check engine NISSAN ALTIMA 2023 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2023, Model line: ALTIMA, Model: NISSAN ALTIMA 2023Pages: 644, PDF Size: 4.12 MB

Page 522 of 644

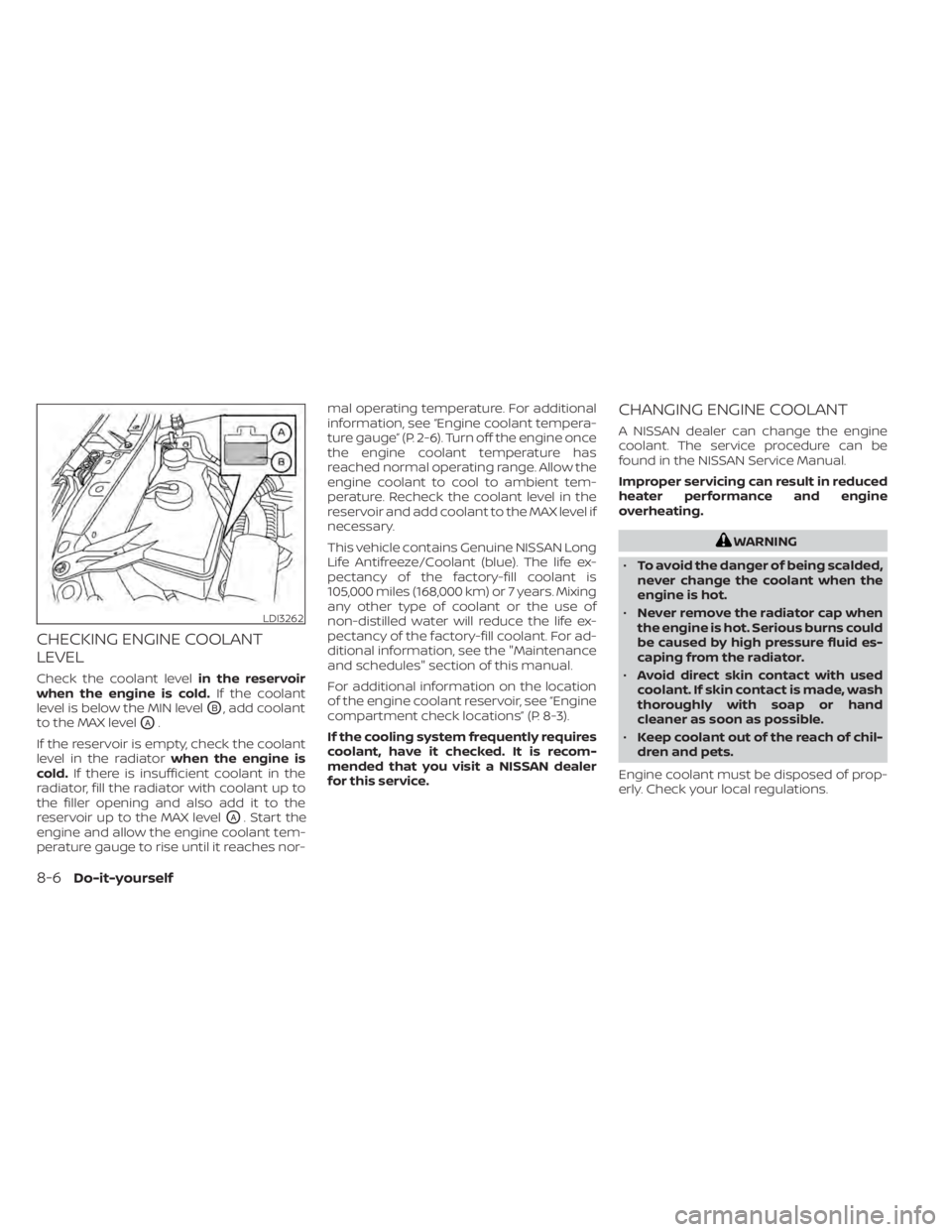

CHECKING ENGINE COOLANT

LEVEL

Check the coolant levelin the reservoir

when the engine is cold. If the coolant

level is below the MIN level

OB, add coolant

to the MAX level

OA.

