MT- NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 61 of 3189

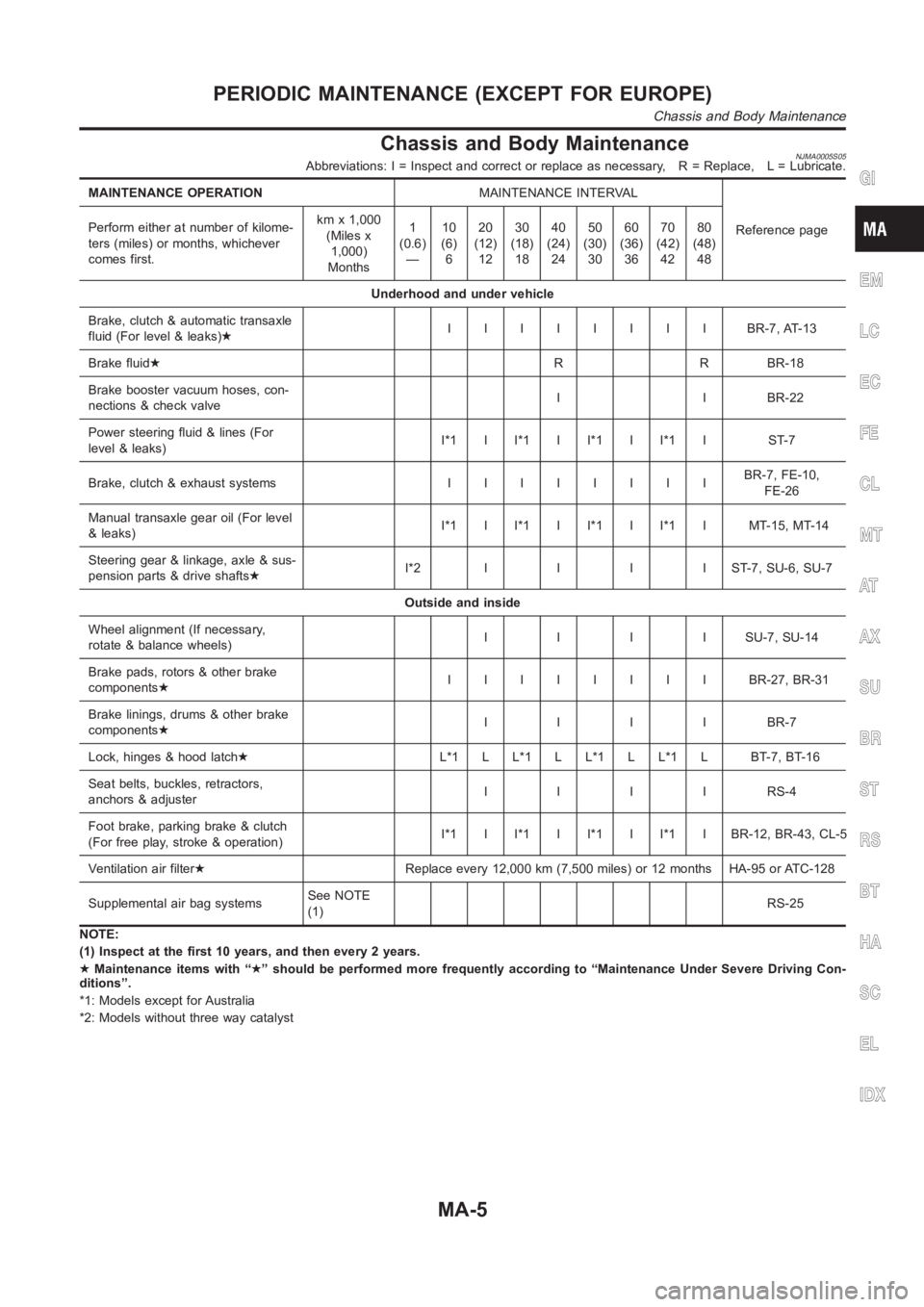

Chassis and Body MaintenanceNJMA0005S05Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page Perform either at number of kilome-

ters (miles) or months, whichever

comes first.kmx1,000

(Miles x

1,000)

Months1

(0.6)

—10

(6)

620

(12)

1230

(18)

1840

(24)

2450

(30)

3060

(36)

3670

(42)

4280

(48)

48

Underhood and under vehicle

Brake, clutch & automatic transaxle

fluid (For level & leaks)★IIIIIIII BR-7,AT-13

Brake fluid★R R BR-18

Brake booster vacuum hoses, con-

nections & check valveI I BR-22

Power steering fluid & lines (For

level & leaks)I*1 I I*1 I I*1 I I*1 I ST-7

Brake, clutch & exhaust systemsIIIIIIIIBR-7, FE-10,

FE-26

Manual transaxle gear oil (For level

& leaks)I*1 I I*1 I I*1 I I*1 I MT-15, MT-14

Steering gear & linkage, axle & sus-

pension parts & drive shafts★I*2IIIIST-7,SU-6,SU-7

Outside and inside

Wheel alignment (If necessary,

rotate & balance wheels)IIIISU-7,SU-14

Brake pads, rotors & other brake

components★IIIIIIII BR-27,BR-31

Brake linings, drums & other brake

components★IIIIBR-7

Lock, hinges & hood latch★L*1 L L*1 L L*1 L L*1 L BT-7, BT-16

Seat belts, buckles, retractors,

anchors & adjusterIIIIRS-4

Foot brake, parking brake & clutch

(For free play, stroke & operation)I*1 I I*1 I I*1 I I*1 I BR-12, BR-43, CL-5

Ventilation air filter★Replace every 12,000 km (7,500 miles) or 12 months HA-95 or ATC-128

