clock NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 34 of 2771

AT-22

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

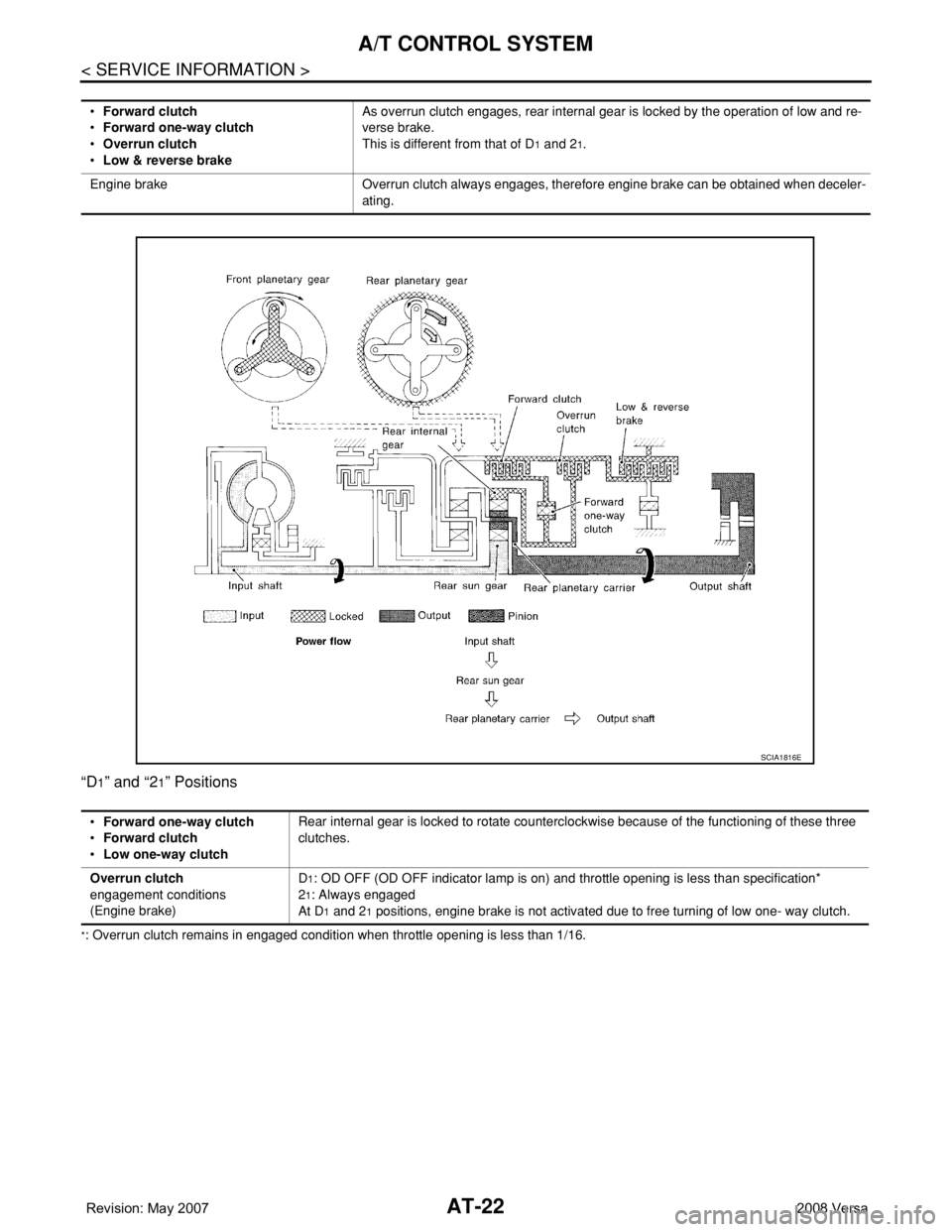

“D1” and “21” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.•Forward clutch

•Forward one-way clutch

•Overrun clutch

•Low & reverse brakeAs overrun clutch engages, rear internal gear is locked by the operation of low and re-

verse brake.

This is different from that of D

1 and 21.

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when deceler-

ating.

SCIA1816E

•Forward one-way clutch

•Forward clutch

•Low one-way clutchRear internal gear is locked to rotate counterclockwise because of the functioning of these three

clutches.

Overrun clutch

engagement conditions

(Engine brake)D

1: OD OFF (OD OFF indicator lamp is on) and throttle opening is less than specification*

2

1: Always engaged

At D

1 and 21 positions, engine brake is not activated due to free turning of low one- way clutch.

