Jack NISSAN FRONTIER 2001 D22 / 1.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: FRONTIER, Model: NISSAN FRONTIER 2001 D22 / 1.GPages: 290, PDF Size: 3.14 MB

Page 14 of 290

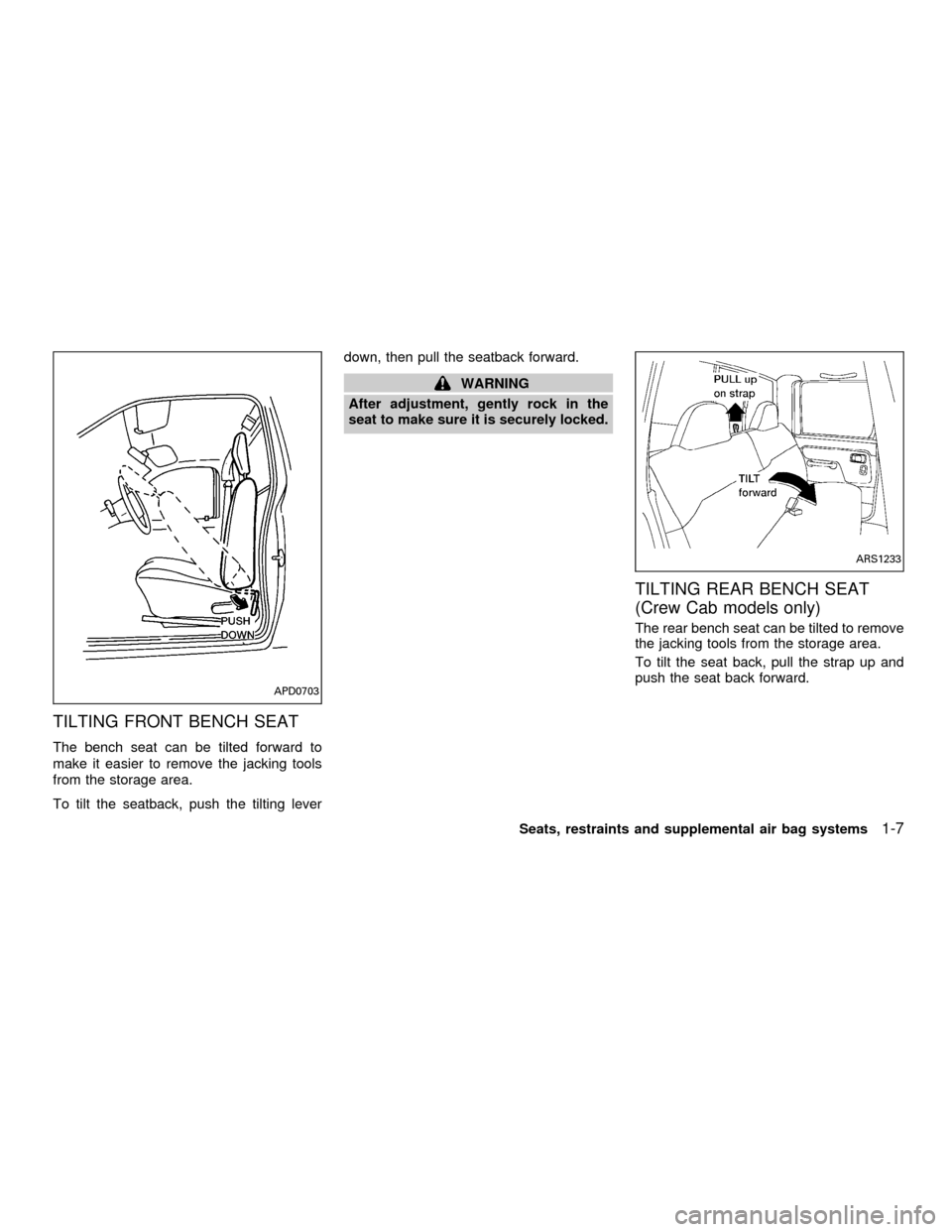

TILTING FRONT BENCH SEAT

The bench seat can be tilted forward to

make it easier to remove the jacking tools

from the storage area.

