hood release NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 752 of 3051

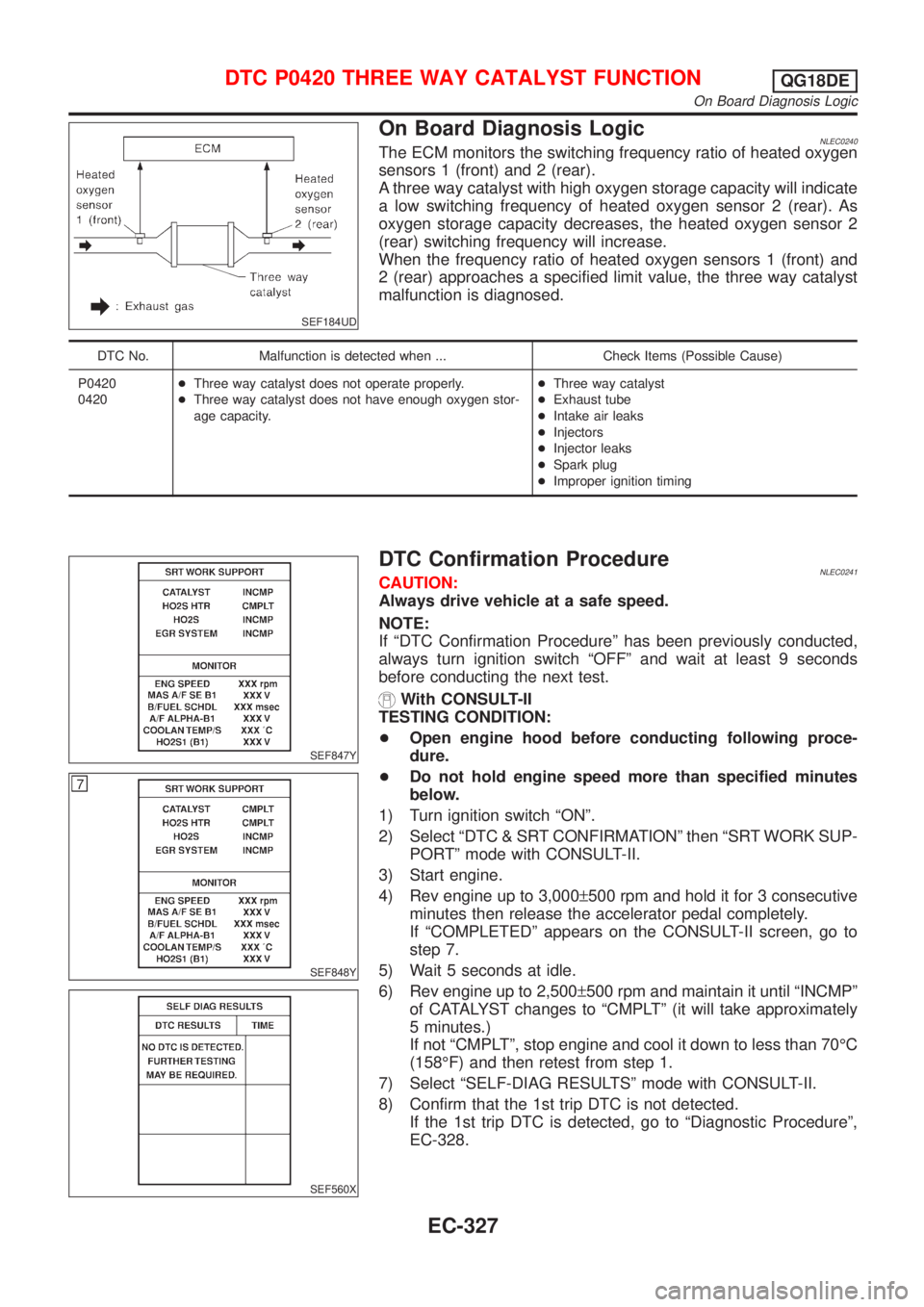

SEF184UD

On Board Diagnosis LogicNLEC0240The ECM monitors the switching frequency ratio of heated oxygen

sensors 1 (front) and 2 (rear).

