wheel torque NISSAN LATIO 2008 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 1852 of 2771

GI-1

GENERAL INFORMATION

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION GI

N

O

P

CONTENTS

GENERAL INFORMATION

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Description ................................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

2

General Precaution ...................................................3

Precaution for Three Way Catalyst ...........................4

Precaution for Fuel (Unleaded Regular Gasoline

Recommended) .........................................................

4

Precaution for Multiport Fuel Injection System or

Engine Control System .............................................

5

Precaution for Hoses .................................................5

Precaution for Engine Oils ........................................6

Precaution for Air Conditioning .................................6

HOW TO USE THIS MANUAL ............................7

Description ................................................................7

Terms ........................................................................7

Units ..........................................................................7

Contents ....................................................................7

Relation between Illustrations and Descriptions .......8

Component ................................................................8

How to Follow Trouble Diagnosis ..............................9

How to Read Wiring Diagram ..................................13

Abbreviations ..........................................................20

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ...........................................................

22

How to Check Terminal ...........................................22

How to Perform Efficient Diagnosis for an Electri-

cal Incident ..............................................................

25

Control Units and Electrical Parts ............................32

CONSULT-III CHECKING SYSTEM .................35

Description ...............................................................35

Function and System Application ............................35

CONSULT-III Data Link Connector (DLC) Circuit ....36

LIFTING POINT .................................................38

Special Service Tool ................................................38

Garage Jack and Safety Stand and 2-Pole Lift .......38

Board-On Lift ...........................................................39

TOW TRUCK TOWING .....................................40

Tow Truck Towing ...................................................40

Vehicle Recovery (Freeing a Stuck Vehicle) ...........40

TIGHTENING TORQUE OF STANDARD

BOLTS ...............................................................

41

Tightening Torque Table .........................................41

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ...............................................

42

Recommended Chemical Product and Sealant .......42

IDENTIFICATION INFORMATION ....................43

Model Variation ........................................................43

Dimensions ..............................................................46

Wheels & Tires ........................................................46

TERMINOLOGY ................................................47

SAE J1930 Terminology List ...................................47

Page 2283 of 2771

CHASSIS AND BODY MAINTENANCE

MA-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Reinstall the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran-

saxle with the same volume of A/T fluid that was drained out.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to MA-22, "

Checking A/T Fluid" .

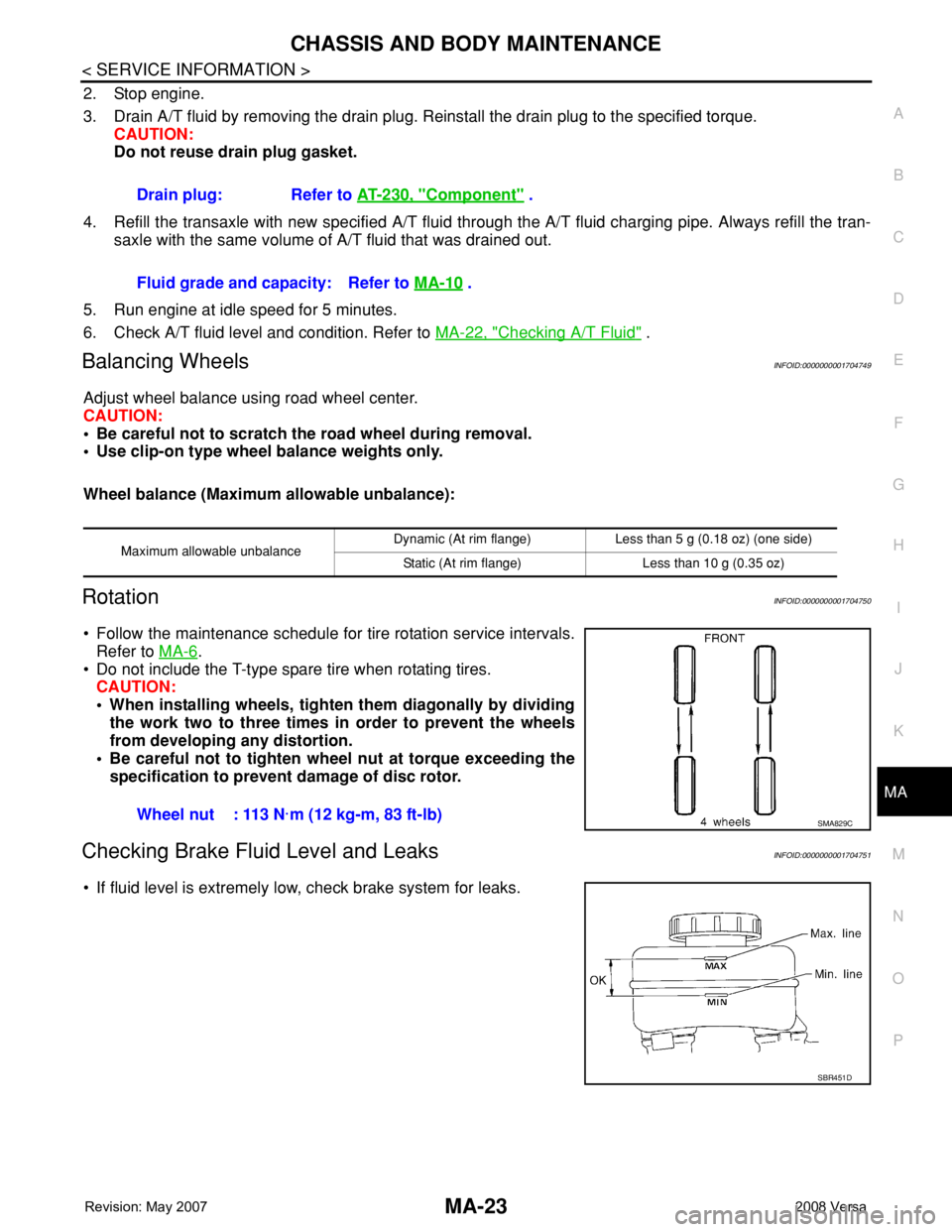

Balancing WheelsINFOID:0000000001704749

Adjust wheel balance using road wheel center.