To tilt the seatback, push the tilting leverdown, then pull the seatback forward.

WARNING

After adjustment, gently rock in the

seat to make sure it is securely locked.

TILTING REAR BENCH SEAT

(Crew Cab models only)

The rear bench seat can be tilted to remove

the jacking tools from the storage area.

To tilt the seat back, pull the strap up and

push the seat back forward.

APD0703

ARS1233

Seats, restraints and supplemental air bag systems1-7

ZX

Page 172 of 290

radiator and on the engine block. Refill

before operating the vehicle. For details,

see ``Changing engine coolant'' in the ``Do-

it-yourself'' section of this manual.

TIRE EQUIPMENT

1. SUMMER tires have a tread designed to

provide superior performance on dry

pavement. However, the performance of

these tires will be substantially reduced

in snowy and icy conditions. If you oper-

ate your vehicle on snowy or icy roads,

NISSAN recommends the use on all four

wheels of MUD & SNOW or ALL SEA-

SON tires. Please consult your NISSAN

dealer for the tire type, size, speed rating

and availability information.

2. For additional traction on icy roads, stud-

ded tires may be used. However, some

U.S. states and Canadian provinces pro-

hibit their use. Check local, state and

provincial laws before installing studded

tires.

Skid and traction capabilities of studded

snow tires on wet or dry surfaces may be

poorer than that of non-studded snow

tires.

3. Tire chains may be used. Use of tirechains may be prohibited according to

location. Check the local laws before

installing tire chains. When installing tire

chains, make sure they are of proper size

for the tires on your vehicle and are

installed according to the chain manufac-

turer's suggestions.Use only SAE

Class ``S'' chains.Other types may

damage your vehicle. Use chain tension-

ers when recommended by the tire chain

manufacturer to ensure a tight fit. Loose

end links of the tire chain must be se-

cured or removed to prevent the possi-

bility of whipping action damage to the

fenders or undercarriage. If possible,

avoid fully loading your vehicle when

using tire chains. In addition, drive at a

reduced speed, otherwise, your vehicle

may be damaged and/or vehicle handling

and performance may be adversely af-

fected. Never install tire chains on a

TEMPORARY USE ONLY spare tire. Do

not use tire chains on dry roads.

SPECIAL WINTER EQUIPMENT

It is recommended that the following items

be carried in the vehicle during winter:

1. A scraper and stiff-bristled brush to re-move ice and snow from the windows

and wiper blades.

2. A sturdy, flat board to be placed under

the jack to give it firm support.

3. A shovel to dig the vehicle out of snow-

drifts.

4. Extra window washer fluid to refill the

reservoir tank.

DRIVING ON SNOW OR ICE

WARNING

cWet ice (32ÉF, 0ÉC and freezing rain),

very cold snow, or ice can be slick

and very hard to drive on. The ve-

hicle will have much less traction or

``grip'' under these conditions. Try to

avoid driving on wet ice until the

road is salted or sanded.

cWhatever the condition, drive with

caution. Accelerate and slow down

with care. If accelerating or down-

shifting too fast, the drive wheels

will lose even more traction.

c

Allow more stopping distance under

these conditions. Braking should be

started sooner than on dry pavement.

5-28Starting and driving

ZX

Page 176 of 290

CHANGING A FLAT TIRE

If you have a flat tire, follow the instructions

below:

Stopping the vehicle

1. Safely move the vehicle off the road and

away from traffic.

2. Turn on the hazard warning flashers.

3. Park on a level surface and apply the

parking brake. Shift the manual transmis-

sion into R (Reverse), or the automatic

transmission into P (Park).

WARNING

c

The transfer control lever

must be in the 2H, 4H or 4L position.

c

Do not leave the transfer control le-

ver in the N (Neutral) position. Other-

wise, the vehicle could roll unexpect-

edly even if the manual transmission

is in any gear or the automatic trans-

mission is in the P (Park) position.

This could result in serious personal

injury or property damage.

4. Turn off the engine.5. Raise the hood to warn other traffic and

to signal professional road assistance

personnel that you require assistance.

