clock NISSAN LATIO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 238 of 4331

AT

N

O P

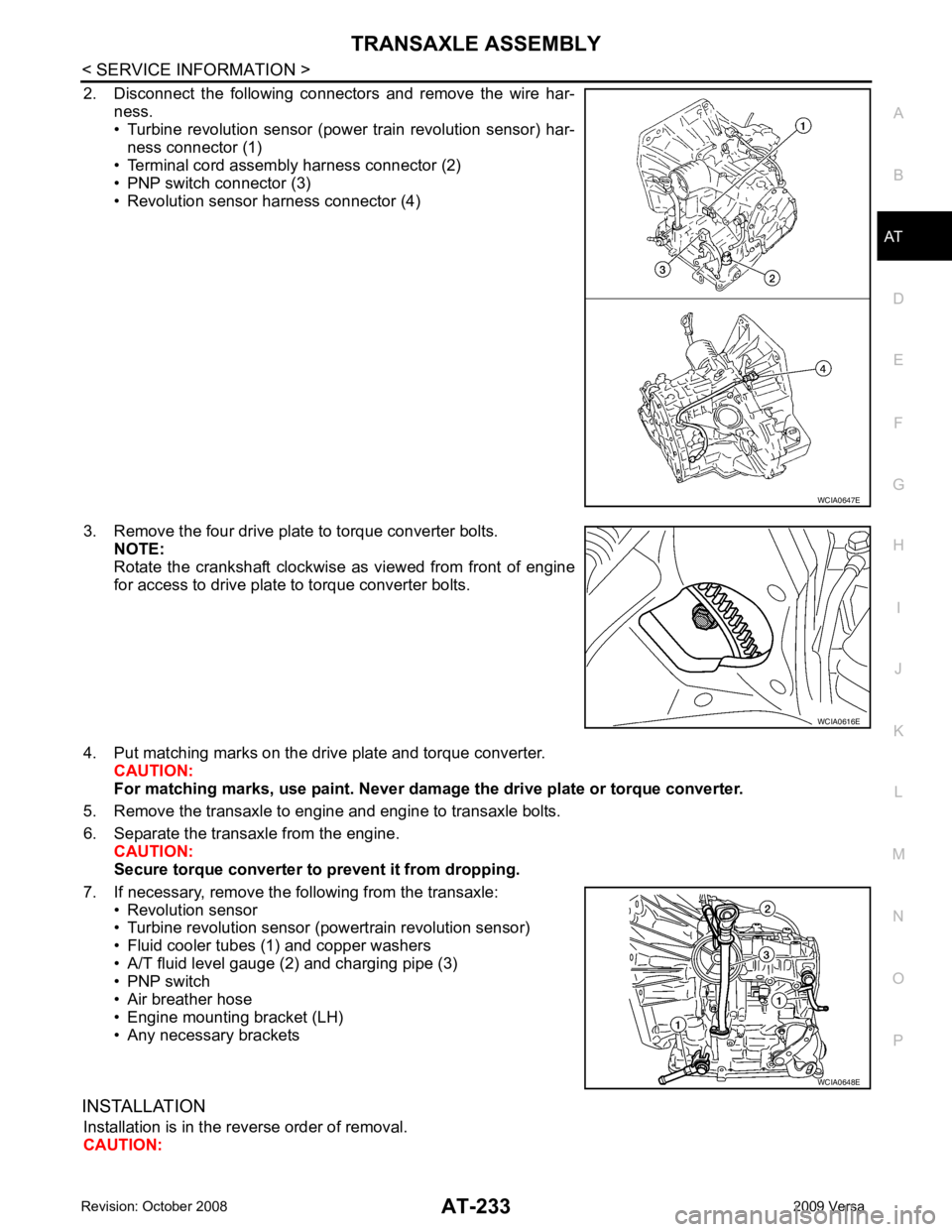

2. Disconnect the following connectors and remove the wire har-

ness.

• Turbine revolution sensor (power train revolution sensor) har-

ness connector (1)

• Terminal cord assembly harness connector (2)

• PNP switch connector (3)

• Revolution sensor harness connector (4)

3. Remove the four drive plate to torque converter bolts. NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter bolts.

4. Put matching marks on the drive plate and torque converter. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

5. Remove the transaxle to engine and engine to transaxle bolts.

6. Separate the transaxle from the engine. CAUTION:

Secure torque converter to prevent it from dropping.

7. If necessary, remove the following from the transaxle: • Revolution sensor

• Turbine revolution sensor (powertrain revolution sensor)

• Fluid cooler tubes (1) and copper washers

• A/T fluid level gauge (2) and charging pipe (3)

• PNP switch

• Air breather hose

• Engine mounting bracket (LH)

• Any necessary brackets

INSTALLATION Installation is in the reverse order of removal.

