fuse NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 66 of 3051

Diagnostic ProcedureNLAT0330

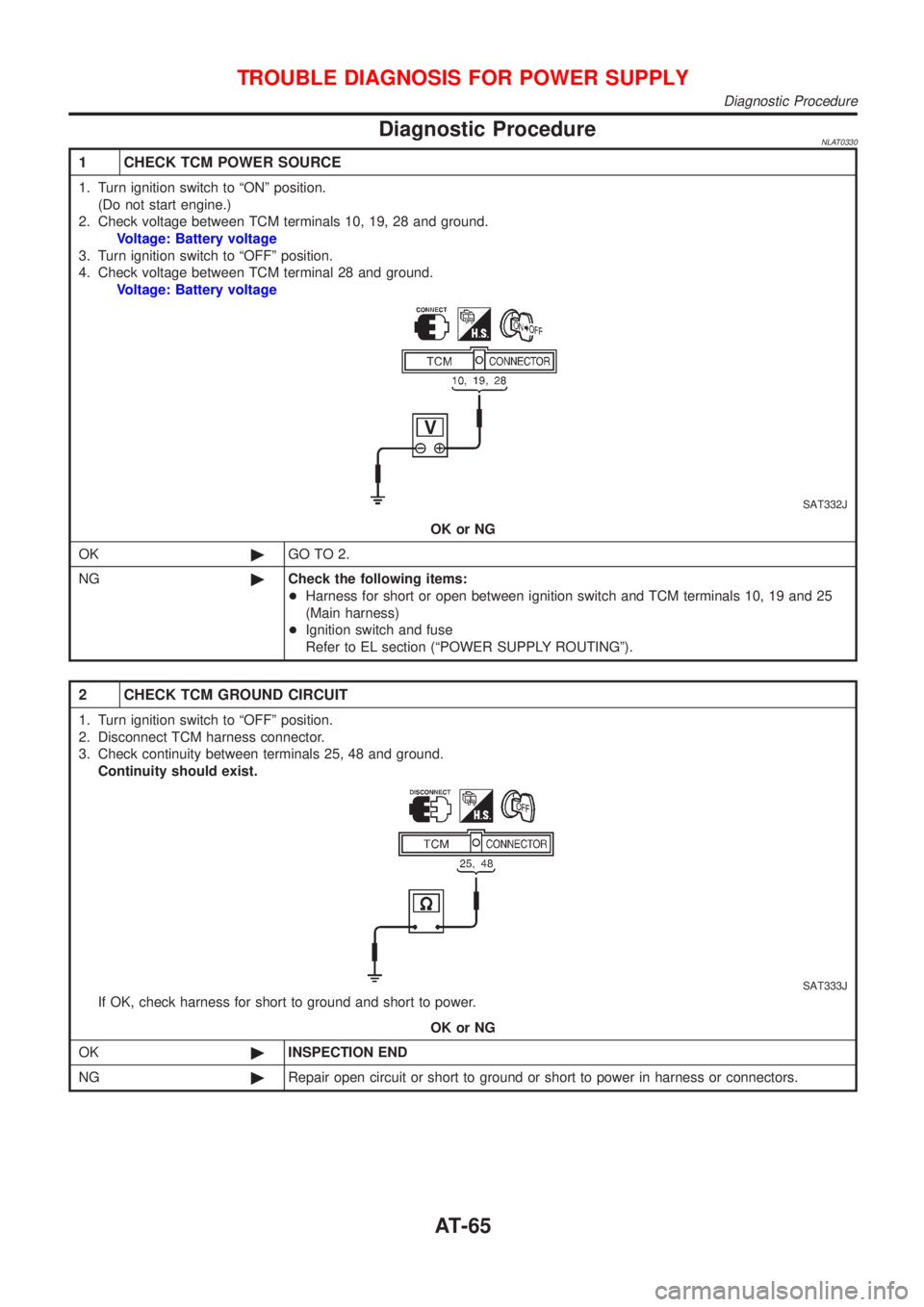

1 CHECK TCM POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 10, 19, 28 and ground.

Voltage: Battery voltage

3. Turn ignition switch to ªOFFº position.

4. Check voltage between TCM terminal 28 and ground.

Voltage: Battery voltage

SAT332J

OK or NG

OK©GO TO 2.

NG©Check the following items:

+Harness for short or open between ignition switch and TCM terminals 10, 19 and 25

(Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

2 CHECK TCM GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check continuity between terminals 25, 48 and ground.

Continuity should exist.

SAT333J

If OK, check harness for short to ground and short to power.

OK or NG

OK©INSPECTION END

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Diagnostic Procedure

AT-65

Page 71 of 3051

Diagnostic ProcedureNLAT0033

1 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT250K

3. Read out ªP/Nº, ªRº, ªDº and ªLº position switches moving selector lever to each position.

Check the signal of the selector lever position is indicated properly.

