Resistor NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1186 of 3189

AEC640

Overall Function Check

SEF111X

SEC163BA

MEC475B

NJEC0664Use this procedure to check the overall function of the cooling fan.

During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

WITH CONSULT-IINJEC0664S011) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to “Diagnos-

tic Procedure”, EC-134.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to “Diagnos-

tic Procedure”, EC-134.

3) Turn ignition switch “ON”.

4) Perform “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II and make sure that cooling fans operate when touch-

ing “HIGH” or “LOW”.

If NG, go to “Diagnostic Procedure”, EC-134.

WITHOUT CONSULT-IINJEC0664S021) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to “Diagnos-

tic Procedure”, EC-134.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to “Diagnos-

tic Procedure”, EC-134.

3) Start engine.

Be careful not to overheat engine.

4) Set temperature control lever to full cold position.

5) Turn air conditioner switch “ON”.

6) Turn blower fan switch “ON”.

7) Run engine at idle for a few minutes with air conditioner oper-

ating.

Be careful not to overheat engine.

8) Make sure that cooling fans operate at low speed.

9) Turn ignition switch “OFF”.

10) Turn air conditioner switch and blower fan switch “OFF”.

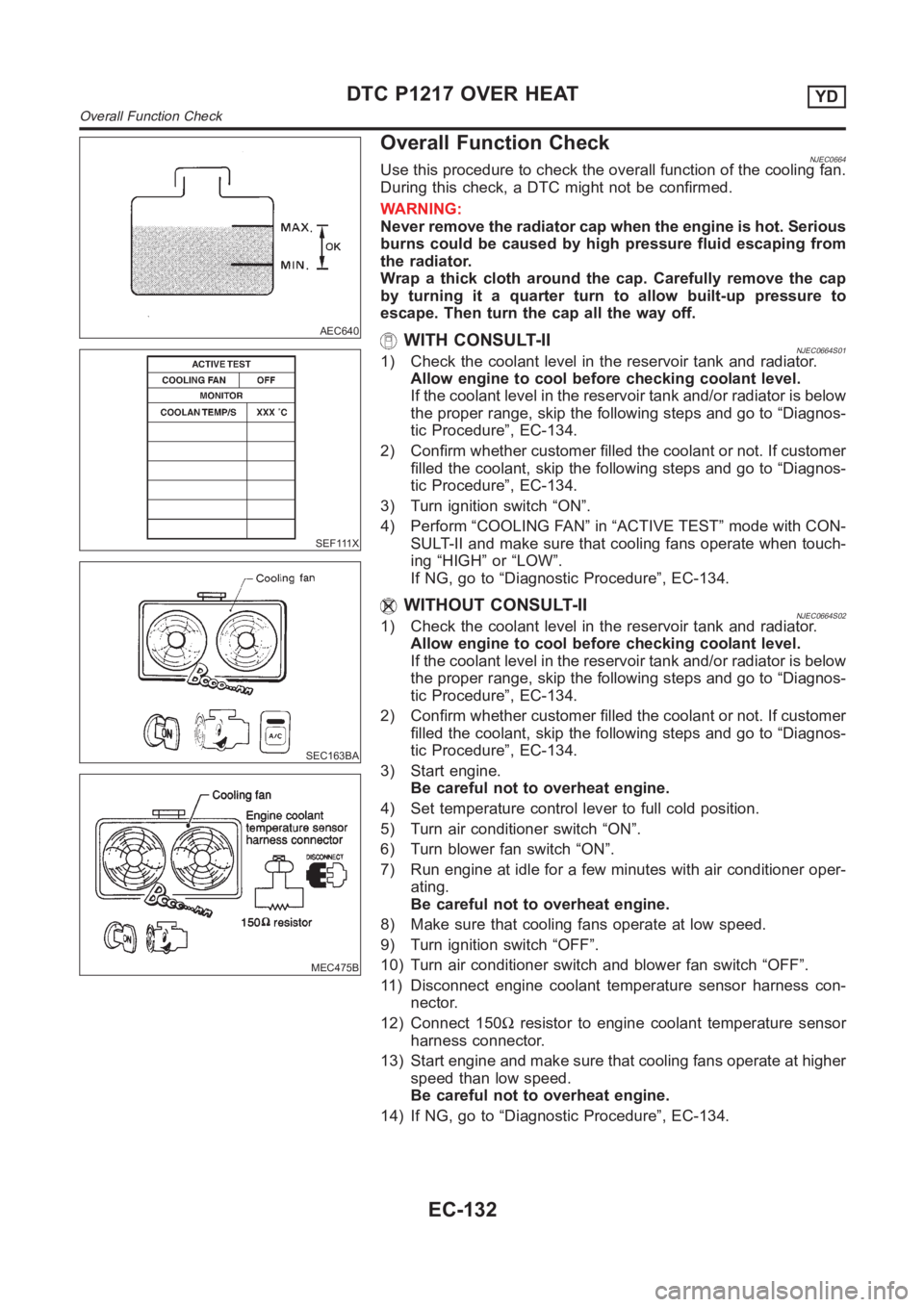

11) Disconnect engine coolant temperature sensor harness con-

nector.

12) Connect 150Ωresistor to engine coolant temperature sensor

harness connector.

13) Start engine and make sure that cooling fans operate at higher

speed than low speed.

Be careful not to overheat engine.

14) If NG, go to “Diagnostic Procedure”, EC-134.

DTC P1217 OVER HEATYD

Overall Function Check

EC-132

Page 1190 of 3189

5 CHECK COOLING FAN HIGH SPEED OPERATION

Without CONSULT-II

1. Turn ignition switch “OFF”.

2. Reconnect cooling fan relay-3.

3. Turn air conditioner switch and blower fan switch “OFF”.

4. Disconnect engine coolant temperature sensor harness connector.

5. Connect 150Ωresistor to engine coolant temperature sensor harness connector.

6. Restart engine and make sure that cooling fans-1 and -2 operate at high speed.

MEC475B

OK or NG

OK GO TO 6.

NG Check cooling fan high speed control circuit. (Go to PROCEDURE B, EC-141.)

6 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm2,23psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK GO TO 8.

NG GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following for leak.

Hose

Radiator

Water pump (Refer to LC-38, “Water Pump”.)

Repair or replace.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-136

Page 1460 of 3189

AT-4

REMOVAL AND INSTALLATION ...........................410

