keyless NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2691 of 3189

SIIA1645E

Trouble Diagnoses/QG and YD Engine Models

with Common Rail

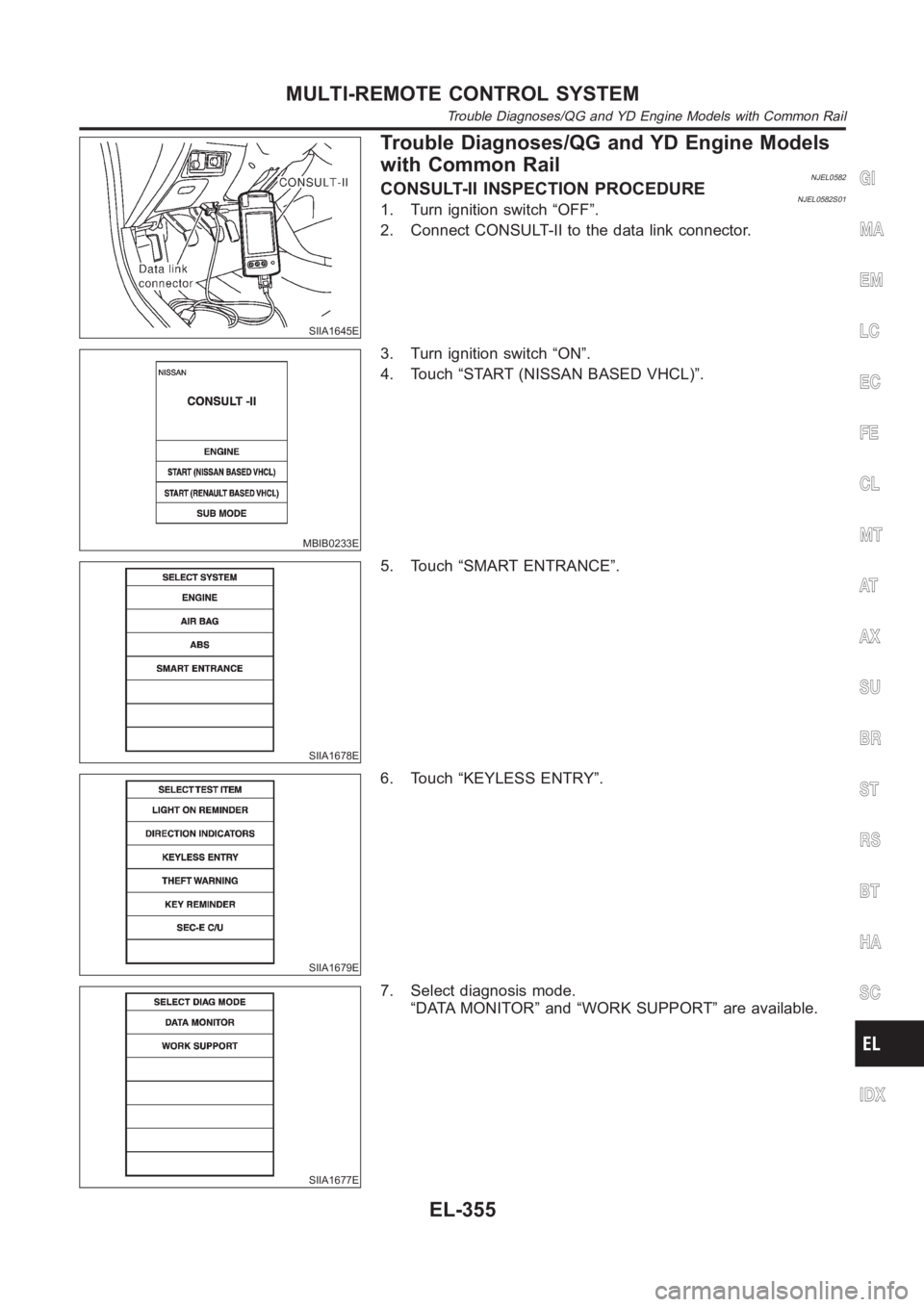

NJEL0582CONSULT-II INSPECTION PROCEDURENJEL0582S011. Turn ignition switch “OFF”.

