Pump NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 8 of 3189

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically. Continued refueling may cause fuel

overflow, resulting in fuel spray and possibly a fire.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do

not carelessly disconnect the harness connectors which are

related to the engine control system and TCM (Transmission

Control Module) system. The connectors should be discon-

nected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

SGI787

PRECAUTIONS FOR MULTIPORT FUEL INJECTION

SYSTEM OR ENGINE CONTROL SYSTEM

NJGI0001S04Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

Be careful not to jar components such as ECM and mass air

flow sensor.

PRECAUTIONS FOR THREE WAY CATALYSTNJGI0001S05If a large amount of unburned fuel flows into the catalyst, the cata-

lyst temperature will be excessively high. To prevent this, follow the

instructions below:

Use unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

When checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

Do not run engine when the fuel tank level is low, otherwise the

engine may misfire, causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

SMA019D

PRECAUTIONS FOR HOSESNJGI0001S06Hose Removal and InstallationNJGI0001S0601To prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

PRECAUTIONS

Precautions (Cont’d)

GI-6

Page 55 of 3189

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnoses

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control

solenoid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-53

Page 79 of 3189

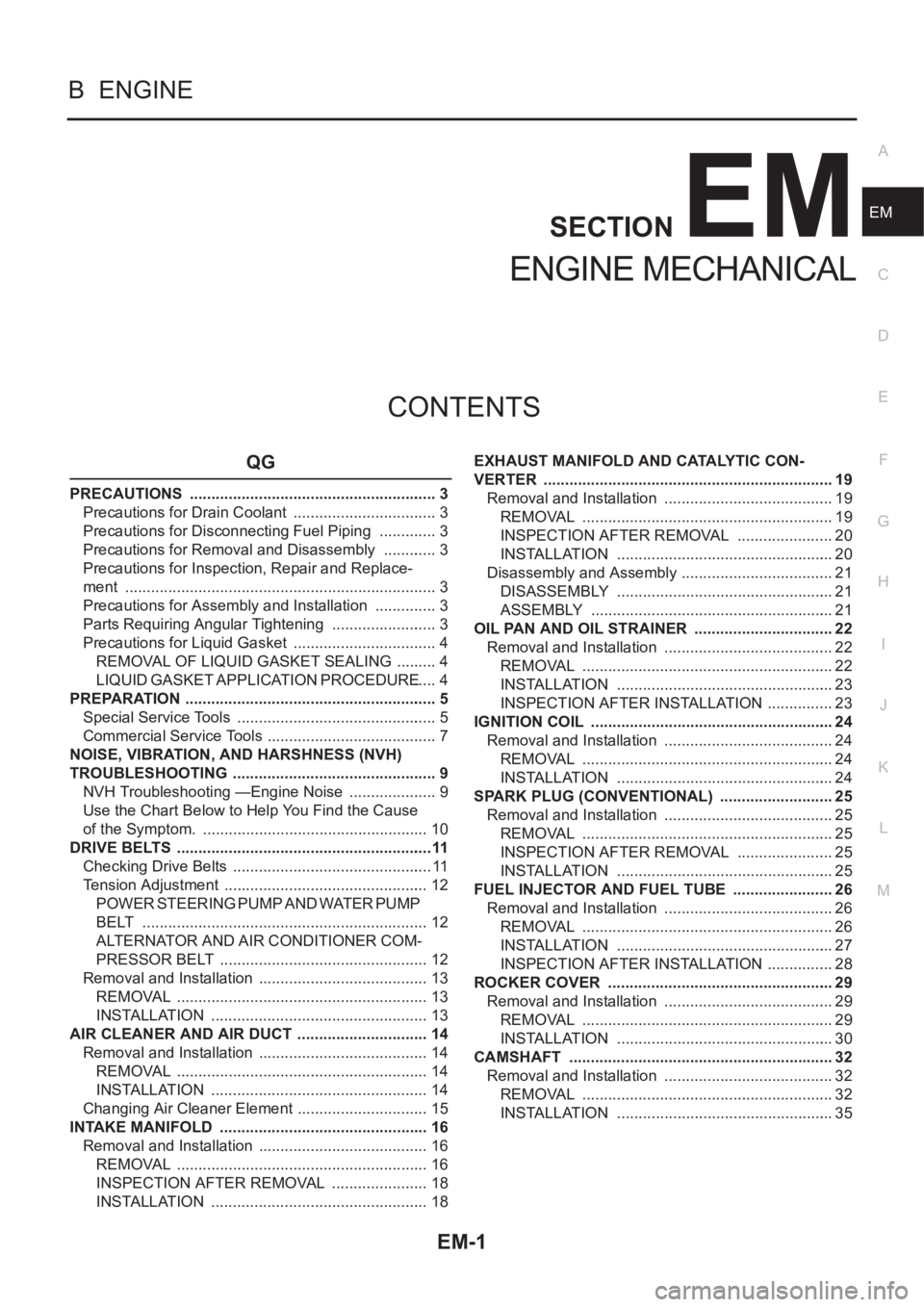

EM-1

ENGINE MECHANICAL

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EM

ENGINE MECHANICAL

QG

PRECAUTIONS .......................................................... 3

Precautions for Drain Coolant .................................. 3

Precautions for Disconnecting Fuel Piping .............. 3

Precautions for Removal and Disassembly ............. 3

Precautions for Inspection, Repair and Replace-

ment ......................................................................... 3

Precautions for Assembly and Installation ............... 3

Parts Requiring Angular Tightening ......................... 3

Precautions for Liquid Gasket .................................. 4

REMOVAL OF LIQUID GASKET SEALING .......... 4

LIQUID GASKET APPLICATION PROCEDURE ..... 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 7

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 9

