sensor NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 980 of 2771

DTC P1778 STEP MOTOR - FUNCTION

CVT-141

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

DTC P1778 STEP MOTOR - FUNCTION

DescriptionINFOID:0000000001703648

• The step motor is included in the control valve assembly.

• The step motor's 4 aspects of ON/OFF change according to the signal from TCM. As a result, the flow of line

pressure to primary pulley is changed and pulley ratio is controlled.

• This diagnosis item is detected when electrical system is OK, but mechanical system is NG.

• This diagnosis item is detected when the state of the changing the speed mechanism in unit does not oper-

ate normally.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703649

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703650

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1778 STEP MOTR/FNC” with CONSULT-III is detected under the following condi-

tions.

- When not changing the pulley ratio according to the instruction of TCM.

Possible CauseINFOID:0000000001703651

Step motor

DTC Confirmation ProcedureINFOID:0000000001703652

CAUTION:

• Always drive vehicle at a safe speed.

• Before starting “DTC Confirmation Procedure”, confirm “Hi” or “Mid” or “Low” fixation by “PRI

SPEED” and “VEHICLE SPEED” on “DATA MONITOR MODE”.

• If hi-geared fixation occurred, go to CVT-142, "

Diagnosis Procedure".

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (cool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds.

TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-142, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

STM STEP

During driving−20 step - 180 step

GEAR RATIO2.56 - 0.43

Page 1017 of 2771

CVT-178

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

TRANSAXLE ASSEMBLY

Removal and InstallationINFOID:0000000001703687

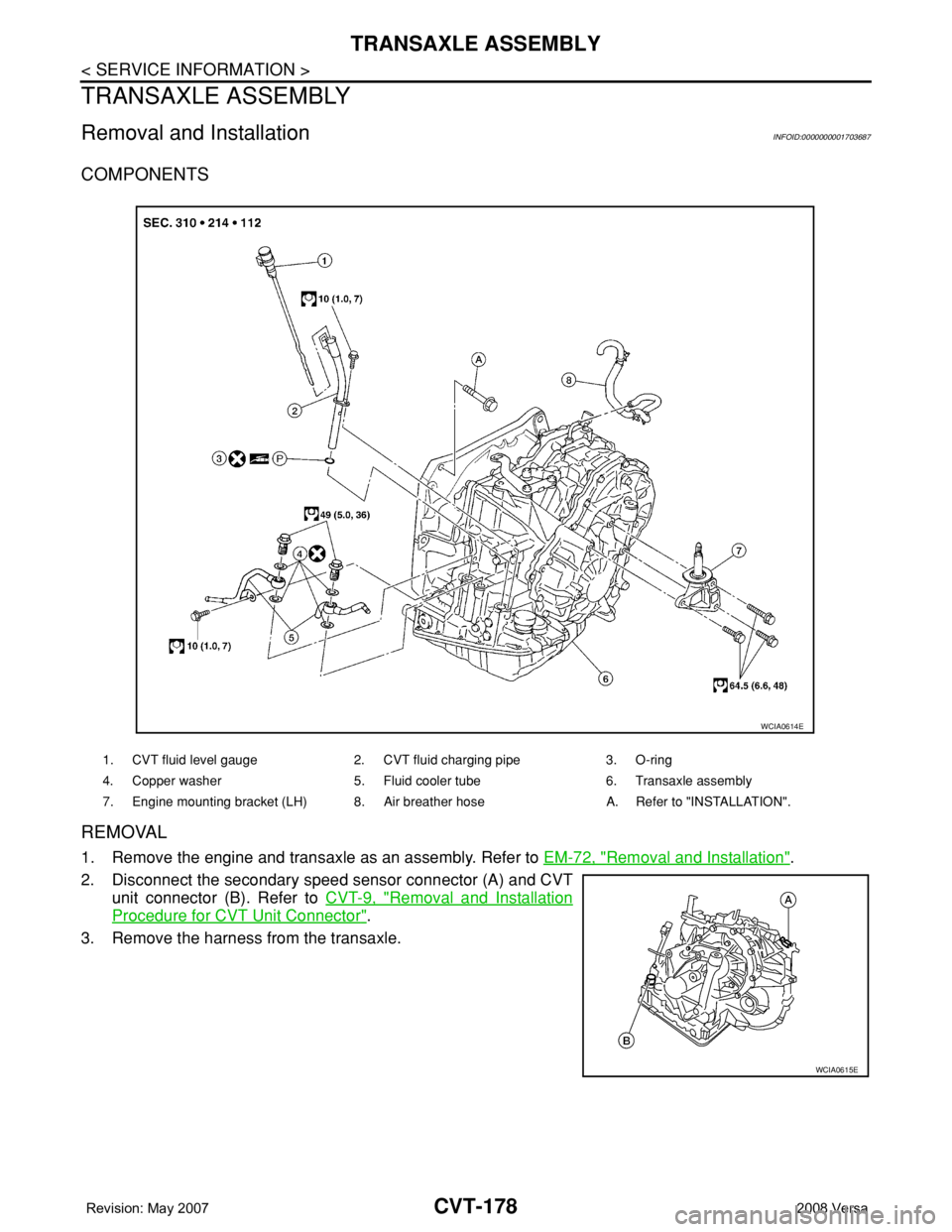

COMPONENTS

REMOVAL

1. Remove the engine and transaxle as an assembly. Refer to EM-72, "Removal and Installation".

2. Disconnect the secondary speed sensor connector (A) and CVT

unit connector (B). Refer to CVT-9, "

Removal and Installation

Procedure for CVT Unit Connector".