If the reservoir is empty, check the coolant

level in the radiator when the engine is

cold. If there is insufficient coolant in the

radiator, fill the radiator with coolant up to

the filler opening and also add it to the

reservoir up to the MAX level

OA. Start the

engine and allow the engine coolant tem-

perature gauge to rise until it reaches nor- mal operating temperature. For additional

information, see “Engine coolant tempera-

ture gauge” (P. 2-6). Turn off the engine once

the engine coolant temperature has

reached normal operating range. Allow the

engine coolant to cool to ambient tem-

perature. Recheck the coolant level in the

reservoir and add coolant to the MAX level if

necessary.

This vehicle contains Genuine NISSAN Long

Life Antifreeze/Coolant (blue). The life ex-

pectancy of the factory-fill coolant is

105,000 miles (168,000 km) or 7 years. Mixing

any other type of coolant or the use of

non-distilled water will reduce the life ex-

pectancy of the factory-fill coolant. For ad-

ditional information, see the "Maintenance

and schedules" section of this manual.

For additional information on the location

of the engine coolant reservoir, see “Engine

compartment check locations” (P. 8-3).

If the cooling system frequently requires

coolant, have it checked. It is recom-

mended that you visit a NISSAN dealer

for this service.

CHANGING ENGINE COOLANT

A NISSAN dealer can change the engine

coolant. The service procedure can be

found in the NISSAN Service Manual.

Improper servicing can result in reduced

heater performance and engine

overheating.

WARNING

• To avoid the danger of being scalded,

never change the coolant when the

engine is hot.

• Never remove the radiator cap when

the engine is hot. Serious burns could

be caused by high pressure fluid es-

caping from the radiator.

• Avoid direct skin contact with used

coolant. If skin contact is made, wash

thoroughly with soap or hand

cleaner as soon as possible.

• Keep coolant out of the reach of chil-

dren and pets.

Engine coolant must be disposed of prop-

erly. Check your local regulations.

