engine coolant NISSAN ALTIMA 2000 L30 / 2.G User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: ALTIMA, Model: NISSAN ALTIMA 2000 L30 / 2.GPages: 242, PDF Size: 1.94 MB

Page 170 of 242

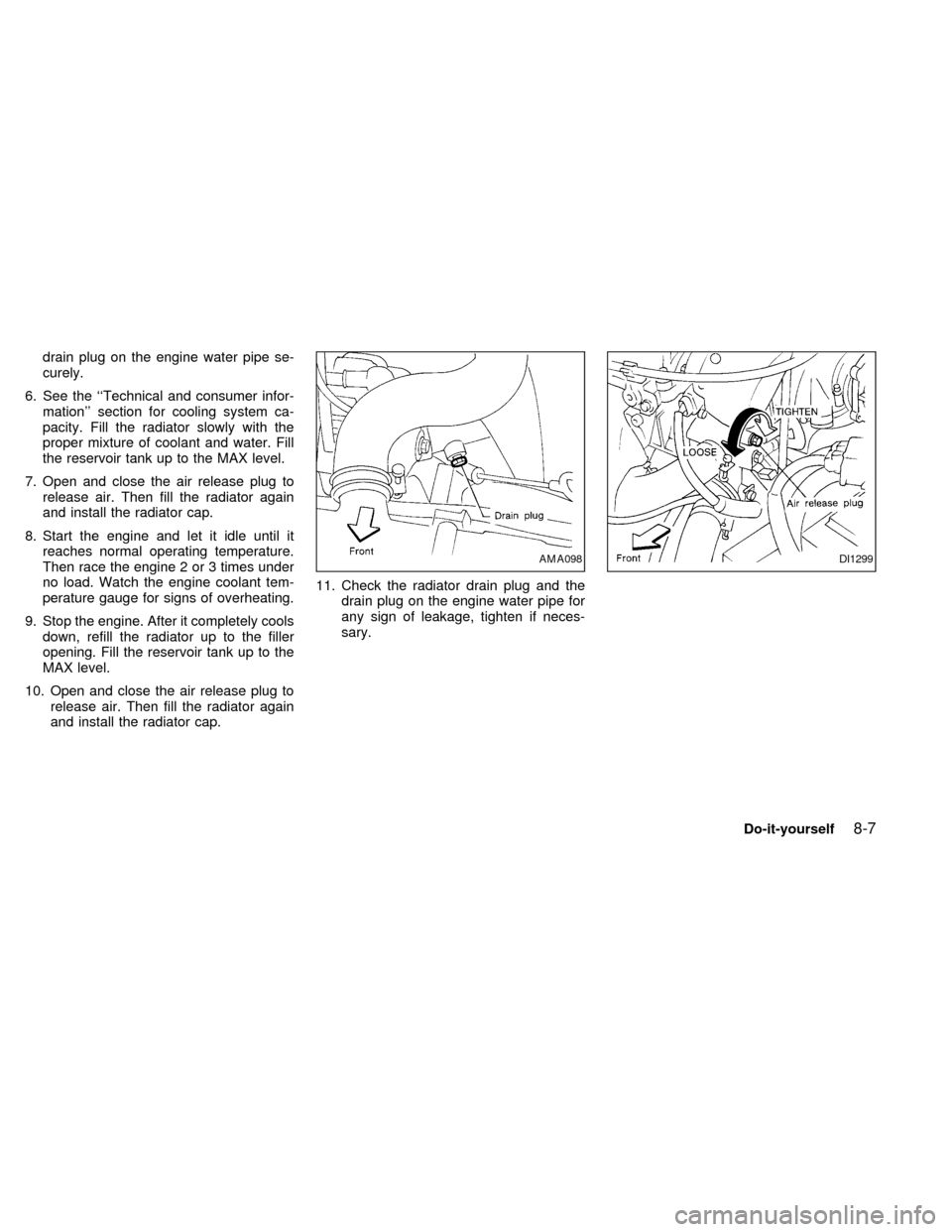

drain plug on the engine water pipe se-

curely.

6. See the ``Technical and consumer infor-

mation'' section for cooling system ca-

pacity. Fill the radiator slowly with the

proper mixture of coolant and water. Fill

the reservoir tank up to the MAX level.

