check engine NISSAN ALTIMA 1998 L30 / 2.G Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: ALTIMA, Model: NISSAN ALTIMA 1998 L30 / 2.GPages: 217, PDF Size: 1.77 MB

Page 152 of 217

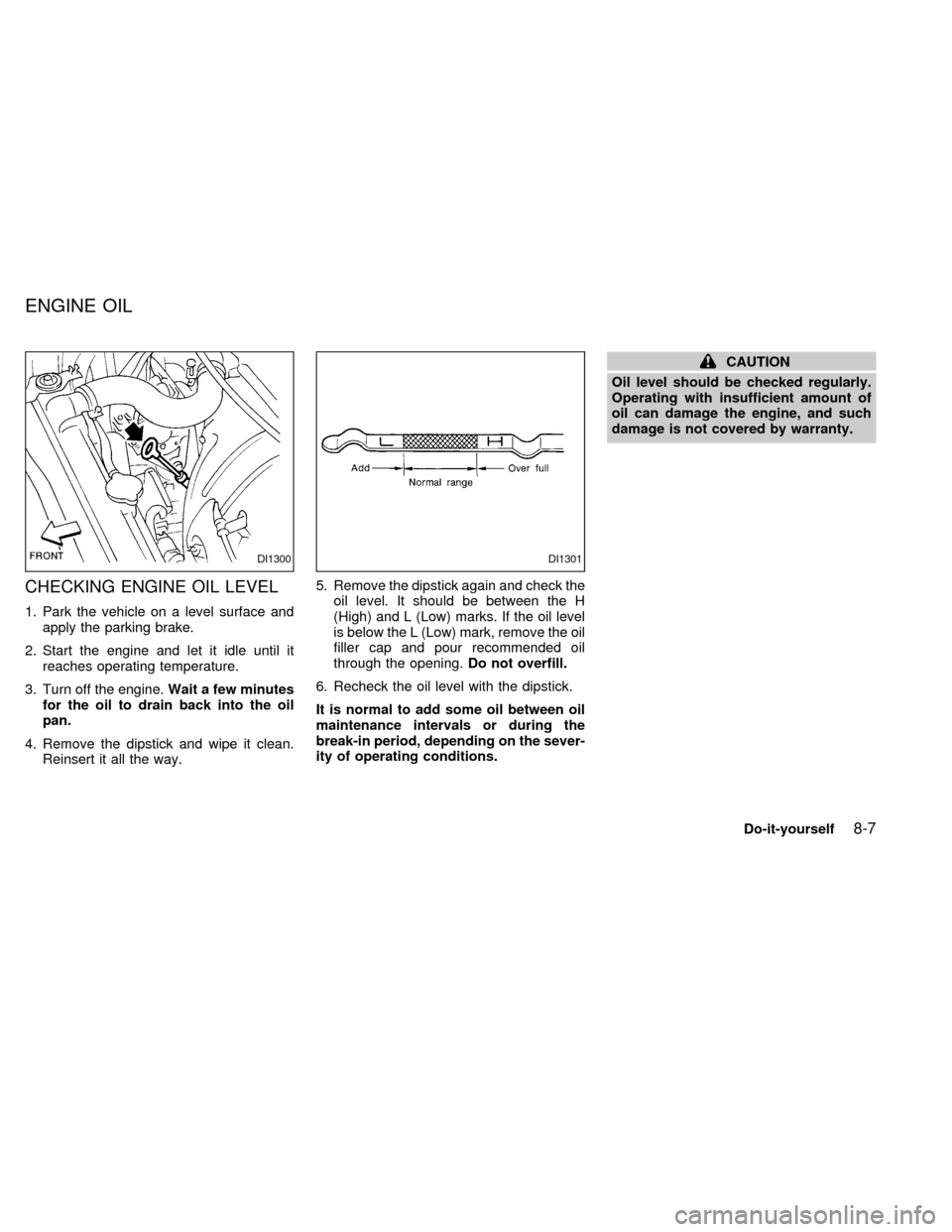

CHECKING ENGINE OIL LEVEL

1. Park the vehicle on a level surface and

apply the parking brake.

2. Start the engine and let it idle until it

reaches operating temperature.

3. Turn off the engine.Wait a few minutes

for the oil to drain back into the oil

pan.

4. Remove the dipstick and wipe it clean.

Reinsert it all the way.5. Remove the dipstick again and check the

oil level. It should be between the H

(High) and L (Low) marks. If the oil level

is below the L (Low) mark, remove the oil

filler cap and pour recommended oil

through the opening.Do not overfill.

6. Recheck the oil level with the dipstick.

It is normal to add some oil between oil

maintenance intervals or during the

break-in period, depending on the sever-

ity of operating conditions.

CAUTION

Oil level should be checked regularly.

Operating with insufficient amount of

oil can damage the engine, and such

damage is not covered by warranty.

