recommended oil NISSAN LATIO 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 1737 of 2771

EM-60

< SERVICE INFORMATION >

OIL SEAL

• Drive belt; Refer to EM-13, "Component".

• Crankshaft pulley; Refer to EM-37, "

Component".

2. Remove front oil seal using a suitable tool.

CAUTION:

Be careful not to damage front cover and crankshaft.

INSTALLATION

1. Apply new engine oil to new front oil seal joint surface and seal lip.

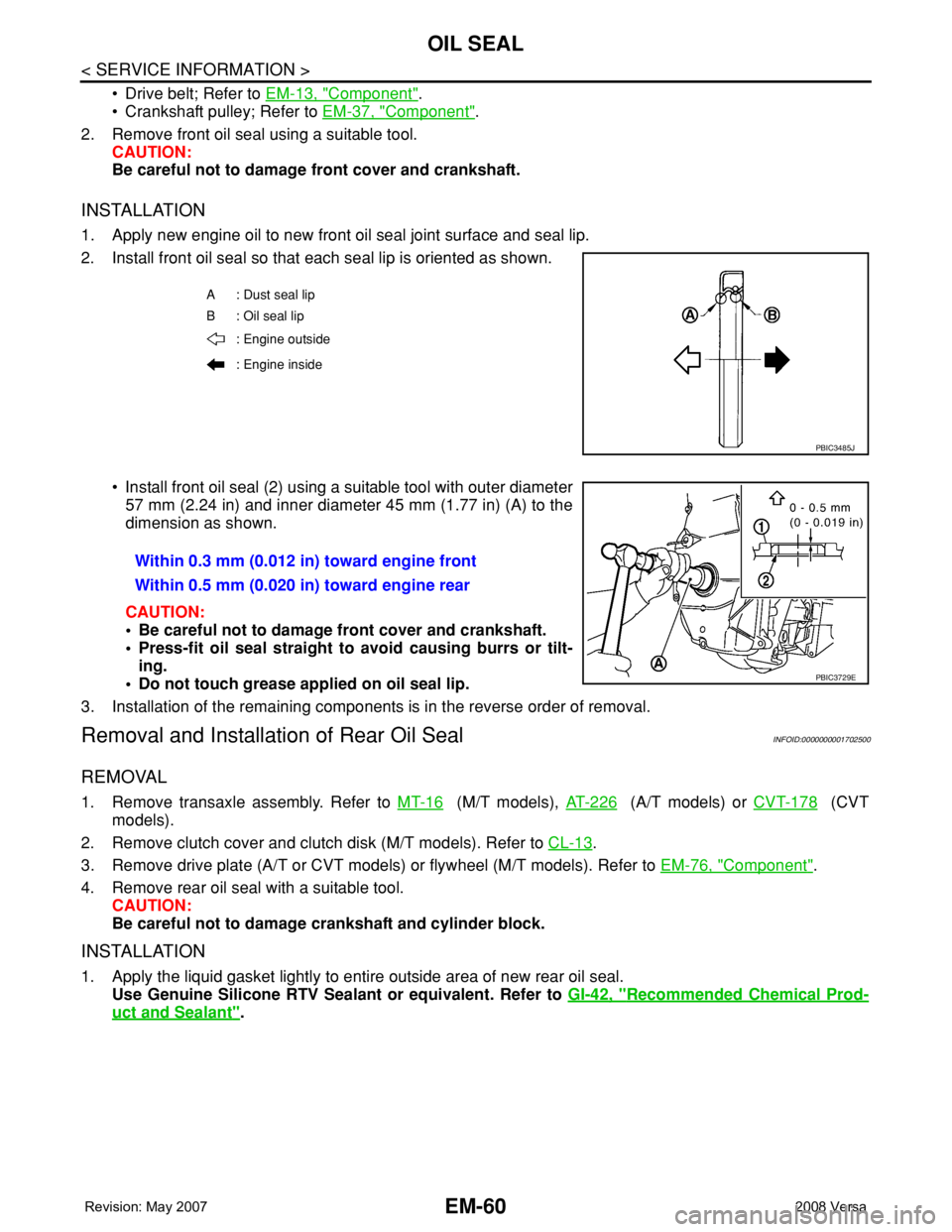

2. Install front oil seal so that each seal lip is oriented as shown.

• Install front oil seal (2) using a suitable tool with outer diameter

57 mm (2.24 in) and inner diameter 45 mm (1.77 in) (A) to the

dimension as shown.

CAUTION:

• Be careful not to damage front cover and crankshaft.

• Press-fit oil seal straight to avoid causing burrs or tilt-

ing.

• Do not touch grease applied on oil seal lip.

