iac NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 53 of 2493

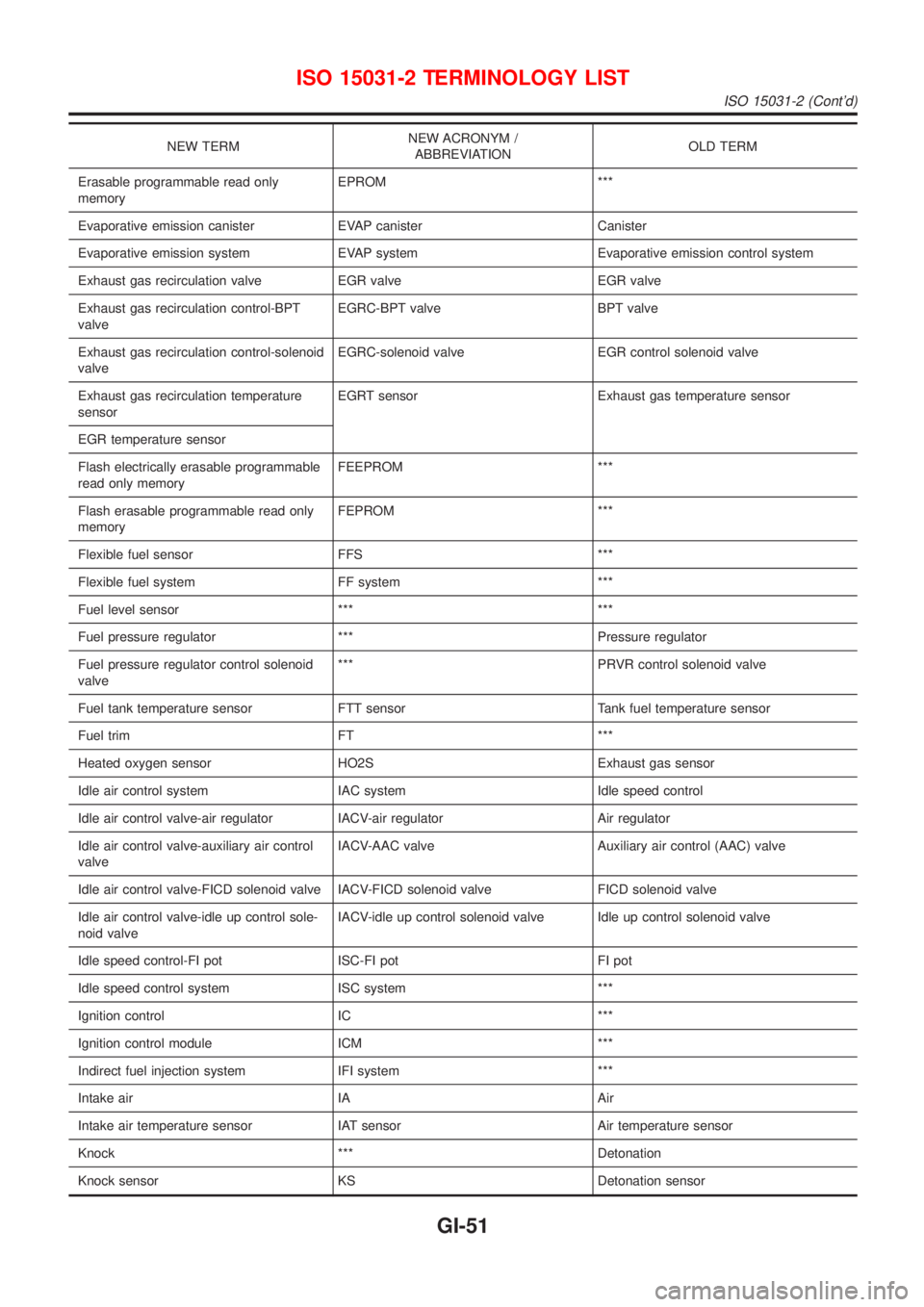

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Erasable programmable read only

memoryEPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature

sensorEGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel level sensor *** ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel tank temperature sensor FTT sensor Tank fuel temperature sensor

Fuel trim FT ***

Heated oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont'd)