CAUTION: WCIA0616E

WCIA0648E

Page 272 of 4331

AT

N

O P

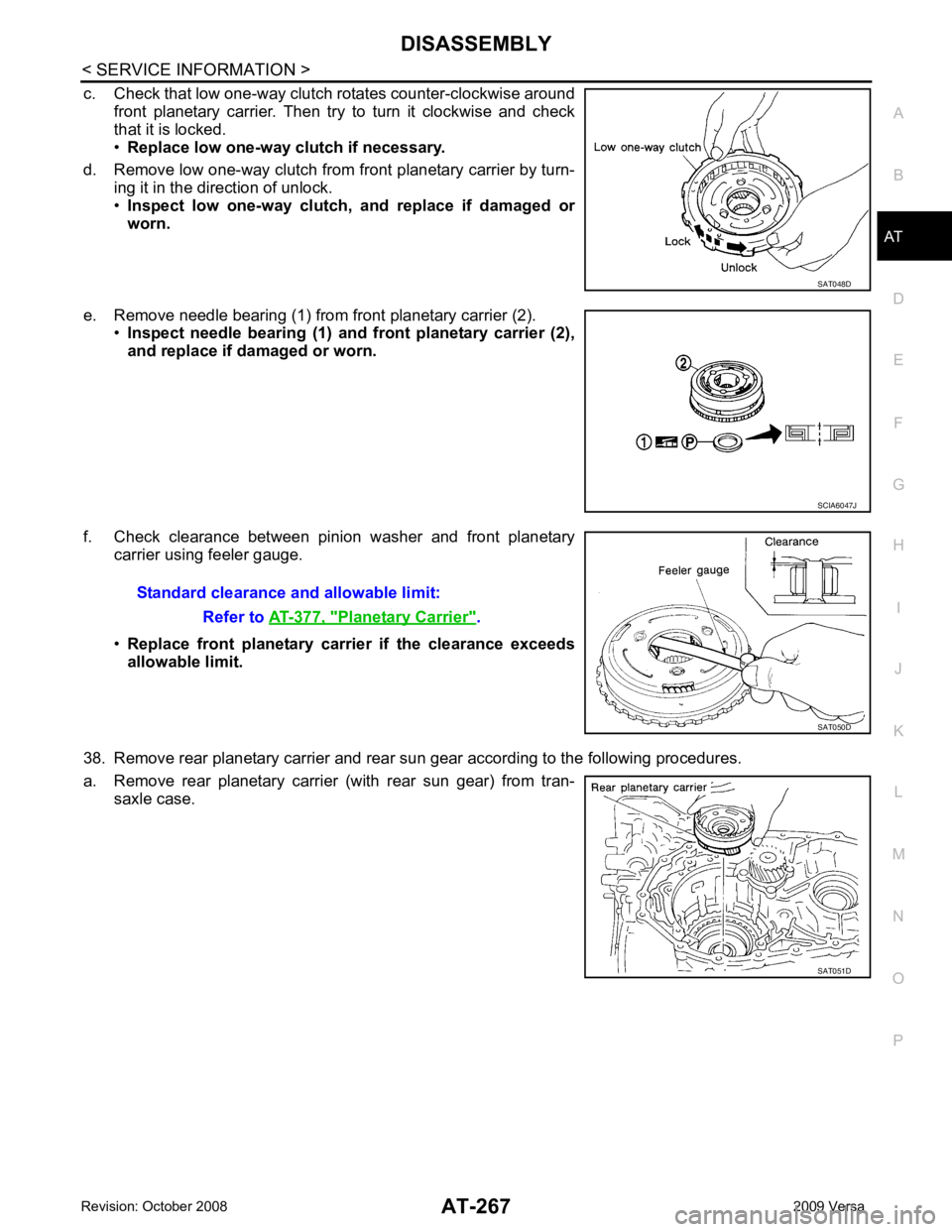

c. Check that low one-way clutch rotates counter-clockwise around

front planetary carrier. Then try to turn it clockwise and check

that it is locked.

• Replace low one-way clutch if necessary.

d. Remove low one-way clutch from front planetary carrier by turn- ing it in the direction of unlock.

• Inspect low one-way clutch , and replace if damaged or

worn.

e. Remove needle bearing (1) from front planetary carrier (2). •Inspect needle bearing (1) a nd front planetary carrier (2),

and replace if damaged or worn.

f. Check clearance between pinion washer and front planetary carrier using feeler gauge.

• Replace front planetary carrier if the clearance exceeds

allowable limit.

38. Remove rear planetary carrier and rear sun gear according to the following procedures.

a. Remove rear planetary carrier (with rear sun gear) from tran- saxle case. SCIA6047J

Planetary Carrier " .