2. Connect CONSULT-II to the data link connector.

MBIB0233E

3. Turn ignition switch “ON”.

4. Touch “START (NISSAN BASED VHCL)”.

SIIA1678E

5. Touch “SMART ENTRANCE”.

SIIA1679E

6. Touch “KEYLESS ENTRY”.

SIIA1677E

7. Select diagnosis mode.

“DATA MONITOR” and “WORK SUPPORT” are available.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

MULTI-REMOTE CONTROL SYSTEM

Trouble Diagnoses/QG and YD Engine Models with Common Rail

EL-355

Page 2692 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CONSULT-II APPLICATION ITEMSNJEL0582S02DATA MONITOR

Monitored Item Description

IGNITION SW Indicates [ON/OFF] condition of ignition switch in ON position.

TRUNK OPEN SW Indicates [ON/OFF] condition of NISSAN ALMERA N16 2003 Electronic Repair Manual CONSULT-II APPLICATION ITEMSNJEL0582S02DATA MONITOR

Monitored Item Description

IGNITION SW Indicates [ON/OFF] condition of ignition switch in ON position.

TRUNK OPEN SW Indicates [ON/OFF] condition of](/img/5/57350/w960_57350-2691.png)

CONSULT-II APPLICATION ITEMSNJEL0582S02DATA MONITOR

Monitored Item Description

IGNITION SW Indicates [ON/OFF] condition of ignition switch in ON position.

TRUNK OPEN SW Indicates [ON/OFF] condition of trunk room lamp switch (sedan) or back door switch (wagon).

RKE LOCK Indicates [ON/OFF] condition of lock signal from remote controller.

RKE UNLOCK Indicates [ON/OFF] condition of unlock signal from remote controller.

RKE SEL UNLOCK Indicates [ON/OFF] condition of select unlock signal from remote controller.

RKE TRUNK RELIndicates [ON/OFF] condition of trunk (sedan) or back door (wagon) open signal from trunk or

back door release switch.

BATTERY CHECK Indicates [OK/NG] condition of remote controller battery.

WORK SUPPORT

Test Item Description

KEYLESS CHECK It can be checked whether remote controller ID code is registered or not in this mode.

KEYLESS REGISTRATION Remote controller ID code can be registered.

KEYLESS DI FLASH This mode can be setting remote controller function.

SYMPTOM CHARTNJEL0582S03First perform the “SELF-DIAG RESULTS” in “SMART ENTRANCE”

with CONSULT-II, when perform the each trounble diagnosis. Refer

to EL-355, “CONSULT-II INSPECTION PROCEDURE”.

NOTE:

Always check remote controller battery before replacing

remote controller.

Symptom Diagnoses/service procedureReference

page

All function of multi-remote control system do not

operate.Remote controller battery check EL-357

Power supply and ground circuit for smart entrance control

unit checkEL-358

.If above systems are OK, replace smart entrance control unit. —

The new ID of remote controller cannot be

entered.Remote controller battery check EL-357

Key switch check —

Door switch check —

Power supply and ground circuit check EL-358

If above systems are OK, replace smart entrance control unit. —

Door lock or unlock does not function.If the power door lock system does not operate manually,

check power door lock system.EL-356

Remote controller battery check EL-357

If above systems are OK, replace smart entrance control unit. —

Hazard reminder does not activate properly

when pressing lock or unlock button of remote

controller.Remote controller battery check EL-357

Hazard reminder check EL-359

If above systems are OK, replace smart entrance control unit. —

MULTI-REMOTE CONTROL SYSTEM

Trouble Diagnoses/QG and YD Engine Models with Common Rail (Cont’d)