A three way catalyst with high oxygen storage capacity will indicate

a low switching frequency of heated oxygen sensor 2 (rear). As

oxygen storage capacity decreases, the heated oxygen sensor 2

(rear) switching frequency will increase.

When the frequency ratio of heated oxygen sensors 1 (front) and

2 (rear) approaches a specified limit value, the three way catalyst

malfunction is diagnosed.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0420

0420+Three way catalyst does not operate properly.

+Three way catalyst does not have enough oxygen stor-

age capacity.+Three way catalyst

+Exhaust tube

+Intake air leaks

+Injectors

+Injector leaks

+Spark plug

+Improper ignition timing

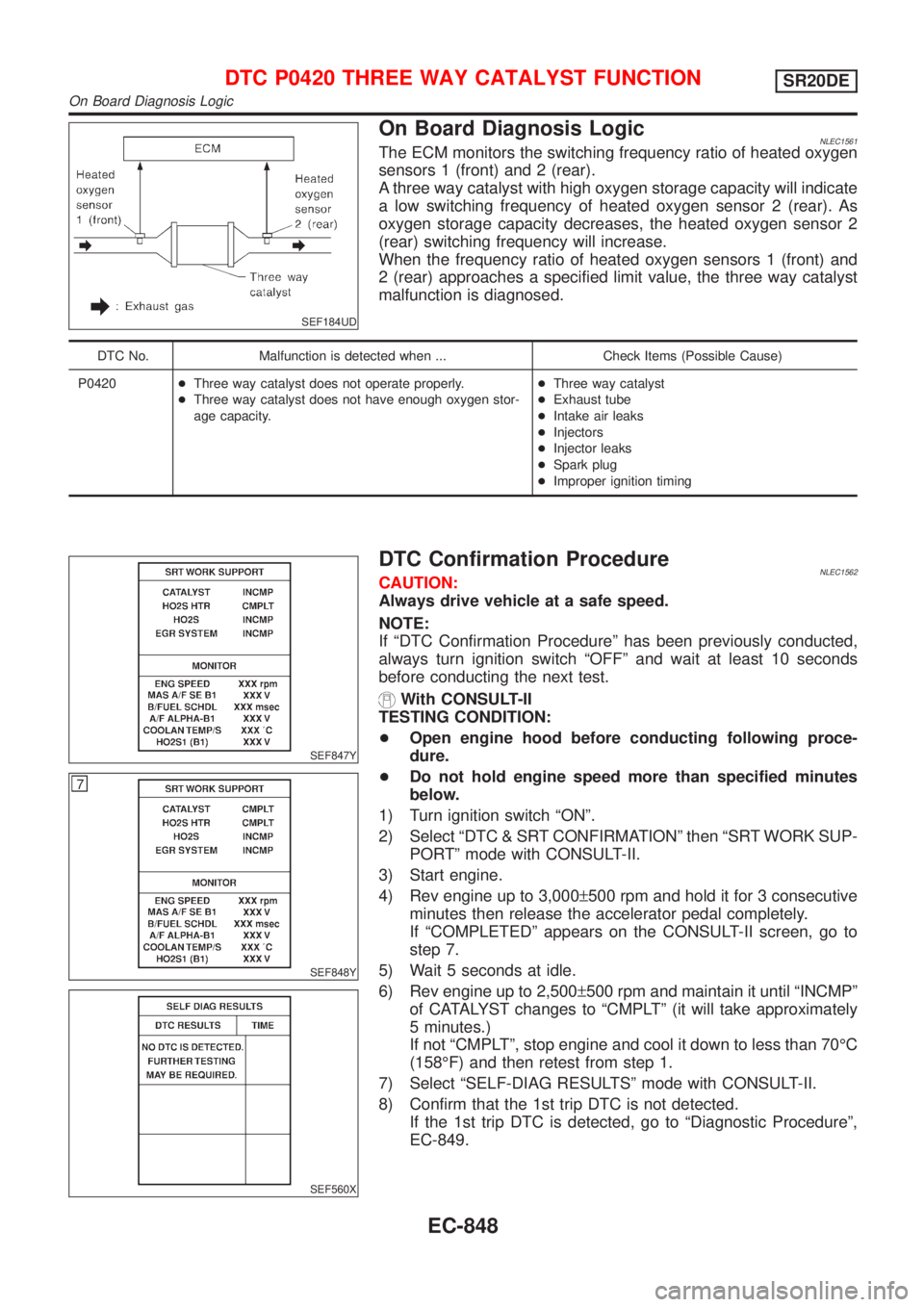

SEF847Y

SEF848Y

SEF560X

DTC Confirmation ProcedureNLEC0241CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

TESTING CONDITION:

+Open engine hood before conducting following proce-

dure.