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-72.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

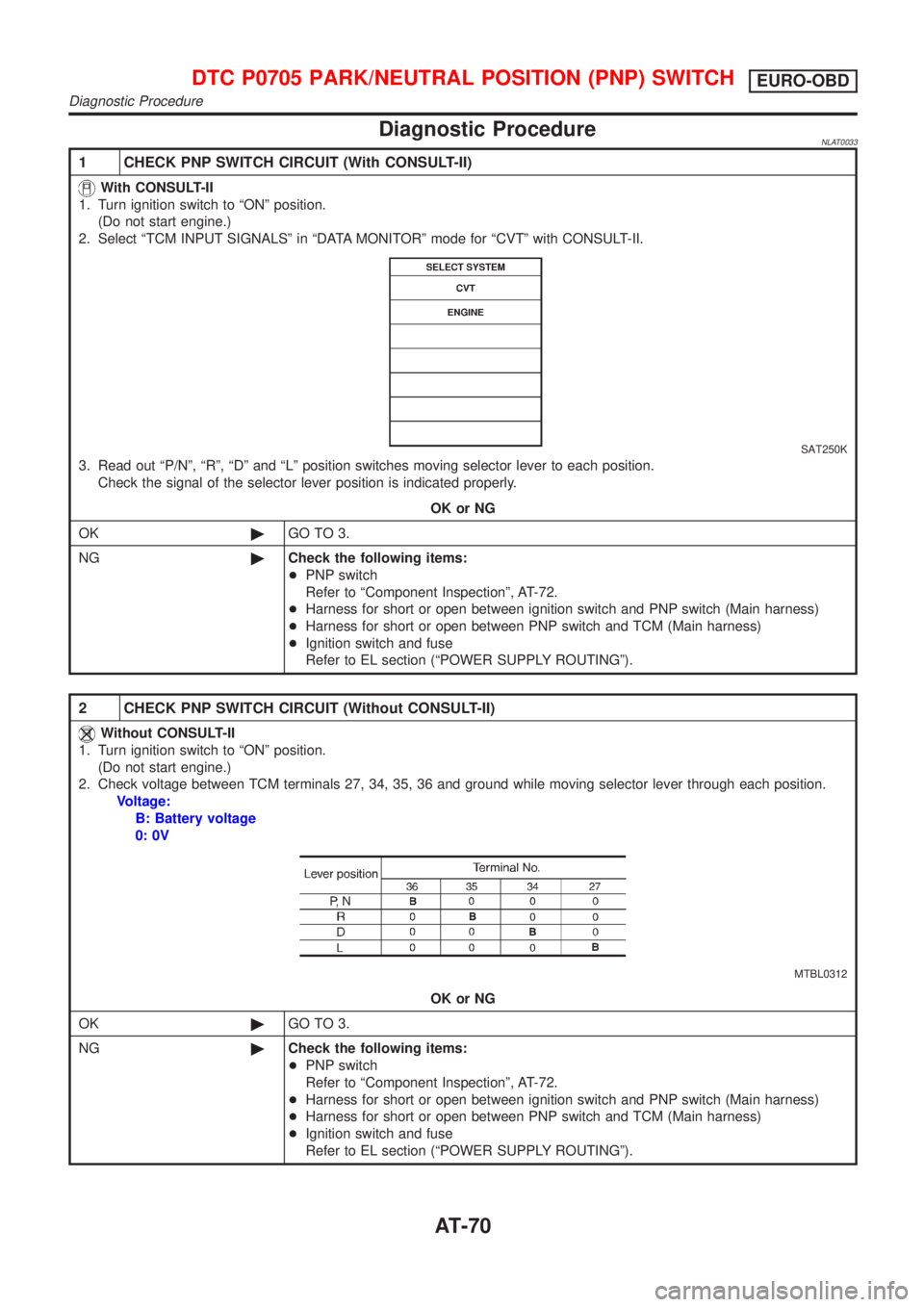

2 CHECK PNP SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 27, 34, 35, 36 and ground while moving selector lever through each position.

Voltage:

B: Battery voltage

0: 0V

MTBL0312

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-72.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Diagnostic Procedure

AT-70

Page 185 of 3051

PNP Switch, Stop Lamp Switch and Throttle

Position Switch

NLAT0290SYMPTOM:

SPORT indicator lamp does not come on in TCM self-diagnos-

tic procedure even the lamp circuit is good.

DESCRIPTIONNLAT0290S01+PNP switch

+The PNP switch assemble includes a transmission position

switch. The transmission position switch detects the selector

position and sends a signal to the TCM.

+Stop lamp switch

Detects the stop lamp switch position (ON or OFF) and sends

a signal to the TCM

+Throttle position switch.

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

Diagnostic ProcedureNLAT0291

1 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT250K

3. Read out ªP/Nº, ªRº, ªDº and ªLº position switches moving selector lever to each position.

Check the signal of the selector lever position is indicated properly.