Supplemental air bag systemsSee NOTE

(1)RS-25

NOTE:

(1) Inspect at the first 10 years, and then every 2 years.

★Maintenance items with “★” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

*1: Models except for Australia

*2: Models without three way catalystGI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Chassis and Body Maintenance

MA-5

Page 64 of 3189

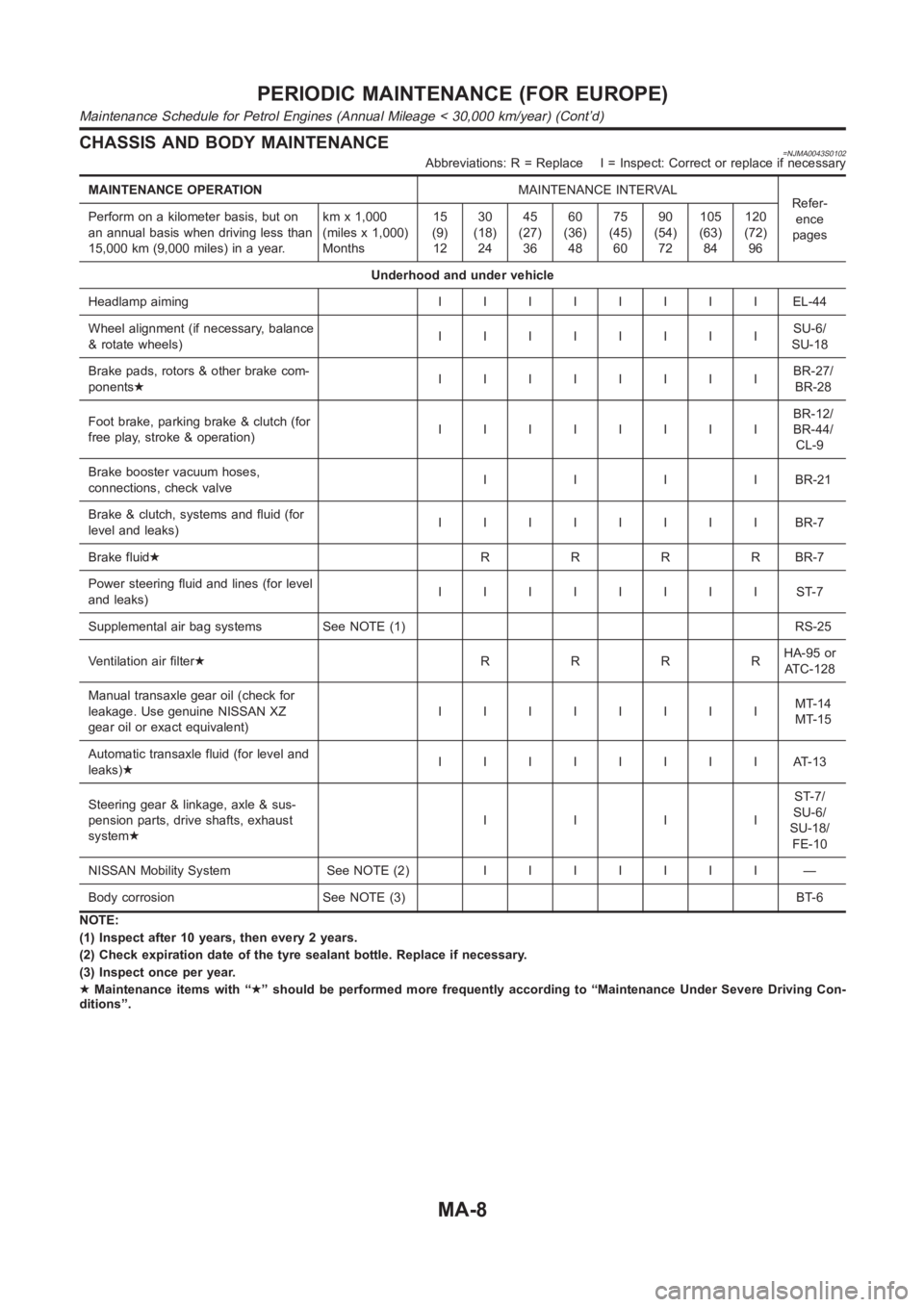

CHASSIS AND BODY MAINTENANCE=NJMA0043S0102Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis, but on

an annual basis when driving less than

15,000 km (9,000 miles) in a year.kmx1,000

(miles x 1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Underhood and under vehicle