CAUTION:

• Be careful not to scratch the road wheel during removal.

• Use clip-on type wheel balance weights only.

Wheel balance (Maximum allowable unbalance):

RotationINFOID:0000000001704750

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-6

.

• Do not include the T-type spare tire when rotating tires.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the

specification to prevent damage of disc rotor.

Checking Brake Fluid Level and LeaksINFOID:0000000001704751

• If fluid level is extremely low, check brake system for leaks.Drain plug: Refer to AT-230, "

Component" .

Fluid grade and capacity: Refer to MA-10

.

Maximum allowable unbalanceDynamic (At rim flange) Less than 5 g (0.18 oz) (one side)

Static (At rim flange) Less than 10 g (0.35 oz)

Wheel nut : 113 N·m (12 kg-m, 83 ft-lb)SMA829C

SBR451D

Page 2510 of 2771

PS-4

< SERVICE INFORMATION >

PREPARATION

PREPARATION

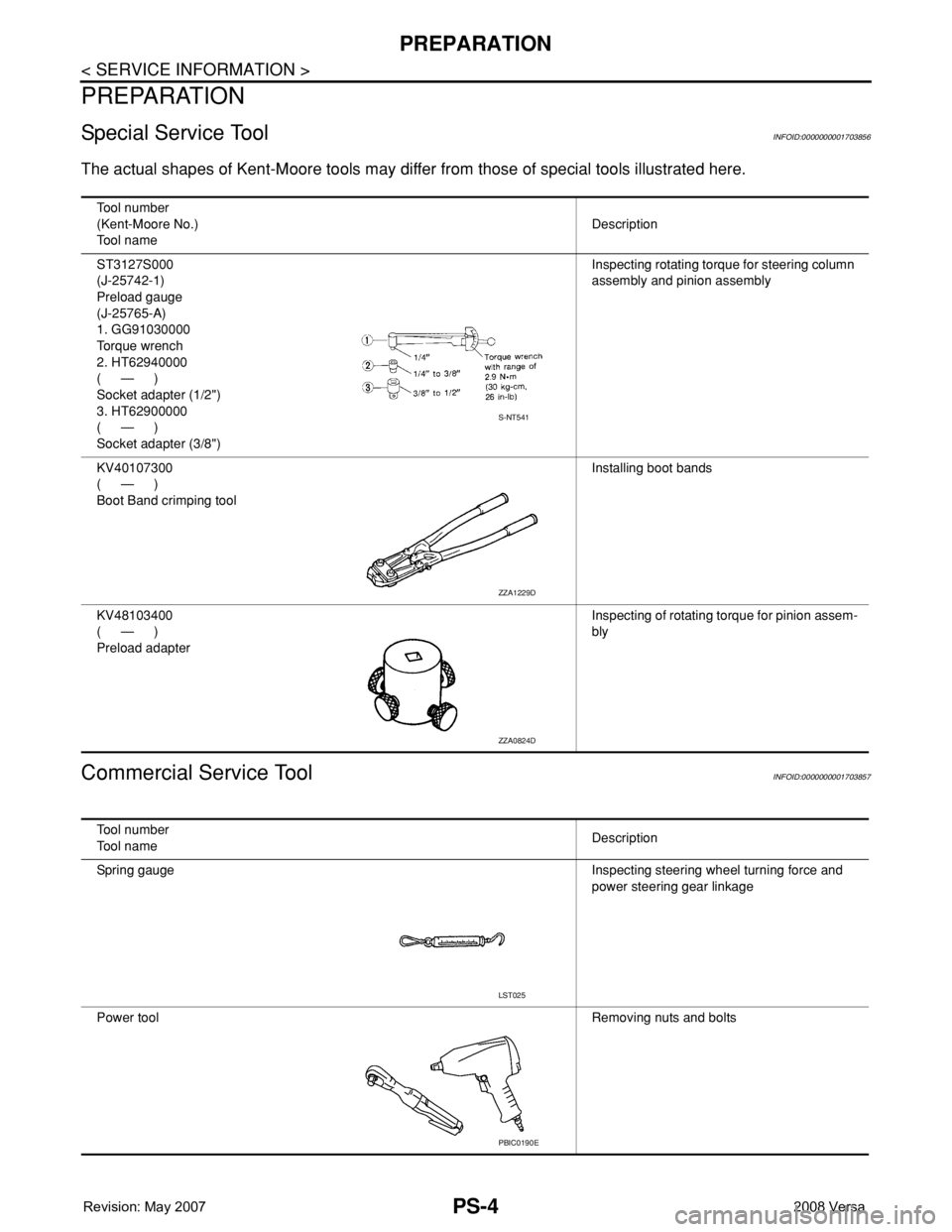

Special Service ToolINFOID:0000000001703856

The actual shapes of Kent-Moore tools may differ from those of special tools illustrated here.

Commercial Service ToolINFOID:0000000001703857

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(J-25742-1)

Preload gauge

(J-25765-A)

1. GG91030000

Torque wrench

2. HT62940000

(—)

Socket adapter (1/2")

3. HT62900000

(—)

Socket adapter (3/8")Inspecting rotating torque for steering column

assembly and pinion assembly

KV40107300

(—)

Boot Band crimping toolInstalling boot bands

KV48103400

(—)

