height NISSAN ARMADA 2019 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2019, Model line: ARMADA, Model: NISSAN ARMADA 2019Pages: 536, PDF Size: 2.56 MB

Page 473 of 536

Information” (Canada) in the

Warranty Information Book-

let.

Replacing wheels and tires

When replacing a tire, use the same size,

tread design, speed rating and load

carrying capacity as originally equipped.

(See “Specifications” (P.10-7) for recom-

mended types and sizes of tires and

wheels.)

WARNING

. The use of tires other than those

recommended or the mixed use

of tires of different brands, con-

struction (bias, bias-belted or ra-

dial), or tread patterns can

adversely affect the ride, braking,

handling, ground clearance,

body-to-tire clearance, tire chain

clearance, speedometer calibra-

tion, headlight aim and bumper

height. Some of these effects

may lead to accidents and could

result in serious personal injury.

. For Two-Wheel Drive (2WD) mod-

els, if your vehicle was originally

equipped with 4 tires that were the same size and you are only

replacing 2 of the 4 tires, install

the new tires on the rear axle.

Placing new tires on the front

axle may cause loss of vehicle

control in some driving condi-

tions and cause an accident and

personal injury.

. If the wheels are changed for any

reason, always replace with

wheels which have the same off-

set dimension. Wheels of a differ-

ent off-set could cause prema-

ture tire wear, degrade vehicle

handling characteristics and/or

interference with the brake

discs/drums. Such interference

can lead to decreased braking

efficiency and/or early brake

pad/shoe wear. See “Wheels and

tires” (P.10-8) for wheel off-set

dimensions.

. Since the spare tire is not

equipped with the TPMS, when a

spare tire is mounted or a wheel

is replaced, the TPMS will not

function and the low tire pressure

warning light will flash for ap-

proximately 1 minute. The light

will remain on after 1 minute.

Have your tires replaced and/or

TPMS system reset as soon as possible. It is recommended you

visit a NISSAN dealer for these

services.

. Replacing tires with those not

originally specified by NISSAN

could affect the proper operation

of the TPMS.

. The TPMS sensor may be da-

maged if it is not handled cor-

rectly. Be careful when handling

the TPMS sensor.

. When replacing the TPMS sensor,

the ID registration may be re-

quired. It is recommended you

visit a NISSAN dealer for ID regis-

tration.

. Do not use a valve stem cap that

is not specified by NISSAN. The

valve stem cap may become

stuck.

. Be sure that the valve stem caps

are correctly fitted. Otherwise the

valve may be clogged up with dirt

and cause a malfunction or loss

of pressure.

. Do not install a damaged or

deformed wheel or tire even if it

has been repaired. Such wheels

or tires could have structural

damage and could fail without

warning.

Do-it-yourself8-39

Page 499 of 536

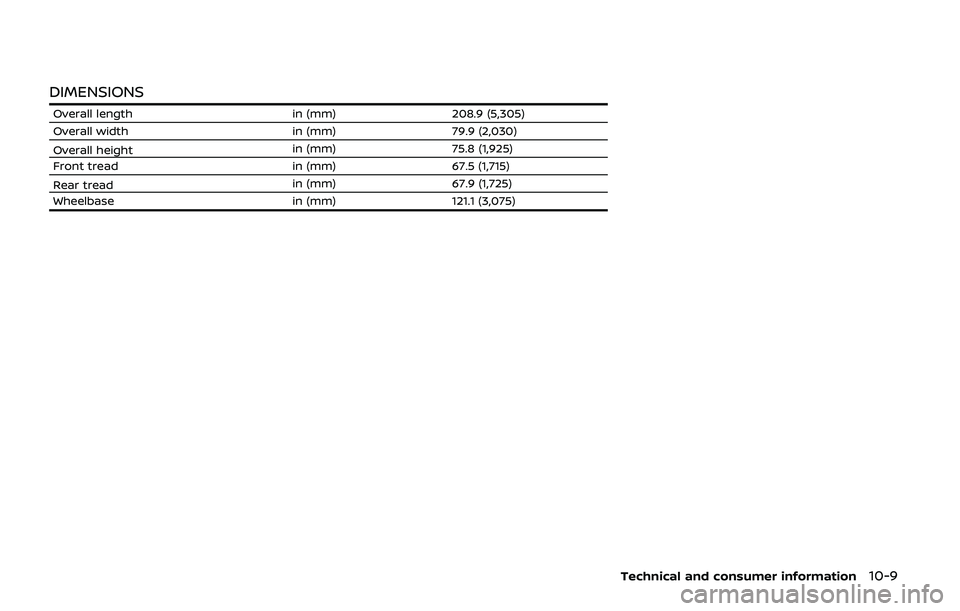

DIMENSIONS

Overall lengthin (mm)208.9 (5,305)

Overall width in (mm)79.9 (2,030)

Overall height in (mm)

75.8 (1,925)

Front tread in (mm)67.5 (1,715)

Rear tread in (mm)

67.9 (1,725)

Wheelbase in (mm)121.1 (3,075)

Technical and consumer information10-9

Page 514 of 536

10-24Technical and consumer information

and towing equipment manufacturers to

determine if they recommend the use of a

weight-distributing hitch system.

