horn NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1733 of 3051

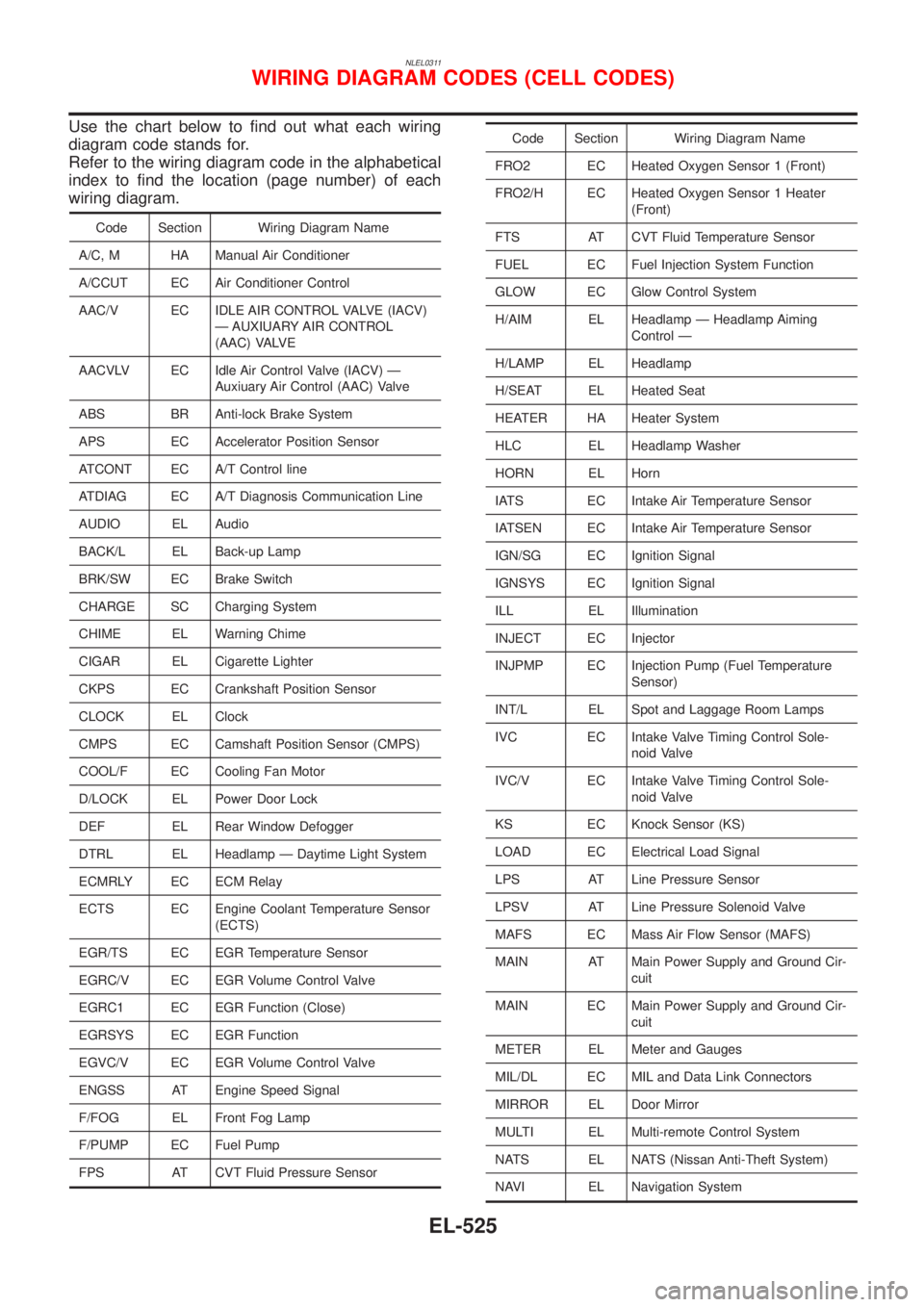

Electrical Components Inspection ...........................164

WARNING CHIME.......................................................165

Component Parts and Harness Connector

Location ...................................................................165

System Description ..................................................165

Wiring Diagram - CHIME - ......................................166

Trouble Diagnoses...................................................170

FRONT WIPER AND WASHER..................................176

System Description ..................................................176

Wiring Diagram - WIPER - ......................................178

Removal and Installation .........................................182

Washer Nozzle Adjustment .....................................183

Washer Tube Layout ...............................................183

REAR WIPER AND WASHER....................................184

Wiring Diagram - WIP/R -........................................184

Removal and Installation .........................................188

Washer Nozzle Adjustment .....................................188

Washer Tube Layout ...............................................189

HEADLAMP WASHER................................................190

Wiring Diagram - HLC - ...........................................190

Washer Tube Layout ...............................................192

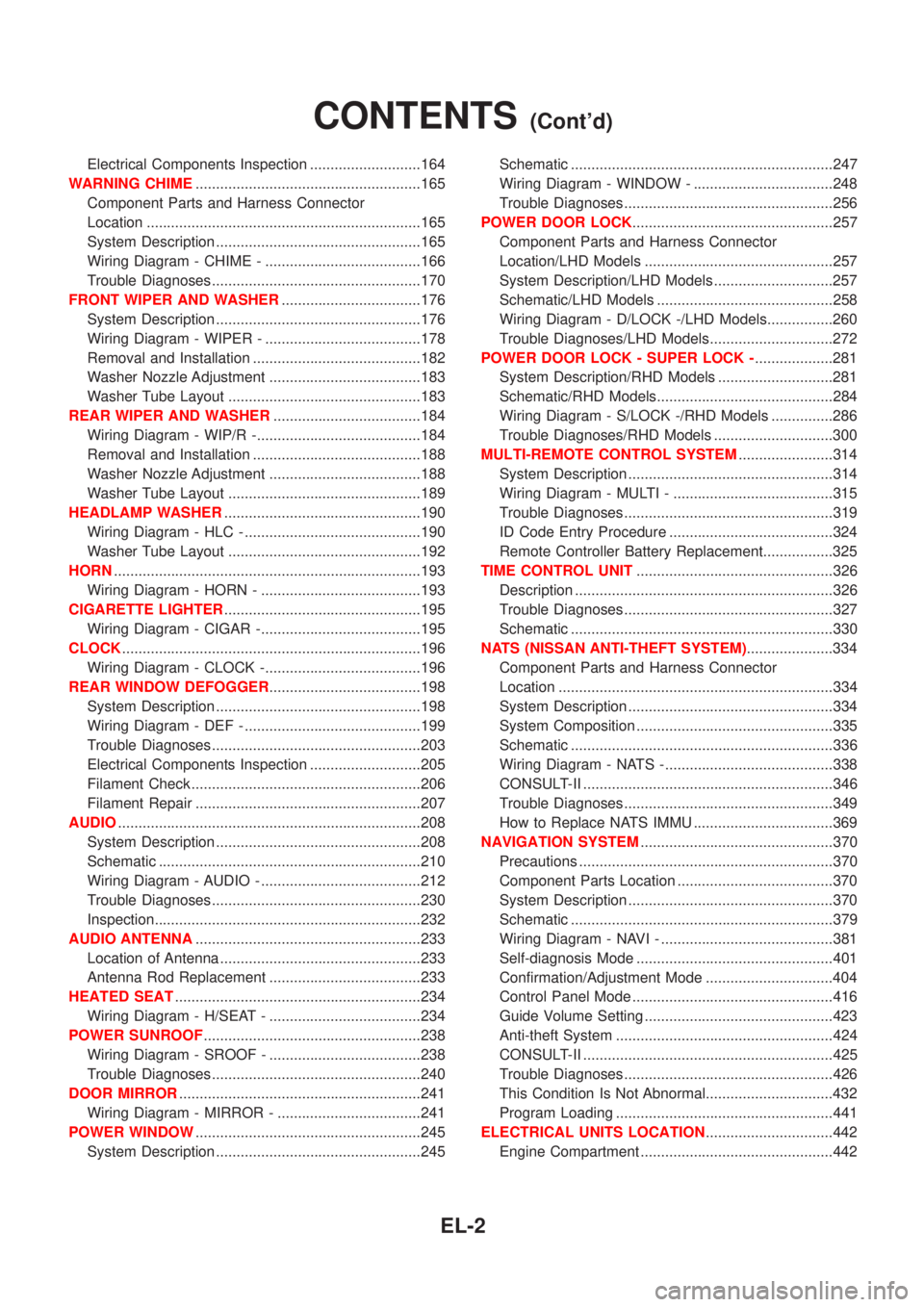

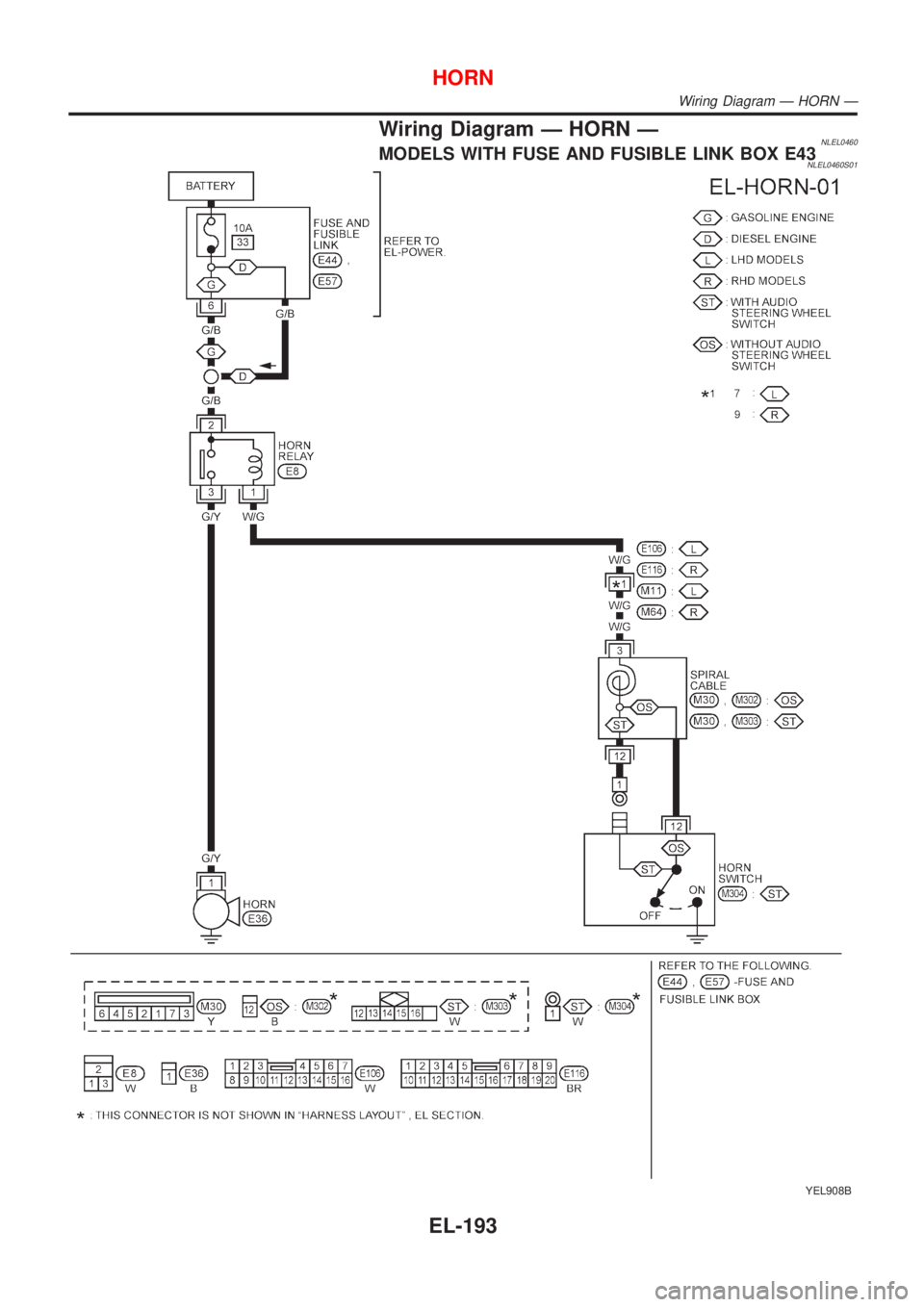

HORN...........................................................................193

Wiring Diagram - HORN - .......................................193

CIGARETTE LIGHTER................................................195

Wiring Diagram - CIGAR -.......................................195

CLOCK.........................................................................196

Wiring Diagram - CLOCK -......................................196

REAR WINDOW DEFOGGER.....................................198

System Description ..................................................198

Wiring Diagram - DEF - ...........................................199

Trouble Diagnoses...................................................203

Electrical Components Inspection ...........................205

Filament Check ........................................................206

Filament Repair .......................................................207

AUDIO..........................................................................208

System Description ..................................................208

Schematic ................................................................210

Wiring Diagram - AUDIO - .......................................212

Trouble Diagnoses...................................................230

Inspection.................................................................232

AUDIO ANTENNA.......................................................233

Location of Antenna .................................................233

Antenna Rod Replacement .....................................233

HEATED SEAT............................................................234

Wiring Diagram - H/SEAT - .....................................234

POWER SUNROOF.....................................................238

Wiring Diagram - SROOF - .....................................238

Trouble Diagnoses...................................................240

DOOR MIRROR...........................................................241

Wiring Diagram - MIRROR - ...................................241

POWER WINDOW.......................................................245

System Description ..................................................245Schematic ................................................................247

