´´´

AXLENoise´´ ´ ´´´´´

Shake´´ ´ ´´´´´

Vibration´´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNJAX0005Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

+Shake each front wheel to check for excessive play.

+Make sure that cotter pin is inserted.

+Retighten all axle and suspension nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to SU-9, ªFRONT SUSPENSIONº.

SFA805B

FRONT WHEEL BEARINGNJAX0006+Check that wheel bearings operate smoothly.

+Check axial end play.

Axial end play:

0.05 mm (0.0020 in)

If out of specification or wheel bearing does not turn smoothly,

replace wheel bearing assembly.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

Page 1669 of 2493

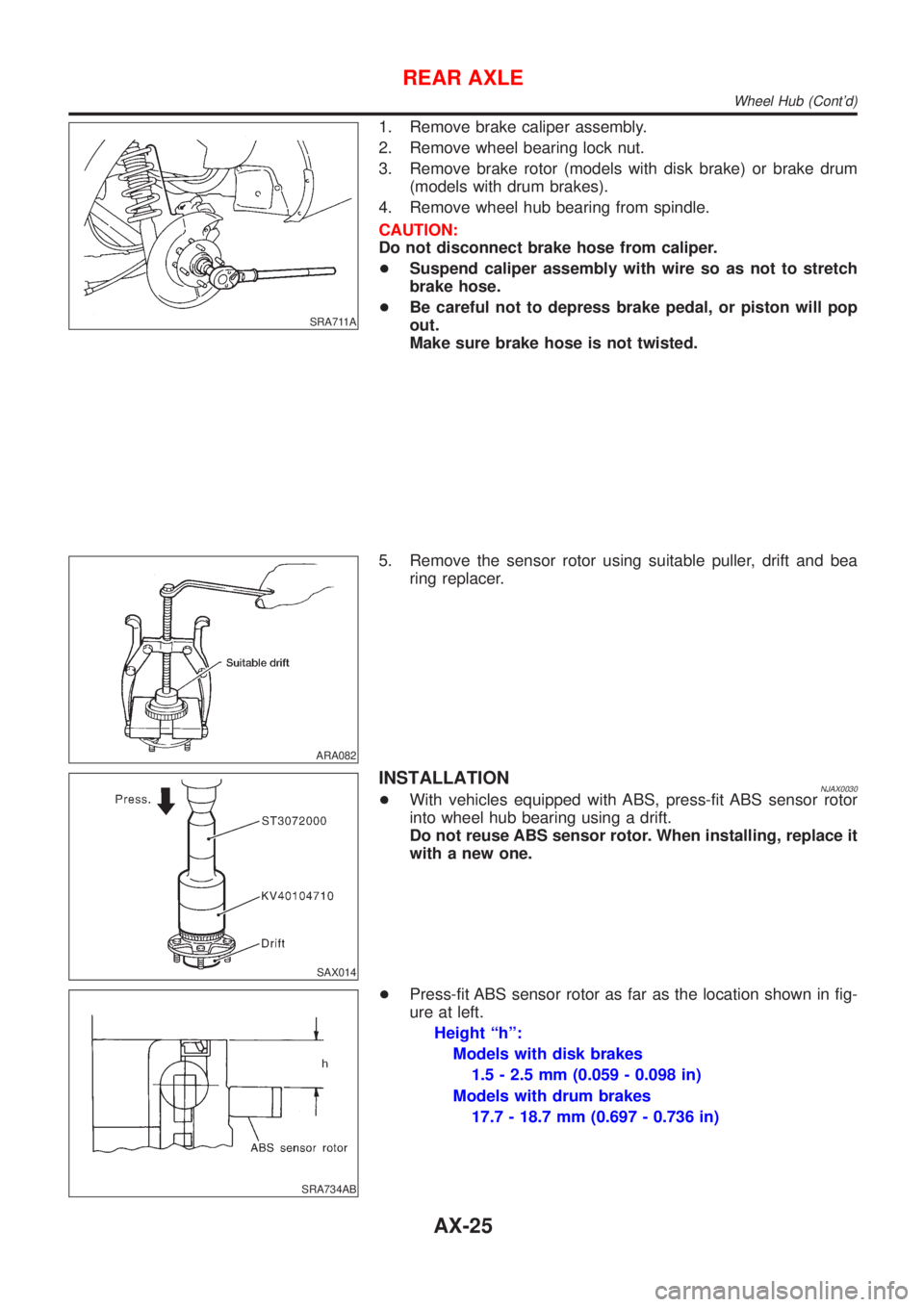

SRA711A

1. Remove brake caliper assembly.

2. Remove wheel bearing lock nut.

3. Remove brake rotor (models with disk brake) or brake drum

(models with drum brakes).

4. Remove wheel hub bearing from spindle.

CAUTION:

Do not disconnect brake hose from caliper.

+Suspend caliper assembly with wire so as not to stretch

brake hose.

+Be careful not to depress brake pedal, or piston will pop

out.

Make sure brake hose is not twisted.

ARA082

5. Remove the sensor rotor using suitable puller, drift and bea

ring replacer.

SAX014

INSTALLATIONNJAX0030+With vehicles equipped with ABS, press-fit ABS sensor rotor

into wheel hub bearing using a drift.

Do not reuse ABS sensor rotor. When installing, replace it

with a new one.

SRA734AB

+Press-fit ABS sensor rotor as far as the location shown in fig-

ure at left.

Height ªhº:

Models with disk brakes

1.5 - 2.5 mm (0.059 - 0.098 in)

Models with drum brakes

17.7 - 18.7 mm (0.697 - 0.736 in)

REAR AXLE

Wheel Hub (Cont'd)

AX-25