3. Installation of the remaining components is in the reverse order of removal.

Removal and Installation of Rear Oil SealINFOID:0000000001702500

REMOVAL

1. Remove transaxle assembly. Refer to MT-16 (M/T models), AT-226 (A/T models) or CVT-178 (CVT

models).

2. Remove clutch cover and clutch disk (M/T models). Refer to CL-13

.

3. Remove drive plate (A/T or CVT models) or flywheel (M/T models). Refer to EM-76, "

Component".

4. Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

1. Apply the liquid gasket lightly to entire outside area of new rear oil seal.

Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Prod-

uct and Sealant".

A : Dust seal lip

B : Oil seal lip

: Engine outside

: Engine inside

PBIC3485J

Within 0.3 mm (0.012 in) toward engine front

Within 0.5 mm (0.020 in) toward engine rear

PBIC3729E

Page 1757 of 2771

EM-80

< SERVICE INFORMATION >

CYLINDER BLOCK

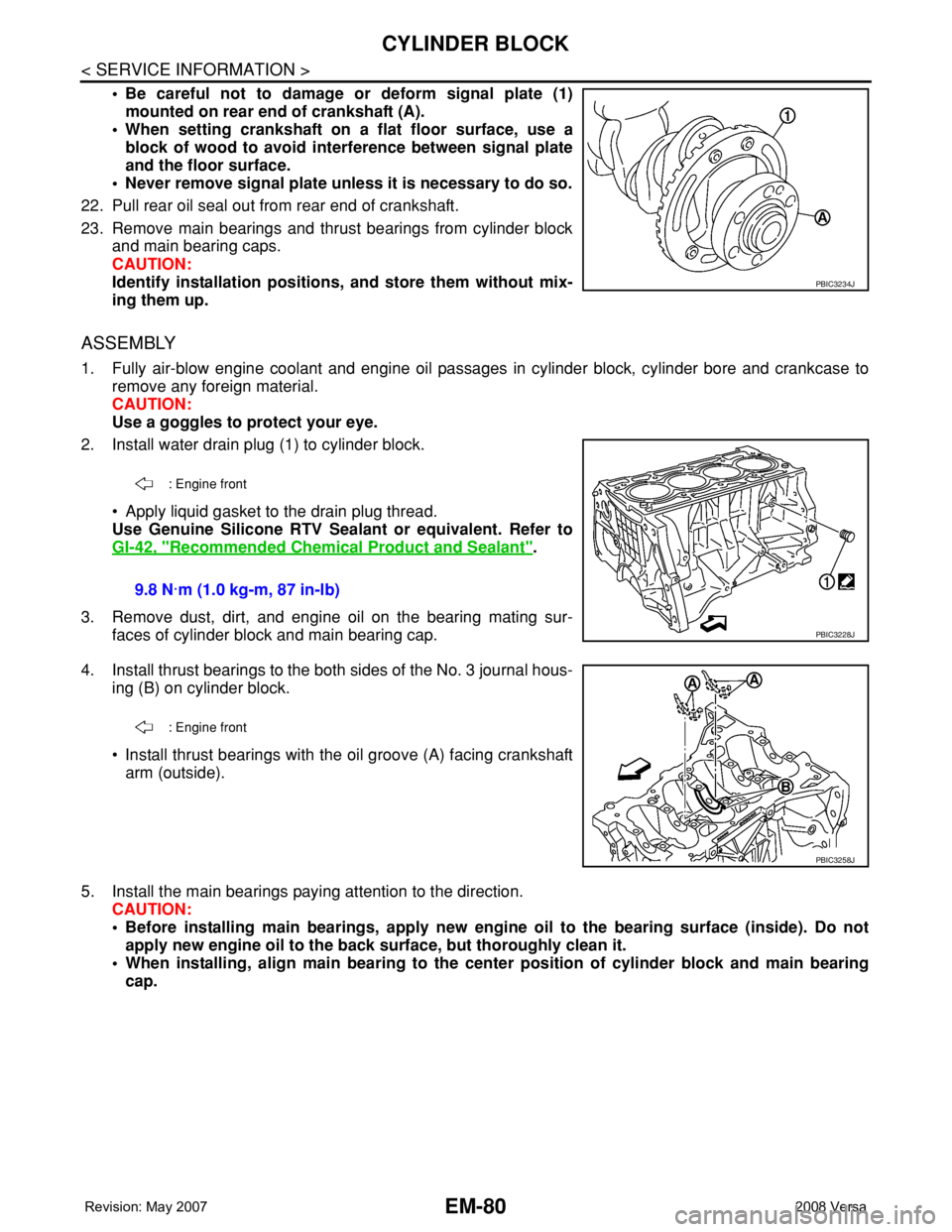

• Be careful not to damage or deform signal plate (1)

mounted on rear end of crankshaft (A).