SAT051D

Page 360 of 4331

ASSEMBLY

AT-355

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

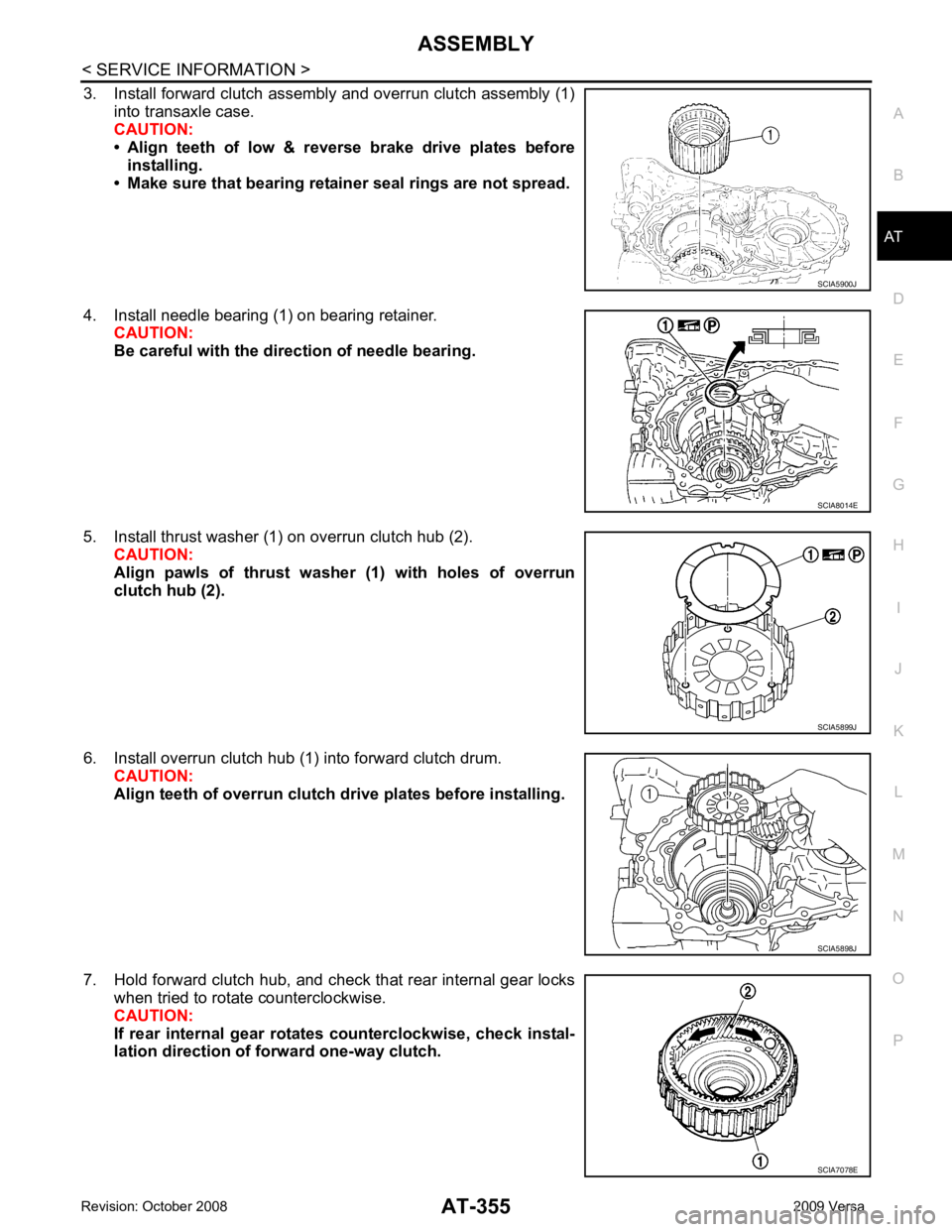

3. Install forward clutch assembly and overrun clutch assembly (1)

into transaxle case.

CAUTION:

• Align teeth of low & r everse brake drive plates before

installing.

• Make sure that bearing retain er seal rings are not spread.

4. Install needle bearing (1) on bearing retainer. CAUTION:

Be careful with the dir ection of needle bearing.

5. Install thrust washer (1) on overrun clutch hub (2). CAUTION:

Align pawls of thrust washer (1) with holes of overrun

clutch hub (2).

6. Install overrun clutch hub (1) into forward clutch drum. CAUTION:

Align teeth of overrun clutch drive plates before installing.

7. Hold forward clutch hub, and check that rear internal gear locks when tried to rotate counterclockwise.

CAUTION:

If rear internal gear rotates counterclockwise, check instal-

lation direction of fo rward one-way clutch. SCIA5900J

SCIA8014E

SCIA5899J

SCIA5898J

SCIA7078E

Page 362 of 4331

ASSEMBLY

AT-357

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

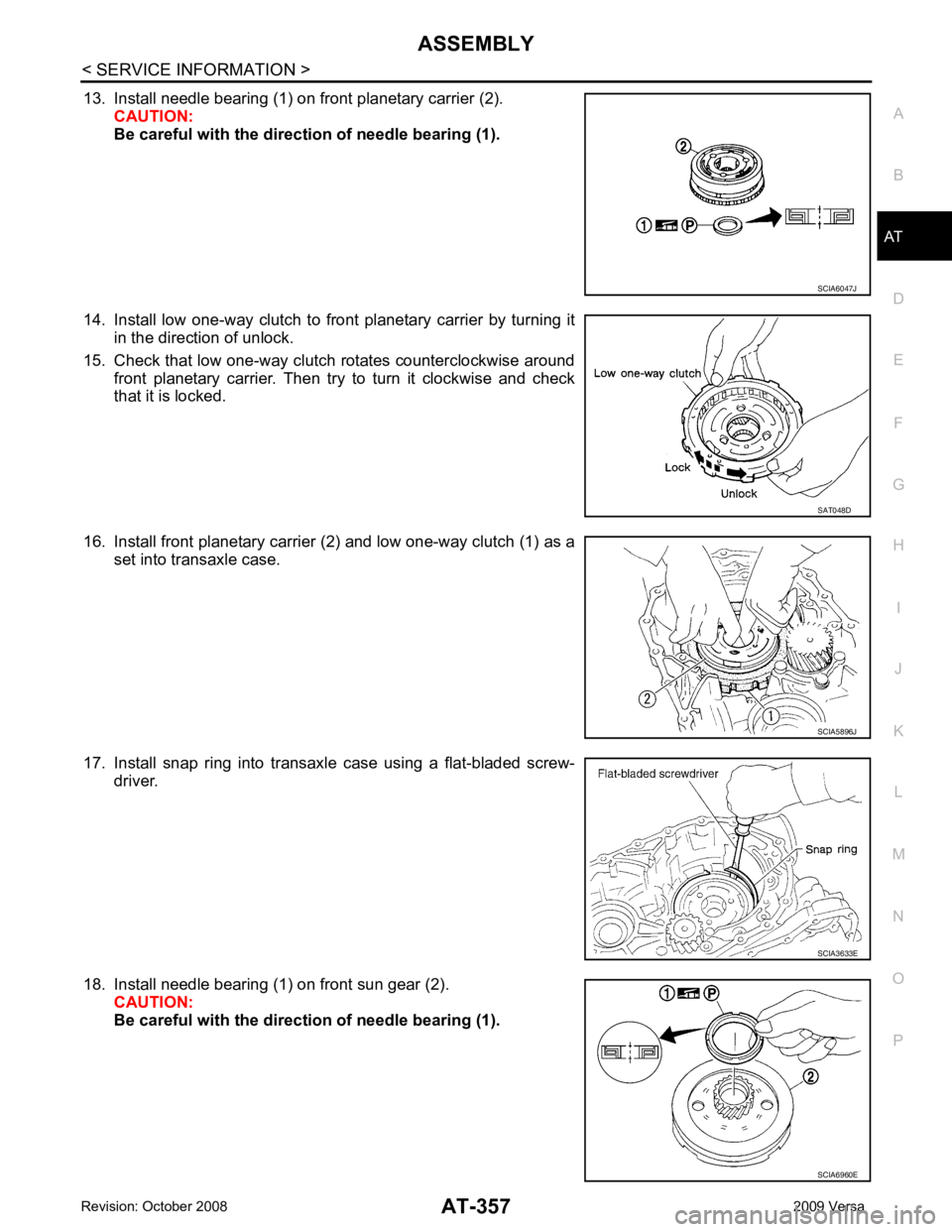

13. Install needle bearing (1) on front planetary carrier (2).

CAUTION:

Be careful with the direct ion of needle bearing (1).

14. Install low one-way clutch to front planetary carrier by turning it in the direction of unlock.

15. Check that low one-way clutch rotates counterclockwise around front planetary carrier. Then try to turn it clockwise and check

that it is locked.