DI1300DI1301

ENGINE OIL

Do-it-yourself8-7

ZX

Page 153 of 217

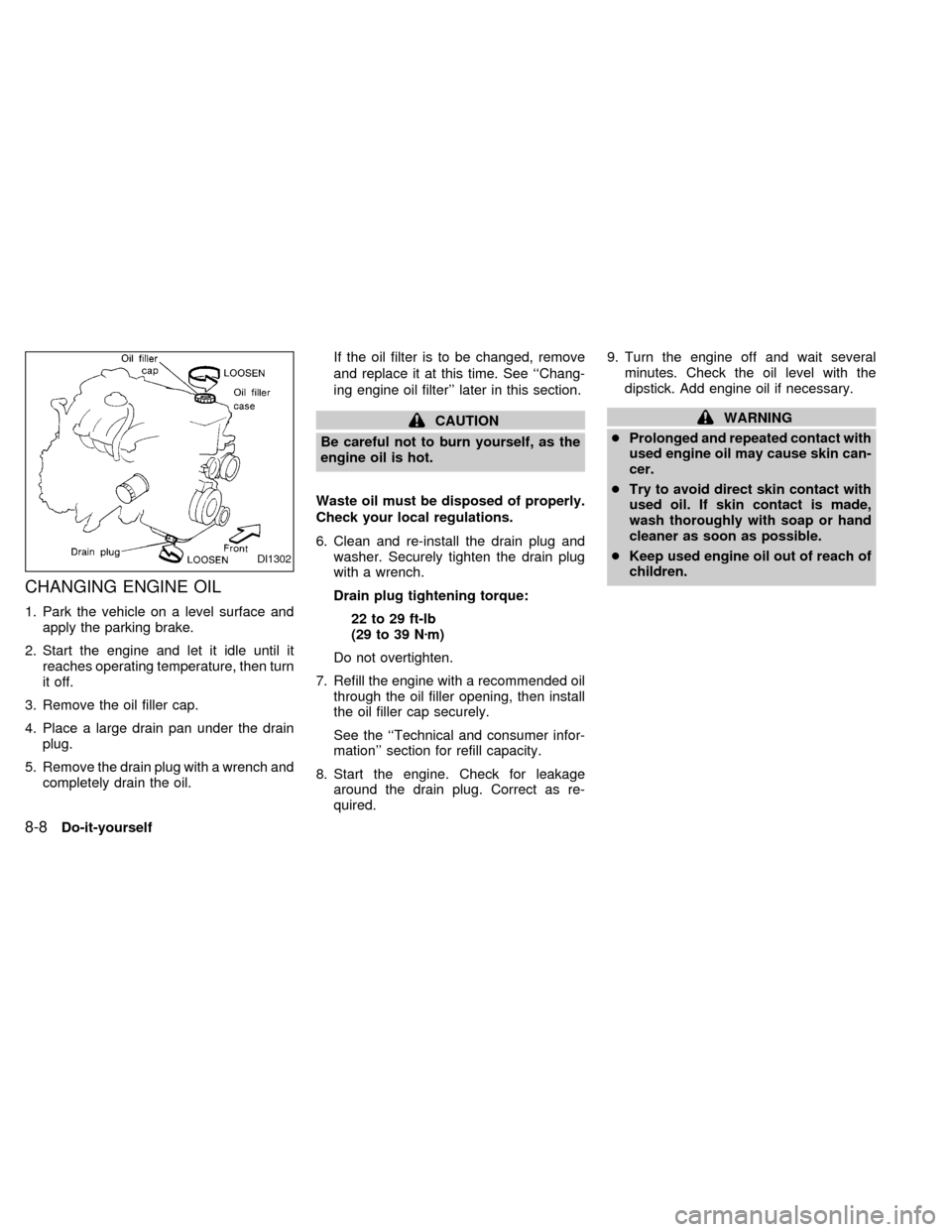

CHANGING ENGINE OIL

1. Park the vehicle on a level surface and

apply the parking brake.

2. Start the engine and let it idle until it

reaches operating temperature, then turn

it off.

3. Remove the oil filler cap.

4. Place a large drain pan under the drain

plug.

5. Remove the drain plug with a wrench and

completely drain the oil.If the oil filter is to be changed, remove

and replace it at this time. See ``Chang-

ing engine oil filter'' later in this section.

CAUTION

Be careful not to burn yourself, as the

engine oil is hot.

Waste oil must be disposed of properly.

Check your local regulations.

6. Clean and re-install the drain plug and

washer. Securely tighten the drain plug

with a wrench.

Drain plug tightening torque:

22 to 29 ft-lb

(29 to 39 Nzm)

Do not overtighten.

7. Refill the engine with a recommended oil

through the oil filler opening, then install

the oil filler cap securely.

See the ``Technical and consumer infor-

mation'' section for refill capacity.

8. Start the engine. Check for leakage

around the drain plug. Correct as re-

quired.9. Turn the engine off and wait several

minutes. Check the oil level with the

dipstick. Add engine oil if necessary.WARNING

cProlonged and repeated contact with

used engine oil may cause skin can-

cer.

cTry to avoid direct skin contact with

used oil. If skin contact is made,

wash thoroughly with soap or hand

cleaner as soon as possible.

cKeep used engine oil out of reach of

children.