NVH Troubleshooting —Engine Noise ..................... 9

Use the Chart Below to Help You Find the Cause

of the Symptom. ..................................................... 10

DRIVE BELTS ............................................................11

Checking Drive Belts ............................................... 11

Tension Adjustment ................................................ 12

POWER STEERING PUMP AND WATER PUMP

BELT ................................................................... 12

ALTERNATOR AND AIR CONDITIONER COM-

PRESSOR BELT ................................................. 12

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

AIR CLEANER AND AIR DUCT ............................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Changing Air Cleaner Element ............................... 15

INTAKE MANIFOLD ................................................. 16

Removal and Installation ........................................ 16

REMOVAL ........................................................... 16

INSPECTION AFTER REMOVAL ....................... 18

INSTALLATION ................................................... 18EXHAUST MANIFOLD AND CATALYTIC CON-

VERTER .................................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 20

INSTALLATION ................................................... 20

Disassembly and Assembly .................................... 21

DISASSEMBLY ................................................... 21

ASSEMBLY ......................................................... 21

OIL PAN AND OIL STRAINER ..............................

... 22

Removal and Installation ........................................ 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 23

INSPECTION AFTER INSTALLATION ................ 23

IGNITION COIL ......................................................... 24

Removal and Installation ........................................ 24

REMOVAL ........................................................... 24

INSTALLATION ................................................... 24

SPARK PLUG (CONVENTIONAL) ........................... 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSPECTION AFTER REMOVAL ....................... 25

INSTALLATION ................................................... 25

FUEL INJECTOR AND FUEL TUBE ........................ 26

Removal and Installation ........................................ 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 27

