P0340 NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 333 of 3189

EC-3

C

D

E

F

G

H

I

J

K

L

M

ECA Component Inspection ......................................... 204

Removal and Installation ...................................... 204

DTC P0222, P0223 TP SENSOR ........................... 205

Component Description ........................................ 205

CONSULT-II Reference Value in Data Monitor Mode

. 205

On Board Diagnosis Logic ................................... 205

DTC Confirmation Procedure ............................... 205

Wiring Diagram .................................................... 207

Diagnostic Procedure ........................................... 208

Component Inspection ......................................... 210

Removal and Installation ...................................... 210

DTC P0226 APP SENSOR ......................................211

Component Description ......................................... 211

CONSULT-II Reference Value in Data Monitor Mode

.. 211

On Board Diagnosis Logic .................................... 211

DTC Confirmation Procedure ................................ 211

Wiring Diagram .................................................... 213

Diagnostic Procedure ........................................... 214

Component Inspection ......................................... 216

Removal and Installation ...................................... 217

DTC P0227, P0228 APP SENSOR ........................ 218

Component Description ........................................ 218

CONSULT-II Reference Value in Data Monitor Mode

. 218

On Board Diagnosis Logic ................................... 218

DTC Confirmation Procedure ............................... 218

Wiring Diagram .................................................... 220

Diagnostic Procedure ........................................... 221

Component Inspection ......................................... 223

Removal and Installation ...................................... 224

DTC P0300 - P0304 MULTIPLE CYLINDER MIS-

FIRE, NO. 1 - 4 CYLINDER MISFIRE ..................... 225

On Board Diagnosis Logic ................................... 225

DTC Confirmation Procedure ............................... 225

Diagnostic Procedure ........................................... 226

DTC P0327, P0328 KS ........................................... 230

Component Description ........................................ 230

On Board Diagnosis Logic ................................... 230

DTC Confirmation Procedure ............................... 230

Wiring Diagram .................................................... 231

Diagnostic Procedure ........................................... 232

Component Inspection ......................................... 233

Removal and Installation ...................................... 233

DTC P0335 CKP SENSOR (POS) .......................... 234

Component Description ........................................ 234

CONSULT-II Reference Value in Data Monitor Mode

. 234

On Board Diagnosis Logic ................................... 234

DTC Confirmation Procedure ............................... 234

Wiring Diagram ...................................................

. 235

Diagnostic Procedure ........................................... 236

Component Inspection ......................................... 238

Removal and Installation ...................................... 239

DTC P0340 CMP SENSOR (PHASE) ..................... 240

Component Description ........................................ 240

On Board Diagnosis Logic ................................... 240

DTC Confirmation Procedure ............................... 240Wiring Diagram .....................................................241

Diagnostic Procedure ...........................................242

Component Inspection ..........................................244

Removal and Installation ......................................245

DTC P0420 THREE WAY CATALYST FUNCTION . 246

On Board Diagnosis Logic ....................................246

DTC Confirmation Procedure ...............................246

Overall Function Check ........................................247

Diagnostic Procedure ...........................................248

DTC P0444 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE ...............................251

Description ............................................................251

CONSULT-II Reference Value in Data Monitor Mode

.251

On Board Diagnosis Logic ....................................252

DTC Confirmation Procedure ...............................252

Wiring Diagram .....................................................253

Diagnostic Procedure ...........................................254

Component Inspection ..........................................256

Removal and Installation ......................................256

DTC P0500 VSS ......................................................257

Description ............................................................257

On Board Diagnosis Logic ....................................257

DTC Confirmation Procedure ...............................257

Overall Function Check ........................................258

Diagnostic Procedure ...........................................259

DTC P0550 PSP SENSOR .....................................260

Component Description ........................................260

CONSULT-II Reference Value in Data Monitor Mode

.260

On Board Diagnosis Logic ....................................260

DTC Confirmation Procedure ...............................260

Wiring Diagram .....................................................261

Diagnostic Procedure ...........................................262

Component Inspection ..........................................264

DTC P0605 ECM .....................................................265

Component Description ........................................265

On Board Diagnosis Logic ....................................265

DTC Confirmation Procedure ...............................265

Diagnostic Procedure ...........................................266

DTC P1065 ECM POWER SUPPLY .......................268

Component Description ........................................268

On Board Diagnosis Logic ....................................268

DTC Confirmation Procedure ...............................268

Wiring Diagram .....................................................269

Diagnostic Procedure ...........................................270

DTC P1111 IVT CONTROL SOLENOID VALVE .....272

Component Description ........................................272

CONSULT-II Reference Value in Data Monitor Mode

.272

On Board Diagnosis Logic ....................................272

DTC Confirmation Procedure ...............................272

Wiring Diagram .....................................................273

Diagnostic Procedure ...........................................274

Component Inspection ..........................................275

Removal and Installation ......................................275

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR .............................................................276