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-72.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

PNP Switch, Stop Lamp Switch and Throttle Position Switch

AT-184

Page 186 of 3051

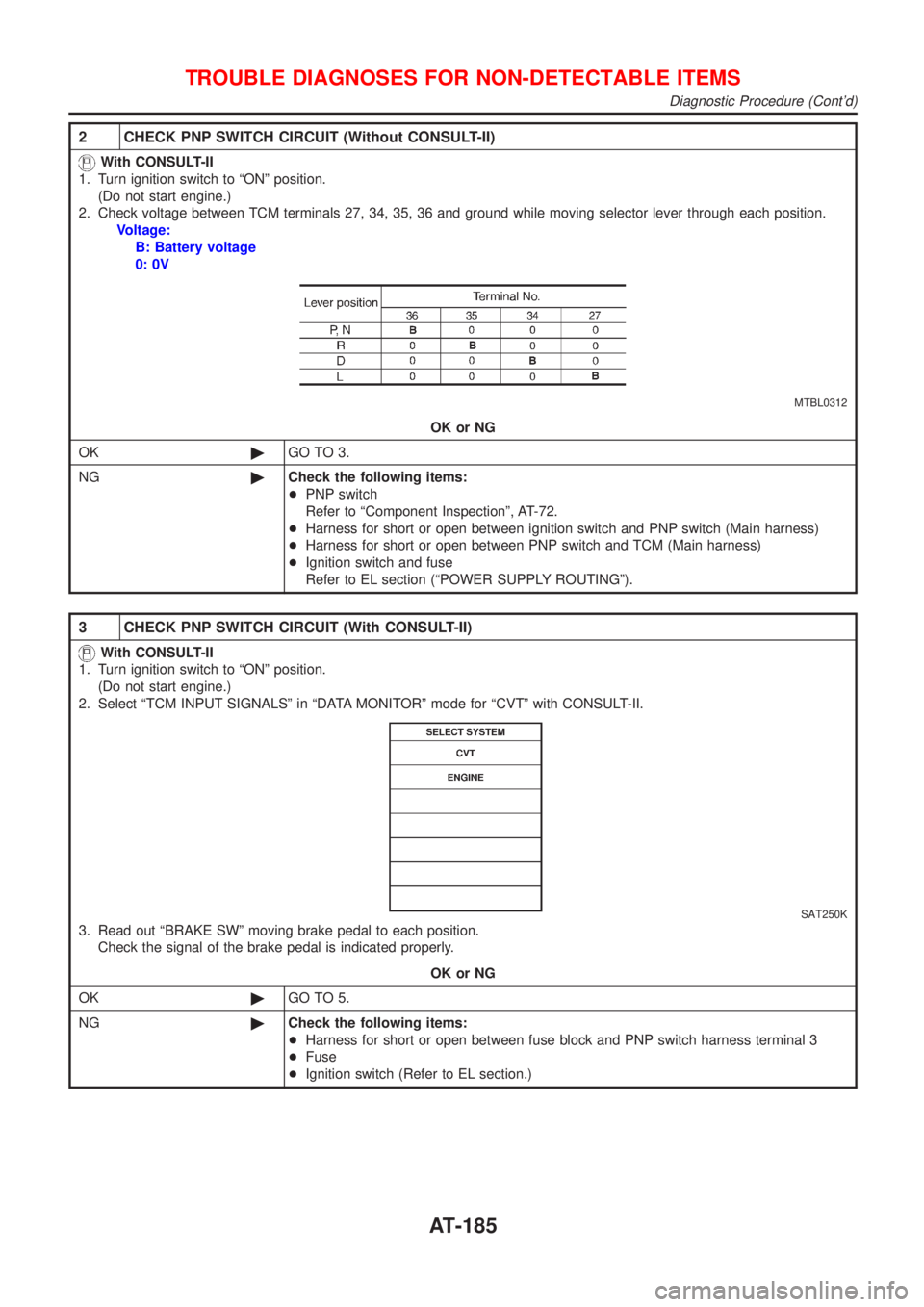

2 CHECK PNP SWITCH CIRCUIT (Without CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 27, 34, 35, 36 and ground while moving selector lever through each position.

Voltage:

B: Battery voltage

0: 0V

MTBL0312

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-72.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

3 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT250K

3. Read out ªBRAKE SWº moving brake pedal to each position.

Check the signal of the brake pedal is indicated properly.

OK or NG

OK©GO TO 5.

NG©Check the following items:

+Harness for short or open between fuse block and PNP switch harness terminal 3

+Fuse

+Ignition switch (Refer to EL section.)

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Diagnostic Procedure (Cont'd)

