Fuel gauge NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 58 of 3189

NJMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard tothe conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 59 of 3189

NJMA0004

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers dothem for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-16

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-7

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.—

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-4

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold. LC-18, LC-43

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-30

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.BR-7

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

GENERAL MAINTENANCE

MA-3

Page 135 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-57

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00LQH

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressu NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-57

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00LQH

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressu](/img/5/57350/w960_57350-134.png)

CYLINDER HEAD

EM-57

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00LQH

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-34, "

FUEL PRESSURE RELEASE" (WITH EURO-OBD), EC-427,

"FUEL PRESSURE RELEASE" (WITHOUT EURO-OBD).

3. Remove ignition coil and spark plug from each cylinder.

Refer to IGNITION COIL EM-24, "

Removal and Installation" and SPARK PLUG EM-25, "Removal and

Installation" .

4. Connect engine tachometer (not required in use of CONSULT-II).

5. Disconnect fuel injector harness connector so that no fuel is injected.

6. Install compression tester with adapter onto spark plug hole.

●Use compression gauge whose picking up end inserted to spark

plug hole is smaller than 20 mm (0.79 in) in diameter. Otherwise,

it may be caught by cylinder head during removal.

7. With accelerator pedal fully depressed, turn ignition switch to

“START” for cranking. When the gauge pointer stabilizes, read

the compression pressure and engine rpm. Perform these steps

to check each cylinder.

Compression pressure

[kPa (bar, kg/cm2 , psi)/rpm]

CAUTION:

Always use a fully changed battery to obtain specified engine speed.

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine speed

again with normal battery gravity.

●If compression pressure is below minimum value, check valve clearances and parts associated with com-

bustion chamber (Valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head gas-

ket). After the checking, measure compression pressure again.

●If some cylinders have low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

–If the added engine oil improves the compression, the piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

–If the compression pressure remains at low level despite the addition of engine oil, the valves may be mal-

functioning. Check the valves for damage. Replace the valve or valve seat accordingly.

●If two adjacent cylinders have respectively low compression pressure and their compression remains low

even after the addition of engine oil, the gaskets are leaking. In such a case, replace the cylinder head

gaskets.

KBIA1402E

Engine type QG15DE QG18DE

Standard1,372 (13.72, 13.99,

198.9)1,324 (13.24, 13.5, 192)

Limit 1,176 (11.76, 12.0, 170.5) 1,128 (11.28, 11.5, 164)