• When setting crankshaft on a flat floor surface, use a

block of wood to avoid interference between signal plate

and the floor surface.

• Never remove signal plate unless it is necessary to do so.

22. Pull rear oil seal out from rear end of crankshaft.

23. Remove main bearings and thrust bearings from cylinder block

and main bearing caps.

CAUTION:

Identify installation positions, and store them without mix-

ing them up.

ASSEMBLY

1. Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

2. Install water drain plug (1) to cylinder block.

• Apply liquid gasket to the drain plug thread.

Use Genuine Silicone RTV Sealant or equivalent. Refer to

GI-42, "

Recommended Chemical Product and Sealant".

3. Remove dust, dirt, and engine oil on the bearing mating sur-

faces of cylinder block and main bearing cap.

4. Install thrust bearings to the both sides of the No. 3 journal hous-

ing (B) on cylinder block.

• Install thrust bearings with the oil groove (A) facing crankshaft

arm (outside).

5. Install the main bearings paying attention to the direction.

CAUTION:

• Before installing main bearings, apply new engine oil to the bearing surface (inside). Do not

apply new engine oil to the back surface, but thoroughly clean it.

• When installing, align main bearing to the center position of cylinder block and main bearing

cap.

PBIC3234J

: Engine front

9.8 N·m (1.0 kg-m, 87 in-lb)

PBIC3228J

: Engine front

PBIC3258J

Page 1840 of 2771

FSU-6

< SERVICE INFORMATION >

FRONT SUSPENSION ASSEMBLY

FRONT SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001703721

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

STRUT INSPECTION

Check for oil leakage, damage and replace as necessary.

Wheel Alignment InspectionINFOID:0000000001703722

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-5, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FA X - 5 , "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-17, "

Wheelarch Height (Unladen*)" .

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

• Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-16, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.Axial end play : 0 mm (0 in)

Page 1852 of 2771

GI-1

GENERAL INFORMATION

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION GI

N

O

P

CONTENTS

GENERAL INFORMATION

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Description ................................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

2

General Precaution ...................................................3

Precaution for Three Way Catalyst ...........................4

Precaution for Fuel (Unleaded Regular Gasoline

Recommended) .........................................................

4

Precaution for Multiport Fuel Injection System or

Engine Control System .............................................

5

Precaution for Hoses .................................................5

Precaution for Engine Oils ........................................6

Precaution for Air Conditioning .................................6

HOW TO USE THIS MANUAL ............................7

Description ................................................................7

Terms ........................................................................7

Units ..........................................................................7

Contents ....................................................................7

Relation between Illustrations and Descriptions .......8

Component ................................................................8

How to Follow Trouble Diagnosis ..............................9

How to Read Wiring Diagram ..................................13

Abbreviations ..........................................................20

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ...........................................................

22

How to Check Terminal ...........................................22

How to Perform Efficient Diagnosis for an Electri-

cal Incident ..............................................................

25

Control Units and Electrical Parts ............................32

CONSULT-III CHECKING SYSTEM .................35

Description ...............................................................35

Function and System Application ............................35

CONSULT-III Data Link Connector (DLC) Circuit ....36

LIFTING POINT .................................................38

Special Service Tool ................................................38

Garage Jack and Safety Stand and 2-Pole Lift .......38

Board-On Lift ...........................................................39

TOW TRUCK TOWING .....................................40

Tow Truck Towing ...................................................40

Vehicle Recovery (Freeing a Stuck Vehicle) ...........40

TIGHTENING TORQUE OF STANDARD

BOLTS ...............................................................

41

Tightening Torque Table .........................................41

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ...............................................