3. Remove the harness from the transaxle.

1. CVT fluid level gauge 2. CVT fluid charging pipe 3. O-ring

4. Copper washer 5. Fluid cooler tube 6. Transaxle assembly

7. Engine mounting bracket (LH) 8. Air breather hose A. Refer to "INSTALLATION".

WCIA0614E

WCIA0615E

Page 1021 of 2771

CVT-182

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

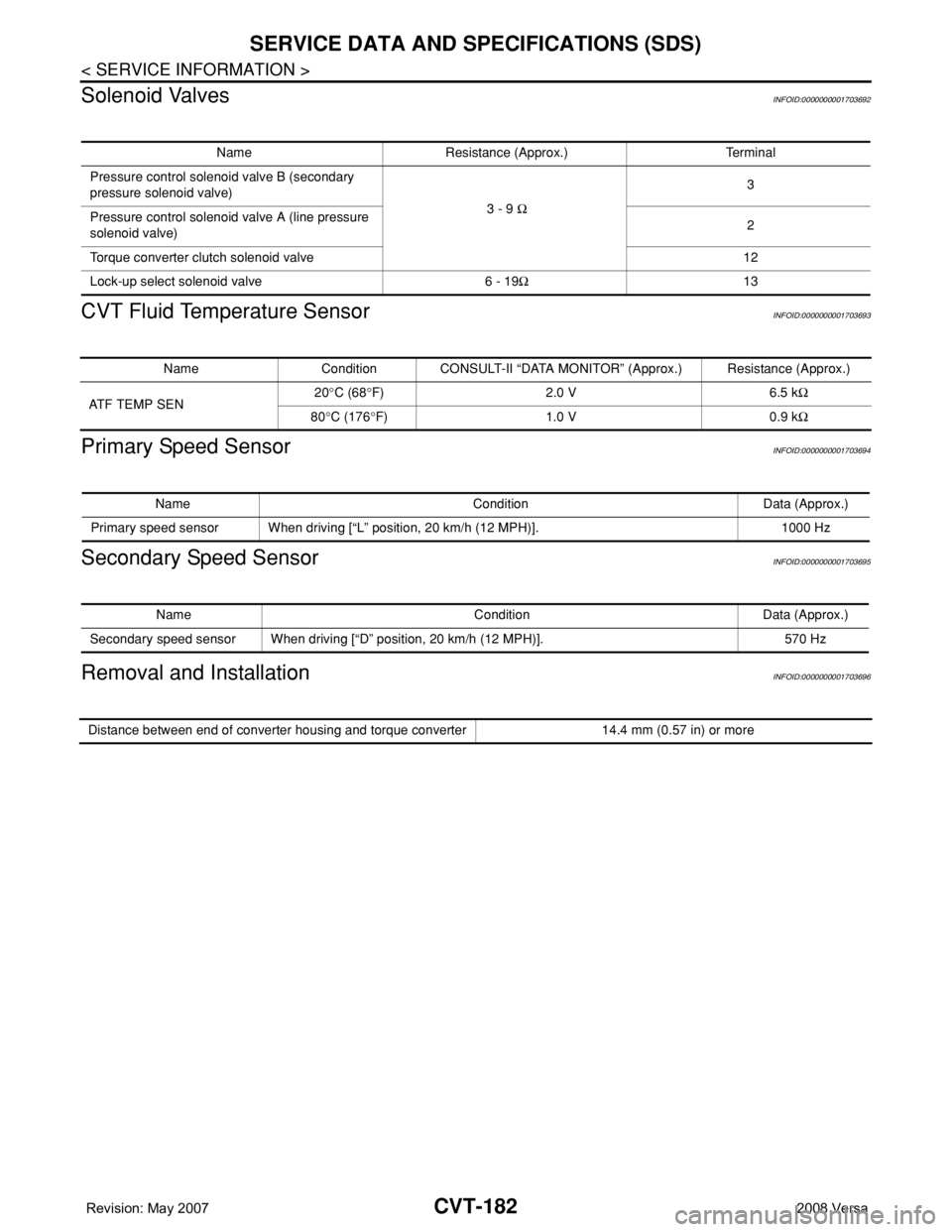

Solenoid Valves

INFOID:0000000001703692

CVT Fluid Temperature SensorINFOID:0000000001703693

Primary Speed SensorINFOID:0000000001703694

Secondary Speed SensorINFOID:0000000001703695

Removal and InstallationINFOID:0000000001703696

Name Resistance (Approx.) Terminal

Pressure control solenoid valve B (secondary

pressure solenoid valve)

3 - 9 Ω3

Pressure control solenoid valve A (line pressure

solenoid valve)2

Torque converter clutch solenoid valve12

Lock-up select solenoid valve 6 - 19Ω13

Name Condition CONSULT-II “DATA MONITOR” (Approx.) Resistance (Approx.)

ATF TEMP SEN20°C (68°F) 2.0 V 6.5 kΩ

80°C (176°F) 1.0 V 0.9 kΩ

Name Condition Data (Approx.)

Primary speed sensor When driving [“L” position, 20 km/h (12 MPH)]. 1000 Hz

Name Condition Data (Approx.)

Secondary speed sensor When driving [“D” position, 20 km/h (12 MPH)]. 570 Hz

Distance between end of converter housing and torque converter 14.4 mm (0.57 in) or more

Page 1022 of 2771

DI-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION DI

A

B

DI

N

O

P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION ............................2

PRECAUTION .....................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Commercial Service Tool ..........................................3

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ............................................................................