GI-51

Page 90 of 2493

YEM020

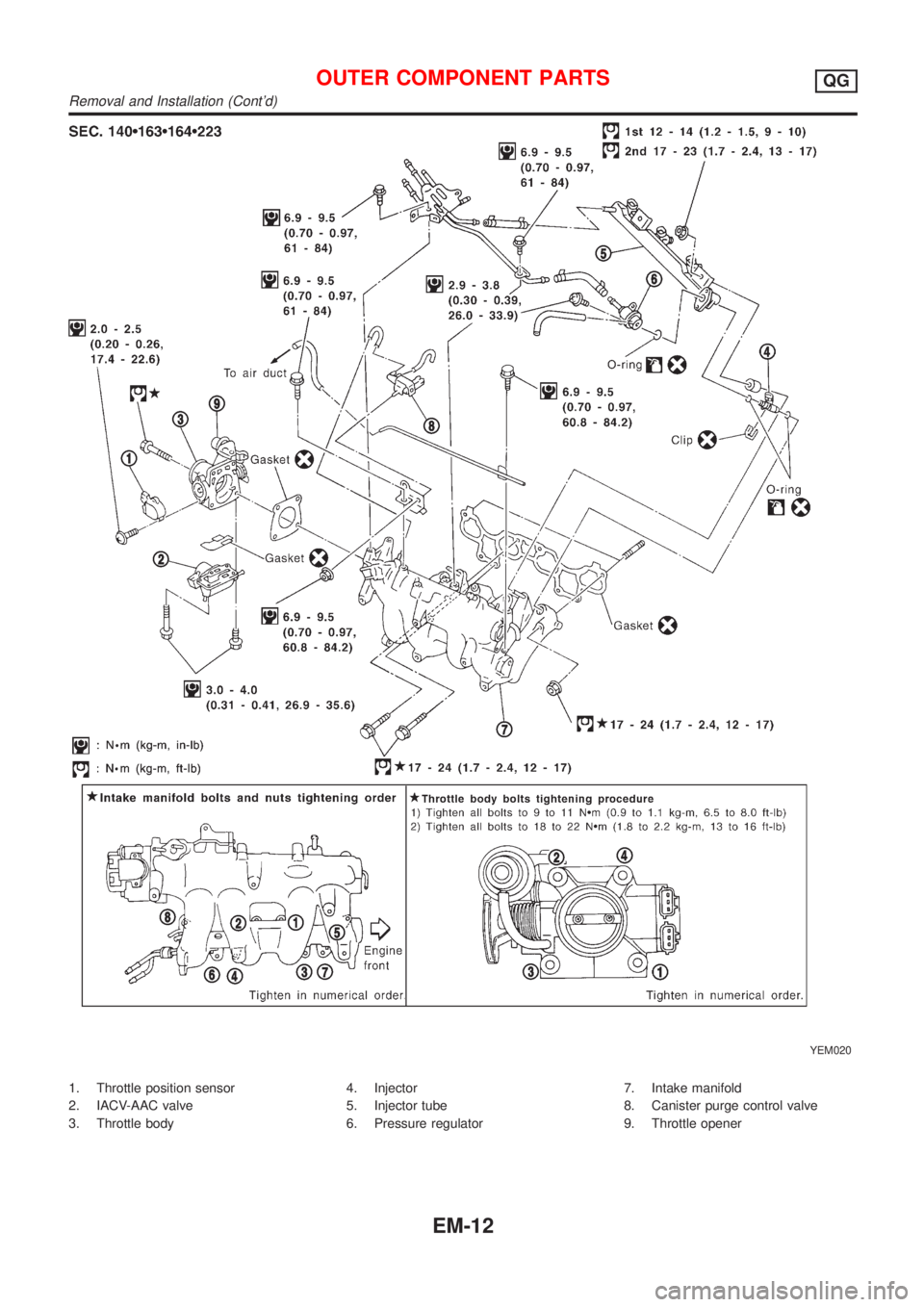

1. Throttle position sensor

2. IACV-AAC valve

3. Throttle body4. Injector

5. Injector tube

6. Pressure regulator7. Intake manifold

8. Canister purge control valve

9. Throttle opener

OUTER COMPONENT PARTSQG

Removal and Installation (Cont'd)

EM-12

Page 300 of 2493

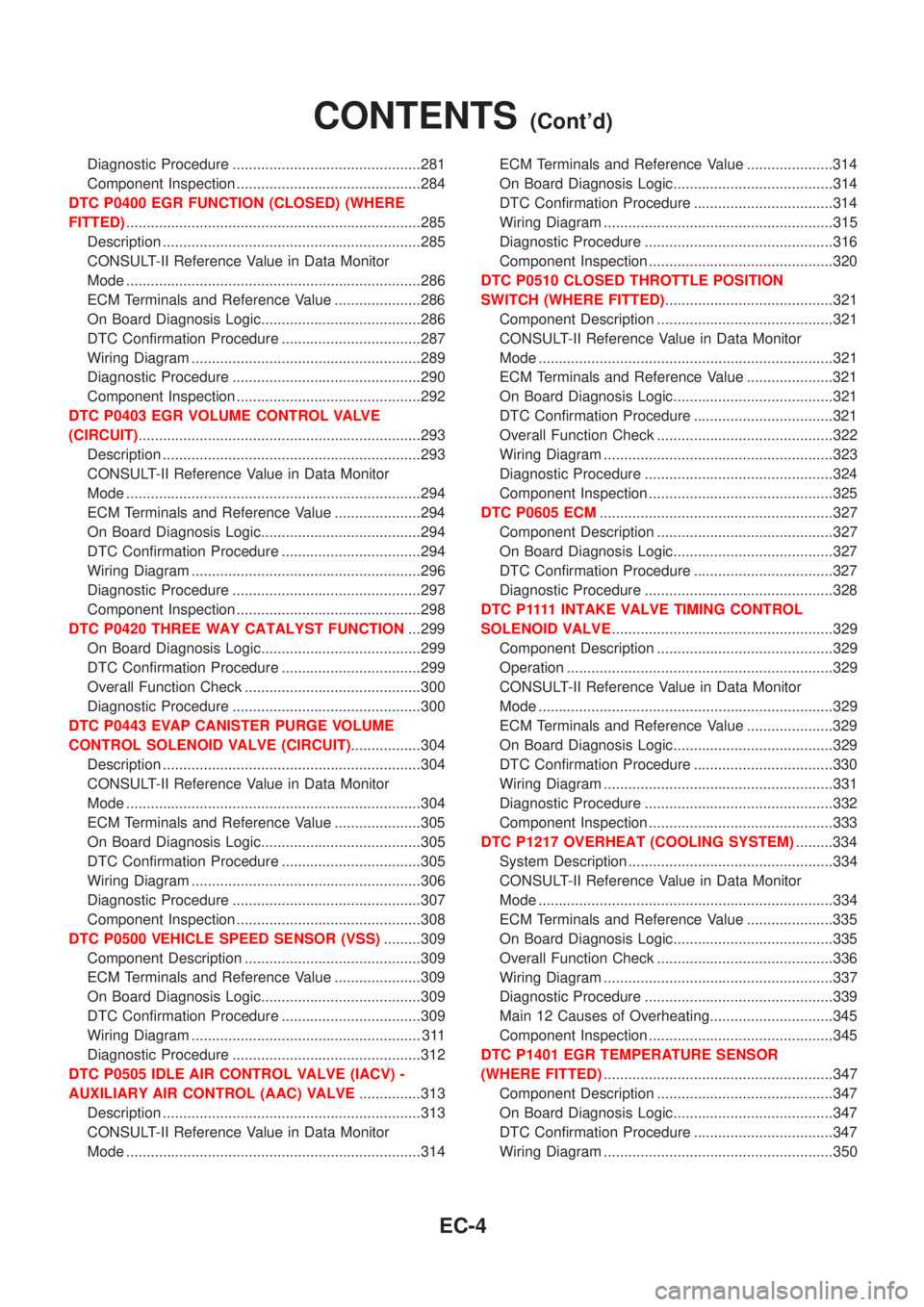

Diagnostic Procedure ..............................................281

Component Inspection .............................................284

DTC P0400 EGR FUNCTION (CLOSED) (WHERE

FITTED)........................................................................285

Description ...............................................................285

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................286

ECM Terminals and Reference Value .....................286

On Board Diagnosis Logic.......................................286

DTC Confirmation Procedure ..................................287

Wiring Diagram ........................................................289

Diagnostic Procedure ..............................................290

Component Inspection .............................................292

DTC P0403 EGR VOLUME CONTROL VALVE

(CIRCUIT).....................................................................293

Description ...............................................................293

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................294

ECM Terminals and Reference Value .....................294

On Board Diagnosis Logic.......................................294

DTC Confirmation Procedure ..................................294

Wiring Diagram ........................................................296

Diagnostic Procedure ..............................................297

Component Inspection .............................................298

DTC P0420 THREE WAY CATALYST FUNCTION...299

On Board Diagnosis Logic.......................................299

DTC Confirmation Procedure ..................................299

Overall Function Check ...........................................300

Diagnostic Procedure ..............................................300

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................304

Description ...............................................................304

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................304

ECM Terminals and Reference Value .....................305

On Board Diagnosis Logic.......................................305

DTC Confirmation Procedure ..................................305

Wiring Diagram ........................................................306

Diagnostic Procedure ..............................................307

Component Inspection .............................................308

DTC P0500 VEHICLE SPEED SENSOR (VSS).........309

Component Description ...........................................309

ECM Terminals and Reference Value .....................309

On Board Diagnosis Logic.......................................309

DTC Confirmation Procedure ..................................309

Wiring Diagram ........................................................ 311

Diagnostic Procedure ..............................................312

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............313

Description ...............................................................313

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................314ECM Terminals and Reference Value .....................314