7. Open and close the air release plug to

release air. Then fill the radiator again

and install the radiator cap.

8. Start the engine and let it idle until it

reaches normal operating temperature.

Then race the engine 2 or 3 times under

no load. Watch the engine coolant tem-

perature gauge for signs of overheating.

9. Stop the engine. After it completely cools

down, refill the radiator up to the filler

opening. Fill the reservoir tank up to the

MAX level.

10. Open and close the air release plug to

release air. Then fill the radiator again

and install the radiator cap.11. Check the radiator drain plug and the

drain plug on the engine water pipe for

any sign of leakage, tighten if neces-

sary.

AMA098DI1299

Do-it-yourself8-7

ZX

Page 176 of 242

WARNING

Use only new fluid from a sealed con-

tainer. Old, inferior, or contaminated

fluid may damage the brake and clutch

systems. The use of improper fluids

can damage the brake system and af-

fect the vehicle's stopping ability.

CAUTION

Do not spill the fluid on painted sur-

faces. This will damage the paint. If

fluid is spilled, immediately wash the

surface with water.

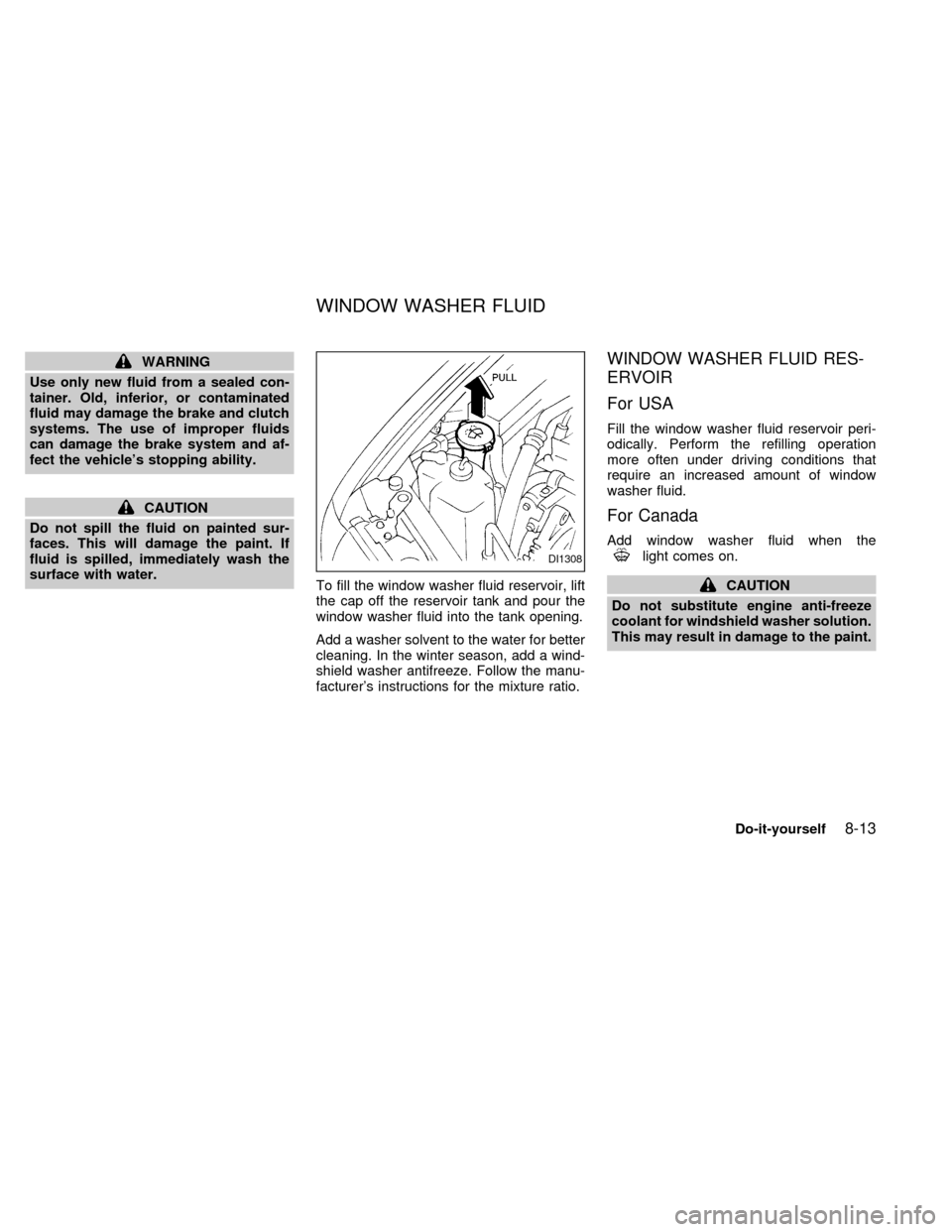

To fill the window washer fluid reservoir, lift

the cap off the reservoir tank and pour the

window washer fluid into the tank opening.

Add a washer solvent to the water for better

cleaning. In the winter season, add a wind-

shield washer antifreeze. Follow the manu-

facturer's instructions for the mixture ratio.

WINDOW WASHER FLUID RES-

ERVOIR

For USA

Fill the window washer fluid reservoir peri-

odically. Perform the refilling operation

more often under driving conditions that

require an increased amount of window

washer fluid.

For Canada

Add window washer fluid when thelight comes on.

CAUTION

Do not substitute engine anti-freeze

coolant for windshield washer solution.

This may result in damage to the paint.