Page 239 of 2771

TRANSAXLE ASSEMBLY

AT-227

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

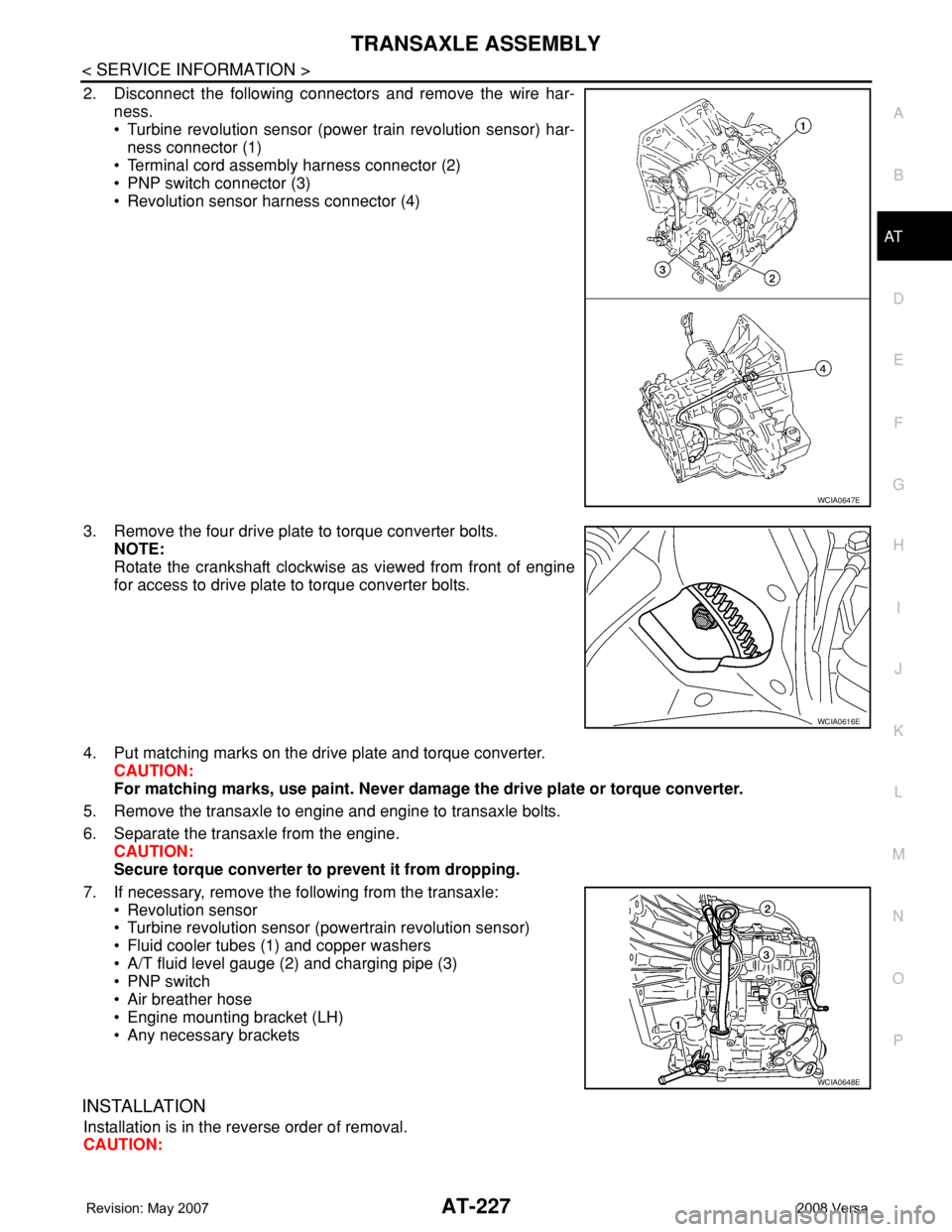

2. Disconnect the following connectors and remove the wire har-

ness.

• Turbine revolution sensor (power train revolution sensor) har-

ness connector (1)

• Terminal cord assembly harness connector (2)

• PNP switch connector (3)

• Revolution sensor harness connector (4)

3. Remove the four drive plate to torque converter bolts.

NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter bolts.

4. Put matching marks on the drive plate and torque converter.

CAUTION:

For matching marks, use paint. Never damage the drive plate or torque converter.

5. Remove the transaxle to engine and engine to transaxle bolts.

6. Separate the transaxle from the engine.

CAUTION:

Secure torque converter to prevent it from dropping.

7. If necessary, remove the following from the transaxle:

• Revolution sensor

• Turbine revolution sensor (powertrain revolution sensor)

• Fluid cooler tubes (1) and copper washers

• A/T fluid level gauge (2) and charging pipe (3)

• PNP switch

• Air breather hose

• Engine mounting bracket (LH)

• Any necessary brackets

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

WCIA0647E

WCIA0616E

WCIA0648E

Page 240 of 2771

AT-228

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

• When replacing an engine or transmission you must make sure any dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings and copper washers. Refer to "COMPONENTS".

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the bolts for the torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-37

.

• After converter is installed to drive plate, rotate crankshaft several turns to check that transaxle

rotates freely without binding.