Headlamp aimingIIIIIIIIEL-44

Wheel alignment (if necessary, balance

& rotate wheels)IIIIIIIISU-6/

SU-18

Brake pads, rotors & other brake com-

ponents★IIIIIIIIBR-27/

BR-28

Foot brake, parking brake & clutch (for

free play, stroke & operation)IIIIIIIIBR-12/

BR-44/

CL-9

Brake booster vacuum hoses,

connections, check valveIIIIBR-21

Brake & clutch, systems and fluid (for

level and leaks)IIIIIIIIBR-7

Brake fluid★RRRRBR-7

Power steering fluid and lines (for level

and leaks)IIIIIIIIST-7

Supplemental air bag systems See NOTE (1) RS-25

Ventilation air filter★RRRRHA-95 or

AT C - 1 2 8

Manual transaxle gear oil (check for

leakage. Use genuine NISSAN XZ

gear oil or exact equivalent)IIIIIIIIMT-14

MT-15

Automatic transaxle fluid (for level and

leaks)★IIIIIIIIAT-13

Steering gear & linkage, axle & sus-

pension parts, drive shafts, exhaust

system★IIIIST-7/

SU-6/

SU-18/

FE-10

NISSAN Mobility System See NOTE (2)IIIIIII —

Body corrosion See NOTE (3) BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

★Maintenance items with “★” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage < 30,000 km/year) (Cont’d)

MA-8

Page 66 of 3189

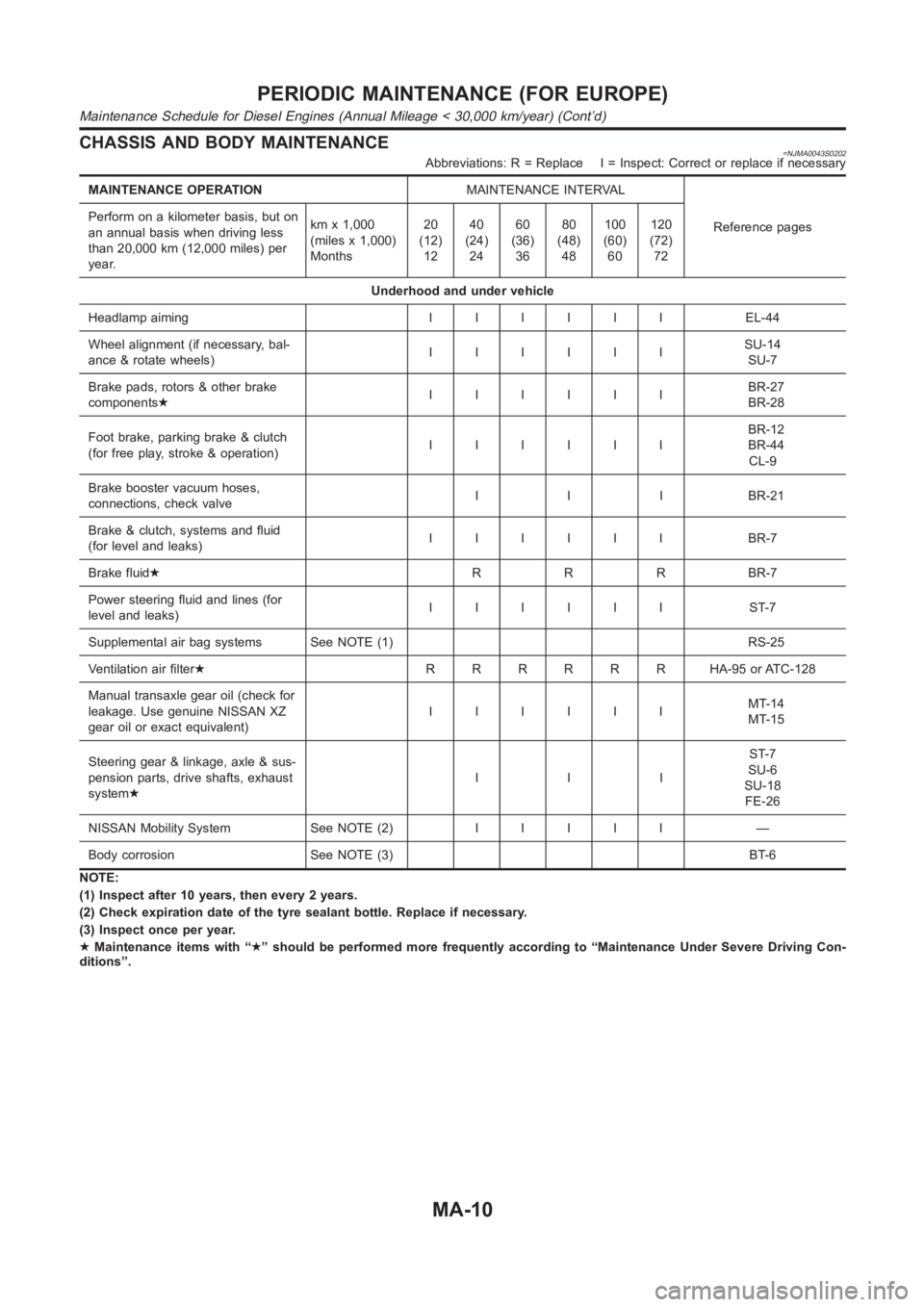

CHASSIS AND BODY MAINTENANCE=NJMA0043S0202Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference pages Perform on a kilometer basis, but on

an annual basis when driving less

than 20,000 km (12,000 miles) per

year.kmx1,000

(miles x 1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Underhood and under vehicle