DI1302

8-8Do-it-yourself

ZX

Page 154 of 217

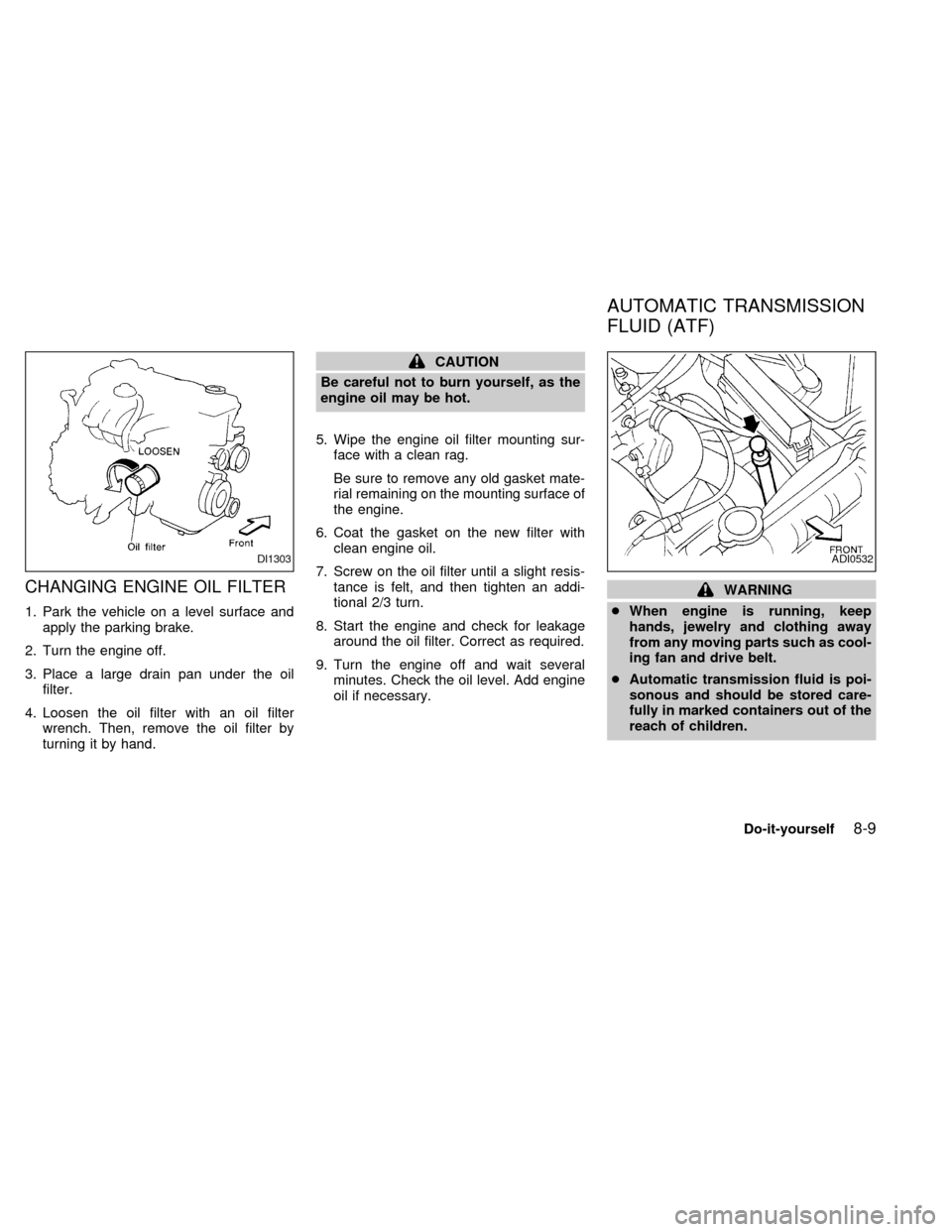

CHANGING ENGINE OIL FILTER

1. Park the vehicle on a level surface and

apply the parking brake.

2. Turn the engine off.

3. Place a large drain pan under the oil

filter.

4. Loosen the oil filter with an oil filter

wrench. Then, remove the oil filter by

turning it by hand.

CAUTION

Be careful not to burn yourself, as the

engine oil may be hot.

5. Wipe the engine oil filter mounting sur-

face with a clean rag.

Be sure to remove any old gasket mate-

rial remaining on the mounting surface of

the engine.

6. Coat the gasket on the new filter with

clean engine oil.

7. Screw on the oil filter until a slight resis-

tance is felt, and then tighten an addi-

tional 2/3 turn.

8. Start the engine and check for leakage

around the oil filter. Correct as required.

9. Turn the engine off and wait several

minutes. Check the oil level. Add engine

oil if necessary.

WARNING

cWhen engine is running, keep

hands, jewelry and clothing away

from any moving parts such as cool-

ing fan and drive belt.

cAutomatic transmission fluid is poi-

sonous and should be stored care-

fully in marked containers out of the

reach of children.

DI1303ADI0532

AUTOMATIC TRANSMISSION

FLUID (ATF)