42

Recommended Chemical Product and Sealant .......42

IDENTIFICATION INFORMATION ....................43

Model Variation ........................................................43

Dimensions ..............................................................46

Wheels & Tires ........................................................46

TERMINOLOGY ................................................47

SAE J1930 Terminology List ...................................47

Page 1855 of 2771

GI-4

< SERVICE INFORMATION >

PRECAUTIONS

• Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

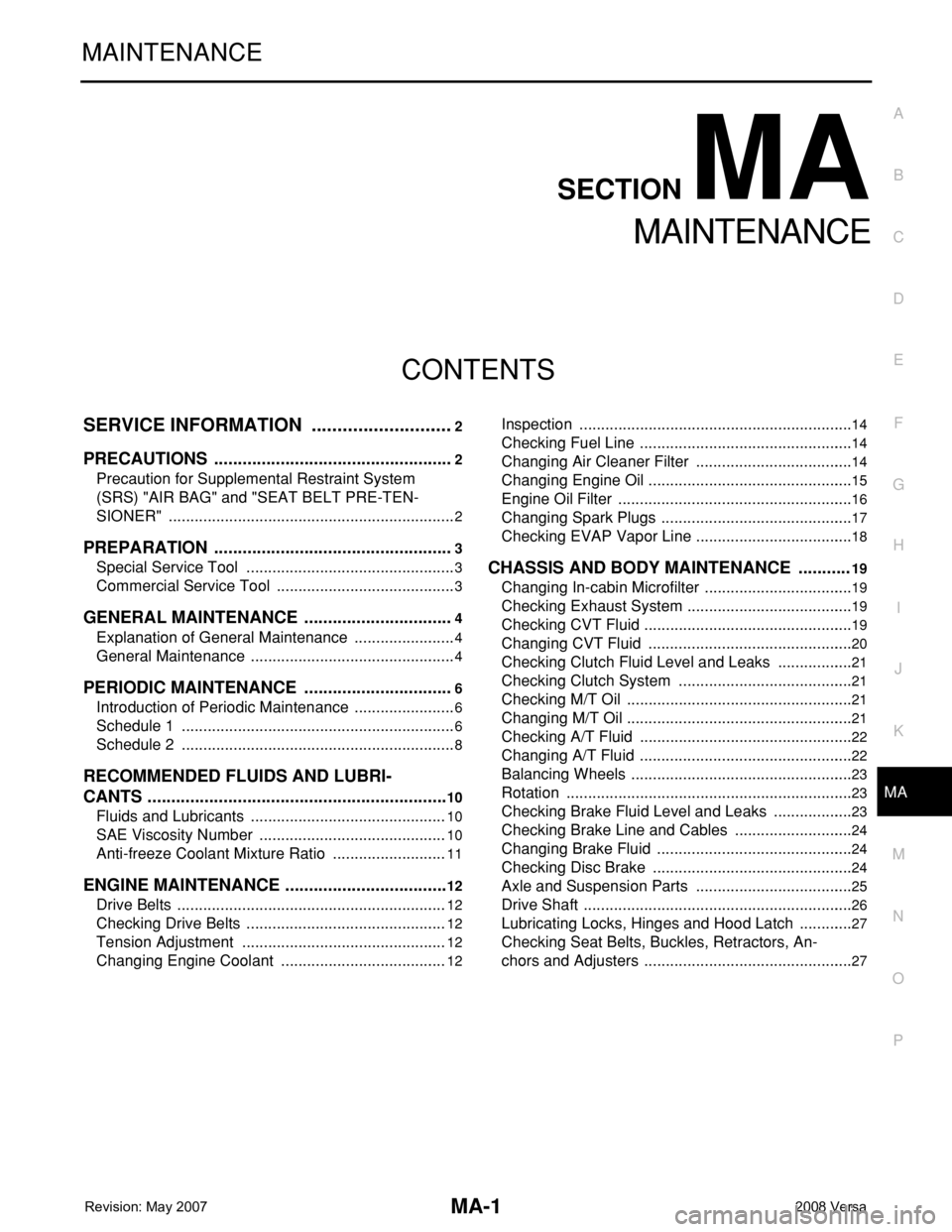

• Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precaution for Three Way CatalystINFOID:0000000001702425

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unleaded Regular Gasoline Recommended)INFOID:0000000001702426

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

PBIC0190E

SGI234

Page 2261 of 2771

MA-1

MAINTENANCE

C

D

E

F

G

H

I

J

K

M

SECTION MA

A

B

MA

N

O

P

CONTENTS

MAINTENANCE

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

GENERAL MAINTENANCE ................................4

Explanation of General Maintenance ........................4

General Maintenance ................................................4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance ........................6

Schedule 1 ................................................................6

Schedule 2 ................................................................8

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

10

Fluids and Lubricants ..............................................10

SAE Viscosity Number ............................................10

Anti-freeze Coolant Mixture Ratio ...........................11

ENGINE MAINTENANCE ...................................12

Drive Belts ...............................................................12

Checking Drive Belts ...............................................12

Tension Adjustment ................................................12

Changing Engine Coolant .......................................12

Inspection ................................................................14

Checking Fuel Line ..................................................14

Changing Air Cleaner Filter .....................................14

Changing Engine Oil ................................................15

Engine Oil Filter .......................................................16

Changing Spark Plugs .............................................17

Checking EVAP Vapor Line .....................................18

CHASSIS AND BODY MAINTENANCE ...........19

Changing In-cabin Microfilter ...................................19

Checking Exhaust System .......................................19

Checking CVT Fluid .................................................19

Changing CVT Fluid ................................................20

Checking Clutch Fluid Level and Leaks ..................21

Checking Clutch System .........................................21

Checking M/T Oil .....................................................21

Changing M/T Oil .....................................................21

Checking A/T Fluid ..................................................22

Changing A/T Fluid ..................................................22

Balancing Wheels ....................................................23

Rotation ...................................................................23

Checking Brake Fluid Level and Leaks ...................23

Checking Brake Line and Cables ............................24

Changing Brake Fluid ..............................................24

Checking Disc Brake ...............................................24

Axle and Suspension Parts .....................................25

Drive Shaft ...............................................................26

Lubricating Locks, Hinges and Hood Latch .............27

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters .................................................