DI1308

WINDOW WASHER FLUID

Do-it-yourself8-13

ZX

Page 188 of 242

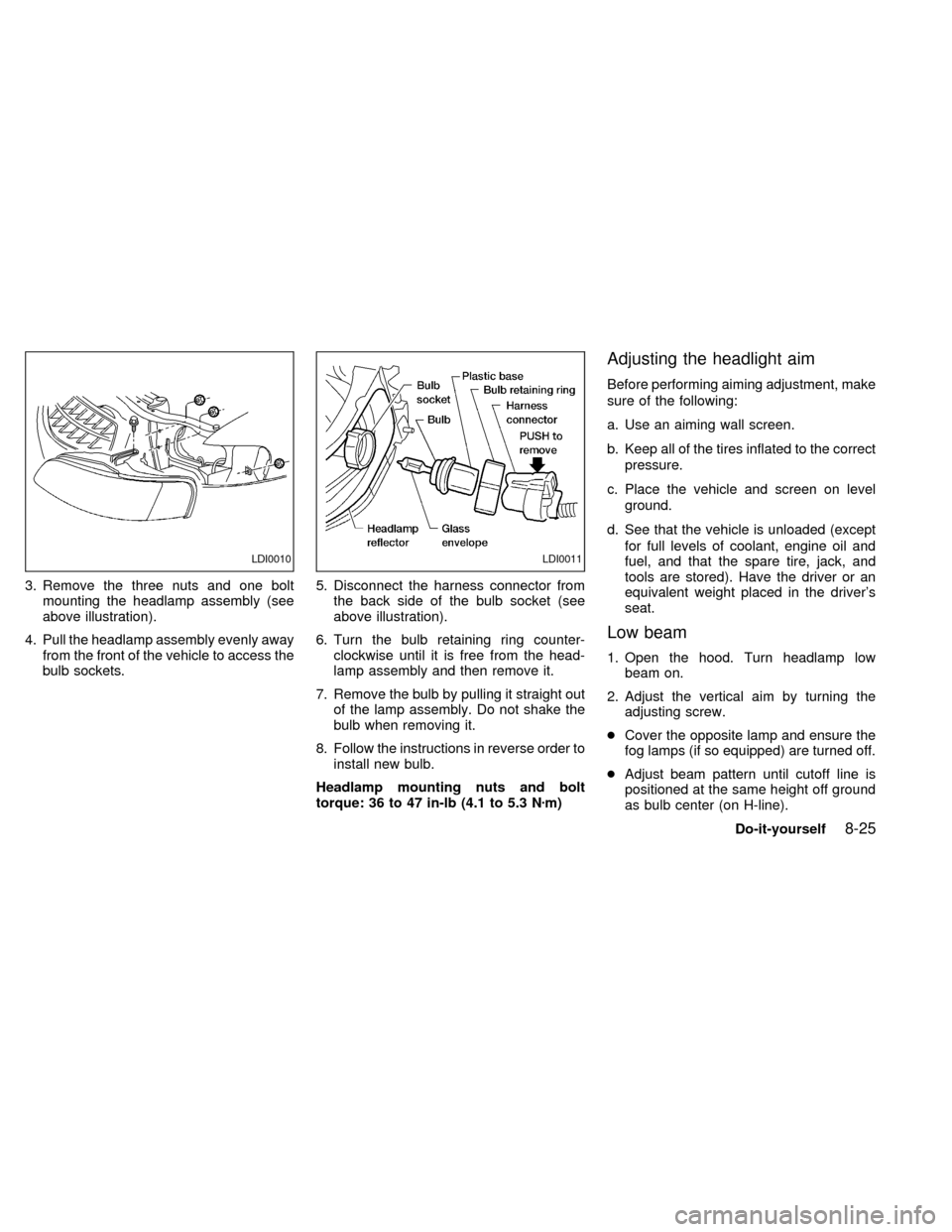

3. Remove the three nuts and one bolt

mounting the headlamp assembly (see

above illustration).

4. Pull the headlamp assembly evenly away

from the front of the vehicle to access the

bulb sockets.5. Disconnect the harness connector from

the back side of the bulb socket (see

above illustration).

6. Turn the bulb retaining ring counter-

clockwise until it is free from the head-

lamp assembly and then remove it.

7. Remove the bulb by pulling it straight out

of the lamp assembly. Do not shake the

bulb when removing it.

8. Follow the instructions in reverse order to

install new bulb.

Headlamp mounting nuts and bolt

torque: 36 to 47 in-lb (4.1 to 5.3 Nzm)

Adjusting the headlight aim

Before performing aiming adjustment, make

sure of the following:

a. Use an aiming wall screen.

b. Keep all of the tires inflated to the correct

pressure.

c. Place the vehicle and screen on level

ground.

d. See that the vehicle is unloaded (except

for full levels of coolant, engine oil and

fuel, and that the spare tire, jack, and

tools are stored). Have the driver or an

equivalent weight placed in the driver's

seat.

Low beam

1. Open the hood. Turn headlamp low

beam on.

2. Adjust the vertical aim by turning the

adjusting screw.

cCover the opposite lamp and ensure the

fog lamps (if so equipped) are turned off.

cAdjust beam pattern until cutoff line is

positioned at the same height off ground

as bulb center (on H-line).

LDI0010LDI0011

Do-it-yourself8-25

ZX

Page 205 of 242

Accelerator pedal ÐCheck the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort.

Keep the floor mat away from the pedal.

Clutch pedal* ÐMake sure the pedal

operates smoothly and check that it has the

proper free travel.