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ............11

CONSULT-III Function (METER/M&A) ...................13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit .............19

Electrical Component Inspection .............................19

Removal and Installation .........................................20

WARNING LAMPS .............................................21

Schematic ................................................................21

Wiring Diagram - WARN - .......................................22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) ..............................................................

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ..........................................

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Wiring Diagram - CVTIND - .....................................38

CVT Indicator Does Not Illuminate ..........................39

WARNING CHIME .............................................41

Component Parts and Harness Connector Loca-

tion ...........................................................................

41

System Description ..................................................41

Wiring Diagram - CHIME - .......................................44

Terminal and Reference Value for BCM ..................45

CONSULT-III Function (BCM) .................................45

Trouble Diagnosis ....................................................46

Combination Meter Buzzer Circuit Inspection .........47

Front Door Switch LH Signal Inspection ..................48

Key Switch Signal Inspection (Without Intelligent

Key) .........................................................................

49

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ............................................................

50

Lighting Switch Signal Inspection ............................52

Parking Brake Switch Signal Inspection ..................52

Electrical Component Inspection .............................53

Page 1025 of 2771

DI-4

< SERVICE INFORMATION >

COMBINATION METERS

COMBINATION METERS

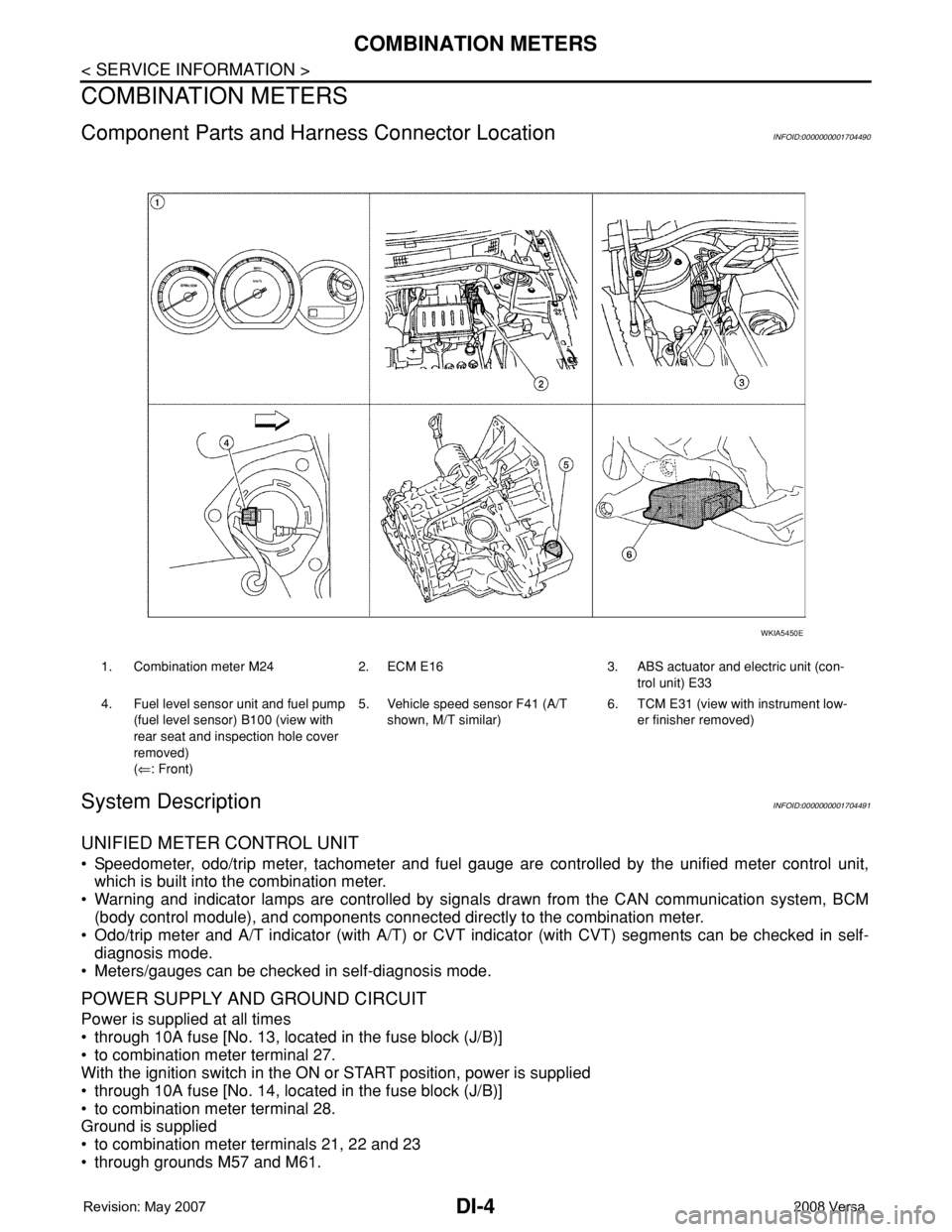

Component Parts and Harness Connector LocationINFOID:0000000001704490

System DescriptionINFOID:0000000001704491

UNIFIED METER CONTROL UNIT

• Speedometer, odo/trip meter, tachometer and fuel gauge are controlled by the unified meter control unit,

which is built into the combination meter.

• Warning and indicator lamps are controlled by signals drawn from the CAN communication system, BCM

(body control module), and components connected directly to the combination meter.