Component Description ........................................276

Page 337 of 3189

EC-7

C

D

E

F

G

H

I

J

K

L

M

ECA Component Inspection ......................................... 548

Removal and Installation ...................................... 549

DTC P0327, P0328 KS ........................................... 550

Component Description ........................................ 550

On Board Diagnosis Logic ................................... 550

DTC Confirmation Procedure ............................... 550

Wiring Diagram .................................................... 551

Diagnostic Procedure ........................................... 552

Component Inspection ......................................... 553

Removal and Installation ...................................... 553

DTC P0335 CKP SENSOR (POS) .......................... 554

Component Description ........................................ 554

CONSULT-II Reference Value in Data Monitor Mode

. 554

On Board Diagnosis Logic ................................... 554

DTC Confirmation Procedure ............................... 554

Wiring Diagram .................................................... 556

Diagnostic Procedure ........................................... 557

Component Inspection ......................................... 559

Removal and Installation ...................................... 560

DTC P0340 CMP SENSOR (PHASE) ..................... 561

Component Description ........................................ 561

On Board Diagnosis Logic ................................... 561

DTC Confirmation Procedure ............................... 561

Wiring Diagram .................................................... 563

Diagnostic Procedure ........................................... 564

Component Inspection ......................................... 566

Removal and Installation ...................................... 567

DTC P0605 ECM .................................................... 568

Component Description ........................................ 568

On Board Diagnosis Logic ................................... 568

DTC Confirmation Procedure ............................... 568

Diagnostic Procedure ........................................... 570

DTC P1065 ECM POWER SUPPLY ....................... 571

Component Description ........................................ 571

On Board Diagnosis Logic ................................... 571

DTC Confirmation Procedure ............................... 571

Wiring Diagram .................................................... 572

Diagnostic Procedure ........................................... 573

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR ............................................................ 575

Component Description ........................................ 575

On Board Diagnosis Logic ................................... 575

DTC Confirmation Procedure ............................... 575

Diagnostic Procedure ........................................... 576

Removal and Installation ...................................... 577

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION .............................................................. 578

Description ..........................................................

. 578

On Board Diagnosis Logic ................................... 578

DTC Confirmation Procedure ............................... 578

Wiring Diagram .................................................... 579

Diagnostic Procedure ........................................... 580

Component Inspection ......................................... 584

Removal and Installation ...................................... 584

DTC P1124, P1126 THROTTLE CONTROL MOTOR

RELAY .................................................................... 585

Component Description ........................................ 585

CONSULT-II Reference Value in Data Monitor Mode .585

On Board Diagnosis Logic ....................................585

DTC Confirmation Procedure ...............................585

Wiring Diagram .....................................................587

Diagnostic Procedure ...........................................588

Component Inspection ..........................................590

DTC P1128 THROTTLE CONTROL MOTOR .........591

Component Description ........................................591

On Board Diagnosis Logic ....................................591

DTC Confirmation Procedure ...............................591

Wiring Diagram .....................................................592

Diagnostic Procedure ...........................................593

Component Inspection ..........................................594

Removal and Installation ......................................595

DTC P1217 ENGINE OVER TEMPERATURE ........596

System Description ...............................................596

CONSULT-II Reference Value in Data Monitor Mode

.596

On Board Diagnosis Logic ....................................597

Overall Function Check ........................................597

Wiring Diagram .....................................................599

Diagnostic Procedure ...........................................600

Main 12 Causes of Overheating ...........................605

Component Inspection ..........................................606

DTC P1223, P1224 TP SENSOR ............................607

Component Description ........................................607

CONSULT-II Reference Value in Data Monitor Mode

.607

On Board Diagnosis Logic ....................................607

DTC Confirmation Procedure ...............................607

Wiring Diagram .....................................................609

Diagnostic Procedure ...........................................610

Component Inspection ..........................................612

Removal and Installation ......................................612

DTC P1225 TP SENSOR ........................................613

Component Description ........................................613

On Board Diagnosis Logic ....................................613

DTC Confirmation Procedure ...............................613

Diagnostic Procedure ...........................................614

Removal and Installation ......................................614

DTC P1226 TP SENSOR .......................................

.615

Component Description ........................................615

On Board Diagnosis Logic ....................................615

DTC Confirmation Procedure ...............................615

Diagnostic Procedure ...........................................616

Removal and Installation ......................................616

DTC P1227, P1228 APP SENSOR .........................617

Component Description ........................................617

CONSULT-II Reference Value in Data Monitor Mode

.617

On Board Diagnosis Logic ....................................617

DTC Confirmation Procedure ...............................617

Wiring Diagram .....................................................619

Diagnostic Procedure ...........................................620

Component Inspection ..........................................622

Removal and Installation ......................................623

DTC P1229 SENSOR POWER SUPPLY ................624

On Board Diagnosis Logic ....................................624

DTC Confirmation Procedure ...............................624

Page 340 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-10

[QG (WITH EURO-OBD)]

INDEX FOR DTC

[QG (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00K2T

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approv NISSAN ALMERA N16 2003 Electronic Repair Manual EC-10

[QG (WITH EURO-OBD)]

INDEX FOR DTC

[QG (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00K2T

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approv](/img/5/57350/w960_57350-339.png)

EC-10

[QG (WITH EURO-OBD)]

INDEX FOR DTC

[QG (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00K2T

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approval number” on the

identification plate. Refer to GI-39.