Removal ...............................................................410

Installation .............................................................411

OVERHAUL .............................................................413

Output Shaft, Idler Gear, Reduction Pinion Gear and

Bearing Retainer ...................................................413

Oil Channel ...........................................................416

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................417

DISASSEMBLY .......................................................418

Disassembly .........................................................418

REPAIR FOR COMPONENT PARTS ......................432

Manual Shaft ........................................................432

Oil Pump ...............................................................435

Control Valve Assembly ........................................439

Control Valve Upper Body ....................................449

Control Valve Lower Body ....................................453

Reverse Clutch .....................................................455

High Clutch ...........................................................459

Forward and Overrun Clutches ............................464

Low & Reverse Brake ...........................................470

Rear Internal Gear, Forward Clutch Hub and Over-

run Clutch Hub ......................................................474

Output Shaft, Idler Gear, Reduction Pinion Gear and

Bearing Retainer ...................................................478

Band Servo Piston Assembly ...............................483

Final Drive ............................................................488

ASSEMBLY .............................................................493

Assembly (1) .........................................................493Adjustment (1) .......................................................494

Assembly (2) .........................................................500

Adjustment (2) .......................................................504

Assembly (3) .........................................................508

SERVICE DATA AND SPECIFICATIONS (SDS) ....515

General Specifications ......................................... .515

Shift Schedule .......................................................515

Stall Revolution .....................................................515

Line Pressure ........................................................515

Control Valves .......................................................516

Clutch and Brakes .................................................516

Clutch and Brake Return Springs .........................518

Oil Pump ......................................................