Wiring Diagram - WINDOW - ..................................248

Trouble Diagnoses...................................................256

POWER DOOR LOCK.................................................257

Component Parts and Harness Connector

Location/LHD Models ..............................................257

System Description/LHD Models .............................257

Schematic/LHD Models ...........................................258

Wiring Diagram - D/LOCK -/LHD Models................260

Trouble Diagnoses/LHD Models..............................272

POWER DOOR LOCK - SUPER LOCK -...................281

System Description/RHD Models ............................281

Schematic/RHD Models...........................................284

Wiring Diagram - S/LOCK -/RHD Models ...............286

Trouble Diagnoses/RHD Models .............................300

MULTI-REMOTE CONTROL SYSTEM.......................314

System Description ..................................................314

Wiring Diagram - MULTI - .......................................315

Trouble Diagnoses...................................................319

ID Code Entry Procedure ........................................324

Remote Controller Battery Replacement.................325

TIME CONTROL UNIT................................................326

Description ...............................................................326

Trouble Diagnoses...................................................327

Schematic ................................................................330

NATS (NISSAN ANTI-THEFT SYSTEM).....................334

Component Parts and Harness Connector

Location ...................................................................334

System Description ..................................................334

System Composition ................................................335

Schematic ................................................................336

Wiring Diagram - NATS -.........................................338

CONSULT-II .............................................................346

Trouble Diagnoses...................................................349

How to Replace NATS IMMU ..................................369

NAVIGATION SYSTEM...............................................370

Precautions ..............................................................370

Component Parts Location ......................................370

System Description ..................................................370

Schematic ................................................................379

Wiring Diagram - NAVI - ..........................................381

Self-diagnosis Mode ................................................401

Confirmation/Adjustment Mode ...............................404

Control Panel Mode .................................................416

Guide Volume Setting ..............................................423

Anti-theft System .....................................................424

CONSULT-II .............................................................425

Trouble Diagnoses...................................................426

This Condition Is Not Abnormal...............................432

Program Loading .....................................................441

ELECTRICAL UNITS LOCATION...............................442

Engine Compartment ...............................................442

CONTENTS(Cont'd)

EL-2

Page 1924 of 3051

Wiring Diagram Ð HORN ÐNLEL0460MODELS WITH FUSE AND FUSIBLE LINK BOX E43NLEL0460S01

YEL908B

HORN

Wiring Diagram Ð HORN Ð

EL-193

Page 1925 of 3051

MODELS WITH FUSE AND FUSIBLE LINK BOX E90NLEL0460S02

YEL431C

HORN

Wiring Diagram Ð HORN Ð (Cont'd)

EL-194

Page 2256 of 3051

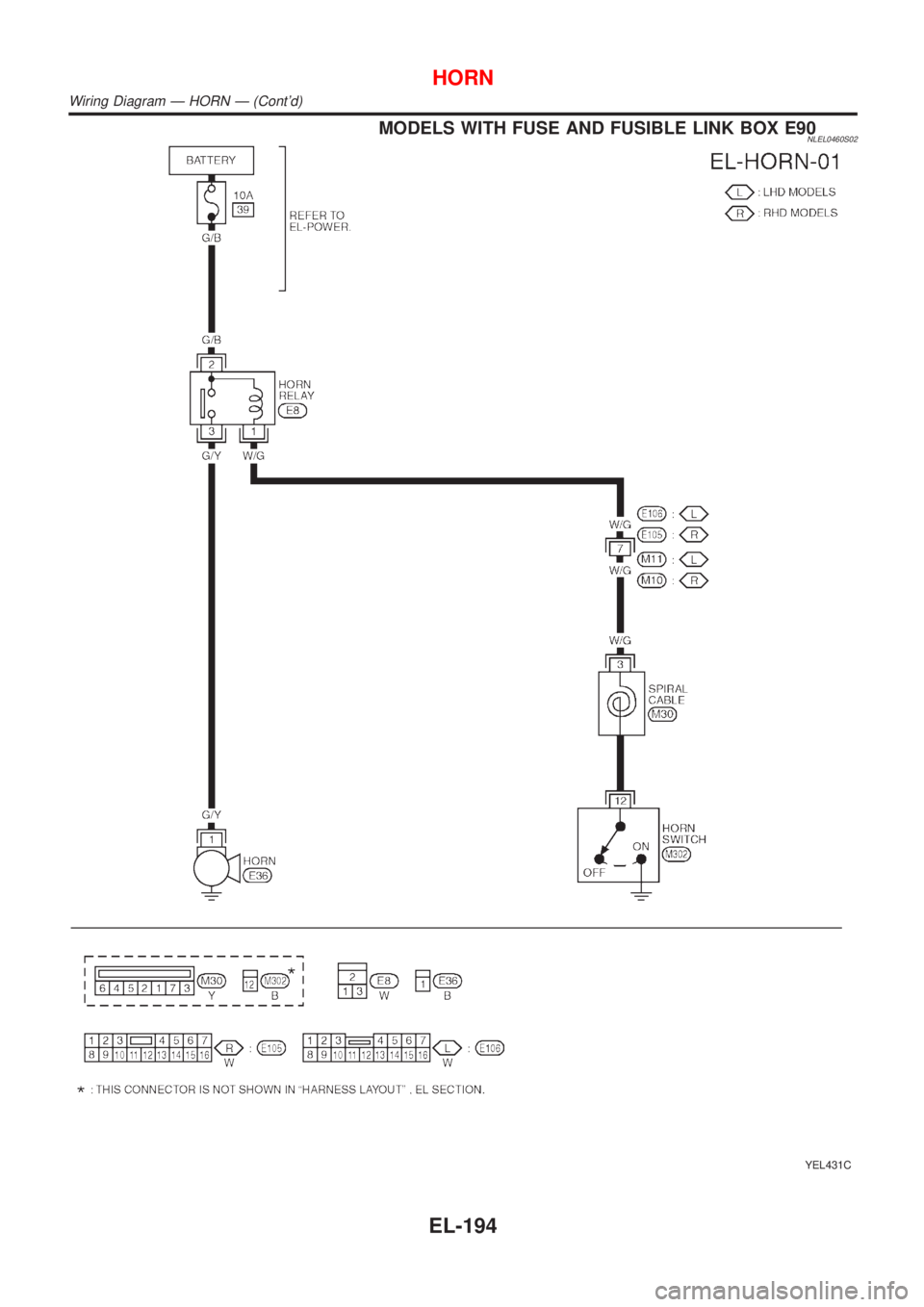

NLEL0311

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

A/C, M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Control

AAC/V EC IDLE AIR CONTROL VALVE (IACV)

Ð AUXIUARY AIR CONTROL

(AAC) VALVE

AACVLV EC Idle Air Control Valve (IACV) Ð

Auxiuary Air Control (AAC) Valve

ABS BR Anti-lock Brake System

APS EC Accelerator Position Sensor

ATCONT EC A/T Control line

ATDIAG EC A/T Diagnosis Communication Line

AUDIO EL Audio

BACK/L EL Back-up Lamp

BRK/SW EC Brake Switch

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CLOCK EL Clock

CMPS EC Camshaft Position Sensor (CMPS)