Headlamp aimingIIIIII EL-44

Wheel alignment (if necessary, bal-

ance & rotate wheels)IIIIIISU-14

SU-7

Brake pads, rotors & other brake

components★IIIIIIBR-27

BR-28

Foot brake, parking brake & clutch

(for free play, stroke & operation)IIIIIIBR-12

BR-44

CL-9

Brake booster vacuum hoses,

connections, check valveI I I BR-21

Brake & clutch, systems and fluid

(for level and leaks)IIIIII BR-7

Brake fluid★R R R BR-7

Power steering fluid and lines (for

level and leaks)IIIIII ST-7

Supplemental air bag systems See NOTE (1) RS-25

Ventilation air filter★RRRRRR HA-95orATC-128

Manual transaxle gear oil (check for

leakage. Use genuine NISSAN XZ

gear oil or exact equivalent)IIIIIIMT-14

MT-15

Steering gear & linkage, axle & sus-

pension parts, drive shafts, exhaust

system★IIIST-7

SU-6

SU-18

FE-26

NISSAN Mobility System See NOTE (2)IIIII —

Body corrosion See NOTE (3) BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

★Maintenance items with “★” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Diesel Engines (Annual Mileage < 30,000 km/year) (Cont’d)

MA-10

Page 70 of 3189

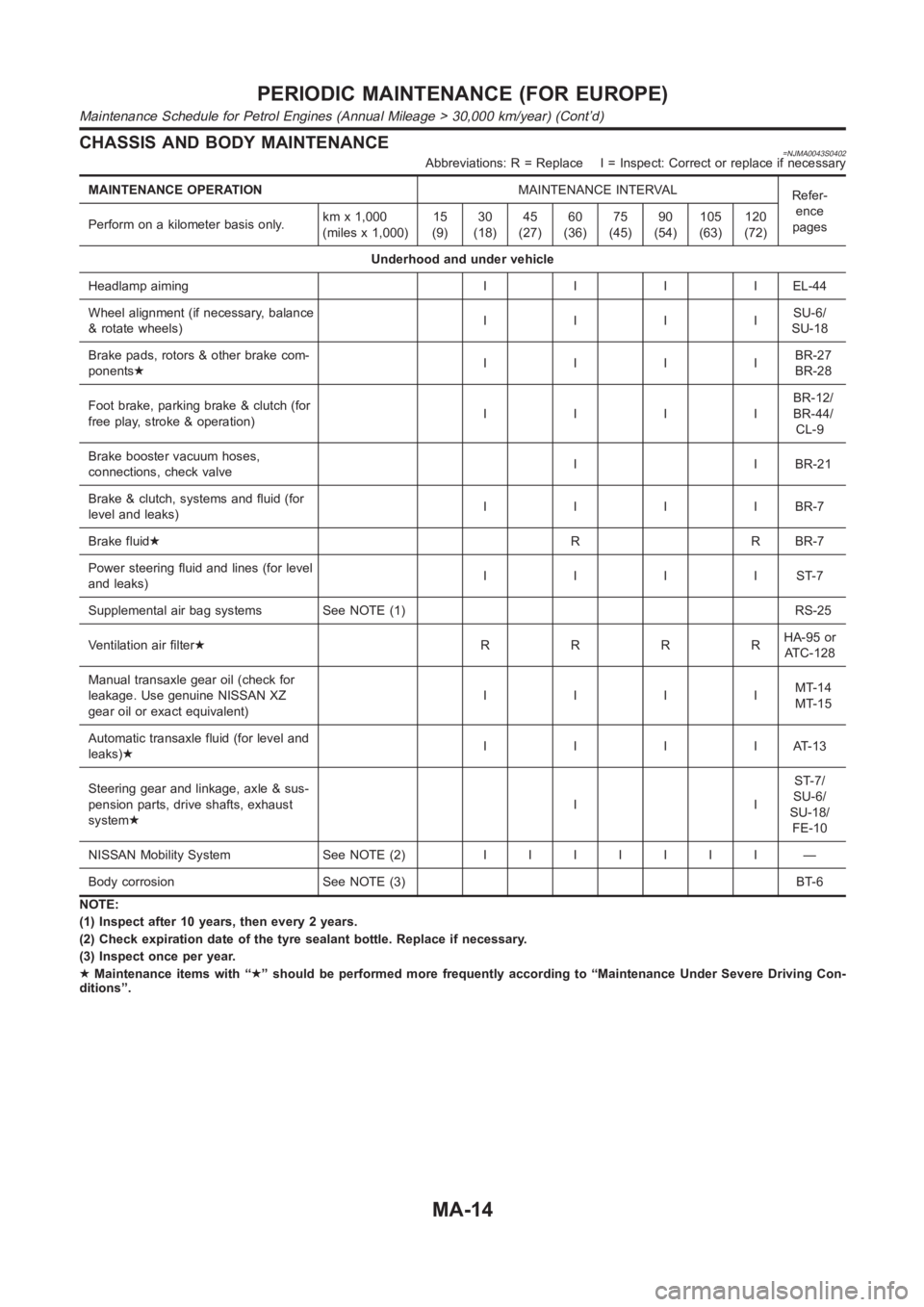

CHASSIS AND BODY MAINTENANCE=NJMA0043S0402Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis only.kmx1,000