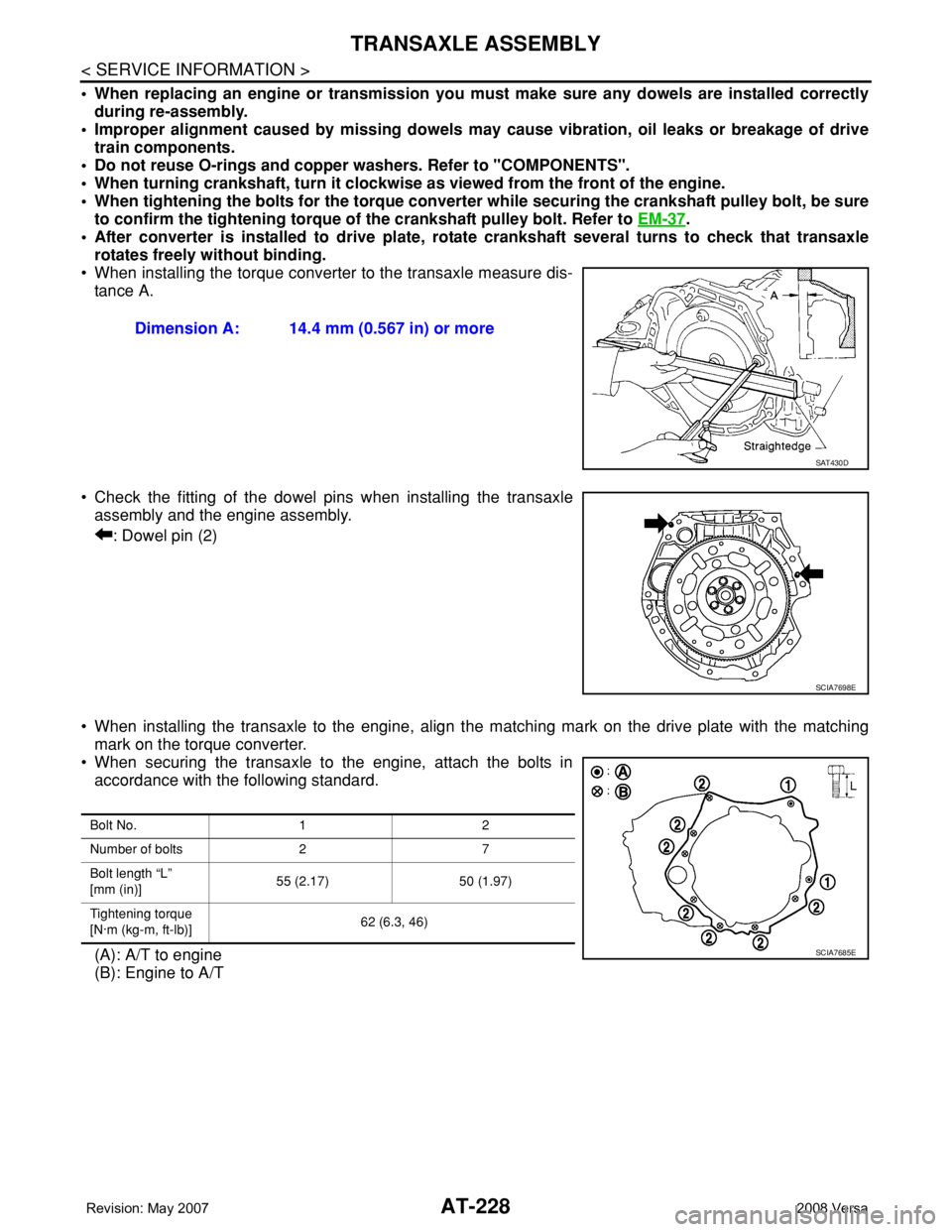

• When installing the torque converter to the transaxle measure dis-

tance A.

• Check the fitting of the dowel pins when installing the transaxle

assembly and the engine assembly.

: Dowel pin (2)

• When installing the transaxle to the engine, align the matching mark on the drive plate with the matching

mark on the torque converter.

• When securing the transaxle to the engine, attach the bolts in

accordance with the following standard.

(A): A/T to engine

(B): Engine to A/TDimension A: 14.4 mm (0.567 in) or more

SAT430D

SCIA7698E

Bolt No. 1 2

Number of bolts 2 7

Bolt length “L”

[mm (in)]55 (2.17) 50 (1.97)

Tightening torque

[N·m (kg-m, ft-lb)]62 (6.3, 46)