27

Page 2267 of 2771

![NISSAN LATIO 2008 Service User Guide PERIODIC MAINTENANCE

MA-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After NISSAN LATIO 2008 Service User Guide PERIODIC MAINTENANCE

MA-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After](/img/5/57360/w960_57360-2266.png)

PERIODIC MAINTENANCE

MA-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, go to the FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

Chassis and Body Maintenance

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Section -

Page or - Content Title Perform at number of

miles, kilometers or

months, whichever

comes first.Miles x

1,000

(km x

1,000)

Months33.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

Drive beltNOTE

(1)I*MA-12

Air cleaner filterNOTE

(2)[R]MA-14

EVAP vapor linesI*MA-18

Fuel linesI*MA-14

Fuel filterNOTE

(3)—

Engine coolantNOTE

(4)R*MA-12

Engine oil R R R R R R R RMA-15

Engine oil filter (Use

genuine oil filter or

equivalent)R R R R RRRRMA-16

Spark plugs (Iridium/

platinum-tipped type)Replace every 105,000 miles (169,000 km)MA-17

Intake and exhaust

valve clearance NOTE

(5)EM-104

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of

miles, kilometers or

months, whichever

comes first.Miles x

1,000

(km x

1,000)

Months3.75

(6)

37.5

(12)

611 . 2 5

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

24

Brake lines & cables I IMA-24

Brake pads, rotors,

drums & liningsIIIIMA-24

Manual transaxle oil or

automatic transaxle

fluidNOTE (1) I IMA-19 , MA-

22 or MA-21

CVT fluid NOTE (2) I I

Steering gear & link-

age, axle & suspen-

sion partsIIIIMA-25

, PS-

12

Tire rotation NOTE (3)WT-6

Front drive shaft boots I I I IMA-26

Page 2269 of 2771

PERIODIC MAINTENANCE

MA-9

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

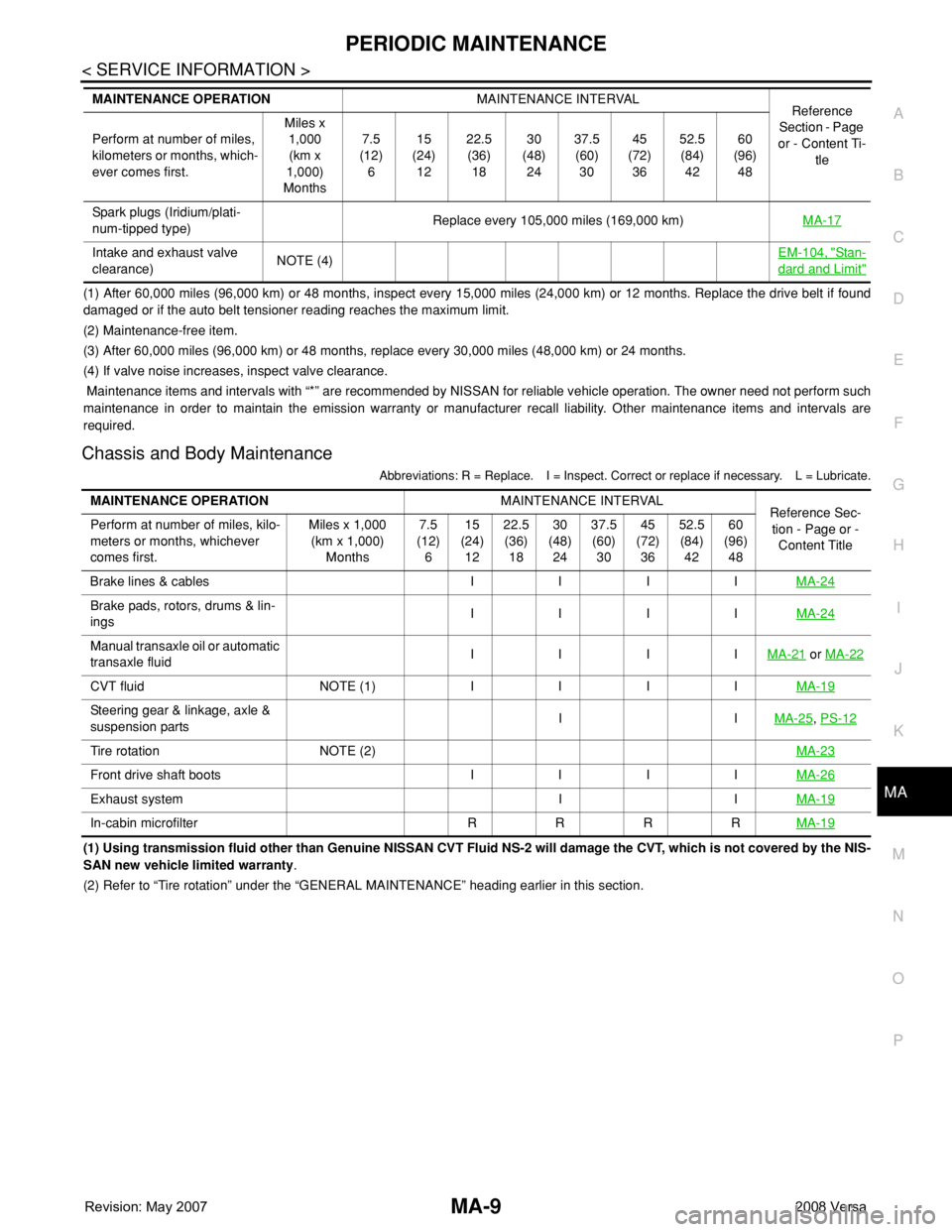

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belt if found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) Maintenance-free item.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform such

maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

Chassis and Body Maintenance

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate.

(1) Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the NIS-

SAN new vehicle limited warranty.

(2) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section. Spark plugs (Iridium/plati-

num-tipped type)Replace every 105,000 miles (169,000 km)MA-17

Intake and exhaust valve

clearance)NOTE (4)EM-104, "Sta n-

dard and Limit"

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section - Page

or - Content Ti-

tle Perform at number of miles,

kilometers or months, which-

ever comes first.Miles x

1,000

(km x

1,000)

Months7.5

(12)

615

(24)

1222.5

(36)

1830

(48)

2437.5

(60)

3045

(72)

3652.5

(84)

4260

(96)

48

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months7.5

(12)

615

(24)

1222.5

(36)

1830

(48)

2437.5

(60)

3045

(72)

3652.5

(84)

4260

(96)