Preload adapterInspecting of rotating torque for pinion assem-

bly

S-NT541

ZZA1229D

ZZA0824D

Tool number

Tool nameDescription

Spring gauge Inspecting steering wheel turning force and

power steering gear linkage

Power toolRemoving nuts and bolts

LST025

PBIC0190E

Page 2511 of 2771

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PS-5

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

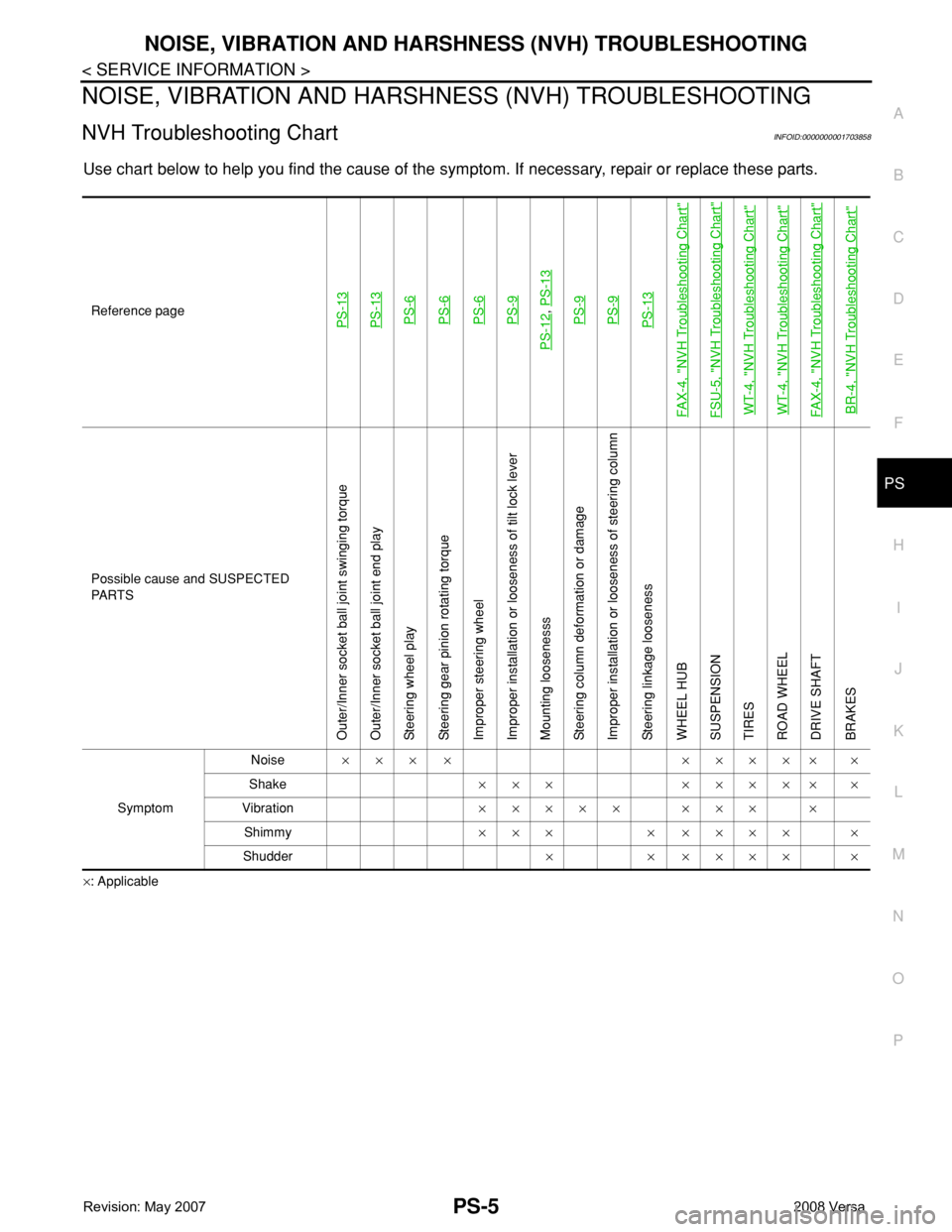

NVH Troubleshooting ChartINFOID:0000000001703858

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

PS-13PS-13PS-6PS-6PS-6PS-9

PS-12

, PS-13PS-9PS-9PS-13

FAX-4, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

BR-4, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED

PA R T S

Outer/Inner socket ball joint swinging torque

Outer/Inner socket ball joint end play

Steering wheel play

Steering gear pinion rotating torque

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting loosenesss

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

SymptomNoise××× × ××××× ×

Shake××× ××××× ×

Vibration××××× ××× ×

Shimmy××× × ×××× ×

Shudder× × ×××× ×

Page 2516 of 2771

PS-10

< SERVICE INFORMATION >

STEERING COLUMN

8. Remove bolt of intermediate shaft (upper side), and then remove intermediate shaft from steering column

assembly.

9. Remove steering column assembly mounting nuts, and then remove steering column assembly from vehi-

cle.

10. Remove bolt of intermediate shaft (lower side), and then remove intermediate shaft from vehicle.

11. Remove screws of bracket and EPS control unit, and then remove bracket and EPS control unit from

steering column assembly.

INSPECTION AFTER REMOVAL

• Check each part of steering column assembly, EPS control unit and intermediate shaft for damage and .

replace as necessary.