SCIA7685E

Page 252 of 2771

AT-240

< SERVICE INFORMATION >

DISASSEMBLY

DISASSEMBLY

DisassemblyINFOID:0000000001703377

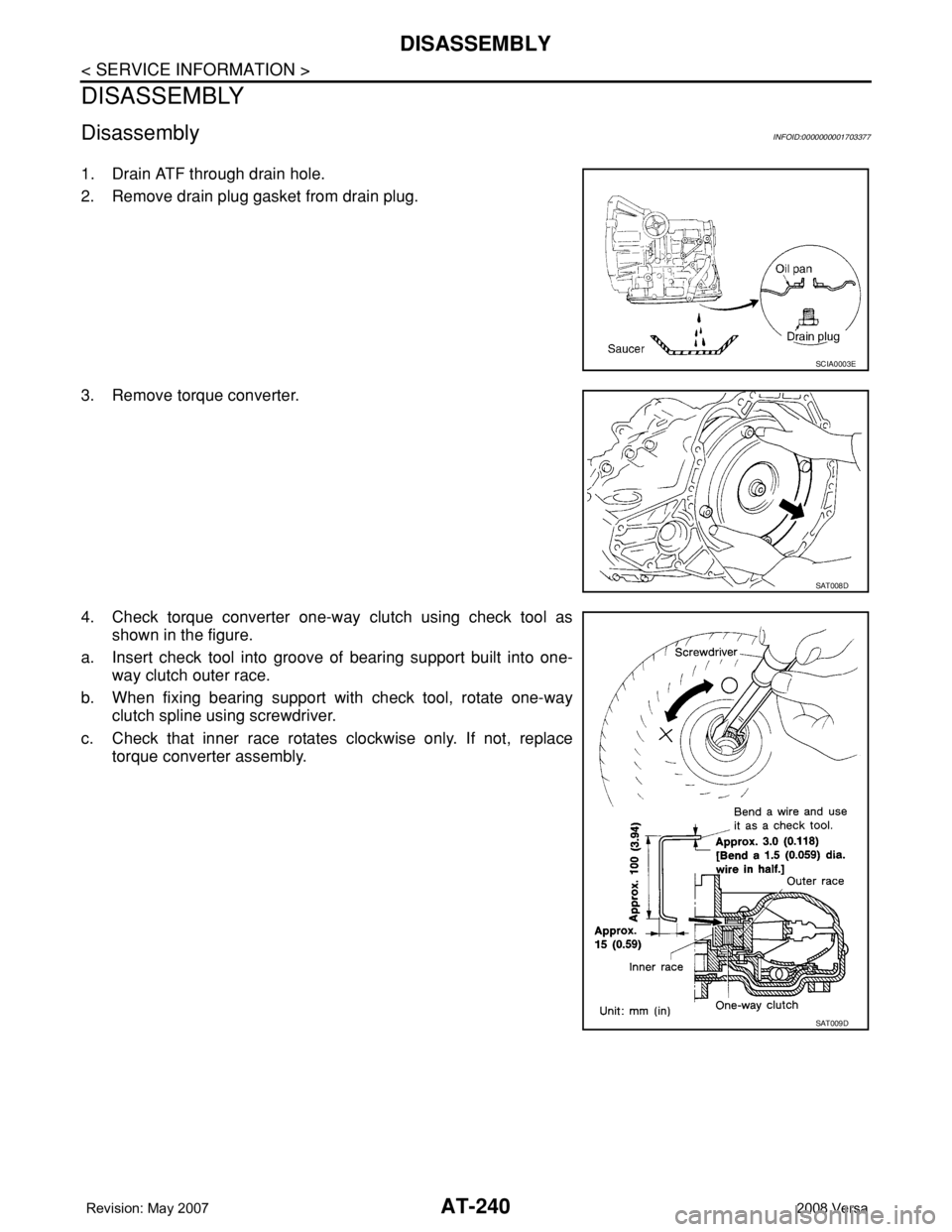

1. Drain ATF through drain hole.

2. Remove drain plug gasket from drain plug.

3. Remove torque converter.

4. Check torque converter one-way clutch using check tool as

shown in the figure.

a. Insert check tool into groove of bearing support built into one-

way clutch outer race.

b. When fixing bearing support with check tool, rotate one-way

clutch spline using screwdriver.

c. Check that inner race rotates clockwise only. If not, replace

torque converter assembly.

SCIA0003E

SAT008D

SAT009D

Page 262 of 2771

AT-250

< SERVICE INFORMATION >

DISASSEMBLY

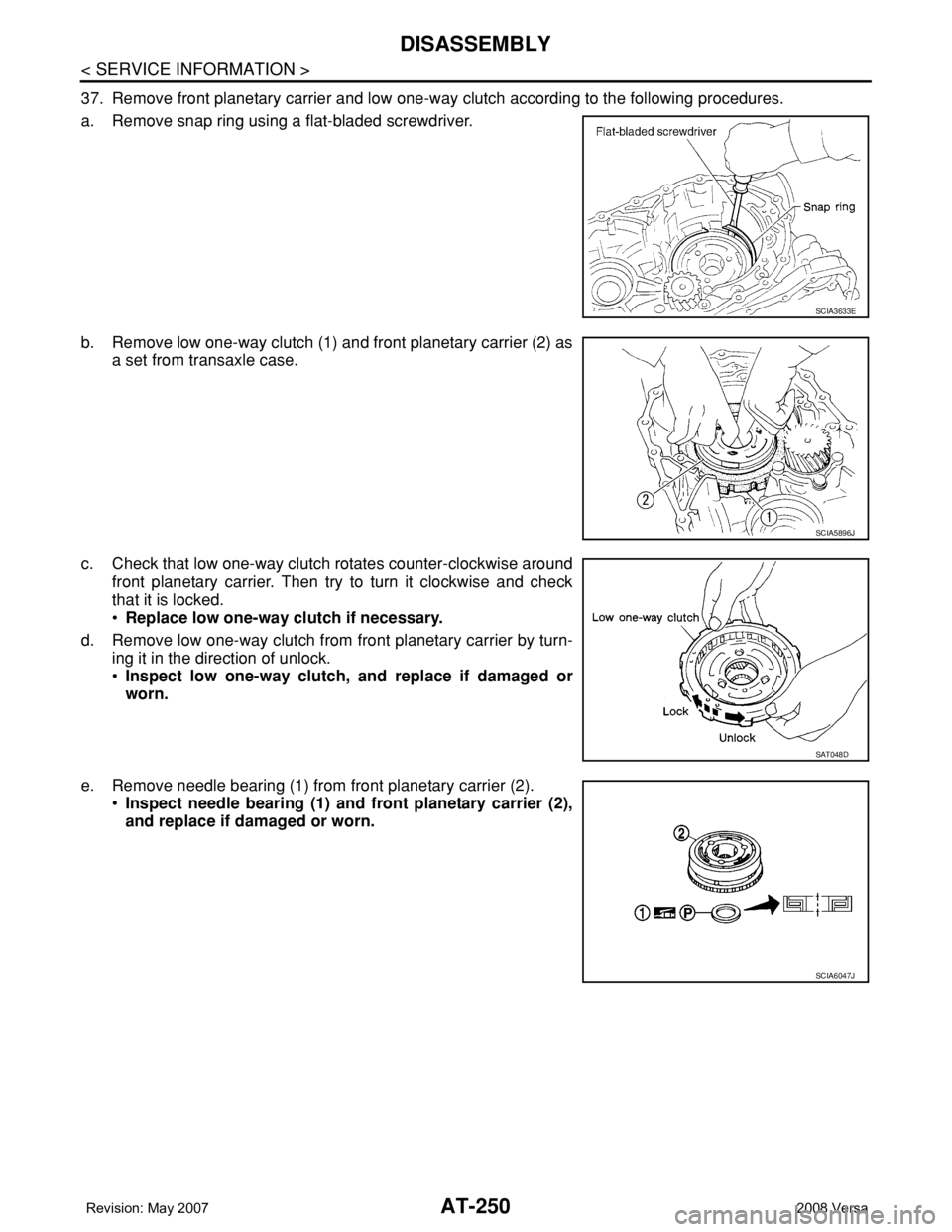

37. Remove front planetary carrier and low one-way clutch according to the following procedures.

a. Remove snap ring using a flat-bladed screwdriver.

b. Remove low one-way clutch (1) and front planetary carrier (2) as

a set from transaxle case.

c. Check that low one-way clutch rotates counter-clockwise around

front planetary carrier. Then try to turn it clockwise and check

that it is locked.

•Replace low one-way clutch if necessary.

d. Remove low one-way clutch from front planetary carrier by turn-

ing it in the direction of unlock.

•Inspect low one-way clutch, and replace if damaged or

worn.

e. Remove needle bearing (1) from front planetary carrier (2).

•Inspect needle bearing (1) and front planetary carrier (2),

and replace if damaged or worn.