6. Have all passengers get out of the ve-

hicle and stand in a safe place away from

traffic and clear of the vehicle.

WARNING

cMake sure the parking brake is se-

curely applied and the manual trans-

mission is shifted into R (Reverse),

or the automatic transmission into P

(Park).

cNever change tires when the vehicle

is on a slope, ice or slippery areas.

This is hazardous.

cNever change tires if oncoming traf-

fic is close to your vehicle. Wait for

professional road assistance.

Blocking wheels

Place suitable blocks at both the front and

back of the wheel diagonally opposite the

flat tire to prevent the vehicle from rolling

when it is jacked up.

WARNING

Be sure to block the wheel as the ve-

hicle may move and result in personal

injury.

MCE0001

FLAT TIRE

6-2In case of emergency

ZX

Page 177 of 290

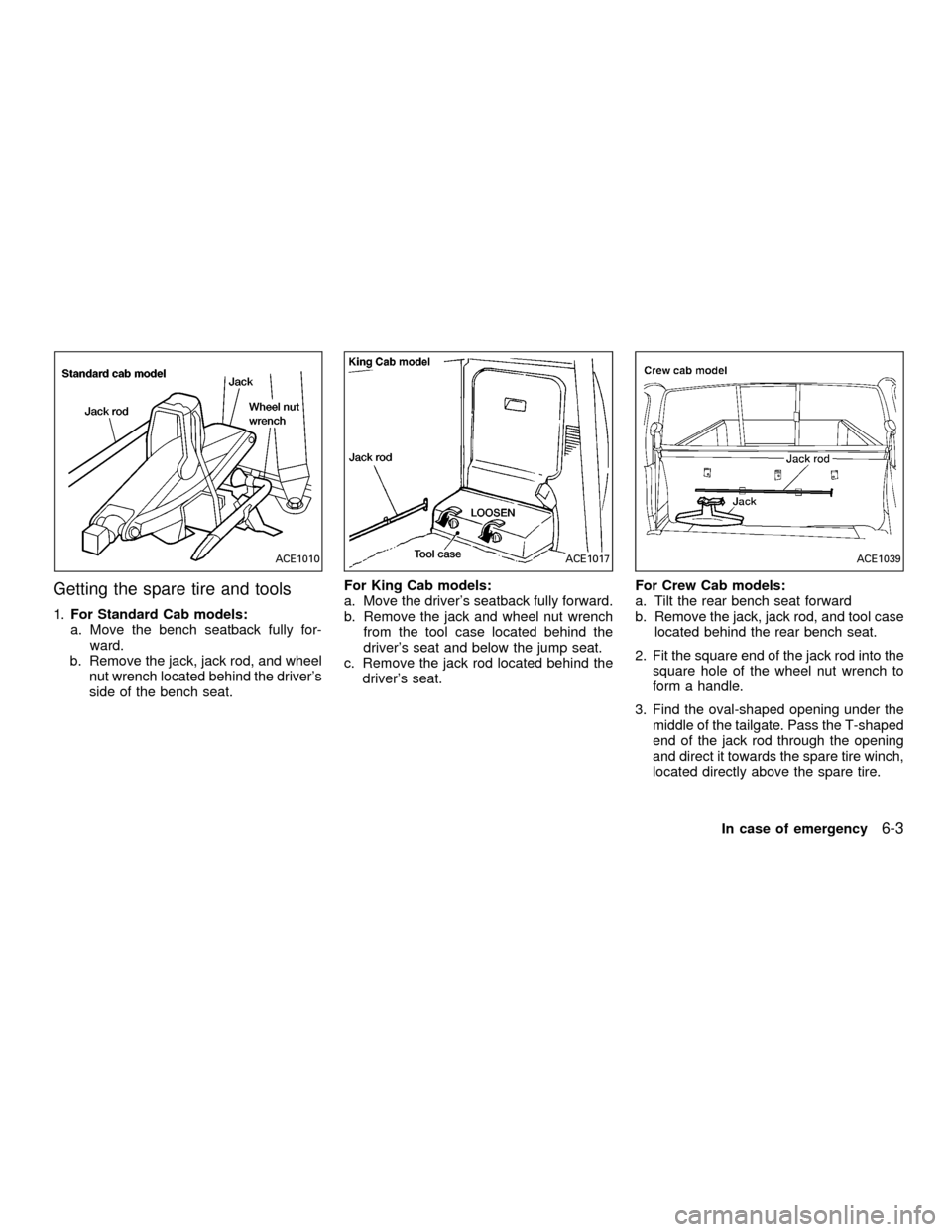

Getting the spare tire and tools

1.For Standard Cab models:

a. Move the bench seatback fully for-

ward.