16. Install front planetary carrier (2) and low one-way clutch (1) as a set into transaxle case.

17. Install snap ring into transaxle case using a flat-bladed screw- driver.

18. Install needle bearing (1) on front sun gear (2). CAUTION:

Be careful with the direct ion of needle bearing (1). SCIA6047J

SAT048D

SCIA5896J

SCIA3633E

SCIA6960E

Page 468 of 4331

BL

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

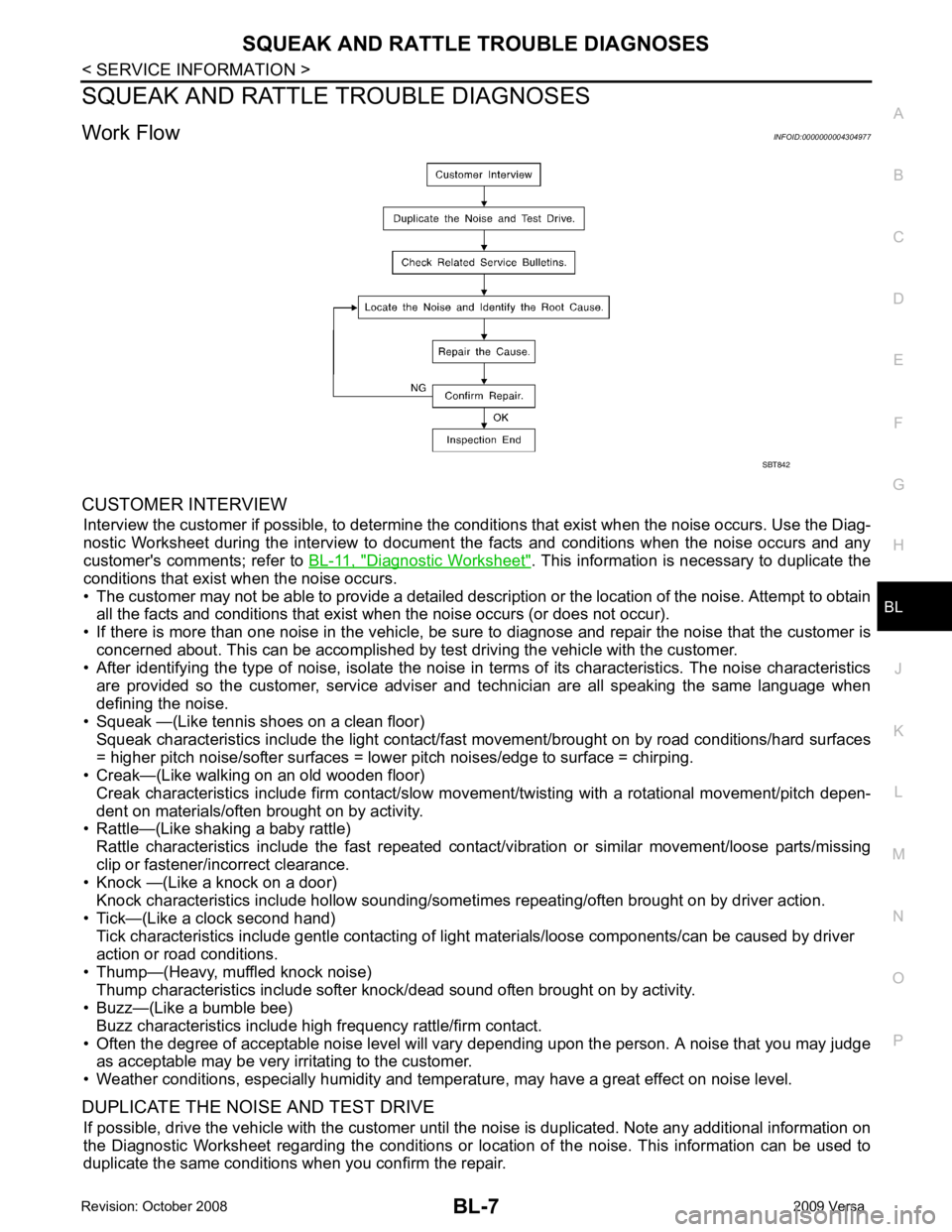

Work Flow INFOID:0000000004304977

CUSTOMER INTERVIEW Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to BL-11, " Diagnostic Worksheet " . This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

