Engine Control NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2937 of 3189

HEATER &

MANUAL AIR CONDITIONER

SECTION

HA

CONTENTS

MANUAL

PRECAUTIONS<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[2

Supplemental Restraint System (SRS)″AIR

BAG″and″SEAT BELT PRE-TENSIONER″...............2

Precautions for Working with HFC-134a (R-134a) .....2

General Refrigerant Precautions .................................2

Precautions for Refrigerant Connection ......................3

Precautions for Servicing Compressor ........................5

Precautions for Service Equipment .............................6

Wiring Diagrams and Trouble Diagnosis .....................8

PREPARATION<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[9

Special Service Tools ..................................................9

HFC-134a (R-134a) Service Tools and

Equipment <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[............10

DESCRIPTION<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[12

Refrigeration System .................................................12

CSV613 Variable Displacement Compressor............13

Component Layout ....................................................17

Control Operation ......................................................18

Discharge Air Flow.....................................................19

System Description ....................................................20

TROUBLE DIAGNOSES................................................21

Component Location..................................................21

Wiring Diagram - Heater............................................23

Circuit Diagram - Air Conditioner...............................24

Wiring Diagram - A/C, M - .........................................25

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................34Operational Check .....................................................35

Intake Door <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[...........37

Mode Door <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[..........41

Air Mix Door <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[..........43

Blower Motor<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[..........45

Magnet Clutch<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11[.........52

Insufficient Cooling ....................................................66

Insufficient Heating ....................................................75

Noise <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011001100110011[................76

SERVICE PROCEDURE................................................77

HFC-134a (R-134a) Service Procedure ....................77

Maintenance of Lubricant Quantity in

Compressor <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[..........79

Compressor <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[..........82

Compressor Clutch - CSV613 (CALSONIC

make) <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011001100110011[...............83

Heater & Cooling Unit (Heater Core) ........................87

A/C Evaporator ..........................................................87

Blower Unit <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[...........89

Refrigerant Lines .......................................................90

Belt <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[..................94

Ventilation Air Filter ....................................................95

SERVICE DATA AND SPECIFICATIONS (SDS).........96

Compressor <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[..........96

Lubricant <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..............96

Refrigerant <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[.............96

Engine Idling Speed (When A/C is On).....................96

Belt Tension <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........96

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SC

EL

IDX

Page 2949 of 3189

CSV613 Variable Displacement Compressor

GENERAL INFORMATIONNJHA02061. The CSV613 compressor differs from previous units. The vent temperatures of the CSV613 compressor

do not drop too far below 5°C (41°F) when:

evaporator intake air temperature is less than 20°C (68°F)

engine is running at speeds less than 1,500 rpm.

This is because the CSV613 compressor provides a means of “capacity” control.

2. The CSV613 compressor provides refrigerant control under varying conditions. During cold winters, it may

not produce high refrigerant pressure discharge (compared to previous units) when used with air condi-

tioning systems.

3. A “clanking” sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the CSV613 compressor, the clutch remains engaged unless: the sys-

tem main switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are

low or when the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.47 to 1.77 bar, 1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying con-

ditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTIONMANUAL

CSV613 Variable Displacement Compressor

HA-13

Page 2954 of 3189

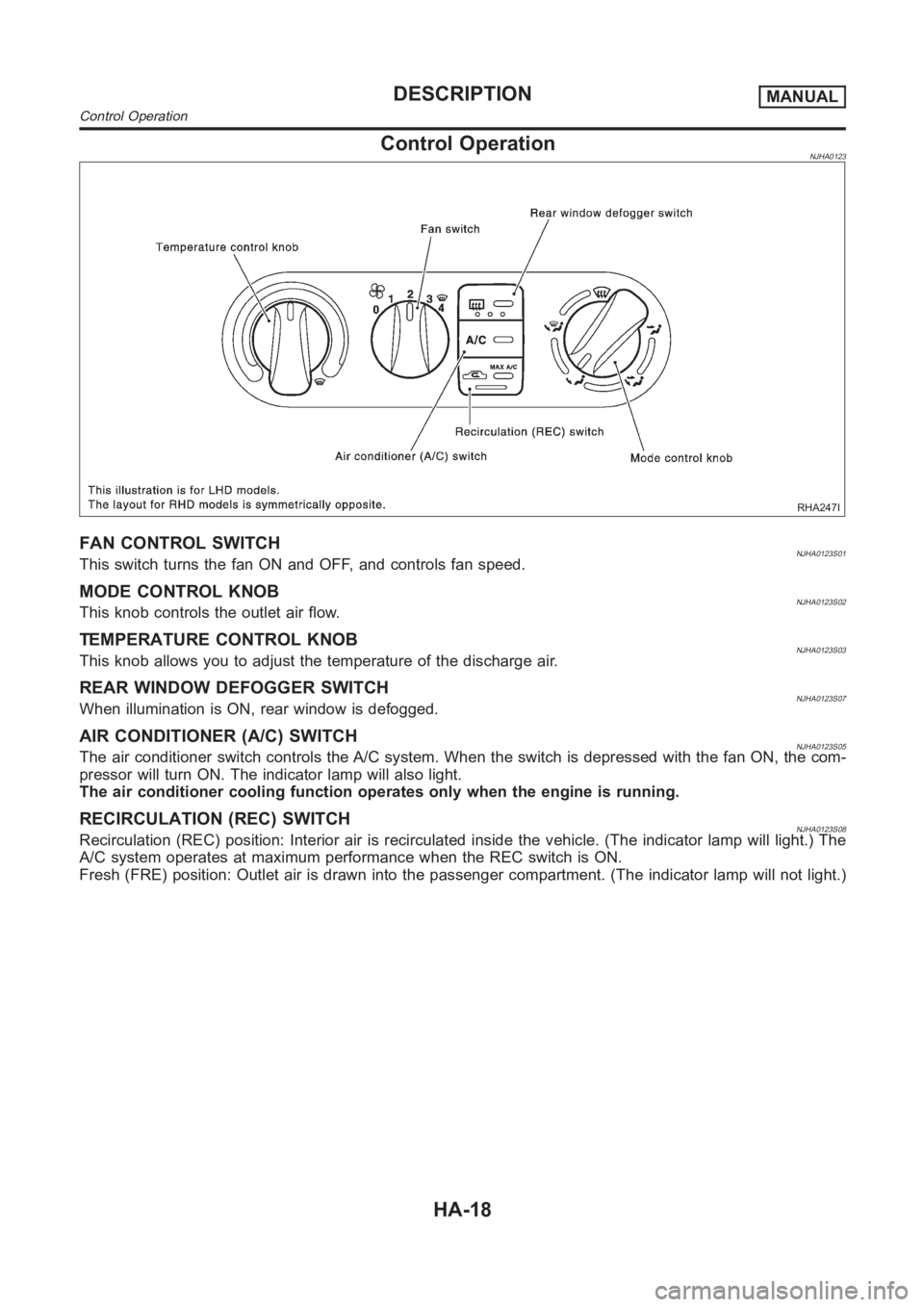

Control OperationNJHA0123

RHA247I

FAN CONTROL SWITCHNJHA0123S01This switch turns the fan ON and OFF, and controls fan speed.

MODE CONTROL KNOBNJHA0123S02This knob controls the outlet air flow.

TEMPERATURE CONTROL KNOBNJHA0123S03This knob allows you to adjust the temperature of the discharge air.

REAR WINDOW DEFOGGER SWITCHNJHA0123S07When illumination is ON, rear window is defogged.

AIR CONDITIONER (A/C) SWITCHNJHA0123S05The air conditioner switch controls the A/C system. When the switch is depressed with the fan ON, the com-

pressor will turn ON. The indicator lamp will also light.

The air conditioner cooling function operates only when the engine is running.

RECIRCULATION (REC) SWITCHNJHA0123S08Recirculation (REC) position: Interior air is recirculated inside the vehicle. (The indicator lamp will light.) The

A/C system operates at maximum performance when the REC switch is ON.

Fresh (FRE) position: Outlet air is drawn into the passenger compartment.(The indicator lamp will not light.)