b. Remove the jack, jack rod, and wheel

nut wrench located behind the driver's

side of the bench seat.For King Cab models:

a. Move the driver's seatback fully forward.

b. Remove the jack and wheel nut wrench

from the tool case located behind the

driver's seat and below the jump seat.

c. Remove the jack rod located behind the

driver's seat.For Crew Cab models:

a. Tilt the rear bench seat forward

b. Remove the jack, jack rod, and tool case

located behind the rear bench seat.

2. Fit the square end of the jack rod into the

square hole of the wheel nut wrench to

form a handle.

3. Find the oval-shaped opening under the

middle of the tailgate. Pass the T-shaped

end of the jack rod through the opening

and direct it towards the spare tire winch,

located directly above the spare tire.

ACE1010ACE1017ACE1039

In case of emergency6-3

ZX

Page 178 of 290

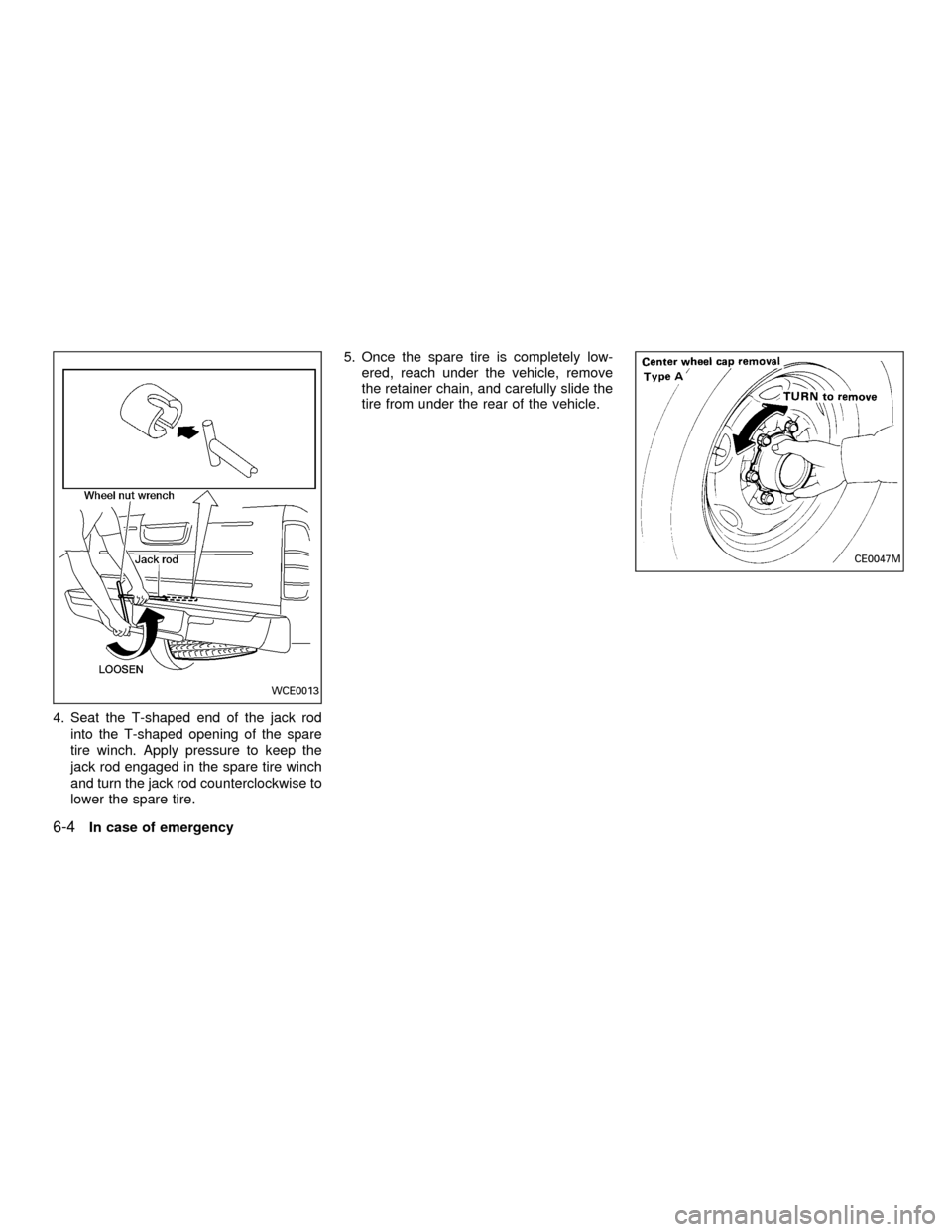

4. Seat the T-shaped end of the jack rod

into the T-shaped opening of the spare

tire winch. Apply pressure to keep the

jack rod engaged in the spare tire winch

and turn the jack rod counterclockwise to

lower the spare tire.5. Once the spare tire is completely low-

ered, reach under the vehicle, remove

the retainer chain, and carefully slide the

tire from under the rear of the vehicle.

WCE0013

CE0047M

6-4In case of emergency

ZX

Page 179 of 290

Removing wheel cover

CAUTION

Do not use your hands to pry off wheel

caps or wheel covers. Doing so could

result in personal injury.

Use caution not to scratch the wheel cover

or wheel surface.

Jacking up the vehicle and remov-

ing the wheel

Always refer to the proper illustrations for

the correct placement and jack-up points for

your specific vehicle model and jack type.

WARNING

cNever get under the vehicle while it

is supported only by the jack.

cUse only the jack provided with your

vehicle to lift the vehicle. Do not use

the jack provided with your vehicle

on other vehicles. The jack is de-

signed for lifting only your vehicle

during a tire change.

cUse the correct jack up points; Never

use any other part of the vehicle for

jack support.

cNever jack up the vehicle more than

necessary.

cNever use blocks on or under the

jack.

cDo not allow passengers to stay in

the vehicle while it is on the jack.

cDo not start or run the engine while

vehicle is on the jack. It may cause

the vehicle to move. This is espe-

cially true for vehicles with limited

slip differential carriers.