.........518

Input Shaft .............................................................518

Planetary carrier ....................................................518

Final Drive .............................................................519

Reduction Pinion Gear ..........................................520

Output Shaft ..........................................................522

Bearing Retainer ...................................................523

Total End Play .......................................................523

Reverse Clutch End Play ......................................523

Accumulator ..........................................................523

Band Servo ...........................................................524

Removal and Installation .......................................524

Shift Solenoid Valves ............................................524

Solenoid Valves ....................................................524

A/T Fluid Temperature Sensor ..............................524

Revolution Sensor .................................................524

Dropping Resistor .................................................524

Page 1524 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual AT-68

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

JUDGEMENT OF LINE PRESSURE TEST

Road TestECS007NZ

DESCRIPTION

●The purpose of the test is to determine overall performance of A/

T and analyze NISSAN ALMERA N16 2003 Electronic Repair Manual AT-68

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

JUDGEMENT OF LINE PRESSURE TEST

Road TestECS007NZ

DESCRIPTION

●The purpose of the test is to determine overall performance of A/

T and analyze](/img/5/57350/w960_57350-1523.png)

AT-68

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

JUDGEMENT OF LINE PRESSURE TEST

Road TestECS007NZ

DESCRIPTION

●The purpose of the test is to determine overall performance of A/

T and analyze causes of problems.

●The road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

3. Cruise test

●Before road test, familiarize yourself with all test procedures and

items to check.

●Conduct tests on all items until specified symptom is found.

Troubleshoot items which check out No Good after road test.

Refer to the following items.

Judgement Suspected parts

At idleLine pressure is low in all positions.

●Oil pump wear

●Control piston damage

●Pressure regulator valve or plug sticking

●Spring for pressure regulator valve damaged

●Line pressure leakage between oil strainer and pressure regulator valve

●Clogged strainer

Line pressure is low in particular posi-

tion.

●Line pressure leakage between manual valve and particular clutch

●For example, line pressure is:

− Low in “R” and “1” positions, but

− Normal in “D” and “2” positions.

Therefore, fluid leakage exists at or around low and reverse brake circuit.

Refer to AT- 1 8 , "

Shift Mechanism" .

Line pressure is high.

●Maladjustment of throttle position sensor

●A/T fluid temperature sensor damaged

●Line pressure solenoid valve sticking

●Short circuit of line pressure solenoid valve circuit

●Pressure modifier valve sticking

●Pressure regulator valve or plug sticking

●Open in dropping resistor circuit

At stall

speedLine pressure is low.

●Maladjustment of throttle position sensor

●Line pressure solenoid valve sticking

●Short circuit of line pressure solenoid valve circuit

●Pressure regulator valve or plug sticking

●Pressure modifier valve sticking

●Pilot valve sticking

SAT786A

SAT496G

Page 1562 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual AT-106

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

TCM Terminals and Reference ValueECS007O1

NISSAN ALMERA N16 2003 Electronic Repair Manual AT-106

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

TCM Terminals and Reference ValueECS007O1](/img/5/57350/w960_57350-1561.png)

AT-106

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

TCM Terminals and Reference ValueECS007O1

PREPARATION

●Measure voltage between each terminal and terminal 25 or 48

by following “TCM INSPECTION TABLE”.

TCM HARNESS CONNECTOR TERMINAL LAYOUT

TCM INSPECTION TABLE

(Data are reference values.)

Monitor item Condition Specification (Approximately)

A/T fluid temperature sensorCold [20°C (68°F)]

↓

Hot [80°C (176°F)]1.5V

↓

0.5V2.5kΩ

↓

0.3kΩ

Line pressure solenoid valve dutySmall throttle opening

(Low line pressure)

↓

Large throttle opening

(High line pressure)Approximately 24%

↓

Approximately 95%

Torque converter clutch solenoid valve dutyLock-up “OFF”

↓

Lock-up “ON”Approximately 4%

↓

Approximately 94%

Throttle position sensor (Accelerator pedal

position (APP) sensor)Fully-closed throttle Approximately 0.5V

Fully-open throttle Approximately 4V

SAT216J

SAT999J

Te r m i -

nal No.Wire color Item ConditionJudgement stan-

dard(Approx.)

1R/WLine pressure

solenoid valveWhen releasing accelerator pedal

after warming up engine.1.5 - 3.0V

When depressing accelerator pedal

fully after warming up engine.0V

2P/BLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal

after warming up engine.4 - 14V

When depressing accelerator pedal

fully after warming up engine.0V

Page 1587 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0725 ENGINE SPEED SIGNAL

AT-131

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS007OH

1.CHECK DTC WITH ECM

Perform “Overall function check” for ignition signal. Refer to EC-369, & NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0725 ENGINE SPEED SIGNAL

AT-131

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS007OH

1.CHECK DTC WITH ECM

Perform “Overall function check” for ignition signal. Refer to EC-369, &](/img/5/57350/w960_57350-1586.png)

DTC P0725 ENGINE SPEED SIGNAL

AT-131

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS007OH

1.CHECK DTC WITH ECM

Perform “Overall function check” for ignition signal. Refer to EC-369, "

Diagnostic Procedure" .