EL-356

Page 2706 of 3189

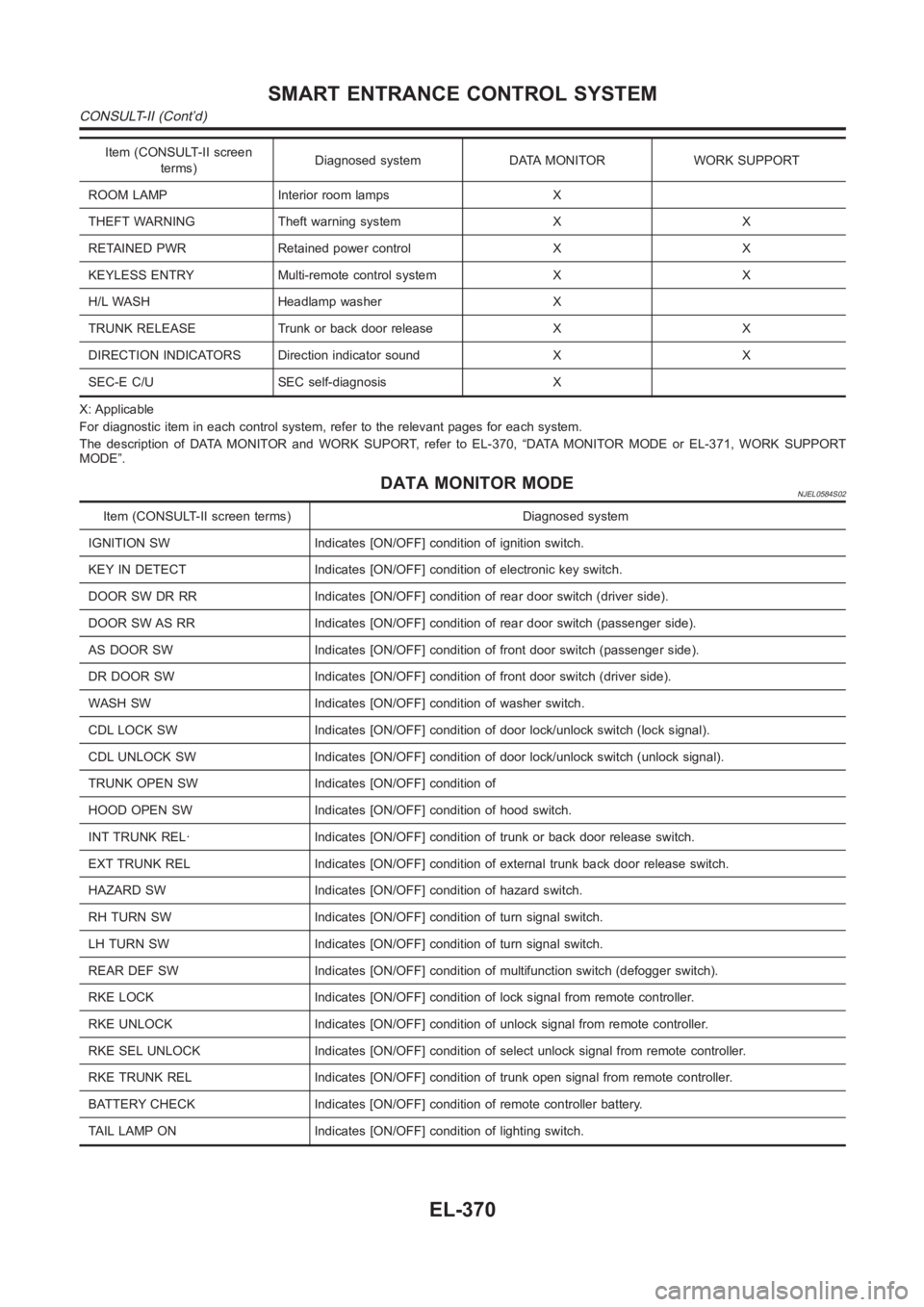

Item (CONSULT-II screen

terms)Diagnosed system DATA MONITOR WORK SUPPORT

ROOM LAMP Interior room lamps X

THEFT WARNING Theft warning system X X

RETAINED PWR Retained power control X X

KEYLESS ENTRY Multi-remote control system X X

H/L WASH Headlamp washer X

TRUNK RELEASE Trunk or back door release X X

DIRECTION INDICATORS Direction indicator sound X X

SEC-E C/U SEC self-diagnosis X

X: Applicable

For diagnostic item in each control system, refer to the relevant pages foreach system.

The description of DATA MONITOR and WORK SUPORT, refer to EL-370, “DATA MONITOR MODE or EL-371, WORK SUPPORT

MODE”.

DATA MONITOR MODENJEL0584S02

Item (CONSULT-II screen terms) Diagnosed system

IGNITION SW Indicates [ON/OFF] condition of ignition switch.

KEY IN DETECT Indicates [ON/OFF] condition of electronic key switch.

DOOR SW DR RR Indicates [ON/OFF] condition of rear door switch (driver side).

DOOR SW AS RR Indicates [ON/OFF] condition of rear door switch (passenger side).