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-116, "

DTC U1000, U1001 CAN COMMUNICATION LINE" .

×: Applicable –: Not applicable

Items

(CONSULT-II screen terms)DTC*

1

TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

A/T 1ST GR FNCTN P0731 0731 2×AT-133

A/T 2ND GR FNCTN P0732 0732 2×AT-139

A/T 3RD GR FNCTN P0733 0733 2×AT-145

A/T 4TH GR FNCTN P0734 0734 2×AT-151

APP SEN 1/CIRC P0227 0227 1×EC-218

APP SEN 1/CIRC P0228 0228 1×EC-218

APP SEN 2/CIRC P1227 1227 1×EC-345

APP SEN 2/CIRC P1228 1228 1×EC-345

APP SENSOR P0226 0226 1×EC-211

ATF TEMP SEN/CIRC P0710 0710 2×AT- 11 7

BRAKE SW/CIRCUIT P1805 1805 2 –EC-360

CAN COMM CIRCUIT U1000

1000*51×EC-116

CAN COMM CIRCUIT U1001

1001*52–EC-116

CKP SEN/CIRCUIT P0335 0335 2×EC-234

CMP SEN/CIRC-B1 P0340 0340 2×EC-240

CTP LEARNING P1225 1225 2 –EC-341

CTP LEARNING P1226 1226 2 –EC-343

CYL 1 MISFIRE P0301 0301 2×EC-225

CYL 2 MISFIRE P0302 0302 2×EC-225

CYL 3 MISFIRE P0303 0303 2×EC-225

CYL 4 MISFIRE P0304 0304 2×EC-225

ECM P0605 0605 1 or 2× or –EC-265

ECM BACK UP/CIRC P1065 1065 2×EC-268

ECT SEN/CIRCUIT P0117 0117 1×EC-144

ECT SEN/CIRCUIT P0118 0118 1×EC-144

ENG OVER TEMP P1217 1217 1×EC-324

ENGINE SPEED SIG P0725 0725 1×AT-129

ETC ACTR P1121 1121 1 or 2×EC-276

ETC FUNCTION/CIRC P1122 1122 1×EC-278

ETC MOT P1128 1128 1×EC-291

ETC MOT PWR P1124 1124 1×EC-285

ETC MOT PWR P1126 1126 1×EC-285

FUEL SYS-LEAN-B1 P0171 0171 2×EC-186

FUEL SYS-RICH-B1 P0172 0172 2×EC-193

HO2S1 (B1) P0132 0132 2×EC-149

Page 343 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual INDEX FOR DTC

EC-13

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

ECP0222 0222 TP SEN 1/CIRC 1×EC-205

P0223 0223 TP SEN 1/CIRC 1×EC-205

P0226 0226 APP SENSOR 1×EC-211

P0227 0227 APP SEN 1/CIRC 1×EC- NISSAN ALMERA N16 2003 Electronic Repair Manual INDEX FOR DTC

EC-13

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

ECP0222 0222 TP SEN 1/CIRC 1×EC-205

P0223 0223 TP SEN 1/CIRC 1×EC-205

P0226 0226 APP SENSOR 1×EC-211

P0227 0227 APP SEN 1/CIRC 1×EC-](/img/5/57350/w960_57350-342.png)