AT-185

Page 187 of 3051

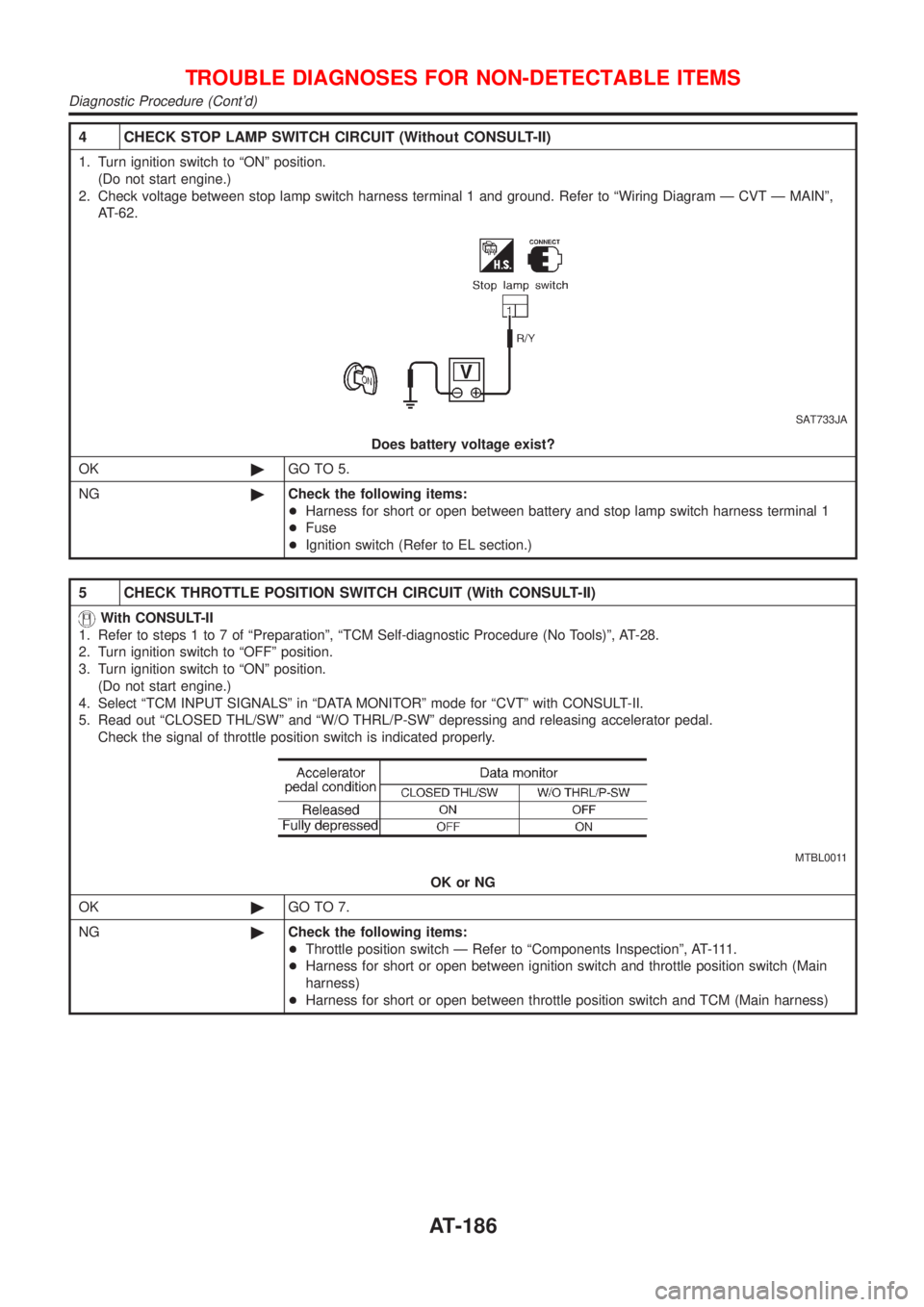

4 CHECK STOP LAMP SWITCH CIRCUIT (Without CONSULT-II)

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground. Refer to ªWiring Diagram Ð CVT Ð MAINº,

AT-62.

SAT733JA

Does battery voltage exist?

OK©GO TO 5.

NG©Check the following items:

+Harness for short or open between battery and stop lamp switch harness terminal 1

+Fuse

+Ignition switch (Refer to EL section.)

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Refer to steps 1 to 7 of ªPreparationº, ªTCM Self-diagnostic Procedure (No Tools)º, AT-28.

2. Turn ignition switch to ªOFFº position.

3. Turn ignition switch to ªONº position.

(Do not start engine.)

4. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

5. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

OK or NG

OK©GO TO 7.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-111.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Diagnostic Procedure (Cont'd)