AS DOOR SW Indicates [ON/OFF] condition of front door switch (passenger side).

DR DOOR SW Indicates [ON/OFF] condition of front door switch (driver side).

WASH SW Indicates [ON/OFF] condition of washer switch.

CDL LOCK SW Indicates [ON/OFF] condition of door lock/unlock switch (locksignal).

CDL UNLOCK SW Indicates [ON/OFF] condition of door lock/unlock switch (unlock signal).

TRUNK OPEN SW Indicates [ON/OFF] condition of

HOOD OPEN SW Indicates [ON/OFF] condition of hood switch.

INT TRUNK REL· Indicates [ON/OFF] condition of trunk or back door release switch.

EXT TRUNK REL Indicates [ON/OFF] condition of external trunk back door release switch.

HAZARD SW Indicates [ON/OFF] condition of hazard switch.

RH TURN SW Indicates [ON/OFF] condition of turn signal switch.

LH TURN SW Indicates [ON/OFF] condition of turn signal switch.

REAR DEF SW Indicates [ON/OFF] condition of multifunction switch (defogger switch).

RKE LOCK Indicates [ON/OFF] condition of lock signal from remote controller.

RKE UNLOCK Indicates [ON/OFF] condition of unlock signal from remote controller.

RKE SEL UNLOCK Indicates [ON/OFF] condition of select unlock signal from remote controller.

RKE TRUNK REL Indicates [ON/OFF] condition of trunk open signal from remote controller.

BATTERY CHECK Indicates [ON/OFF] condition of remote controller battery.

TAIL LAMP ON Indicates [ON/OFF] condition of lighting switch.

SMART ENTRANCE CONTROL SYSTEM

CONSULT-II (Cont’d)