DESCRIPTIONMANUAL

Control Operation

HA-18

Page 2971 of 3189

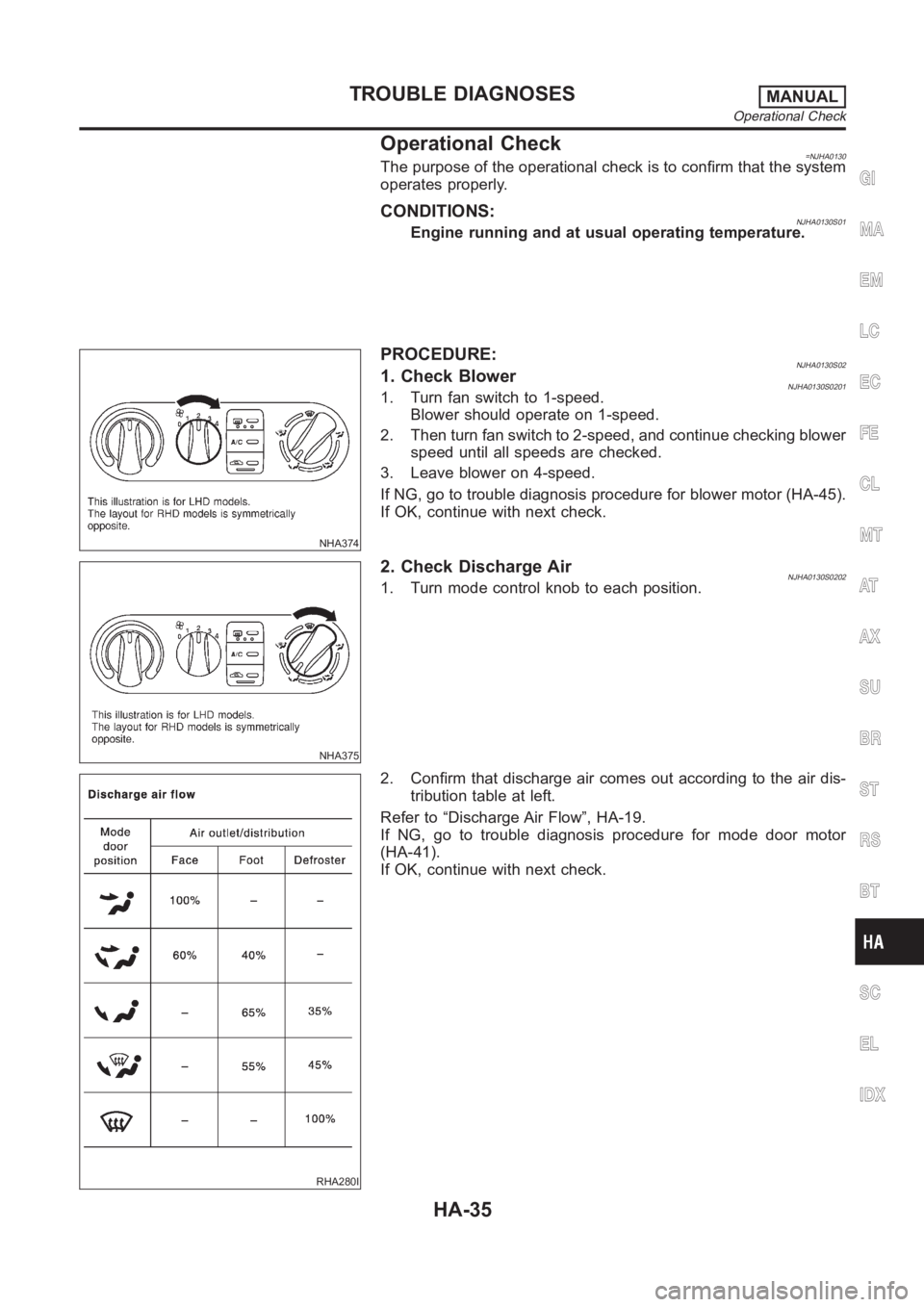

Operational Check=NJHA0130The purpose of the operational check is to confirm that the system

operates properly.

CONDITIONS:NJHA0130S01Engine running and at usual operating temperature.

NHA374

PROCEDURE:NJHA0130S021. Check BlowerNJHA0130S02011. Turn fan switch to 1-speed.

Blower should operate on 1-speed.

2. Then turn fan switch to 2-speed, and continue checking blower

speed until all speeds are checked.

3. Leave blower on 4-speed.

If NG, go to trouble diagnosis procedure for blower motor (HA-45).

If OK, continue with next check.

NHA375

2. Check Discharge AirNJHA0130S02021. Turn mode control knob to each position.

RHA280I

2. Confirm that discharge air comes out according to the air dis-

tribution table at left.

Refer to “Discharge Air Flow”, HA-19.

If NG, go to trouble diagnosis procedure for mode door motor

(HA-41).

