stop start NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 35 of 2493

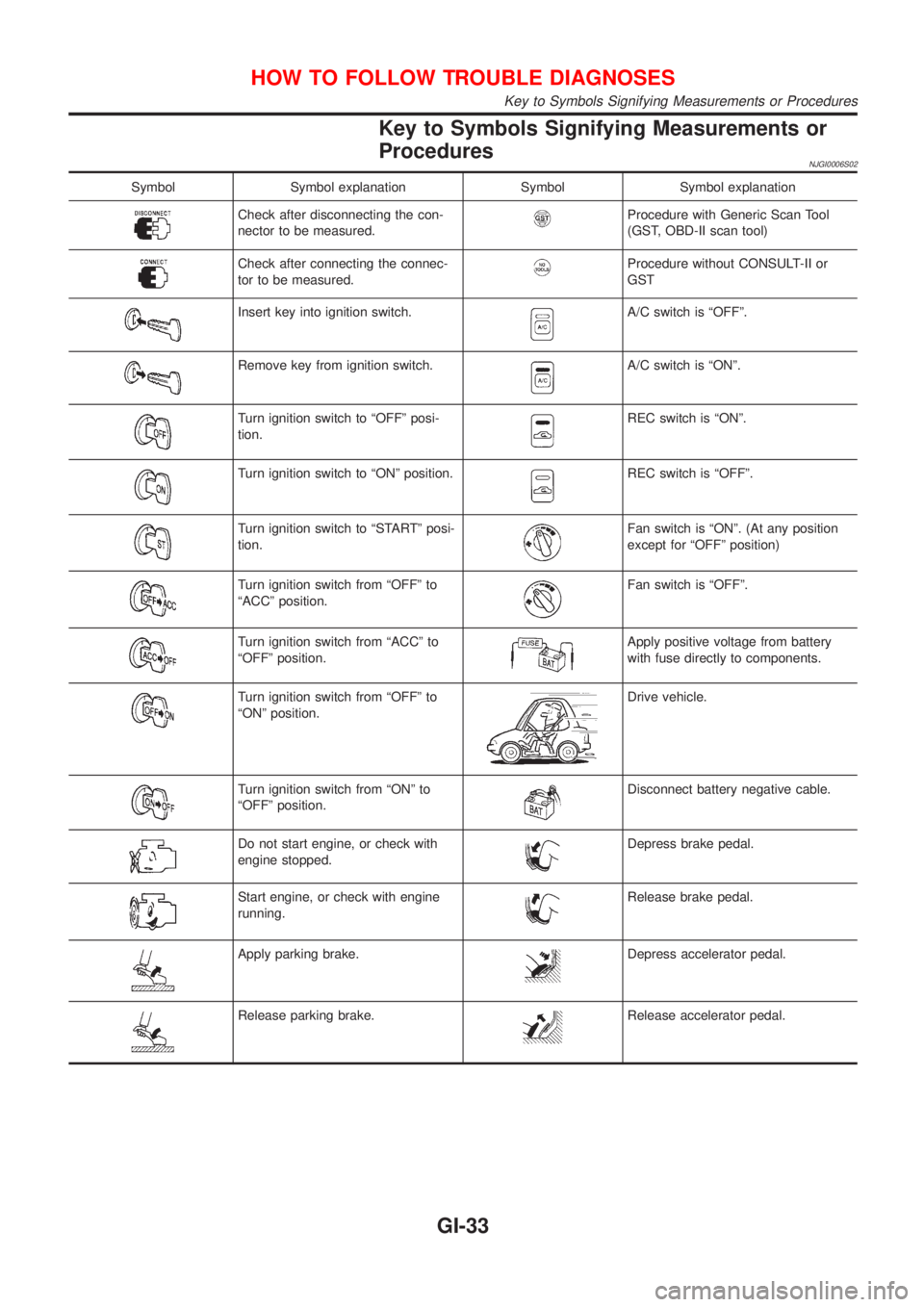

Key to Symbols Signifying Measurements or

Procedures

NJGI0006S02

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the con-

nector to be measured.Procedure with Generic Scan Tool

(GST, OBD-II scan tool)

Check after connecting the connec-

tor to be measured.Procedure without CONSULT-II or

GST

Insert key into ignition switch.A/C switch is ªOFFº.

Remove key from ignition switch.A/C switch is ªONº.

Turn ignition switch to ªOFFº posi-

tion.REC switch is ªONº.

Turn ignition switch to ªONº position.REC switch is ªOFFº.

Turn ignition switch to ªSTARTº posi-

tion.Fan switch is ªONº. (At any position

except for ªOFFº position)

Turn ignition switch from ªOFFº to

ªACCº position.Fan switch is ªOFFº.

Turn ignition switch from ªACCº to

ªOFFº position.Apply positive voltage from battery

with fuse directly to components.

Turn ignition switch from ªOFFº to

ªONº position.Drive vehicle.

Turn ignition switch from ªONº to

ªOFFº position.Disconnect battery negative cable.

Do not start engine, or check with

engine stopped.Depress brake pedal.

Start engine, or check with engine

running.Release brake pedal.

Apply parking brake.Depress accelerator pedal.

Release parking brake.Release accelerator pedal.