(miles x 1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Underhood and under vehicle

Headlamp aimingIIIIEL-44

Wheel alignment (if necessary, balance

& rotate wheels)IIIISU-6/

SU-18

Brake pads, rotors & other brake com-

ponents★IIIIBR-27

BR-28

Foot brake, parking brake & clutch (for

free play, stroke & operation)IIIIBR-12/

BR-44/

CL-9

Brake booster vacuum hoses,

connections, check valveI I BR-21

Brake & clutch, systems and fluid (for

level and leaks)IIIIBR-7

Brake fluid★R R BR-7

Power steering fluid and lines (for level

and leaks)IIIIST-7

Supplemental air bag systems See NOTE (1) RS-25

Ventilation air filter★RRRRHA-95 or

AT C - 1 2 8

Manual transaxle gear oil (check for

leakage. Use genuine NISSAN XZ

gear oil or exact equivalent)IIIIMT-14

MT-15

Automatic transaxle fluid (for level and

leaks)★IIIIAT-13

Steering gear and linkage, axle & sus-

pension parts, drive shafts, exhaust

system★IIST-7/

SU-6/

SU-18/

FE-10

NISSAN Mobility System See NOTE (2)IIIIIII —

Body corrosion See NOTE (3) BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

★Maintenance items with “★” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage > 30,000 km/year) (Cont’d)

