NISSAN LATIO 2009 Service Repair Manual

LATIO 2009

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57359/w960_57359-0.png

NISSAN LATIO 2009 Service Repair Manual

Trending: gas type, inflation pressure, child restraint, dashboard, fuel, tow, stop start

Page 3461 of 4331

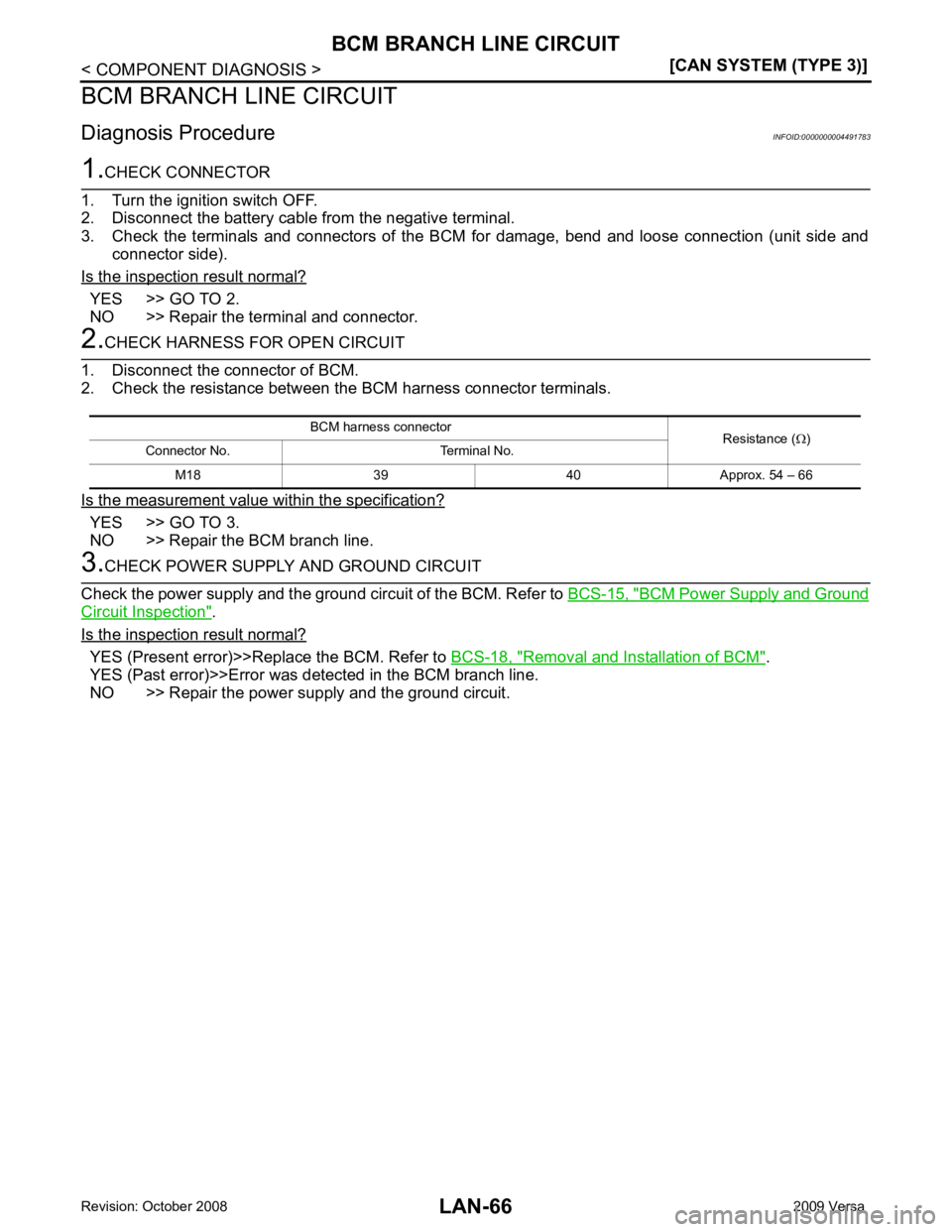

YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the BCM branch line. BCM Power Supply and Ground

Circuit Inspection " .

Is the inspection result normal? YES (Present error)>>Replace the BCM. Refer to

BCS-18, " Removal and Installation of BCM " .