Do-it-yourself8-9

ZX

Page 155 of 217

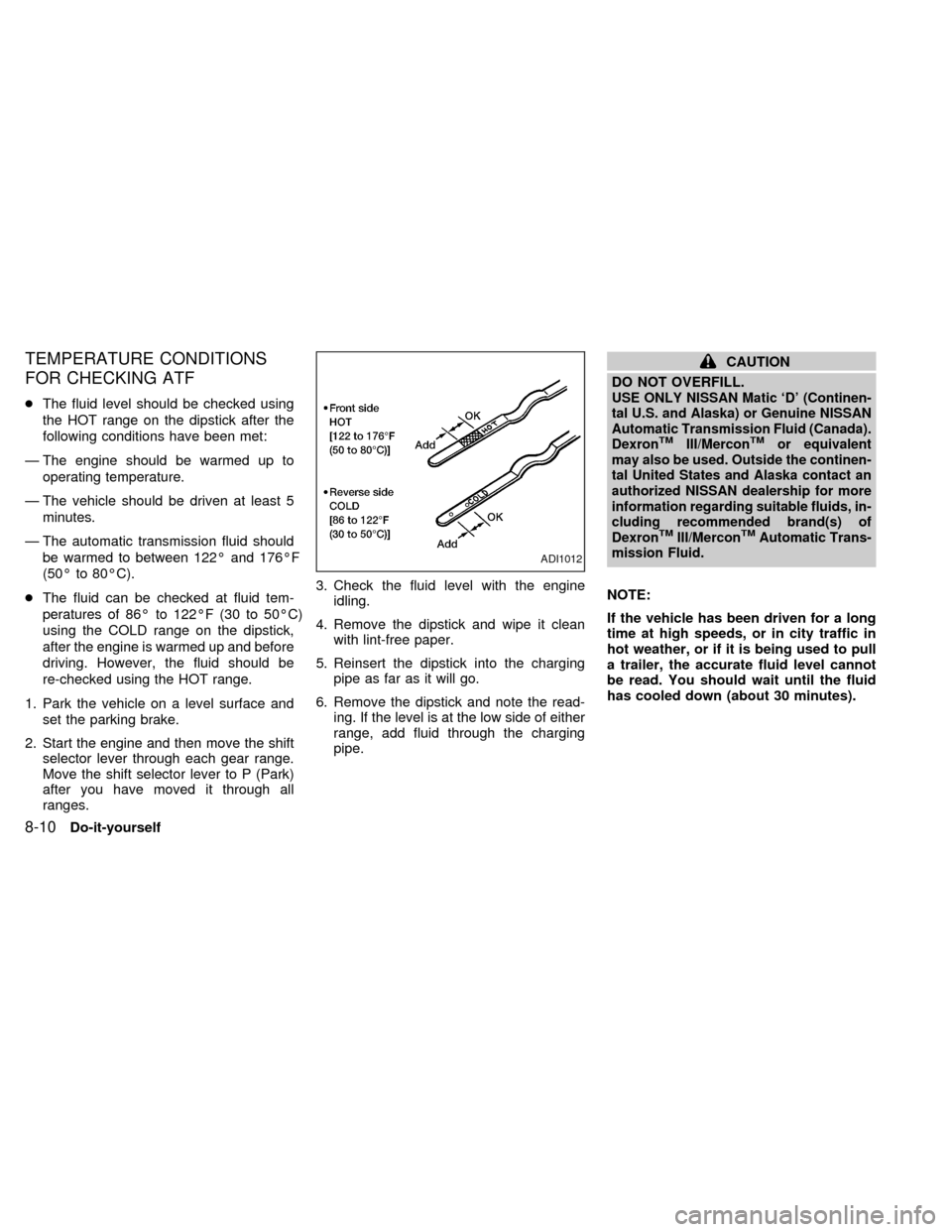

TEMPERATURE CONDITIONS

FOR CHECKING ATF

cThe fluid level should be checked using

the HOT range on the dipstick after the

following conditions have been met:

Ð The engine should be warmed up to

operating temperature.

Ð The vehicle should be driven at least 5

minutes.

Ð The automatic transmission fluid should

be warmed to between 122É and 176ÉF

(50É to 80ÉC).

cThe fluid can be checked at fluid tem-

peratures of 86É to 122ÉF (30 to 50ÉC)

using the COLD range on the dipstick,

after the engine is warmed up and before

driving. However, the fluid should be

re-checked using the HOT range.

1. Park the vehicle on a level surface and

set the parking brake.

2. Start the engine and then move the shift

selector lever through each gear range.

Move the shift selector lever to P (Park)

after you have moved it through all

ranges.3. Check the fluid level with the engine

idling.

4. Remove the dipstick and wipe it clean

with lint-free paper.

5. Reinsert the dipstick into the charging

pipe as far as it will go.

6. Remove the dipstick and note the read-

ing. If the level is at the low side of either

range, add fluid through the charging

pipe.

CAUTION

DO NOT OVERFILL.

USE ONLY NISSAN Matic `D' (Continen-

tal U.S. and Alaska) or Genuine NISSAN

Automatic Transmission Fluid (Canada).

Dexron

TMIII/MerconTMor equivalent

may also be used. Outside the continen-

tal United States and Alaska contact an

authorized NISSAN dealership for more

information regarding suitable fluids, in-

cluding recommended brand(s) of

Dexron

TMIII/MerconTMAutomatic Trans-

mission Fluid.

NOTE:

If the vehicle has been driven for a long

time at high speeds, or in city traffic in

hot weather, or if it is being used to pull

a trailer, the accurate fluid level cannot

be read. You should wait until the fluid

has cooled down (about 30 minutes).