HOW TO FOLLOW TROUBLE DIAGNOSES

Key to Symbols Signifying Measurements or Procedures

GI-33

Page 103 of 2493

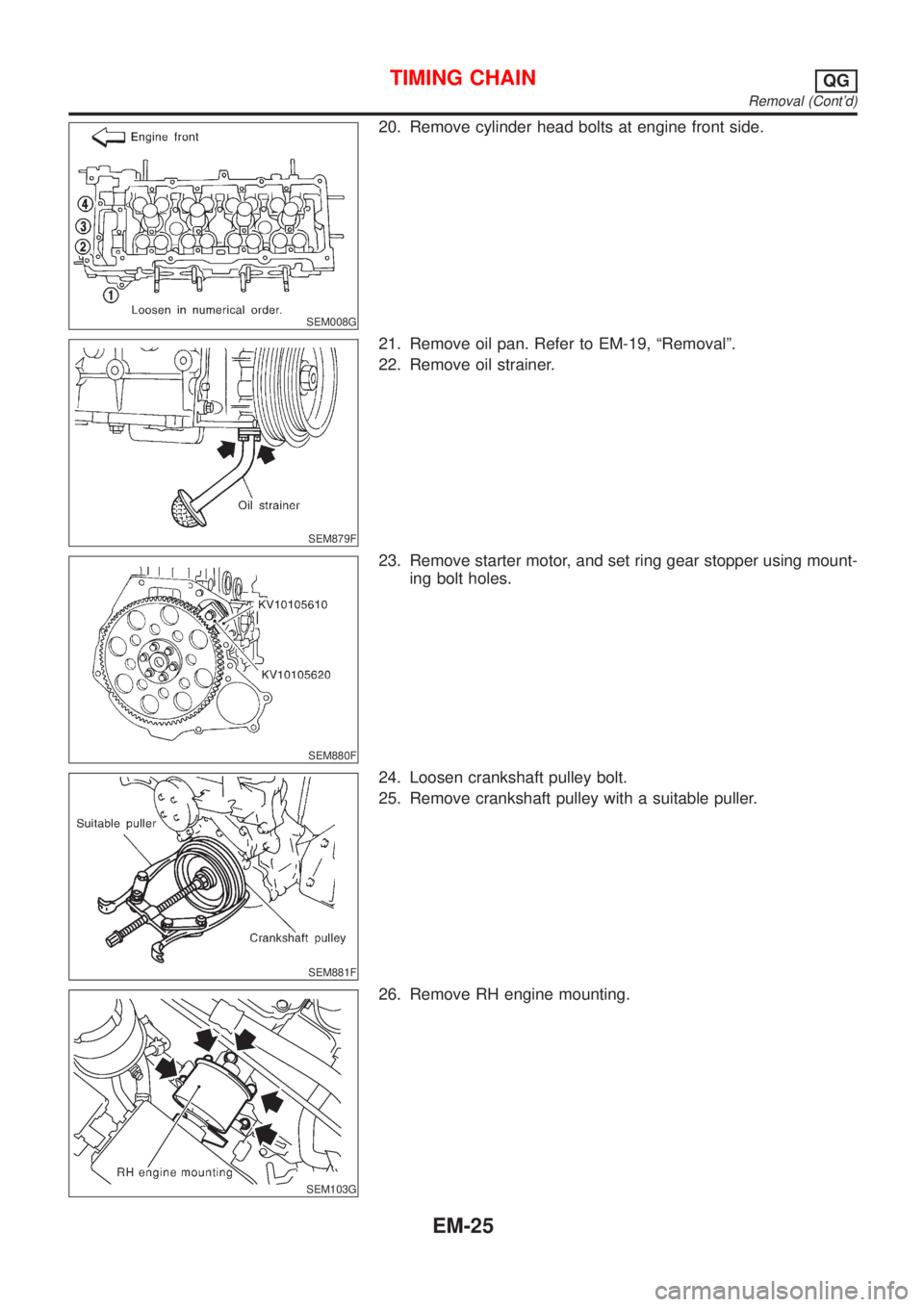

SEM008G

20. Remove cylinder head bolts at engine front side.

SEM879F

21. Remove oil pan. Refer to EM-19, ªRemovalº.

22. Remove oil strainer.

SEM880F

23. Remove starter motor, and set ring gear stopper using mount-

ing bolt holes.

SEM881F

24. Loosen crankshaft pulley bolt.

25. Remove crankshaft pulley with a suitable puller.

SEM103G

26. Remove RH engine mounting.

TIMING CHAINQG

Removal (Cont'd)

