check engine NISSAN LATIO 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 59 of 4331

AT-54< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

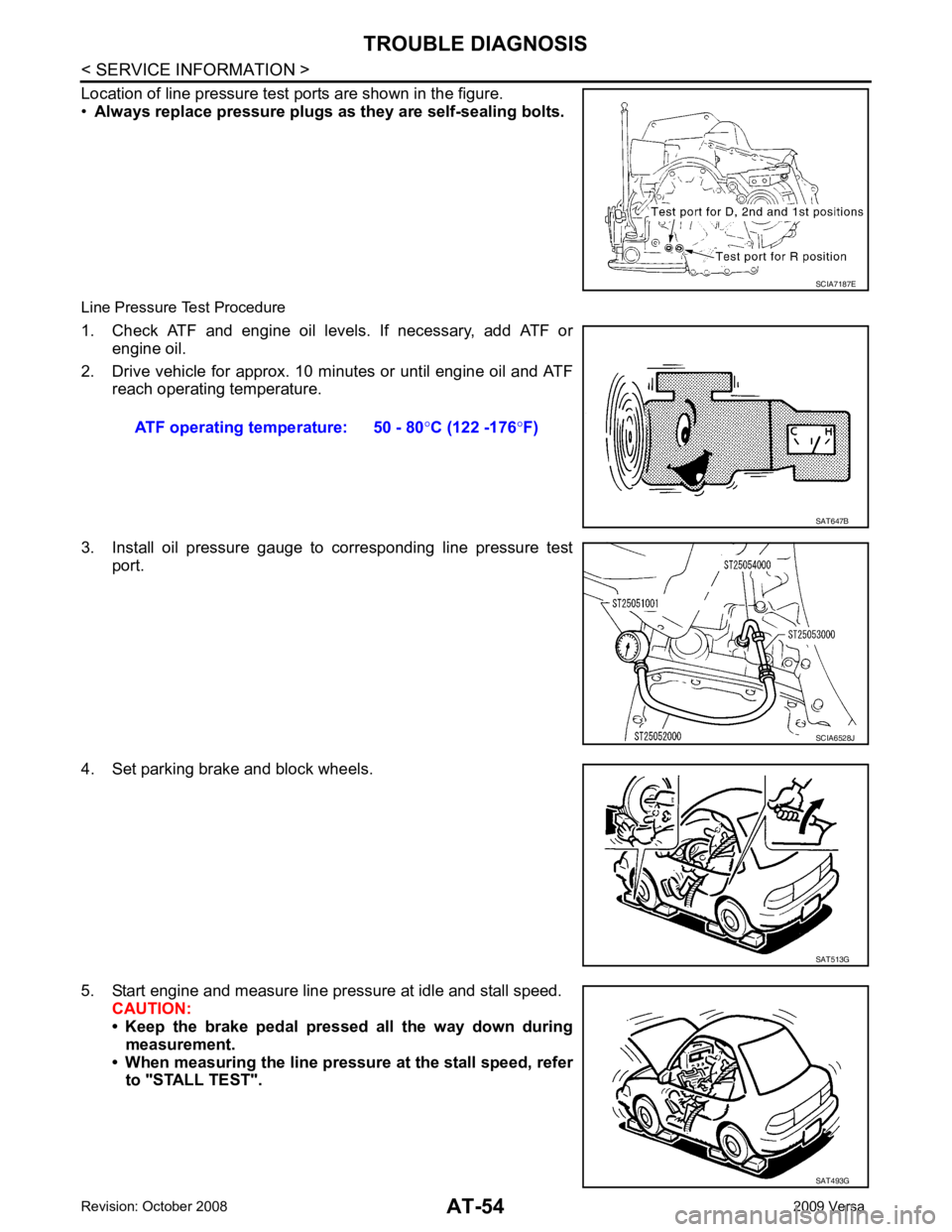

Location of line pressure test ports are shown in the figure.

• Always replace pressure plugs as they are self-sealing bolts.

Line Pressure Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF or engine oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF reach operating temperature.

3. Install oil pressure gauge to corresponding line pressure test port.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed. CAUTION:

• Keep the brake pedal pressed all the way down during

measurement.

• When measuring the line pressure at the stall speed, refer to "STALL TEST". SCIA7187E