ACE1011WCE0014

In case of emergency6-5

ZX

Page 181 of 290

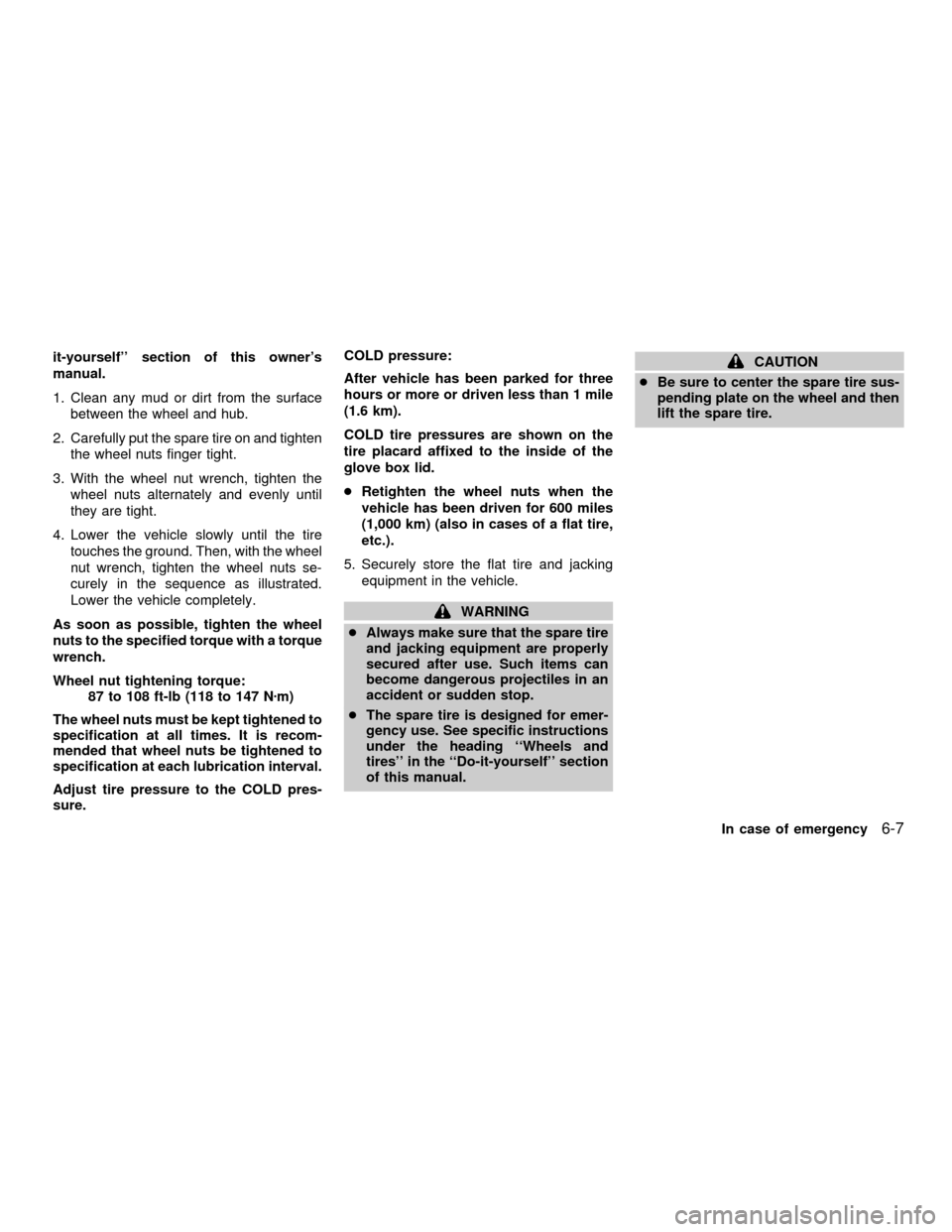

it-yourself'' section of this owner's

manual.

1. Clean any mud or dirt from the surface

between the wheel and hub.

2. Carefully put the spare tire on and tighten

the wheel nuts finger tight.

3. With the wheel nut wrench, tighten the

wheel nuts alternately and evenly until

they are tight.

4. Lower the vehicle slowly until the tire

touches the ground. Then, with the wheel

nut wrench, tighten the wheel nuts se-

curely in the sequence as illustrated.

Lower the vehicle completely.

As soon as possible, tighten the wheel

nuts to the specified torque with a torque

wrench.

Wheel nut tightening torque:

87 to 108 ft-lb (118 to 147 Nzm)

The wheel nuts must be kept tightened to

specification at all times. It is recom-

mended that wheel nuts be tightened to

specification at each lubrication interval.

Adjust tire pressure to the COLD pres-

sure.COLD pressure:

After vehicle has been parked for three

hours or more or driven less than 1 mile

(1.6 km).

COLD tire pressures are shown on the

tire placard affixed to the inside of the

glove box lid.

cRetighten the wheel nuts when the

vehicle has been driven for 600 miles

(1,000 km) (also in cases of a flat tire,

etc.).

5. Securely store the flat tire and jacking

equipment in the vehicle.

WARNING

cAlways make sure that the spare tire

and jacking equipment are properly

secured after use. Such items can

become dangerous projectiles in an

accident or sudden stop.

cThe spare tire is designed for emer-

gency use. See specific instructions

under the heading ``Wheels and

tires'' in the ``Do-it-yourself'' section

of this manual.

CAUTION

cBe sure to center the spare tire sus-

pending plate on the wheel and then

lift the spare tire.