EM-25

Page 107 of 2493

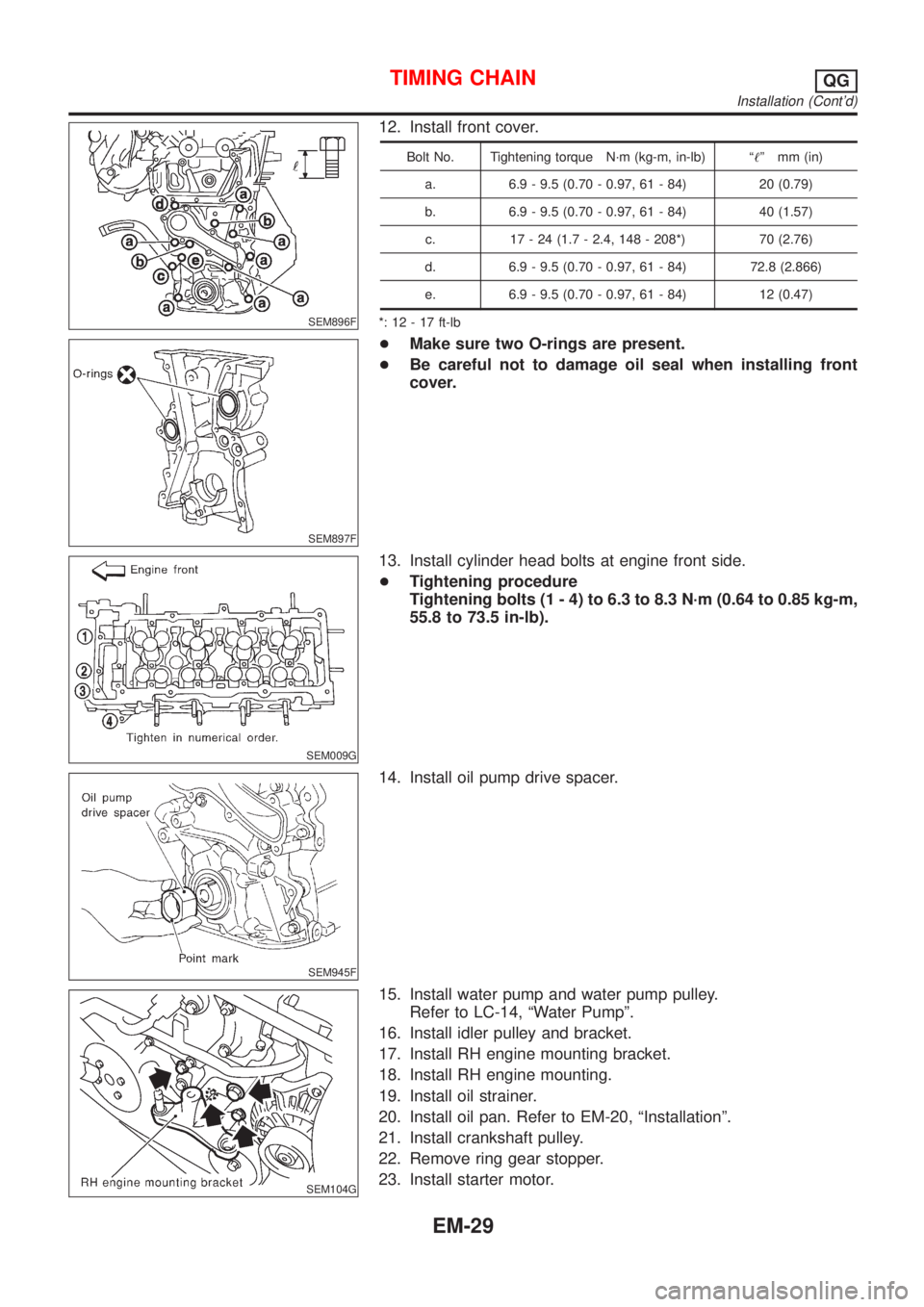

SEM896F

12. Install front cover.

Bolt No. Tightening torque N´m (kg-m, in-lb) ª!º mm (in)

a. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 20 (0.79)

b. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 40 (1.57)

c. 17 - 24 (1.7 - 2.4, 148 - 208*) 70 (2.76)

d. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 72.8 (2.866)

e. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 12 (0.47)

*: 12 - 17 ft-lb

SEM897F

+Make sure two O-rings are present.

+Be careful not to damage oil seal when installing front

cover.

SEM009G

13. Install cylinder head bolts at engine front side.

+Tightening procedure

Tightening bolts (1 - 4) to 6.3 to 8.3 N´m (0.64 to 0.85 kg-m,

55.8 to 73.5 in-lb).

SEM945F

14. Install oil pump drive spacer.

SEM104G

15. Install water pump and water pump pulley.

Refer to LC-14, ªWater Pumpº.

16. Install idler pulley and bracket.

17. Install RH engine mounting bracket.

18. Install RH engine mounting.

19. Install oil strainer.

20. Install oil pan. Refer to EM-20, ªInstallationº.

21. Install crankshaft pulley.

22. Remove ring gear stopper.

23. Install starter motor.

TIMING CHAINQG

Installation (Cont'd)