ATF operating temperature: 50 - 80

°C (122 -176 °F) SAT647B

SCIA6528J

SAT513G

SAT493G

Page 60 of 4331

AT

N

O P

Line Pressure

Judgement of Line Pressure Test

Road Test INFOID:0000000004305320

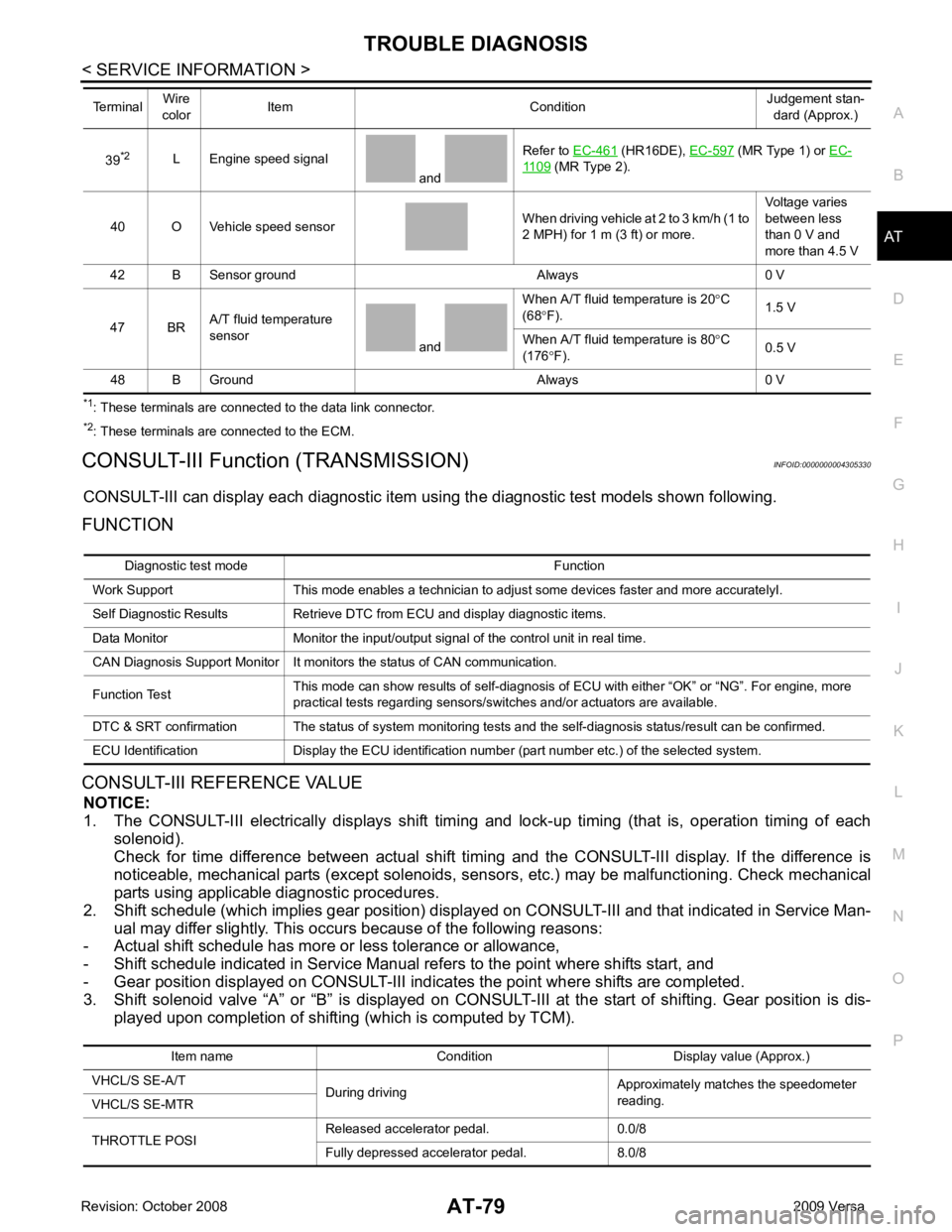

DESCRIPTION • The purpose of the test is to det ermine overall performance of A/T

and analyze causes of malfunctions.

• The road test consists of the following three parts:

1. Check before engine is started. Refer to AT-56 .

2. Check at idle. Refer to AT-56 .

3. Cruise test • Inspection all the item from Part 1 to Part 3. Refer to AT-58 ,

AT-61 and

AT-62 .

Engine speed

Line pressure [kPa (kg/cm

2

, psi)]

D, 2nd and 1st positions R position

Idle speed AT-373, " Line Pressure "

Stall speed

Judgement Suspected parts

At idle Line pressure is low in all positions. • Oil pump wear

• Control piston damage

• Pressure regulator valve or plug sticking

• Spring for pressure regulator valve damaged

• Fluid pressure leakage between oil strainer and pressure regulator valve

• Clogged strainer

Line pressure is low in particular posi-

tion. • Fluid pressure leakage between manual valve and particular clutch

• For example, line pressure is: − Low in “R” and “1 ” positions, but

− Normal in “D”, and “2” positions.

Therefore, fluid leakage exists at or around low and reverse brake circuit.

Refer to AT-22, " Shift Mechanism " .

Line pressure is high. • Accelerator pedal position signal malfunction • A/T fluid temperature sensor damaged

• Line pressure solenoid valve sticking

• Short circuit of line pressure solenoid valve circuit

• Pressure modifier valve sticking

• Pressure regulator valve or plug sticking

• Open in dropping resistor circuit

At stall

speed Line pressure is low. • Accelerator pedal position signal malfunction

• Line pressure solenoid valve sticking

• Short circuit of line pressure solenoid valve circuit

• Pressure regulator valve or plug sticking

• Pressure modifier valve sticking

• Pilot valve sticking

Page 61 of 4331

). Per-

form a diagnosis of the NG items after the completion of all the

road tests.

Check Before Engine Is Started INFOID:0000000004305321YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.Refer to AT-79, " CONSULT-III Function (TRANS-

MISSION) " ,

AT-83, " Diagnosis Procedure without

CONSULT-III " .

3. Go to AT-56, " Check at Idle " .

NO >> Stop “Road Test”. Go to AT-181, " OD OFF Indicator

Lamp Does Not Come On " .

Check at Idle INFOID:0000000004305322YES >> GO TO 2.

NO >> • Stop “Road Test”. Mark the box on the “Diagnostic

Worksheet Chart”.

• Go to AT-183, " Engine Cannot Be Started in "P" and

"N" Position " . SAT772B

SAT769B

Page 66 of 4331

TROUBLE DIAGNOSIS

AT-61

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

• Continue “Road Test”. 8.