48

Brake lines & cables I I I IMA-24

Brake pads, rotors, drums & lin-

ings IIIIMA-24

Manual transaxle oil or automatic

transaxle fluidIIIIMA-21 or MA-22

CVT fluid NOTE (1) IIIIMA-19

Steering gear & linkage, axle &

suspension partsIIMA-25, PS-12

Tire rotation NOTE (2)MA-23

Front drive shaft boots I I I IMA-26

Exhaust system I IMA-19

In-cabin microfilter R R R RMA-19

Page 2270 of 2771

MA-10

< SERVICE INFORMATION >

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

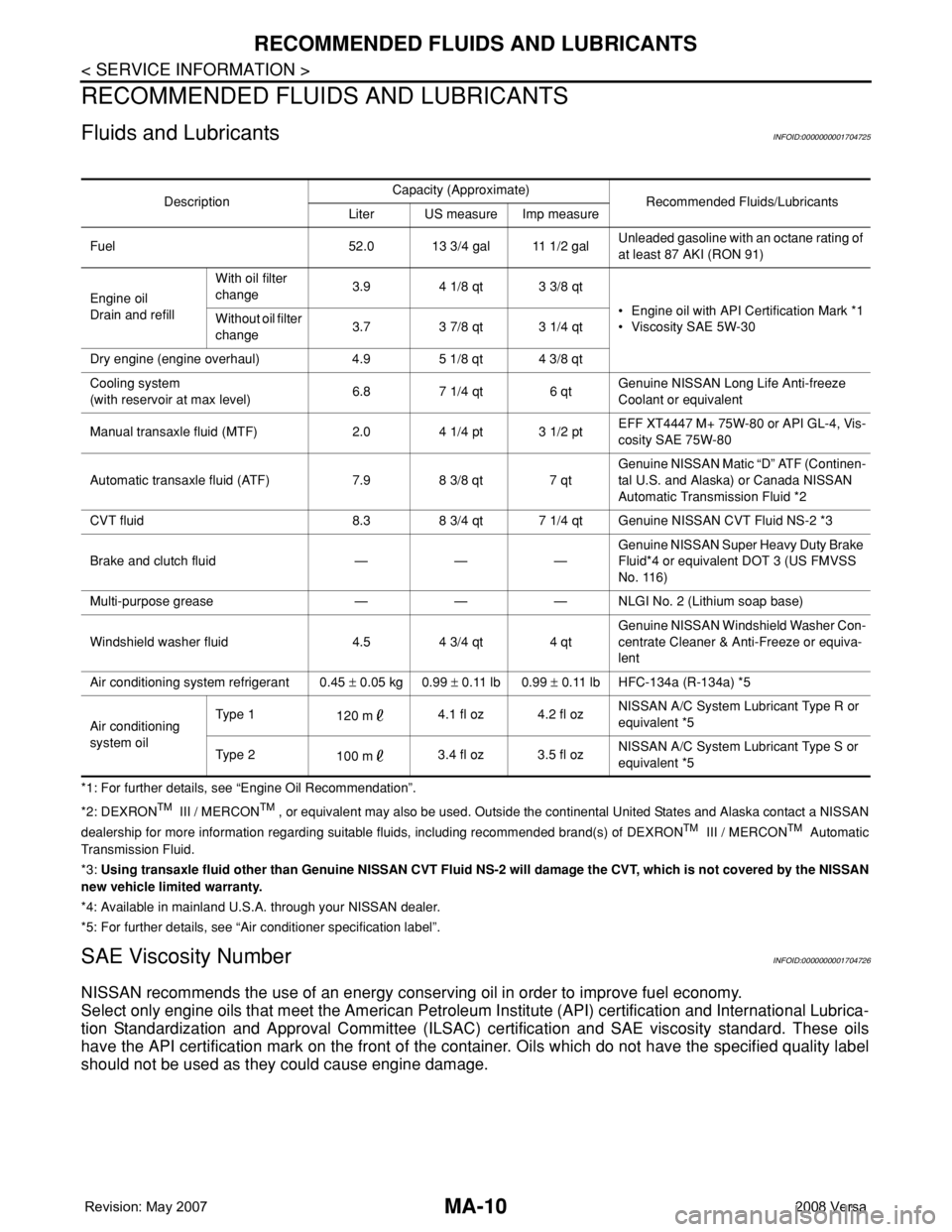

Fluids and LubricantsINFOID:0000000001704725

*1: For further details, see “Engine Oil Recommendation”.

*2: DEXRON

TM III / MERCONTM , or equivalent may also be used. Outside the continental United States and Alaska contact a NISSAN

dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTM III / MERCONTM Automatic

Transmission Fluid.

*3: Using transaxle fluid other than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the NISSAN

new vehicle limited warranty.

*4: Available in mainland U.S.A. through your NISSAN dealer.

*5: For further details, see “Air conditioner specification label”.

SAE Viscosity NumberINFOID:0000000001704726

NISSAN recommends the use of an energy conserving oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubrica-