AT-186

Page 193 of 3051

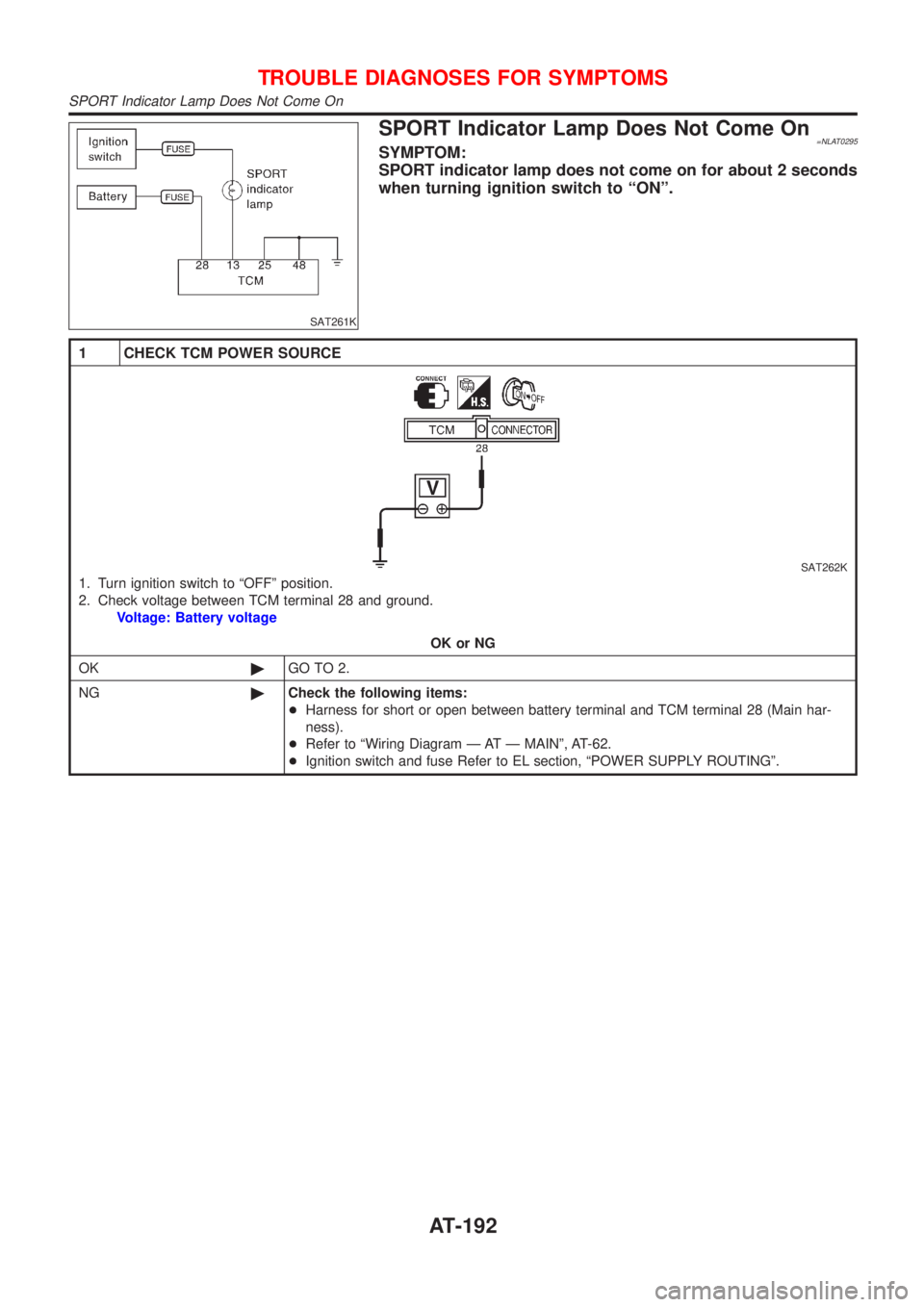

SAT261K

SPORT Indicator Lamp Does Not Come On=NLAT0295SYMPTOM:

SPORT indicator lamp does not come on for about 2 seconds

when turning ignition switch to ªONº.

1 CHECK TCM POWER SOURCE

SAT262K

1. Turn ignition switch to ªOFFº position.

2. Check voltage between TCM terminal 28 and ground.

Voltage: Battery voltage

OK or NG

OK©GO TO 2.

NG©Check the following items:

+Harness for short or open between battery terminal and TCM terminal 28 (Main har-

ness).

+Refer to ªWiring Diagram Ð AT Ð MAINº, AT-62.

+Ignition switch and fuse Refer to EL section, ªPOWER SUPPLY ROUTINGº.