INSPECTION AFTER INSTALLATION ................ 28

ROCKER COVER ..................................................... 29

Removal and Installation ........................................ 29

REMOVAL ........................................................... 29

INSTALLATION ................................................... 30

CAMSHAFT .............................................................. 32

Removal and Installation ........................................ 32

REMOVAL ........................................................... 32

INSTALLATION ................................................... 35

Page 88 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-10

[QG]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS00LPX

1. Locate the area where noise occurs.

2. Confirm the type of n NISSAN ALMERA N16 2003 Electronic Repair Manual EM-10

[QG]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS00LPX

1. Locate the area where noise occurs.

2. Confirm the type of n](/img/5/57350/w960_57350-87.png)

EM-10

[QG]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS00LPX

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noiseTy p e o f

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

Top of

engine

Rocker

cover

Cylinder

headTick in g o r

clickingCA—AB—Tappet

noise

●Valve clearanceEM-42

Rattle C A — A B CCamshaft

bearing

noise

●Camshaft journal

clearance

●Camshaft runoutEM-39EM-39

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock—A—B B—Piston pin

noise

●Piston and piston pin

clearance

●Connecting rod

bushing clearanceEM-84EM-87

Slap or

rapA——B B APiston

slap noise

●Piston-to-bore clear-

ance

●Piston ring side

clearance

●Piston ring end gap

●Connecting rod bend

and torsionEM-88

EM-85

EM-86

EM-86

Knock A B C B B BConnect-

ing rod

bearing

noise

●Connecting rod

bushing clearance

(Small end)

●Connecting rod bear-

ing clearance (Big

end)EM-87EM-87

Knock A B — A B CMain

bearing

noise

●Main bearing oil

clearance

●Crankshaft runoutEM-91EM-90

Front of

engine

Timing

chain

coverTapping or

tickingAA—BBBTiming

chain and

chain ten-

sioner

noise●Timing chain cracks

and wear

●Timing chain ten-

sioner operationEM-51EM-47

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belts

(Sticking

or slip-

ping)

●Drive belts deflection

EM-11

CreakingABABABDrive belts

(Slipping)●Idler pulley bearing

operation

Squall

CreakAB—BABWater

pump

noise

●Water pump opera-

tionLC-14

Page 89 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DRIVE BELTS

EM-11

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

DRIVE BELTSPFP:02117

Checking Drive BeltsEBS00LPY

●Before inspecting the engine, make sure the engine has cooled down; wait approximately NISSAN ALMERA N16 2003 Electronic Repair Manual DRIVE BELTS

EM-11

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

DRIVE BELTSPFP:02117

Checking Drive BeltsEBS00LPY

●Before inspecting the engine, make sure the engine has cooled down; wait approximately](/img/5/57350/w960_57350-88.png)

DRIVE BELTS

EM-11

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

DRIVE BELTSPFP:02117

Checking Drive BeltsEBS00LPY

●Before inspecting the engine, make sure the engine has cooled down; wait approximately 30 minutes

after the engine has been stopped.

●Visually inspect all belts for wear, damage, or cracks on contacting surfaces and edge areas.

●When measuring deflection, apply 98 N (10 kg, 22 lb) at the ▼ marked point.

CAUTION:

When measuring belt tension immediately after belt is installed, first set the tension to the standard.

Then, rotate crankshaft for more than two turns in order to eliminate variance in belt deflection

between the pulleys. Re-measure and adjust the tension to the standard.

PBIC0764E

Deflection adjustment Unit: mm (in)

Used belt

New belt

Limit After adjustment

AlternatorWithout air conditioner compressor 10.2 (0.402)6.5 - 7.0

(0.256 - 0.276)5.5 - 6.1

(0.217 - 0.240)

With air conditioner compressor 8.1 (0.319)5.3 - 5.7

(0.209 - 0.224)4.5 - 5.0

(0.177 - 0.197)

Power steering oil pump 7.1 (0.280)4.4 - 4.9

(0.173 - 0.193)3.9 - 4.4

(0.154 - 0.173)

Applied pushing force 98 N (10 kg, 22 lb)

Page 90 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-12

[QG]

DRIVE BELTS

Tension Adjustment

EBS00LPZ

CAUTION:

●When belt is replaced with a new one, tighten it a little

stronger than current one to accommodate for insufficient

ada NISSAN ALMERA N16 2003 Electronic Repair Manual EM-12

[QG]

DRIVE BELTS

Tension Adjustment

EBS00LPZ

CAUTION:

●When belt is replaced with a new one, tighten it a little

stronger than current one to accommodate for insufficient

ada](/img/5/57350/w960_57350-89.png)

EM-12

[QG]

DRIVE BELTS

Tension Adjustment

EBS00LPZ

CAUTION:

●When belt is replaced with a new one, tighten it a little

stronger than current one to accommodate for insufficient

adaptability with pulley grooves.