On Board Diagnosis Logic.......................................314

DTC Confirmation Procedure ..................................314

Wiring Diagram ........................................................315

Diagnostic Procedure ..............................................316

Component Inspection .............................................320

DTC P0510 CLOSED THROTTLE POSITION

SWITCH (WHERE FITTED).........................................321

Component Description ...........................................321

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................321

ECM Terminals and Reference Value .....................321

On Board Diagnosis Logic.......................................321

DTC Confirmation Procedure ..................................321

Overall Function Check ...........................................322

Wiring Diagram ........................................................323

Diagnostic Procedure ..............................................324

Component Inspection .............................................325

DTC P0605 ECM.........................................................327

Component Description ...........................................327

On Board Diagnosis Logic.......................................327

DTC Confirmation Procedure ..................................327

Diagnostic Procedure ..............................................328

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE......................................................329

Component Description ...........................................329

Operation .................................................................329

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................329

ECM Terminals and Reference Value .....................329

On Board Diagnosis Logic.......................................329

DTC Confirmation Procedure ..................................330

Wiring Diagram ........................................................331

Diagnostic Procedure ..............................................332

Component Inspection .............................................333

DTC P1217 OVERHEAT (COOLING SYSTEM).........334

System Description ..................................................334

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................334

ECM Terminals and Reference Value .....................335

On Board Diagnosis Logic.......................................335

Overall Function Check ...........................................336

Wiring Diagram ........................................................337

Diagnostic Procedure ..............................................339

Main 12 Causes of Overheating..............................345

Component Inspection .............................................345

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................347

Component Description ...........................................347

On Board Diagnosis Logic.......................................347

DTC Confirmation Procedure ..................................347

Wiring Diagram ........................................................350

CONTENTS(Cont'd)