LDI3262

8-6Do-it-yourself

Page 523 of 644

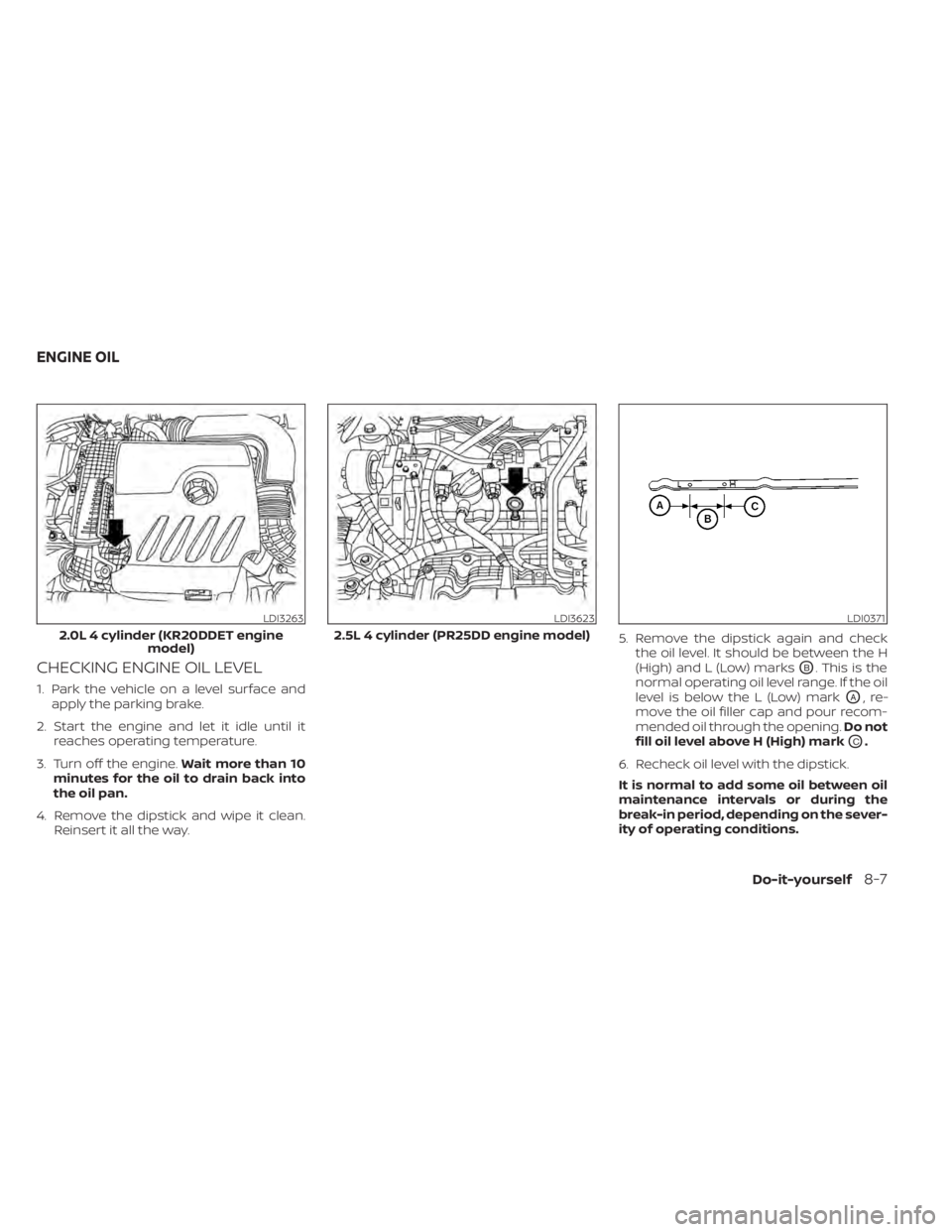

CHECKING ENGINE OIL LEVEL

1. Park the vehicle on a level surface andapply the parking brake.

2. Start the engine and let it idle until it reaches operating temperature.

3. Turn off the engine. Wait more than 10

minutes for the oil to drain back into

the oil pan.

4. Remove the dipstick and wipe it clean. Reinsert it all the way. 5. Remove the dipstick again and check

the oil level. It should be between the H

(High) and L (Low) marks

OB. This is the

normal operating oil level range. If the oil

level is below the L (Low) mark

OA,re-

move the oil filler cap and pour recom-

mended oil through the opening. Do not

fill oil level above H (High) mark

OC.

6. Recheck oil level with the dipstick.

It is normal to add some oil between oil

maintenance intervals or during the

break-in period, depending on the sever-

ity of operating conditions.

LDI3263

2.0L 4 cylinder (KR20DDET engine model)

LDI3623

2.5L 4 cylinder (PR25DD engine model)

LDI0371

ENGINE OIL

Do-it-yourself8-7

Page 524 of 644

CAUTION

• Oil level should be checked regularly.

Operating the engine with an insuffi-

cient amount of oil can damage the

engine, and such damage is not cov-

ered by warranty.

• It is normal to add some oil between

oil maintenance intervals or during

the break-in period, depending on

the severity of operating conditions.

CHANGING ENGINE OIL AND OIL

FILTER

For additional information on engine oil

and oil filter change, refer to the instruc-

tions outlined in this section.

Vehicle set-up

1. Park the vehicle on a level surface and apply the parking brake.

2. Run the engine until it reaches operating temperature.

3. Turn the engine off and wait for 15 minutes.

4. Raise and support the vehicle using a suitable floor jack and safety jack

stands. • Place the safety jack stands under the

vehicle jack-up points.