If OK, continue with next check.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSESMANUAL

Operational Check

HA-35

Page 2992 of 3189

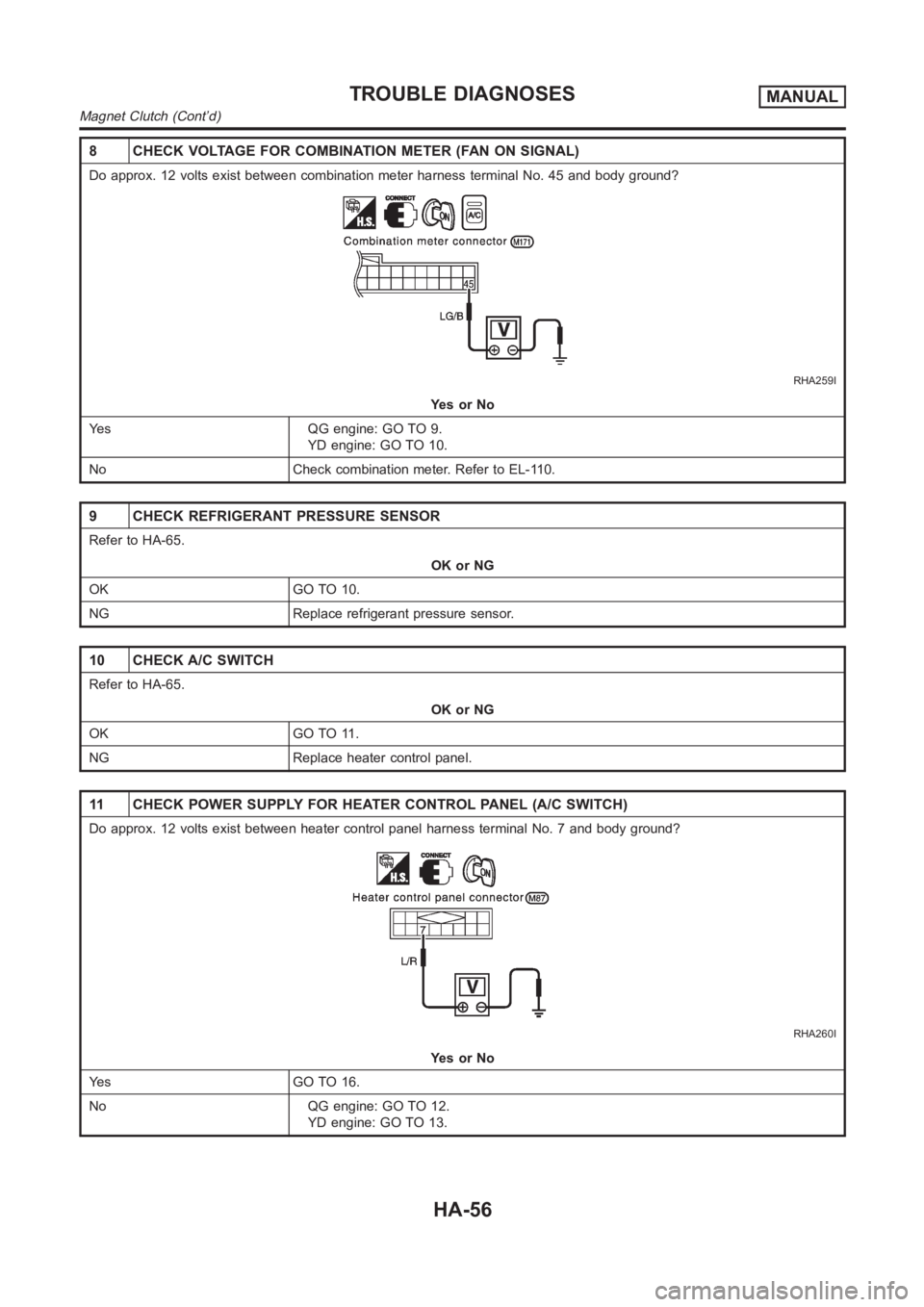

8 CHECK VOLTAGE FOR COMBINATION METER (FAN ON SIGNAL)

Do approx. 12 volts exist between combination meter harness terminal No. 45 and body ground?

RHA259I

YesorNo

Yes QG engine: GO TO 9.

YD engine: GO TO 10.

No Check combination meter. Refer to EL-110.

9 CHECK REFRIGERANT PRESSURE SENSOR

Refer to HA-65.