EC-4

Page 301 of 2493

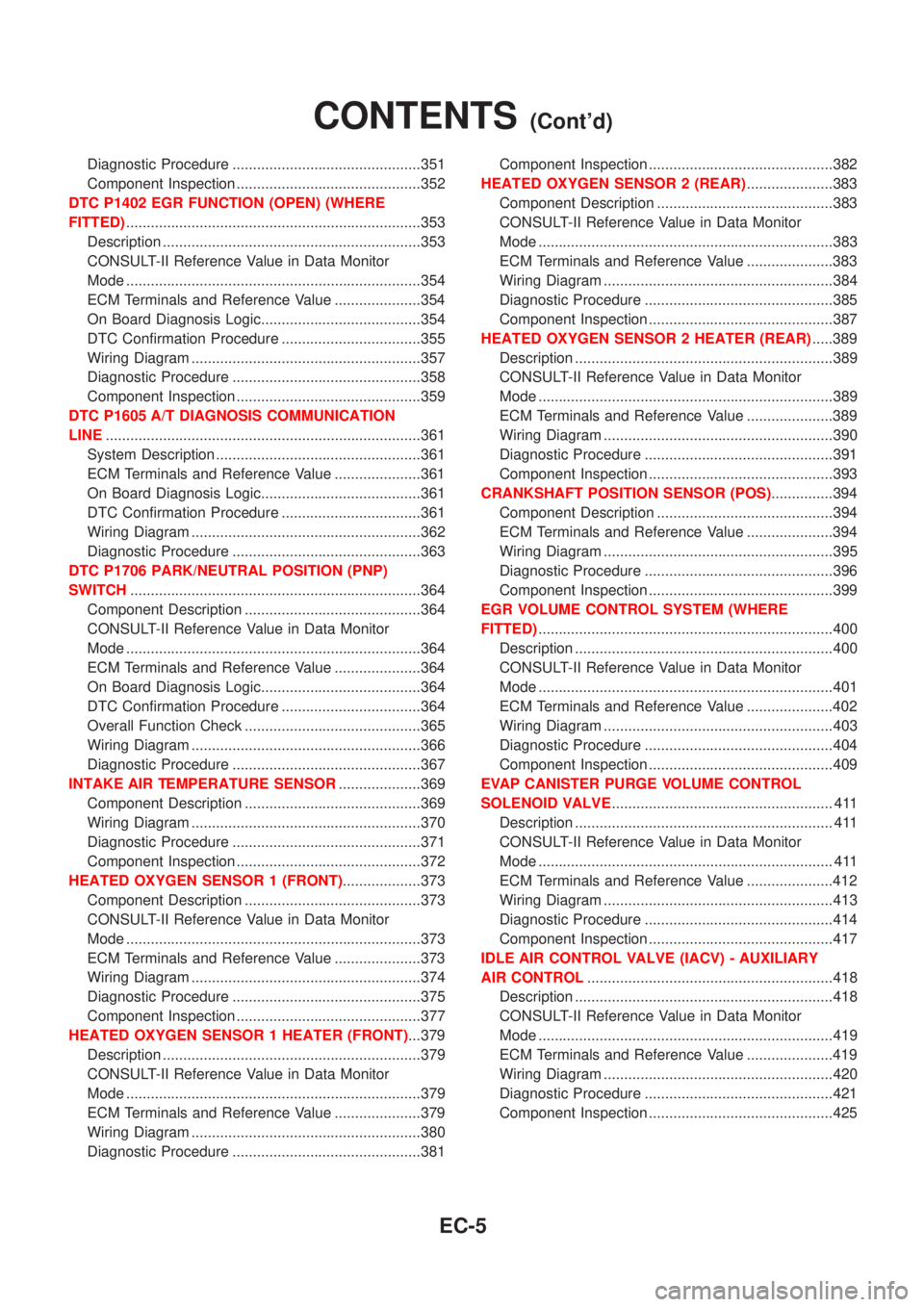

Diagnostic Procedure ..............................................351

Component Inspection .............................................352

DTC P1402 EGR FUNCTION (OPEN) (WHERE

FITTED)........................................................................353

Description ...............................................................353

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................354

ECM Terminals and Reference Value .....................354

On Board Diagnosis Logic.......................................354

DTC Confirmation Procedure ..................................355

Wiring Diagram ........................................................357

Diagnostic Procedure ..............................................358

Component Inspection .............................................359

DTC P1605 A/T DIAGNOSIS COMMUNICATION

LINE.............................................................................361

System Description ..................................................361

ECM Terminals and Reference Value .....................361

On Board Diagnosis Logic.......................................361

DTC Confirmation Procedure ..................................361

Wiring Diagram ........................................................362

Diagnostic Procedure ..............................................363

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................364

Component Description ...........................................364

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................364

ECM Terminals and Reference Value .....................364

On Board Diagnosis Logic.......................................364

DTC Confirmation Procedure ..................................364

Overall Function Check ...........................................365

Wiring Diagram ........................................................366

Diagnostic Procedure ..............................................367

INTAKE AIR TEMPERATURE SENSOR....................369

Component Description ...........................................369

Wiring Diagram ........................................................370

Diagnostic Procedure ..............................................371

Component Inspection .............................................372

HEATED OXYGEN SENSOR 1 (FRONT)...................373

Component Description ...........................................373

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................373

ECM Terminals and Reference Value .....................373

Wiring Diagram ........................................................374

Diagnostic Procedure ..............................................375

Component Inspection .............................................377

HEATED OXYGEN SENSOR 1 HEATER (FRONT)...379

Description ...............................................................379

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................379

ECM Terminals and Reference Value .....................379

Wiring Diagram ........................................................380

Diagnostic Procedure ..............................................381Component Inspection .............................................382

HEATED OXYGEN SENSOR 2 (REAR).....................383

Component Description ...........................................383

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................383

ECM Terminals and Reference Value .....................383

Wiring Diagram ........................................................384

Diagnostic Procedure ..............................................385

Component Inspection .............................................387

HEATED OXYGEN SENSOR 2 HEATER (REAR).....389

Description ...............................................................389

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................389

ECM Terminals and Reference Value .....................389

Wiring Diagram ........................................................390

Diagnostic Procedure ..............................................391

Component Inspection .............................................393

CRANKSHAFT POSITION SENSOR (POS)...............394

Component Description ...........................................394

ECM Terminals and Reference Value .....................394

Wiring Diagram ........................................................395

Diagnostic Procedure ..............................................396

Component Inspection .............................................399

EGR VOLUME CONTROL SYSTEM (WHERE

FITTED)........................................................................400

Description ...............................................................400

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................401

ECM Terminals and Reference Value .....................402

Wiring Diagram ........................................................403

Diagnostic Procedure ..............................................404

Component Inspection .............................................409

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE...................................................... 411

Description ............................................................... 411

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 411

ECM Terminals and Reference Value .....................412

Wiring Diagram ........................................................413

Diagnostic Procedure ..............................................414

Component Inspection .............................................417

IDLE AIR CONTROL VALVE (IACV) - AUXILIARY

AIR CONTROL............................................................418

Description ...............................................................418

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................419

ECM Terminals and Reference Value .....................419

Wiring Diagram ........................................................420

Diagnostic Procedure ..............................................421

Component Inspection .............................................425

CONTENTS(Cont'd)