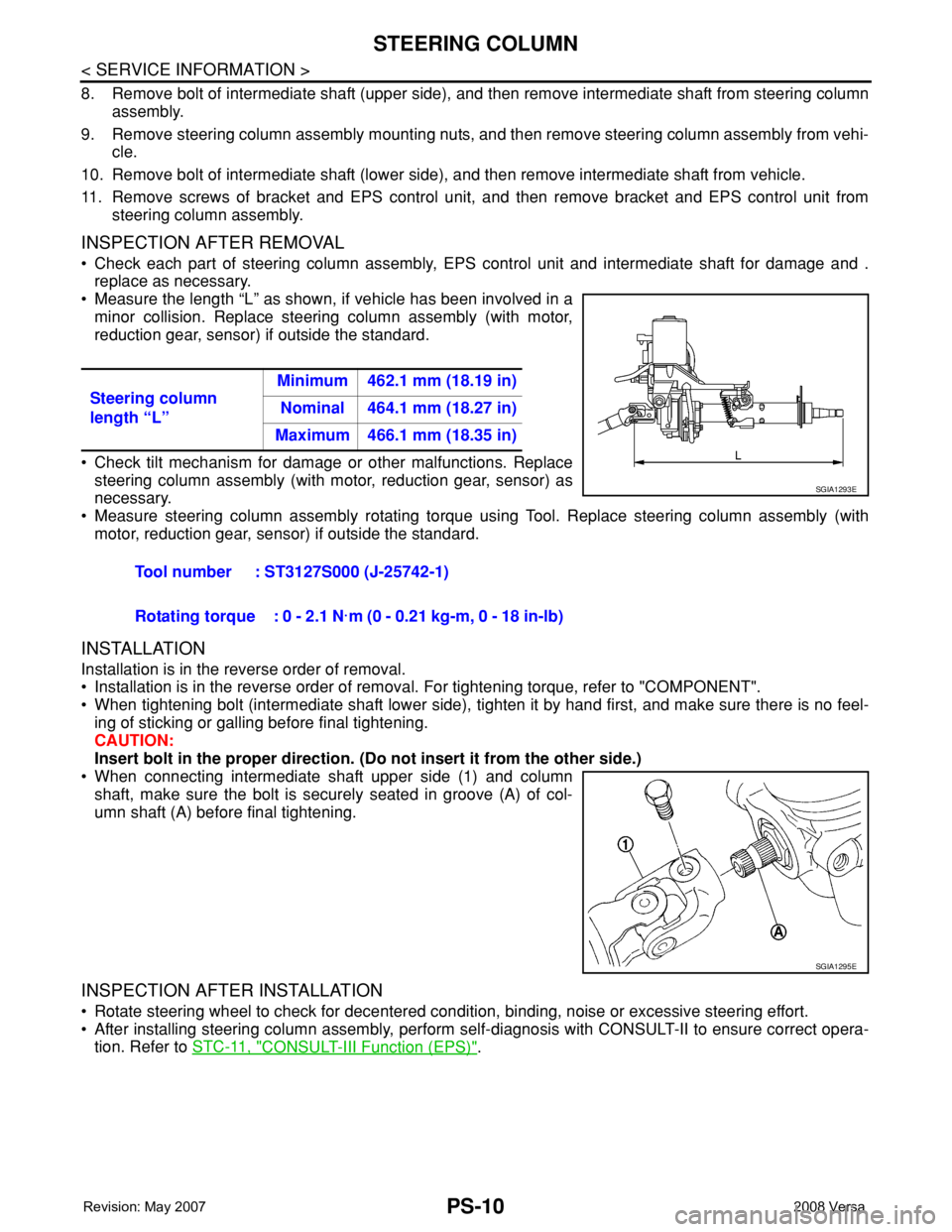

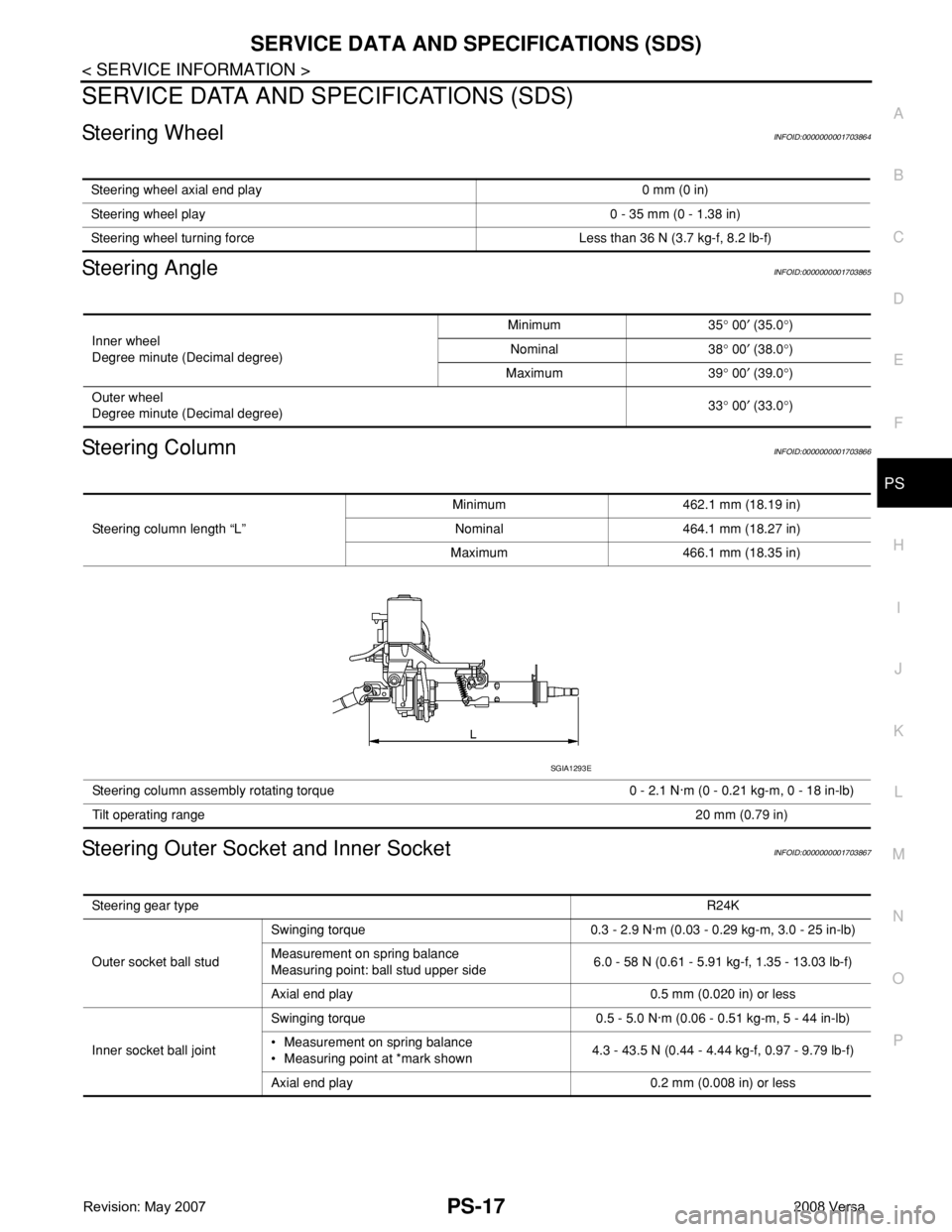

• Measure the length “L” as shown, if vehicle has been involved in a

minor collision. Replace steering column assembly (with motor,

reduction gear, sensor) if outside the standard.