COOL/F EC Cooling Fan Motor

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DTRL EL Headlamp Ð Daytime Light System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

(ECTS)

EGR/TS EC EGR Temperature Sensor

EGRC/V EC EGR Volume Control Valve

EGRC1 EC EGR Function (Close)

EGRSYS EC EGR Function

EGVC/V EC EGR Volume Control Valve

ENGSS AT Engine Speed Signal

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FPS AT CVT Fluid Pressure Sensor

Code Section Wiring Diagram Name

FRO2 EC Heated Oxygen Sensor 1 (Front)

FRO2/H EC Heated Oxygen Sensor 1 Heater

(Front)

FTS AT CVT Fluid Temperature Sensor

FUEL EC Fuel Injection System Function

GLOW EC Glow Control System

H/AIM EL Headlamp Ð Headlamp Aiming

Control Ð

H/LAMP EL Headlamp

H/SEAT EL Heated Seat

HEATER HA Heater System

HLC EL Headlamp Washer

HORN EL Horn

IATS EC Intake Air Temperature Sensor

IATSEN EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

IGNSYS EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP EC Injection Pump (Fuel Temperature

Sensor)

INT/L EL Spot and Laggage Room Lamps

IVC EC Intake Valve Timing Control Sole-

noid Valve

IVC/V EC Intake Valve Timing Control Sole-

noid Valve

KS EC Knock Sensor (KS)

LOAD EC Electrical Load Signal

LPS AT Line Pressure Sensor

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor (MAFS)

MAIN AT Main Power Supply and Ground Cir-

cuit

MAIN EC Main Power Supply and Ground Cir-

cuit

METER EL Meter and Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL NATS (Nissan Anti-Theft System)

NAVI EL Navigation System

WIRING DIAGRAM CODES (CELL CODES)

EL-525

Page 2699 of 3051

Engine control component parts

location ................................ EC-26, 560, 1071

Engine control module (ECM) ........ EC-358, 880

Engine control system diagram and

chart .................................... EC-32, 566, 1076

Engine coolant temperature sensor

(ECTS) .............................. EC-169, 694, 1150

Engine fail-safe system .................. EC-123, 647

Engine oil precautions .................................. GI-7

Engine outer component parts ........... EM-12, 82

Engine removal ........................ EM-49, 130, 218

Engine room - See Engine

compartment .......................................... BT-66

Engine serial number ................................. GI-39

Evaporative emission (EVAP)

system ........................................... EC-39, 573

Exhaust gas recirculation (EGR)

valve ........... EC-310, 393, 446, 834, 921, 975

Exhaust system ................................... FE-11, 23

Exterior ...................................................... BT-38

F

F/PUMP - Wiring diagram ............. EC-518, 1034

FR02 - Wiring diagram .. EC-187, 207, 216, 415,

712, 732, 741, 945

FR02/H - Wiring diagram ............... EC-223, 422,

748, 952

FUEL - Wiring diagram ... EC-271, 279, 794, 802

Fan switch ................................................. HA-61

Final drive (FF M/T) ...................... MT-47, 63, 77

Finisher, interior - See Trim ....................... BT-28

Finisher, trunk lid ....................................... BT-31

Floor trim ................................................... BT-28

Fluids ........................................................ MA-20

Flywheel (clutch) ....................................... CL-22

Flywheel runout ........................ EM-60, 142, 235

Fog lamp, front, removal and

installation ................................................ BT-7

Fog lamp, front .......................................... EL-95

Fork rod (M/T) ..................................... MT-26, 64

Freeze frame data .............. EC-61, 71, 585, 596

Front axle .................................................... AX-2

Front bumper ............................................... BT-7

Front combination lamp removal and

installation ................................................ BT-7

Front disc brake ........................................ BR-24

Front door .................................................. BT-13

Front fog lamp removal and

installation ................................................ BT-7

Front fog lamp ........................................... EL-95

Front heated oxygen sensor (HO2S)

heater .......................... EC-221, 421, 746, 951

Front heated oxygen sensor (HO2S) ..... EC-184,

192, 198, 204, 214, 414, 709,

717, 723, 729, 739, 944Front seat belt ............................................. RS-5

Front seat .................................................. BT-46

Front suspension ........................................ SU-2

Front washer ............................................ EL-176

Front wiper ............................................... EL-176

Fuel cut control (at no load & high

engine speed) ..................... EC-39, 573, 1081

Fuel gauge ............................................... EL-130

Fuel injection system ............. EC-269, 277, 792,

800, 1079

Fuel injector .................................. EC-494, 1021

Fuel precautions ........................................... GI-8

Fuel pressure check ......................... EC-43, 577

Fuel pressure regulator .................... EC-44, 578

Fuel pressure release ....................... EC-43, 577

Fuel pump relay ............................ EC-516, 1032

Fuel pump ..................................... EC-516, 1032

Fuel system ........................................... FE-5, 15

Fuel tank vacuum relief valve ........... EC-40, 574

Fuse block ............................................... EL-527

Fuse ........................................................... EL-32

Fusible link ................................................. EL-32G

GLOW - Wiring diagram ....................... EC-1267

Garage jack and safety stand .................... GI-43

Gauges .................................................... EL-130

Gear components (M/T) ..................... MT-25, 63

Generator - See Alternator ....................... SC-28

Generic scan tool (GST) ................... EC-93, 617

Glass .......................................................... BT-14

Glow plug .............................................. EC-1267

Glow relay ............................................. EC-1267

Grease ...................................................... MA-20

Ground distribution .............................. EL-33, 48

H

H/LAMP - Wiring diagram .......................... EL-69

HEATER - Wiring diagram ........................ HA-23

HFC134a (R134a) system

precaution ................................................ HA-2

HFC134a (R134a) system service

procedure .............................................. HA-85

HFC134a (R134a) system service

tools ....................................................... HA-10

HFC134a system service equipment

precaution ................................................ HA-6

HORN - Wiring diagram .......................... EL-193

HSEAT - Wiring diagram ......................... EL-234

Harness connector ...................................... EL-5

Harness layout ......................................... EL-452

Hazard warning lamp .............................. EL-101

Headlamp removal and installation ............. BT-7

Headlamp washer .................................... EL-190

ALPHABETICAL INDEX

IDX-4

Page 2700 of 3051

Headlamp .................................................. EL-69

Headlining - See Roof trim ........................ BT-35

Heated oxygen sensor (HO2S)