EC-5

Page 302 of 2493

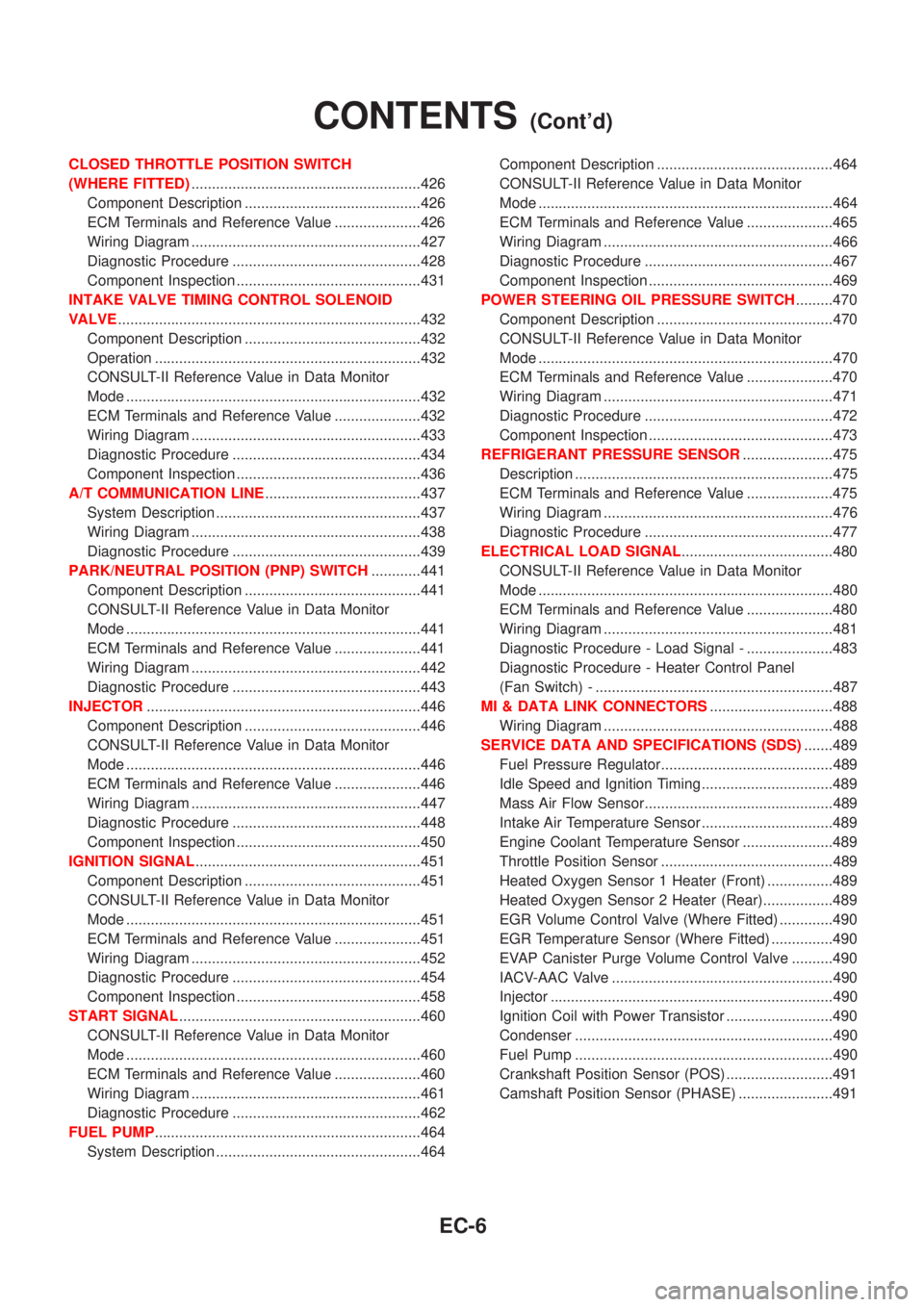

CLOSED THROTTLE POSITION SWITCH

(WHERE FITTED)........................................................426

Component Description ...........................................426

ECM Terminals and Reference Value .....................426

Wiring Diagram ........................................................427

Diagnostic Procedure ..............................................428

Component Inspection .............................................431

INTAKE VALVE TIMING CONTROL SOLENOID

VALVE..........................................................................432

Component Description ...........................................432

Operation .................................................................432

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................432

ECM Terminals and Reference Value .....................432

Wiring Diagram ........................................................433

Diagnostic Procedure ..............................................434

Component Inspection .............................................436

A/T COMMUNICATION LINE......................................437

System Description ..................................................437

Wiring Diagram ........................................................438

Diagnostic Procedure ..............................................439

PARK/NEUTRAL POSITION (PNP) SWITCH............441

Component Description ...........................................441

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................441

ECM Terminals and Reference Value .....................441

Wiring Diagram ........................................................442

Diagnostic Procedure ..............................................443

INJECTOR...................................................................446

Component Description ...........................................446

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................446

ECM Terminals and Reference Value .....................446

Wiring Diagram ........................................................447

Diagnostic Procedure ..............................................448

Component Inspection .............................................450

IGNITION SIGNAL.......................................................451

Component Description ...........................................451

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................451

ECM Terminals and Reference Value .....................451

Wiring Diagram ........................................................452

Diagnostic Procedure ..............................................454

Component Inspection .............................................458

START SIGNAL...........................................................460

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................460

ECM Terminals and Reference Value .....................460

Wiring Diagram ........................................................461

Diagnostic Procedure ..............................................462

FUEL PUMP.................................................................464

System Description ..................................................464Component Description ...........................................464

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................464

ECM Terminals and Reference Value .....................465

Wiring Diagram ........................................................466

Diagnostic Procedure ..............................................467

Component Inspection .............................................469

POWER STEERING OIL PRESSURE SWITCH.........470

Component Description ...........................................470

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................470

ECM Terminals and Reference Value .....................470

Wiring Diagram ........................................................471

Diagnostic Procedure ..............................................472

Component Inspection .............................................473

REFRIGERANT PRESSURE SENSOR......................475

Description ...............................................................475

ECM Terminals and Reference Value .....................475

Wiring Diagram ........................................................476

Diagnostic Procedure ..............................................477

ELECTRICAL LOAD SIGNAL.....................................480

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................480

ECM Terminals and Reference Value .....................480

Wiring Diagram ........................................................481

Diagnostic Procedure - Load Signal - .....................483

Diagnostic Procedure - Heater Control Panel

(Fan Switch) - ..........................................................487

MI & DATA LINK CONNECTORS..............................488

Wiring Diagram ........................................................488

SERVICE DATA AND SPECIFICATIONS (SDS).......489

Fuel Pressure Regulator..........................................489

Idle Speed and Ignition Timing ................................489

Mass Air Flow Sensor..............................................489

Intake Air Temperature Sensor ................................489

Engine Coolant Temperature Sensor ......................489

Throttle Position Sensor ..........................................489

Heated Oxygen Sensor 1 Heater (Front) ................489

Heated Oxygen Sensor 2 Heater (Rear).................489

EGR Volume Control Valve (Where Fitted) .............490

EGR Temperature Sensor (Where Fitted) ...............490

EVAP Canister Purge Volume Control Valve ..........490

IACV-AAC Valve ......................................................490

Injector .....................................................................490

Ignition Coil with Power Transistor ..........................490

Condenser ...............................................................490

Fuel Pump ...............................................................490

Crankshaft Position Sensor (POS) ..........................491

Camshaft Position Sensor (PHASE) .......................491

CONTENTS(Cont'd)