TROUBLE DIAGNOSES FOR SYMPTOMS

SPORT Indicator Lamp Does Not Come On

AT-192

Page 194 of 3051

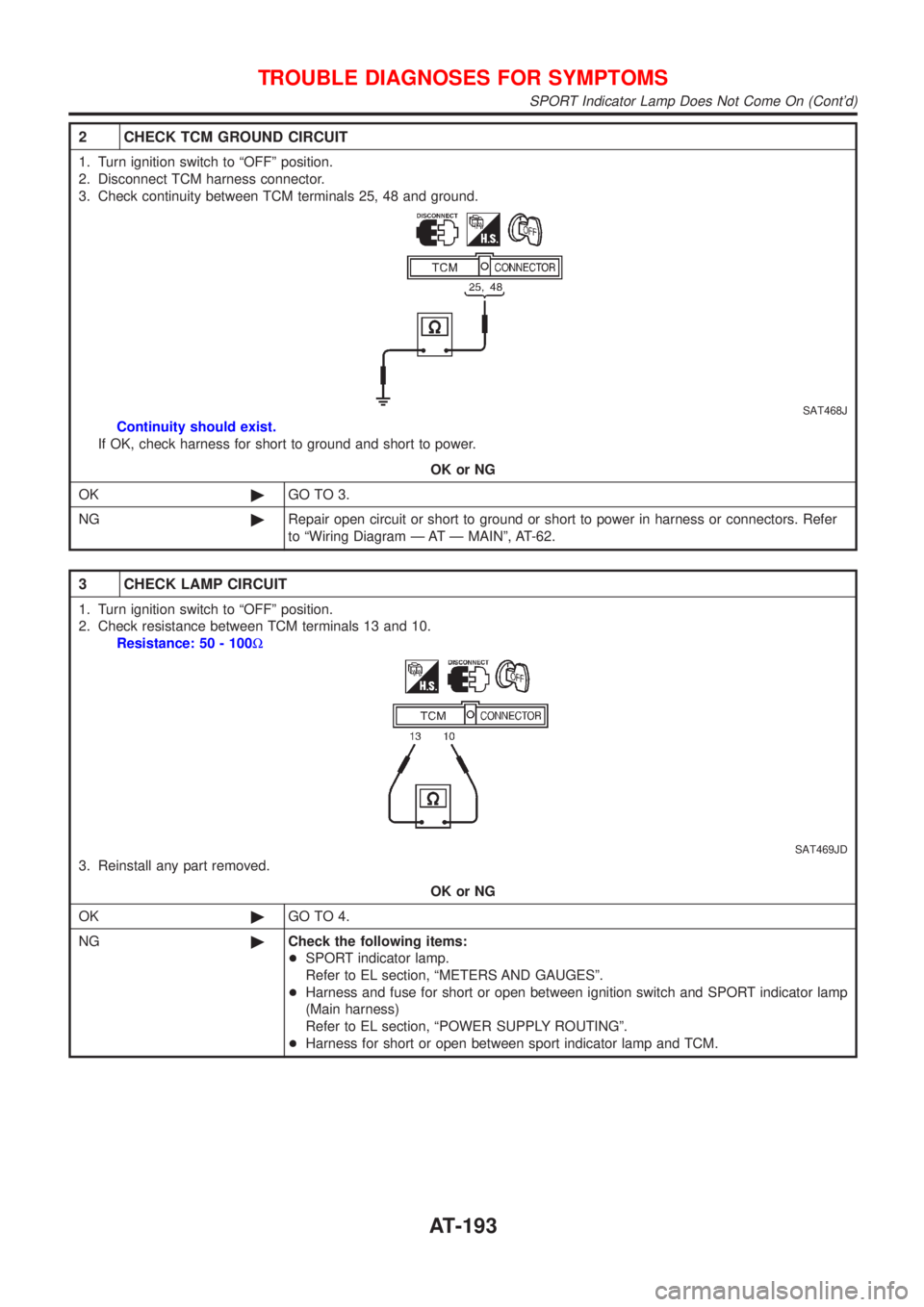

2 CHECK TCM GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check continuity between TCM terminals 25, 48 and ground.

SAT468J

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors. Refer

to ªWiring Diagram Ð AT Ð MAINº, AT-62.

3 CHECK LAMP CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Check resistance between TCM terminals 13 and 10.

Resistance: 50 - 100W

SAT469JD

3. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Check the following items:

+SPORT indicator lamp.

Refer to EL section, ªMETERS AND GAUGESº.

+Harness and fuse for short or open between ignition switch and SPORT indicator lamp

(Main harness)

Refer to EL section, ªPOWER SUPPLY ROUTINGº.

+Harness for short or open between sport indicator lamp and TCM.

TROUBLE DIAGNOSES FOR SYMPTOMS

SPORT Indicator Lamp Does Not Come On (Cont'd)

