oil NISSAN LATIO 2009 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 254 of 4331

AT

N

O P

Oil Channel

INFOID:0000000004305511

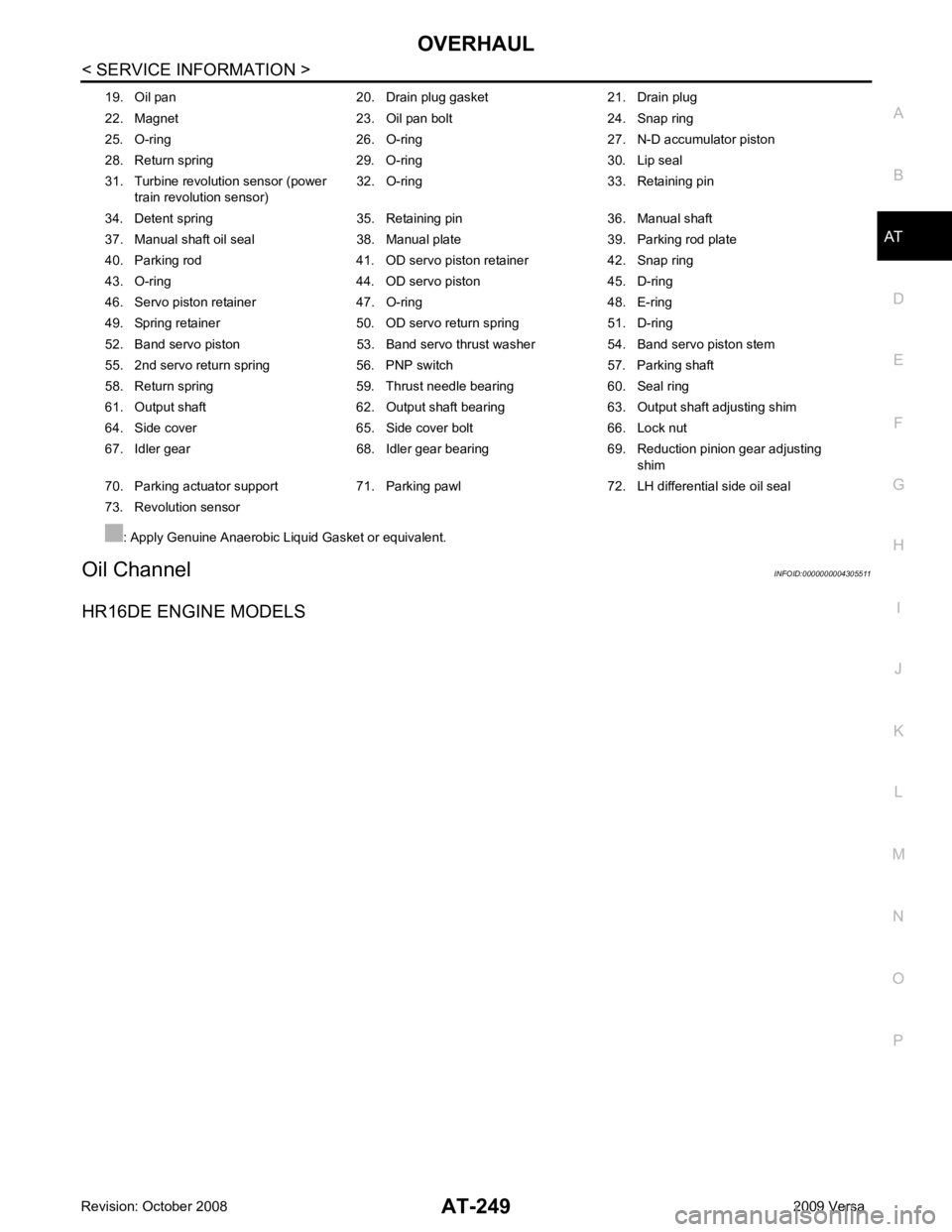

HR16DE ENGINE MODELS 19. Oil pan 20. Drain plug gasket 21. Drain plug

22. Magnet 23. Oil pan bolt 24. Snap ring

25. O-ring 26. O-ring 27. N-D accumulator piston

28. Return spring 29. O-ring 30. Lip seal

31. Turbine revolution sensor (power train revolution sensor) 32. O-ring 33. Retaining pin

34. Detent spring 35. Retaining pin 36. Manual shaft

37. Manual shaft oil seal 38. Manual plate 39. Parking rod plate

40. Parking rod 41. OD servo piston retainer 42. Snap ring

43. O-ring 44. OD servo piston 45. D-ring

46. Servo piston retainer 47. O-ring 48. E-ring

49. Spring retainer 50. OD servo return spring 51. D-ring

52. Band servo piston 53. Band servo thrust washer 54. Band servo piston stem

55. 2nd servo return spring 56. PNP switch 57. Parking shaft

58. Return spring 59. Thrust needle bearing 60. Seal ring

61. Output shaft 62. Output shaft bearing 63. Output shaft adjusting shim

64. Side cover 65. Side cover bolt 66. Lock nut

67. Idler gear 68. Idler gear bearing 69. Reduction pinion gear adjusting shim

70. Parking actuator support 71. Parking pawl 72. LH differential side oil seal

73. Revolution sensor

: Apply Genuine Anaerobic Liquid Gasket or equivalent.

Page 263 of 4331

.