• A suitable adapter should be attached to the jack stand saddle.

CAUTION

Make sure the correct lif ting and sup-

port points are used to avoid vehicle

damage.

LDI3369

O1Oil filler cap

8-8Do-it-yourself

Page 527 of 644

CAUTION

Be careful not to burn yourself, as the

engine oil is hot.

WARNING

• Prolonged and repeated contact

with used engine oil may cause skin

cancer.

• Try to avoid direct skin contact with

used oil. If skin contact is made, wash

thoroughly with soap or hand

cleaner as soon as possible.

• Keep used engine oil out of reach of

children.

4. Loosen the oil filter with an oil filter wrench by turning it counterclockwise.

Remove the oil filter by turning it by

hand.

5. Wipe the engine oil filter mounting sur- face with a clean rag.

CAUTION

Be sure to remove any old gasket ma-

terial remaining on the sealing surface

of the engine. Failure to do so could

lead to an oil leak and engine damage. •

The dipstick must be inserted in

place to prevent oil spillage from the

dipstick hole when filling the engine

with oil.

6. Coat the gasket on the new filter with clean engine oil.

7. Screw in the oil filter clockwise until a slight resistance is felt, then tighten addi-

tionally more than 2/3 turn.

Oil filter tightening torque: 11 to 15 f t-lb (14.7 to 20.6 N·m)

8. Clean and re-install the drain plug with a new washer. Securely tighten the drain

plug with a wrench. Do not use exces-

sive force.

Drain plug tightening torque: 22 to 29 f t-lb (29.4 to 39.2 N·m)

9. Refill the engine with the recommended oil through the oil filler opening, and in-

stall the oil filler cap securely.

For additional information about drain and

refill capacity, see “Recommended fluids/

lubricants and capacities” (P. 10-2). The

drain and refill capacity depends on the oil

temperature and drain time. Use these

specifications for reference only. Always use the dipstick to determine the proper

amount of oil in the engine.

10. Start the engine and check for leakage

around the drain plug and the oil filter.

Correct as required. Turn the engine off

and wait more than 15 minutes. Check

the oil level with the dipstick. Add en-

gine oil if necessary.

Af ter the operation

1. Reinstall undercover in reverse order ofremoval.

2. Lower the vehicle carefully to the ground.

3. Reset the oil control system (if so equipped) and oil and filter maintenance

reminder. For additional information,

see “Vehicle information display – 5 inch

(13 cm) Type A” (P. 2-18) or “Vehicle infor-

mation display – 7 inch (18 cm) Type B”

(P. 2-34)

• Dispose of waste oil and filter properly.

• Check your local regulations.

Do-it-yourself8-11

Page 529 of 644

WINDSHIELD-WASHER FLUID

RESERVOIR

Fill the windshield-washer fluid reservoir

periodically. Add windshield-washer fluid

when the “Low Washer Fluid” warning ap-

pears in the vehicle information display.

To check the fluid level with the dip tube,

use your finger to plug the center hole

OAof

the cap/tube assembly, then remove it

from the reservoir. If there is no fluid in the

dip tube, add fluid. To fill the windshield-washer fluid reservoir,

lif t the cap off the reservoir and pour the

windshield-washer fluid into the reservoir

opening.

Add a washer solvent to the washer for

better cleaning. In the winter season, add a

windshield washer antifreeze. Follow the

manufacturer's instructions for the mix-

ture ratio.

Refill the reservoir more frequently when

driving conditions require an increased

amount of windshield-washer fluid.

Recommended fluid is Genuine NISSAN

Windshield Washer Concentrate Cleaner &

Antifreeze or equivalent.

WARNING

Antifreeze is poisonous and should be

stored carefully in marked containers

out of the reach of children.

CAUTION

• Do not substitute engine antifreeze

coolant for windshield-washer fluid.

This may result in damage to the

paint.