Brakes ÐCheck that the brakes do not pull

the vehicle to one side when applied.

Brake pedal and booster* ÐCheck the

pedal for smooth operation and make sure it

has the proper distance under it when de-

pressed fully. Check the brake booster func-

tion. Be certain to keep the floor mat away

from the pedal.

Parking brake* ÐCheck that the lever has

the proper travel and confirm that your

vehicle is held securely on a fairly steep hill

with only the parking brake applied.

Automatic transmission P position

mechanism ÐOn a fairly steep hill check

that your vehicle is held securely with the

shift selector lever in the P (Park) position

without applying any brakes.Under the hood and vehicle

The maintenance items listed here should

be checked periodically, such as each time

you check the engine oil or refuel.

Additional information on the items

marked with an ª*º can be found in the

ªDo-it-yourself'' section of this manual.

Windshield washer fluid* ÐCheck that

there is adequate fluid in the tank.

Engine oil level* ÐCheck the level after

parking the vehicle on a level surface, with

the engine off. Wait a few minutes for the oil

to drain back into the oil pan.

Brake and (if so equipped) clutch fluid

levels* ÐMake sure that the brake and

clutch fluid level are between the MIN and

MAX lines on each reservoir.

Power steering fluid level* and lines Ð

Check the level when the fluid is cold and

with the engine off. Check the lines for

proper attachment, leaks, cracks, etc.

Automatic transmission fluid level* Ð

Check the level after putting the shift selec-

tor lever in P (Park) with the engine idling at

operating temperature.Engine coolant level* ÐCheck the cool-

ant level when the engine is cold.

Radiator and hoses ÐCheck the front of

the radiator and clean off any dirt, insects,

leaves, etc., that may have accumulated.