• Check tilt mechanism for damage or other malfunctions. Replace

steering column assembly (with motor, reduction gear, sensor) as

necessary.

• Measure steering column assembly rotating torque using Tool. Replace steering column assembly (with

motor, reduction gear, sensor) if outside the standard.

INSTALLATION

Installation is in the reverse order of removal.

• Installation is in the reverse order of removal. For tightening torque, refer to "COMPONENT".

• When tightening bolt (intermediate shaft lower side), tighten it by hand first, and make sure there is no feel-

ing of sticking or galling before final tightening.

CAUTION:

Insert bolt in the proper direction. (Do not insert it from the other side.)

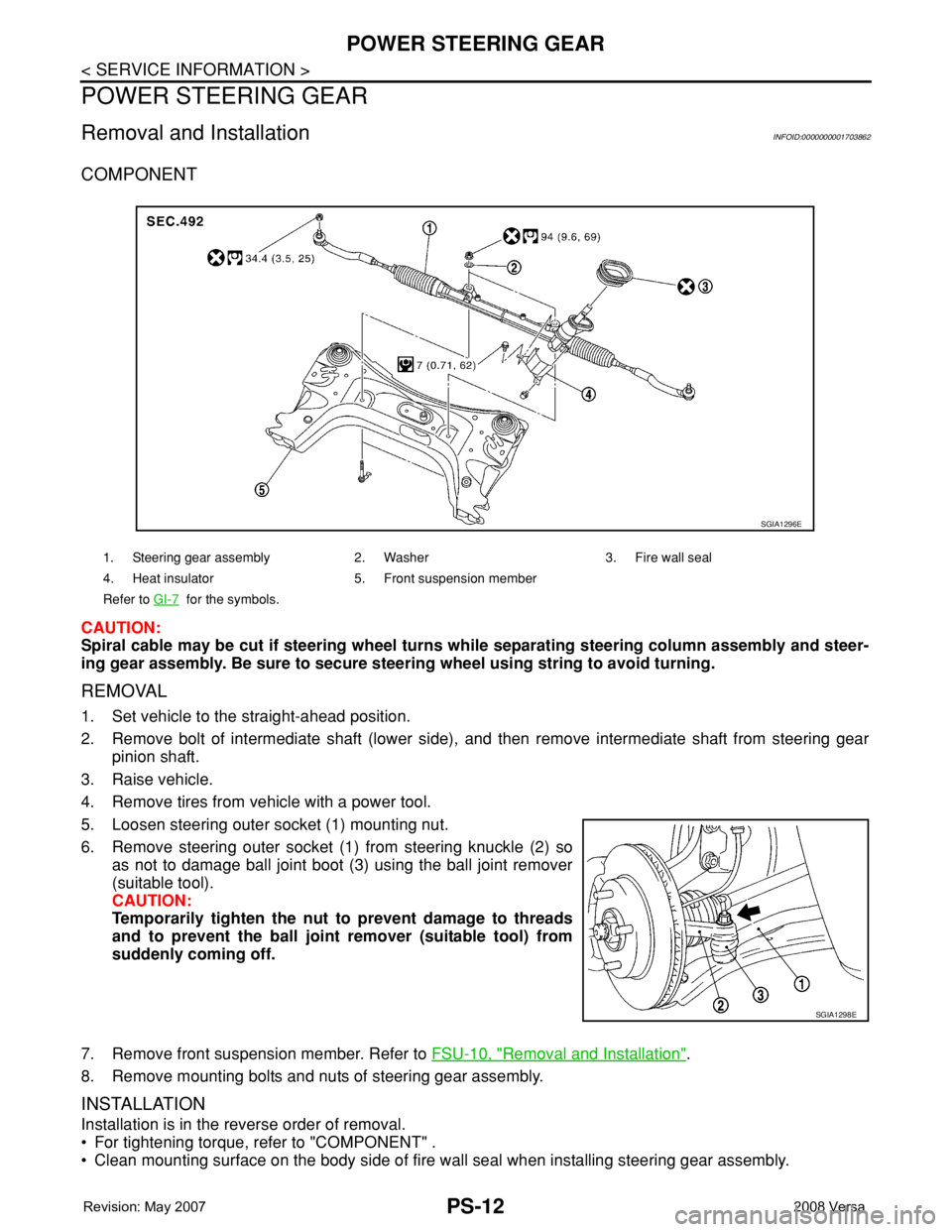

• When connecting intermediate shaft upper side (1) and column

shaft, make sure the bolt is securely seated in groove (A) of col-

umn shaft (A) before final tightening.

INSPECTION AFTER INSTALLATION

• Rotate steering wheel to check for decentered condition, binding, noise or excessive steering effort.

• After installing steering column assembly, perform self-diagnosis with CONSULT-II to ensure correct opera-

tion. Refer to STC-11, "

CONSULT-III Function (EPS)". Steering column

length “L”Minimum 462.1 mm (18.19 in)

Nominal 464.1 mm (18.27 in)

Maximum 466.1 mm (18.35 in)

Tool number : ST3127S000 (J-25742-1)

Rotating torque : 0 - 2.1 N·m (0 - 0.21 kg-m, 0 - 18 in-lb)