INDEX FOR DTC

EC-13

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

ECP0222 0222 TP SEN 1/CIRC 1×EC-205

P0223 0223 TP SEN 1/CIRC 1×EC-205

P0226 0226 APP SENSOR 1×EC-211

P0227 0227 APP SEN 1/CIRC 1×EC-218

P0228 0228 APP SEN 1/CIRC 1×EC-218

P0300 0300 MULTI CYL MISFIRE 2×EC-225

P0301 0301 CYL 1 MISFIRE 2×EC-225

P0302 0302 CYL 2 MISFIRE 2×EC-225

P0303 0303 CYL 3 MISFIRE 2×EC-225

P0304 0304 CYL 4 MISFIRE 2×EC-225

P0327 0327 KNOCK SEN/CIRC-B1 2 –EC-230

P0328 0328 KNOCK SEN/CIRC-B1 2 –EC-230

P0335 0335 CKP SEN/CIRCUIT 2×EC-234

P0340 0340 CMP SEN/CIRC-B1 2×EC-240

P0420 0420 TW CATALYST SYS-B1 2×EC-246

P0444 0444 PURG VOLUME CONT/V 2×EC-251

P0500 0500 VEH SPEED SEN/CIRC 2×EC-257

P0550 0550 PW ST P SEN/CIRC 2 –EC-260

P0605 0605 ECM 1 or 2× or –EC-265

P0705 0705 PNP SW/CIRC 2×AT- 111

P0710 0710 ATF TEMP SEN/CIRC 2×AT- 11 7

P0720 0720

VEH SPD SEN/CIRC AT*62×AT-123

P0725 0725 ENGINE SPEED SIG 2×AT-129

P0731 0731 A/T 1ST GR FNCTN 2×AT-133

P0732 0732 A/T 2ND GR FNCTN 2×AT-139

P0733 0733 A/T 3RD GR FNCTN 2×AT-145

P0734 0734 A/T 4TH GR FNCTN 2×AT-151

P0740 0740 TCC SOLENOID/CIRC 2×AT-159

P0745 0745 L/PRESS SOL/CIRC 2×AT-164

P0750 0750 SFT SOL A/CIRC 1×AT-171

P0755 0755 SFT SOL B/CIRC 1×AT-176

P1065 1065 ECM BACK UP/CIRC 2×EC-268

P 1111 1111 I N T / V T I M V / C I R - B 1 2×EC-272

P1121 1121 ETC ACTR 1 or 2×EC-276

P1122 1122 ETC FUNCTION/CIRC 1×EC-278

P1124 1124 ETC MOT PWR 1×EC-285

P1126 1126 ETC MOT PWR 1×EC-285

P1128 1128 ETC MOT 1×EC-291

P1143 1143 HO2S1 (B1) 2×EC-296

P1144 1144 HO2S1 (B1) 2×EC-302

P1146 1146 HO2S2 (B1) 2×EC-308

P1147 1147 HO2S2 (B1) 2×EC-316

DTC*1

Items

(CONSULT-II screen terms)TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

Page 368 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-38

[QG (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

CMP SEN/CIRC-B1 P0340 0340 — —×EC-240

TW CATALYST SYS-B1 P0420 0420××

×*4EC-246

PURG VOLUME CONT/V P0444 0444 — —×EC-251

VEH SP NISSAN ALMERA N16 2003 Electronic Repair Manual EC-38

[QG (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

CMP SEN/CIRC-B1 P0340 0340 — —×EC-240

TW CATALYST SYS-B1 P0420 0420××

×*4EC-246

PURG VOLUME CONT/V P0444 0444 — —×EC-251

VEH SP](/img/5/57350/w960_57350-367.png)