●When tension of belt being used exceeds “Retightening

limit”, adjust it to value for “Used belt”.

●When installing belt, make sure that it is correctly engaged with pulley groove.

●Keep oil and water away from belt.

●Do not twist or bend belt excessively.

●When adjusting belt, remove snap retainer from adjusting bolt thread (to prevent the retainer from

becoming pinched or missing).

●After adjustment, be sure to install snap retainer to adjusting bolt thread.

NOTE:

Snap retainer can prevent adjusting bolt from dropping due to vibration during driving.

POWER STEERING PUMP AND WATER PUMP BELT

1. Loosen lock nut (A) and power steering pump mounting nut (B).

2. Turn adjusting bolt (C) to adjust. Refer to EM-11, "

Checking

Drive Belts" .

3. Tighten lock nut (A) and power steering pump mounting nut (B)

in this order.

ALTERNATOR AND AIR CONDITIONER COMPRESSOR BELT

1. Remove RH splash cover (with undercover attached).

2. Loosen lock nut (G).

3. Turn adjusting bolt (H) to adjust.

Refer to EM-11, "

Checking Drive Belts" .

4. Tighten lock nut (G).

Portion Belt tightening method for adjustment

Power steering pump and water pump

beltAdjusting bolt on power steering pump

Alternator and air conditioner compres-

sor beltAdjusting bolt on idler pulley

PBIC0531E

Nut A :

: 16.7 - 23.5 N·m (1.7 - 2.4 kg-m, 13 - 17 ft-lb)

Nut B :

: 26.5 - 36.3 N·m (2.7 - 3.7 kg-m, 20 - 26 ft-lb)

PBIC0532E

Nut G :

: 24.5 - 31.4 N·m (2.5 - 3.2 kg-m, 18 - 23 ft-lb)

Page 101 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.

NISSAN ALMERA N16 2003 Electronic Repair Manual OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.](/img/5/57350/w960_57350-100.png)

OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.

Remove oil pan.

8. Remove oil strainer.

INSTALLATION

1. Install oil strainer.

NOTE:

Gasket and O-ring are not used for sealed area with oil pump.

2. Install oil pan drain plug.

●Referring to “Components”, install drain plug washer.

3. Apply a continuous bead of liquid gasket to position shown in figure.

Use Genuine Liquid Gasket or equivalent.

4. Tighten mounting nuts and bolts in order shown in figure.

●Install mounting nuts and bolts as follows.

5. Install center member.

Refer to ENGINE ASSEMBLY, EM-67, "

Removal and Installa-

tion" .

6. Install remaining parts in the reverse order of removal.

INSPECTION AFTER INSTALLATION

●Check for leakage of engine oil when engine is warmed.

●Pour engine oil or start engine at least 30 minutes after oil pan is installed.

SEM365EA

PBIC0549E

Mounting bolt:

[Shank length under

head 10 mm (0.39 in)]: Nos. 1 - 10, 13, 14

[Shank length under

head 12 mm (0.47 in)]: Nos. 11, 12

SEM072F

Page 125 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TIMING CHAIN

EM-47

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

TIMING CHAINPFP:13028

Removal and InstallationEBS00LQD

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1. P NISSAN ALMERA N16 2003 Electronic Repair Manual TIMING CHAIN

EM-47

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

TIMING CHAINPFP:13028

Removal and InstallationEBS00LQD

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1. P](/img/5/57350/w960_57350-124.png)

TIMING CHAIN

EM-47

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

TIMING CHAINPFP:13028

Removal and InstallationEBS00LQD

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

1. Place vehicle on lift.

PBIC0971E

1. Cylinder head front cover 2. Camshaft sprocket (INT) 3. Washer

4. Camshaft sprocket (EXH) 5. Chain tensioner 6. Chain slack guide

7. O-ring 8. Power steering pump adjusting bar 9. Crankshaft pulley

10. Front oil seal 11. Front cover 12. Chain tension guide

13. Dowel pin 14. Timing chain 15. Oil pump drive spacer

16. Crankshaft sprocket 17. O-ring (with collar) 18. Auxiliary bolt of cylinder head

Page 126 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-48

[QG]