ADI1012

8-10Do-it-yourself

ZX

Page 158 of 217

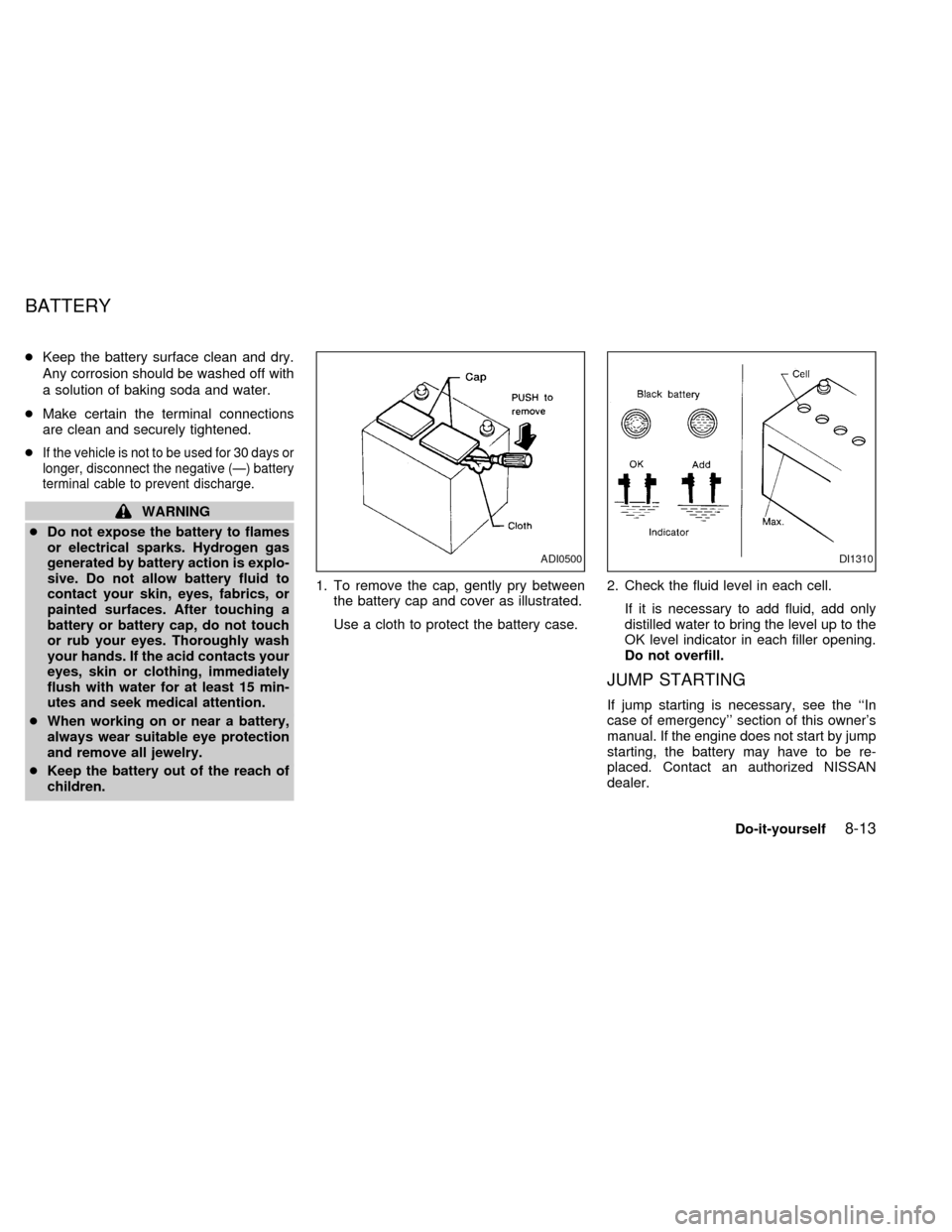

cKeep the battery surface clean and dry.

Any corrosion should be washed off with

a solution of baking soda and water.

cMake certain the terminal connections

are clean and securely tightened.

c

If the vehicle is not to be used for 30 days or

longer, disconnect the negative (Ð) battery

terminal cable to prevent discharge.

WARNING

cDo not expose the battery to flames

or electrical sparks. Hydrogen gas

generated by battery action is explo-

sive. Do not allow battery fluid to

contact your skin, eyes, fabrics, or

painted surfaces. After touching a

battery or battery cap, do not touch

or rub your eyes. Thoroughly wash

your hands. If the acid contacts your

eyes, skin or clothing, immediately

flush with water for at least 15 min-

utes and seek medical attention.

cWhen working on or near a battery,

always wear suitable eye protection

and remove all jewelry.

cKeep the battery out of the reach of

children.1. To remove the cap, gently pry between

the battery cap and cover as illustrated.

Use a cloth to protect the battery case.2. Check the fluid level in each cell.

If it is necessary to add fluid, add only

distilled water to bring the level up to the

OK level indicator in each filler opening.

Do not overfill.

JUMP STARTING

If jump starting is necessary, see the ``In

case of emergency'' section of this owner's

manual. If the engine does not start by jump

starting, the battery may have to be re-

placed. Contact an authorized NISSAN

dealer.