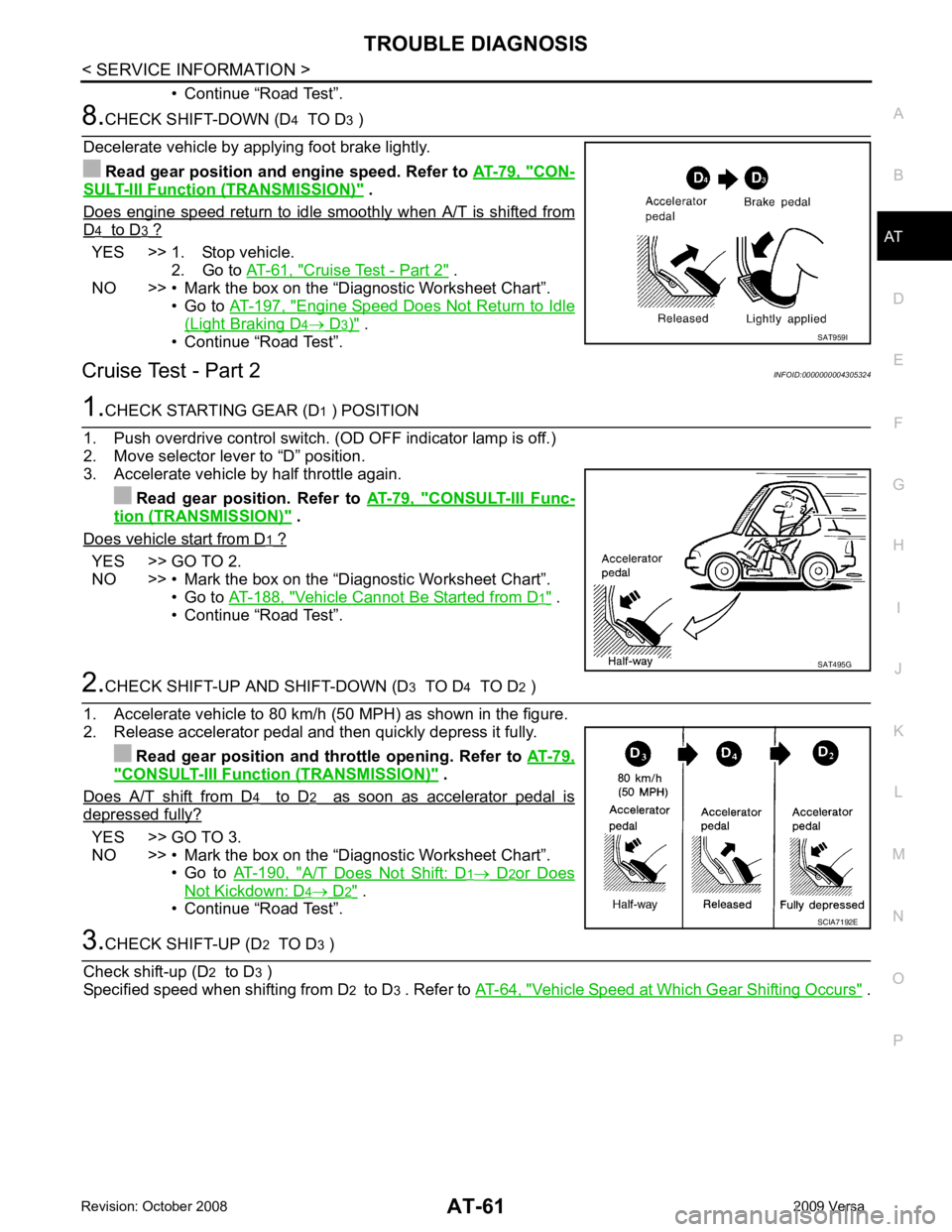

CHECK SHIFT-DOWN (D 4 TO D 3 )

Decelerate vehicle by applying foot brake lightly. Read gear position and engine speed. Refer to AT-79, " CON-

SULT-III Functi

on (TRANSMISSION) " .

Does engine speed return to idle smoothly when A/T is shifted from D 4 to D 3 ?

YES >> 1. Stop vehicle.

2. Go to AT-61, " Cruise Test - Part 2 " .

NO >> • Mark the box on the “D iagnostic Worksheet Chart”.

• Go to AT-197, " Engine Speed Does Not Return to Idle

(Light Braking D 4 → D 3 ) " .

• Continue “Road Test”.

Cruise Test - Part 2 INFOID:00000000043053241.

CHECK STARTING GEAR (D 1 ) POSITION

1. Push overdrive control switch. (OD OFF indicator lamp is off.)

2. Move selector lever to “D” position.

3. Accelerate vehicle by half throttle again.

Read gear position. Refer to AT-79, " CONSULT-III Func-

tion (TRANSMISSION) " .

Does vehicle start from D 1 ?

YES >> GO TO 2.

NO >> • Mark the box on the “D iagnostic Worksheet Chart”.

• Go to AT-188, " Vehicle Cannot Be Started from D 1 " .

• Continue “Road Test”. 2.

CHECK SHIFT-UP AND SHIFT-DOWN (D 3 TO D 4 TO D 2 )

1. Accelerate vehicle to 80 km/h (50 MPH) as shown in the figure.

2. Release accelerator pedal and then quickly depress it fully.

Read gear position and th rottle opening. Refer to AT-79," CONSULT-III Function (TRANSMISSION) " .