Page 807 of 4331

BR

N

O P

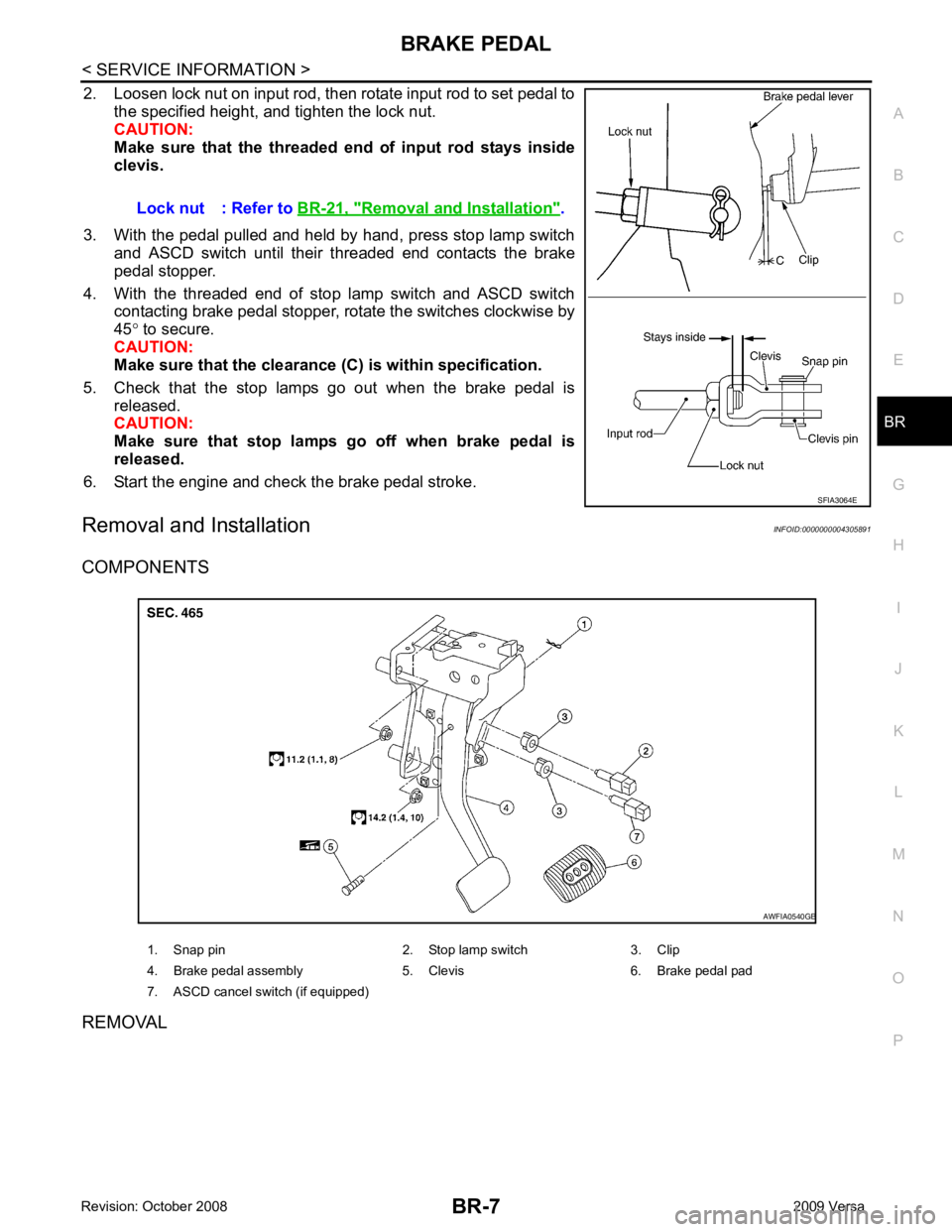

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten the lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch and ASCD switch until their threaded end contacts the brake

pedal stopper.

4. With the threaded end of stop lamp switch and ASCD switch contacting brake pedal stopper, rotate the switches clockwise by

45 ° to secure.

CAUTION:

Make sure that the clearance (C) is within specification.

5. Check that the stop lamps go out when the brake pedal is released.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start the engine and check the brake pedal stroke.

Removal and Installation INFOID:0000000004305891

COMPONENTS

REMOVAL Lock nut : Refer to

BR-21, " Removal and Installation " .

Page 886 of 4331

CL-10< SERVICE INFORMATION >

CLUTCH MASTER CYLINDER

CLUTCH MASTER CYLINDER

Removal and Installation INFOID:0000000004305171

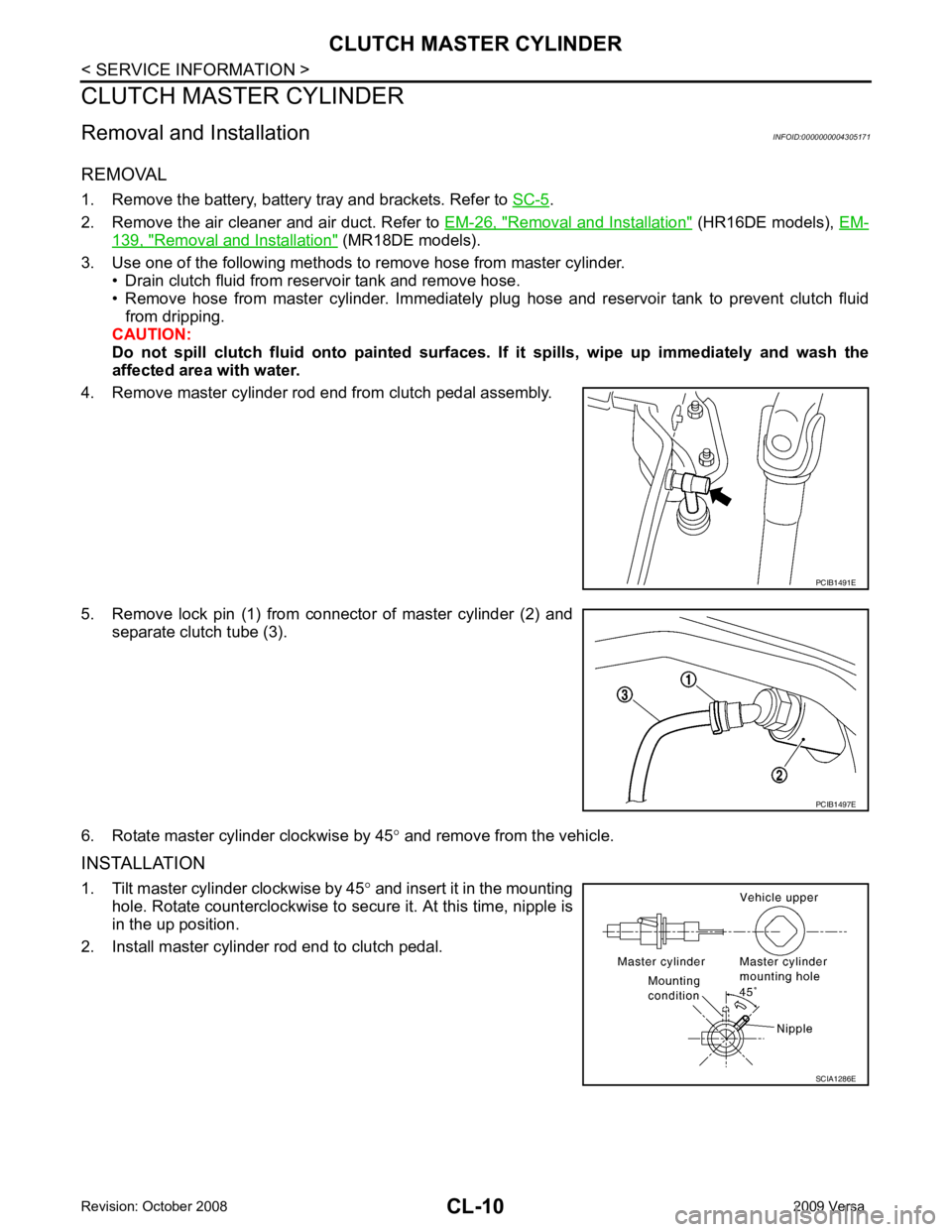

REMOVAL

1. Remove the battery, battery tray and brackets. Refer to SC-5 .

2. Remove the air cleaner and air duct. Refer to EM-26, " Removal and Installation " (HR16DE models),

EM-139, " Removal and Installation " (MR18DE models).