+Do not hold engine speed more than specified minutes

below.

1) Turn ignition switch ªONº.

2) Select ªDTC & SRT CONFIRMATIONº then ªSRT WORK SUP-

PORTº mode with CONSULT-II.

3) Start engine.

4) Rev engine up to 3,000±500 rpm and hold it for 3 consecutive

minutes then release the accelerator pedal completely.

If ªCOMPLETEDº appears on the CONSULT-II screen, go to

step 7.

5) Wait 5 seconds at idle.

6) Rev engine up to 2,500±500 rpm and maintain it until ªINCMPº

of CATALYST changes to ªCMPLTº (it will take approximately

5 minutes.)

If not ªCMPLTº, stop engine and cool it down to less than 70ÉC

(158ÉF) and then retest from step 1.

7) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

8) Confirm that the 1st trip DTC is not detected.

If the 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-328.

DTC P0420 THREE WAY CATALYST FUNCTIONQG18DE

On Board Diagnosis Logic

EC-327

Page 1273 of 3051

SEF184UD

On Board Diagnosis LogicNLEC1561The ECM monitors the switching frequency ratio of heated oxygen

sensors 1 (front) and 2 (rear).

A three way catalyst with high oxygen storage capacity will indicate

a low switching frequency of heated oxygen sensor 2 (rear). As

oxygen storage capacity decreases, the heated oxygen sensor 2

(rear) switching frequency will increase.

When the frequency ratio of heated oxygen sensors 1 (front) and

2 (rear) approaches a specified limit value, the three way catalyst

malfunction is diagnosed.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0420+Three way catalyst does not operate properly.

+Three way catalyst does not have enough oxygen stor-

age capacity.+Three way catalyst

+Exhaust tube

+Intake air leaks

+Injectors

+Injector leaks

+Spark plug

+Improper ignition timing

SEF847Y

SEF848Y

SEF560X

DTC Confirmation ProcedureNLEC1562CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

With CONSULT-II

TESTING CONDITION:

+Open engine hood before conducting following proce-

dure.

+Do not hold engine speed more than specified minutes

below.

1) Turn ignition switch ªONº.

2) Select ªDTC & SRT CONFIRMATIONº then ªSRT WORK SUP-

PORTº mode with CONSULT-II.

3) Start engine.

4) Rev engine up to 3,000±500 rpm and hold it for 3 consecutive

minutes then release the accelerator pedal completely.

If ªCOMPLETEDº appears on the CONSULT-II screen, go to

step 7.

5) Wait 5 seconds at idle.

6) Rev engine up to 2,500±500 rpm and maintain it until ªINCMPº

of CATALYST changes to ªCMPLTº (it will take approximately

5 minutes.)

If not ªCMPLTº, stop engine and cool it down to less than 70ÉC

(158ÉF) and then retest from step 1.

7) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

8) Confirm that the 1st trip DTC is not detected.

If the 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-849.