EC-6

Page 307 of 2493

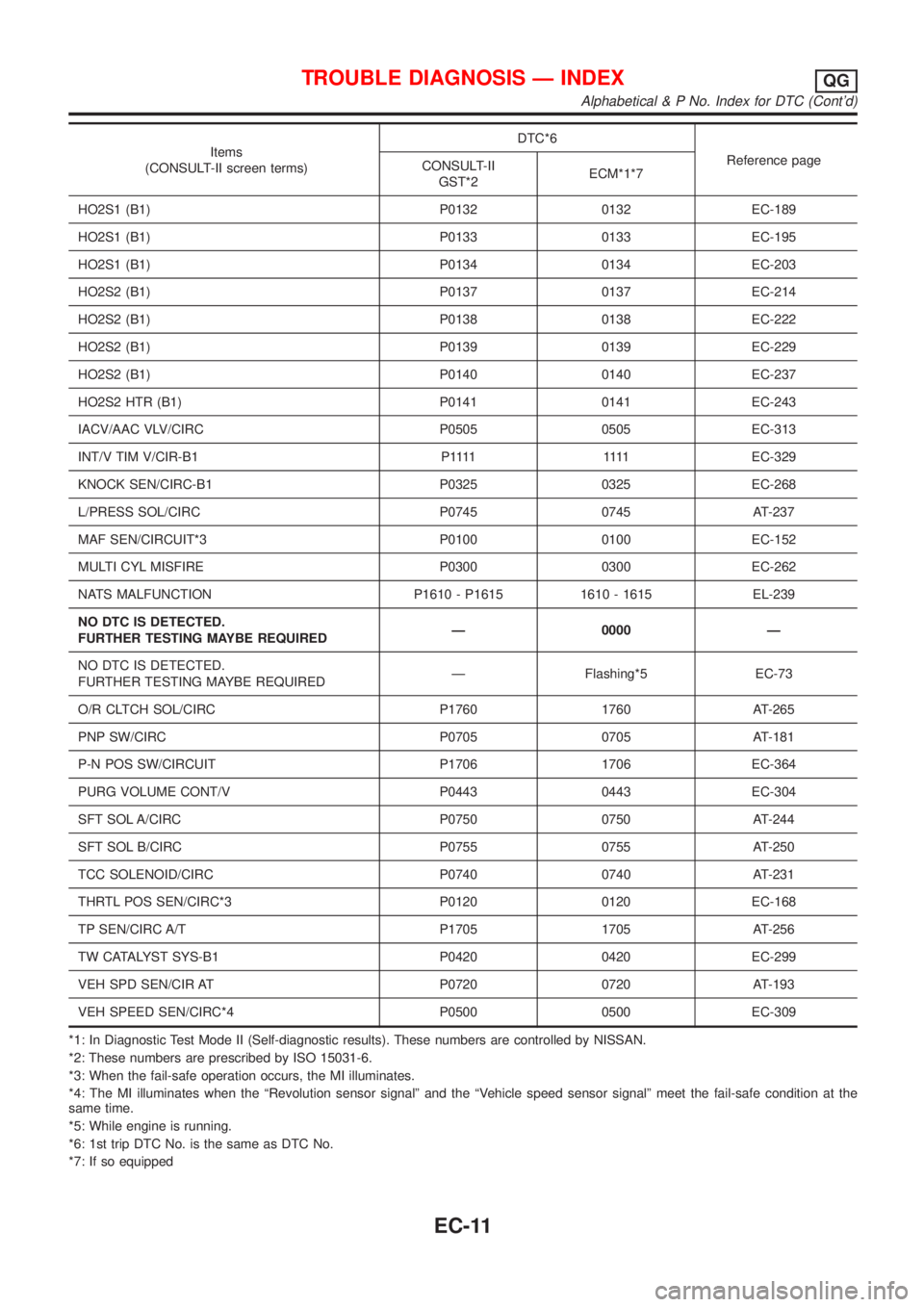

Items

(CONSULT-II screen terms)DTC*6

Reference page

CONSULT-II

GST*2ECM*1*7

HO2S1 (B1) P0132 0132 EC-189

HO2S1 (B1) P0133 0133 EC-195

HO2S1 (B1) P0134 0134 EC-203

HO2S2 (B1) P0137 0137 EC-214

HO2S2 (B1) P0138 0138 EC-222

HO2S2 (B1) P0139 0139 EC-229

HO2S2 (B1) P0140 0140 EC-237

HO2S2 HTR (B1) P0141 0141 EC-243

IACV/AAC VLV/CIRC P0505 0505 EC-313

INT/V TIM V/CIR-B1 P1111 1111EC-329

KNOCK SEN/CIRC-B1 P0325 0325 EC-268

L/PRESS SOL/CIRC P0745 0745 AT-237

MAF SEN/CIRCUIT*3 P0100 0100 EC-152

MULTI CYL MISFIRE P0300 0300 EC-262

NATS MALFUNCTION P1610 - P1615 1610 - 1615 EL-239

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ 0000 Ð

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ Flashing*5 EC-73

O/R CLTCH SOL/CIRC P1760 1760 AT-265

PNP SW/CIRC P0705 0705 AT-181

P-N POS SW/CIRCUIT P1706 1706 EC-364

PURG VOLUME CONT/V P0443 0443 EC-304

SFT SOL A/CIRC P0750 0750 AT-244

SFT SOL B/CIRC P0755 0755 AT-250

TCC SOLENOID/CIRC P0740 0740 AT-231

THRTL POS SEN/CIRC*3 P0120 0120 EC-168

TP SEN/CIRC A/T P1705 1705 AT-256

TW CATALYST SYS-B1 P0420 0420 EC-299

VEH SPD SEN/CIR AT P0720 0720 AT-193

VEH SPEED SEN/CIRC*4 P0500 0500 EC-309

*1: In Diagnostic Test Mode II (Self-diagnostic results). These numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO 15031-6.

*3: When the fail-safe operation occurs, the MI illuminates.

*4: The MI illuminates when the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at the

same time.

*5: While engine is running.

*6: 1st trip DTC No. is the same as DTC No.