• Odo/trip meter and A/T indicator (with A/T) or CVT indicator (with CVT) segments can be checked in self-

diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

1. Combination meter M24 2. ECM E16 3. ABS actuator and electric unit (con-

trol unit) E33

4. Fuel level sensor unit and fuel pump

(fuel level sensor) B100 (view with

rear seat and inspection hole cover

removed)

(⇐: Front)5. Vehicle speed sensor F41 (A/T

shown, M/T similar)6. TCM E31 (view with instrument low-

er finisher removed)

WKIA5450E

Page 1026 of 2771

COMBINATION METERS

DI-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

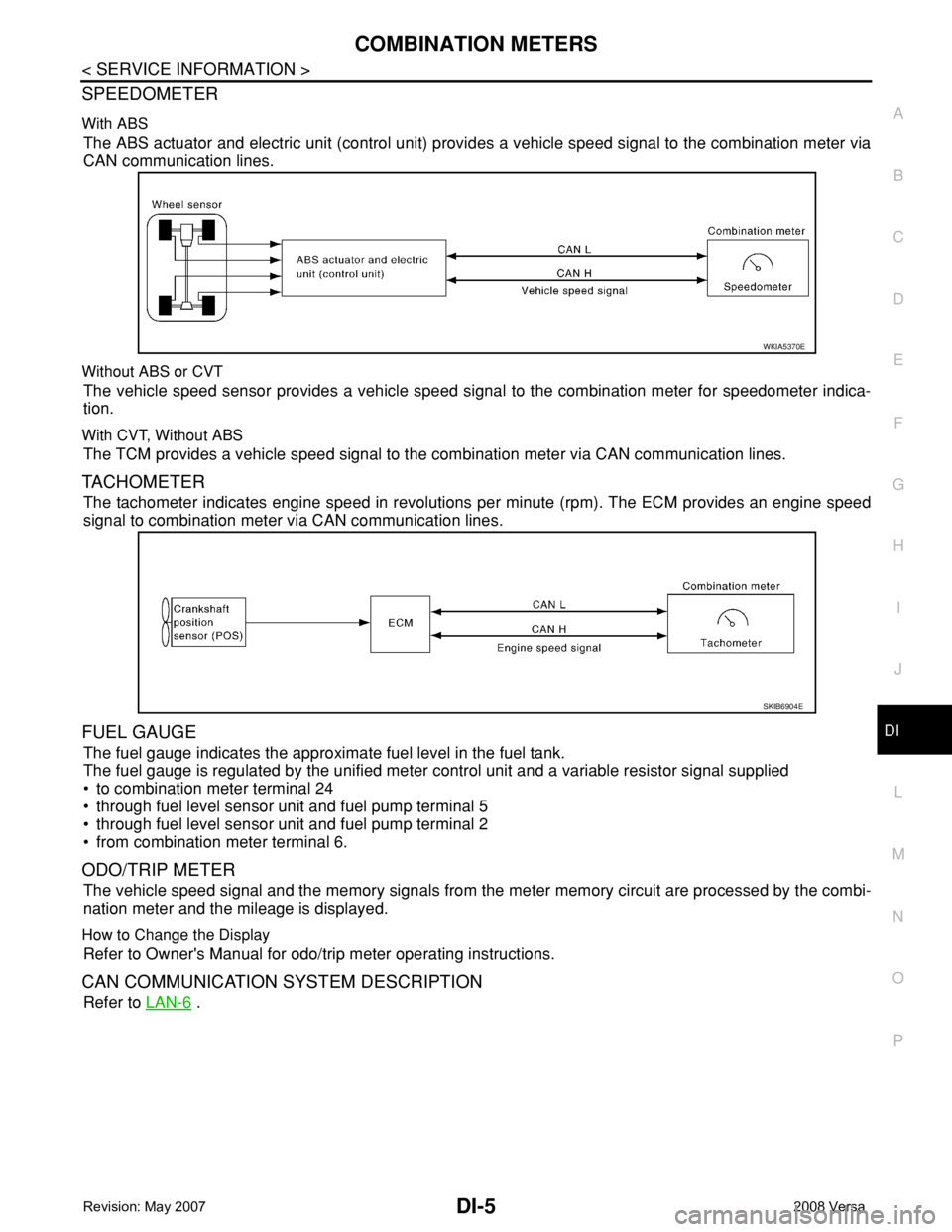

SPEEDOMETER

With ABS

The ABS actuator and electric unit (control unit) provides a vehicle speed signal to the combination meter via

CAN communication lines.

Without ABS or CVT

The vehicle speed sensor provides a vehicle speed signal to the combination meter for speedometer indica-

tion.

With CVT, Without ABS

The TCM provides a vehicle speed signal to the combination meter via CAN communication lines.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm). The ECM provides an engine speed

signal to combination meter via CAN communication lines.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by the unified meter control unit and a variable resistor signal supplied

• to combination meter terminal 24

• through fuel level sensor unit and fuel pump terminal 5

• through fuel level sensor unit and fuel pump terminal 2

• from combination meter terminal 6.

ODO/TRIP METER

The vehicle speed signal and the memory signals from the meter memory circuit are processed by the combi-

nation meter and the mileage is displayed.

How to Change the Display

Refer to Owner's Manual for odo/trip meter operating instructions.

CAN COMMUNICATION SYSTEM DESCRIPTION

Refer to LAN-6 .