EC-38

[QG (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

CMP SEN/CIRC-B1 P0340 0340 — —×EC-240

TW CATALYST SYS-B1 P0420 0420××

×*4EC-246

PURG VOLUME CONT/V P0444 0444 — —×EC-251

VEH SPEED SEN/CIRC P0500 0500 — —×EC-257

PW ST P SEN/CIRC P0550 0550 — —×EC-260

ECM P0605 0605 — —×EC-265

PNP SW/CIRC P0705 0705 — —×AT- 111

ATF TEMP SEN/CIRC P0710 0710 — —×AT- 11 7

VEH SPD SEN/CIRC AT*5P0720 0720 — —×AT- 1 2 3

ENGINE SPEED SIG P0725 0725 — —×AT- 1 2 9

A/T 1ST GR FNCTN P0731 0731 — —×AT- 1 3 3

A/T 2ND GR FNCTN P0732 0732 — —×AT- 1 3 9

A/T 3RD GR FNCTN P0733 0733 — —×AT- 1 4 5

A/T 4TH GR FNCTN P0734 0734 — —×AT- 1 5 1

TCC SOLENOID/CIRC P0740 0740 — —×AT- 1 5 9

L/PRESS SOL/CIRC P0745 0745 — —×AT- 1 6 4

SFT SOL A/CIRC P0750 0750 — — —AT- 1 7 1

SFT SOL B/CIRC P0755 0755 — — —AT- 1 7 6

ECM BACK UP/CIRC P1065 1065 — —×EC-268

INT/V TIM V/CIR-B1 P1111 1111 — —×EC-272

ETC ACTR P1121 1121 — —×EC-276

ETC FUNCTION/CIRC P1122 1122 — — —EC-278

ETC MOT PWR P1124 1124 — — —EC-285

ETC MOT PWR P1126 1126 — — —EC-285

ETC MOT P11281128———EC-291

HO2S1 (B1) P1143 1143××

×*4EC-296

HO2S1 (B1) P1144 1144××

×*4EC-302

HO2S2 (B1) P1146 1146××

×*4EC-308

HO2S2 (B1) P1147 1147××

×*4EC-316

ENG OVER TEMP P1217 1217 — — —EC-324

TP SEN 2/CIRC P1223 1223 — — —EC-335

TP SEN 2/CIRC P1224 1224 — — —EC-335

CTP LEARNING P1225 1225 — —×EC-341

CTP LEARNING P1226 1226 — —×EC-343

APP SEN 2/CIRC P1227 1227 — — —EC-345

APP SEN 2/CIRC P1228 1228 — — —EC-345

SENSOR POWER/CIRC P1229 1229 — — —EC-352

NATS MALFUNCTION P1610 - P1615 1610 - 1615 — —×EC-49

TPV SEN/CIRC A/T P1705 1705 — — —AT- 1 8 1

P-N POS SW/CIRCUIT P1706 1706 — —×EC-356

Items

(CONSULT-II screen terms)DTC*

1

SRT codeTest Value/

Test Limit

(GST only)1st trip DTC Reference page

CONSULT-II

GST*

2ECM

Page 369 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-39

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: The trouble shoot NISSAN ALMERA N16 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-39

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: The trouble shoot](/img/5/57350/w960_57350-368.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-39

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: The trouble shooting for this DTC needs CONSULT-II.

*4: These are not displayed with GST.

DTC AND 1ST TRIP DTC

The 1st trip DTC (whose number is the same as the DTC number) is displayed for the latest self-diagnostic

result obtained. If the ECM memory was cleared previously, and the 1st trip DTC did not reoccur, the 1st trip

DTC will not be displayed.

If a malfunction is detected during the 1st trip, the 1st trip DTC is stored in the ECM memory. The MI will not

light up (two trip detection logic). If the same malfunction is not detected in the 2nd trip (meeting the required

driving pattern), the 1st trip DTC is cleared from the ECM memory. If the same malfunction is detected in the

2nd trip, both the 1st trip DTC and DTC are stored in the ECM memory and the MI lights up. In other words,

the DTC is stored in the ECM memory and the MI lights up when the same malfunction occurs in two consec-

utive trips. If a 1st trip DTC is stored and a non-diagnostic operation is performed between the 1st and 2nd

trips, only the 1st trip DTC will continue to be stored. For malfunctions that blink or light up the MI during the

1st trip, the DTC and 1st trip DTC are stored in the ECM memory.

Procedures for clearing the DTC and the 1st trip DTC from the ECM memory are described in EC-48, "

HOW

TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION" .

For malfunctions in which 1st trip DTCs are displayed, refer to EC-37, "

EMISSION-RELATED DIAGNOSTIC

INFORMATION ITEMS" . These items are required by legal regulations to continuously monitor the system/

component. In addition, the items monitored non-continuously are also displayed on CONSULT-II.

1st trip DTC is specified in Mode 7 of ISO 15031-5. 1st trip DTC detection occurs without lighting up the MI

and therefore does not warn the driver of a malfunction. However, 1st trip DTC detection will not prevent the

vehicle from being tested, for example during Inspection/Maintenance (I/M) tests.

When a 1st trip DTC is detected, check, print out or write down and erase (1st trip) DTC and Freeze Frame

data as specified in “Work Flow” procedure Step II, refer to EC-59, "

WORK FLOW" . Then perform “DTC Con-

firmation Procedure” or “Overall Function Check” to try to duplicate the malfunction. If the malfunction is dupli-

cated, the item requires repair.

How to Read DTC and 1st Trip DTC

DTC and 1st trip DTC can be read by the following methods.

With CONSULT-II

With GST

CONSULT-II or GST (Generic Scan Tool) Examples: P0340, P0705, P0750, etc.

These DTCs are prescribed by ISO 15031-5.

(CONSULT-II also displays the malfunctioning component or system.)

No Tools

The number of blinks of the MI in the Diagnostic Test Mode II (Self-Diagnostic Results) indicates the DTC.

Example: 0102, 0340 etc.

These DTCs are controlled by NISSAN.

●1st trip DTC No. is the same as DTC No.

●Output of a DTC indicates a malfunction. However, GST or the Diagnostic Test Mode II do not indi-

cate whether the malfunction is still occurring or has occurred in the past and has returned to nor-

mal. CONSULT-II can identify malfunction status as shown below. Therefore, using CONSULT-II (if

available) is recommended.

A sample of CONSULT-II display for DTC and 1st trip DTC is shown below. DTC or 1st trip DTC of a malfunc-

tion is displayed in SELF-DIAGNOSTIC RESULTS mode of CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be “0”.

O/R CLTCH SOL/CIRC P1760 1760 — —×AT-187

BRAKE SW/CIRCUIT P1805 1805 — —×EC-360

Items

(CONSULT-II screen terms)DTC*

1

SRT codeTest Value/

Test Limit

(GST only)1st trip DTC Reference page

CONSULT-II

GST*

2ECM

Page 393 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-63

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fail-safe ChartEBS00K3N

●When the DTC listed below is detected, the ECM enters fail-safe mode and the MI lights up.