SCIA3633E

SCIA5896J

SAT048D

SCIA6047J

Page 338 of 2771

AT-326

< SERVICE INFORMATION >

ASSEMBLY

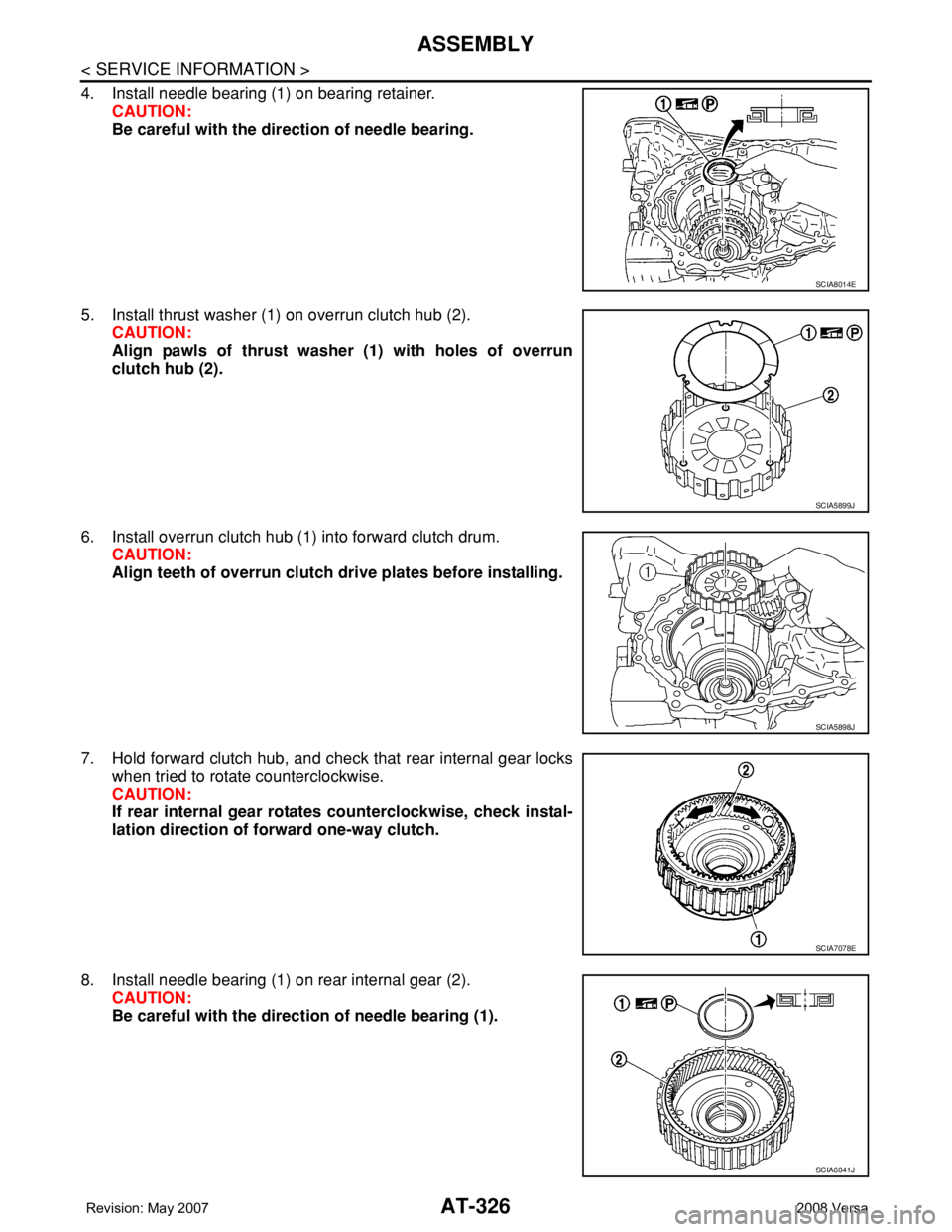

4. Install needle bearing (1) on bearing retainer.

CAUTION:

Be careful with the direction of needle bearing.

5. Install thrust washer (1) on overrun clutch hub (2).

CAUTION:

Align pawls of thrust washer (1) with holes of overrun

clutch hub (2).

6. Install overrun clutch hub (1) into forward clutch drum.

CAUTION:

Align teeth of overrun clutch drive plates before installing.

7. Hold forward clutch hub, and check that rear internal gear locks

when tried to rotate counterclockwise.

CAUTION:

If rear internal gear rotates counterclockwise, check instal-

lation direction of forward one-way clutch.

8. Install needle bearing (1) on rear internal gear (2).

CAUTION:

Be careful with the direction of needle bearing (1).