• Do not fill the windshield-washer

fluid reservoir with washer fluid con-

centrates at full strength. Some

methyl alcohol based washer fluid

concentrates may permanently stain

the grille if spilled while filling the

windshield-washer fluid reservoir.

• Pre-mix washer fluid concentrates

with water to the manufacturer's

recommended levels before pouring

the fluid into the windshield-washer

fluid reservoir. Do not use the

windshield-washer fluid reservoir to

mix the washer fluid concentrate and

water.

LDI3271

WINDSHIELD-WASHER FLUID

Do-it-yourself8-13

Page 531 of 644

• If the battery is labeled “do not open” it ismaintenance free and battery fluid

should not be checked. It is recom-

mended that you visit a NISSAN dealer or

a qualified specialist workshop to con-

firm the battery’s performance.

• Keep the battery surface clean and dry. Clean the battery with a solution of bak-

ing soda and water.

• Make certain the terminal connections are clean and securely tightened.

• If the vehicle is not to be used for 30 days or longer, disconnect the negative (-) bat-

tery terminal cable to prevent discharge.

NOTE:

Care should be taken to avoid situations

that can lead to potential battery dis-

charge and potential no-start conditions

such as:

1. Installation or extended use of elec- tronic accessories that consume bat-

tery power when the engine is not

running (Phone chargers, GPS, DVD

players, etc.)

2. Vehicle is not driven regularly and/or only driven short distances.

In these cases, the battery may need to

be charged to maintain battery health.

WARNING

• Do not expose the battery to flames,

an electrical spark or a cigarette. Hy-

drogen gas generated by the battery

is explosive. Explosive gases can

cause blindness or injury. Do not al-

low battery fluid to contact your skin,

eyes, fabrics or painted surfaces. Sul-

furic acid can cause blindness or in-

jury. Af ter touching a battery or bat-

tery cap, do not touch or rub your

eyes. Thoroughly wash your hands. If

the acid contacts your eyes, skin or

clothing, immediately flush with wa-

ter for at least 15 minutes and seek

medical attention.

• When working on or near a battery,

always wear suitable eye protection

and remove all jewelry.

• Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands af ter

handling.

• Keep battery out of the reach of

children.

• Do not tip the battery.

NOTE:

Do not try to open the top of the battery.

This battery is not equipped with remov-

able vent caps.

JUMP STARTING

If jump starting is necessary, see “Jump

starting” (P. 6-17). If the engine does not

start by jump starting, the battery may

have to be replaced. It is recommended

that you visit a NISSAN dealer for this

service.

LDI3302

Do-it-yourself8-15

Page 533 of 644

1. Visually inspect the belt for signs of un-usual wear, cuts, or fraying. If the belt is in

poor condition, have it replaced. It is rec-

ommended that you visit a NISSAN

dealer for this service.