ADI0500DI1310

BATTERY

Do-it-yourself8-13

ZX

Page 159 of 217

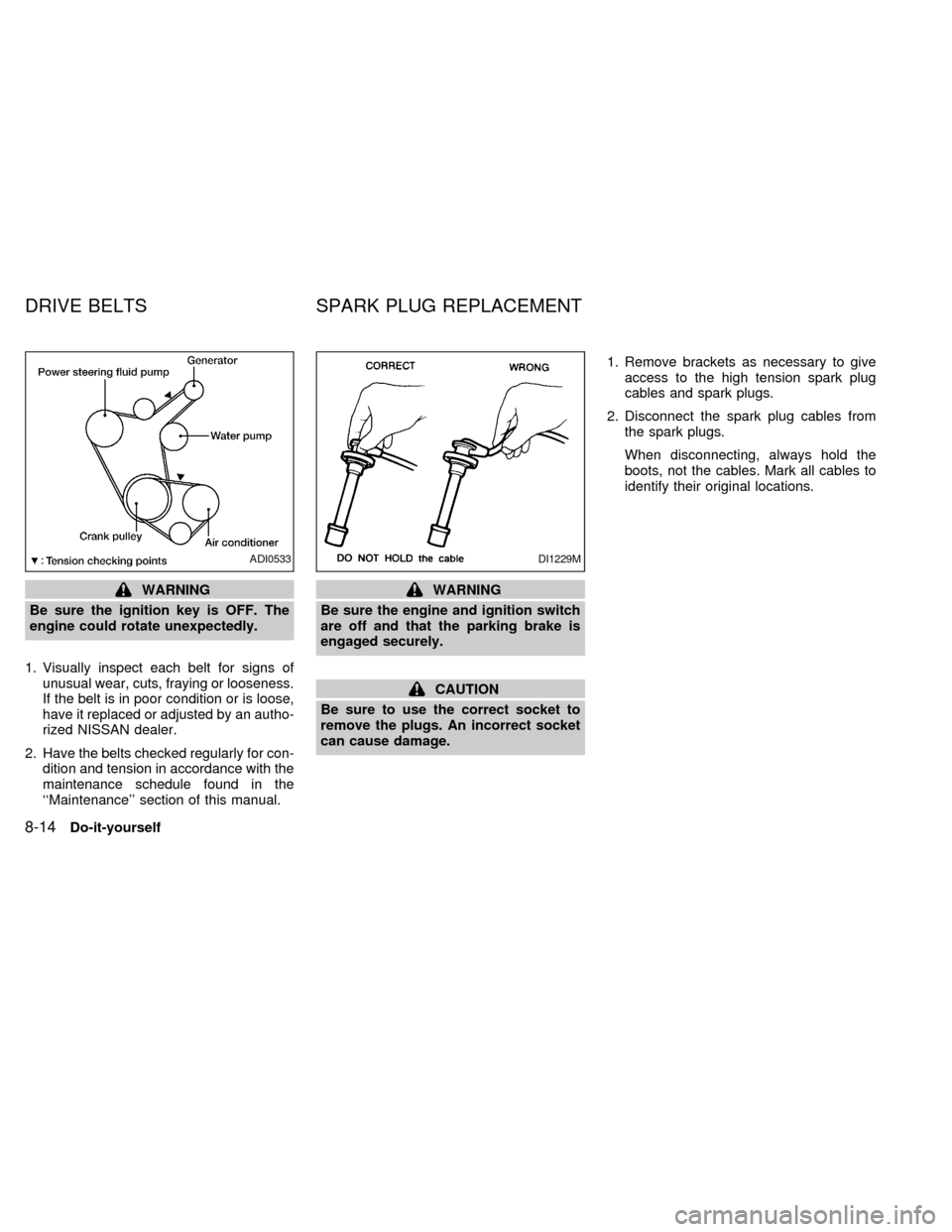

WARNING

Be sure the ignition key is OFF. The

engine could rotate unexpectedly.

1. Visually inspect each belt for signs of

unusual wear, cuts, fraying or looseness.

If the belt is in poor condition or is loose,

have it replaced or adjusted by an autho-

rized NISSAN dealer.

2. Have the belts checked regularly for con-

dition and tension in accordance with the

maintenance schedule found in the

``Maintenance'' section of this manual.WARNING

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

CAUTION

Be sure to use the correct socket to

remove the plugs. An incorrect socket

can cause damage.1. Remove brackets as necessary to give

access to the high tension spark plug

cables and spark plugs.

2. Disconnect the spark plug cables from

the spark plugs.

When disconnecting, always hold the

boots, not the cables. Mark all cables to

identify their original locations.

ADI0533DI1229M

DRIVE BELTS SPARK PLUG REPLACEMENT

8-14Do-it-yourself

ZX

Page 163 of 217

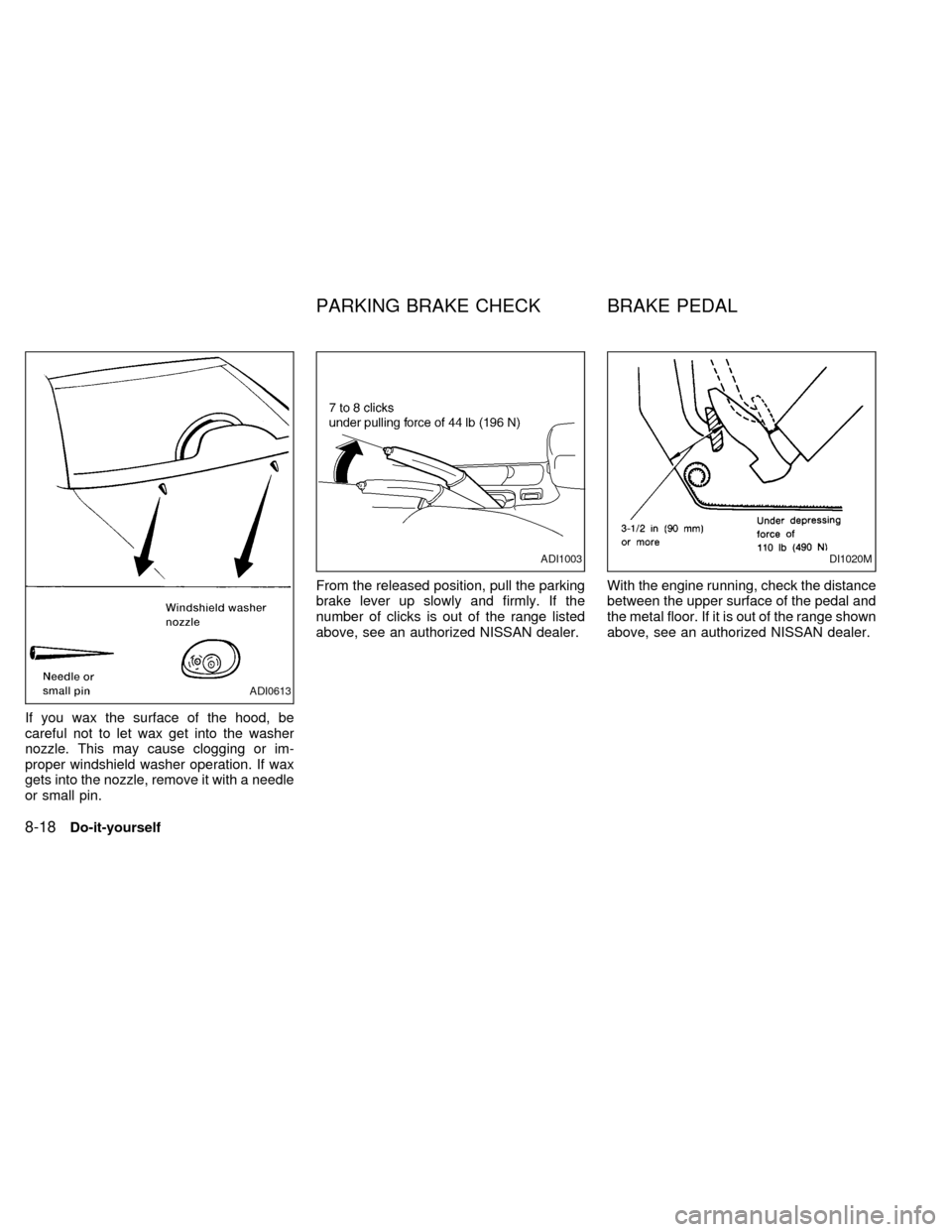

If you wax the surface of the hood, be

careful not to let wax get into the washer

nozzle. This may cause clogging or im-

proper windshield washer operation. If wax

gets into the nozzle, remove it with a needle

or small pin.From the released position, pull the parking

brake lever up slowly and firmly. If the

number of clicks is out of the range listed

above, see an authorized NISSAN dealer.With the engine running, check the distance