YES (Past error)>>Error was detected in the BCM branch line.

NO >> Repair the power supply and the ground circuit. BCM harness connector

Resistance (Ω)

Connector No. Terminal No.

M18 39 40 Approx. 54 – 66

Page 3462 of 4331

LAN

N

O P

DLC BRANCH LINE CIRCUIT

Diagnosis Procedure INFOID:0000000004491784YES >> GO TO 2.

NO >> Repair the terminal and connector. YES (Present error)>>Check CA

N system type decision again.

YES (Past error)>>Error was detected in the data link connector branch line circuit.

NO >> Repair the data link connector branch line. Data link connector

Resistance (Ω)

Connector No. Terminal No.

M22 6 14 Approx. 54 – 66

Page 3463 of 4331

YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the EPS control unit branch line. DTC C1601 BAT-

TERY VOLT " .

Is the inspection result normal? YES (Present error)>>Replace the EPS control unit. Refer to

PS-9, " Removal and Installation " .

YES (Past error)>>Error was detected in the EPS control unit branch line.

NO >> Repair the power supply and the ground circuit. EPS control unit harness connector

Resistance (Ω)

Connector No. Terminal No.

M53 9 16 Approx. 54 – 66

Page 3464 of 4331

LAN

N

O P

M&A BRANCH LINE CIRCUIT

Diagnosis Procedure INFOID:0000000004491787YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the combination meter branch line. Power Supply and

Ground Circuit Inspection " .

Is the inspection result normal? YES (Present error)>>Replace the combination meter. Refer to

IP-12, " Removal and Installation " .

YES (Past error)>>Error was detected in the combination meter branch line.

NO >> Repair the power supply and the ground circuit. Combination meter harness connector

Resistance (Ω)

Connector No. Terminal No.

M24 1 2 Approx. 54 – 66

Page 3465 of 4331

YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line. ABS Control Unit Power and Ground Systems Inspection " .

Is the inspection result normal? YES (Present error)>>Replace t

he ABS actuator and electric unit (control unit). Refer to BRC-35, " Removal

and Installation " .

YES (Past error)>>Error was detected in the ABS ac tuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit. ABS actuator and electric unit (c

ontrol unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E33 26 15 Approx. 54 – 66