SCIA8014E

SCIA5899J

SCIA5898J

SCIA7078E

SCIA6041J

Page 340 of 2771

AT-328

< SERVICE INFORMATION >

ASSEMBLY

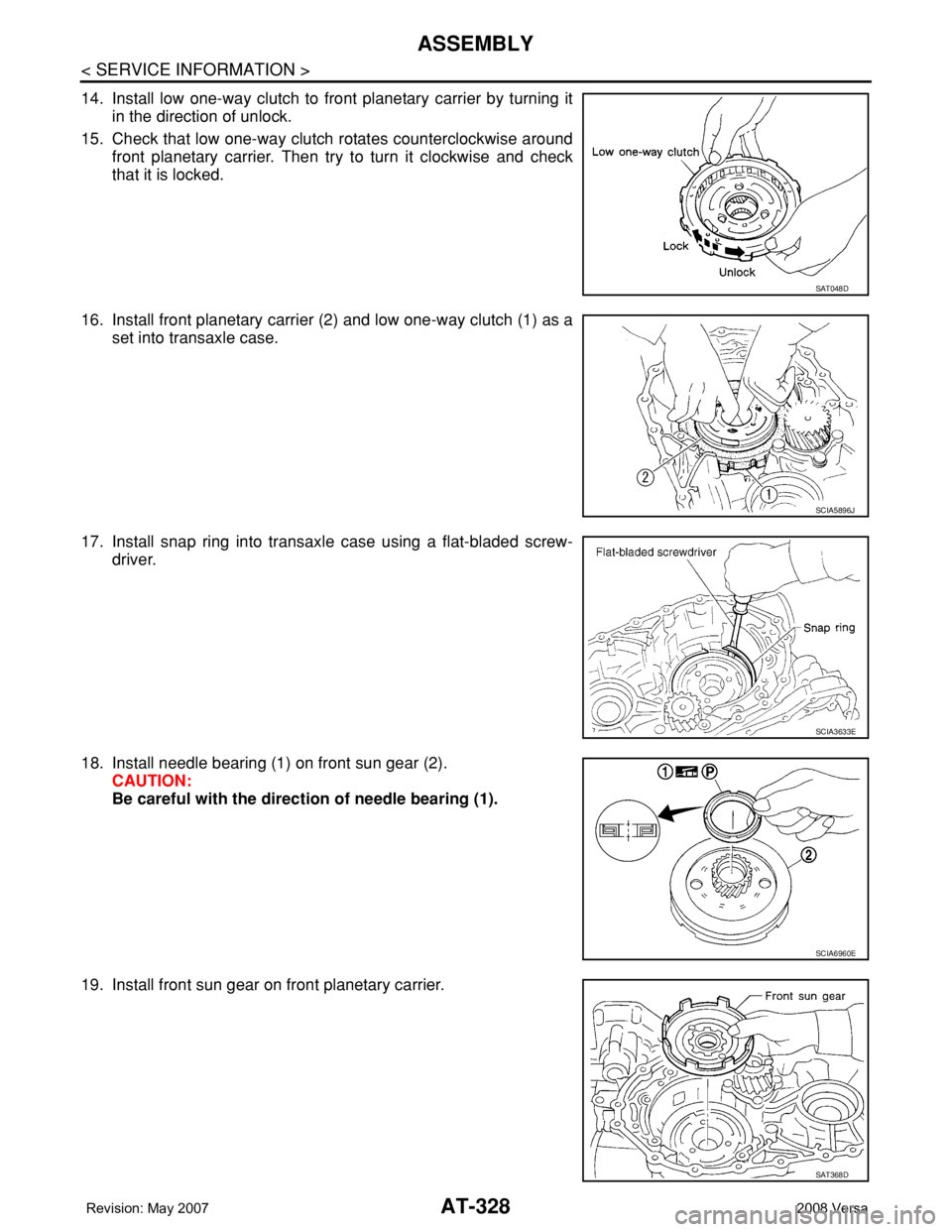

14. Install low one-way clutch to front planetary carrier by turning it

in the direction of unlock.

15. Check that low one-way clutch rotates counterclockwise around

front planetary carrier. Then try to turn it clockwise and check

that it is locked.

16. Install front planetary carrier (2) and low one-way clutch (1) as a

set into transaxle case.

17. Install snap ring into transaxle case using a flat-bladed screw-

driver.

18. Install needle bearing (1) on front sun gear (2).

CAUTION:

Be careful with the direction of needle bearing (1).