OK or NG

OK GO TO 10.

NG Replace refrigerant pressure sensor.

10 CHECK A/C SWITCH

Refer to HA-65.

OK or NG

OK GO TO 11.

NG Replace heater control panel.

11 CHECK POWER SUPPLY FOR HEATER CONTROL PANEL (A/C SWITCH)

Do approx. 12 volts exist between heater control panel harness terminal No. 7 and body ground?

RHA260I

YesorNo

Yes GO TO 16.

No QG engine: GO TO 12.

YD engine: GO TO 13.

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont’d)

HA-56

Page 2996 of 3189

20 CHECK CAN COMMUNICATION

Check CAN communication. Refer to EL-509.

Combination meter - Smart entrance control unit

Combination meter - ECM

ECM - Smart entrance control unit

OK or NG

OK INSPECTION END

NG Repair or replace malfunctioning part(s).

MAGNET CLUTCH CIRCUIT (YD ENGINE WITHOUT

COMMON RAIL)

NJHA0203SYMPTOM:

Magnet clutch does not engage when A/C switch and fan

switch are ON.

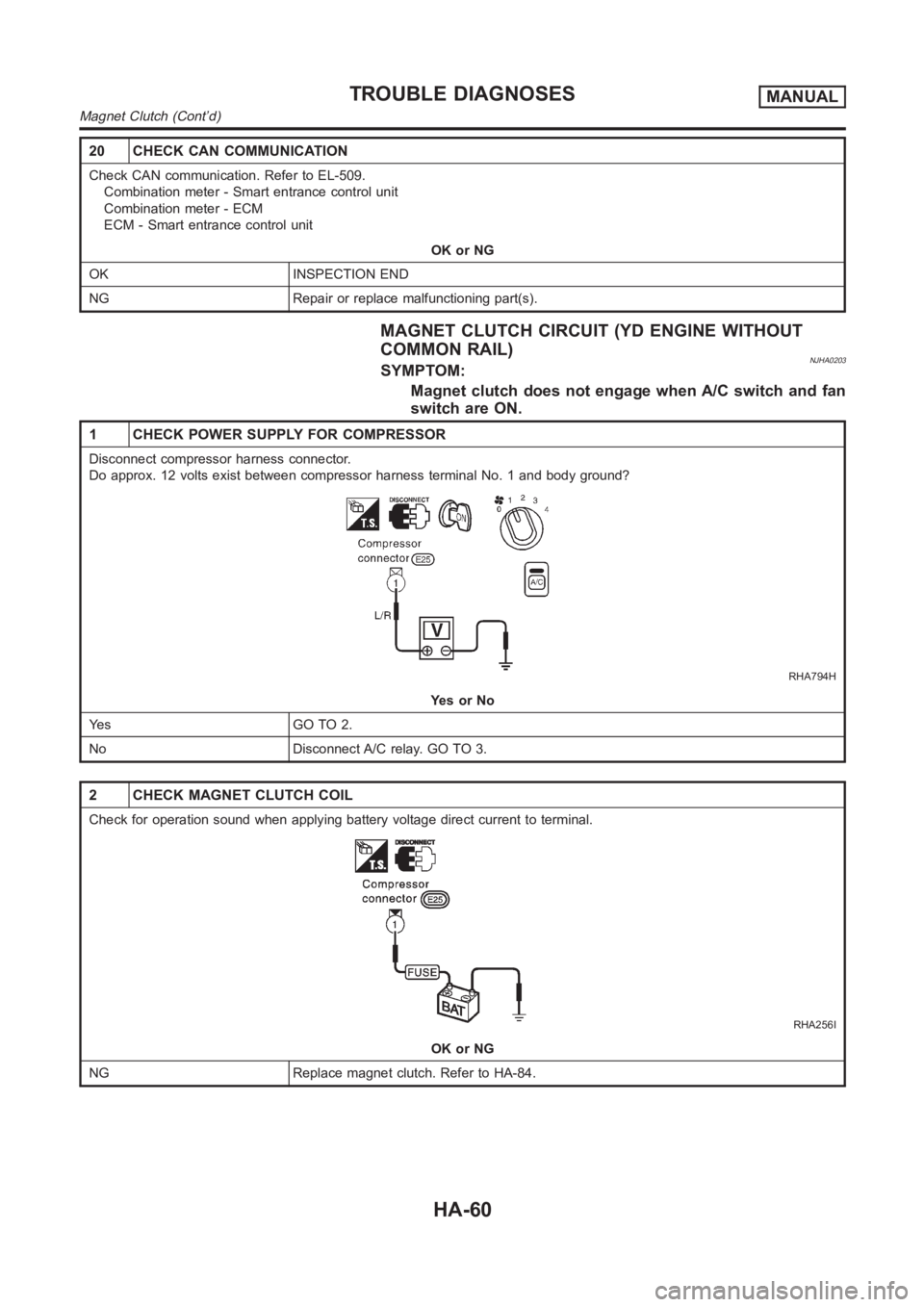

1 CHECK POWER SUPPLY FOR COMPRESSOR

Disconnect compressor harness connector.

Do approx. 12 volts exist between compressor harness terminal No. 1 and body ground?

RHA794H

YesorNo

Ye s G O T O 2 .

No Disconnect A/C relay. GO TO 3.

2 CHECK MAGNET CLUTCH COIL

Check for operation sound when applying battery voltage direct current toterminal.

RHA256I

OK or NG

NG Replace magnet clutch. Refer to HA-84.

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont’d)