Page 3466 of 4331

LAN

N

O P

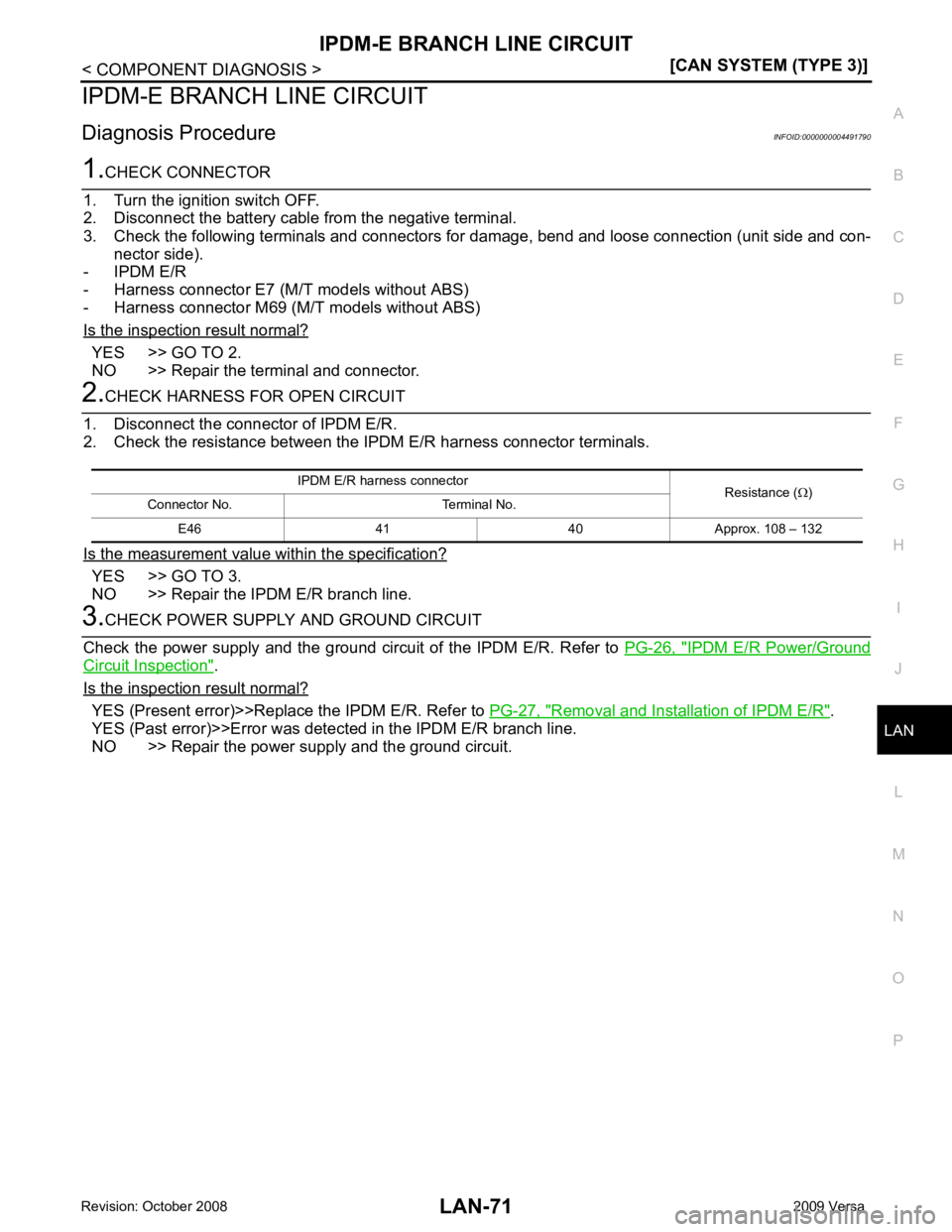

IPDM-E BRANCH

LINE CIRCUIT

Diagnosis Procedure INFOID:0000000004491790YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the IPDM E/R branch line. IPDM E/R Power/Ground

Circuit Inspection " .

Is the inspection result normal? YES (Present error)>>Replace the IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

YES (Past error)>>Error was detec ted in the IPDM E/R branch line.

NO >> Repair the power supply and the ground circuit. IPDM E/R harness connector

Resistance (Ω)

Connector No. Terminal No.

E46 41 40 Approx. 108 – 132

Page 3467 of 4331

![NISSAN LATIO 2009 Service Repair Manual LAN-72< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000044917911.

CONNECTOR INSPECTION

1. Turn the ignition switch O NISSAN LATIO 2009 Service Repair Manual LAN-72< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000044917911.

CONNECTOR INSPECTION

1. Turn the ignition switch O](/img/5/57359/w960_57359-3466.png)

LAN-72< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000044917911.

CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect all the unit connectors on CAN communication system.

4. Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector. 2.

CHECK HARNESS CONTI NUITY (SHORT CIRCUIT)

Check the continuity between t he data link connector terminals.

Is the inspection result normal? YES >> GO TO 3.

NO >> Check the harness and repair the root cause. 3.

CHECK HARNESS CONTI NUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Check the harness and repair the root cause. 4.

CHECK ECM AND IPDM E/R TERMINATION CIRCUIT

1. Remove the ECM and the IPDM E/R.

2. Check the resistance between the ECM terminals.

3. Check the resistance between the IPDM E/R terminals.

Is the measurement value within the specification? YES >> GO TO 5.

NO >> Replace the ECM and/or the IPDM E/R. 5.

CHECK SYMPTOM

Connect all the connectors. Check if the symptoms descri bed in the “Symptom (Results from interview with

customer)” are reproduced. Data link connector

Continuity

Connector No. Terminal No.

M22 6 14 Not existed Data link connector

GroundContinuity

Connector No. Terminal No.

M22 6 Not existed

14 Not existed ECM

Resistance (Ω)

Terminal No.

84 83 Approx. 108 – 132

IPDM E/R Resistance (Ω)

Terminal No.