14. Remove magnets from oil pan.

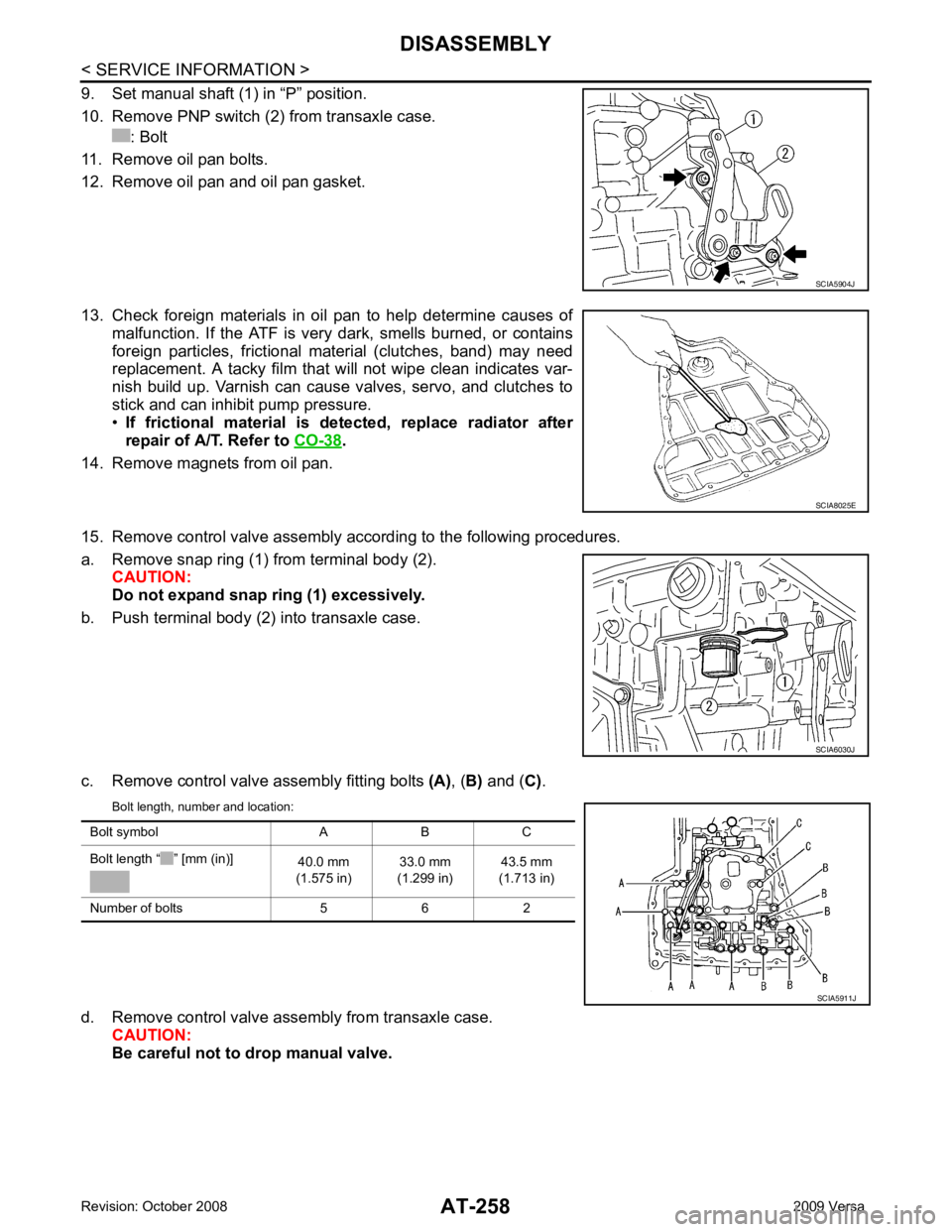

15. Remove control valve assembly according to the following procedures.

a. Remove snap ring (1) from terminal body (2). CAUTION:

Do not expand snap ring (1) excessively.

b. Push terminal body (2) into transaxle case.

c. Remove control valve assembly fitting bolts (A), (B) and ( C).

Bolt length, number and location:

d. Remove control valve assembly from transaxle case. CAUTION:

Be careful not to drop manual valve. SCIA8025E

SCIA6030J

Page 264 of 4331

AT

N

O P

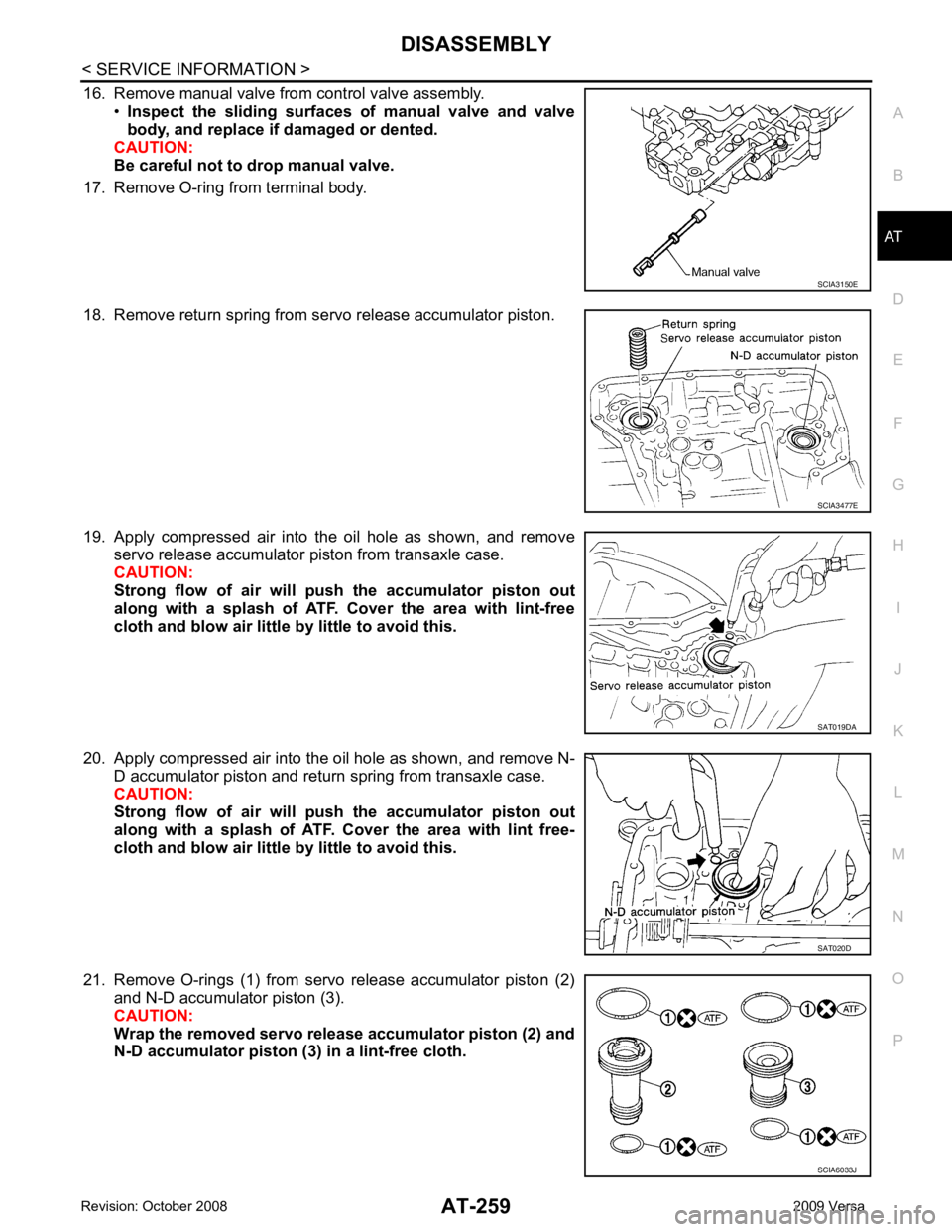

16. Remove manual valve from control valve assembly.

•Inspect the sliding surfaces of manual valve and valve

body, and replace if damaged or dented.

CAUTION:

Be careful not to drop manual valve.

17. Remove O-ring from terminal body.

18. Remove return spring from servo release accumulator piston.

19. Apply compressed air into the oil hole as shown, and remove servo release accumulator piston from transaxle case.

CAUTION:

Strong flow of air will pu sh the accumulator piston out

along with a splash of ATF. Cover the area with lint-free

cloth and blow air little by little to avoid this.

20. Apply compressed air into the oil hole as shown, and remove N- D accumulator piston and return spring from transaxle case.

CAUTION:

Strong flow of air will pu sh the accumulator piston out

along with a splash of ATF. Cover the area with lint free-

cloth and blow air little by little to avoid this.

21. Remove O-rings (1) from servo release accumulator piston (2) and N-D accumulator piston (3).

CAUTION:

Wrap the removed servo rel ease accumulator piston (2) and

N-D accumulator piston (3) in a lint-free cloth. SCIA3477E

SAT019DA

Page 268 of 4331

AT

N

O P

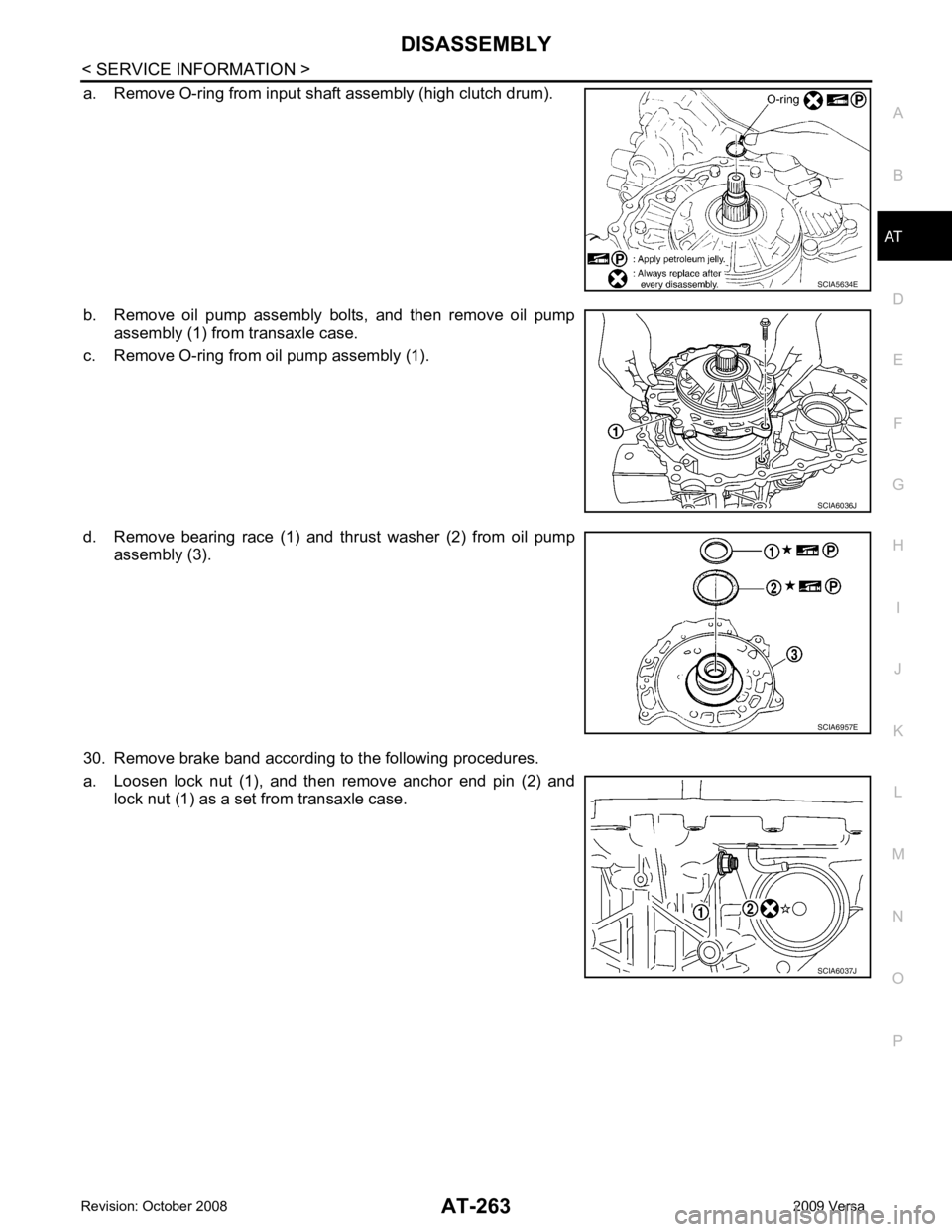

a. Remove O-ring from input shaft assembly (high clutch drum).

b. Remove oil pump assembly bolts, and then remove oil pump assembly (1) from transaxle case.

c. Remove O-ring from oil pump assembly (1).

d. Remove bearing race (1) and thrust washer (2) from oil pump assembly (3).

30. Remove brake band according to the following procedures.

a. Loosen lock nut (1), and then remove anchor end pin (2) and lock nut (1) as a set from transaxle case.