SGIA1293E

SGIA1295E

Page 2518 of 2771

PS-12

< SERVICE INFORMATION >

POWER STEERING GEAR

POWER STEERING GEAR

Removal and InstallationINFOID:0000000001703862

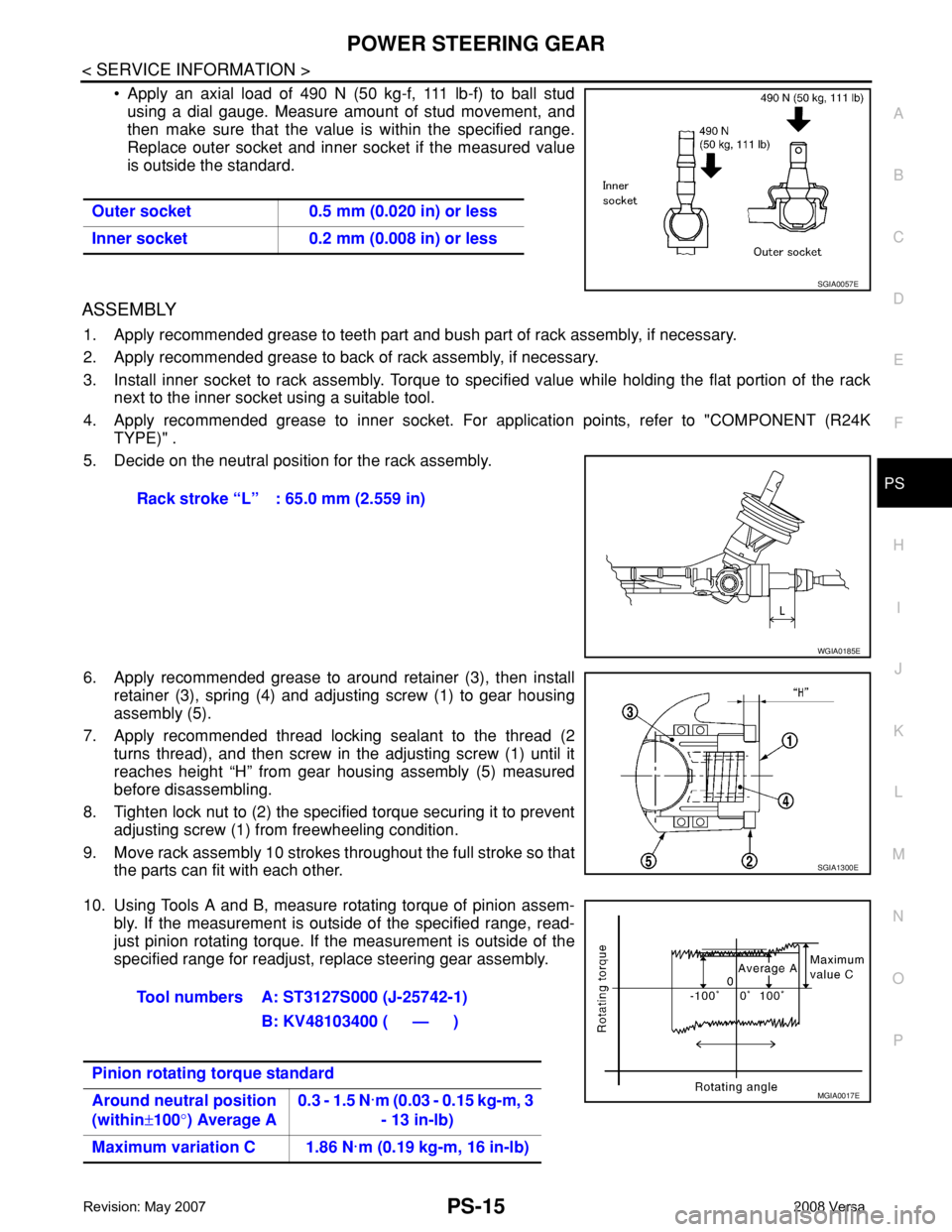

COMPONENT

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using string to avoid turning.

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove bolt of intermediate shaft (lower side), and then remove intermediate shaft from steering gear

pinion shaft.