tion Standardization and Approval Committee (ILSAC) certification and SAE viscosity standard. These oils

have the API certification mark on the front of the container. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

DescriptionCapacity (Approximate)

Recommended Fluids/Lubricants

Liter US measure Imp measure

Fuel 52.0 13 3/4 gal 11 1/2 galUnleaded gasoline with an octane rating of

at least 87 AKI (RON 91)

Engine oil

Drain and refillWith oil filter

change3.9 4 1/8 qt 3 3/8 qt

• Engine oil with API Certification Mark *1

• Viscosity SAE 5W-30 Without oil filter

change3.7 3 7/8 qt 3 1/4 qt

Dry engine (engine overhaul) 4.9 5 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level)6.8 7 1/4 qt 6 qtGenuine NISSAN Long Life Anti-freeze

Coolant or equivalent

Manual transaxle fluid (MTF) 2.0 4 1/4 pt 3 1/2 ptEFF XT4447 M+ 75W-80 or API GL-4, Vis-

cosity SAE 75W-80

Automatic transaxle fluid (ATF) 7.9 8 3/8 qt 7 qtGenuine NISSAN Matic “D” ATF (Continen-

tal U.S. and Alaska) or Canada NISSAN

Automatic Transmission Fluid *2

CVT fluid 8.3 8 3/4 qt 7 1/4 qt Genuine NISSAN CVT Fluid NS-2 *3

Brake and clutch fluid — — —Genuine NISSAN Super Heavy Duty Brake

Fluid*4 or equivalent DOT 3 (US FMVSS

No. 116)