3. Use one of the following methods to remove hose from master cylinder. • Drain clutch fluid from reservoir tank and remove hose.

• Remove hose from master cylinder. Immediately plug hose and reservoir tank to prevent clutch fluid

from dripping.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wi pe up immediately and wash the

affected area with water.

4. Remove master cylinder rod end from clutch pedal assembly.

5. Remove lock pin (1) from connector of master cylinder (2) and separate clutch tube (3).

6. Rotate master cylinder clockwise by 45 ° and remove from the vehicle.

INSTALLATION

1. Tilt master cylinder clockwise by 45 ° and insert it in the mounting

hole. Rotate counterclockwise to secure it. At this time, nipple is

in the up position.

2. Install master cylinder rod end to clutch pedal. PCIB1491E

PCIB1497E

SCIA1286E

Page 957 of 4331

CVT

N

O P

Do not start engine.

6. Select “SELF-DIAG RESULTS”.

7. Shift the selector lever to “R” position.

8. Depress slightly the accelerator pedal (Pedal angle: 2/8) while depressing the brake pedal.

9. Perform “ERASE”.

10. Shift the selector lever to “R” position afte r replacing TCM. Turn the ignition switch OFF.

11. Wait approximately 10 minutes after turning the ignition switch OFF.

12. Turn the ignition switch ON while shifting the selector lever to “R” position. CAUTION:

Do not start engine.

13. Select “CALIBRATION DATA”.

14. Check that the value on “CALIBRATION DATA” is same as the data after erasing "Calibration Data". • Restart the procedure from step 3 if the values are not same.

15. Shift the selector lever to “P” position.

16. Check that the shift position indicator in the combi nation meter turns ON (It indicates approximately 1 or 2

seconds after shifting the selector lever to “P” position.)

• Check the following items if the shift position indicato r does not turn ON. Repair or replace the shift posi-

tion indicator if necessary.

- The harness between TCM and ROM ASSY in the transaxle assembly is open or short.

- Cable disconnected, loosen, or bent from the connector housing.

- Power supply and ground of TCM. Refer to CVT-125, " Description " .

PATTERN C 1. Replace the transaxle assembly first, and then replace TCM.