Page 278 of 4331

AT

N

O P

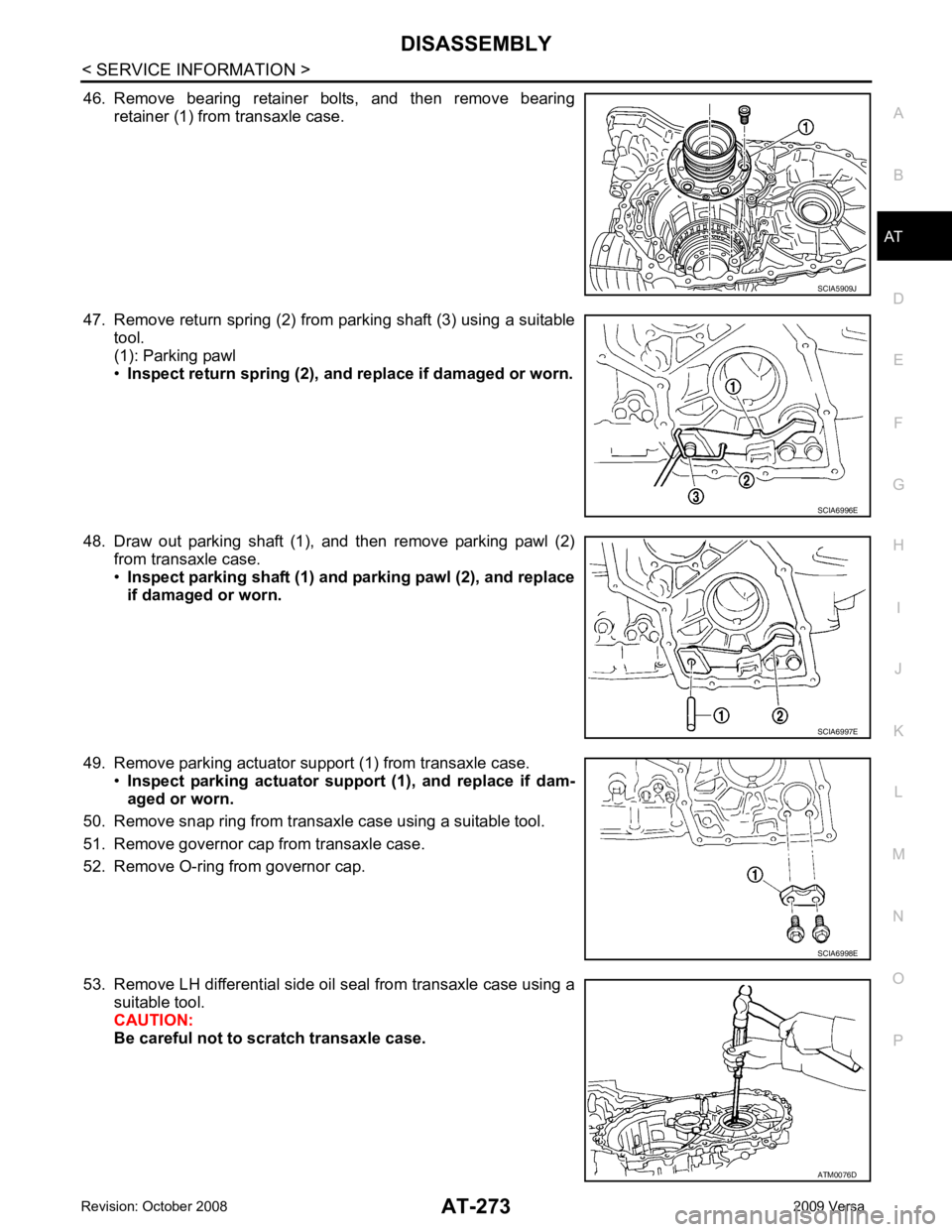

46. Remove bearing retainer bolts, and then remove bearing

retainer (1) from transaxle case.

47. Remove return spring (2) from parking shaft (3) using a suitable tool.

(1): Parking pawl

• Inspect return spring (2), and replace if damaged or worn.

48. Draw out parking shaft (1), and then remove parking pawl (2) from transaxle case.

• Inspect parking shaft (1) and parking pawl (2), and replace

if damaged or worn.

49. Remove parking actuator support (1) from transaxle case. •Inspect parking actuator sup port (1), and replace if dam-

aged or worn.

50. Remove snap ring from transaxle case using a suitable tool.

51. Remove governor cap from transaxle case.

52. Remove O-ring from governor cap.

53. Remove LH differential side oil seal from transaxle case using a suitable tool.

CAUTION:

Be careful not to scratch transaxle case. ATM0076D

Page 280 of 4331

AT

N

O P

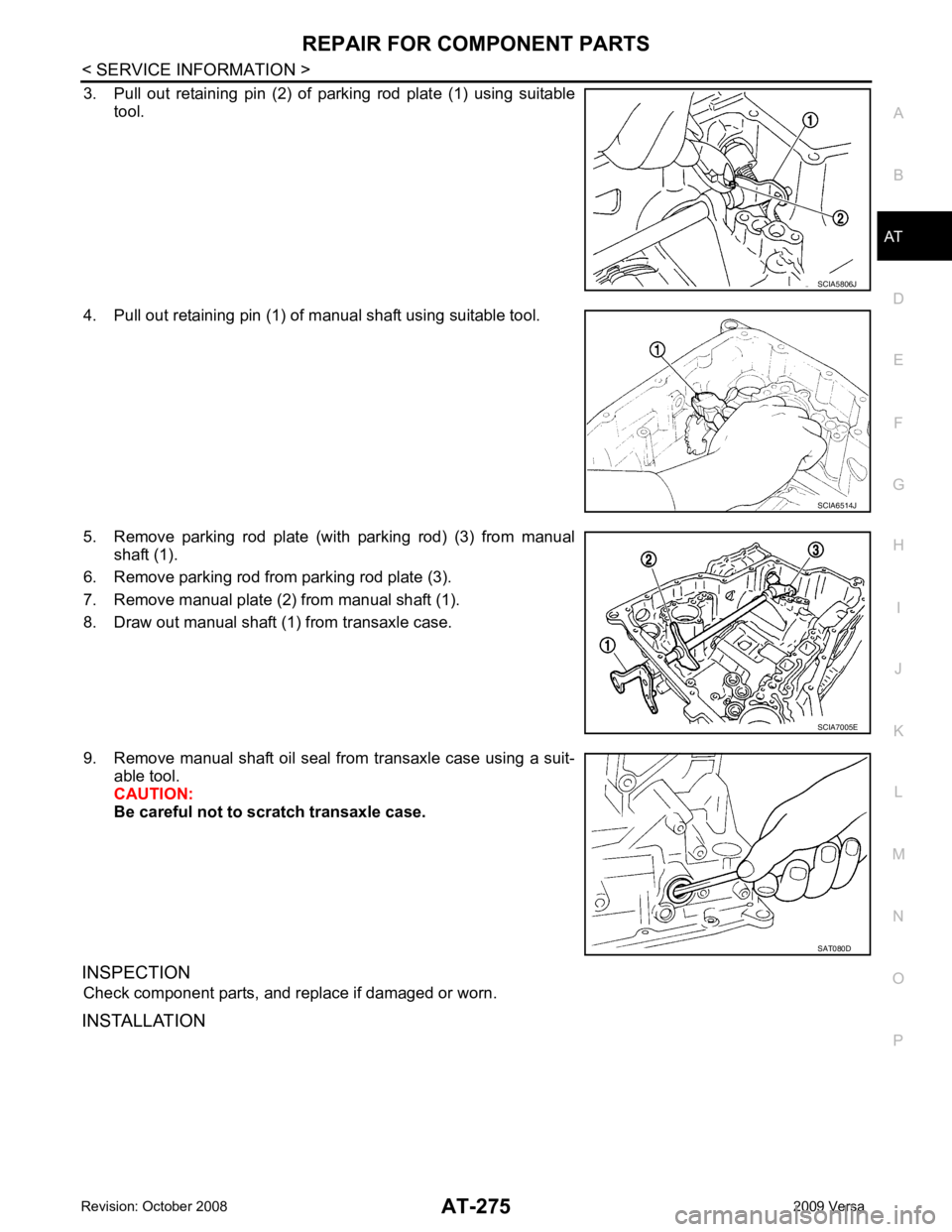

3. Pull out retaining pin (2) of parking rod plate (1) using suitable

tool.