2. Have the belt checked regularly for condition.

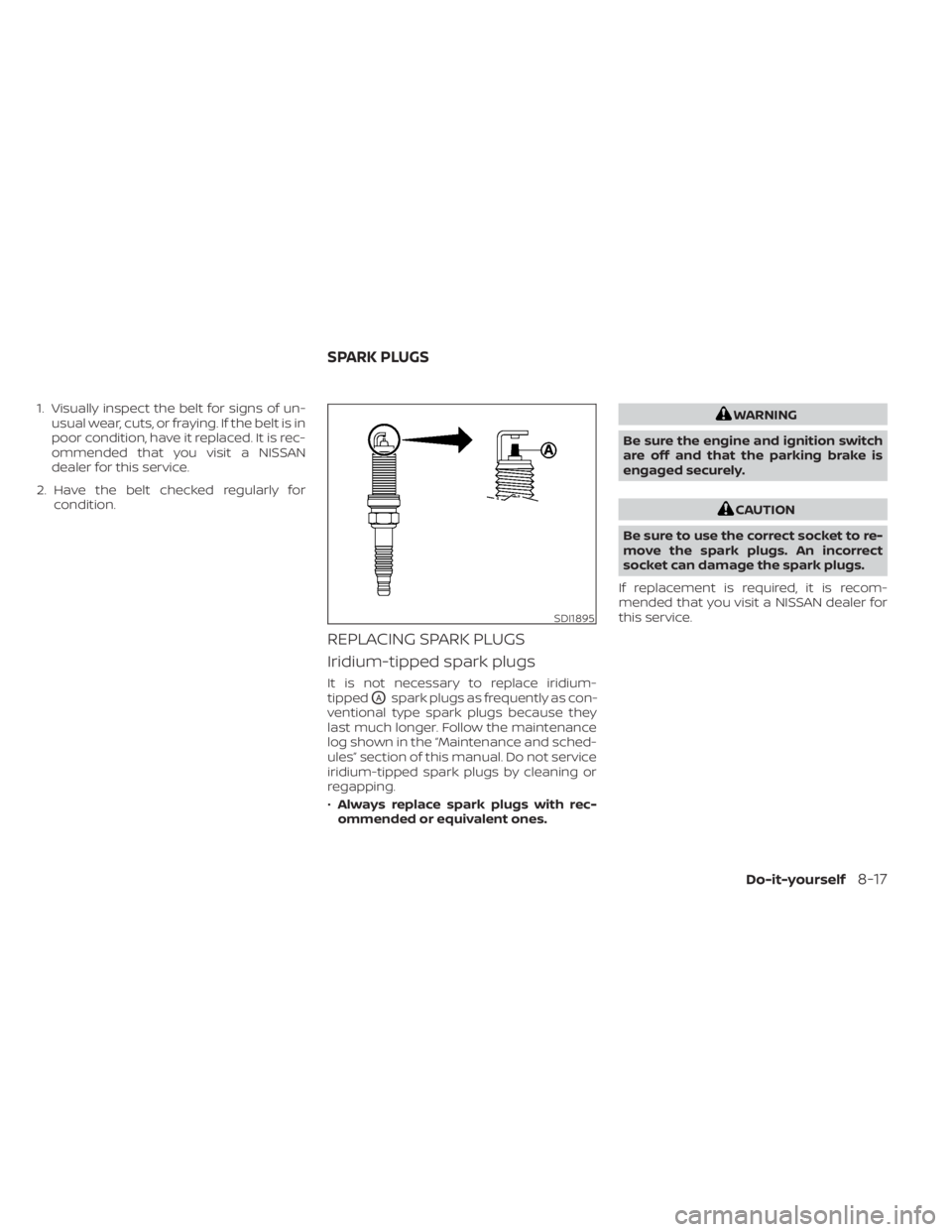

REPLACING SPARK PLUGS

Iridium-tipped spark plugs

It is not necessary to replace iridium-

tipped

OAspark plugs as frequently as con-

ventional type spark plugs because they

last much longer. Follow the maintenance

log shown in the “Maintenance and sched-

ules” section of this manual. Do not service

iridium-tipped spark plugs by cleaning or

regapping.

• Always replace spark plugs with rec-

ommended or equivalent ones.

WARNING

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

CAUTION

Be sure to use the correct socket to re-

move the spark plugs. An incorrect

socket can damage the spark plugs.

If replacement is required, it is recom-

mended that you visit a NISSAN dealer for

this service.

SDI1895

SPARK PLUGS

Do-it-yourself8-17

Page 537 of 644

If any electrical equipment does not oper-

ate, check for an open fuse.

Fuses are used in the passenger and en-

gine compartment. Spare fuses are pro-

vided and can be found in the passenger

compartment fuse box.

When installing a fuse make sure the fuse is

installed in the fuse box securely.ENGINE COMPARTMENT

WARNING

Never use a fuse of a higher or lower

amperage rating than that specified on

the fuse box cover. This could damage

the electrical system or electronic con-

trol units or cause a fire. If any electrical equipment does not come

on, check for an open fuse.