Priority De NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-63

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fail-safe ChartEBS00K3N

●When the DTC listed below is detected, the ECM enters fail-safe mode and the MI lights up.

Priority De](/img/5/57350/w960_57350-392.png)

TROUBLE DIAGNOSIS

EC-63

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fail-safe ChartEBS00K3N

●When the DTC listed below is detected, the ECM enters fail-safe mode and the MI lights up.

Priority Detected items (DTC)

1

●U1000 U1001 CAN communication line

●P0102 P0103 Mass air flow sensor

●P0112 P0113 Intake air temperature sensor

●P0117 P0118 Engine coolant temperature sensor

●P0221 P0222 P0223 P1223 P1224 P1225 P1226 P1229 Throttle position sensor

●P0226 P0227 P0228 P1227 P1228 Accelerator pedal position sensor

●P0327 P0328 Knock sensor

●P0335 Crankshaft position sensor (POS)

●P0340 Camshaft position sensor (PHASE)

●P0500 Vehicle speed sensor

●P0705 Park/Neutral position (PNP) switch

●P0605 ECM

●P1610-P1615 NATS

●P1706 Park/Neutral position (PNP) switch

2

●P0031 P0032 Heated oxygen sensor 1 heater

●P0037 P0038 Heated oxygen sensor 2 heater

●P0132 P0133 P0134 P1143 P1144 Heated oxygen sensor 1

●P0138 P0139 P1146 P1147 Heated oxygen sensor 2

●P0550 Power steering pressure sensor

●P0710-P0725 P0740-P0755 P1705 P1760 A/T related sensors and solenoid valves

●P1065 ECM power supply

●P 1111 I n ta k e v a l v e t i m i n g c o n t r o l s o l e n o i d v a l v e

●P1122 Electric throttle control function

●P1124 P1126 P1128 Electric throttle control actuator

●P1805 Brake switch

3

●P0011 Intake valve timing control

●P0171 P0172 Fuel injection system function

●P0300 - P0304 Misfire

●P0420 Three way catalyst function

●P0444 EVAP canister purge volume control solenoid valve

●P0731-P0734 A/T function

●P1121 Electric throttle control actuator

●P1217 Engine over temperature (OVERHEAT)

DTC No. Detected items Engine operating condition in fail-safe mode

P0102

P0103Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

Page 570 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-240

[QG (WITH EURO-OBD)]

DTC P0340 CMP SENSOR (PHASE)

DTC P0340 CMP SENSOR (PHASE)

PFP:23731

Component DescriptionEBS00K8C

The camshaft position sensor (PHASE) senses the retraction with

in NISSAN ALMERA N16 2003 Electronic Repair Manual EC-240

[QG (WITH EURO-OBD)]

DTC P0340 CMP SENSOR (PHASE)

DTC P0340 CMP SENSOR (PHASE)

PFP:23731

Component DescriptionEBS00K8C

The camshaft position sensor (PHASE) senses the retraction with

in](/img/5/57350/w960_57350-569.png)

EC-240

[QG (WITH EURO-OBD)]

DTC P0340 CMP SENSOR (PHASE)

DTC P0340 CMP SENSOR (PHASE)

PFP:23731

Component DescriptionEBS00K8C

The camshaft position sensor (PHASE) senses the retraction with

intake valve camshaft to identify a particular cylinder. The camshaft

position sensor (PHASE) senses the piston position.

When the crankshaft position sensor (POS) system becomes inoper-

ative, the camshaft position sensor (PHASE) provides various con-

trols of engine parts instead, utilizing timing of cylinder identification

signals.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause

the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor changes.

On Board Diagnosis LogicEBS00K8D

DTC Confirmation ProcedureEBS00K8E

NOTE:

If “DTC Confirmation Procedure” has been previously conducted, always turn ignition switch “OFF” and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5V with igni-

tion switch “ON”.

WITH CONSULT-II

1. Turn ignition switch “ON”.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Crank engine for at least 2 seconds and run it for at least 5 sec-

onds at idle speed.

4. If 1st trip DTC is detected, go to EC-242, "

Diagnostic Procedure"

.

If 1st trip DTC is not detected, go to next step.

5. Maintain engine speed at more than 800 rpm for at least 5 sec-

onds.

6. If 1st trip DTC is detected, go to EC-242, "

Diagnostic Procedure"

.

WITH GST

Follow the procedure “WITH CONSULT-II” above.

PBIB0562E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0340

0340Camshaft position sensor

(PHASE) circuit

●The cylinder No. signal is not sent to ECM

for the first few seconds during engine

cranking.

●The cylinder No. signal is not set to ECM

during engine running.

●The cylinder No. signal is not in the normal

pattern during engine running.

●Harness or connectors

(The sensor circuit is open or shorted.)