OK or NG

OK (With CONSULT-II)>>GO TO 2

OK (Without CONSULT-II)>>GO TO 3

NG >> Follow the construction of EC-369, "

Diagnostic Procedure" .

2.CHECK INPUT SIGNAL (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out the value of “ENGINE SPEED”.

Check engine speed changes according to throttle position.

OK or NG

OK >> GO TO 4

NG >> Check the following items:

●Harness for short or open between TCM and ECM

●Resistor and ignition coil Refer to EC-365, "IGNITION

SIGNAL" .

3.CHECK INPUT SIGNAL (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 39 and ground.

OK or NG

OK >> GO TO 4

NG >> Check the following items:

●Harness for short or open between TCM and ECM

●Resistor and ignition coil EC-365, "IGNITION SIG-

NAL" .

SAT014K

SAT645J

Voltage (Idle speed): Refer to EC-65, "Basic Inspection" .

SCIA0740E

Page 1607 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0734 A/T 4TH GEAR FUNCTION

AT-151

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0734 A/T 4TH GEAR FUNCTIONPFP:31940

DescriptionECS007OU

●This is an OBD-II self-diagnostic item and not available in NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0734 A/T 4TH GEAR FUNCTION

AT-151

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0734 A/T 4TH GEAR FUNCTIONPFP:31940

DescriptionECS007OU

●This is an OBD-II self-diagnostic item and not available in](/img/5/57350/w960_57350-1606.png)

DTC P0734 A/T 4TH GEAR FUNCTION

AT-151

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0734 A/T 4TH GEAR FUNCTIONPFP:31940

DescriptionECS007OU

●This is an OBD-II self-diagnostic item and not available in TCM self-diagnosis.

●This malfunction will not be detected while the O/D OFF indicator lamp is indicating another self-diagnosis

malfunction.

●This malfunction is detected when the A/T does not shift into fourth gear position or the torque converter

clutch does not lock up as instructed by the TCM. This is not caused by electrical malfunction (circuits

open or shorted) but by mechanical malfunction such as control valve sticking, improper solenoid valve

operation, malfunctioning oil pump or torque converter clutch, etc.

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

TCM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values.

ON BOARD DIAGNOSTIC LOGIC

This diagnosis monitors actual gear position by checking the torque converter slip ratio calculated by TCM as

follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the position (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach the specified value, TCM judges this diagnosis malfunction.

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

Monitor item Condition Specification

Line pressure solenoid valve dutySmall throttle opening

(Low line pressure)

↓

Large throttle opening

(High line pressure)Approximately 24%

↓

Approximately 95%

Te r m i -

nal No.Wire color Item ConditionJudgement stan-

dard

(Approx.)

1R/WLine pressure

solenoid valveWhen releasing accelerator pedal

after warming up engine.1.5 - 3.0V

When depressing accelerator pedal

fully after warming up engine.0V

2P/BLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal

after warming up engine.5 - 14V

When depressing accelerator pedal

fully after warming up engine.0V

11 L / WShift solenoid

valve AWhen shift solenoid valve A oper-

ates.

(When driving in “D

1 ” or “D4 ”.)Battery voltage

When shift solenoid valve A does not

operate.

(When driving in “D

2 ” or “D3 ”.)0V

12 L/YShift solenoid

valve BWhen shift solenoid valve B oper-

ates.

(When driving in “D

1 ” or “D2 ”.)Battery voltage

When shift solenoid valve B does not

operate.