MA-14

Page 72 of 3189

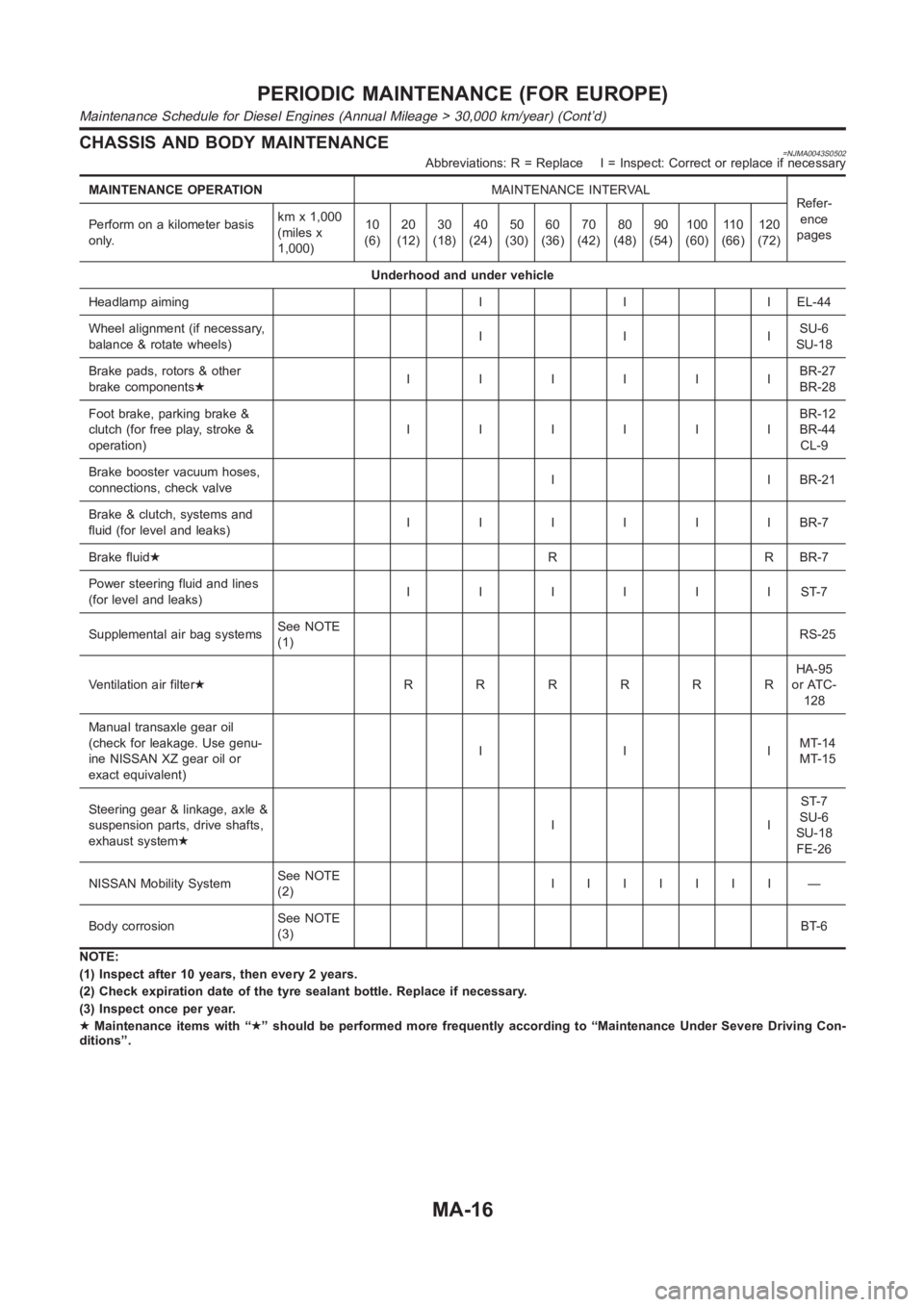

CHASSIS AND BODY MAINTENANCE=NJMA0043S0502Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis

only.kmx1,000

(miles x

1,000)10

(6)20

(12)30

(18)40

(24)50

(30)60

(36)70

(42)80

(48)90

(54)100

(60)11 0

(66)120

(72)

Underhood and under vehicle

Headlamp aiming I I I EL-44

Wheel alignment (if necessary,

balance & rotate wheels)IIISU-6

SU-18

Brake pads, rotors & other

brake components★IIIIIIBR-27

BR-28

Foot brake, parking brake &

clutch (for free play, stroke &

operation)IIIIIIBR-12

BR-44

CL-9

Brake booster vacuum hoses,

connections, check valveI I BR-21

Brake & clutch, systems and

fluid (for level and leaks)IIIIIIBR-7

Brake fluid★R R BR-7

Power steering fluid and lines

(for level and leaks)IIIIIIST-7

Supplemental air bag systemsSee NOTE

(1)RS-25

Ventilation air filter★RRRRRRHA-95

or ATC-

128

Manual transaxle gear oil

(check for leakage. Use genu-

ine NISSAN XZ gear oil or

exact equivalent)IIIMT-14

MT-15

Steering gear & linkage, axle &

suspension parts, drive shafts,

exhaust system★IIST-7

SU-6

SU-18

FE-26

NISSAN Mobility SystemSee NOTE

(2)IIIIIII —

Body corrosionSee NOTE

(3)BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

★Maintenance items with “★” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Diesel Engines (Annual Mileage > 30,000 km/year) (Cont’d)

MA-16

Page 133 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual OIL SEAL

EM-55

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

Removal and Installation of Front Oil SealEBS00LQF

REMOVAL

1. Remove the following parts:

●Undercover (with splash cover)

●Drive belt; Refer to EM-11, NISSAN ALMERA N16 2003 Electronic Repair Manual OIL SEAL

EM-55

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

Removal and Installation of Front Oil SealEBS00LQF

REMOVAL

1. Remove the following parts:

●Undercover (with splash cover)

●Drive belt; Refer to EM-11,](/img/5/57350/w960_57350-132.png)

OIL SEAL

EM-55

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

Removal and Installation of Front Oil SealEBS00LQF

REMOVAL

1. Remove the following parts:

●Undercover (with splash cover)

●Drive belt; Refer to EM-11, "DRIVE BELTS" .

●Crankshaft pulley; Refer to EM-47, "TIMING CHAIN" .

2. Using flat-head screwdriver, remove front oil seal.

CAUTION:

Be careful not to damage front timing chain cover and crankshaft.

INSTALLATION

1. Apply engine oil on new front oil seal.

2. Using a suitable drift, press fit until the height of front oil seal is

level with the mounting surface.

●Suitable drift : outer diameter 50 mm (1.97 in), inner diameter

44 mm (1.73 in).

CAUTION:

●Be careful not to damage front cover and crankshaft.

●Press oil seal straight so that it is not curling up or

inclined.

3. Perform steps in the reverse order of removal for the following

operations.

Removal and Installation of Rear Oil SealEBS00LQG

REMOVAL

1. Remove transaxle assembly. Refer to MT-23, "Removal" (RS5F30A), MT-23, "Removal" (RS5F70A) and

AT-411, "Removal" (AUTOMATIC TRANSAXLE).

2. Remove drive plate. Refer to EM-70, "

CYLINDER BLOCK" .

3. Using flat-head screwdriver, remove front oil seal.

CAUTION:

Be careful not to damage mounting surface.

INSTALLATION

1. Using a suitable drift, press rear oil seal to rear oil seal retainer.

●Suitable drift : outer diameter 102 mm (4.02 in), inner diame-

ter 90 mm (3.54 in).

CAUTION:

●Do not touch grease applied on oil seal lip

●Be careful not to damage rear oil seal retainer and crank-

shaft.

●Press in straight to avoid causing any burrs or tilting of

oil seal.

SEM912F

SEM715A

SEM097F

Page 146 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete](/img/5/57350/w960_57350-145.png)

EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has completely cooled off, otherwise, you may burn

yourself and/or fire may break out in fuel line.