HA-60

Page 3015 of 3189

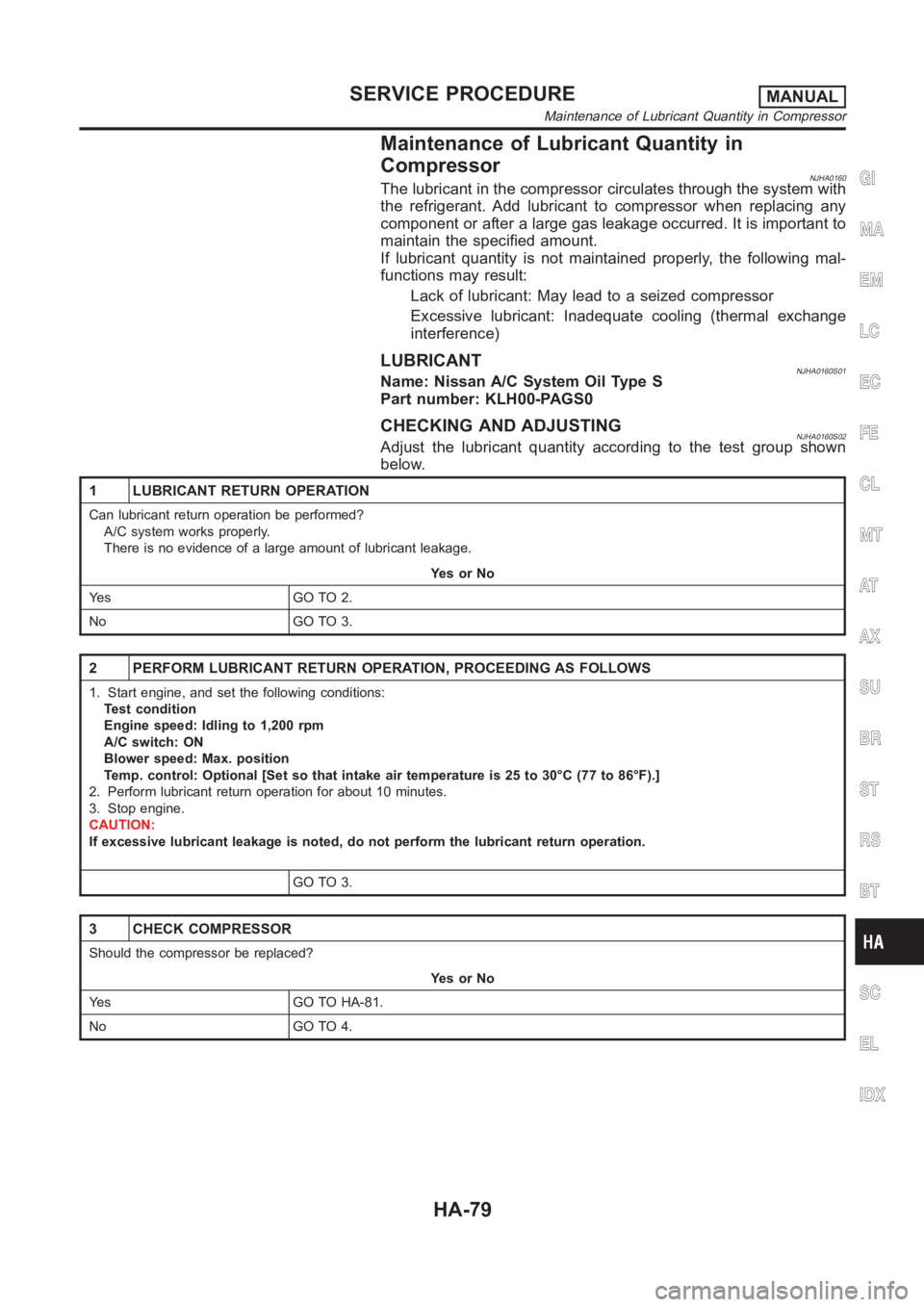

Maintenance of Lubricant Quantity in

Compressor

NJHA0160The lubricant in the compressor circulates through the system with

the refrigerant. Add lubricant to compressor when replacing any

component or after a large gas leakage occurred. It is important to

maintain the specified amount.

If lubricant quantity is not maintained properly, the following mal-

functions may result:

Lack of lubricant: May lead to a seized compressor

Excessive lubricant: Inadequate cooling (thermal exchange

interference)

LUBRICANTNJHA0160S01Name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

CHECKING AND ADJUSTINGNJHA0160S02Adjust the lubricant quantity according to the test group shown

below.

1 LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

A/C system works properly.

There is no evidence of a large amount of lubricant leakage.

YesorNo

Ye s G O T O 2 .

No GO TO 3.

2 PERFORM LUBRICANT RETURN OPERATION, PROCEEDING AS FOLLOWS

1. Start engine, and set the following conditions:

Test condition

Engine speed: Idling to 1,200 rpm

A/C switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to 30°C (77 to 86°F).]

2. Perform lubricant return operation for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

GO TO 3.

3 CHECK COMPRESSOR

Should the compressor be replaced?

YesorNo

Yes GO TO HA-81.