19. Install front sun gear on front planetary carrier.

SAT048D

SCIA5896J

SCIA3633E

SCIA6960E

SAT368D

Page 441 of 2771

SQUEAK AND RATTLE TROUBLE DIAGNOSES

BL-7

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

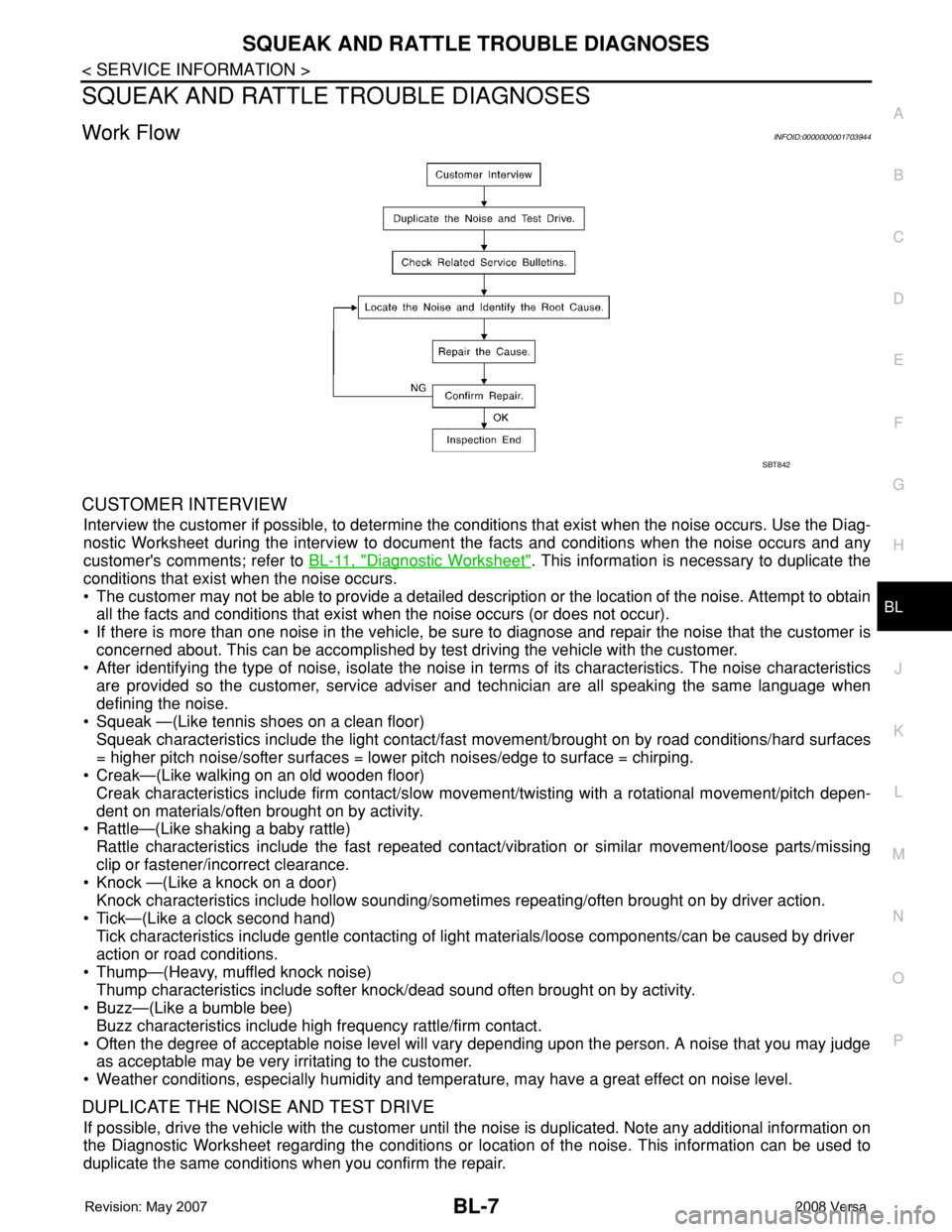

Work FlowINFOID:0000000001703944

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to BL-11, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

• Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Page 737 of 2771

BR-6

< SERVICE INFORMATION >

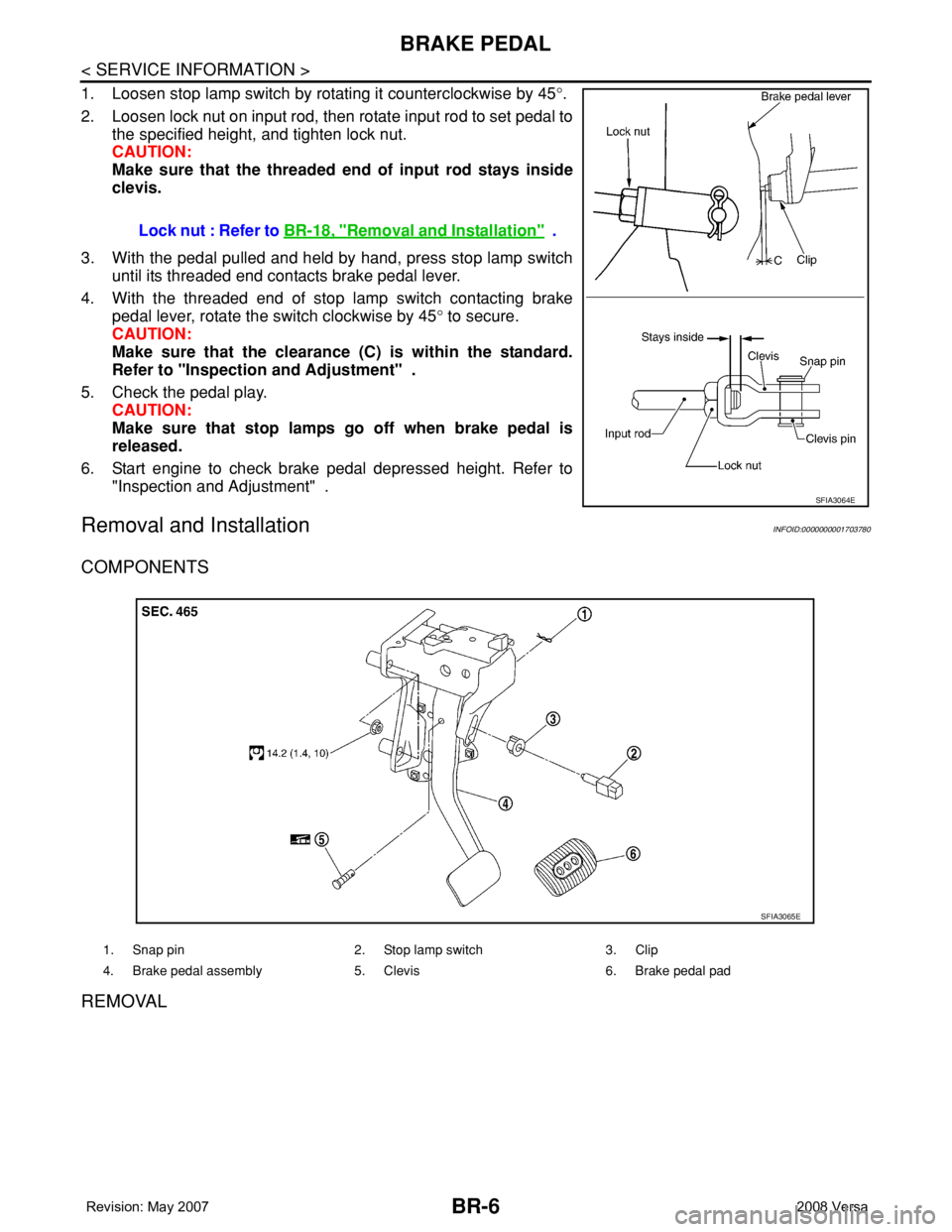

BRAKE PEDAL

1. Loosen stop lamp switch by rotating it counterclockwise by 45°.

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch

until its threaded end contacts brake pedal lever.

4. With the threaded end of stop lamp switch contacting brake

pedal lever, rotate the switch clockwise by 45° to secure.