●Before disconnecting fuel hose, release pressure.

Refer to EC-34 (WITH EURO-OBD), EC-428 (WITHOUT EURO-OBD).

●Be sure to lift engine and transaxle in a safe manner.

●For engines not equipped with engine slingers, attach proper slingers and bolts described in

PARTS CATALOG.

CAUTION:

●When lifting engine, be sure to clear surrounding parts. Use special care near accelerator wire

casing, brake lines and brake master cylinder.

●When lifting the engine, always use engine slingers in a safe manner.

●When removing drive shaft, be careful not to damage grease seal of transaxle.

●Before separating engine and transaxle, remove crankshaft position sensor (POS) from the cylin-

der block assembly.

●Always be extra careful not to damage edge of crankshaft position sensor (POS), or signal plate

teeth.

Engine cannot be removed separately from transaxle. Remove engine with transaxle as an assembly.

REMOVAL

1. Drain coolant from radiator and cylinder block. Refer to LC-17, "Chacking Engine Coolant".

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from engine.

8. Remove power steering oil pump from engine and position aside.

Power steering oil pump does not need to be disconnected from power steering tubes.

9. Remove the following parts:

●RH and LH front tires

●Splash covers

●RH and LH brake caliper assemblies

Refer to BR-28,"Removal".

Brake hose does not need to be disconnected from brake

caliper assembly. Never depress brake pedal.

●RH & LH drive shaft. Refer to AX-11, "Removal".

When removing drive shaft, be careful not to damage

transaxle side grease seal.

●Disconnect control rod and support rod from transaxle. (M/T

models.)

Refer to MT-26, "Removal".

●Disconnect control cable from transaxle. (A/T models.)

Refer to AT-411, "Removal".

SEM174D

SEM109G

Page 202 of 3189

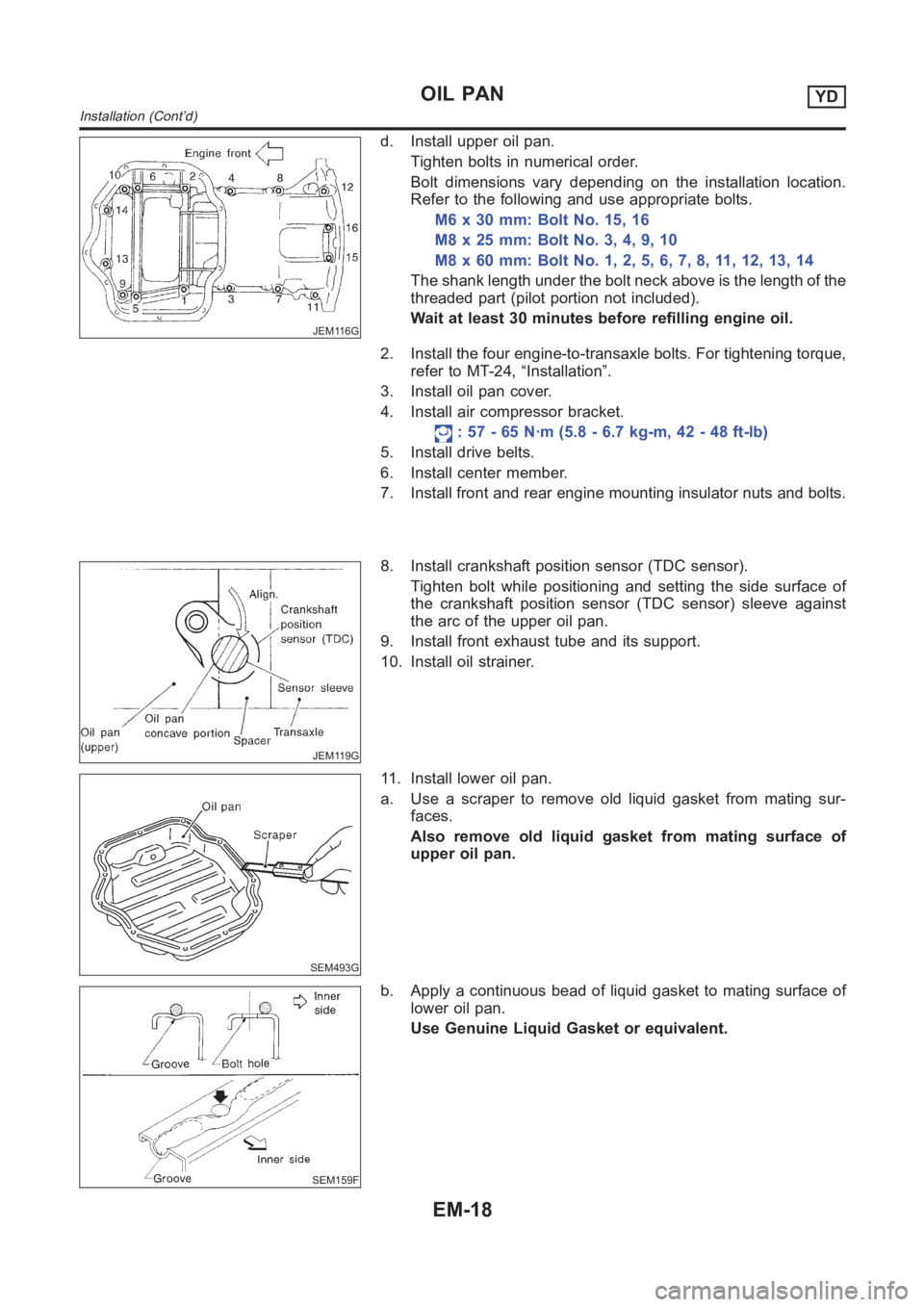

JEM116G

d. Install upper oil pan.