4. Pull out retaining pin (1) of manual shaft using suitable tool.

5. Remove parking rod plate (with parking rod) (3) from manual shaft (1).

6. Remove parking rod from parking rod plate (3).

7. Remove manual plate (2) from manual shaft (1).

8. Draw out manual shaft (1) from transaxle case.

9. Remove manual shaft oil seal from transaxle case using a suit- able tool.

CAUTION:

Be careful not to scratch transaxle case.

INSPECTION Check component parts, and replace if damaged or worn.

INSTALLATION SCIA6514J

Page 281 of 4331

![NISSAN LATIO 2009 Service Service Manual AT-276< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

1. Drive manual shaft oil seal into transaxle case using a drift [com- mercial service tool: 22 mm (0.87 in) dia.].

CAUTION:

• Do not reuse m NISSAN LATIO 2009 Service Service Manual AT-276< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

1. Drive manual shaft oil seal into transaxle case using a drift [com- mercial service tool: 22 mm (0.87 in) dia.].

CAUTION:

• Do not reuse m](/img/5/57359/w960_57359-280.png)

AT-276< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

1. Drive manual shaft oil seal into transaxle case using a drift [com- mercial service tool: 22 mm (0.87 in) dia.].

CAUTION:

• Do not reuse manual shaft oil seal.

• Apply ATF to outer surface of manual shaft oil seal.

2. Install parking rod to parking rod plate.

3. Insert manual shaft (1) to transaxle case, and install manual plate (2) to manual shaft (1).

4. Install parking rod plate (with parking rod) (3) to manual shaft (1).

5. Align groove of manual shaft and hole of transaxle case using a pin punch (A) [commercial service tool: 2 mm (0.08 in) dia.].

6. Drive retaining pin of manual shaft into transaxle case using Tool (B).

CAUTION:

Do not reuse retaining pin.

7. Set parking rod plate (1) onto manual shaft, and drive retaining pin (2) of parking rod plate (1) using tool (A).

CAUTION:

The retaining pin end should protrude approx. 3mm (0.12

in) (B) from the outer surface of parking rod plate (1).

8. Set manual plate (1) onto manual shaft, and drive retaining pin (2) of manual plate (1) using tool (A).

CAUTION:

The retaining pin end should protrude approx. 3mm (0.12

in) (B) from the outer surface of manual plate (1). SAT081D

SCIA7005E

Tool number: ST23540000 (J-25689-A)

SCIA7006E

Tool number: ST23540000 (J-25689-A)

SCIA7107E

Tool number: ST23540000 (J-25698-A)