NOTE:

A weight-distributing hitch system may

affect the operation of trailer surge

brakes. If you are considering use of a

weight-distributing hitch system with a

surge brake-equipped trailer, check

with the surge brake, hitch or trailer

manufacturer to determine if and how

this can be done.

Follow the instructions provided by the

manufacturer for installing and using the

weight-distributing hitch system.

General set-up instructions are as follows:

1. Park unloaded vehicle on a level sur-face. With the ignition switch in the ON

position and the doors closed, allow

the vehicle to stand for several min-

utes so that it can level.

2. Measure the height of a reference point on the front and rear bumpers

at the center of the vehicle.

3. Attach the trailer to the vehicle and adjust the hitch equalizers so that the

front bumper height is within 0 - .5

inches (0 - 13 mm) of the reference

height measured in step 2. The rear

bumper should be no higher than the

reference height measured in step 2.

WARNING

Properly adjust the weight distribut-

ing hitch so the rear of the bumper is

no higher than the measured refer-

ence height when the trailer is at-

tached. If the rear bumper is higher

than the measured reference height

when loaded, the vehicle may handle

unpredictably which could cause a

loss of vehicle control and cause

serious personal injury or property

damage.

Sway control device

Sudden maneuvers, wind gusts and buf-

feting caused by other vehicles can affect

trailer handling. Sway control devices

may be used to help control these affects.

If you choose to use one, contact a

reputable trailer hitch supplier to make

sure the sway control device will work

with the vehicle, hitch, trailer and the

trailer’s brake system. Follow the instruc-

tions provided by the manufacturer for

installing and using the sway control

device.

Class I hitch

Class I trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of

2,000 lb (907 kg).

Class II hitch

Class II trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of

3,500 lb (1,588 kg).

Class III hitch

Class III trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of

5,000 lb (2,267 kg).

Class IV hitch

Class IV trailer hitch equipment (receiver,

ball mount and hitch ball) can be used to

tow trailers of a maximum weight of

10,000 lb (4,545 kg). A weight distributing

hitch should be used to tow trailers that

weigh over 5,000 lb (2,267 kg).

Your vehicle may be equipped with Class

IV trailer hitch equipment that has a

10,000 lb (4,545 kg) maximum weight

rating, but your vehicle is only capable of

towing the maximum trailer weights

shown in the “Towing Load/Specification”

chart earlier in this section.

Page 516 of 536

10-26Technical and consumer information

trailer lights while using the ve-

hicle tail light, stoplight and turn

signal circuits as a signal source.

The module/converter must draw

no more than 15 milliamps from

the stop and tail lamp circuits.

Using a module/converter that

exceeds these power require-

ments may damage the vehicle’s

electrical system. See a reputable

trailer retailer to obtain the prop-

er equipment and to have it

installed.

. Do not connect electrical devices

that draw more than 40 amps to

the vehicle. The fusible link may

melt.

Trailer lights should comply with federal

and/or local regulations. For assistance in

hooking up trailer lights, contact a NISSAN

dealer or reputable trailer retailer.

Trailer brakes

When towing a trailer load of 3,500 lbs.

(1,587 kg) or more, trailers with a brake

system MUST be used. However, most

states require a separate braking system

on trailers with a loaded weight above a

specific amount. Make sure the trailer

meets the local regulations and the

regulations where you plan to tow. Several types of braking systems are

available.

Surge Brakes -

The surge brake actuator

is mounted on the trailer tongue with a

hydraulic line running to each trailer

wheel. Surge brakes are activated by the

trailer pushing against the hitch ball

when the tow vehicle is braking. Hydraulic

surge brakes are common on rental

trailers and some boat trailers. In this

type of system, there is no hydraulic or

electric connection for brake operation

between the tow vehicle and the trailer.

Electric Trailer Brakes - Electric braking

systems are activated by an electronic

signal sent from a trailer brake controller

(special brake sensing module).

Have a professional supplier of towing

equipment make sure the trailer brakes

are properly installed and demonstrate

proper brake function testing.

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

. Be certain your vehicle maintains a

level position when a loaded or un-

loaded trailer is hitched. Do not drive

the vehicle if it has an abnormal nose-

up or nose-down condition; check for

improper tongue load, overload, worn

suspension or other possible causes

of either condition.

. Always secure items in the trailer to

prevent load shift while driving.

. Keep the cargo load as low as possible

in the trailer to keep the trailer center

of gravity low.

. Load the trailer so approximately 60%

of the trailer load is in the front half

and 40% is in the back half. Also make

sure the load is balanced side to side.

. Check your hitch, trailer tire pressure,

vehicle tire pressure, trailer light op-

eration, and trailer wheel lug nuts

every time you attach a trailer to the

vehicle.

. Be certain your rearview mirrors con-

form to all federal, state or local

regulations. If not, install any mirrors

required for towing before driving the

vehicle.

. Determine the overall height of the

vehicle and trailer so the required

clearance is known.