WKIA5370E

SKIB6904E

Page 1031 of 2771

DI-10

< SERVICE INFORMATION >

COMBINATION METERS

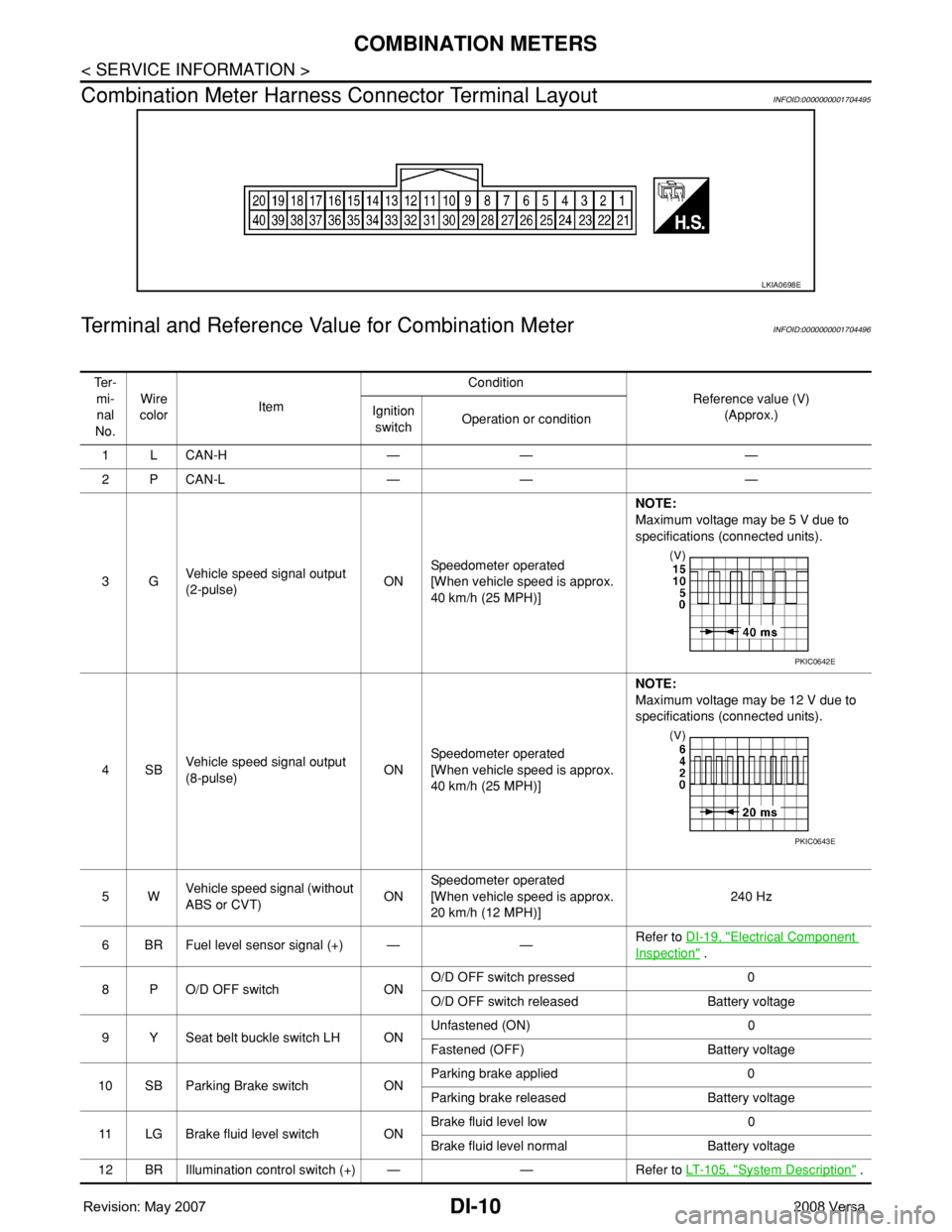

Combination Meter Harness Connector Terminal Layout

INFOID:0000000001704495

Terminal and Reference Value for Combination MeterINFOID:0000000001704496

LKIA0698E

Te r -

mi-

nal

No.Wire

colorItemCondition

Reference value (V)

(Approx.) Ignition

switchOperation or condition

1LCAN-H — — —

2PCAN-L — — —

3GVehicle speed signal output

(2-pulse)ONSpeedometer operated

[When vehicle speed is approx.

40 km/h (25 MPH)] NOTE:

Maximum voltage may be 5 V due to

specifications (connected units).

4SBVehicle speed signal output

(8-pulse)ONSpeedometer operated

[When vehicle speed is approx.

40 km/h (25 MPH)]NOTE:

Maximum voltage may be 12 V due to

specifications (connected units).

5WVehicle speed signal (without

ABS or CVT)ONSpeedometer operated

[When vehicle speed is approx.

20 km/h (12 MPH)]240 Hz

6 BR Fuel level sensor signal (+) — —Refer to DI-19, "

Electrical Component

Inspection" .

8 P O/D OFF switch ONO/D OFF switch pressed 0

O/D OFF switch released Battery voltage

9 Y Seat belt buckle switch LH ONUnfastened (ON) 0

Fastened (OFF) Battery voltage

10 SB Parking Brake switch ONParking brake applied 0

Parking brake released Battery voltage

11 LG Brake fluid level switch ONBrake fluid level low 0

Brake fluid level normal Battery voltage

12 BR Illumination control switch (+) — — Refer to LT- 1 0 5 , "

System Description" .