2. Perform the service of “PATTERN A”. (Perform the service of “Pattern B” if TCM is replaced first.)

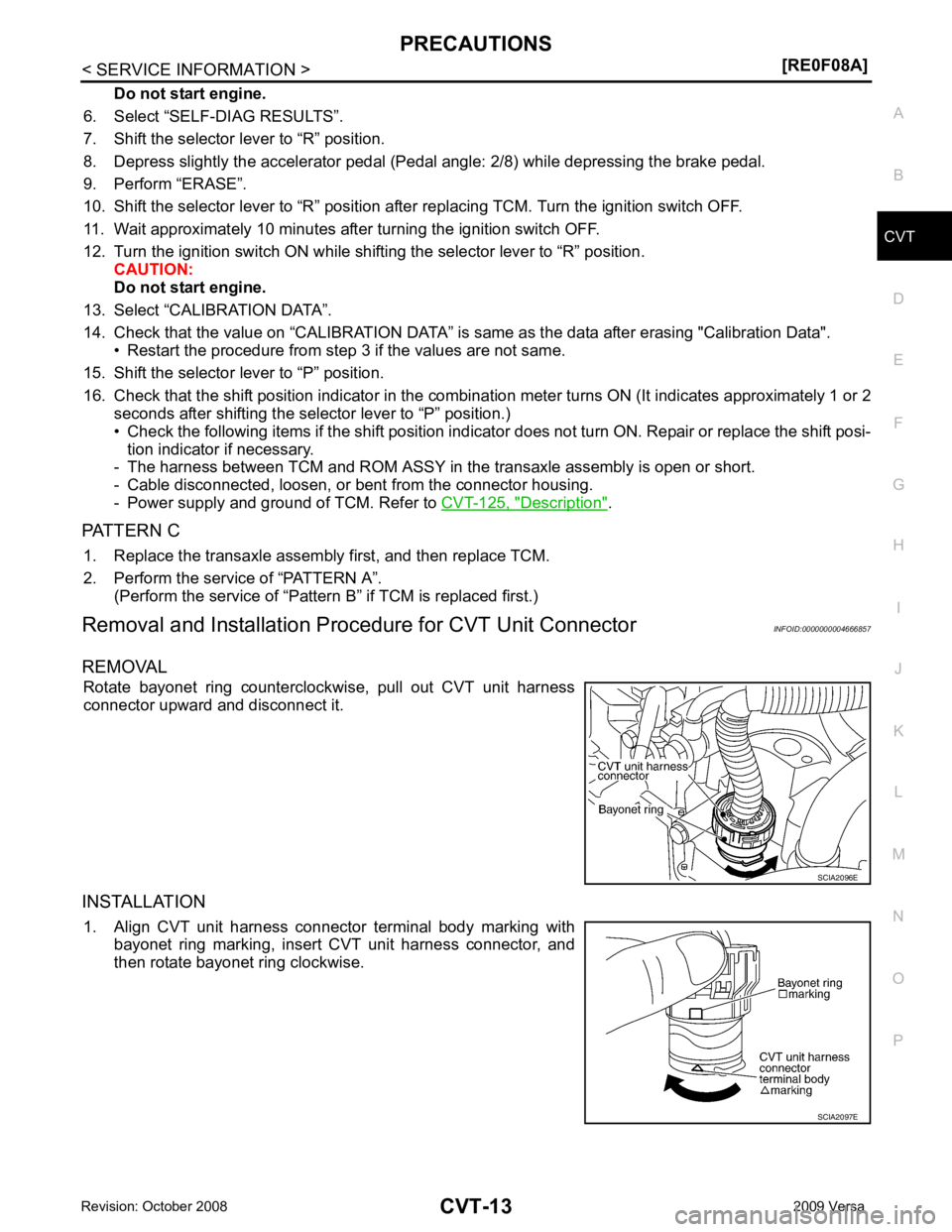

Removal and Installation Proc edure for CVT Unit Connector INFOID:0000000004666857

REMOVAL Rotate bayonet ring counterclockwise, pull out CVT unit harness

connector upward and disconnect it.

INSTALLATION 1. Align CVT unit harness connector terminal body marking with bayonet ring marking, insert CVT unit harness connector, and

then rotate bayonet ring clockwise.

Page 1127 of 4331

![NISSAN LATIO 2009 Service Repair Manual TRANSAXLE ASSEMBLY

CVT-183

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

4. Remove the four drive plate to torque converter nuts.

NOTE:

Rotate the crankshaft clockwise as vi NISSAN LATIO 2009 Service Repair Manual TRANSAXLE ASSEMBLY

CVT-183

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

4. Remove the four drive plate to torque converter nuts.

NOTE:

Rotate the crankshaft clockwise as vi](/img/5/57359/w960_57359-1126.png)

TRANSAXLE ASSEMBLY

CVT-183

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

4. Remove the four drive plate to torque converter nuts.

NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter nuts.

5. Put matching marks on the drive plate and torque converter alignment stud. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

6. Remove the transaxle to engine and engine to transaxle bolts.

7. Separate the transaxle from the engine.

8. If necessary, remove the following from the transaxle: • CVT fluid charging pipe

• Engine mounting bracket (LH)

• Fluid cooler tubes

• Air breather hose

• Any necessary brackets

INSTALLATION Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you mu st make sure any dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels m ay cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings and copper washers.

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the nuts for the torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-160 .

• After converter is installed to drive plate, ro tate crankshaft several turns to check that transaxle

rotates freely without binding.

• When installing the torque converter to the transaxle measure dis- tance A. WCIA0616E

Distance A: 14.4 mm (0.57 in) or more

WCIA0617E

Page 1136 of 4331

![NISSAN LATIO 2009 Service Repair Manual CVT-192< SERVICE INFORMATION >

[RE0F08B]

PRECAUTIONS

Rotate bayonet ring counterclockwise, pull out CVT unit harness

connector upward and disconnect it.

INSTALLATION

1. Align CVT unit harne NISSAN LATIO 2009 Service Repair Manual CVT-192< SERVICE INFORMATION >

[RE0F08B]

PRECAUTIONS

Rotate bayonet ring counterclockwise, pull out CVT unit harness

connector upward and disconnect it.

INSTALLATION

1. Align CVT unit harne](/img/5/57359/w960_57359-1135.png)

CVT-192< SERVICE INFORMATION >

[RE0F08B]

PRECAUTIONS

Rotate bayonet ring counterclockwise, pull out CVT unit harness

connector upward and disconnect it.

INSTALLATION

1. Align CVT unit harness connector terminal body marking with bayonet ring marking, insert CVT unit harness connector, and

then rotate bayonet ring clockwise.

2. Rotate bayonet ring clockwise until CVT unit harness connector terminal body marking is aligned with the bayonet ring marking

(linear slit) as shown.

CAUTION:

• Securely align CVT unit ha rness connector terminal body

marking with bayonet ring mark ing (linear slit). Do not

make a half fit condition as shown.

• Do not mistake the bayonet ring marking (linear slit) for

other dent portion.

Precaution INFOID:0000000004305566

NOTE:

If any malfunction occurs in the RE0F08B m odel transaxle, replace the entire transaxle assembly. SCIA2096E

SCIA2097E

SCIA2098E

SCIA2099E