(When driving in “D

3 ” or “D4 ”.)0V

Page 1620 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual AT-164

[EURO-OBD]

DTC P0745 LINE PRESSURE SOLENOID VALVE

DTC P0745 LINE PRESSURE SOLENOID VALVE

PFP:31940

DescriptionECS007P2

The line pressure solenoid valve regulates the oil pump discharge NISSAN ALMERA N16 2003 Electronic Repair Manual AT-164

[EURO-OBD]

DTC P0745 LINE PRESSURE SOLENOID VALVE

DTC P0745 LINE PRESSURE SOLENOID VALVE

PFP:31940

DescriptionECS007P2

The line pressure solenoid valve regulates the oil pump discharge](/img/5/57350/w960_57350-1619.png)

AT-164

[EURO-OBD]

DTC P0745 LINE PRESSURE SOLENOID VALVE

DTC P0745 LINE PRESSURE SOLENOID VALVE

PFP:31940

DescriptionECS007P2

The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

NOTE:

The line pressure duty cycle value is not consistent when the

closed throttle position switch is “ON”. To confirm the line

pressure duty cycle at low pressure, the accelerator (throttle)

should be open until the closed throttle position switch is

“OFF”.

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

NOTE:

The line pressure duty cycle value is not consistent when the closed throttle position switch is “ON”. To confirm the line pressure duty

cycle at low pressure, the accelerator (throttle) should be open until the closed throttle position switch is “OFF”.

TCM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values.

ON BOARD DIAGNOSIS LOGIC

SCIA0735E

Monitor item Condition Specification

Line pressure solenoid valve dutySmall throttle opening

(Low line pressure)

↓

Large throttle opening

(High line pressure)Approximately 24%

↓

Approximately 95%

Termi-

nal No.Wire color Item ConditionJudgement stan-

dard

(Approx.)

1R/WLine pressure

solenoid valveWhen releasing accelerator pedal

after warming up engine.1.5 - 3.0V

When depressing accelerator pedal

fully after warming up engine.0V

2P/BLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal

after warming up engine.4 - 14V

When depressing accelerator pedal

fully after warming up engine.0V

Diagnostic trouble code Malfunction is detected when... Check items (Possible cause)

: L/PRESS SOL/CIRC

TCM detects an improper voltage drop

when it tries to operate the solenoid valve.

●Harness or connectors

(The solenoid circuit is open or shorted.)

●Line pressure solenoid valve

: P0745

Page 1623 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0745 LINE PRESSURE SOLENOID VALVE

AT-167

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS007P4

1.CHECK VALVE RESISTANCE

1. Turn ignition switch to “OFF” position.

2. Disconnect te NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0745 LINE PRESSURE SOLENOID VALVE

AT-167

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS007P4

1.CHECK VALVE RESISTANCE

1. Turn ignition switch to “OFF” position.

2. Disconnect te](/img/5/57350/w960_57350-1622.png)

DTC P0745 LINE PRESSURE SOLENOID VALVE

AT-167

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS007P4

1.CHECK VALVE RESISTANCE

1. Turn ignition switch to “OFF” position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 4 and ground.

OK or NG

OK >> GO TO 2

NG >>1.Remove control valve assembly. Refer to AT- 4 0 6 ,

"Control Valve Assembly and Accumulators" .

2. Check the following items:

–Line pressure solenoid valve

Refer to AT- 1 6 9 , "

Component Inspection" .

–Harness of terminal cord assembly for short or open

2.CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to “OFF” position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 4 and TCM harness connector terminal 2.

OK or NG

OK >> GO TO 3

NG >> Check the following items:

●Dropping resistor

Refer to AT- 1 6 9 , "

Component Inspection" .

●Harness for short or open between TCM terminal 2

and terminal cord assembly Resistance: 2.5 - 5Ω

SAT895JA

Resistance: 10 - 15Ω

SAT896JB

Page 1626 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual AT-170

[EURO-OBD]

DTC P0745 LINE PRESSURE SOLENOID VALVE

DROPPING RESISTOR

●Check resistance between two terminals.

Resistance: 10 - 15Ω

SAT003K NISSAN ALMERA N16 2003 Electronic Repair Manual AT-170

[EURO-OBD]

DTC P0745 LINE PRESSURE SOLENOID VALVE

DROPPING RESISTOR

●Check resistance between two terminals.

Resistance: 10 - 15Ω

SAT003K](/img/5/57350/w960_57350-1625.png)

AT-170

[EURO-OBD]

DTC P0745 LINE PRESSURE SOLENOID VALVE

DROPPING RESISTOR

●Check resistance between two terminals.

Resistance: 10 - 15Ω

SAT003K