Difference limit among

cylinders98 (0.98, 1.0, 14) 98 (0.98, 1.0, 14)SEM387C

Page 193 of 3189

NJEM0053

JEM111G

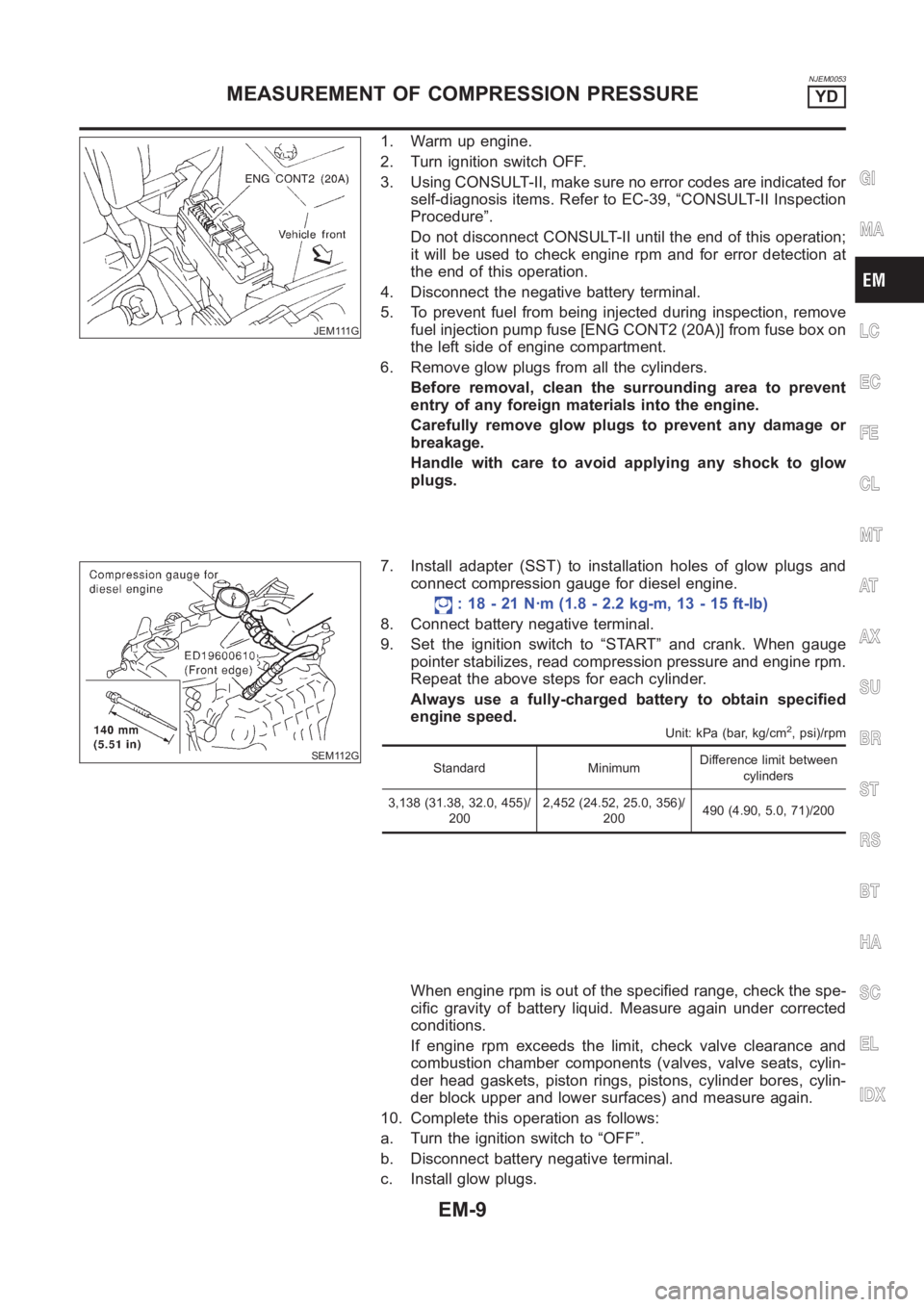

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC-39, “CONSULT-II Inspection

Procedure”.

Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT2 (20A)] from fuse box on

the left side of engine compartment.

6. Remove glow plugs from all the cylinders.

Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

Carefully remove glow plugs to prevent any damage or

breakage.

Handle with care to avoid applying any shock to glow

plugs.

SEM112G

7. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

: 18 - 21 N·m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

8. Connect battery negative terminal.

9. Set the ignition switch to “START” and crank. When gauge

pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

3,138 (31.38, 32.0, 455)/

2002,452 (24.52, 25.0, 356)/

200490 (4.90, 5.0, 71)/200

When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylin-

der head gaskets, piston rings, pistons, cylinder bores, cylin-

der block upper and lower surfaces) and measure again.

10. Complete this operation as follows:

a. Turn the ignition switch to “OFF”.

b. Disconnect battery negative terminal.

c. Install glow plugs.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MEASUREMENT OF COMPRESSION PRESSUREYD

EM-9

Page 364 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-34

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2 NISSAN ALMERA N16 2003 Electronic Repair Manual EC-34

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2](/img/5/57350/w960_57350-363.png)

EC-34

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2.Check PCV valve operation.

3.Check that downstream of throttle valve is free from air leakage.

4.When the above three items check out OK, engine component parts and their installation condi-

tion are questionable. Check and eliminate the cause of the incident.

It is useful to perform EC-105, "

TROUBLE DIAGNOSIS - SPECIFICATION VALUE" .

5.If any of the following conditions occur after the engine has started, eliminate the cause of the

incident and perform “Idle air volume learning” all over again:

–Engine stalls.

–Erroneous idle.

Fuel Pressure CheckEBS00K3E

FUEL PRESSURE RELEASE

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pres-

sure cannot be completely released because N16 models do not have fuel return system.

With CONSULT-II

1. Turn ignition switch “ON”.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch “OFF”.

Without CONSULT-II

1. Remove fuel pump fuse located in fuse box.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch “OFF”.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

NOTE:

●When reconnecting fuel line, always use new clamps.

●Make sure that clamp screw does not contact adjacent parts.

●Use a torque driver to tighten clamps.

●Use Pressure Gauge to check fuel pressure.

1. Release fuel pressure to zero. Refer to EC-34, "

FUEL PRESSURE RELEASE" .

SEF214Y

MBIB0262E

Page 365 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-35

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

2. Install the fuel pressure gauge into the fuel line as shown in the

figure.