Make sure the hoses have no cracks, de-

formation, rot or loose connections.

Engine drive belts* ÐMake sure the drive

belts are not frayed, worn, cracked or oily.

Battery* ÐCheck the fluid level in each

cell. It should be between the MAX and MIN

lines.

Exhaust system ÐMake sure there are no

cracks, holes, loose joints or supports. If the

sound of the exhaust seems unusual or

there is a smell of exhaust fumes, immedi-

ately have the exhaust system inspected by

a qualified individual. (See the carbon mon-

oxide warning in the ``Starting and driving''

section of this manual.)

Underbody ÐThe underbody is frequently

exposed to corrosive substances such as

those used on icy roads or to control dust. It

is very important to remove these sub-

stances from the underbody, otherwise rust

may form on the floor pan, frame, fuel lines

9-4Maintenance

ZX

Page 207 of 242

![NISSAN ALTIMA 2000 L30 / 2.G User Guide Schedule 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers NISSAN ALTIMA 2000 L30 / 2.G User Guide Schedule 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers](/img/5/637/w960_637-206.png)

Schedule 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months,

whichever comes first.Miles x 1,000 3.75 7.5 11.25 15 18.75 22.5 26.25 30 33.75 37.5 41.25 45 48.75 52.5 56.25 60

(km x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72) (78) (84) (90) (96)

Months 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48

Emission control system maintenance

Drive belts See NOTE (1)I*

Air cleaner filter See NOTE (2) [R] [R]

EVAP vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (3)*

Engine coolant See NOTE (4)R*

Engine oilRRRRRRRRRRRRRRRR

Engine oil filterRRRRRRRRRRRRRRRR

Spark plugs (Use PLATINUM-TIPPED type) Replace every 105,000 miles (169,000 km)

Intake & exhaust valve clearance See NOTE (5)*

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event,

replace the filter.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals marked with an ``*'' are recommended by NISSAN for reliable vehicle operation. The

owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability.

Other maintenance items and intervals are required.

9-6Maintenance

ZX

Page 209 of 242

![NISSAN ALTIMA 2000 L30 / 2.G User Guide Schedule 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers NISSAN ALTIMA 2000 L30 / 2.G User Guide Schedule 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers](/img/5/637/w960_637-208.png)

Schedule 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles x 1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km x 1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48

Emission control system maintenance

Drive belts See NOTE (1)I*

Air cleaner filter[R] [R]

EVAP vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (2)*

Engine coolant See NOTE (3)R*

Engine oilRRRRRRRR

Engine oil filterRRRRRRRR

Spark plugs (Use PLATINUM-TIPPED type) Replace every 105,000 miles (169,000 km)

Intake & exhaust valve clearance See NOTE (4)*

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event,

replace the filter.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals marked with an ``*'' are recommended by NISSAN for reliable vehicle operation. The

owner need not perform such maintenance in order to maintain the emission warranty or manufacturer recall liability.

Other maintenance items and intervals are required.

9-8Maintenance

ZX

Page 211 of 242

EXPLANATION OF

MAINTENANCE ITEMS

Additional information on the following

items marked with an ``*'' is found in the

``Do-it- yourself'' section of this manual.

Emission control system

maintenance

Drive belts* ÐCheck drive belts for wear,

fraying or cracking and also for proper ten-

sion. Replace any damaged drive belts.

Air cleaner filter ÐUnder normal driving

conditions, the air cleaner filter should be

replaced in accordance with the mainte-

nance schedule. However, driving the ve-

hicle in dusty areas may cause rapid clog-

ging of the element. Consequently, the

element may have to be replaced more

frequently.

EVAP vapor lines ÐCheck vapor lines

and connections for leaks, looseness or

deterioration. If leaks are found, replace

them.

Fuel lines ÐCheck the fuel hoses, piping

and connections for leaks, looseness or

deterioration. Replace any damaged parts.Fuel filter ÐIf the vehicle is operated

under extremely adverse weather condi-

tions or in areas where ambient tempera-

tures are either extremely low or extremely

high, the filter might become clogged. In

such an event, replace the filter immedi-

ately.

Engine coolant* ÐDrain and flush the

cooling system.