EM-29

Page 203 of 2493

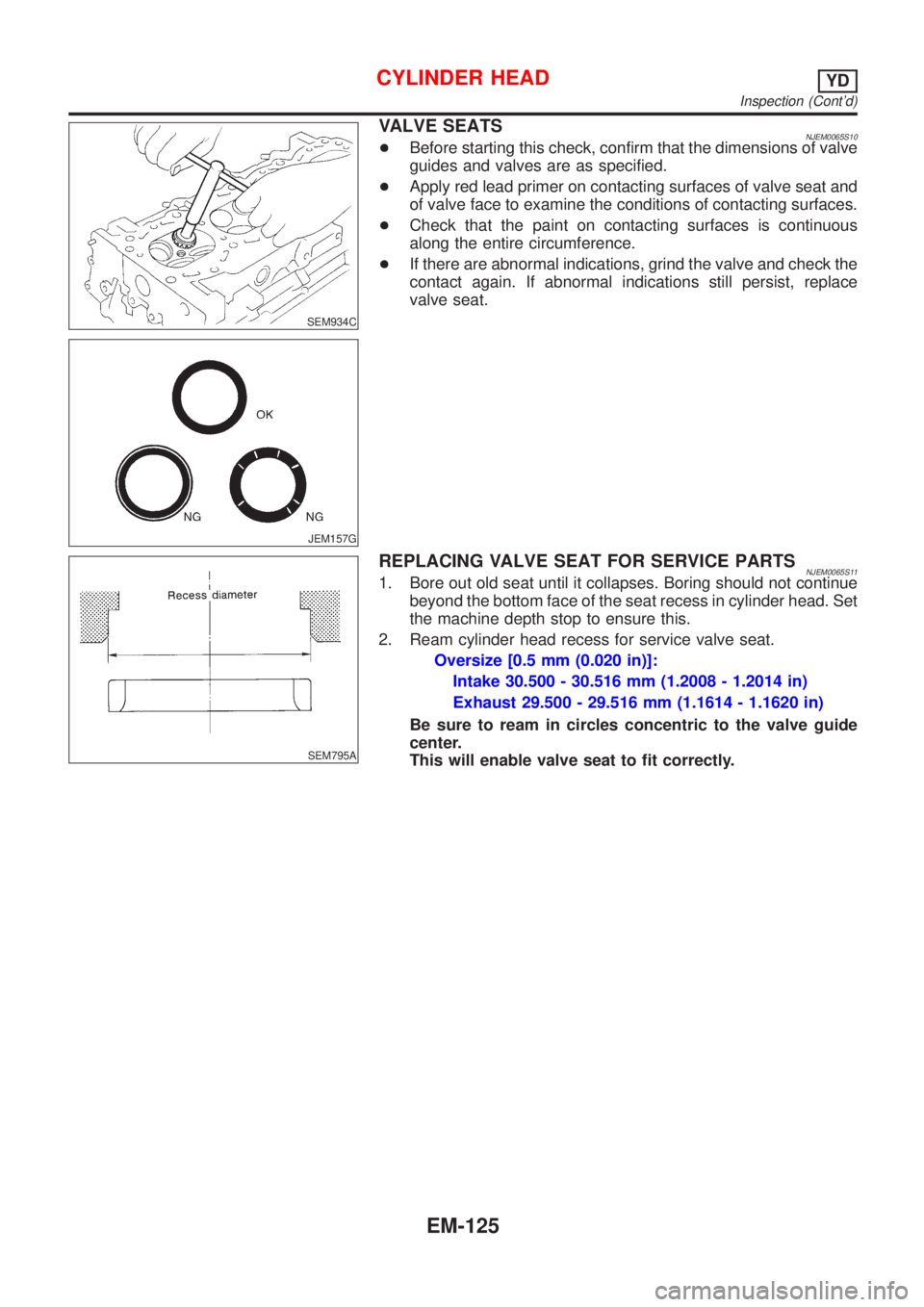

SEM934C

JEM157G

VALVE SEATSNJEM0065S10+Before starting this check, confirm that the dimensions of valve

guides and valves are as specified.

+Apply red lead primer on contacting surfaces of valve seat and

of valve face to examine the conditions of contacting surfaces.

+Check that the paint on contacting surfaces is continuous

along the entire circumference.

+If there are abnormal indications, grind the valve and check the

contact again. If abnormal indications still persist, replace

valve seat.

SEM795A

REPLACING VALVE SEAT FOR SERVICE PARTSNJEM0065S111. Bore out old seat until it collapses. Boring should not continue

beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess for service valve seat.

Oversize [0.5 mm (0.020 in)]:

Intake 30.500 - 30.516 mm (1.2008 - 1.2014 in)

Exhaust 29.500 - 29.516 mm (1.1614 - 1.1620 in)

Be sure to ream in circles concentric to the valve guide

center.

This will enable valve seat to fit correctly.

CYLINDER HEADYD

Inspection (Cont'd)

EM-125

Page 278 of 2493

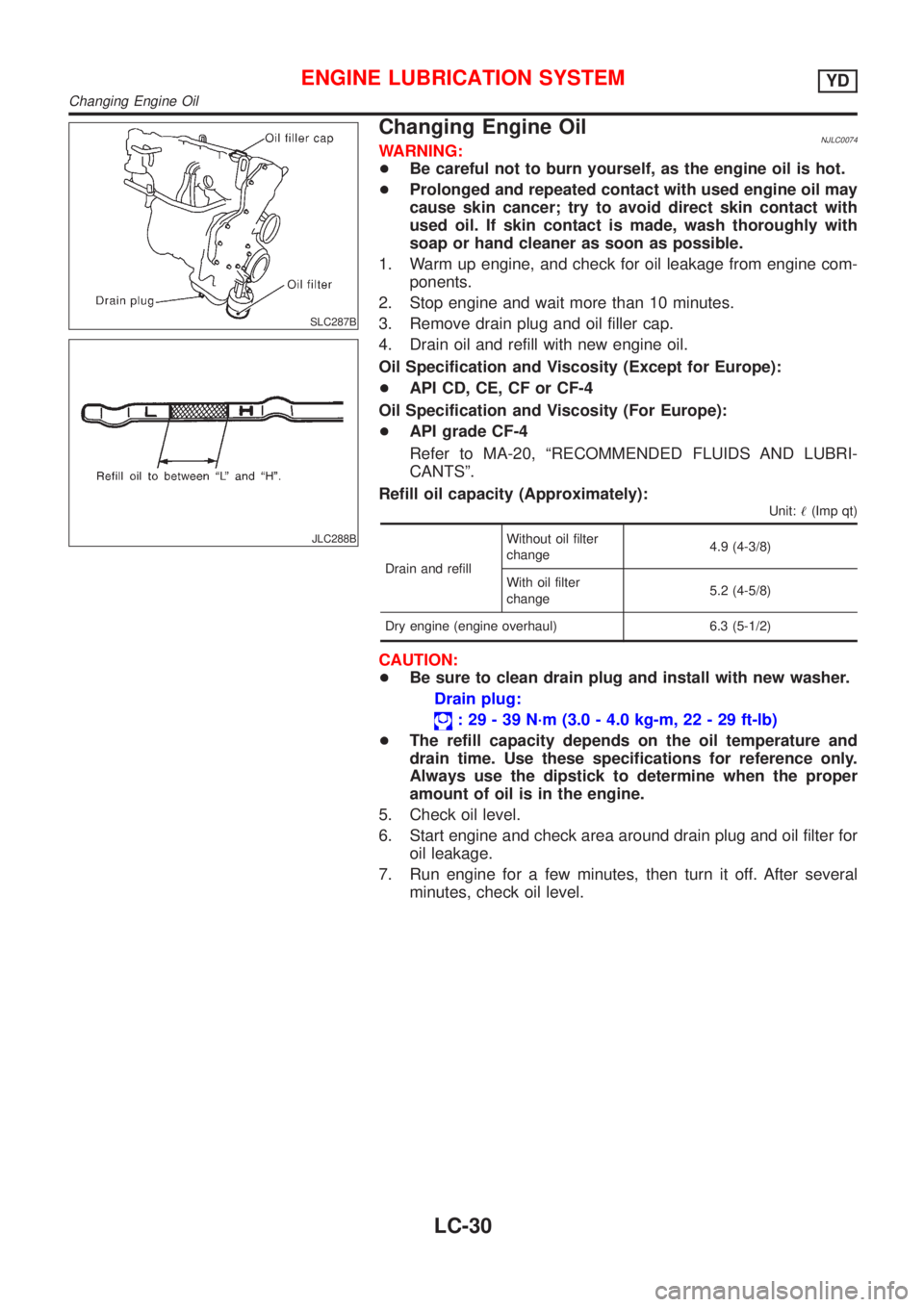

SLC287B

JLC288B

Changing Engine OilNJLC0074WARNING:

+Be careful not to burn yourself, as the engine oil is hot.

+Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine and wait more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil Specification and Viscosity (Except for Europe):

+API CD, CE, CF or CF-4

Oil Specification and Viscosity (For Europe):

+API grade CF-4

Refer to MA-20, ªRECOMMENDED FLUIDS AND LUBRI-

CANTSº.

Refill oil capacity (Approximately):

Unit:!(Imp qt)

Drain and refillWithout oil filter

change4.9 (4-3/8)

With oil filter

change5.2 (4-5/8)

Dry engine (engine overhaul) 6.3 (5-1/2)

CAUTION:

+Be sure to clean drain plug and install with new washer.

Drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

+The refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

5. Check oil level.

6. Start engine and check area around drain plug and oil filter for

oil leakage.

7. Run engine for a few minutes, then turn it off. After several

minutes, check oil level.

ENGINE LUBRICATION SYSTEMYD

Changing Engine Oil

LC-30

Page 292 of 2493

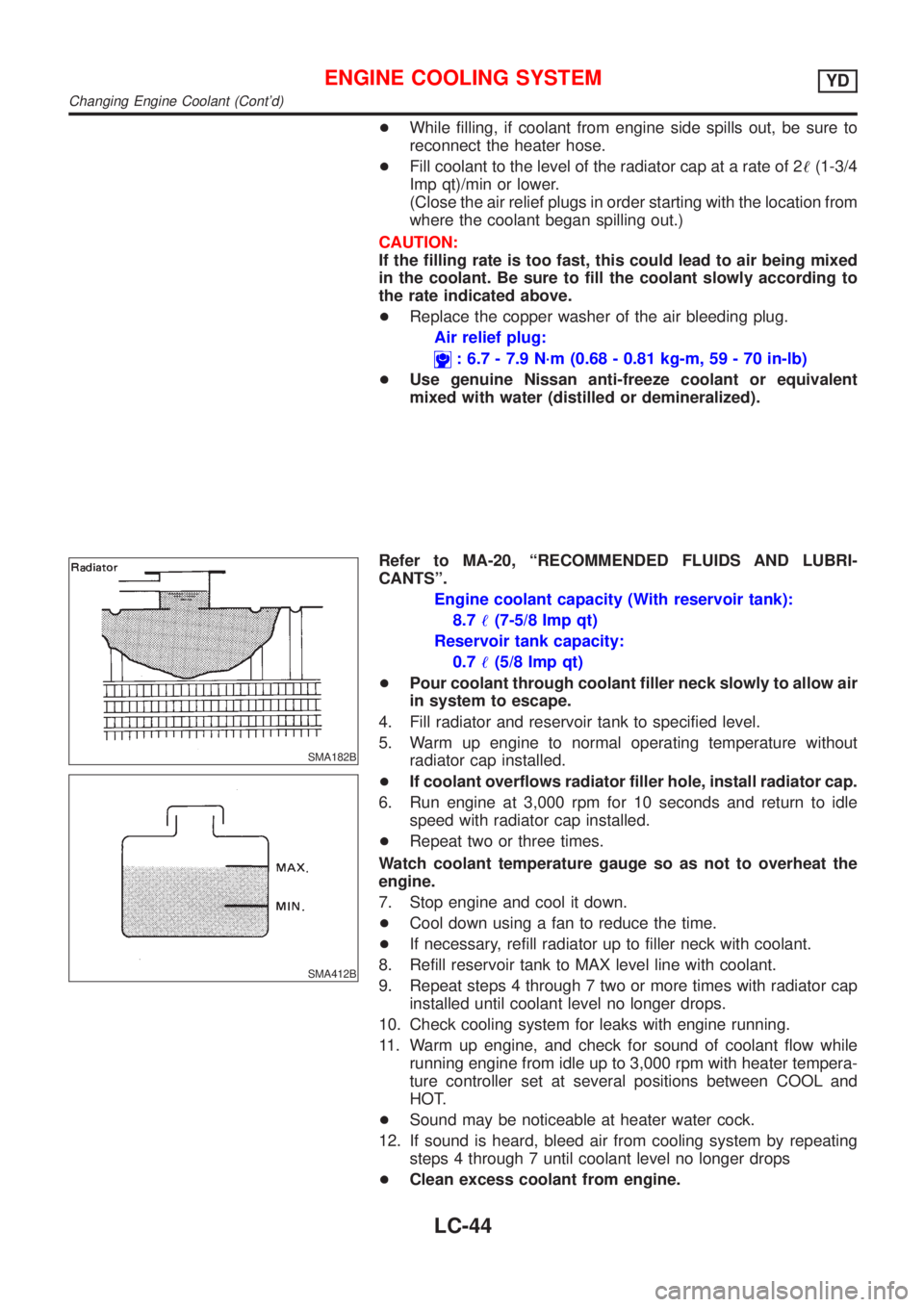

+While filling, if coolant from engine side spills out, be sure to

reconnect the heater hose.

+Fill coolant to the level of the radiator cap at a rate of 2!(1-3/4

Imp qt)/min or lower.

(Close the air relief plugs in order starting with the location from

where the coolant began spilling out.)

CAUTION:

If the filling rate is too fast, this could lead to air being mixed

in the coolant. Be sure to fill the coolant slowly according to

the rate indicated above.

+Replace the copper washer of the air bleeding plug.

Air relief plug:

: 6.7 - 7.9 N´m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

+Use genuine Nissan anti-freeze coolant or equivalent

mixed with water (distilled or demineralized).

SMA182B

SMA412B

Refer to MA-20, ªRECOMMENDED FLUIDS AND LUBRI-

CANTSº.