Does A/T shift from D 4 to D 2 as soon as accelerator pedal is

depressed fully?

YES >> GO TO 3.

NO >> • Mark the box on the “D iagnostic Worksheet Chart”.

• Go to AT-190, " A/T Does Not Shift: D 1 → D 2 or Does

Not Kickdown: D 4 → D 2 " .

• Continue “Road Test”. 3.

CHECK SHIFT-UP (D 2 TO D 3 )

Check shift-up (D 2 to D 3 )

Specified speed when shifting from D 2 to D 3 . Refer to AT-64, " Vehicle Speed at Which Gear Shifting Occurs " .SAT959I

SAT495G

SCIA7192E

Page 84 of 4331

AT

N

O P

*1

: These terminals are connected to the data link connector.

*2 : These terminals are connected to the ECM.

CONSULT-III Function (TRANSMISSION) INFOID:0000000004305330

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE NOTICE:

1. The CONSULT-III electrically displays shift timi ng and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timi ng and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sens ors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) display ed on CONSULT-III and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual re fers to the point where shifts start, and

- Gear position displayed on CONSULT-III indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSUL T-III at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

39

*2

L Engine speed signal

and Refer to

EC-461 (HR16DE),

EC-597 (MR Type 1) or

EC- 1109 (MR Type 2).

40 O Vehicle speed sensor When driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more. Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always 0 V

47 BR A/T fluid temperature

sensor and When A/T fluid temperature is 20

°C

(68 °F). 1.5 V

When A/T fluid temperature is 80 °C

(176 °F). 0.5 V

48 B Ground Always 0 V

Terminal

Wire

color Item Condition Judgement stan-

dard (Approx.) Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accuratelyI.

Self Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis Support Monitor It monitors the status of CAN communication.

Function Test This mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For engine, more

practical tests regarding sensors/switches and/or actuators are available.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECU Identification Display the ECU identification number (part number etc.) of the selected system. Item name Condition Display value (Approx.)

VHCL/S SE-A/T During driving Approximately matches the speedometer

reading.

VHCL/S SE-MTR

THROTTLE POSI Released accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

Page 88 of 4331

AT

N

O P

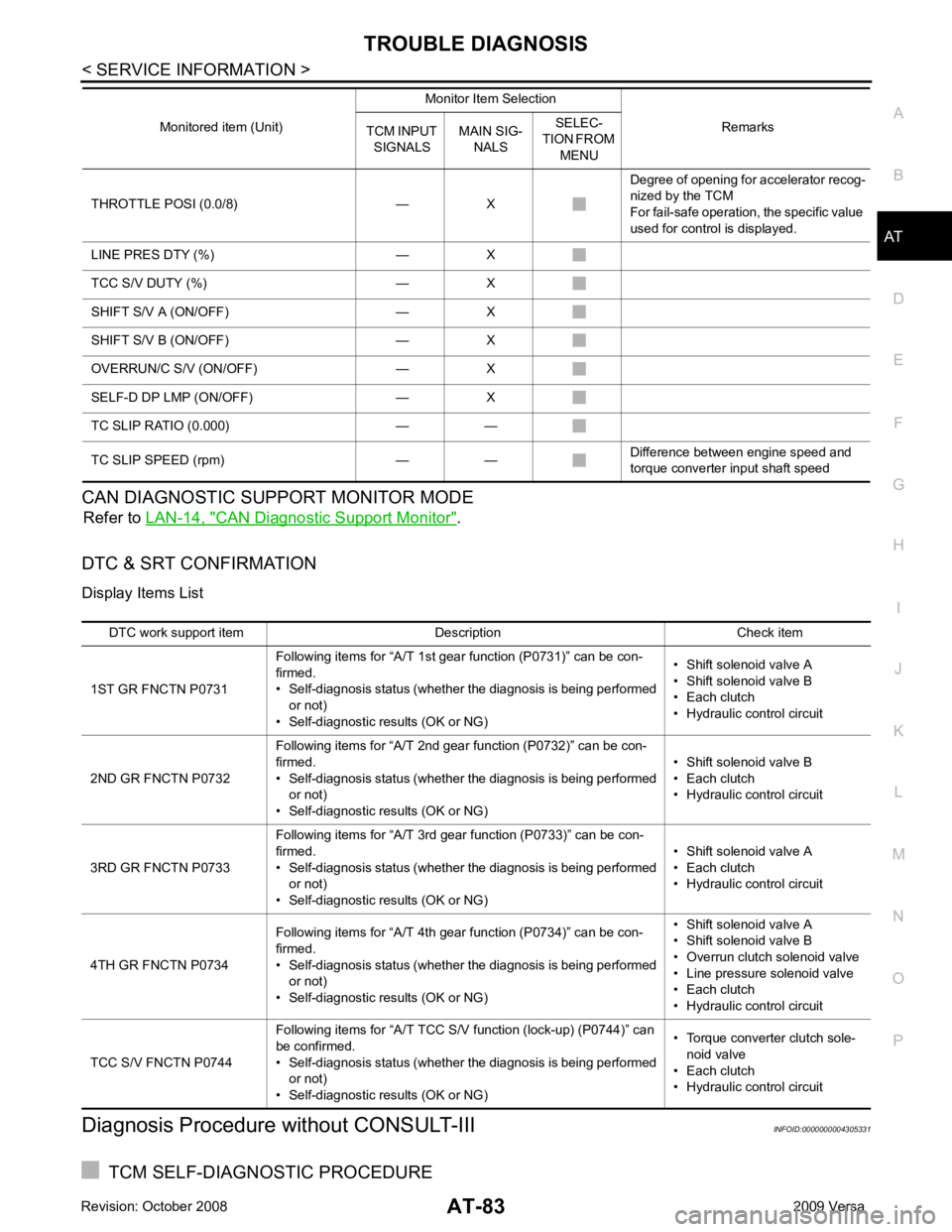

CAN DIAGNOSTIC SUPPORT MONITOR MODE

Refer to LAN-14, " CAN Diagnostic Support Monitor " .