SCIA7108E

Page 282 of 4331

AT

N

O P

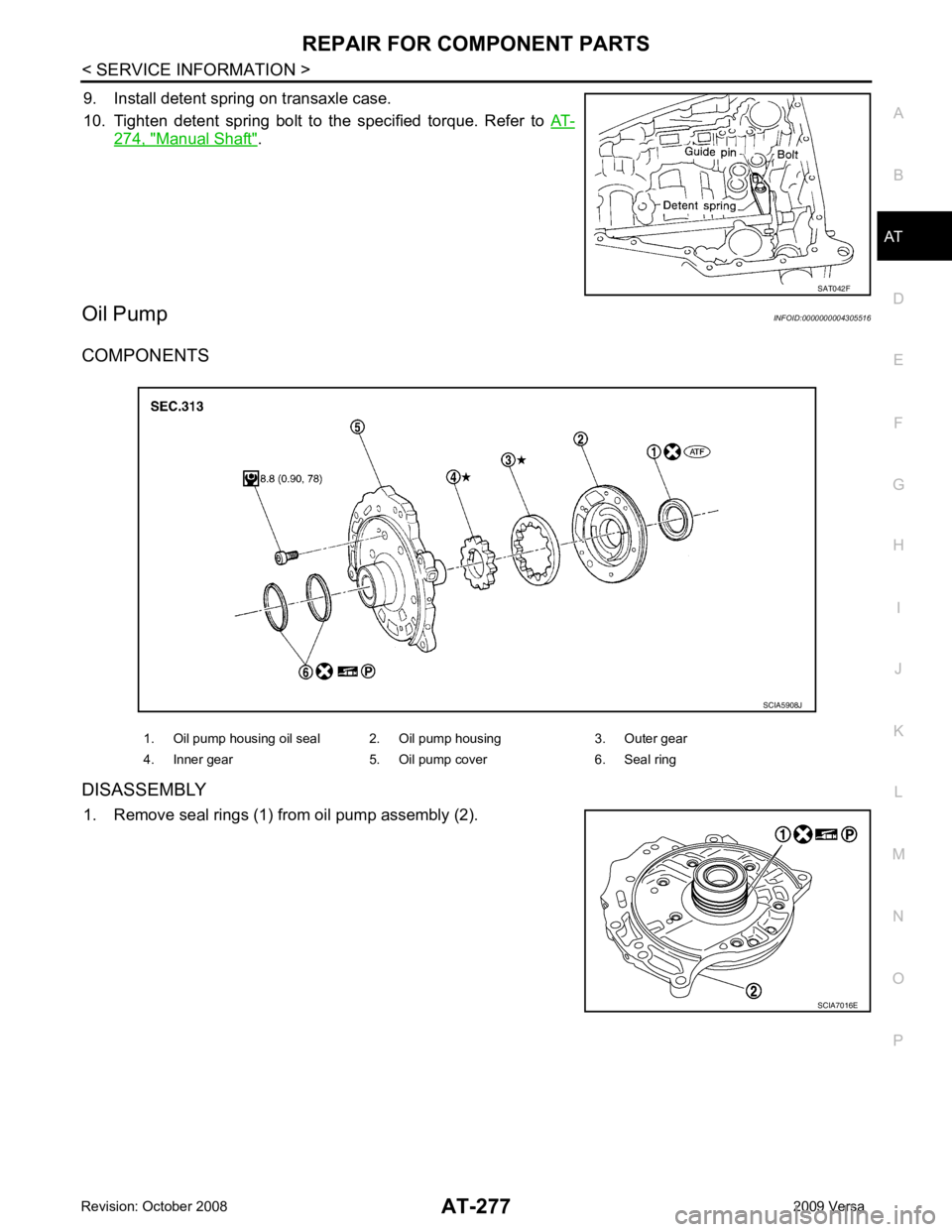

9. Install detent spring on transaxle case.

10. Tighten detent spring bolt to the specified torque. Refer to AT-274, " Manual Shaft " .

Oil Pump INFOID:0000000004305516

COMPONENTS

DISASSEMBLY 1. Remove seal rings (1) from oil pump assembly (2).

Page 284 of 4331

AT

N

O P

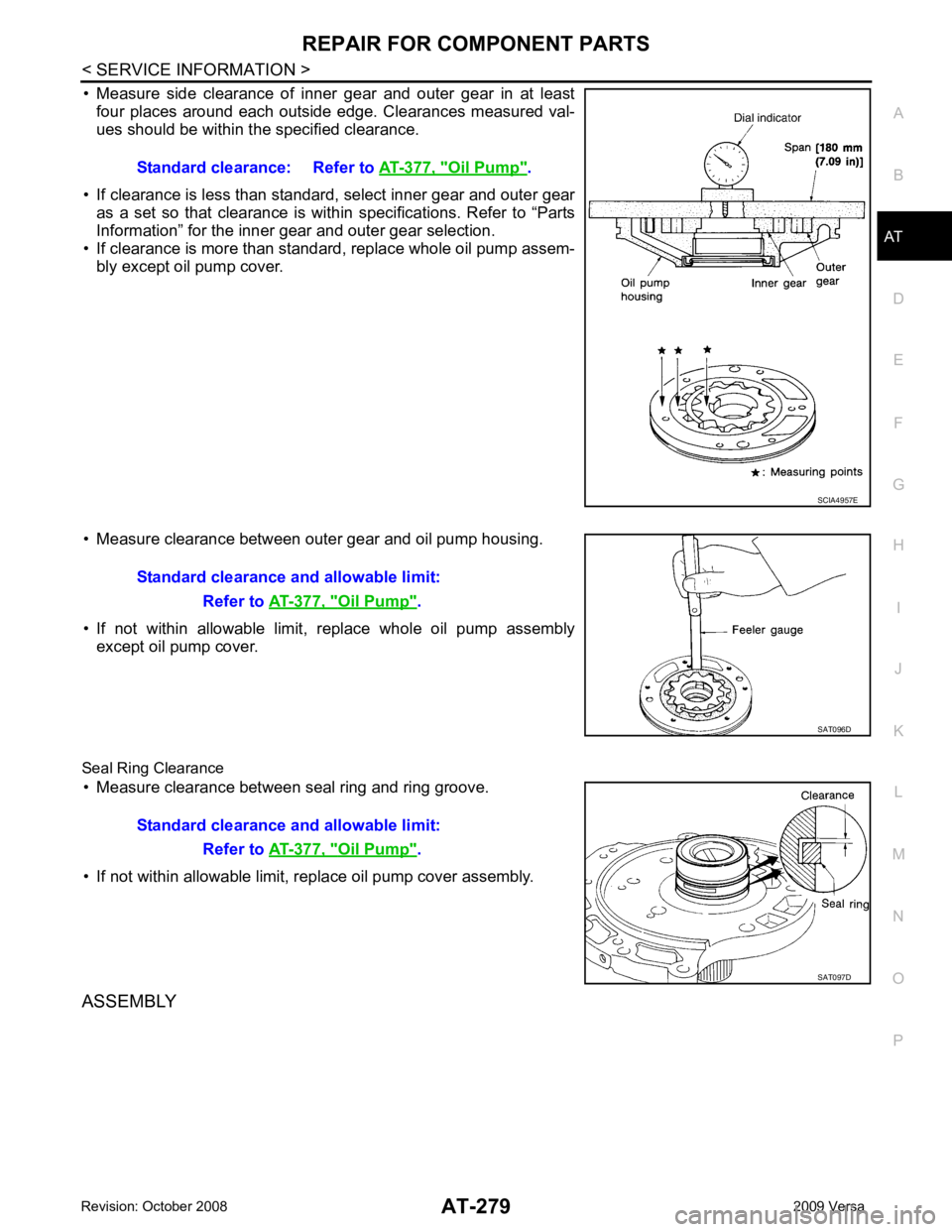

• Measure side clearance of inner gear and outer gear in at least

four places around each outside edge. Clearances measured val-

ues should be within the specified clearance.