PKIC0642E

PKIC0643E

Page 1032 of 2771

COMBINATION METERS

DI-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

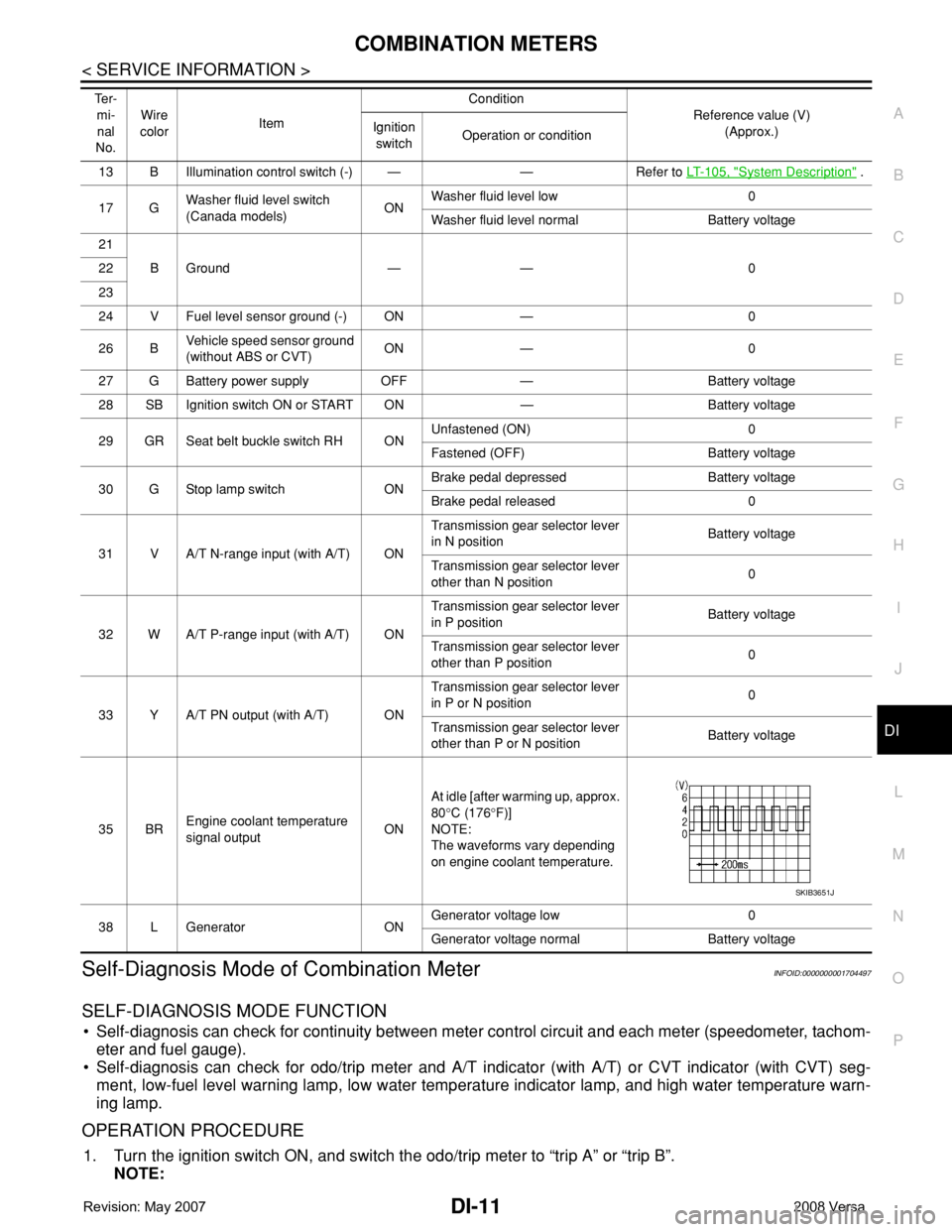

Self-Diagnosis Mode of Combination MeterINFOID:0000000001704497

SELF-DIAGNOSIS MODE FUNCTION

• Self-diagnosis can check for continuity between meter control circuit and each meter (speedometer, tachom-

eter and fuel gauge).

• Self-diagnosis can check for odo/trip meter and A/T indicator (with A/T) or CVT indicator (with CVT) seg-

ment, low-fuel level warning lamp, low water temperature indicator lamp, and high water temperature warn-

ing lamp.

OPERATION PROCEDURE

1. Turn the ignition switch ON, and switch the odo/trip meter to “trip A” or “trip B”.

NOTE:

13 B Illumination control switch (-) — — Refer to LT- 1 0 5 , "System Description" .

17 GWasher fluid level switch

(Canada models)ONWasher fluid level low 0

Washer fluid level normal Battery voltage

21

BGround — — 0 22

23

24 V Fuel level sensor ground (-) ON — 0

26 BVehicle speed sensor ground

(without ABS or CVT)ON — 0

27 G Battery power supply OFF — Battery voltage

28 SB Ignition switch ON or START ON — Battery voltage

29 GR Seat belt buckle switch RH ONUnfastened (ON) 0

Fastened (OFF) Battery voltage

30 G Stop lamp switch ONBrake pedal depressed Battery voltage

Brake pedal released 0

31 V A/T N-range input (with A/T) ONTransmission gear selector lever

in N positionBattery voltage

Transmission gear selector lever

other than N position0

32 W A/T P-range input (with A/T) ONTransmission gear selector lever

in P positionBattery voltage

Transmission gear selector lever

other than P position0

33 Y A/T PN output (with A/T) ONTransmission gear selector lever

in P or N position0

Transmission gear selector lever

other than P or N positionBattery voltage

35 BREngine coolant temperature

signal outputONAt idle [after warming up, approx.

80°C (176°F)]

NOTE:

The waveforms vary depending

on engine coolant temperature.

38 L Generator ONGenerator voltage low 0

Generator voltage normal Battery voltage Te r -

mi-

nal

No.Wire

colorItemCondition

Reference value (V)

(Approx.) Ignition

switchOperation or condition

SKIB3651J

Page 1036 of 2771

COMBINATION METERS

DI-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

NO >> Check power supply and ground circuit of combination meter. Refer to DI-15, "Power Supply and

Ground Circuit Inspection" .