AT-193

Page 199 of 3051

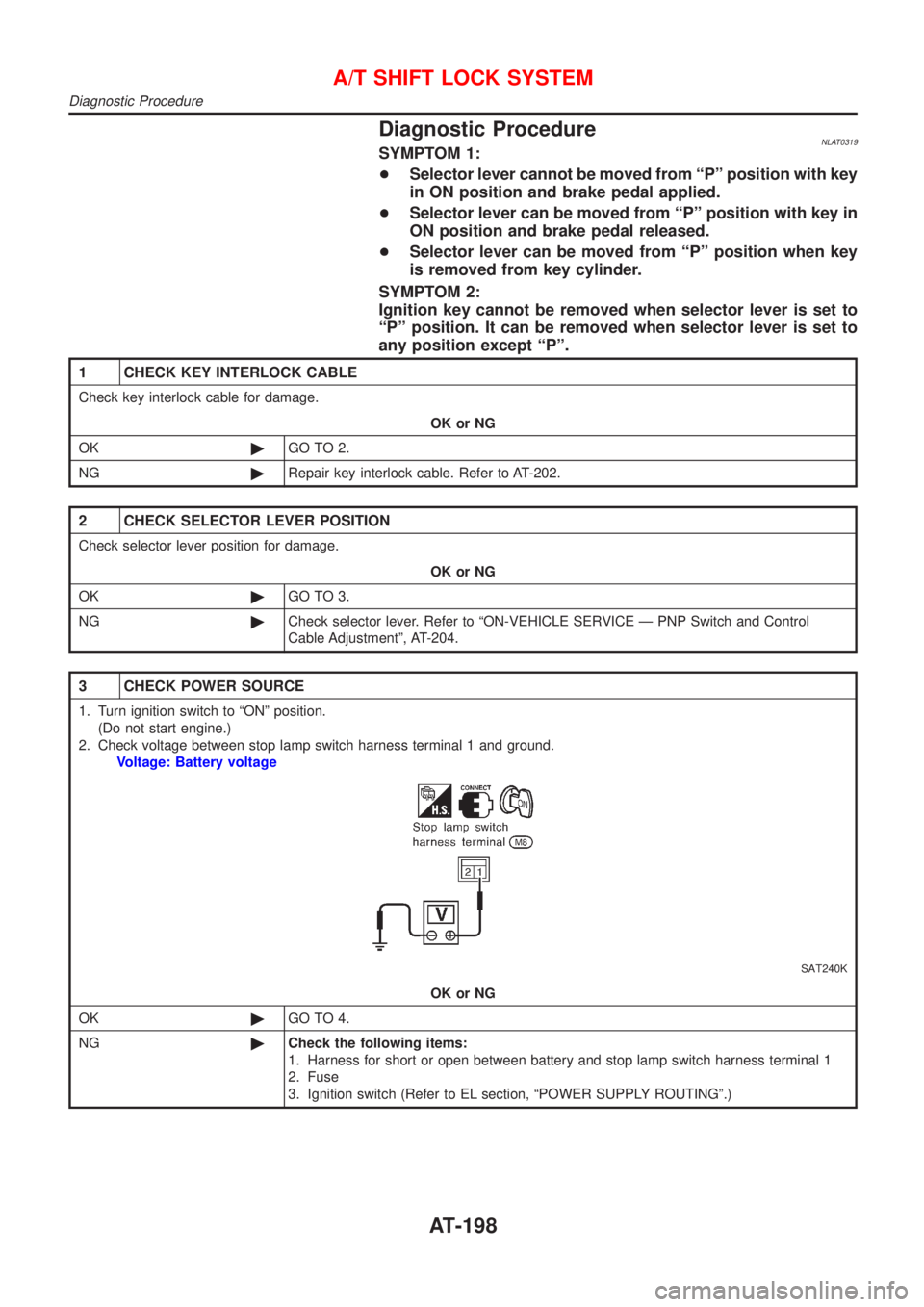

Diagnostic ProcedureNLAT0319SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with key

in ON position and brake pedal applied.

+Selector lever can be moved from ªPº position with key in

ON position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to AT-202.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Control

Cable Adjustmentº, AT-204.

3 CHECK POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

Voltage: Battery voltage

SAT240K

OK or NG

OK©GO TO 4.

NG©Check the following items:

1. Harness for short or open between battery and stop lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer to EL section, ªPOWER SUPPLY ROUTINGº.)

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-198

Page 200 of 3051

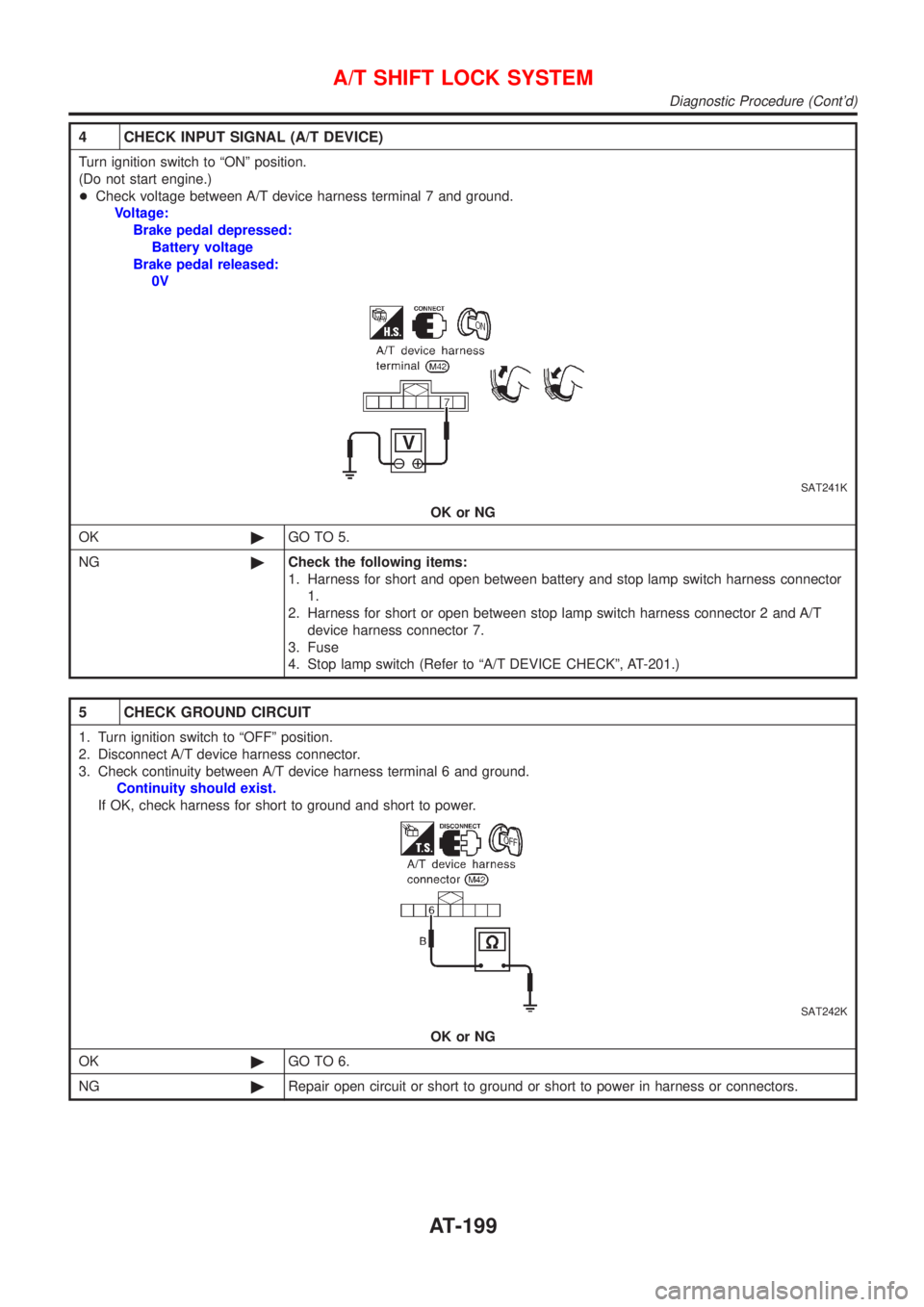

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 7 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT241K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 7.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-201.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 6 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT242K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-199