Engine coolant capacity (With reservoir tank):

8.7!(7-5/8 Imp qt)

Reservoir tank capacity:

0.7!(5/8 Imp qt)

+Pour coolant through coolant filler neck slowly to allow air

in system to escape.

4. Fill radiator and reservoir tank to specified level.

5. Warm up engine to normal operating temperature without

radiator cap installed.

+If coolant overflows radiator filler hole, install radiator cap.

6. Run engine at 3,000 rpm for 10 seconds and return to idle

speed with radiator cap installed.

+Repeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

7. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

+If necessary, refill radiator up to filler neck with coolant.

8. Refill reservoir tank to MAX level line with coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap

installed until coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater tempera-

ture controller set at several positions between COOL and

HOT.

+Sound may be noticeable at heater water cock.

12. If sound is heard, bleed air from cooling system by repeating

steps 4 through 7 until coolant level no longer drops

+Clean excess coolant from engine.

ENGINE COOLING SYSTEMYD

Changing Engine Coolant (Cont'd)

LC-44

Page 313 of 2493

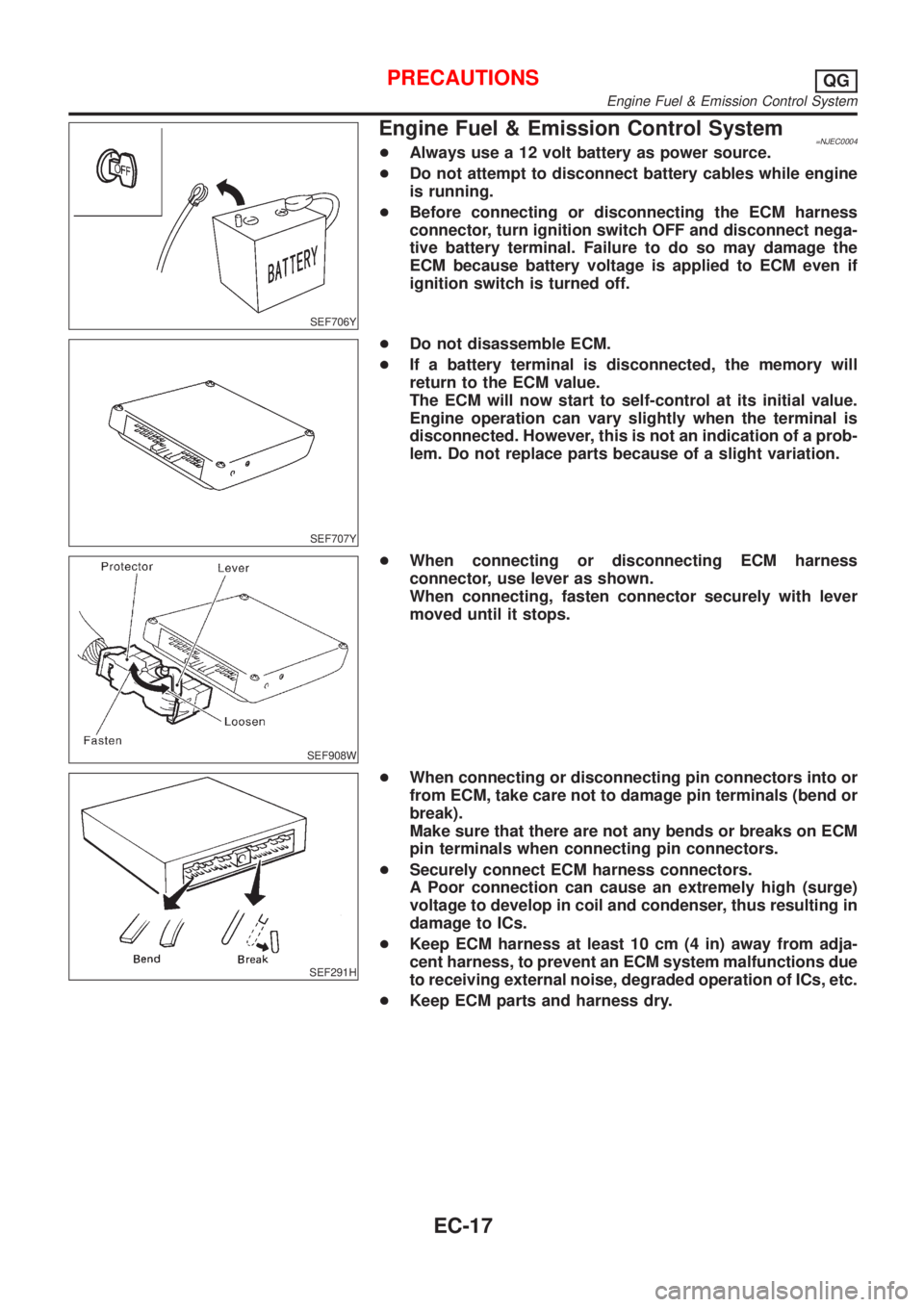

SEF706Y

Engine Fuel & Emission Control System=NJEC0004+Always use a 12 volt battery as power source.

+Do not attempt to disconnect battery cables while engine

is running.

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if

ignition switch is turned off.

SEF707Y

+Do not disassemble ECM.

+If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

SEF908W

+When connecting or disconnecting ECM harness

connector, use lever as shown.

When connecting, fasten connector securely with lever

moved until it stops.

SEF291H

+When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminals when connecting pin connectors.

+Securely connect ECM harness connectors.

A Poor connection can cause an extremely high (surge)

voltage to develop in coil and condenser, thus resulting in

damage to ICs.

+Keep ECM harness at least 10 cm (4 in) away from adja-

cent harness, to prevent an ECM system malfunctions due

to receiving external noise, degraded operation of ICs, etc.

+Keep ECM parts and harness dry.