1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the engine hood.

3. Remove the fuse box cover by pushing the tab and lif ting the cover up.

4. Remove the fuse with the fuse puller. The fuse puller is located in the center of

the fuse block in the passenger

compartment.

LDI2997LDI3274

FUSES

Do-it-yourself8-21

Page 555 of 644

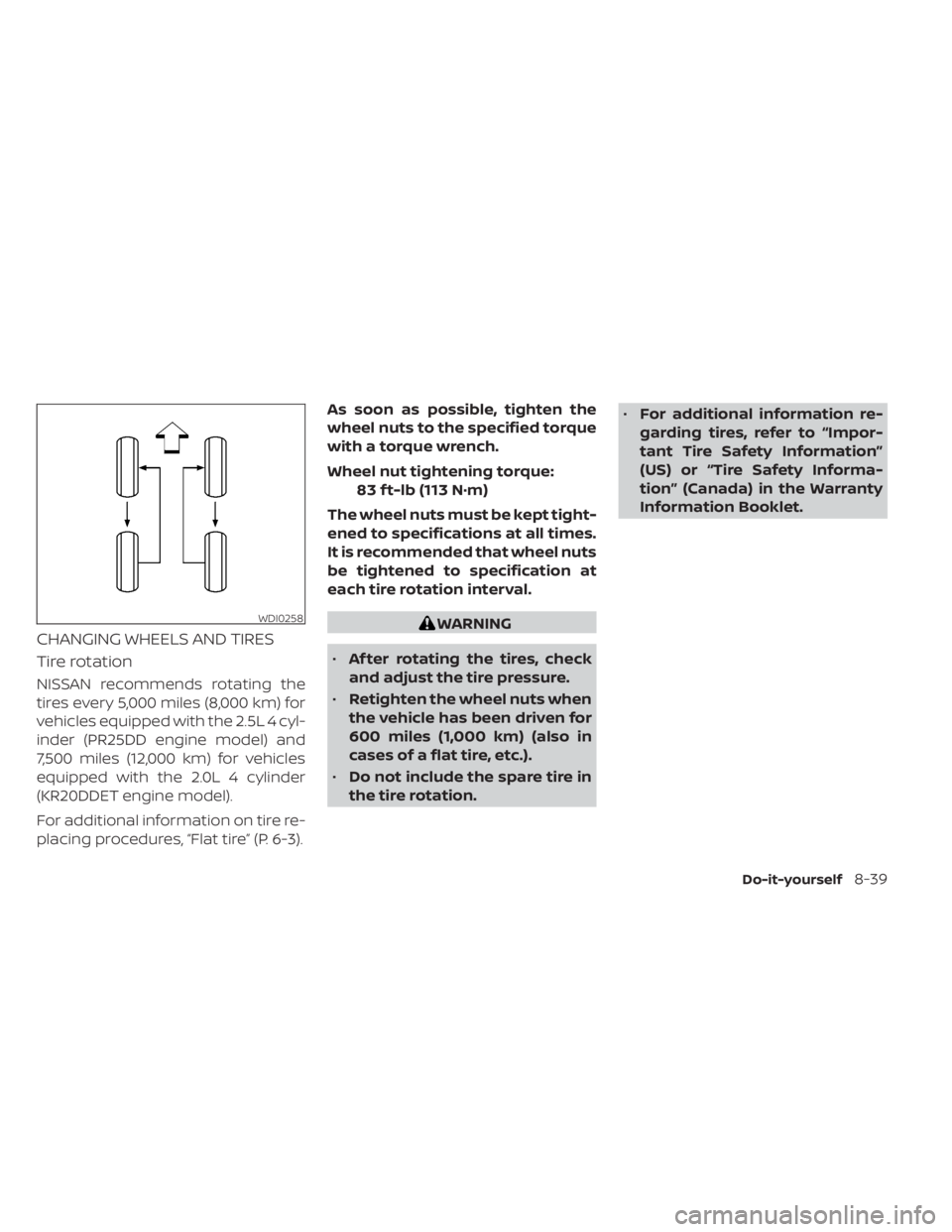

CHANGING WHEELS AND TIRES

Tire rotation

NISSAN recommends rotating the

tires every 5,000 miles (8,000 km) for

vehicles equipped with the 2.5L 4 cyl-

inder (PR25DD engine model) and

7,500 miles (12,000 km) for vehicles

equipped with the 2.0L 4 cylinder

(KR20DDET engine model).

For additional information on tire re-

placing procedures, “Flat tire” (P. 6-3).As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

Wheel nut tightening torque:

83 f t-lb (113 N·m)

The wheel nuts must be kept tight-

ened to specifications at all times.

It is recommended that wheel nuts

be tightened to specification at

each tire rotation interval.

WARNING

• Af ter rotating the tires, check

and adjust the tire pressure.

• Retighten the wheel nuts when

the vehicle has been driven for

600 miles (1,000 km) (also in

cases of a flat tire, etc.).

• Do not include the spare tire in

the tire rotation. •

For additional information re-

garding tires, refer to “Impor-

tant Tire Safety Information”

(US) or “Tire Safety Informa-

tion” (Canada) in the Warranty

Information Booklet.WDI0258

Do-it-yourself8-39

Page 562 of 644

Some day-to-day and regular mainte-

nance is essential to maintain your vehicle

good mechanical condition, as well as its

emissions and engine performance.

It is the owner's responsibility to make sure

that the scheduled maintenance, as well as

general maintenance, is performed.

As the vehicle owner, you are the only one

who can ensure that your vehicle receives

proper maintenance. You are a vital link in

the maintenance chain.

GENERAL MAINTENANCE

General maintenance includes those items

which should be checked during normal

day-to-day operation. They are essential

for proper vehicle operation. It is your re-

sponsibility to perform these procedures