*7: If so equipped

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-11

Page 308 of 2493

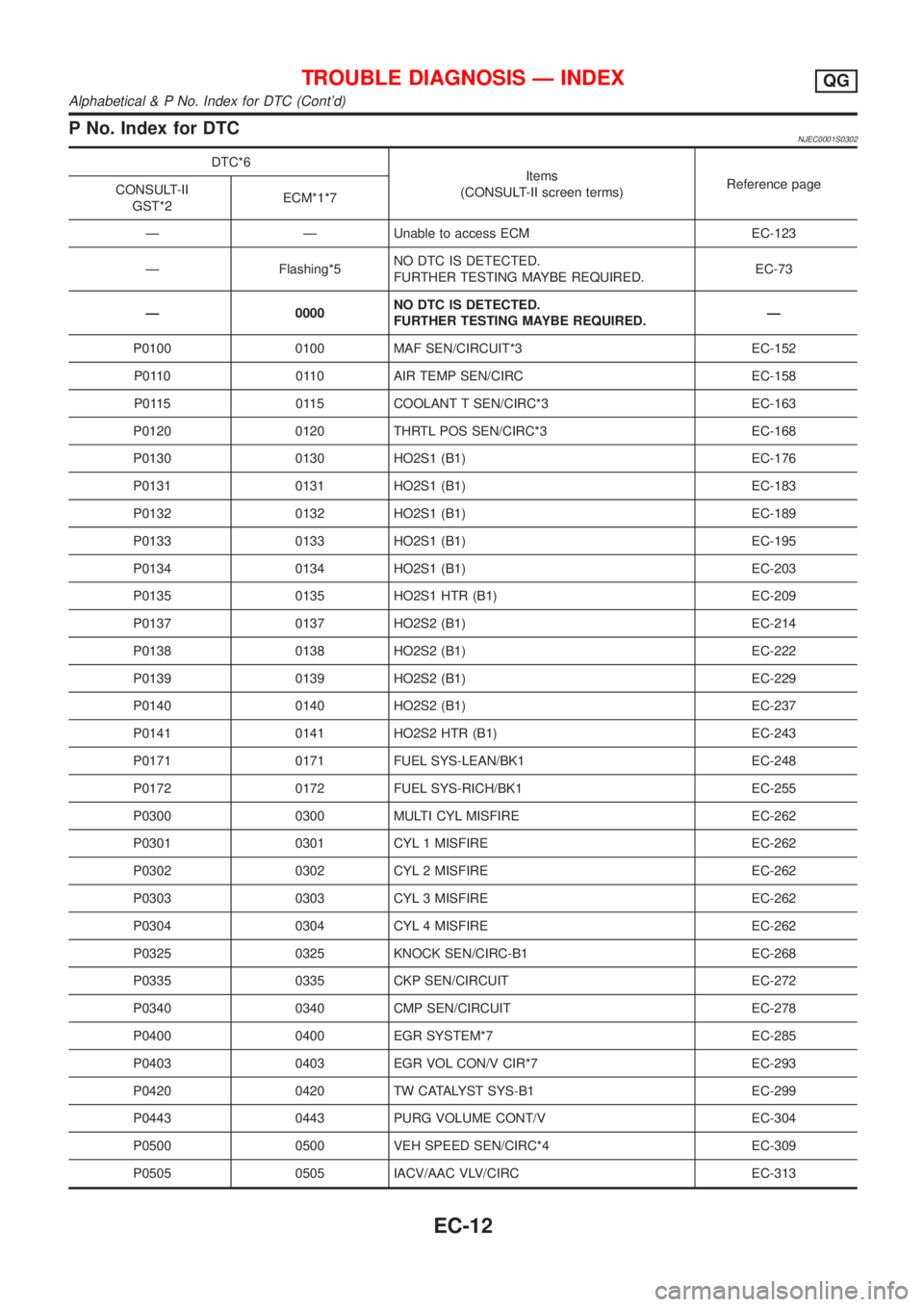

P No. Index for DTCNJEC0001S0302

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1*7

Ð Ð Unable to access ECM EC-123

Ð Flashing*5NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.EC-73

Ð 0000NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.Ð

P0100 0100 MAF SEN/CIRCUIT*3 EC-152

P0110 0110 AIR TEMP SEN/CIRC EC-158

P0115 0115 COOLANT T SEN/CIRC*3 EC-163

P0120 0120 THRTL POS SEN/CIRC*3 EC-168

P0130 0130 HO2S1 (B1) EC-176

P0131 0131 HO2S1 (B1) EC-183

P0132 0132 HO2S1 (B1) EC-189

P0133 0133 HO2S1 (B1) EC-195

P0134 0134 HO2S1 (B1) EC-203

P0135 0135 HO2S1 HTR (B1) EC-209

P0137 0137 HO2S2 (B1) EC-214

P0138 0138 HO2S2 (B1) EC-222

P0139 0139 HO2S2 (B1) EC-229

P0140 0140 HO2S2 (B1) EC-237

P0141 0141 HO2S2 HTR (B1) EC-243

P0171 0171 FUEL SYS-LEAN/BK1 EC-248

P0172 0172 FUEL SYS-RICH/BK1 EC-255

P0300 0300 MULTI CYL MISFIRE EC-262

P0301 0301 CYL 1 MISFIRE EC-262

P0302 0302 CYL 2 MISFIRE EC-262

P0303 0303 CYL 3 MISFIRE EC-262

P0304 0304 CYL 4 MISFIRE EC-262

P0325 0325 KNOCK SEN/CIRC-B1 EC-268

P0335 0335 CKP SEN/CIRCUIT EC-272

P0340 0340 CMP SEN/CIRCUIT EC-278

P0400 0400 EGR SYSTEM*7 EC-285

P0403 0403 EGR VOL CON/V CIR*7 EC-293

P0420 0420 TW CATALYST SYS-B1 EC-299

P0443 0443 PURG VOLUME CONT/V EC-304

P0500 0500 VEH SPEED SEN/CIRC*4 EC-309

P0505 0505 IACV/AAC VLV/CIRC EC-313

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-12

Page 314 of 2493

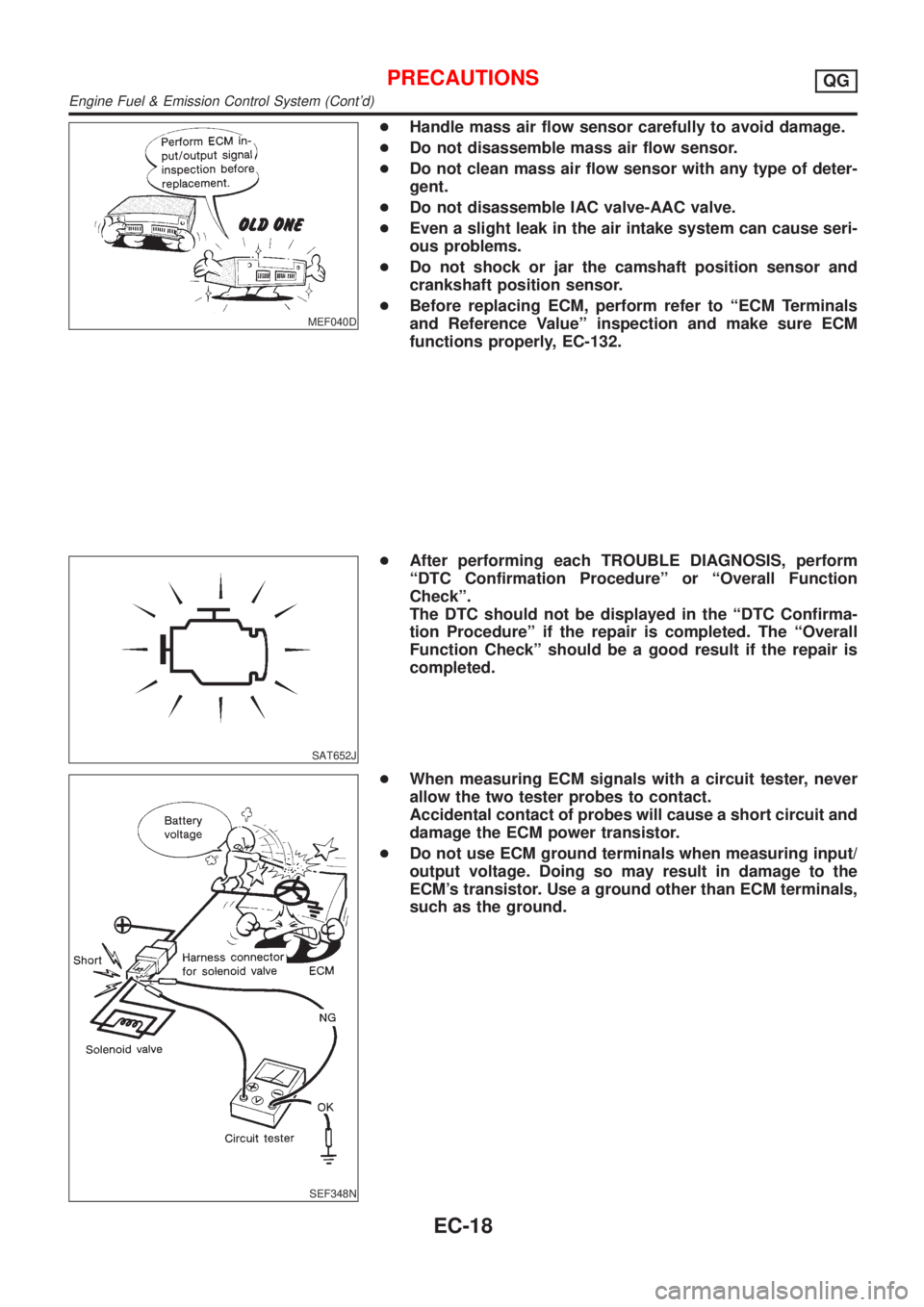

MEF040D

+Handle mass air flow sensor carefully to avoid damage.