Tighten bolts in numerical order.

Bolt dimensions vary depending on the installation location.

Refer to the following and use appropriate bolts.

M6 x 30 mm: Bolt No. 15, 16

M8x25mm:BoltNo.3,4,9,10

M8x60mm:BoltNo.1,2,5,6,7,8,11,12,13,14

The shank length under the bolt neck above is the length of the

threaded part (pilot portion not included).

Wait at least 30 minutes before refilling engine oil.

2. Install the four engine-to-transaxle bolts. For tightening torque,

refer to MT-24, “Installation”.

3. Install oil pan cover.

4. Install air compressor bracket.

: 57 - 65 N·m (5.8 - 6.7 kg-m, 42 - 48 ft-lb)

5. Install drive belts.

6. Install center member.

7. Install front and rear engine mounting insulator nuts and bolts.

JEM119G

8. Install crankshaft position sensor (TDC sensor).

Tighten bolt while positioning and setting the side surface of

the crankshaft position sensor (TDC sensor) sleeve against

the arc of the upper oil pan.

9. Install front exhaust tube and its support.

10. Install oil strainer.

SEM493G

11. Install lower oil pan.

a. Use a scraper to remove old liquid gasket from mating sur-

faces.

Also remove old liquid gasket from mating surface of

upper oil pan.

SEM159F

b. Apply a continuous bead of liquid gasket to mating surface of

lower oil pan.

Use Genuine Liquid Gasket or equivalent.

OIL PANYD

Installation (Cont’d)

EM-18

Page 402 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-72

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

Air Air duct

55555 5EM-14

Air cleanerEM-14

Air leakage from air duct

(Mass air flow sensor —electric

throttle control actuator)

5555EM-14

Electric throt NISSAN ALMERA N16 2003 Electronic Repair Manual EC-72

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

Air Air duct

55555 5EM-14

Air cleanerEM-14

Air leakage from air duct

(Mass air flow sensor —electric

throttle control actuator)

5555EM-14

Electric throt](/img/5/57350/w960_57350-401.png)

EC-72

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

Air Air duct

55555 5EM-14

Air cleanerEM-14

Air leakage from air duct

(Mass air flow sensor —electric

throttle control actuator)

5555EM-14

Electric throttle control actuatorEM-16

Air leakage from intake manifold/

Collector/GasketEM-16

Cranking Battery

111111 11SC-3

Alternator circuitSC-27

Starter circuit 3 SC-13

Signal plate/Flywheel/Drive plate 6EM-70

PNP switch

4AT- 11 6,

MT-21

Engine Cylinder head

55555 55 5EM-57

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-70

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nismTimin g c hain

55555 55 5EM-47

CamshaftEM-32

Intake valve timing controlEM-47

Intake valve

3EM-57

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5EM-19

, FE-

26

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 55 52EM-22

, LC-

5, LC-9,

LC-4

Oil level (Low)/Filthy oilLC-8 SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 689 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P1706 PNP SWITCH

EC-359

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground ter NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P1706 PNP SWITCH

EC-359

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground ter](/img/5/57350/w960_57350-688.png)

DTC P1706 PNP SWITCH

EC-359

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Diagnostic ProcedureEBS00KCK

1.CHECK PNP SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch “OFF”.

2. Disconnect PNP switch harness connector.

3. Check harness continuity between PNP switch terminal 2 and

body ground.

Refer to Wiring Diagram.

4. Also check harness for short to power.

OK or NG

OK >> GO TO 2.

NG >> Repair open circuit or short to power in harness or con-

nectors.

2.CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 102 and PNP switch terminal 1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK PNP SWITCH

Refer to AT- 111 , "

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH" (A/T models) or MT-21 (M/T

models).

OK or NG

OK >> GO TO 4.

NG >> Replace PNP switch.

4.CHECK INTERMITTENT INCIDENT

Refer to EC-109, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

>>INSPECTION END

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

102P (A/T)

G/OR (M/T)PNP switch[Ignition switch “ON”]

●Shift lever position is “P” or “N” (A/T models).

●Shift lever position is ″Neutral″ (M/T models).Approximately 0V

[Ignition switch “ON”]

●Except the above gear positionA/T models

BATTERY VOLTAGE

(11 - 14V)

M/T models

Approximately 5V

Continuity should exist.

MBIB0253E

Continuity should exist.