41 40 Approx. 108 – 132 LKIA0037E

Page 3468 of 4331

LAN

N

O P

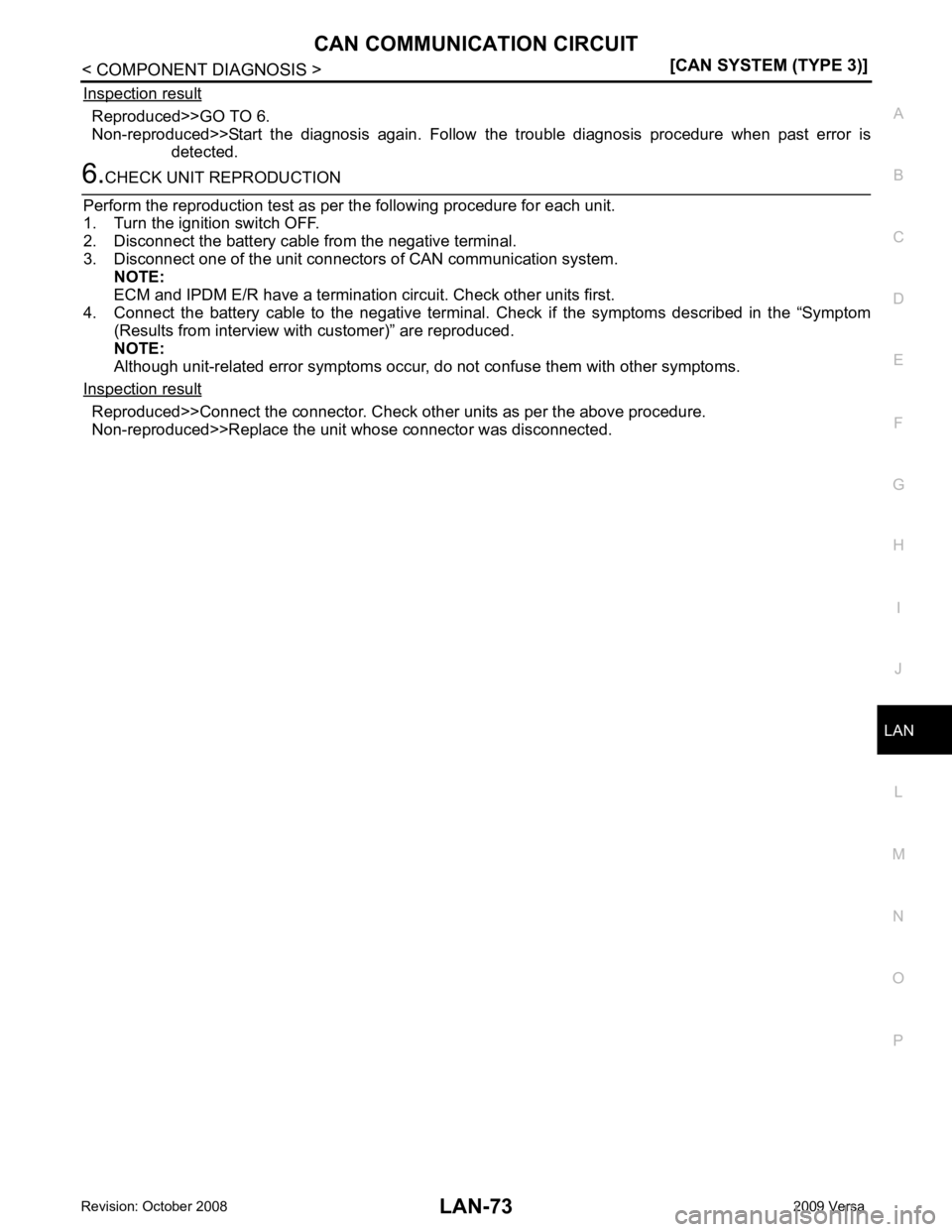

Inspection result Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected. Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3469 of 4331