(front) . EC-184, 192, 198, 204, 214, 414, 709,

717, 723, 729, 739, 944

Heated oxygen sensor (HO2S) heater

(front) .......................... EC-221, 421, 746, 951

Heated oxygen sensor (HO2S) heater

(rear) ........................... EC-263, 433, 786, 963

Heated oxygen sensor (rear) . EC-227, 237, 246,

256, 426, 752, 761, 770, 779, 956

Heated seat ............................................. EL-234

Height (Dimensions) ................................... GI-41

Hood ............................................................ BT-7

Horn ......................................................... EL-193

How to erase DTC for OBD system .. EC-69, 71,

594, 596, 1096

I

IACV-AAC valve ............. EC-343, 466, 863, 995

IATS - Wiring diagram .... EC-163, 409, 689, 939

IGN/SG - Wiring diagram ................ EC-501, 903

ILL - Wiring diagram ................................ EL-109

INJECT - Wiring diagram .............. EC-495, 1022

IVC - Wiring diagram ...................... EC-362, 476

Identification plate ...................................... GI-39

Idle air control (IAC) system .......... EC-343, 466,

863, 995

Idle air control valve (IACV) ........... EC-343, 466,

863, 995

Idle speed ........................................ EC-46,1111

Ignition coil .................................... EC-907, 1010

Ignition control system ............................ EC-500

Ignition timing ............................................ EC-46

Ignition wire inspection ........................... EC-814

Illumination ............................................... EL-107

Injection nozzle ..................................... EC-1083

Injector removal and installation ....... EC-44, 578

Input shaft (FF M/T) ..................... MT-34, 63, 68

Instrument panel ........................................ BT-22

Intake air temperature sensor ........ EC-161, 407,

687, 937

Intake valve timing control solenoid

valve ............................................ EC-360, 475

Interior lamp on-off control ....................... EL-117

Interior lamp ............................................. EL-116

Interior ........................................................ BT-28

J

Jacking points ............................................ GI-43

Joint connector (J/C) ............................... EL-531

Junction box (J/B) .................................... EL-527

K

KS - Wiring diagram ............................... EC-292

Keyless entry system - See Multi-re-

mote control system ............................. EL-314

Knock sensor (KS) ................. EC-291, 815, 816

Knuckle spindle ........................................... AX-5

L

LOAD - Wiring diagram ................ EC-536, 1051

Length (Dimensions) .................................. GI-41

License lamp ............................................. EL-87

Lifting points ............................................... GI-44

Line pressure test (A/T) ............................. AT-52

Liquid gasket application .............. EM-5, 76, 158

Location of electrical units ....................... EL-442

Lock, door .................................................. BT-18

Lubricant (R134a) A/C .............................. HA-87

Lubricants ................................................. MA-20

Lubrication circuit (engine) .............. LC-4, 24, 43

M

M/T major overhaul ............................. MT-24, 62

M/T removal and installation ..................... MT-18

MAFS - Wiring diagram ........ EC-156, 682, 1143

MAIN - Wiring diagram ......... EC-146, 671, 1136

MIL & Data link connectors circuit ......... EC-545,

1060

MIL/DL - Wiring diagram .... EC-545, 1060, 1303

MIRROR - Wiring diagram ...................... EL-241

Magnet clutch ............................................ HA-90

Mainshaft (M/T) ............................ MT-39, 63, 73

Malfunction indicator lamp (MIL) .............. EC-73,

598, 1097

Manual air conditioner - Wiring

diagram .................................................. HA-27

Manual transaxle number .......................... GI-40

Mass air flow sensor (MAFS) ................ EC-154,

679, 1143

Master cylinder (clutch) ............................. CL-11

Meter ........................................................ EL-130

Mirror defogger ........................................ EL-198

Mirror, door ................................................ BT-63

Misfire ............................................. EC-285, 808

Mode door control linkage

adjustment ............................................. HA-48

Model variation ........................................... GI-37

Molding - See Exterior ............................... BT-38

Multi-remote control system .................... EL-314

Multiport fuel injection (MFI) system . EC-35, 569

Multiport fuel injection precautions ............... GI-6

ALPHABETICAL INDEX

IDX-5

Page 2716 of 3051

CHECKING RADIATORNLLC0017S04Check radiator for mud or clogging. If necessary, clean radiator as

follows.

+Be careful not to bend or damage the radiator fins.

+When radiator is cleaned without removal, remove all sur-

rounding parts such as cooling fan, radiator shroud and horns.

Then tape the harness and connectors to prevent water from

entering.

1. Apply water by hose to the back side of the radiator core ver-

tically download.

2. Apply water again to all radiator core surfaces once per

minute.

3. Stop washing if any stains no longer flow out from the radia-

tor.

4. Blow air into the back side of radiator core vertically download.

+Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2,71

psi) and keep distance more than 30 cm (11.8 in).

5. Blow air again into all the radiator core surfaces once per

minute until no water sprays out.