3. Turn ignition switch “ON”, and check f NISSAN ALMERA N16 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-35

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

2. Install the fuel pressure gauge into the fuel line as shown in the

figure.

3. Turn ignition switch “ON”, and check f](/img/5/57350/w960_57350-364.png)

BASIC SERVICE PROCEDURE

EC-35

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

2. Install the fuel pressure gauge into the fuel line as shown in the

figure.

3. Turn ignition switch “ON”, and check for fuel leakage.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

6. If result is unsatisfactory, go to next step.

7. Check the following.

●Fuel hoses and fuel tubes for clogging

●Fuel filter for clogging

●Fuel pump

●Fuel pressure regulator for clogging

If OK, replace fuel pressure regulator.

If NG, repair or replace.At idling:

Approximately 350 kPa (3.5 bar, 3.57 kg/cm

2

, 51 psi)

MBIB0050E

Page 382 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-52

[QG (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

codes can be identified by using the CONSULT-II or GST. A DTC will be used as an example for how to read a

code.

A particular trouble code c NISSAN ALMERA N16 2003 Electronic Repair Manual EC-52

[QG (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

codes can be identified by using the CONSULT-II or GST. A DTC will be used as an example for how to read a

code.

A particular trouble code c](/img/5/57350/w960_57350-381.png)

EC-52

[QG (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

codes can be identified by using the CONSULT-II or GST. A DTC will be used as an example for how to read a

code.

A particular trouble code can be identified by the number of four-digit numeral flashes. The “zero” is indicated

by the number of ten flashes. The length of time the 1,000th-digit numeral flashes on and off is 1.2 seconds

consisting of an ON (0.6-second) - OFF (0.6-second) cycle.

The 100th-digit numeral and lower digit numerals consist of a 0.3-second ON and 0.3-second OFF cycle.

A change from one digit numeral to another occurs at an interval of 1.0-second OFF. In other words, the later

numeral appears on the display 1.3 seconds after the former numeral has disappeared.

A change from one trouble code to another occurs at an interval of 1.8-second OFF.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC “0000” refers to no

malfunction. (See EC-10, "

INDEX FOR DTC" )

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

The DTC can be erased from the back up memory in the ECM by depressing accelerator pedal. Refer to EC-

51, "HOW TO SWITCH DIAGNOSTIC TEST MODE" .

●If the battery is disconnected, the DTC will be lost from the backup memory after approx 24 hours.

●Be careful not to erase the stored memory before starting trouble diagnoses.

DIAGNOSTIC TEST MODE II — HEATED OXYGEN SENSOR 1 MONITOR

In this mode, the MI displays the condition of the fuel mixture (lean or rich) which is monitored by the heated

oxygen sensor 1.

*: Maintains conditions just before switching to open loop.

To check the heated oxygen sensor 1 function, start engine in the Diagnostic Test Mode II and warm it up until

engine coolant temperature indicator points to the middle of the gauge.

Next run engine at about 2,000 rpm for about 2 minutes under no-load conditions. Then make sure that the MI

comes ON more than 5 times within 10 seconds with engine running at 2,000 rpm under no-load.

OBD System Operation ChartEBS00K3K

RELATIONSHIP BETWEEN MI, 1ST TRIP DTC, DTC, AND DETECTABLE ITEMS

●When a malfunction is detected for the first time, the 1st trip DTC and the 1st trip freeze frame data are

stored in the ECM memory.

●When the same malfunction is detected in two consecutive trips, the DTC and the freeze frame data are

stored in the ECM memory, and the MI will come on. For details, refer to EC-36, "

Two Trip Detection

Logic" .

SEF952W

MI Fuel mixture condition in the exhaust gas Air fuel ratio feedback control condition

ON Lean

Closed loop system

OFF Rich

*Remains ON or OFF Any condition Open loop system

Page 520 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-190

[QG (WITH EURO-OBD)]

DTC P0171 FUEL INJECTION SYSTEM FUNCTION

4. CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-34, "

FUEL PRESSURE RELEASE" .

2. Install fuel pressur NISSAN ALMERA N16 2003 Electronic Repair Manual EC-190

[QG (WITH EURO-OBD)]

DTC P0171 FUEL INJECTION SYSTEM FUNCTION

4. CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-34, "

FUEL PRESSURE RELEASE" .

2. Install fuel pressur](/img/5/57350/w960_57350-519.png)

EC-190

[QG (WITH EURO-OBD)]

DTC P0171 FUEL INJECTION SYSTEM FUNCTION

4. CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-34, "

FUEL PRESSURE RELEASE" .