2.CHECK COMBINATION METER (CONSULT-III)

Select “METER/M&A” on CONSULT-III and perform self-diagnosis of combination meter. Refer to DI-13,

"CONSULT-III Function (METER/M&A)" .

Self

-diagnostic results content

No malfunction detected>> Refer to DI-15, "Symptom Chart" .

Malfunction detected>> Refer to DI-13, "

CONSULT-III Function (METER/M&A)" .

Symptom ChartINFOID:0000000001704500

Power Supply and Ground Circuit InspectionINFOID:0000000001704501

1.CHECK FUSE

Check for blown combination meter fuses.

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3

.

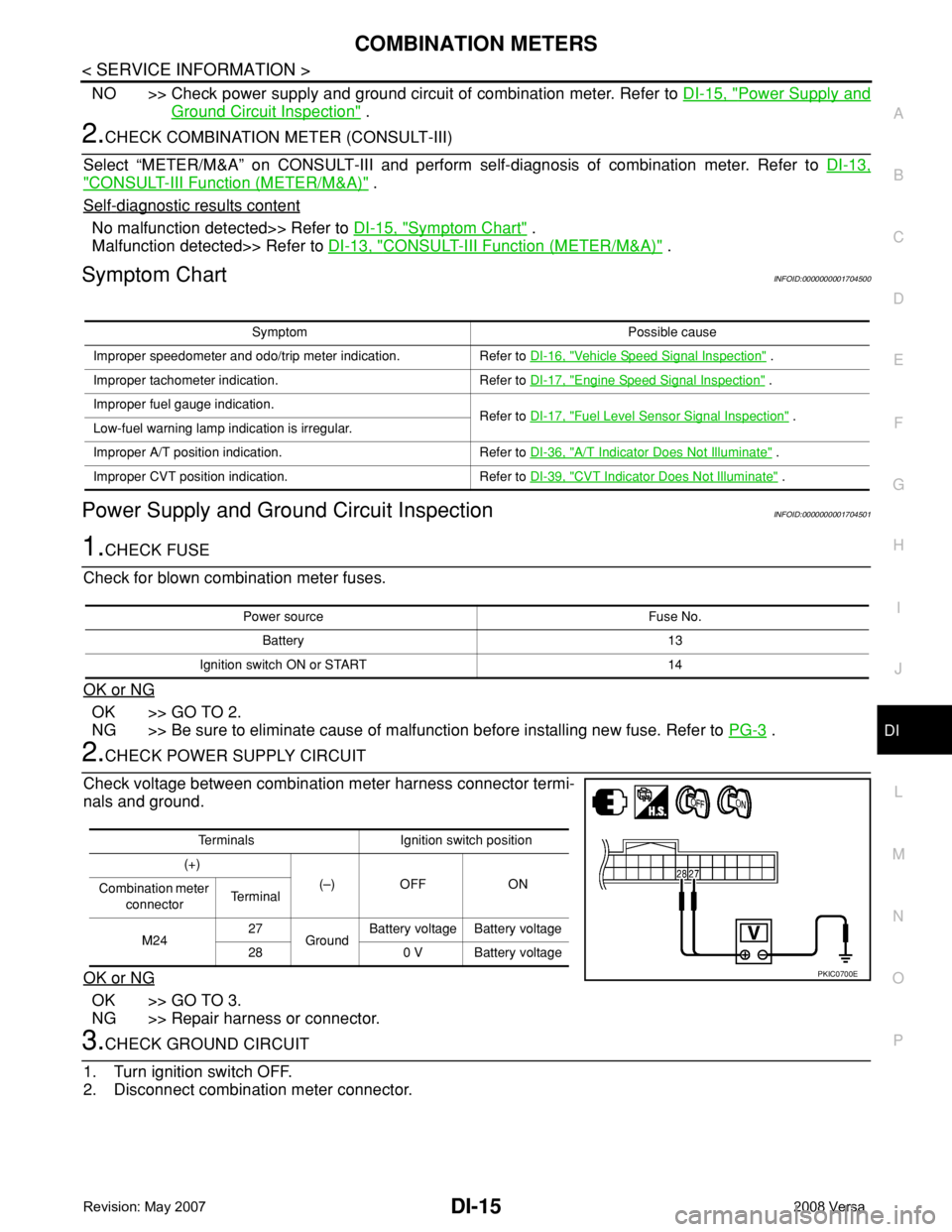

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between combination meter harness connector termi-

nals and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

Symptom Possible cause

Improper speedometer and odo/trip meter indication. Refer to DI-16, "

Vehicle Speed Signal Inspection" .

Improper tachometer indication. Refer to DI-17, "

Engine Speed Signal Inspection" .

Improper fuel gauge indication.

Refer to DI-17, "

Fuel Level Sensor Signal Inspection" .

Low-fuel warning lamp indication is irregular.

Improper A/T position indication. Refer to DI-36, "

A/T Indicator Does Not Illuminate" .

Improper CVT position indication. Refer to DI-39, "

CVT Indicator Does Not Illuminate" .

Power source Fuse No.