SLC613-A

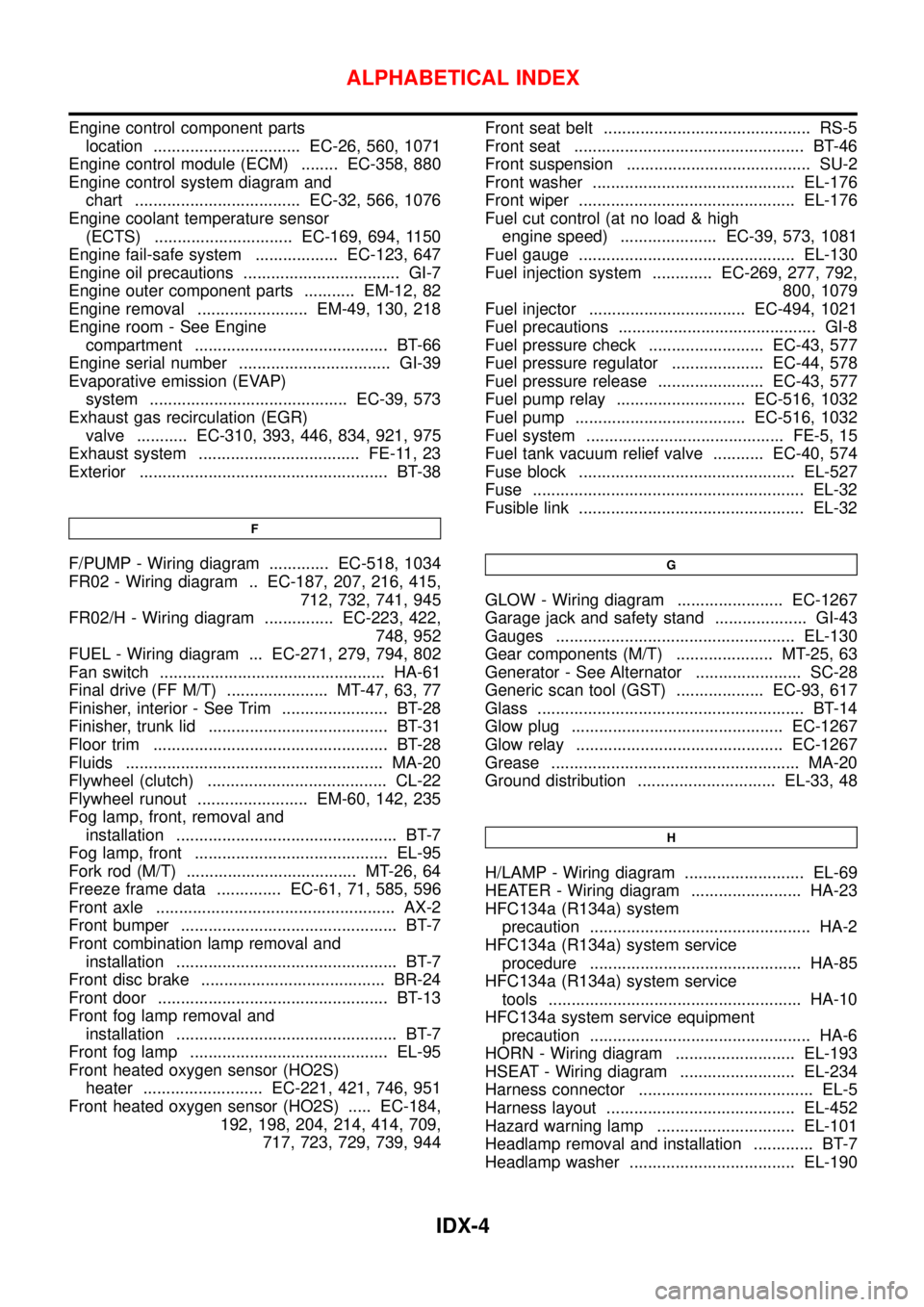

CHECKING RADIATOR CAPNLLC0017S03To check radiator cap, apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59-98kPa

(0.59 - 0.98 bar, 0.6 - 1.0 kg/cm

2,9-14psi)

SMA967B

Pull the negative pressure valve to open it.

Check that it closes completely when released.

SLC756AA

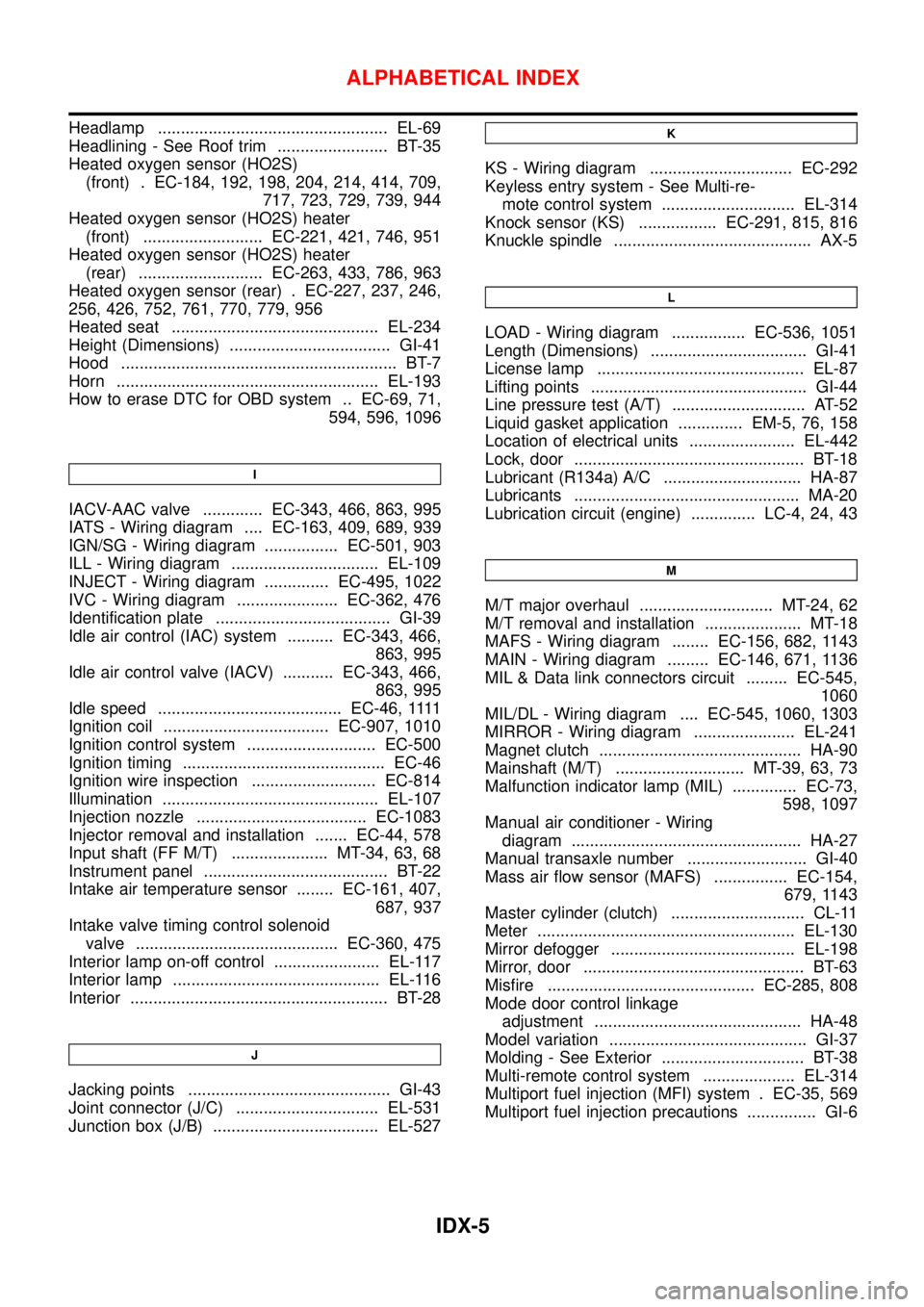

CHECKING COOLING SYSTEM FOR LEAKSNLLC0017S02To check for leakage, apply pressure to the cooling system with a

tester.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLING SYSTEMQG

System Check (Cont'd)

LC-13

Page 2736 of 3051

CHECKING RADIATORNLLC0133S03Check radiator for mud or clogging. If necessary, clean radiator as

follows.

+Be careful not to bend or damage the radiator fins.

+When radiator is cleaned without removal, remove all sur-

rounding parts such as cooling fan, rediator shroud and horns.

Then tape the harness and connectors to prevent water from

entering.

1. Apply water by hose to the back side of the radiator core ver-

tically download.

2. Apply water again to all radiator core surfaces once per

minute.

3. Stop washing if any stains no longer flow out from the radia-

tor.

4. Blow air into the back side of radiator core vertically download.

+Use compressesd air lower than 490 kPa (5 kg/cm

2, 71 psi)

and keep distance more than 30 cm (11.8 in).

5. Blow air again into all the radiator core surfaces once per

minute until no water sprays out.