●Camshaft position sensor (PHASE)

●Camshaft (Intake)

●Starter motor (Refer to SC-13.)

●Starting system circuit (Refer to SC-13.)

●Dead (Weak) battery

SEF013Y

Page 571 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0340 CMP SENSOR (PHASE)

EC-241

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

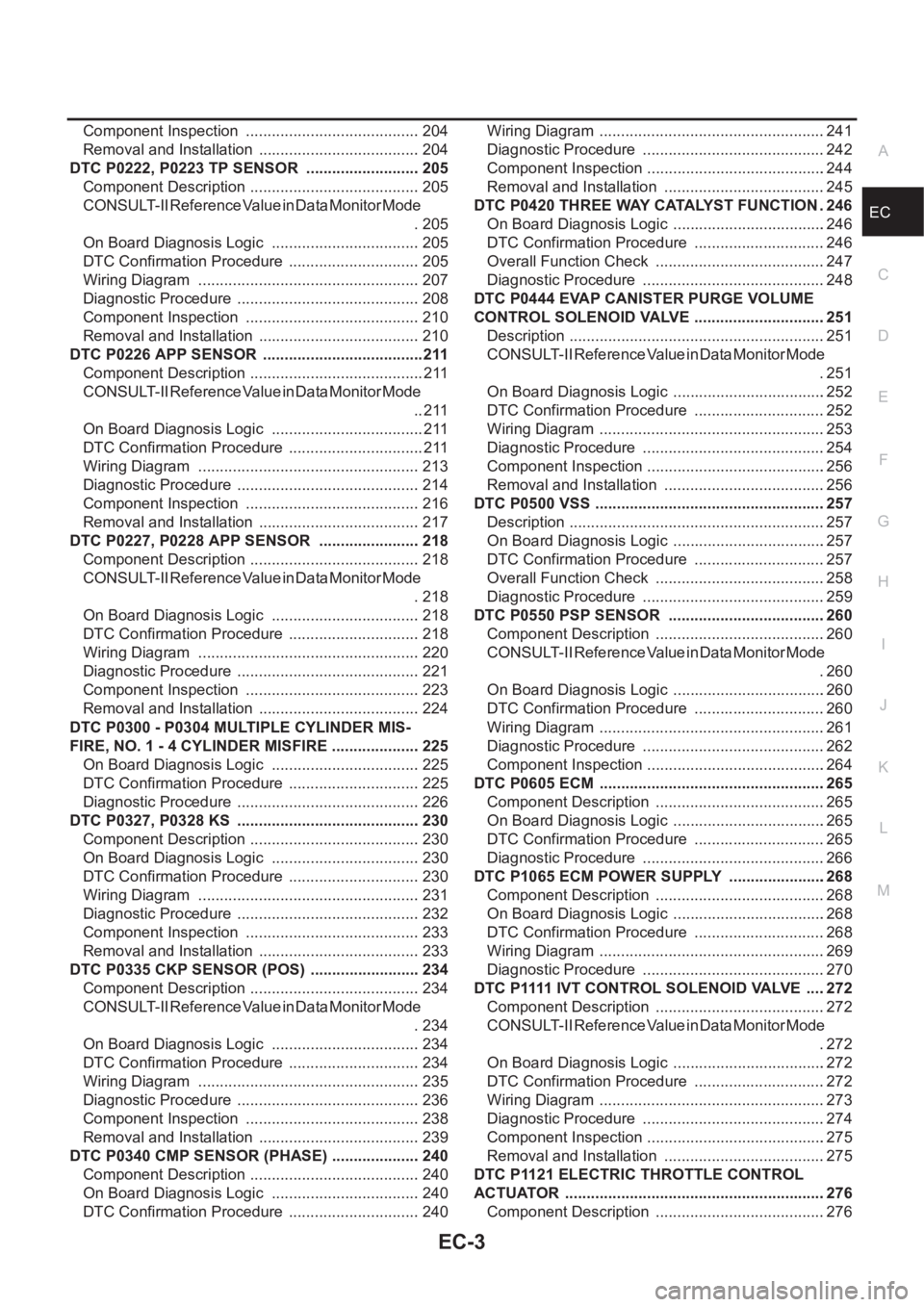

Wiring DiagramEBS00K8F

YEC292A NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0340 CMP SENSOR (PHASE)

EC-241

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Wiring DiagramEBS00K8F

YEC292A](/img/5/57350/w960_57350-570.png)

DTC P0340 CMP SENSOR (PHASE)

EC-241

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Wiring DiagramEBS00K8F

YEC292A

Page 572 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-242

[QG (WITH EURO-OBD)]

DTC P0340 CMP SENSOR (PHASE)

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measur NISSAN ALMERA N16 2003 Electronic Repair Manual EC-242

[QG (WITH EURO-OBD)]

DTC P0340 CMP SENSOR (PHASE)

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measur](/img/5/57350/w960_57350-571.png)