TIMING CHAIN

2. Disconnect battery ground cable.

3. Remove undercover, front RH wheel and RH splash cover.

4. Drain engine coolant from radiator and cylinder block. Refer to LC-17, "Cha NISSAN ALMERA N16 2003 Electronic Repair Manual EM-48

[QG]

TIMING CHAIN

2. Disconnect battery ground cable.

3. Remove undercover, front RH wheel and RH splash cover.

4. Drain engine coolant from radiator and cylinder block. Refer to LC-17, "Cha](/img/5/57350/w960_57350-125.png)

EM-48

[QG]

TIMING CHAIN

2. Disconnect battery ground cable.

3. Remove undercover, front RH wheel and RH splash cover.

4. Drain engine coolant from radiator and cylinder block. Refer to LC-17, "Changing Engine Coolant".

5. Drain engine oil from oil pan.

6. Remove drive belt. Refer to EM-13, "

Removal and Installation" .

7. Remove power steering pump from adjusting bar.

8. Remove alternator. SC-33, "Removal and Installation".

9. Remove ignition coils. Refer to EM-24, "

IGNITION COIL" .

10. Remove rocker cover. Refer to EM-29, "

Removal and Installation" .

11. Remove oil level gauge.

12. Remove exhaust front tube. Refer to FE-10, "Removal and Installation".

13. Remove center member.

14. Remove gusset.

15. Remove rear plate (lower) (A/T models).

16. Remove oil pan and oil strainer. Refer to EM-22, "

Removal and Installation" .

17. For safe operation, and to reduce load to mount insulator, install removed center member again.

18. Remove engine front-side (right side of vehicle) engine mount. Refer to EM-67, "

ENGINE ASSEMBLY" .

a. Remove any parts that cause difficulties for operation around mount, or perform transfer.

b. Support cylinder block bottom surface with a transmission jack.

CAUTION:

●When applying jack, use a wooden block to avoid damage to oil pan mounting surface.

●While performing following operations, support engine front-side with jack.

c. Separate engine mounting insulator and bracket.

d. Remove engine mounting bracket.

19. Remove cylinder head front cover.

●Move harness which was previously fixed on front surface.

20. Remove auxiliary bolts of cylinder head.

21. Set the No. 1 cylinder to the compression TDC.

a. Turn the crankshaft pulley clockwise, and align the timing indica-

tor of the gear case to the timing mark of the crankshaft pulley.

PBIC0557E

PBIC0750E

Page 127 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TIMING CHAIN

EM-49

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

b. Make sure that the camshaft sprocket mating mark is in the

position shown in the figure.

●If the mating mark is not in position, turn t NISSAN ALMERA N16 2003 Electronic Repair Manual TIMING CHAIN

EM-49

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

b. Make sure that the camshaft sprocket mating mark is in the

position shown in the figure.

●If the mating mark is not in position, turn t](/img/5/57350/w960_57350-126.png)

TIMING CHAIN

EM-49

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

b. Make sure that the camshaft sprocket mating mark is in the

position shown in the figure.

●If the mating mark is not in position, turn the crankshaft pulley

once more and position it.

22. Remove crankshaft pulley with the following procedure:

a. Secure crankshaft counter weight with handle of a hammer, and

loosen crankshaft pulley bolts.

CAUTION:

Take care to prevent foreign material from entering the

engine.

b. Remove crankshaft pulley using crankshaft pulley puller (com-

mercial service tool).

CAUTION:

●Hook tab onto back of crankshaft pulley only.

●Do not remove crankshaft pulley bolt. Fully loosen, and

then use it as support point.

NOTE:

If oil pan is not removed, remove crankshaft pulley as follows.

i. Remove rear plate (lower).

ii. Engage drive plate ring gear with a flat-head screwdriver to fix

crankshaft in position, and loosen crankshaft pulley bolt.

iii. Remove crankshaft pulley using crankshaft pulley puller (com-

mercial service tool).

23. Remove water pump pulley and idler pulley bracket assembly.

MBIB0194E

PBIC0565E

KBIA1437E

KBIA1438E