SLC613-A

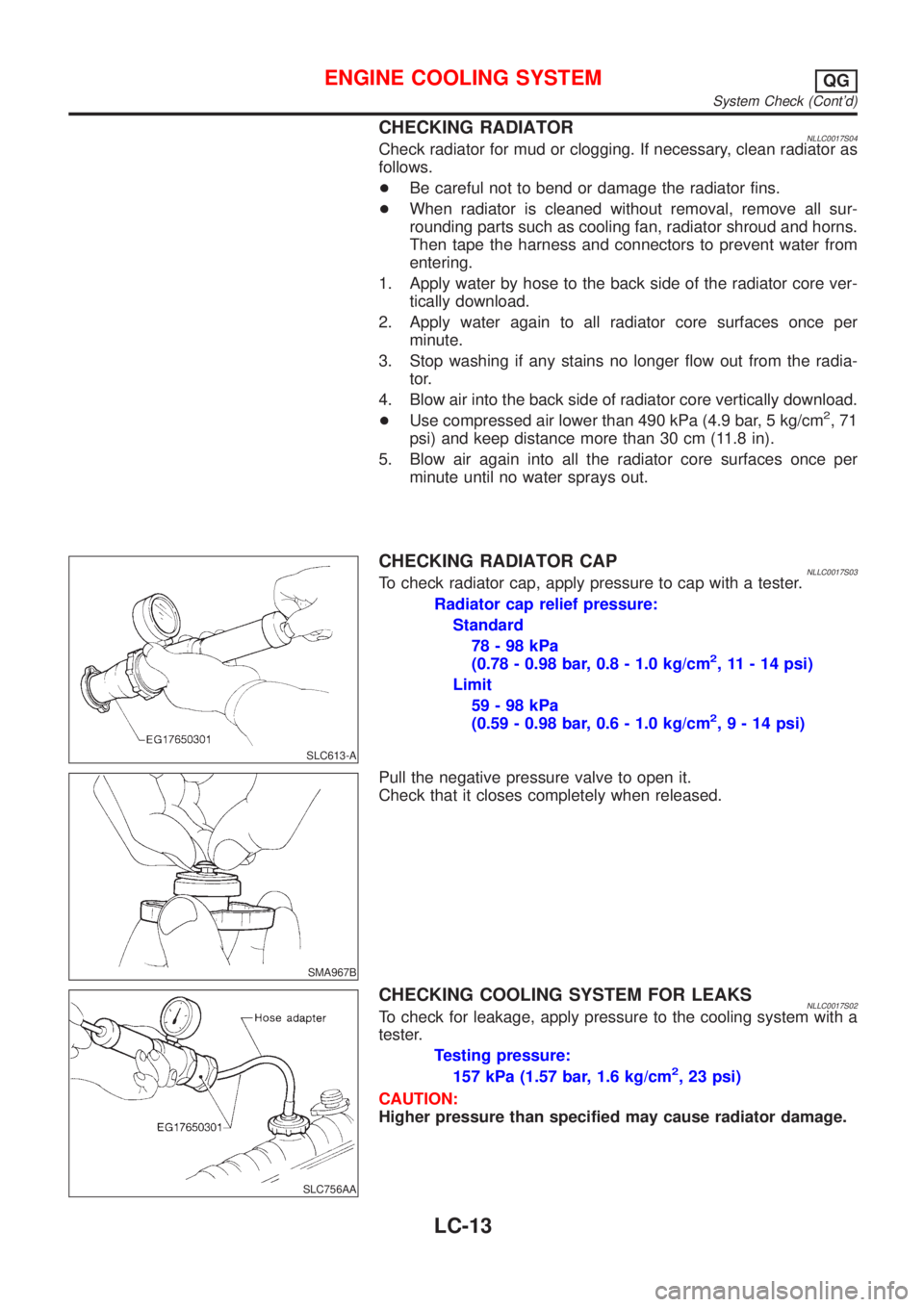

CHECKING RADIATOR CAPNLLC0133S04To check radiator cap, apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78 - 98 kPa (0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59 - 98 kPa (0.6 - 1.0 kg/cm

2,9-14psi)

SMA967B

Pull the negative pressure valve to open it.

Check that it closes completely when released.

SLC266B

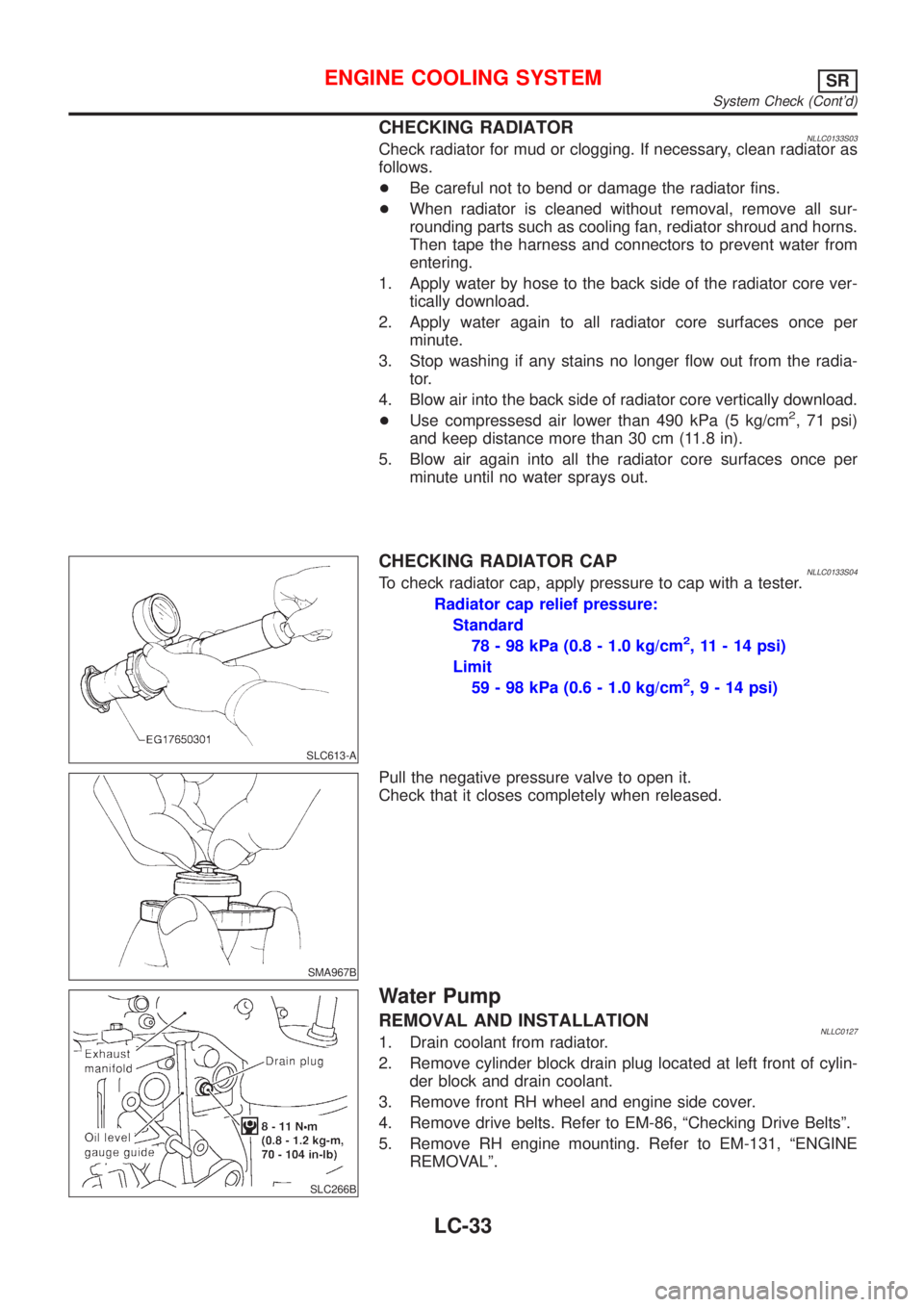

Water Pump

REMOVAL AND INSTALLATIONNLLC01271. Drain coolant from radiator.