In case of emergency

6-7

ZX

Page 198 of 290

When performing any inspection or mainte-

nance work on your vehicle, always take

care to prevent serious accidental injury to

yourself or damage to the vehicle. The

following are general precautions which

should be closely observed.

WARNING

cPark the vehicle on a level surface,

apply the parking brake securely and

block the wheels to prevent the ve-

hicle from moving. For manual trans-

mission models, move the shift lever

to N (Neutral). For automatic trans-

mission models, move the selector

lever to P (Park).

cBe sure the ignition key is in the OFF

or LOCK position when performing

any parts replacement or repairs.

cNever leave the engine or automatic

transmission related component

harnesses disconnected while the

ignition switch is in the ON position.

cNever connect or disconnect the bat-

tery or any transistorized compo-

nent while the ignition switch is in

the ON position.cIf you must work with the engine

running, keep your hands, clothing,

hair and tools away from moving

fans, belts, and any other moving

parts.

cIt is advisable to secure or remove

any loose clothing and remove any

jewelry, such as rings, watches, etc.,

before working on your vehicle.

cAlways wear eye protection when-

ever you work on your vehicle.

cIf you must run the engine in an

enclosed space such as a garage, be

sure there is proper ventilation for

exhaust gases to escape.

cNever get under the vehicle while it

is supported only by a jack. If it is

necessary to work under the vehicle,

support it with safety stands.

cKeep smoking materials, flame and

sparks away from fuel tank and bat-

tery.

cOn gasoline engine models with the

multiport fuel injection (MFI) system,

the fuel filter or fuel lines should be

serviced by an authorized NISSANdealer because the fuellines are un-

der high pressure even when the

engine is off.

CAUTION

cDo not work under the hood while

the engine is hot. Turn the engine off

and wait until it cools down.

cNever connect or disconnect either

the battery or any transistorized

component connector while the igni-

tion is on.

cAvoid contact with used engine oil

and coolant. Improperly disposed

engine oil, engine coolant and/or

other vehicle fluids can damage the

environment. Always conform to lo-

cal regulations for disposal of ve-

hicle fluid.

This ``Do-it-yourself'' section gives instruc-

tions regarding only those items which are

relatively easy for an owner to perform.

You should be aware that incomplete or

improper servicing may result in operating

difficulties or excessive emissions, and

could affect your warranty coverage.If in

doubt about any servicing, have it done

by an authorized NISSAN dealer.

MAINTENANCE

PRECAUTIONS

8-2Do-it-yourself

ZX

Page 226 of 290

cAiming is not necessary after replac-

ing the bulb. When aiming adjust-

ment is necessary, contact an autho-

rized NISSAN dealer.

cDo not leave the bulb out of the

headlight reflector for a long period

of time as dust, moisture, and smoke

may enter the headlight body and

affect the performance of the head-

light.

Replacing the headlight bulb

1. Open the hood.

2. Disconnect the negative (2) battery

cable.

3 Disconnect the electrical connector from

the rear end of the bulb.

4. Turn the bulb retaining ring counterclock-

wise until it is free from the headlamp

reflector and then remove it.

5. Carefully remove the headlight bulb. Do

not shake or rotate the bulb when remov-

ing it.

DO NOT TOUCH THE BULB.6. Install the new bulb in the reverse order

of removal.

cBe sure the lip of the bulb socket

contacts the headlight body.

Adjusting the headlight aim

Before performing aiming adjustment, make

sure of the following:

a. Use an aiming wall screen.

b. Keep all of the tires inflated to the correct

pressure.

c. Place the vehicle and screen on level

ground.

d. See that the vehicle is unloaded (except

for full levels of coolant, engine oil and

fuel, and that the spare tire, jack, and

tools are stored). Have the driver or an

equivalent weight placed in the driver's

seat.

1. Open the hood. Turn headlamp low

beam on.

2. Adjust the vertical aim by turning the

adjustment screw.

cCover the opposite lamp and ensure the

fog lamps (if so equipped) are turned off.cAdjust beam pattern until cutoff line is

positioned at the same height off ground

as bulb center (on H-line).

8-30Do-it-yourself

ZX