EL-370

Page 2707 of 3189

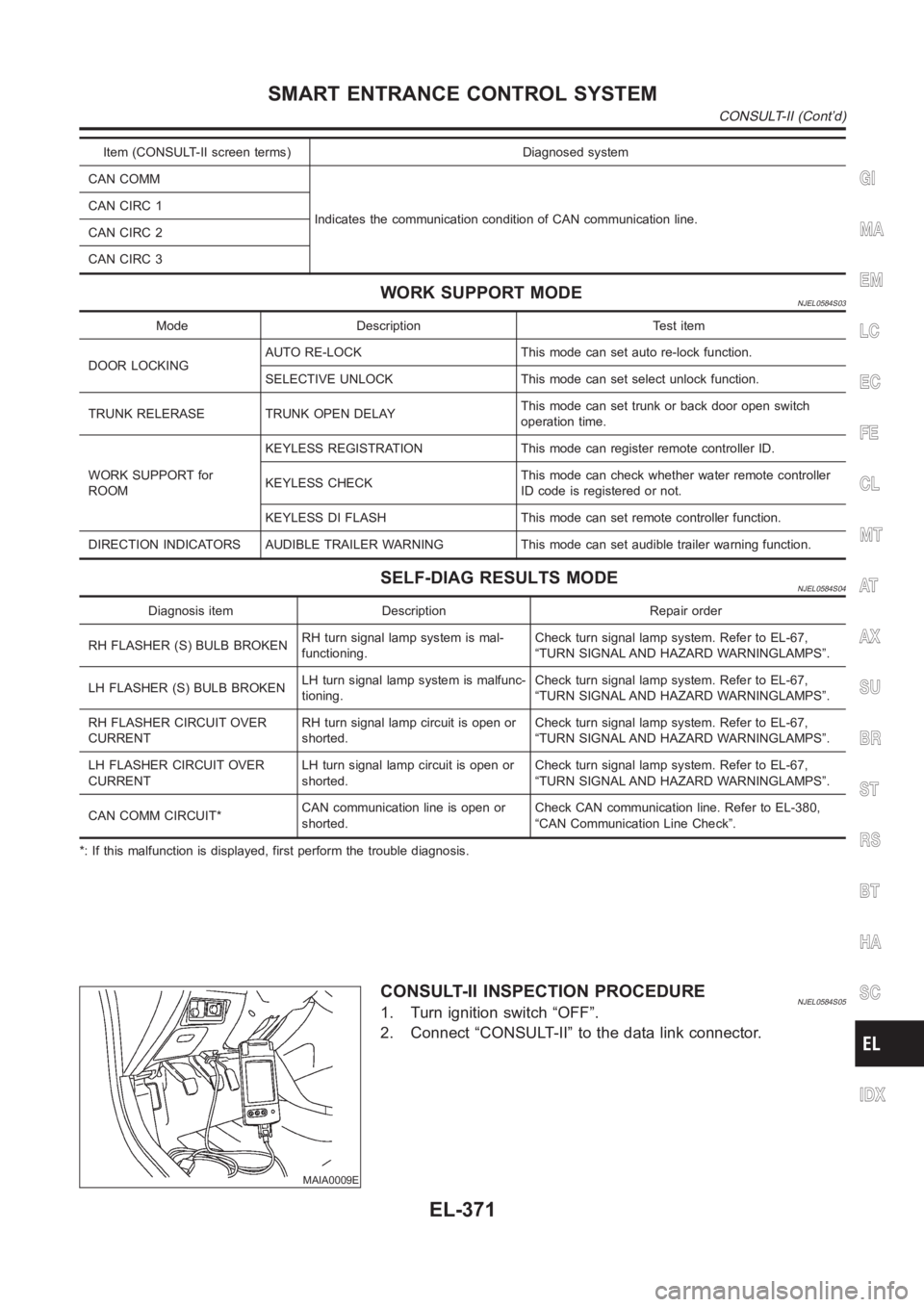

Item (CONSULT-II screen terms) Diagnosed system

CAN COMM

Indicates the communication condition of CAN communication line. CANCIRC1

CANCIRC2

CANCIRC3

WORK SUPPORT MODENJEL0584S03

Mode Description Test item

DOOR LOCKINGAUTO RE-LOCK This mode can set auto re-lock function.

SELECTIVE UNLOCK This mode can set select unlock function.

TRUNK RELERASE TRUNK OPEN DELAYThis mode can set trunk or back door open switch

operation time.

WORK SUPPORT for

ROOMKEYLESS REGISTRATION This mode can register remote controller ID.

KEYLESS CHECKThis mode can check whether water remote controller

ID code is registered or not.

KEYLESS DI FLASH This mode can set remote controller function.

DIRECTION INDICATORS AUDIBLE TRAILER WARNING This mode can set audible trailer warning function.

SELF-DIAG RESULTS MODENJEL0584S04

Diagnosis item Description Repair order

RH FLASHER (S) BULB BROKENRH turn signal lamp system is mal-

functioning.Check turn signal lamp system. Refer to EL-67,

“TURN SIGNAL AND HAZARD WARNINGLAMPS”.

LH FLASHER (S) BULB BROKENLH turn signal lamp system is malfunc-

tioning.Check turn signal lamp system. Refer to EL-67,

“TURN SIGNAL AND HAZARD WARNINGLAMPS”.

RH FLASHER CIRCUIT OVER

CURRENTRH turn signal lamp circuit is open or

shorted.Check turn signal lamp system. Refer to EL-67,

“TURN SIGNAL AND HAZARD WARNINGLAMPS”.

LH FLASHER CIRCUIT OVER

CURRENTLH turn signal lamp circuit is open or

shorted.Check turn signal lamp system. Refer to EL-67,

“TURN SIGNAL AND HAZARD WARNINGLAMPS”.

CAN COMM CIRCUIT*CAN communication line is open or

shorted.Check CAN communication line. Refer to EL-380,

“CAN Communication Line Check”.

*: If this malfunction is displayed, first perform the trouble diagnosis.

MAIA0009E

CONSULT-II INSPECTION PROCEDURENJEL0584S051. Turn ignition switch “OFF”.

2. Connect “CONSULT-II” to the data link connector.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

SMART ENTRANCE CONTROL SYSTEM

CONSULT-II (Cont’d)

EL-371

Page 3180 of 3189

Heated oxygen sensor 2 heater

(QG engine)................................EC-129, EC-640

Heated seat<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110028002f[-247

HEATER - Wiring diagram (manual

A/C) <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[..HA-23

Heater and cooling unit (Heater core)