2. Remove cylinder block drain plug located at left front of cylin-

der block and drain coolant.

3. Remove front RH wheel and engine side cover.

4. Remove drive belts. Refer to EM-86, ªChecking Drive Beltsº.

5. Remove RH engine mounting. Refer to EM-131, ªENGINE

REMOVALº.

ENGINE COOLING SYSTEMSR

System Check (Cont'd)

LC-33

Page 2757 of 3051

System CheckNLLC0054WARNING:

Never remove the radiator cap when the engine is hot; serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap and carefully remove it by

turning it a quarter turn to allow built-up pressure to escape

and then turn the cap all the way off.

CHECKING COOLING SYSTEM HOSESNLLC0054S01Check hoses for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

CHECKING RADIATORNLLC0054S02Check radiator for mud or clogging. If necessary, clean radiator as

follows.

+Be careful not to bend or damage the radiator fins.

+When radiator is cleaned without removal, remove all sur-

rounding parts such as cooling fan, radiator shroud and horns.

Then tape the harness and connectors to prevent water from

entering.

1. Apply water by hose to the back side of the radiator core ver-

tically downward.

2. Apply water again to all radiator core surfaces once per

minute.

3. Stop washing if any stains no longer flow out from the radia-

tor.

4. Blow air into the back side of radiator core vertically downward.

+Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2,71

psi) and keep distance more than 30 cm (11.8 in).

5. Blow air again into all the radiator core surfaces once per

minute until no water sprays out.

SLC755AC

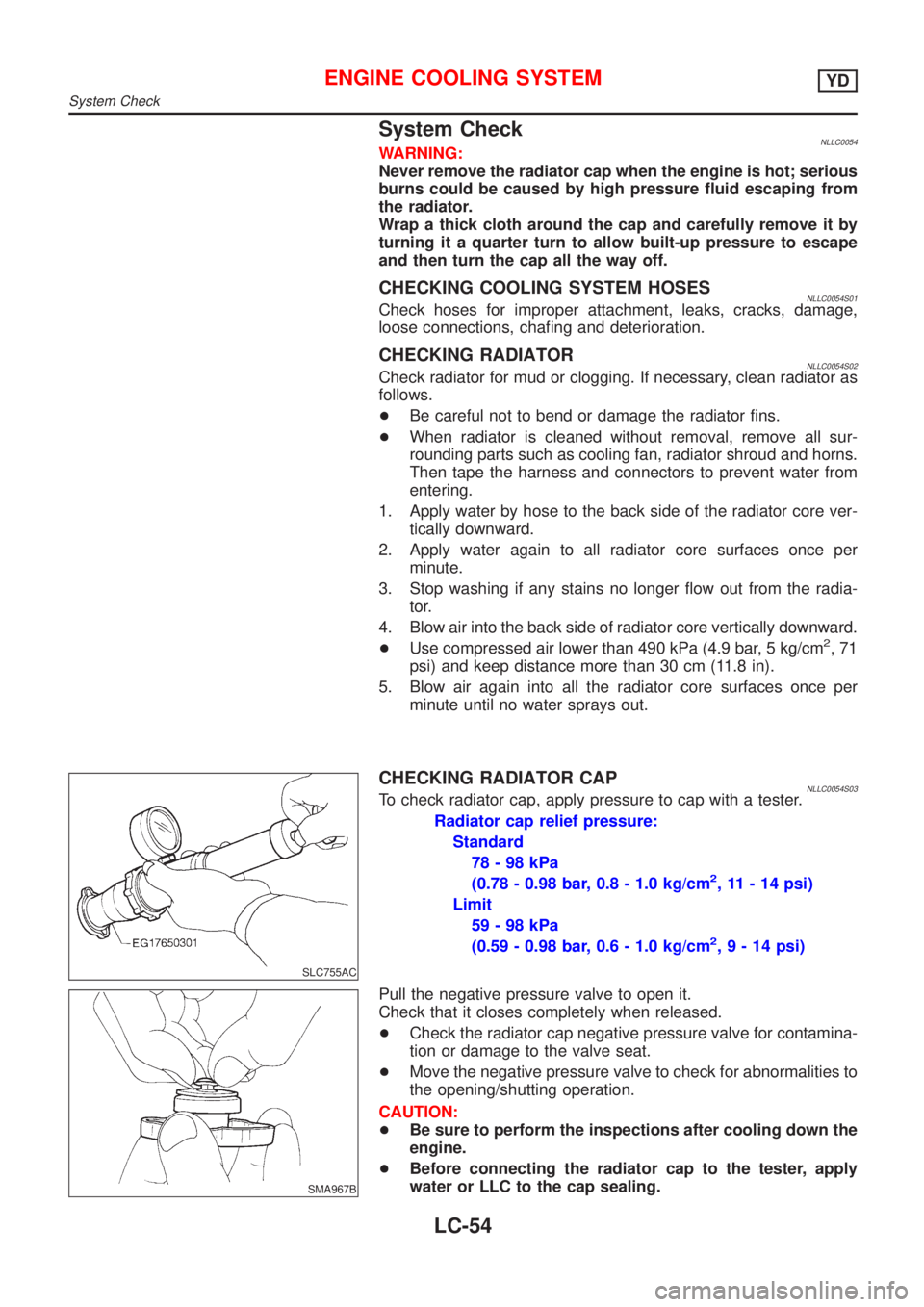

CHECKING RADIATOR CAPNLLC0054S03To check radiator cap, apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59-98kPa

(0.59 - 0.98 bar, 0.6 - 1.0 kg/cm

2,9-14psi)

SMA967B

Pull the negative pressure valve to open it.

Check that it closes completely when released.

+Check the radiator cap negative pressure valve for contamina-

tion or damage to the valve seat.

+Move the negative pressure valve to check for abnormalities to

the opening/shutting operation.

CAUTION:

+Be sure to perform the inspections after cooling down the

engine.

+Before connecting the radiator cap to the tester, apply

water or LLC to the cap sealing.

ENGINE COOLING SYSTEMYD

System Check

LC-54

Page 2769 of 3051

NLMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2