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

Windshield washer fluid 4.5 4 3/4 qt 4 qtGenuine NISSAN Windshield Washer Con-

centrate Cleaner & Anti-Freeze or equiva-

lent

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb HFC-134a (R-134a) *5

Air conditioning

system oilTyp e 1

120 m4.1 fl oz 4.2 fl ozNISSAN A/C System Lubricant Type R or

equivalent *5

Typ e 2

100 m3.4 fl oz 3.5 fl ozNISSAN A/C System Lubricant Type S or

equivalent *5

Page 2275 of 2771

ENGINE MAINTENANCE

MA-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

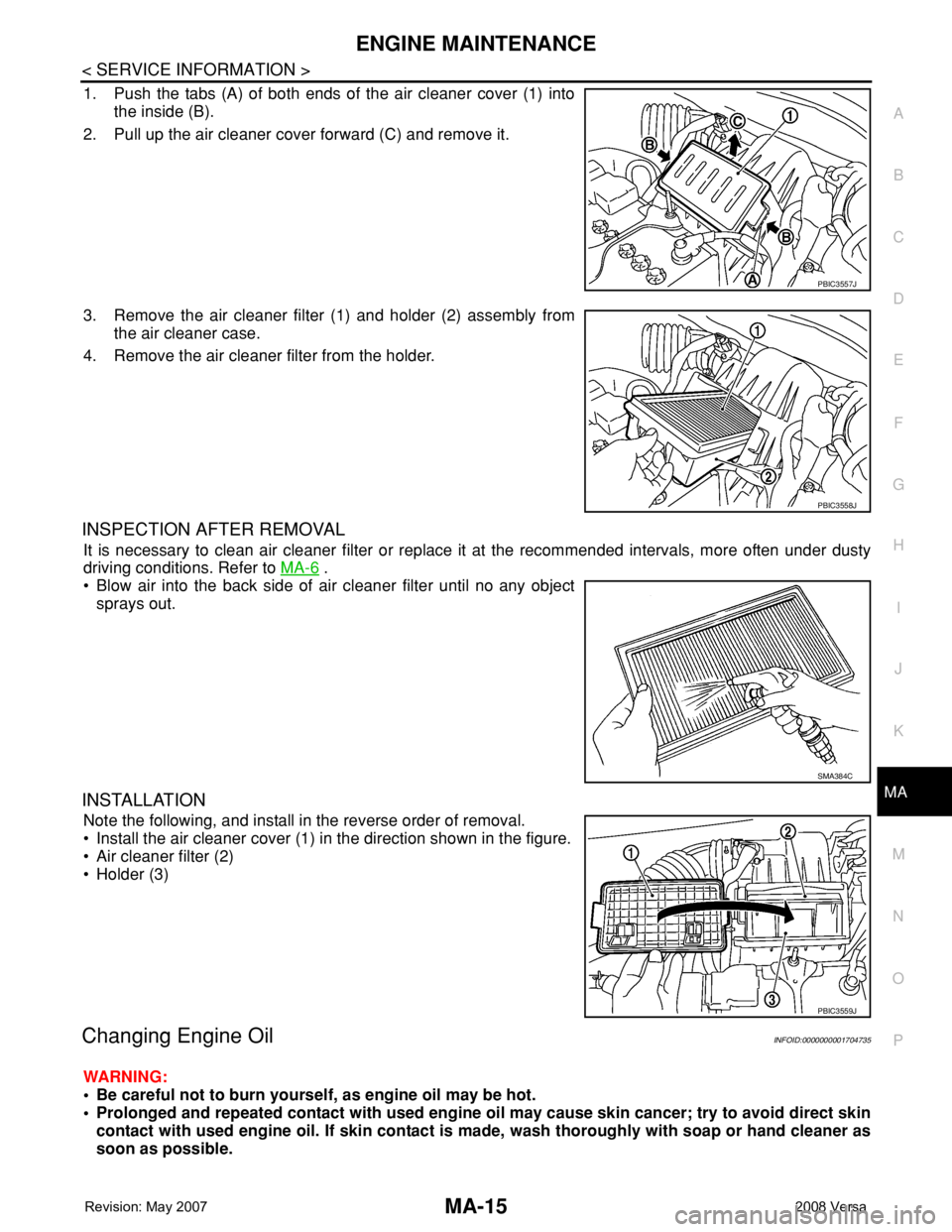

1. Push the tabs (A) of both ends of the air cleaner cover (1) into

the inside (B).

2. Pull up the air cleaner cover forward (C) and remove it.

3. Remove the air cleaner filter (1) and holder (2) assembly from

the air cleaner case.

4. Remove the air cleaner filter from the holder.

INSPECTION AFTER REMOVAL

It is necessary to clean air cleaner filter or replace it at the recommended intervals, more often under dusty

driving conditions. Refer to MA-6

.

• Blow air into the back side of air cleaner filter until no any object

sprays out.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Install the air cleaner cover (1) in the direction shown in the figure.

• Air cleaner filter (2)

• Holder (3)

Changing Engine OilINFOID:0000000001704735

WARNING:

• Be careful not to burn yourself, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

PBIC3557J

PBIC3558J

SMA384C

PBIC3559J