DTC & SRT CONFIRMATION

Display Items List

Diagnosis Procedure without CONSULT-III INFOID:0000000004305331

TCM SELF-DIAGNOSTIC PROCEDURE

THROTTLE POSI (0.0/8) — X

Degree of opening for accelerator recog-

nized by the TCM

For fail-safe operation, the specific value

used for control is displayed.

LINE PRES DTY (%) — X

TCC S/V DUTY (%) — X

SHIFT S/V A (ON/OFF) — X

SHIFT S/V B (ON/OFF) — X

OVERRUN/C S/V (ON/OFF) — X

SELF-D DP LMP (ON/OFF) — X

TC SLIP RATIO (0.000) — —

TC SLIP SPEED (rpm) — — Difference between engine speed and

torque converter input shaft speed

Monitored item (Unit)

Monitor Item Selection

Remarks

TCM INPUT

SIGNALS MAIN SIG-

NALS SELEC-

TION FROM

MENU DTC work support item Description Check item

1ST GR FNCTN P0731 Following items for “A/T 1st gear function (P0731)” can be con-

firmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve A

• Shift solenoid valve B

• Each clutch

• Hydraulic control circuit

2ND GR FNCTN P0732 Following items for “A/T 2nd gear function (P0732)” can be con-

firmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve B

• Each clutch

• Hydraulic control circuit

3RD GR FNCTN P0733 Following items for “A/T 3rd gear function (P0733)” can be con-

firmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve A

• Each clutch

• Hydraulic control circuit

4TH GR FNCTN P0734 Following items for “A/T 4th gear function (P0734)” can be con-

firmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG) • Shift solenoid valve A

• Shift solenoid valve B

• Overrun clutch solenoid valve

• Line pressure solenoid valve

• Each clutch

• Hydraulic control circuit

TCC S/V FNCTN P0744 Following items for “A/T TCC S/V

function (lock-up) (P0744)” can

be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG) • Torque converter clutch sole-