Battery 13

Ignition switch ON or START 14

Terminals Ignition switch position

(+)

(–) OFF ON

Combination meter

connectorTe r m i n a l

M2427

GroundBattery voltage Battery voltage

28 0 V Battery voltage

PKIC0700E

Page 1037 of 2771

DI-16

< SERVICE INFORMATION >

COMBINATION METERS

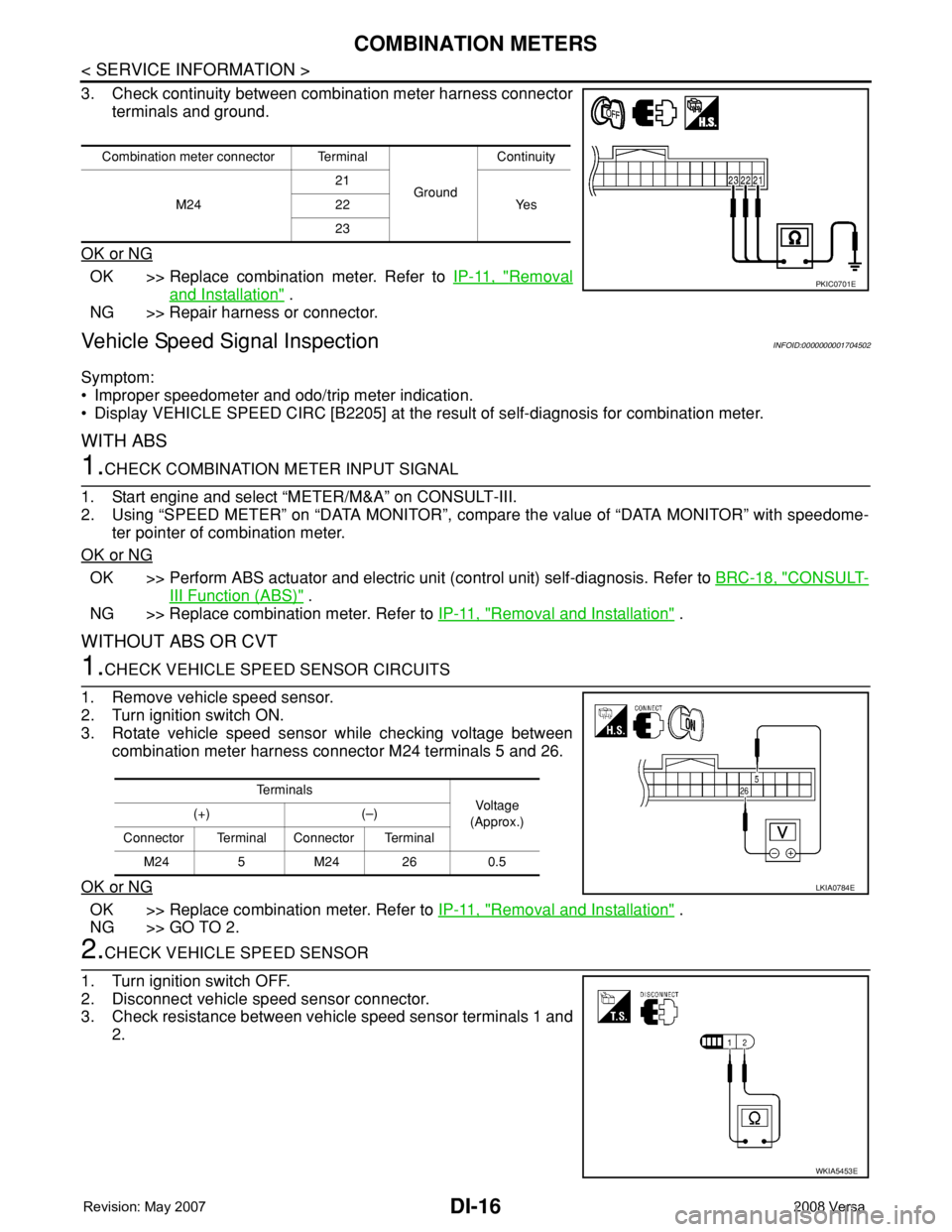

3. Check continuity between combination meter harness connector

terminals and ground.

OK or NG

OK >> Replace combination meter. Refer to IP-11, "Removal

and Installation" .

NG >> Repair harness or connector.

Vehicle Speed Signal InspectionINFOID:0000000001704502

Symptom:

• Improper speedometer and odo/trip meter indication.

• Display VEHICLE SPEED CIRC [B2205] at the result of self-diagnosis for combination meter.

WITH ABS

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “METER/M&A” on CONSULT-III.

2. Using “SPEED METER” on “DATA MONITOR”, compare the value of “DATA MONITOR” with speedome-

ter pointer of combination meter.

OK or NG

OK >> Perform ABS actuator and electric unit (control unit) self-diagnosis. Refer to BRC-18, "CONSULT-

III Function (ABS)" .

NG >> Replace combination meter. Refer to IP-11, "

Removal and Installation" .

WITHOUT ABS OR CVT

1.CHECK VEHICLE SPEED SENSOR CIRCUITS

1. Remove vehicle speed sensor.

2. Turn ignition switch ON.

3. Rotate vehicle speed sensor while checking voltage between

combination meter harness connector M24 terminals 5 and 26.

OK or NG

OK >> Replace combination meter. Refer to IP-11, "Removal and Installation" .

NG >> GO TO 2.

2.CHECK VEHICLE SPEED SENSOR

1. Turn ignition switch OFF.

2. Disconnect vehicle speed sensor connector.

3. Check resistance between vehicle speed sensor terminals 1 and

2.

Combination meter connector Terminal

GroundContinuity

M2421

Ye s 22

23

PKIC0701E

Te r m i n a l s

Voltag e

(Approx.) (+) (–)

Connector Terminal Connector Terminal

M24 5 M24 26 0.5

LKIA0784E

WKIA5453E