PRECAUTIONSQG

Engine Fuel & Emission Control System

EC-17

Page 326 of 2493

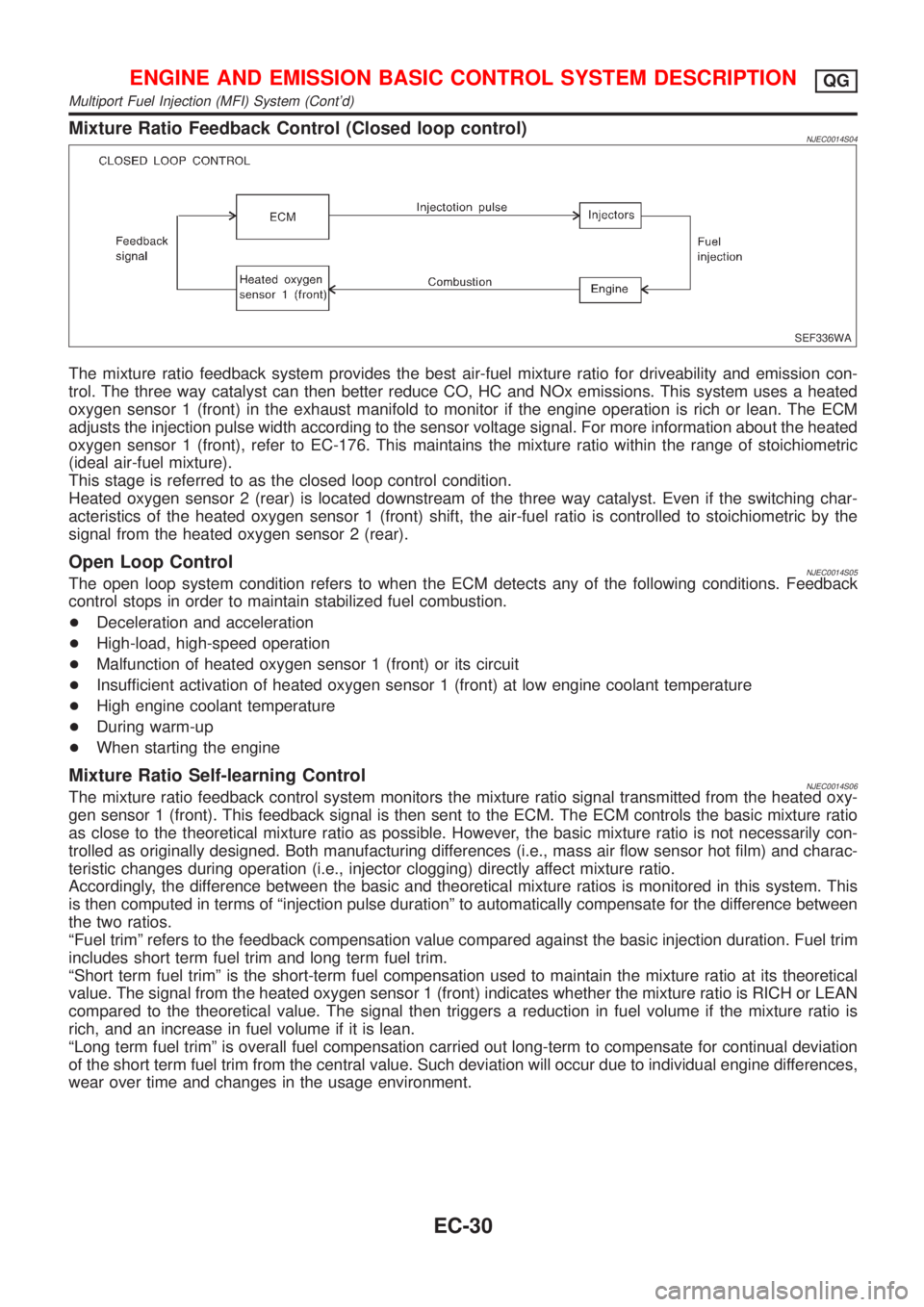

Mixture Ratio Feedback Control (Closed loop control)NJEC0014S04

SEF336WA

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission con-

trol. The three way catalyst can then better reduce CO, HC and NOx emissions. This system uses a heated

oxygen sensor 1 (front) in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about the heated

oxygen sensor 1 (front), refer to EC-176. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 (rear) is located downstream of the three way catalyst. Even if the switching char-

acteristics of the heated oxygen sensor 1 (front) shift, the air-fuel ratio is controlled to stoichiometric by the

signal from the heated oxygen sensor 2 (rear).

Open Loop ControlNJEC0014S05The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

+Deceleration and acceleration

+High-load, high-speed operation

+Malfunction of heated oxygen sensor 1 (front) or its circuit

+Insufficient activation of heated oxygen sensor 1 (front) at low engine coolant temperature

+High engine coolant temperature

+During warm-up

+When starting the engine

Mixture Ratio Self-learning ControlNJEC0014S06The mixture ratio feedback control system monitors the mixture ratio signal transmitted from the heated oxy-

gen sensor 1 (front). This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio

as close to the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily con-

trolled as originally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and charac-

teristic changes during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This

is then computed in terms of ªinjection pulse durationº to automatically compensate for the difference between

the two ratios.

ªFuel trimº refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

ªShort term fuel trimº is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from the heated oxygen sensor 1 (front) indicates whether the mixture ratio is RICH or LEAN

compared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is

rich, and an increase in fuel volume if it is lean.

ªLong term fuel trimº is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONQG

Multiport Fuel Injection (MFI) System (Cont'd)

EC-30

Page 335 of 2493

If results are unsatisfactory, perform Fuel Pressure Regulator

Check, EC-39.