noid valve

• Each clutch

• Hydraulic control circuit

Page 89 of 4331

AT-84< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

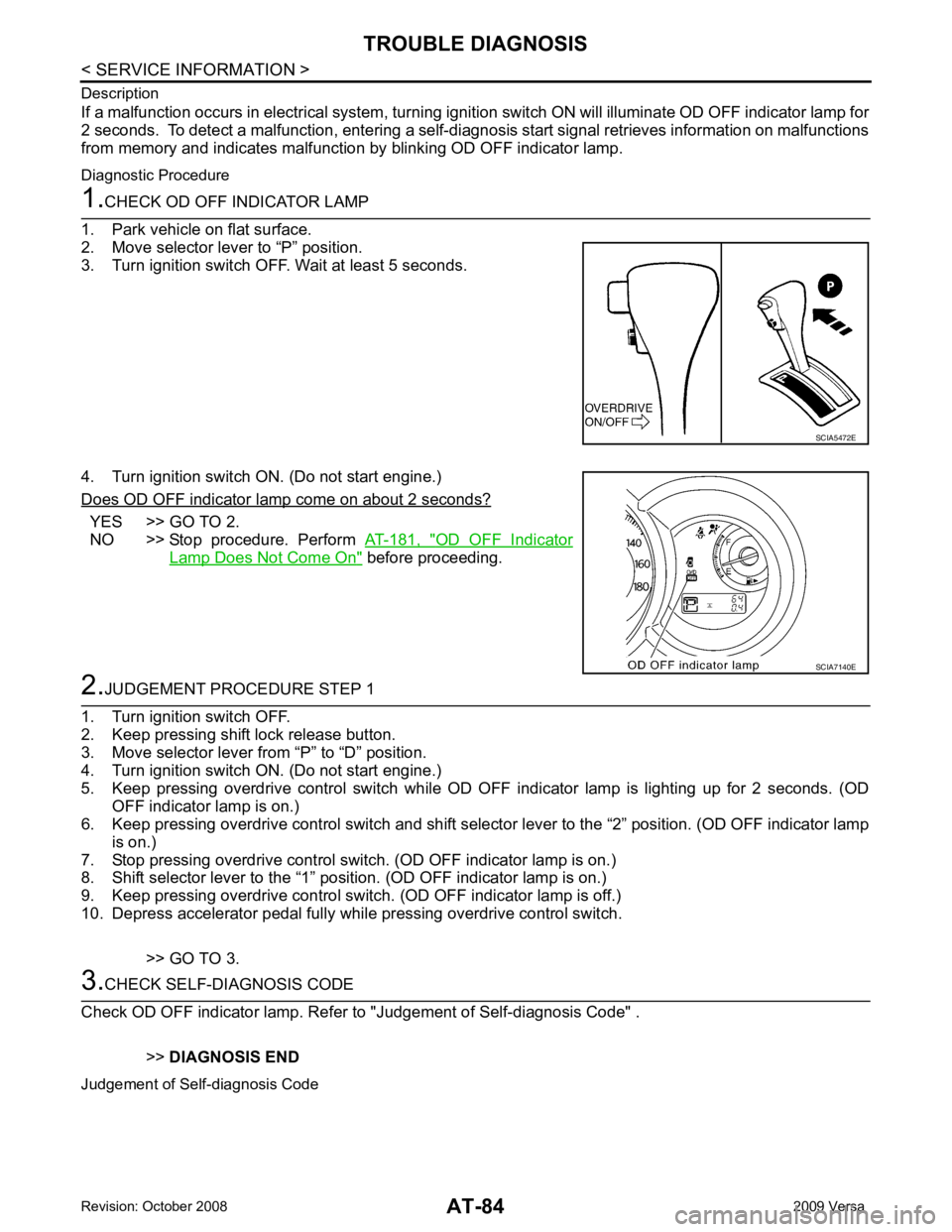

Description

If a malfunction occurs in electrical system, turning igni tion switch ON will illuminate OD OFF indicator lamp for

2 seconds. To detect a malfunction, entering a self-diagnosis start signal retrieves information on malfunctions

from memory and indicates malfunction by blinking OD OFF indicator lamp.

Diagnostic Procedure 1.

CHECK OD OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does OD OFF indicator lamp come on about 2 seconds? YES >> GO TO 2.

NO >> Stop procedure. Perform AT-181, " OD OFF Indicator

Lamp Does Not Come On " before proceeding.

2.

JUDGEMENT PROCEDURE STEP 1

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Turn ignition switch ON. (Do not start engine.)

5. Keep pressing overdrive control switch while OD OF F indicator lamp is lighting up for 2 seconds. (OD

OFF indicator lamp is on.)

6. Keep pressing overdrive control switch and shift select or lever to the “2” position. (OD OFF indicator lamp

is on.)

7. Stop pressing overdrive control switch. (OD OFF indicator lamp is on.)

8. Shift selector lever to the “1” position. (OD OFF indicator lamp is on.)

9. Keep pressing overdrive control switch. (OD OFF indicator lamp is off.)

10. Depress accelerator pedal fully while pressing overdrive control switch.

>> GO TO 3. 3.

CHECK SELF-DIAGNOSIS CODE

Check OD OFF indicator lamp. Refer to "Judgement of Self-diagnosis Code" .

>>DIAGNOSIS END

Judgement of Self-diagnosis Code SCIA5472E

SCIA7140E

Page 96 of 4331

AT

N

O P

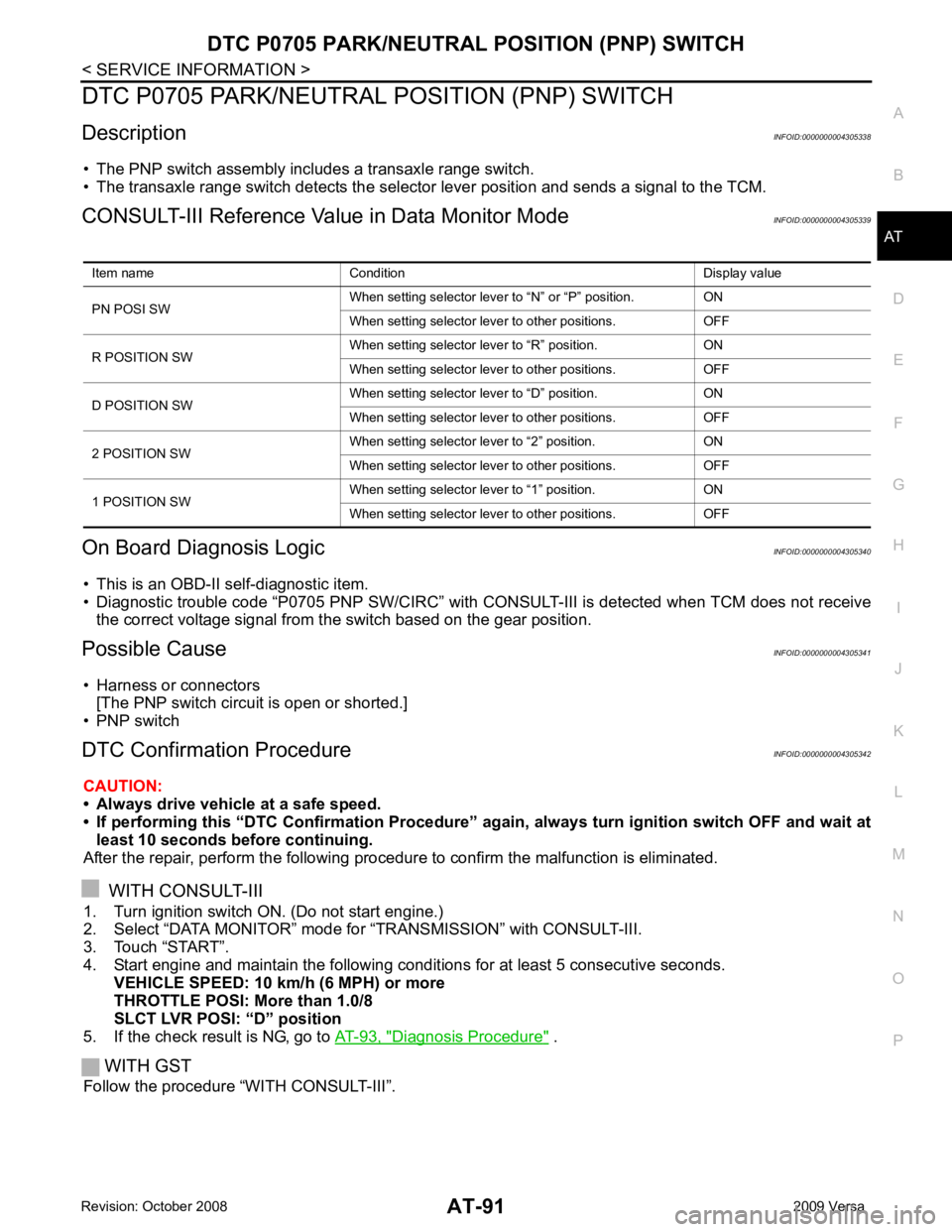

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Description INFOID:0000000004305338