3. Raise vehicle.

4. Remove tires from vehicle with a power tool.

5. Loosen steering outer socket (1) mounting nut.

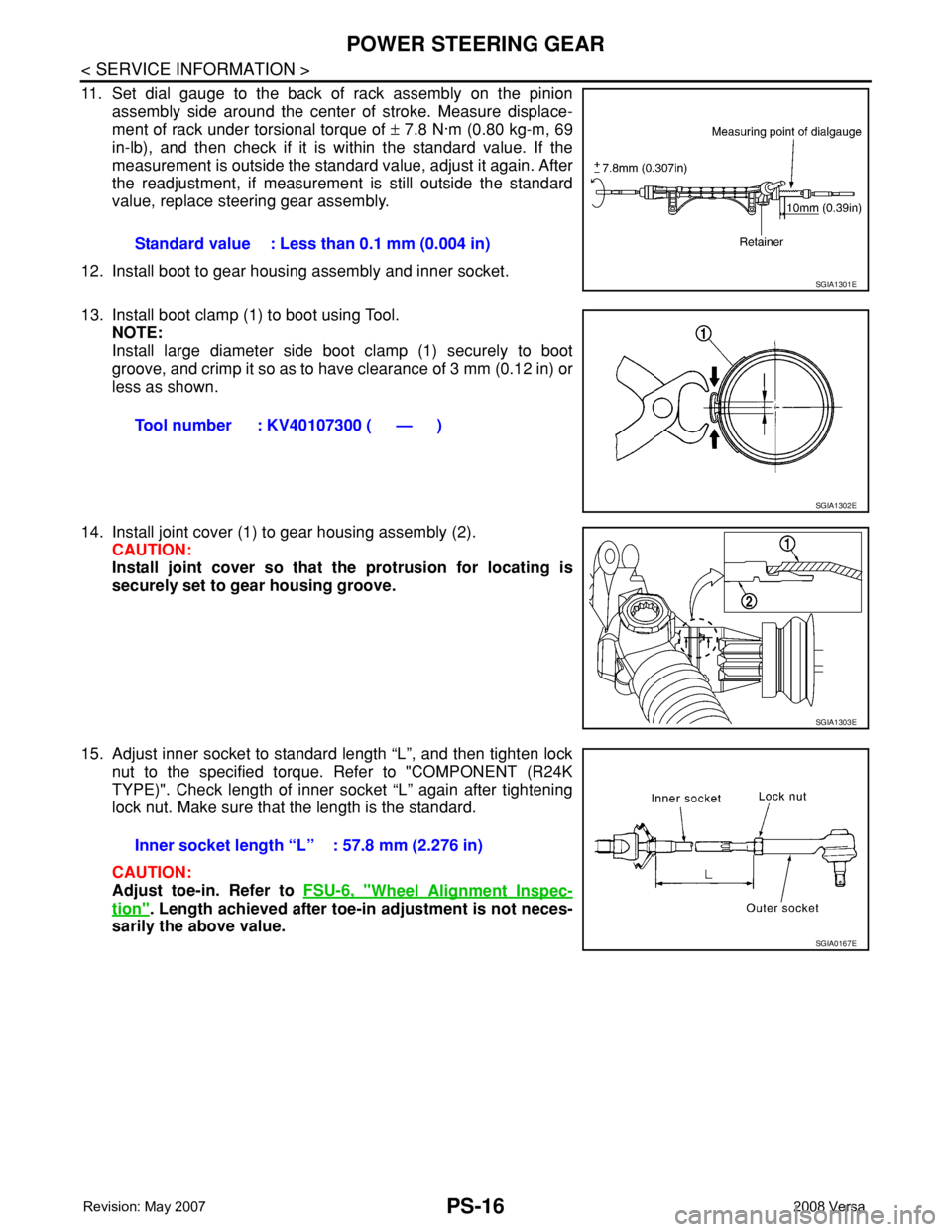

6. Remove steering outer socket (1) from steering knuckle (2) so

as not to damage ball joint boot (3) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

7. Remove front suspension member. Refer to FSU-10, "

Removal and Installation".

8. Remove mounting bolts and nuts of steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to "COMPONENT" .

• Clean mounting surface on the body side of fire wall seal when installing steering gear assembly.

1. Steering gear assembly 2. Washer 3. Fire wall seal

4. Heat insulator 5. Front suspension member

Refer to GI-7

for the symbols.

SGIA1296E

SGIA1298E

Page 2521 of 2771

POWER STEERING GEAR

PS-15

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

• Apply an axial load of 490 N (50 kg-f, 111 lb-f) to ball stud

using a dial gauge. Measure amount of stud movement, and

then make sure that the value is within the specified range.

Replace outer socket and inner socket if the measured value

is outside the standard.

ASSEMBLY

1. Apply recommended grease to teeth part and bush part of rack assembly, if necessary.

2. Apply recommended grease to back of rack assembly, if necessary.

3. Install inner socket to rack assembly. Torque to specified value while holding the flat portion of the rack

next to the inner socket using a suitable tool.

4. Apply recommended grease to inner socket. For application points, refer to "COMPONENT (R24K

TYPE)" .

5. Decide on the neutral position for the rack assembly.

6. Apply recommended grease to around retainer (3), then install

retainer (3), spring (4) and adjusting screw (1) to gear housing

assembly (5).

7. Apply recommended thread locking sealant to the thread (2

turns thread), and then screw in the adjusting screw (1) until it

reaches height “H” from gear housing assembly (5) measured

before disassembling.

8. Tighten lock nut to (2) the specified torque securing it to prevent

adjusting screw (1) from freewheeling condition.

9. Move rack assembly 10 strokes throughout the full stroke so that

the parts can fit with each other.

10. Using Tools A and B, measure rotating torque of pinion assem-

bly. If the measurement is outside of the specified range, read-

just pinion rotating torque. If the measurement is outside of the

specified range for readjust, replace steering gear assembly. Outer socket 0.5 mm (0.020 in) or less

Inner socket 0.2 mm (0.008 in) or less

SGIA0057E

Rack stroke “L” : 65.0 mm (2.559 in)

WGIA0185E

SGIA1300E

Tool numbers A: ST3127S000 (J-25742-1)

B: KV48103400 ( — )

Pinion rotating torque standard

Around neutral position

(within±100°) Average A0.3 - 1.5 N·m (0.03 - 0.15 kg-m, 3

- 13 in-lb)

Maximum variation C 1.86 N·m (0.19 kg-m, 16 in-lb)

MGIA0017E

Page 2522 of 2771

PS-16

< SERVICE INFORMATION >

POWER STEERING GEAR

11. Set dial gauge to the back of rack assembly on the pinion

assembly side around the center of stroke. Measure displace-

ment of rack under torsional torque of ± 7.8 N·m (0.80 kg-m, 69

in-lb), and then check if it is within the standard value. If the

measurement is outside the standard value, adjust it again. After

the readjustment, if measurement is still outside the standard

value, replace steering gear assembly.

12. Install boot to gear housing assembly and inner socket.

13. Install boot clamp (1) to boot using Tool.

NOTE:

Install large diameter side boot clamp (1) securely to boot

groove, and crimp it so as to have clearance of 3 mm (0.12 in) or

less as shown.

14. Install joint cover (1) to gear housing assembly (2).

CAUTION:

Install joint cover so that the protrusion for locating is

securely set to gear housing groove.

15. Adjust inner socket to standard length “L”, and then tighten lock

nut to the specified torque. Refer to "COMPONENT (R24K

TYPE)". Check length of inner socket “L” again after tightening

lock nut. Make sure that the length is the standard.

CAUTION:

Adjust toe-in. Refer to FSU-6, "

Wheel Alignment Inspec-

tion". Length achieved after toe-in adjustment is not neces-

sarily the above value.Standard value : Less than 0.1 mm (0.004 in)

SGIA1301E

Tool number : KV40107300 ( — )

SGIA1302E

SGIA1303E

Inner socket length “L” : 57.8 mm (2.276 in)

SGIA0167E

Page 2523 of 2771

SERVICE DATA AND SPECIFICATIONS (SDS)

PS-17

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering WheelINFOID:0000000001703864

Steering AngleINFOID:0000000001703865

Steering ColumnINFOID:0000000001703866

Steering Outer Socket and Inner SocketINFOID:0000000001703867

Steering wheel axial end play 0 mm (0 in)

Steering wheel play 0 - 35 mm (0 - 1.38 in)

Steering wheel turning force Less than 36 N (3.7 kg-f, 8.2 lb-f)

Inner wheel

Degree minute (Decimal degree)Minimum 35° 00′ (35.0°)

Nominal 38° 00′ (38.0°)

Maximum 39° 00′ (39.0°)

Outer wheel

Degree minute (Decimal degree)33° 00′ (33.0°)

Steering column length “L”Minimum 462.1 mm (18.19 in)

Nominal 464.1 mm (18.27 in)