between the upper surface of the pedal and

the metal floor. If it is out of the range shown

above, see an authorized NISSAN dealer.

ADI0613

ADI1003DI1020M

PARKING BRAKE CHECK BRAKE PEDAL

8-18Do-it-yourself

ZX

Page 164 of 217

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.

The front (and rear, if equipped) disc-type

brakes self-adjust every time the brake

pedal is applied. The rear drum-type brakes

also self-adjust every time the brake pedal

is applied.

If the brake pedal goes down farther than

normal, it may be due to a lack of adjust-

ment of the rear drum brakes. To adjust,

apply the parking brake several times.

WARNING

See your NISSAN dealer and have it

checked if the brake pedal height does

not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it makes a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wearindicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brake

noise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise from

the rear drum brakes, have them inspected

as soon as possible by an authorized

NISSAN dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance'' section of this manual.Check the brake booster function as fol-

lows:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to the

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keep the pedal depressed for

about 30 seconds. The pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, see an

authorized NISSAN dealer.

BRAKE BOOSTER

Do-it-yourself8-19

ZX

Page 165 of 217

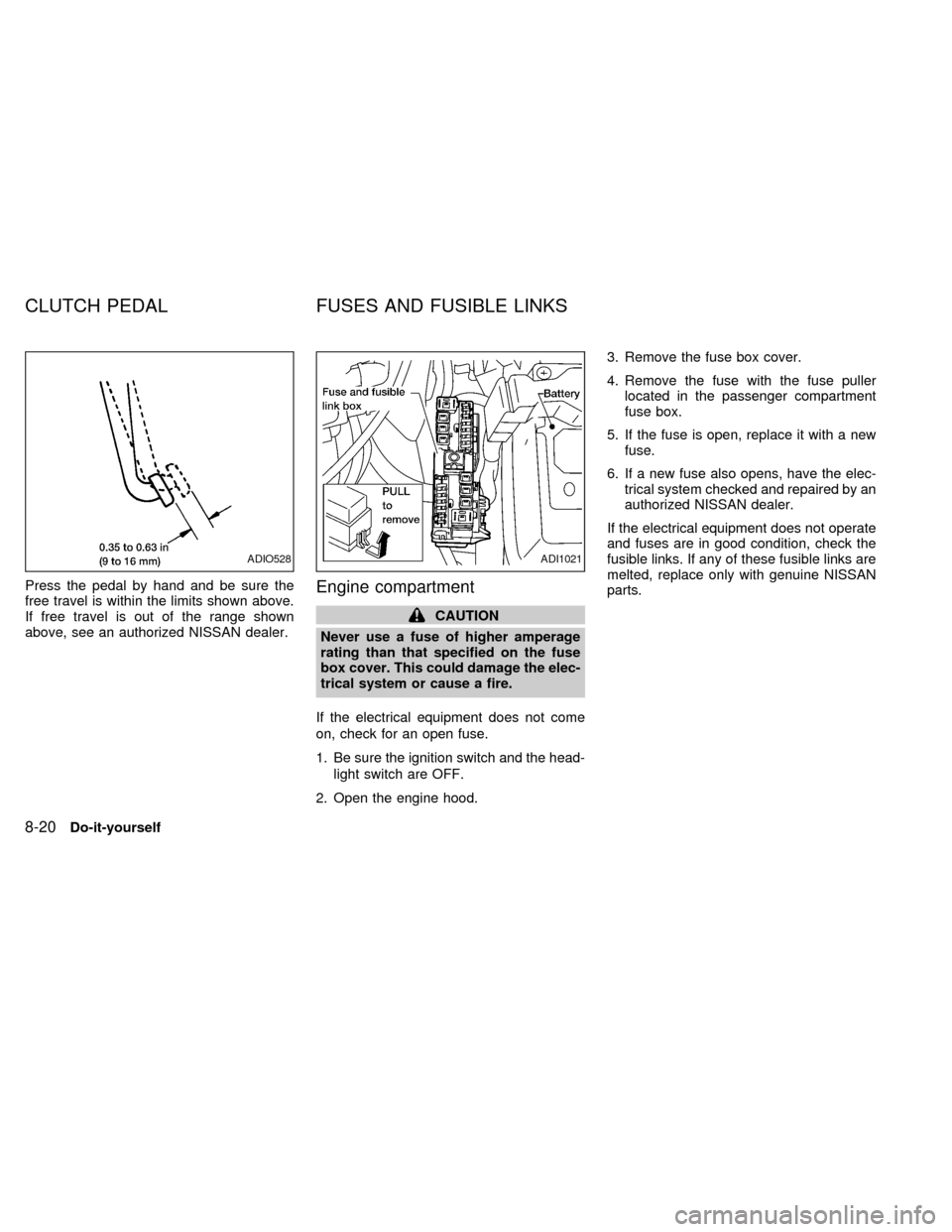

Press the pedal by hand and be sure the

free travel is within the limits shown above.