CAUTION:

Make sure that the clearance (C) is within the standard.

Refer to "Inspection and Adjustment" .

5. Check the pedal play.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start engine to check brake pedal depressed height. Refer to

"Inspection and Adjustment" .

Removal and InstallationINFOID:0000000001703780

COMPONENTS

REMOVAL

Lock nut : Refer to BR-18, "Removal and Installation" .

SFIA3064E

1. Snap pin 2. Stop lamp switch 3. Clip

4. Brake pedal assembly 5. Clevis 6. Brake pedal pad

SFIA3065E

Page 741 of 2771

BR-10

< SERVICE INFORMATION >

BRAKE TUBE AND HOSE

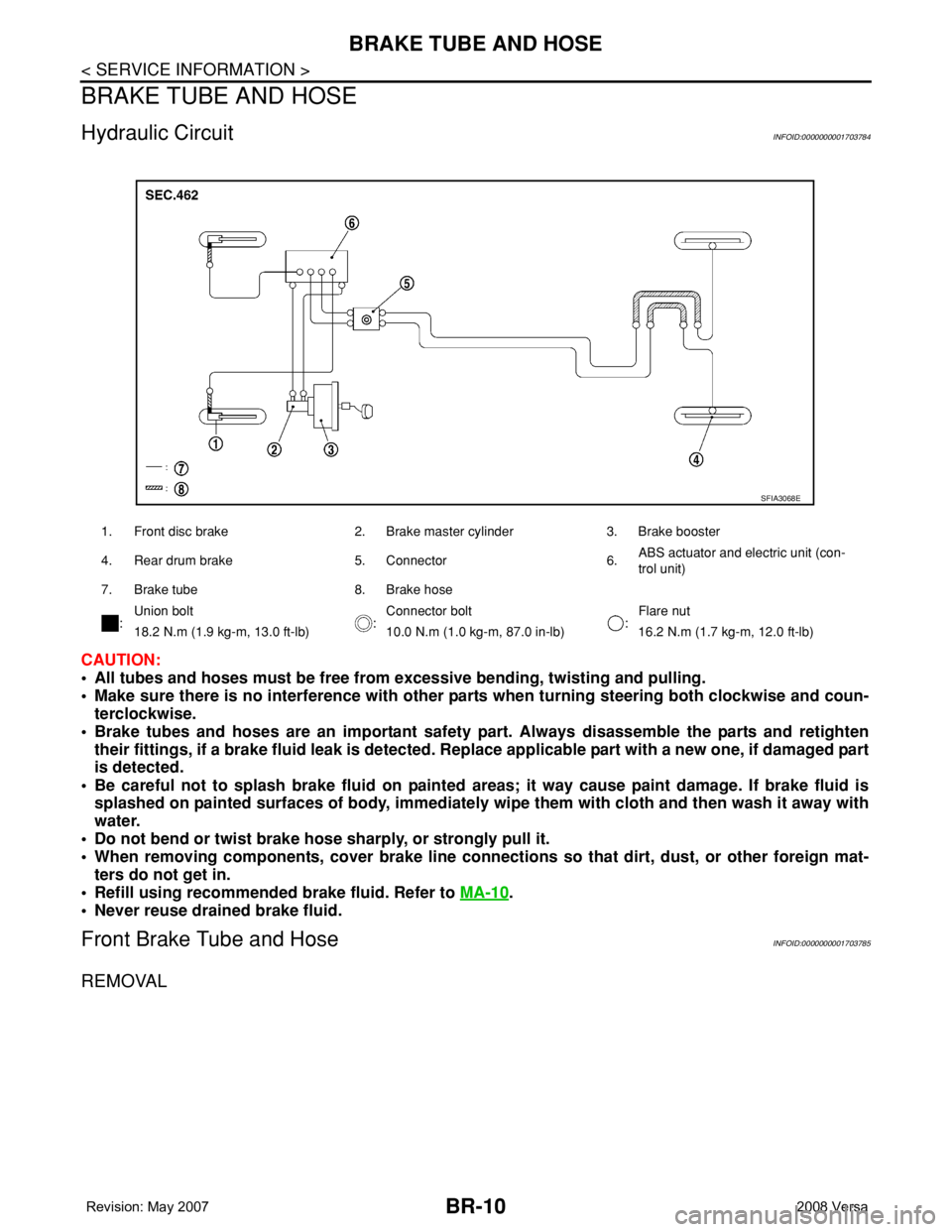

BRAKE TUBE AND HOSE

Hydraulic CircuitINFOID:0000000001703784

CAUTION:

• All tubes and hoses must be free from excessive bending, twisting and pulling.

• Make sure there is no interference with other parts when turning steering both clockwise and coun-

terclockwise.

• Brake tubes and hoses are an important safety part. Always disassemble the parts and retighten

their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part

is detected.

• Be careful not to splash brake fluid on painted areas; it way cause paint damage. If brake fluid is

splashed on painted surfaces of body, immediately wipe them with cloth and then wash it away with

water.

• Do not bend or twist brake hose sharply, or strongly pull it.

• When removing components, cover brake line connections so that dirt, dust, or other foreign mat-

ters do not get in.

• Refill using recommended brake fluid. Refer to MA-10

.

• Never reuse drained brake fluid.

Front Brake Tube and HoseINFOID:0000000001703785

REMOVAL

1. Front disc brake 2. Brake master cylinder 3. Brake booster

4. Rear drum brake 5. Connector 6.ABS actuator and electric unit (con-

trol unit)

7. Brake tube 8. Brake hose

:Union bolt

:Connector bolt

:Flare nut

18.2 N.m (1.9 kg-m, 13.0 ft-lb) 10.0 N.m (1.0 kg-m, 87.0 in-lb) 16.2 N.m (1.7 kg-m, 12.0 ft-lb)

SFIA3068E