DTC P0420 THREE WAY CATALYST FUNCTIONSR20DE

On Board Diagnosis Logic

EC-848

Page 2555 of 3051

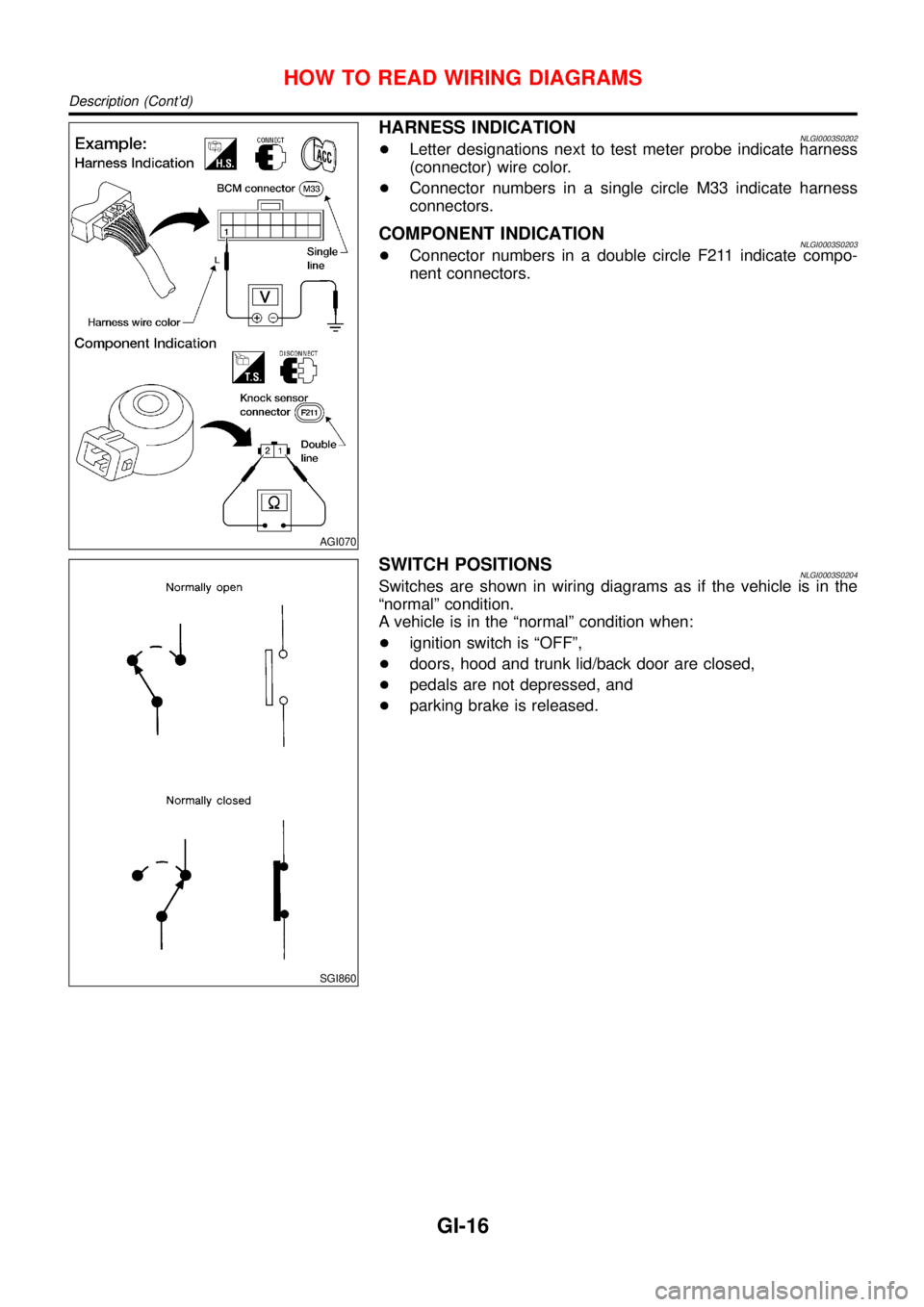

AGI070

HARNESS INDICATIONNLGI0003S0202+Letter designations next to test meter probe indicate harness

(connector) wire color.

+Connector numbers in a single circle M33 indicate harness

connectors.

COMPONENT INDICATIONNLGI0003S0203+Connector numbers in a double circle F211 indicate compo-

nent connectors.

SGI860

SWITCH POSITIONSNLGI0003S0204Switches are shown in wiring diagrams as if the vehicle is in the

“normal”condition.

A vehicle is in the“normal”condition when:

+ignition switch is“OFF”,

+doors, hood and trunk lid/back door are closed,

+pedals are not depressed, and

+parking brake is released.

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

GI-16

Page 2770 of 3051

NLMA0004

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-13

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-8

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.—

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-3

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold. LC-19, LC-59

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-28

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.BR-7

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

GENERAL MAINTENANCE

MA-3