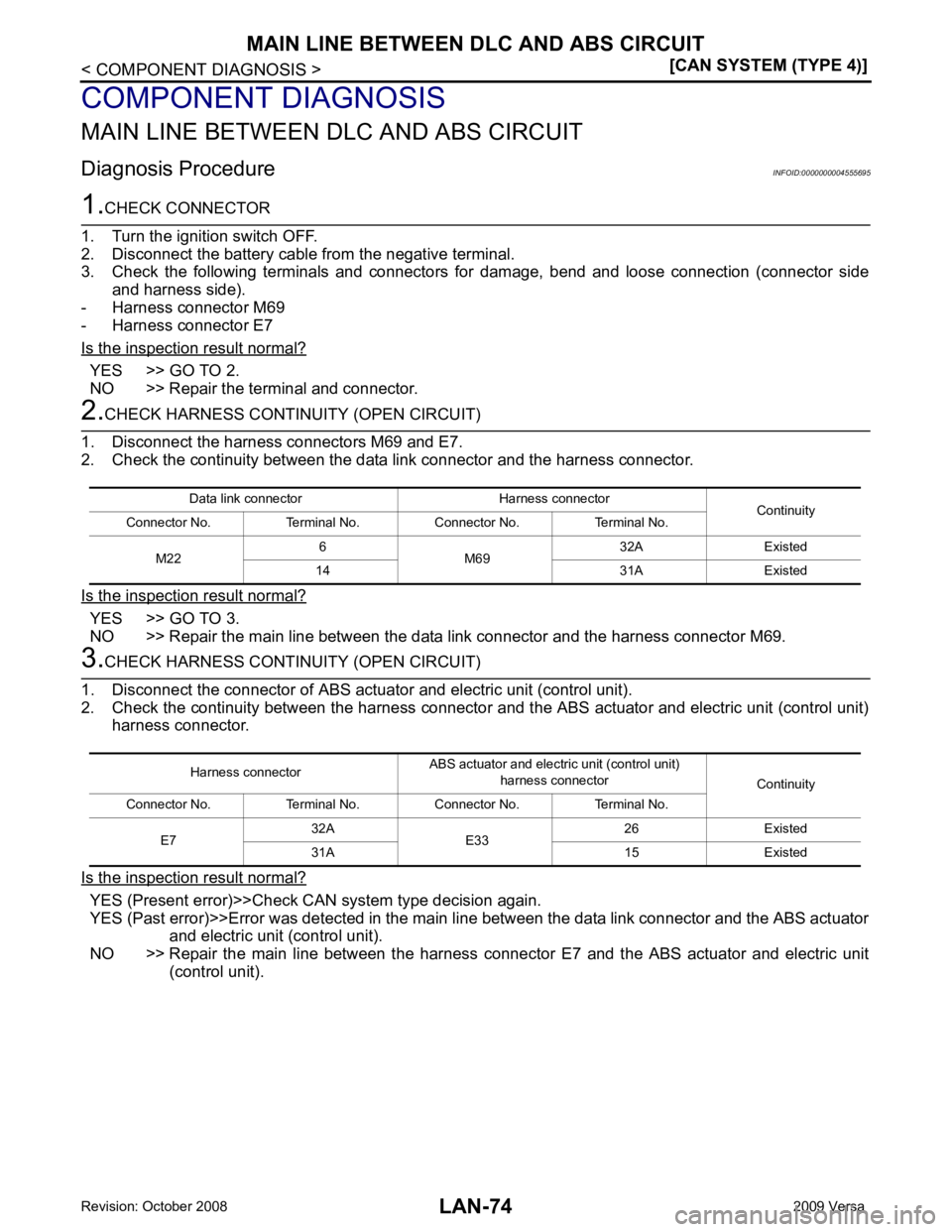

YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the main line between the data link connector and the harness connector M69.YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the data link connector and the ABS actuator

and electric unit (control unit).

NO >> Repair the main line between the harness connec tor E7 and the ABS actuator and electric unit

(control unit). Data link connector Harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

M22 6

M69 32A Existed

14 31A Existed Harness connector

ABS actuator and electric unit (control unit)