+Do not disassemble mass air flow sensor.

+Do not clean mass air flow sensor with any type of deter-

gent.

+Do not disassemble IAC valve-AAC valve.

+Even a slight leak in the air intake system can cause seri-

ous problems.

+Do not shock or jar the camshaft position sensor and

crankshaft position sensor.

+Before replacing ECM, perform refer to ªECM Terminals

and Reference Valueº inspection and make sure ECM

functions properly, EC-132.

SAT652J

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC Confirmation Procedureº or ªOverall Function

Checkº.

The DTC should not be displayed in the ªDTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

SEF348N

+When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

+Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than ECM terminals,

such as the ground.

PRECAUTIONSQG

Engine Fuel & Emission Control System (Cont'd)

EC-18

Page 324 of 2493

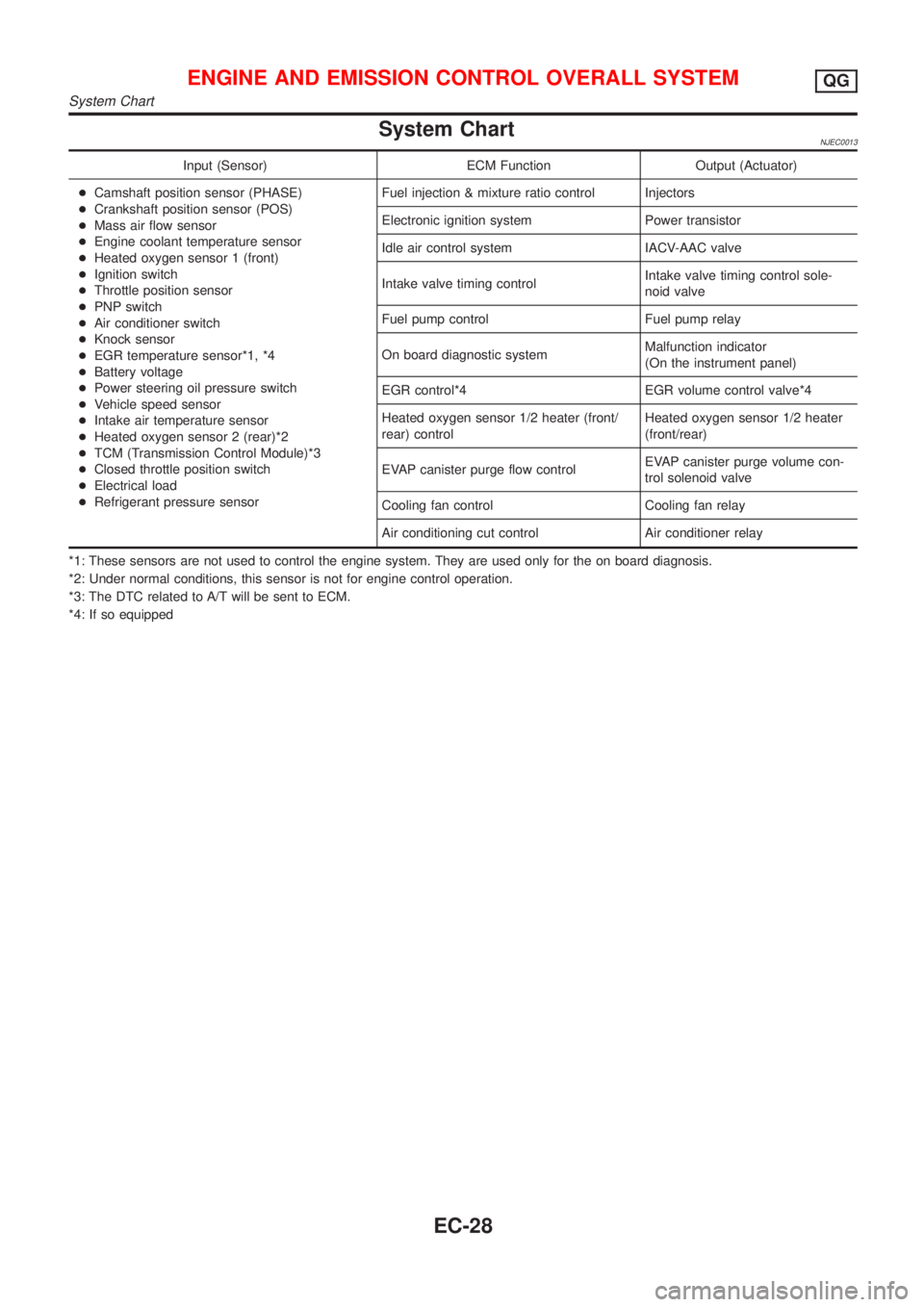

System ChartNJEC0013

Input (Sensor) ECM Function Output (Actuator)

+Camshaft position sensor (PHASE)

+Crankshaft position sensor (POS)

+Mass air flow sensor

+Engine coolant temperature sensor

+Heated oxygen sensor 1 (front)

+Ignition switch

+Throttle position sensor

+PNP switch

+Air conditioner switch

+Knock sensor

+EGR temperature sensor*1, *4

+Battery voltage

+Power steering oil pressure switch

+Vehicle speed sensor

+Intake air temperature sensor

+Heated oxygen sensor 2 (rear)*2

+TCM (Transmission Control Module)*3

+Closed throttle position switch

+Electrical load

+Refrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Intake valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

On board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control*4 EGR volume control valve*4

Heated oxygen sensor 1/2 heater (front/

rear) controlHeated oxygen sensor 1/2 heater

(front/rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

*3: The DTC related to A/T will be sent to ECM.

*4: If so equipped

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG

System Chart

EC-28

Page 339 of 2493

h)Fuel pressure

i)Engine compression

j)EGR valve operation

k)Throttle valve

l)EVAP system

+On models equipped with air conditioner, checks should

be carried out while the air conditioner is ªOFFº.

+When checking idle speed on models equipped with A/T,

ignition timing and mixture ratio, checks should be carried

out while shift lever is in ªPº or ªNº position.

+When measuring ªCOº percentage, insert probe more

than 40 cm (15.7 in) into tail pipe.

+Turn off headlamps, heater blower, rear window defogger.

+On vehicles equipped with daytime light systems, set

lighting switch to the 1st position to light only small

lamps.

+Keep front wheels pointed straight ahead.

+If engine stops immediately after starting or idle condition

is unstable, perform the following to initialize IACV-AAC

valve:

a)Stop engine and wait 9 seconds.

b)Turn ignition ªONº and wait 1 second.

c)Turn ignition ªOFFº and wait 9 seconds.

+Make sure the cooling fan has stopped.

BASIC SERVICE PROCEDUREQG

Preparation (Cont'd)

EC-43