2. Install fuel pressure gauge and check fuel pressure. Refer to EC-34, "

FUEL PRESSURE CHECK" .

OK or NG

OK >> GO TO 5.

NG >> Follow the construction of “FUEL PRESSURE CHECK”.

5. CHECK MASS AIR FLOW SENSOR

With CONSULT-II

1. Install all removed parts.

2. Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT-II.

With GST

1. Install all removed parts.

2. Check mass air flow sensor signal in MODE 1 with GST.

OK or NG

OK >> GO TO 6.

NG >> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

engine grounds. Refer to EC-134, "

DTC P0102, P0103 MAF SENSOR" . At idling: Approximately 350 kPa (3.5 bar, 3.57 kg/cm

2 , 51 psi)

1.0 - 4.0 g·m/sec: at idling

5.0 - 10 g·m/sec: at 2,500 rpm

1.0 - 4.0 g·m/sec: at idling

5.0 - 10 g·m/sec: at 2,500 rpm

Page 526 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-196

[QG (WITH EURO-OBD)]

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

Diagnostic Procedure

EBS00K6X

1. CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak befor NISSAN ALMERA N16 2003 Electronic Repair Manual EC-196

[QG (WITH EURO-OBD)]

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

Diagnostic Procedure

EBS00K6X

1. CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak befor](/img/5/57350/w960_57350-525.png)

EC-196

[QG (WITH EURO-OBD)]

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

Diagnostic Procedure

EBS00K6X

1. CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before three way catalyst (manifold).

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

2. CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace.

3. CHECK HEATED OXYGEN SENSOR 1 CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch “OFF”.

2. Disconnect heated oxygen sensor 1 (HO2S1) harness connec-

tor.

3. Disconnect ECM harness connector.

4. Check harness continuity between ECM terminal 35 and HO2S1

terminal 2, ECM terminal 74 and HO2S1 terminal 3.

Refer to Wiring Diagram.

5. Check harness continuity between ECM terminals 35 or HO2S1

terminals 2 and ground.

Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4. CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-34, "

FUEL PRESSURE RELEASE" .

2. Install fuel pressure gauge and check fuel pressure. Refer to EC-34, "

FUEL PRESSURE CHECK" .

OK or NG

OK >> GO TO 5.

NG >> Follow the construction of “FUEL PRESSURE CHECK”.

SEC502D

Continuity should exist.

Continuity should not exist.

MBIB0091E

At idling: 350 kPa (3.5 bar, 3.57 kg/cm2, 51 psi)

Page 558 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-228

[QG (WITH EURO-OBD)]

DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

6. CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

OK or NG

OK >> GO TO 7.

NG NISSAN ALMERA N16 2003 Electronic Repair Manual EC-228

[QG (WITH EURO-OBD)]

DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

6. CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

OK or NG

OK >> GO TO 7.

NG](/img/5/57350/w960_57350-557.png)

EC-228

[QG (WITH EURO-OBD)]

DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

6. CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace spark plug(s) with standard type

one(s). For spark plug type, refer to MA-7.

7. CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-57, "

CHECKING COMPRESSION PRESSURE" .

QG15DE engine

QG18DE engine

OK or NG

OK >> GO TO 8.

NG >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

8. CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-34, "

FUEL PRESSURE RELEASE" .

3. Install fuel pressure gauge and check fuel pressure. Refer to EC-34, "

FUEL PRESSURE CHECK" .

OK or NG

OK >> GO TO 9.

NG >> Follow the construction of “FUEL PRESSURE CHECK”.

SEF156I

Standard:

1,372 kPa (13.720 bar, 13.99 kg/cm2 , 198.9 psi)/350 rpm

Minimum:

1,176 kPa (11.759 bar, 11.99 kg/cm

2 , 170.5 psi)/350 rpm

Difference between each

cylinder:98 kPa (0.98 bar, 1.0 kg/cm

2 , 14 psi)/350 rpm

Standard:

1,324 kPa (13.24 bar, 13.5 kg/cm

2 , 192 psi)/350 rpm

Minimum:

1,128 kPa (11.28 bar, 11.5 kg/cm

2 , 164 psi)/350 rpm

Difference between each

cylinder:98 kPa (0.98 bar, 1.0 kg/cm

2 , 14 psi)/350 rpm

At idle: Approx. 350 kPa (3.5 bar, 3.57 kg/cm

2 , 51 psi)