If free travel is out of the range shown

above, see an authorized NISSAN dealer.Engine compartment

CAUTION

Never use a fuse of higher amperage

rating than that specified on the fuse

box cover. This could damage the elec-

trical system or cause a fire.

If the electrical equipment does not come

on, check for an open fuse.

1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the engine hood.3. Remove the fuse box cover.

4. Remove the fuse with the fuse puller

located in the passenger compartment

fuse box.

5. If the fuse is open, replace it with a new

fuse.

6. If a new fuse also opens, have the elec-

trical system checked and repaired by an

authorized NISSAN dealer.

If the electrical equipment does not operate

and fuses are in good condition, check the

fusible links. If any of these fusible links are

melted, replace only with genuine NISSAN

parts.

ADIO528ADI1021

CLUTCH PEDAL FUSES AND FUSIBLE LINKS

8-20Do-it-yourself

ZX

Page 168 of 217

a. Keep all of the tires inflated to the correct

pressure.

b. Place the vehicle on level ground.

c. See that the vehicle is unloaded (except

for full levels of coolant, engine oil and

fuel, and spare tire, jack, and tools).

Have the driver or an equivalent weight

placed in the driver's seat.

Low beam

1. Open the hood.

2. Adjust the vertical aim by turning the

adjusting screw with a Phillips screw-

driver.

3. Adjust the horizontal aim by turning the

adjusting screw with a Phillips screw-

driver.

ADJUSTMENT AFTER

HEADLIGHT ASSEMBLY

REPLACEMENT

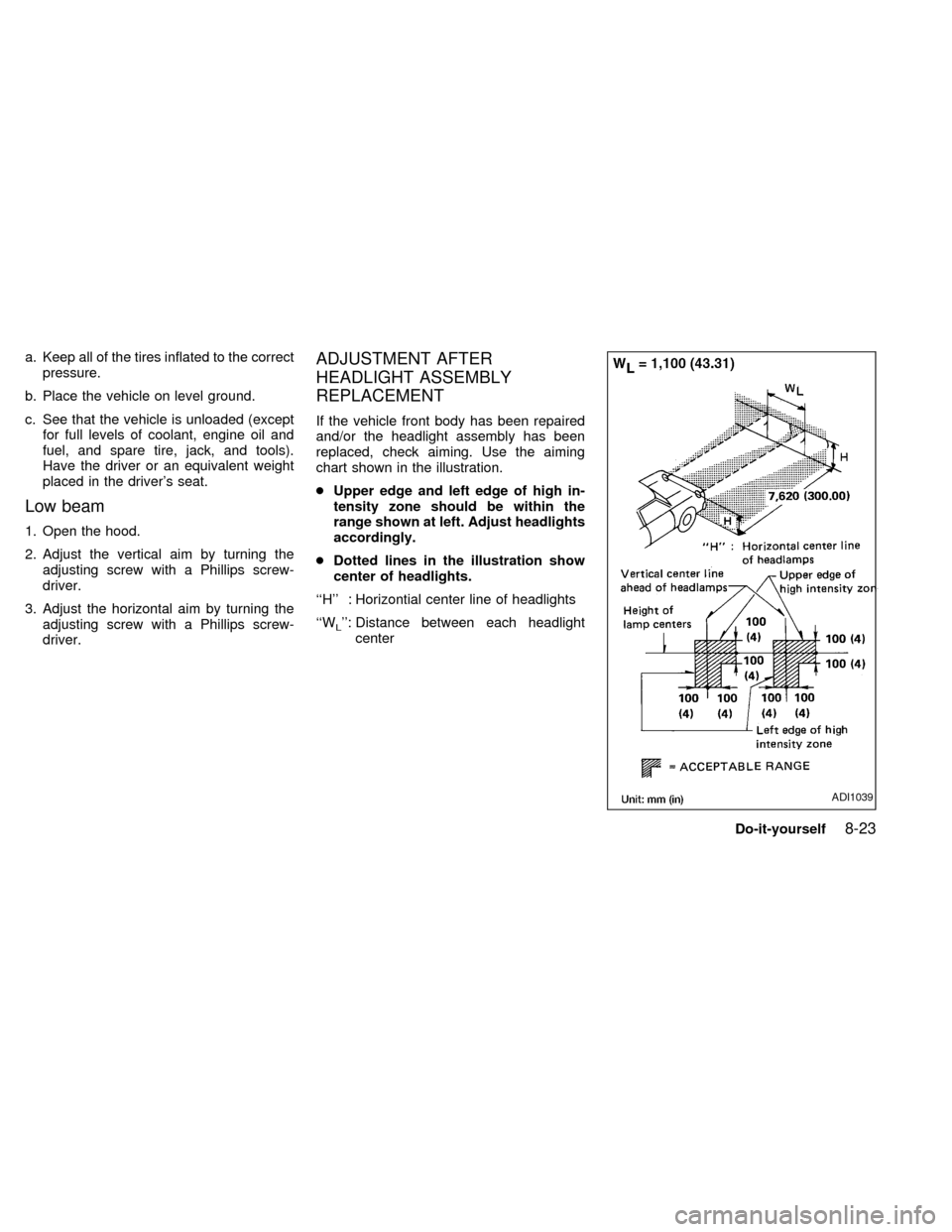

If the vehicle front body has been repaired

and/or the headlight assembly has been

replaced, check aiming. Use the aiming

chart shown in the illustration.

cUpper edge and left edge of high in-

tensity zone should be within the

range shown at left. Adjust headlights

accordingly.

cDotted lines in the illustration show

center of headlights.

``H'' : Horizontial center line of headlights

``W

L'': Distance between each headlight

center

ADI1039

Do-it-yourself8-23

ZX