• If clearance is less than standard, select inner gear and outer gear as a set so that clearance is withi n specifications. Refer to “Parts

Information” for the inner gear and outer gear selection.

• If clearance is more than standard, replace whole oil pump assem-

bly except oil pump cover.

• Measure clearance between outer gear and oil pump housing.

• If not within allowable limit, replace whole oil pump assembly except oil pump cover.

Seal Ring Clearance • Measure clearance between seal ring and ring groove.

• If not within allowable limit, replace oil pump cover assembly.

ASSEMBLY Standard clearance: Refer to

AT-377, " Oil Pump " .

Oil Pump " .

Oil Pump " .

Page 285 of 4331

AT-280< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

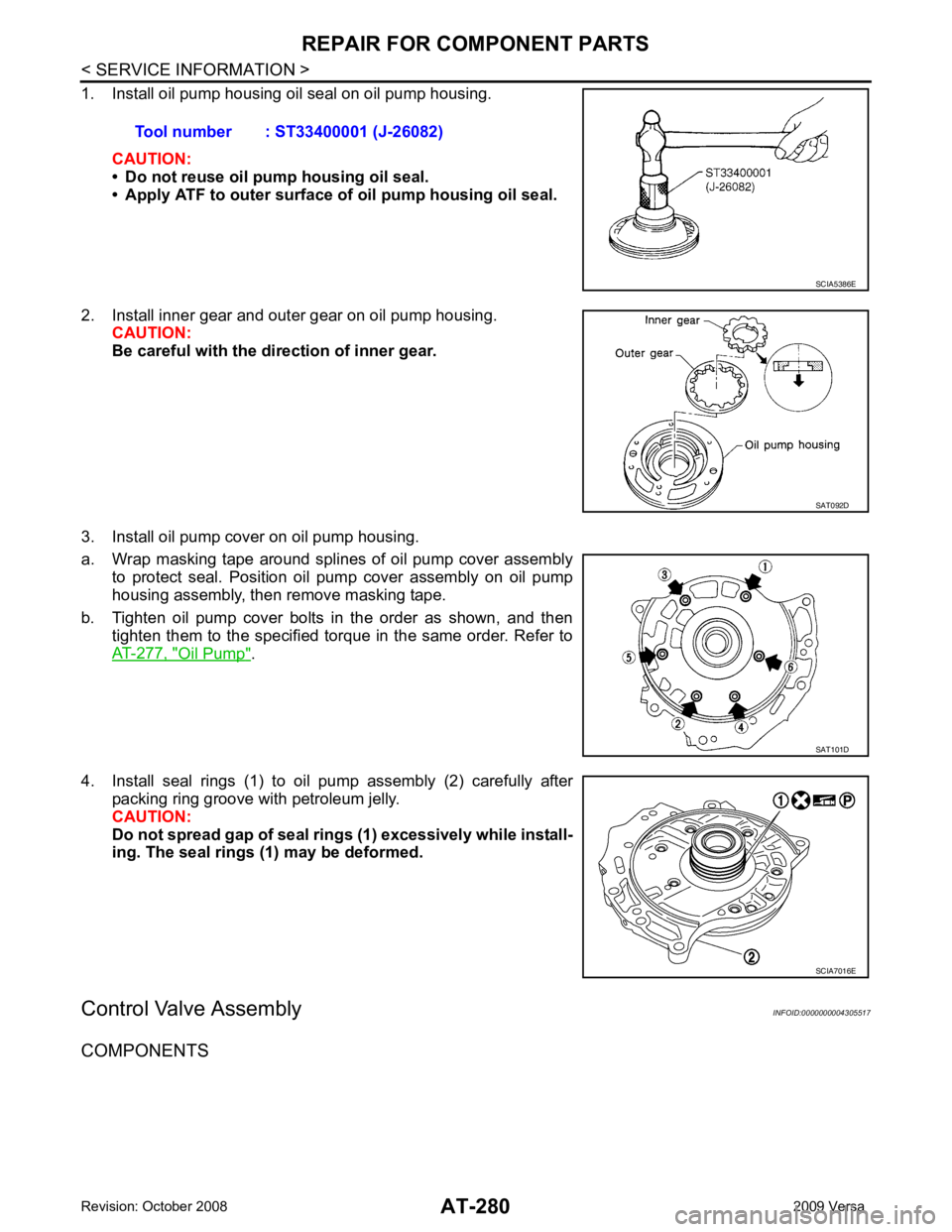

1. Install oil pump housing oil seal on oil pump housing.

CAUTION:

• Do not reuse oil pump housing oil seal.

• Apply ATF to outer surface of oil pump housing oil seal.

2. Install inner gear and outer gear on oil pump housing. CAUTION:

Be careful with the direction of inner gear.

3. Install oil pump cover on oil pump housing.

a. Wrap masking tape around splines of oil pump cover assembly to protect seal. Position oil pump cover assembly on oil pump

housing assembly, then remove masking tape.

b. Tighten oil pump cover bolts in the order as shown, and then tighten them to the specified torque in the same order. Refer to

AT-277, " Oil Pump " .

4. Install seal rings (1) to oil pump assembly (2) carefully after packing ring groove with petroleum jelly.

CAUTION:

Do not spread gap of seal ri ngs (1) excessively while install-

ing. The seal rings (1) may be deformed.

Control Valve Assembly INFOID:0000000004305517

COMPONENTS Tool number : ST33400001 (J-26082) SCIA5386E

SAT092D

SAT101D

SCIA7016E