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

E7 32A

E33 26 Existed

31A 15 Existed

Page 3470 of 4331

LAN

N

O P

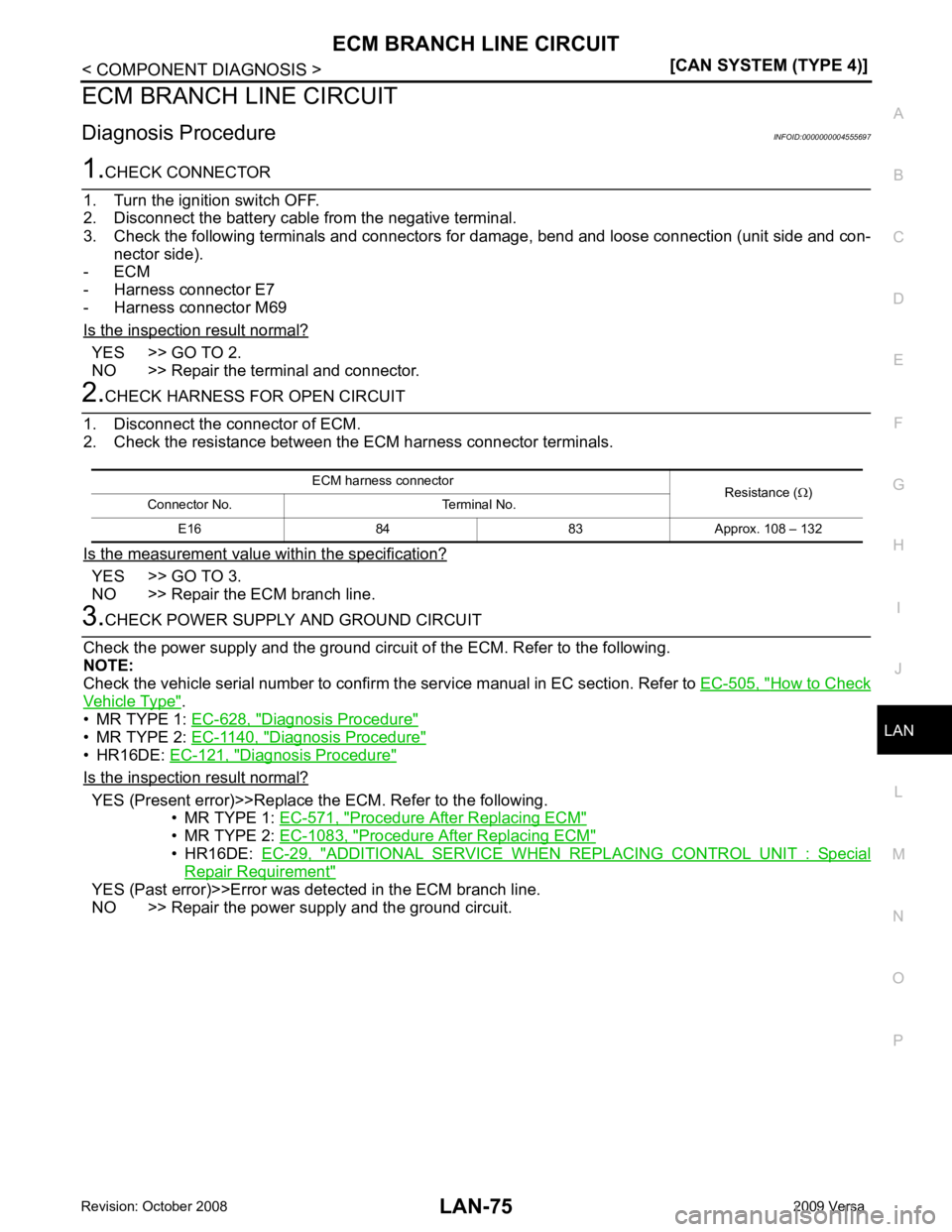

ECM BRANCH LINE CIRCUIT

Diagnosis Procedure INFOID:0000000004555697YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the ECM branch line. How to Check

Vehicle Type " .

• MR TYPE 1: EC-628, " Diagnosis Procedure "

• MR TYPE 2:

EC-1140, " Diagnosis Procedure "

• HR16DE:

EC-121, " Diagnosis Procedure "

Is the inspection result normal?

YES (Present error)>>Replace the ECM. Refer to the following.

• MR TYPE 1: EC-571, " Procedure After Replacing ECM "

• MR TYPE 2:

EC-1083, " Procedure After Replacing ECM "

• HR16DE:

EC-29, " ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special

Repair Requirement "

YES (Past error)>>Error was det

ected in the ECM branch line.

NO >> Repair the power supply and the ground circuit. ECM harness connector

Resistance (Ω)

Connector No. Terminal No.

E16 84 83 Approx. 108 – 132

Trending: power steering fluid, engine overheat, fuel filter, hood open, jump cable, key fob battery, phone

![NISSAN LATIO 2009 Service Repair Manual LAN-72< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000044917911.

CONNECTOR INSPECTION

1. Turn the ignition switch O NISSAN LATIO 2009 Service Repair Manual LAN-72< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000044917911.

CONNECTOR INSPECTION

1. Turn the ignition switch O](/img/5/57359/w960_57359-3466.png)