Engine oil & oil filter* ÐUnder normal

driving conditions, the engine oil and oil filter

should be replaced in accordance with the

maintenance schedule. However, under se-

vere driving conditions, they may have to be

replaced more frequently.

Spark plugs* ÐReplace with new plugs

having the correct heat range.

Intake & exhaust valve clearance Ð

Check the valve clearance if valve noise

increases.

Chassis and body maintenance

Brake lines & cables ÐCheck the brake

lines and hoses (including brake booster

vacuum hoses, connections & check valve)and parking brake cables for proper attach-

ment, leaks, cracks, chafing, abrasion, de-

terioration, etc.

Brake pads, rotors, drums & linings Ð

Check these and the other neighboring

brake components for wear, deterioration

and leaks. Under severe driving conditions,

they may have to be inspected more fre-

quently.

Manual & automatic transmission fluid*

ÐCheck the fluid level and visually inspect

for signs of leakage.

Under severe driving conditions, the fluid

should be replaced at the specified interval.

Steering gear & linkage, axle & suspen-

sion parts, and drive shaft boots Ð

Check for damage, looseness and leakage

of oil or grease. Under severe driving con-

ditions, inspection should be performed

more frequently.

Exhaust system ÐVisually check the ex-

haust pipes, muffler, and hangers for proper

attachment, leaks, cracks, chafing, abra-

sion, deterioration, etc. Under severe driv-

ing conditions, inspection should be per-

formed more frequently.