(manual A/C) ...............................................HA-87

Heater and cooling unit (Heater core)........ATC-123

Heater unit (heater core) ............................ATC-130

Height (Dimensions) ........................................GI-44

HFC134a (R134a) system precaution

(manual A/C) .................................................HA-2

HFC134a (R134a) system precaution............ATC-4

HFC134a (R134a) system service pro-

cedure (manual A/C)...................................HA-77

HFC134a (R134a) system service

procedure ................................................ATC-133

HFC134a (R134a) system service tools

(manual A/C) ...............................................HA-10

HFC134a (R134a) system service tools ......ATC-11

HFC134a system service equipment

precaution (manual A/C) ...............................HA-6

HFC134a system service equipment

precaution <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110024>�TC-7

HO2S1 - Wiring diaram

(QG engine) ................EC-152, EC-159, EC-169,

EC-510, EC-516

HO2S1H - Wiring diagram (QG engine) ......EC-125

HO2S2 - Wiring diagram

(QG engine) ................EC-175, EC-182, EC-312,

EC-320, EC-522

HO2S2H - Wiring diagram (QG engine) ......EC-131

Hood<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.......BT-7

HORN - Wiring diagram................................EL-170

Horn <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[...EL-170

How to erase DTC for OBD system

(QG engine)..................................EC-48, EC-431

How to erase DTC for OBD system

(YD engine).................................................EC-34

HSEAT - Wiring diagram ......................EL-246, 247

I

IATS - Wiring diagram (QG engine) .............EC-142

IATSEN - Wiring diagram (QG engine) ........EC-646

Identification plate............................................GI-41

Identification .....................................ATC-9, ATC-10

Idle air volume learning

(QG engine)..................................EC-31, EC-426

Idle speed (QG engine) ...................EC-65, EC-444

Idle speed (YD engine) ..................................EC-48

Ignition coil (QG engine) ................EC-366, EC-662

Ignition coil (QG engine) ................................EM-24

Ignition control system

(QG engine)................................EC-366, EC-662

Ignition timing (QG engine)..............EC-65, EC-444

IGNSYS - Wiring diagram

(QG engine)................................EC-367, EC-663

ILL - Wiring diagram .......................................EL-76

Illumination <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11[...EL-75In vehicle sensor ........ATC-103, ATC-105, ATC-117

INJECT - Wiring diagram

(QG engine)................................EC-377, EC-696

Injection nozzle (YD engine) ..........................EC-21

Injector (QG engine) ......................EC-376, EC-695

Input shaft (FF M/T).....................MT-36, 64, 93, 98

Instrument panel .............................................BT-25

INT/L - Wiring diagram..................................EL-108

Intake air temperature sensor

(QG engine)................................EC-141, EC-645

Intake door control linkage adjustment ........ATC-67

Intake door motor .........................ATC-66, ATC-122

Intake manifold (QG engine) .........................EM-16

Intake sensor ..............................ATC-109, ATC-119

Intake valve timing control

(QG engine) .................EC-120, EC-273, EC-685

Intake valve timing control solenoid

valve (QG engine) ......................EC-273, EC-685

Interior lamp on-off control........................EL-81, 83

Interior lamp <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11[.EL-80

Interior <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[......BT-31

ISO 15031-2 Terminology ................................GI-51

ISO 15031-5 Mode 1 - 9 (QG engine) ...........EC-36

IVC - Wiring diagram (QG engine)...............EC-274

IVC/V - Wiring diagram (QG engine) ...........EC-687

J

Jacking points ..................................................GI-46

Joint connector (J/C) ....................................Foldout

Junction box (J/B).........................................Foldout

K

Keyless entry system - See Multi-re-

mote control system ..................................EL-352

Knock sensor (KS) (QG engine) ....EC-231, EC-552

Knuckle spindle ................................................AX-5

KS - Wiring diagram

(QG engine)................................EC-232, EC-553

L

LAN system circuit........................................ATC-57

Length (Dimensions) .......................................GI-44

License lamp <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110028[L-55

Lifting points ....................................................GI-47

Line pressure solenoid valve ........................AT-159

Line pressure test (A/T) .....................AT-67, AT-266

Liquid gasket application (QG engine) ............EM-4

Liquid gasket application (YD engine) .............EM-3

LOAD - Wiring diagram

(QG engine)................................EC-394, EC-713

Location of electrical units ............................EL-543

Lock, door <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[.BT-21

Lubricant (R134a) A/C (manual A/C) .............HA-79

Lubricant (R134a) A/C......................ATC-5, ATC-20

ALPHABETICAL INDEX

IDX-6