regularly as prescribed.

Performing general maintenance checks

requires minimal mechanical skill and only

a few general automotive tools.

These checks or inspections can be done

by yourself, a qualified technician or, if you

prefer, a NISSAN dealer.

SCHEDULED MAINTENANCE

The maintenance items listed in this sec-

tion are required to be serviced at regular

intervals. However under severe driving

conditions, additional or more frequent

maintenance will be required.

WHERE TO GO FOR SERVICE

If maintenance service is required or your

vehicle appears to malfunction, have the

systems checked and serviced. It is recom-

mended that you visit a NISSAN dealer for

this service.

NISSAN technicians are well-trained spe-

cialists and are kept up-to-date with the

latest service information through techni-

cal bulletins, service tips and training pro-

grams. They are fully qualified to work on

NISSAN vehiclesbeforework begins.

If your vehicle is involved in a collision, it is

recommended that you ask your NISSAN

dealer where the nearest NISSAN Certified

Collision Center is located, or go to

http://collision.nissanusa.com.

You can be confident that a NISSAN deal-

er's service department can perform the

service needed to meet the maintenance

requirements on your vehicle. During the normal day-to-day operation of

the vehicle, general maintenance should

be performed regularly as prescribed in

this section. If you detect any unusual

sounds, vibrations or smells, be sure to

check for the cause or have it checked

promptly. In addition, it is recommended

that you visit a NISSAN dealer if you think

that repairs are required.

When performing any checks or mainte-

nance work, closely observe the “Mainte-

nance precautions” in the “Do-it-yourself ”

section of this manual.

EXPLANATION OF GENERAL

MAINTENANCE ITEMS

WARNING

Failure to follow the procedures listed

within this section may result in per-

sonal injury.

Additional information on the following

items with“*”isf ound in the “Do-it-

yourself ” section of this manual.

MAINTENANCE REQUIREMENTS GENERAL MAINTENANCE

9-2Maintenance and schedules