SEF718B

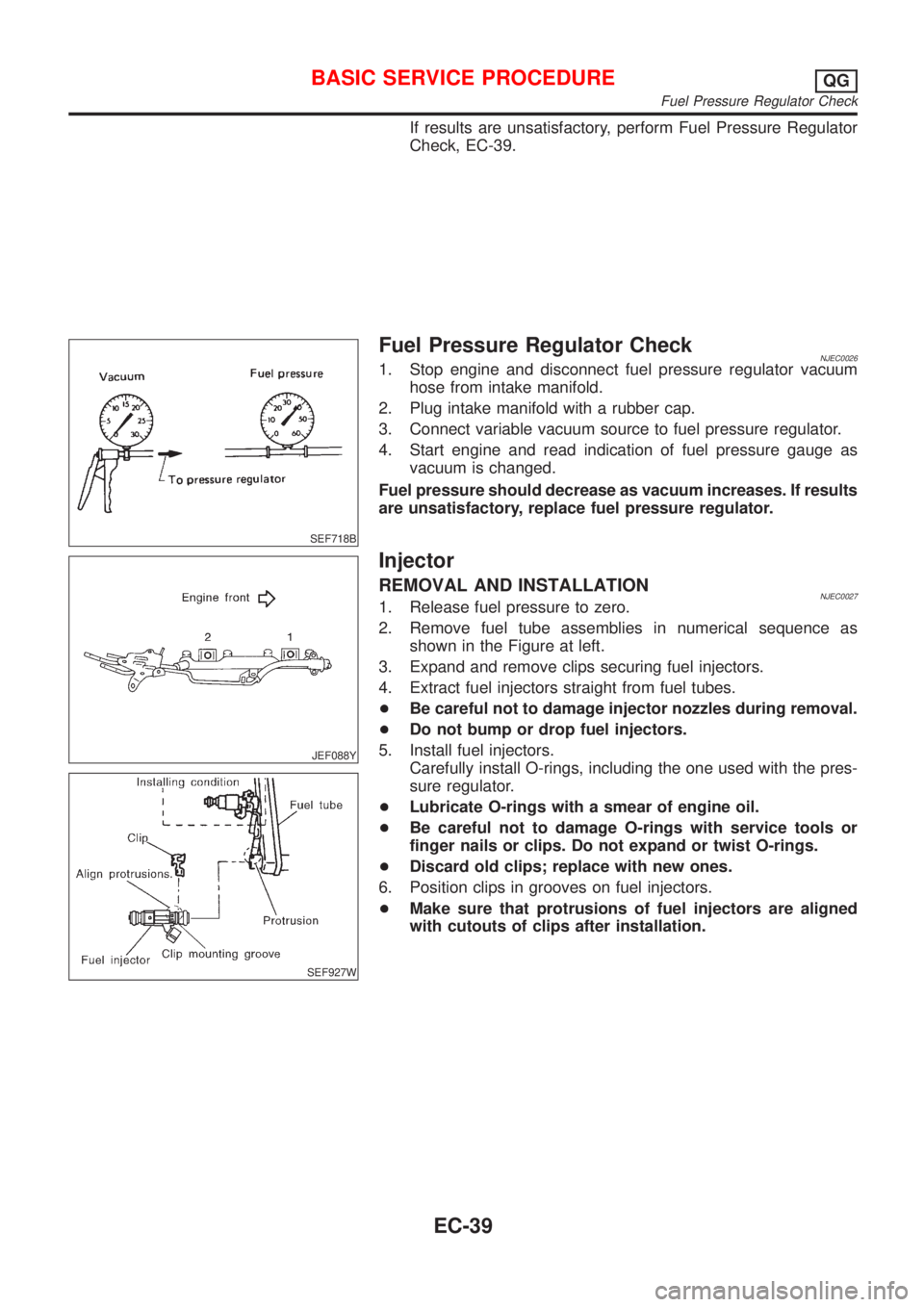

Fuel Pressure Regulator CheckNJEC00261. Stop engine and disconnect fuel pressure regulator vacuum

hose from intake manifold.

2. Plug intake manifold with a rubber cap.

3. Connect variable vacuum source to fuel pressure regulator.

4. Start engine and read indication of fuel pressure gauge as

vacuum is changed.

Fuel pressure should decrease as vacuum increases. If results

are unsatisfactory, replace fuel pressure regulator.

JEF088Y

SEF927W

Injector

REMOVAL AND INSTALLATIONNJEC00271. Release fuel pressure to zero.

2. Remove fuel tube assemblies in numerical sequence as

shown in the Figure at left.

3. Expand and remove clips securing fuel injectors.

4. Extract fuel injectors straight from fuel tubes.

+Be careful not to damage injector nozzles during removal.

+Do not bump or drop fuel injectors.

5. Install fuel injectors.

Carefully install O-rings, including the one used with the pres-

sure regulator.

+Lubricate O-rings with a smear of engine oil.

+Be careful not to damage O-rings with service tools or

finger nails or clips. Do not expand or twist O-rings.

+Discard old clips; replace with new ones.

6. Position clips in grooves on fuel injectors.

+Make sure that protrusions of fuel injectors are aligned

with cutouts of clips after installation.

BASIC SERVICE PROCEDUREQG

Fuel Pressure Regulator Check

EC-39

Page 339 of 2493

h)Fuel pressure

i)Engine compression

j)EGR valve operation

k)Throttle valve

l)EVAP system

+On models equipped with air conditioner, checks should

be carried out while the air conditioner is ªOFFº.

+When checking idle speed on models equipped with A/T,

ignition timing and mixture ratio, checks should be carried

out while shift lever is in ªPº or ªNº position.

+When measuring ªCOº percentage, insert probe more

than 40 cm (15.7 in) into tail pipe.

+Turn off headlamps, heater blower, rear window defogger.

+On vehicles equipped with daytime light systems, set

lighting switch to the 1st position to light only small

lamps.

+Keep front wheels pointed straight ahead.

+If engine stops immediately after starting or idle condition

is unstable, perform the following to initialize IACV-AAC

valve:

a)Stop engine and wait 9 seconds.

b)Turn ignition ªONº and wait 1 second.

c)Turn ignition ªOFFº and wait 9 seconds.

+Make sure the cooling fan has stopped.

BASIC SERVICE PROCEDUREQG

Preparation (Cont'd)

EC-43