Page 304 of 3051

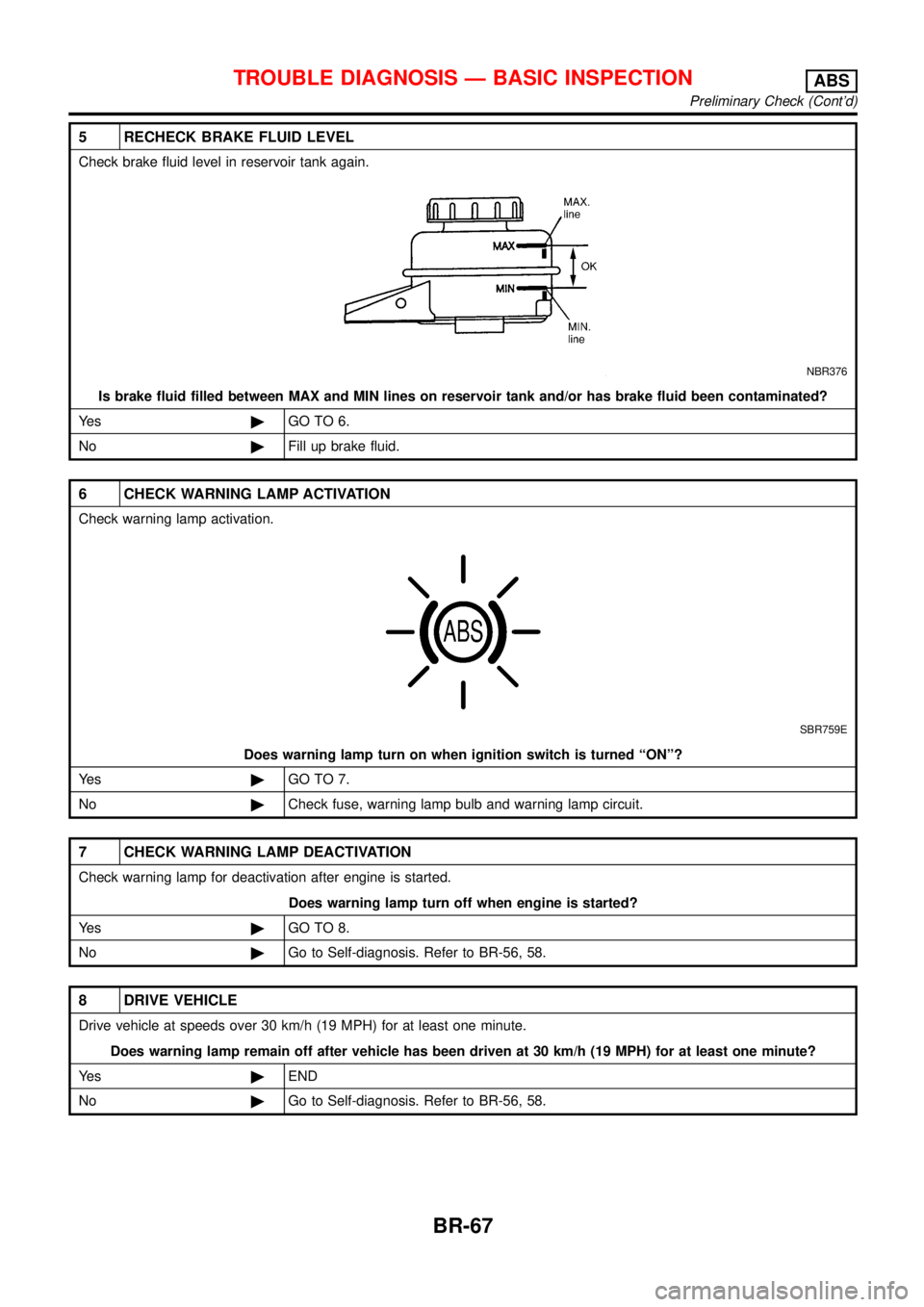

5 RECHECK BRAKE FLUID LEVEL

Check brake fluid level in reservoir tank again.

NBR376

Is brake fluid filled between MAX and MIN lines on reservoir tank and/or has brake fluid been contaminated?

Ye s©GO TO 6.

No©Fill up brake fluid.

6 CHECK WARNING LAMP ACTIVATION

Check warning lamp activation.

SBR759E

Does warning lamp turn on when ignition switch is turned“ON”?

Ye s©GO TO 7.

No©Check fuse, warning lamp bulb and warning lamp circuit.

7 CHECK WARNING LAMP DEACTIVATION

Check warning lamp for deactivation after engine is started.

Does warning lamp turn off when engine is started?

Ye s©GO TO 8.

No©Go to Self-diagnosis. Refer to BR-56, 58.

8 DRIVE VEHICLE

Drive vehicle at speeds over 30 km/h (19 MPH) for at least one minute.

Does warning lamp remain off after vehicle has been driven at 30 km/h (19 MPH) for at least one minute?

Ye s©END

No©Go to Self-diagnosis. Refer to BR-56, 58.

TROUBLE DIAGNOSIS—BASIC INSPECTIONABS

Preliminary Check (Cont’d)

BR-67