No GO TO 4.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SC

EL

IDX

SERVICE PROCEDUREMANUAL

Maintenance of Lubricant Quantity in Compressor

HA-79

Page 3030 of 3189

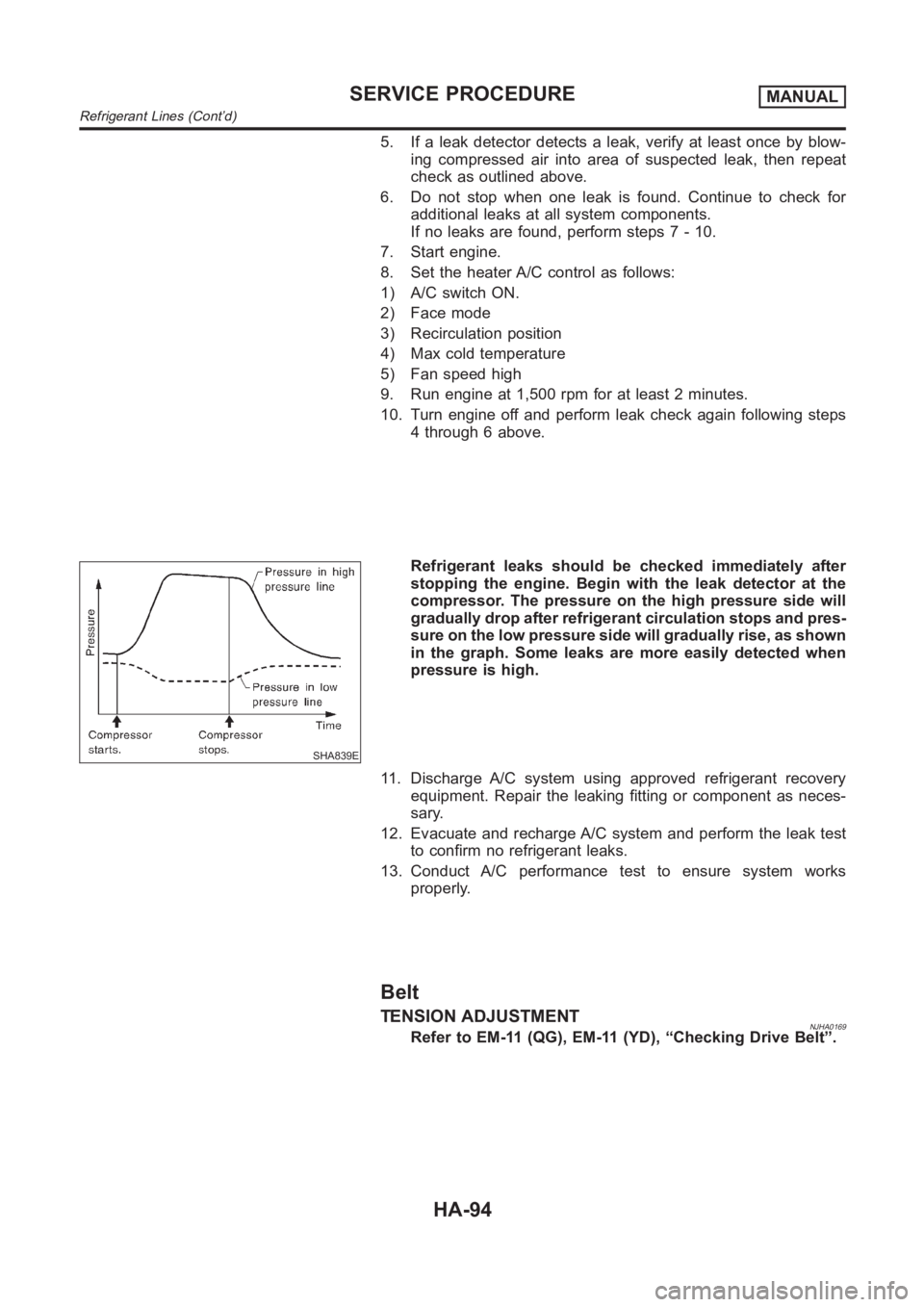

5. If a leak detector detects a leak, verify at least once by blow-

ing compressed air into area of suspected leak, then repeat

check as outlined above.

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows:

1) A/C switch ON.

2) Face mode

3) Recirculation position

4) Max cold temperature

5) Fan speed high

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps

4 through 6 above.

SHA839E

Refrigerant leaks should be checked immediately after

stopping the engine. Begin with the leak detector at the

compressor. The pressure on the high pressure side will

gradually drop after refrigerant circulation stops and pres-

sure on the low pressure side will gradually rise, as shown

in the graph. Some leaks are more easily detected when

pressure is high.

11. Discharge A/C system using approved refrigerant recovery

equipment. Repair the leaking fitting or component as neces-

sary.

12. Evacuate and recharge A/C system and perform the leak test

to confirm no refrigerant leaks.

13. Conduct A/C performance test to ensure system works

properly.

Belt

TENSION ADJUSTMENTNJHA0169Refer to EM-11 (QG), EM-11 (YD), “Checking Drive Belt”.

SERVICE PROCEDUREMANUAL

Refrigerant Lines (Cont’d)

HA-94

Page 3119 of 3189

System DescriptionNJSC0004M/T MODELSNJSC0004S01Power is supplied at all times

through 40A fusible link (letterB, located in the fuse and fusible link box)

to ignition switch terminal 1.

With the ignition switch in START position, power is supplied

from ignition switch terminal 5

to smart entrance control unit terminal 58

from smart entrance control unit terminal 59

to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between thebattery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

A/T MODELSNJSC0004S02Power is supplied at all times

through 40A fusible link (letterB, located in the fuse and fusible link box)

to ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

from ignition switch terminal 5

to park/neutral position relay terminal 5.

With the ignition switch ON or START position, power is supplied

through 10A fuse [No. 20, located in the fuse block (J/B)]

to park/neutral position (PNP) relay terminal 1.

With the selector lever in the P or N position, ground is supplied

to park/neutral position relay terminal 2 through the park/neutral position switch

to smart entrance control unit terminal 59

from smart entrance control unit terminal 58

from body grounds, F9 and F10.

Then park/neutral position relay is energized and power is supplied

from park/neutral position relay terminal 3

to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between thebattery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EL

IDX

STARTING SYSTEM

System Description

SC-13

Page 3133 of 3189

System DescriptionNJSC0009The alternator provides DC voltage to operate the vehicle’s electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

10A fuse (No. 39, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle’s electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 100A fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 30, located in the fuse block (J/B)]

to combination meter terminal 30

Ground is supplied to terminal 18 of the combination meter through terminal 3 (L) of the alternator. With power

and ground supplied, the charge warning lamp will illuminate. When the alternator is providing sufficient volt-

age with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

System Description

SC-27