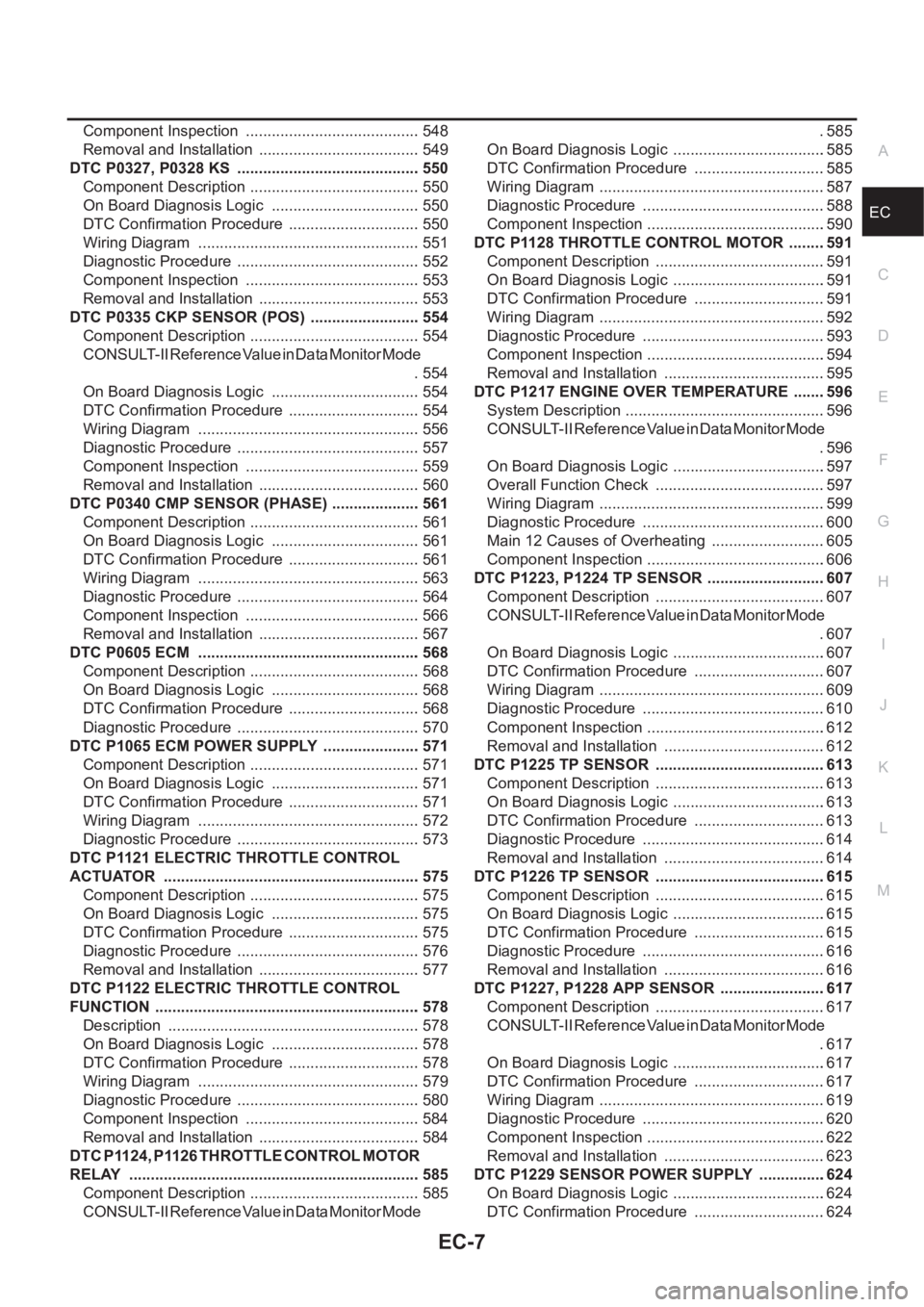

EC-242

[QG (WITH EURO-OBD)]

DTC P0340 CMP SENSOR (PHASE)

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnostic ProcedureEBS00K8G

1. CHECK STARTING SYSTEM

Turn ignition switch to “START” position.

Ye s o r N o

Yes >> GO TO 2.

No >> Check starting system. (Refer to SC-13.)

2. RETIGHTEN GROUND SCREWS

1. Turn ignition switch “OFF”.

2. Loosen and retighten engine ground screws.

>> GO TO 3.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 RCamshaft position

sensor (PHASE)[Engine is running]

●Warm-up condition

●Idle speed1.0 - 4.0V

[Engine is running]

●Engine speed is 2,000 rpm.1.0 - 4.0V

29 BCamshaft position

sensor (PHASE)

ground[Engine is running]

●Idle speedApproximately 0V

PBIB0525E

PBIB0526E

Does the engine turn over?

Does the starter motor operate?

MBIB0095E