• The PNP switch assembly includes a transaxle range switch.

• The transaxle range switch detects the selector lever position and sends a signal to the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305339

On Board Diagnosis Logic INFOID:0000000004305340

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 PNP SW/CIRC” with CONS ULT-III is detected when TCM does not receive

the correct voltage signal from the switch based on the gear position.

Possible Cause INFOID:0000000004305341

• Harness or connectors [The PNP switch circuit is open or shorted.]

• PNP switch

DTC Confirmation Procedure INFOID:0000000004305342

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

5. If the check result is NG, go to AT-93, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 106 of 4331

AT

N

O P

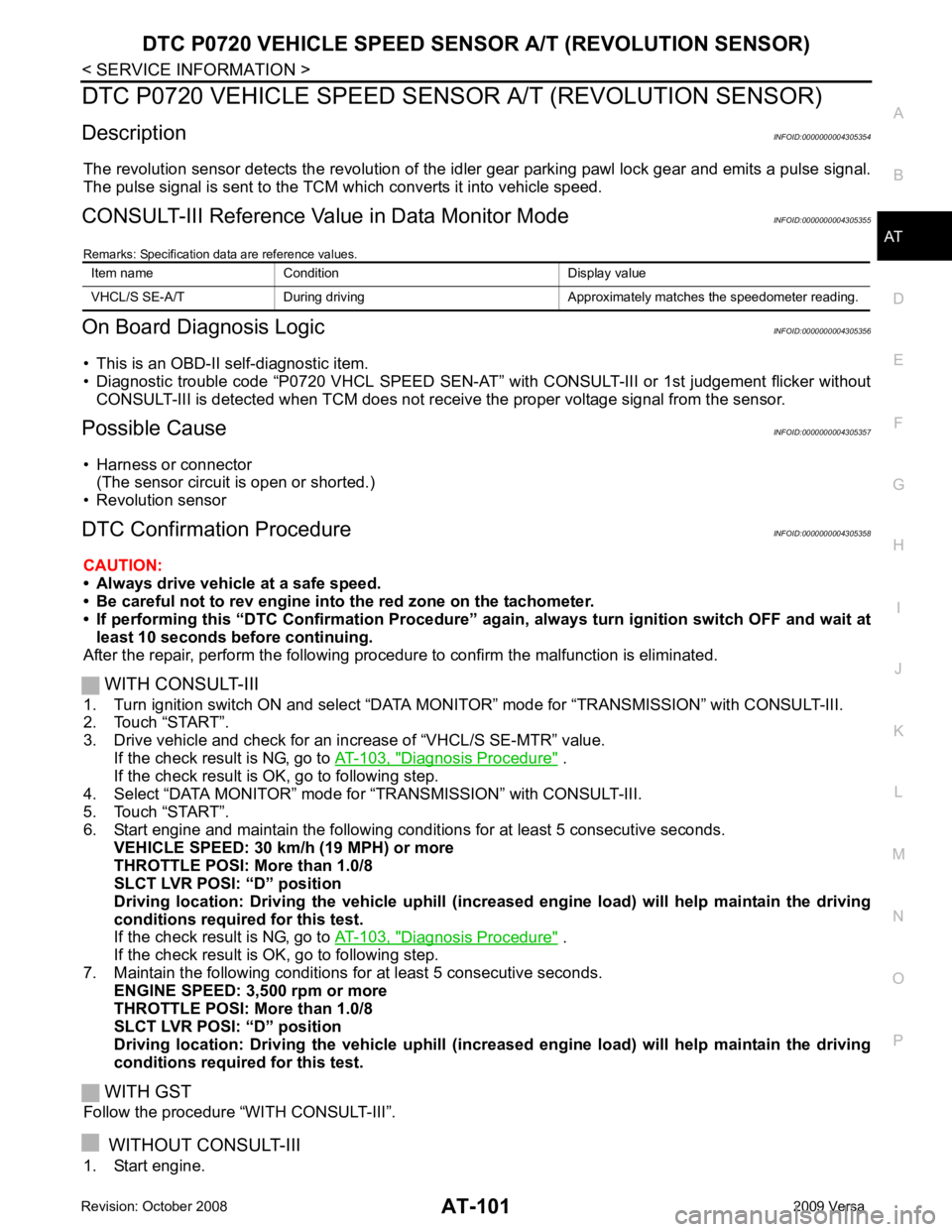

DTC P0720 VEHICLE SPEED SENS

OR A/T (REVOLUTION SENSOR)

Description INFOID:0000000004305354

The revolution sensor detects the revolution of the id ler gear parking pawl lock gear and emits a pulse signal.