9-10Maintenance

ZX

Page 215 of 242

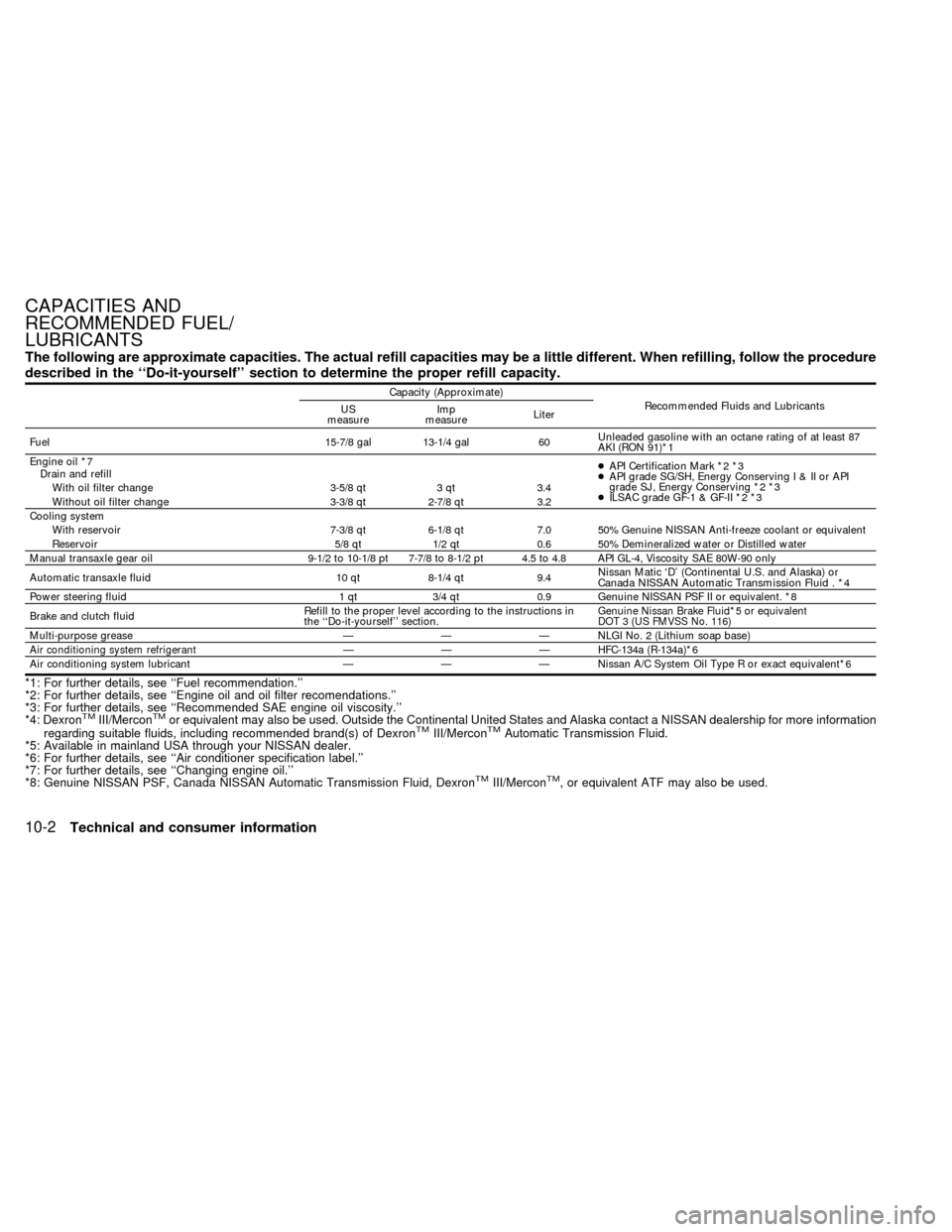

The following are approximate capacities. The actual refill capacities may be a little different. When refilling, follow the procedure

described in the ``Do-it-yourself'' section to determine the proper refill capacity.

Capacity (Approximate)

Recommended Fluids and Lubricants

US

measureImp

measureLiter

Fuel 15-7/8 gal 13-1/4 gal 60Unleaded gasoline with an octane rating of at least 87

AKI (RON 91)*1

Engine oil *7

Drain and refillcAPI Certification Mark *2 *3

cAPI grade SG/SH, Energy ConservingI&IIorAPI

grade SJ, Energy Conserving *2 *3

cILSAC grade GF-1 & GF-II *2 *3 With oil filter change 3-5/8 qt 3 qt 3.4

Without oil filter change 3-3/8 qt 2-7/8 qt 3.2

Cooling system

With reservoir 7-3/8 qt 6-1/8 qt 7.0 50% Genuine NISSAN Anti-freeze coolant or equivalent

Reservoir 5/8 qt 1/2 qt 0.6 50% Demineralized water or Distilled water

Manual transaxle gear oil 9-1/2 to 10-1/8 pt 7-7/8 to 8-1/2 pt 4.5 to 4.8 API GL-4, Viscosity SAE 80W-90 only

Automatic transaxle fluid 10 qt 8-1/4 qt 9.4

Nissan Matic `D' (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid . *4

Power steering fluid 1 qt 3/4 qt 0.9 Genuine NISSAN PSF II or equivalent. *8

Brake and clutch fluidRefill to the proper level according to the instructions in

the ``Do-it-yourself'' section.Genuine Nissan Brake Fluid*5 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium soap base)Air conditioning system refrigerantÐ Ð Ð HFC-134a (R-134a)*6

Air conditioning system lubricant Ð Ð Ð Nissan A/C System Oil Type R or exact equivalent*6

*1: For further details, see ``Fuel recommendation.''

*2: For further details, see ``Engine oil and oil filter recomendations.''

*3: For further details, see ``Recommended SAE engine oil viscosity.''

*4: Dexron

TMIII/MerconTMor equivalent may also be used. Outside the Continental United States and Alaska contact a NISSAN dealership for more information

regarding suitable fluids, including recommended brand(s) of DexronTMIII/MerconTMAutomatic Transmission Fluid.

*5: Available in mainland USA through your NISSAN dealer.

*6: For further details, see ``Air conditioner specification label.''

*7: For further details, see ``Changing engine oil.''

*8: Genuine NISSAN PSF, Canada NISSAN Automatic Transmission Fluid, Dexron

TMIII/MerconTM, or equivalent ATF may also be used.

CAPACITIES AND

RECOMMENDED FUEL/

LUBRICANTS

10-2Technical and consumer information

ZX

Page 230 of 242

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

cBe certain your vehicle maintains a level

position when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle if

it has an abnormal nose-up or nose- down

condition; check for improper tongue load,

overload, worn suspension or other pos-

sible causes of either condition.

cAlways secure items in the trailer to

prevent load shift while driving.

cBe certain your rear view mirrors conform

to all federal, state or local regulations. If

not, install any mirrors required for towing

before driving the vehicle.