Maximum 466.1 mm (18.35 in)

Steering column assembly rotating torque 0 - 2.1 N·m (0 - 0.21 kg-m, 0 - 18 in-lb)

Tilt operating range20 mm (0.79 in)

SGIA1293E

Steering gear typeR24K

Outer socket ball studSwinging torque 0.3 - 2.9 N·m (0.03 - 0.29 kg-m, 3.0 - 25 in-lb)

Measurement on spring balance

Measuring point: ball stud upper side6.0 - 58 N (0.61 - 5.91 kg-f, 1.35 - 13.03 lb-f)

Axial end play 0.5 mm (0.020 in) or less

Inner socket ball jointSwinging torque 0.5 - 5.0 N·m (0.06 - 0.51 kg-m, 5 - 44 in-lb)

• Measurement on spring balance

• Measuring point at *mark shown4.3 - 43.5 N (0.44 - 4.44 kg-f, 0.97 - 9.79 lb-f)

Axial end play 0.2 mm (0.008 in) or less

Page 2567 of 2771

RSU-8

< SERVICE INFORMATION >

SHOCK ABSORBER

SHOCK ABSORBER

Removal and InstallationINFOID:0000000001703739

REMOVAL

1. Remove rear tires from vehicle using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly and rear suspension beam. Refer to BRC-

32 .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove shock absorber mask from trunk side finisher using a flat-bladed screwdriver. Refer to EI-51

.

CAUTION:

Wrap the tip of a screwdriver with cloth to avoid damaging components.

4. Set jack under rear suspension beam.

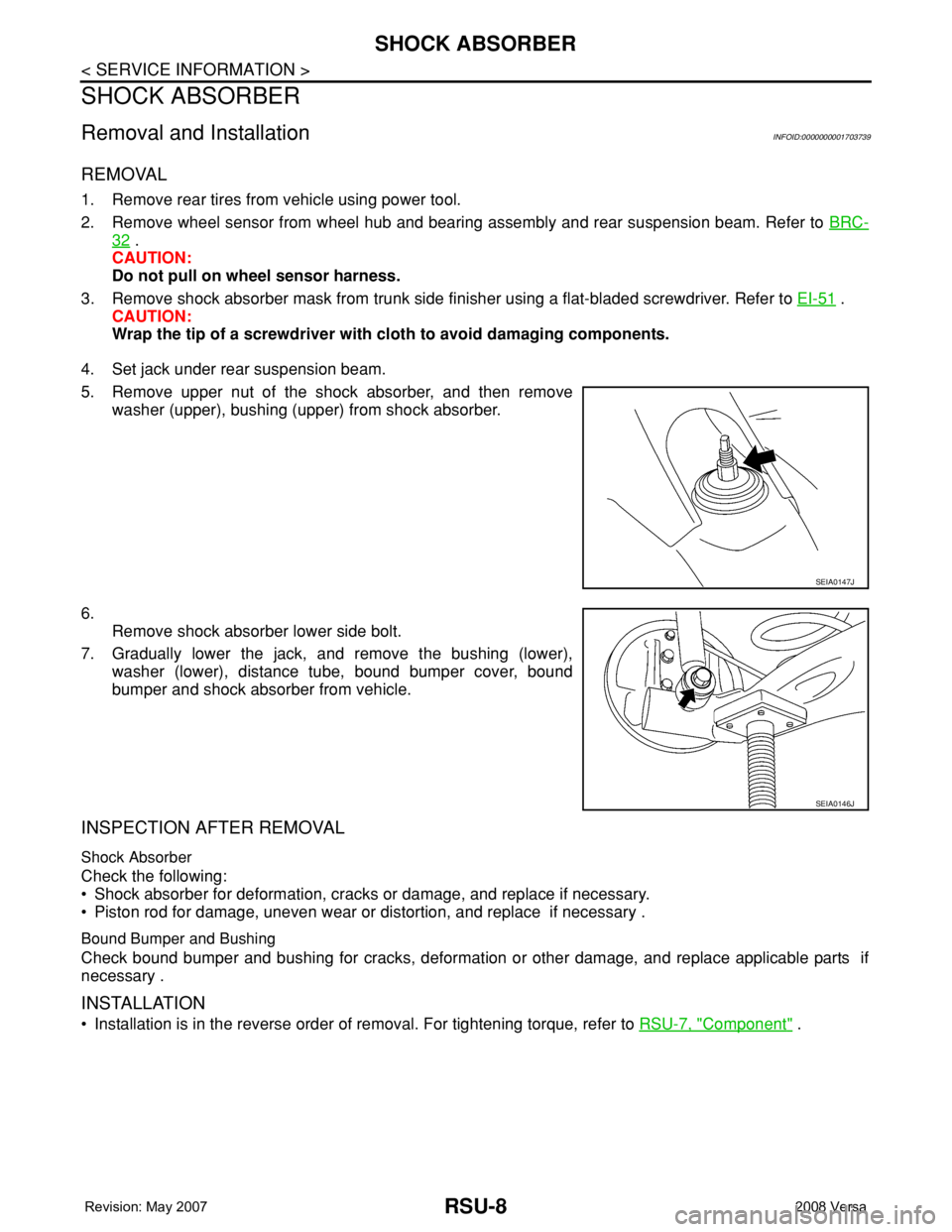

5. Remove upper nut of the shock absorber, and then remove

washer (upper), bushing (upper) from shock absorber.

6.

Remove shock absorber lower side bolt.

7. Gradually lower the jack, and remove the bushing (lower),

washer (lower), distance tube, bound bumper cover, bound

bumper and shock absorber from vehicle.

INSPECTION AFTER REMOVAL

Shock Absorber

Check the following:

• Shock absorber for deformation, cracks or damage, and replace if necessary.

• Piston rod for damage, uneven wear or distortion, and replace if necessary .

Bound Bumper and Bushing

Check bound bumper and bushing for cracks, deformation or other damage, and replace applicable parts if

necessary .

INSTALLATION

• Installation is in the reverse order of removal. For tightening torque, refer to RSU-7, "Component" .

SEIA0147J

SEIA0146J