The pulse signal is sent to the TCM which converts it into vehicle speed.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305355

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305356

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0720 VHCL SPEED SEN-AT” with CONSULT-III or 1st judgement flicker without

CONSULT-III is detected when TCM does not rece ive the proper voltage signal from the sensor.

Possible Cause INFOID:0000000004305357

• Harness or connector (The sensor circuit is open or shorted.)

• Revolution sensor

DTC Confirmation Procedure INFOID:0000000004305358

CAUTION:

• Always drive vehicle at a safe speed.

• Be careful not to rev engine into the red zone on the tachometer.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Drive vehicle and check for an in crease of “VHCL/S SE-MTR” value.

If the check result is NG, go to AT-103, " Diagnosis Procedure " .

If the check result is OK, go to following step.

4. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

5. Touch “START”.

6. Start engine and maintain the following conditions for at least 5 consecutive seconds. VEHICLE SPEED: 30 km/h (19 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

If the check result is NG, go to AT-103, " Diagnosis Procedure " .

If the check result is OK, go to following step.

7. Maintain the following conditions for at least 5 consecutive seconds. ENGINE SPEED: 3,500 rpm or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine. Item name Condition Display value

VHCL/S SE-A/T During driving Approxima tely matches the speedometer reading.

Page 111 of 4331

Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle under the following conditions for more than 10 seconds.

Selector lever position: “D” position

Vehicle speed: Higher than 10 km/h (6 MPH)

Throttle position: Greater than 1. 0/8 of the full throttle position

3. Perform self-diagnosis. Refer to AT-83, " Diagnosis Procedure without CONSULT-III " .

4. If the check result is NG, go to AT-108, " Diagnosis Procedure " .

Item name Condition Display value

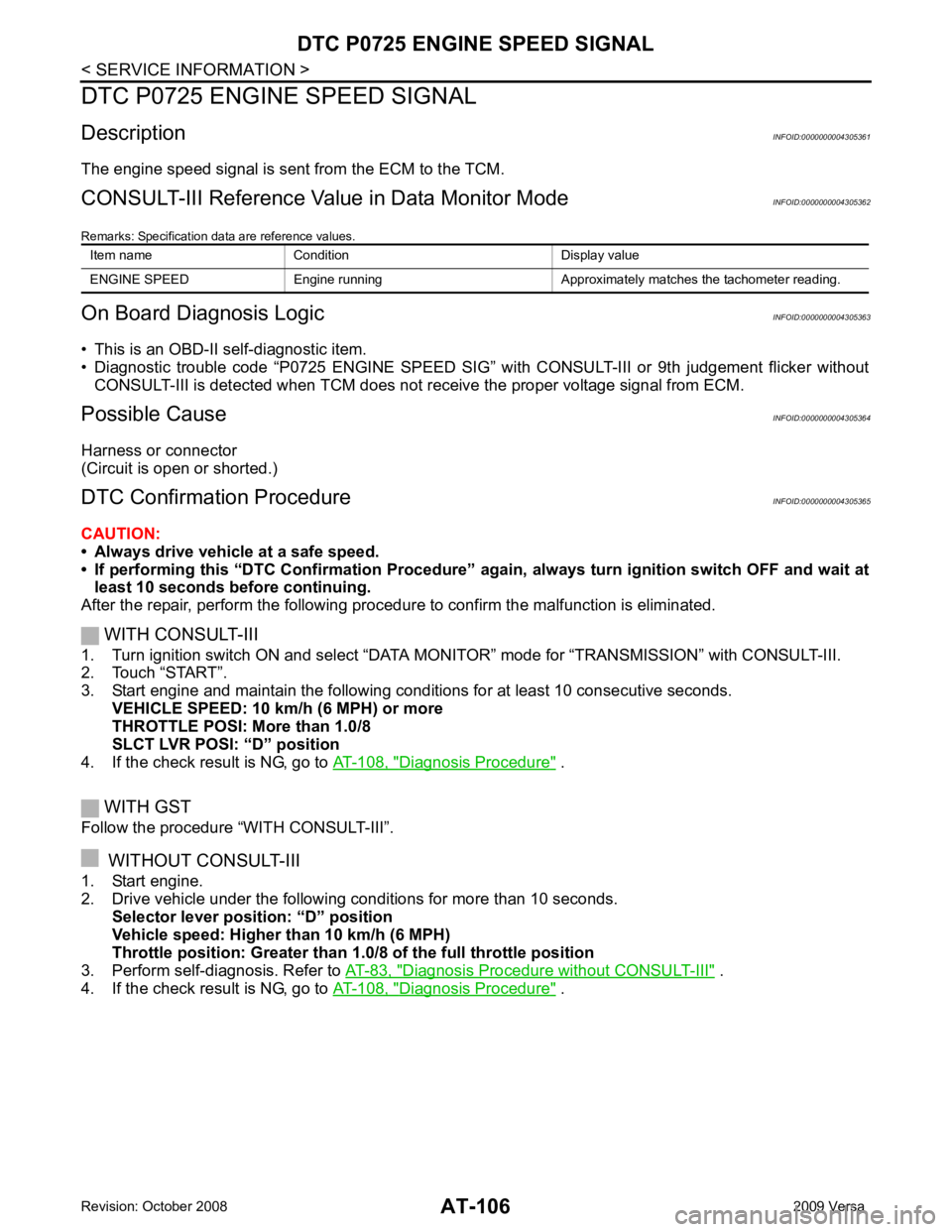

ENGINE SPEED Engine running Approximately matches the tachometer reading.