Trailer towing tips

In order to gain skill and an understanding

of the vehicle's behavior, you should prac-

tice turning, stopping and backing up in an

area which is free from traffic. Steering

stability and braking performance will be

somewhat different than under normal driv-

ing conditions.cAlways secure items in the trailer to

prevent load shift while driving.

cAvoid abrupt starts, acceleration or

stops.

cAvoid sharp turns or lane changes.

cAlways drive your vehicle at a moderate

speed.

cAlways block the wheels on both vehicle

and trailer when parking. Parking on a

slope is not recommended; however, if

you must do so, and if your vehicle is

equipped with an automatic transmis-

sion, first block the wheels and apply the

parking brake, and then move the shift

lever into the P position. If you move the

shift lever to the P position before block-

ing the wheels and applying the parking

brake, transmission damage could occur.

cWhen going down a hill, shift into a lower

gear and use the engine braking effect.

When ascending a long grade, downshift

the transmission to a lower gear and

reduce speed to reduce chances of en-

gine overloading and/or overheating.

cIf the engine coolant rises to an ex-

tremely high temperature when the airconditioner system is on, turn off the air

conditioner. Coolant heat can be addi-

tionally vented by opening the windows,

switching the fan control to high and

setting the temperature control to the

HOT position.

cTrailer towing requires more fuel than

normal circumstances.

cAvoid towing a trailer for the first 500

miles (800 km).

cHave your vehicle serviced more often

than at intervals specified in the recom-

mended Maintenance Schedule.

cWhen making a turn, your trailer wheels

will be closer to the inside of the turn than

your vehicle wheels. To compensate for

this, make a larger than normal turning

radius during the turn.

cCrosswinds and rough roads will ad-

versely affect vehicle/trailer handling,

possibly causing vehicle sway. When

being passed by larger vehicles, be pre-

pared for possible changes in crosswinds

that could affect vehicle handling. If

swaying does occur, firmly grip the steer-

ing wheel, steer straight ahead, and im-

mediately (but gradually) reduce vehicle

Technical and consumer information

10-17

ZX

Page 233 of 242

Due to legal requirements in some states

and Canadian Provinces, your vehicle may

be required to be in what is called the ``ready

condition'' for an Inspection/Maintenance

(I/M) test of the emission control system.

The vehicle is set to the ``ready condition''

when it is driven through certain driving

patterns. Usually, the ready condition can be

obtained by ordinary usage of the vehicle.

If a powertrain system component is repaired

or the battery is disconnected, the vehicle

may be reset to a ``not ready'' condition.

Before taking the I/M test, drive the vehicle

through the following pattern to set the ve-

hicle to the ready condition. If you cannot or

do not want to perform the driving pattern, a

NISSAN dealer can conduct it for you.

WARNING

Always drive the vehicle in a safe and

prudent manner according to traffic

conditions and obey all traffic laws.

1. Start the engine when the engine coolant

temperature gauge needle points to C.

Allow the engine to idle until the gauge

needle points between the C and H (nor-

mal operating temperature).2. Accelerate the vehicle to 55 mph (88

km/h), then quickly release the accelera-

tor pedal completely and keep it released

for at least 6 seconds.

3. Quickly depress the accelerator pedal for

a moment, then drive the vehicle at a

speed of 53 to 60 mph (86 to 96 km/h) for

at least 5 minutes.

4. Stop the vehicle.

5. Accelerate the vehicle to 35 mph (55

km/h) and maintain the speed for 20

seconds.

6. Repeat steps four through five at least

three times.

7. Accelerate the vehicle to 55 mph (88

km/h) and maintain the speed for at least

3 minutes.

8. Stop the vehicle (shift lever in the ``P'' or

``N'' position).

9. Rev the engine up between 2,500 and

3,500 rpm and hold it for 3 consecutive

minutes, then release the accelerator

pedal completely.

10. Wait 5 seconds at idle.

11. Rev the engine up between 2,000 and3,000 rpm and maintain it for 5 consecu-

tive minutes.

12. Stop the vehicle and turn the engine off.

13. Repeat steps one through twelve at

least one more time.

If step one through seven is interrupted,

repeat the preceding step. Any safe driving

mode is acceptable between steps. Do not

stop the engine until step seven is com-

pleted.

READINESS FOR

INSPECTION/MAINTENANCE

(I/M) TEST (US only)

10-20Technical and consumer information

ZX